Patents

Literature

70results about How to "High Strength Mechanical Properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

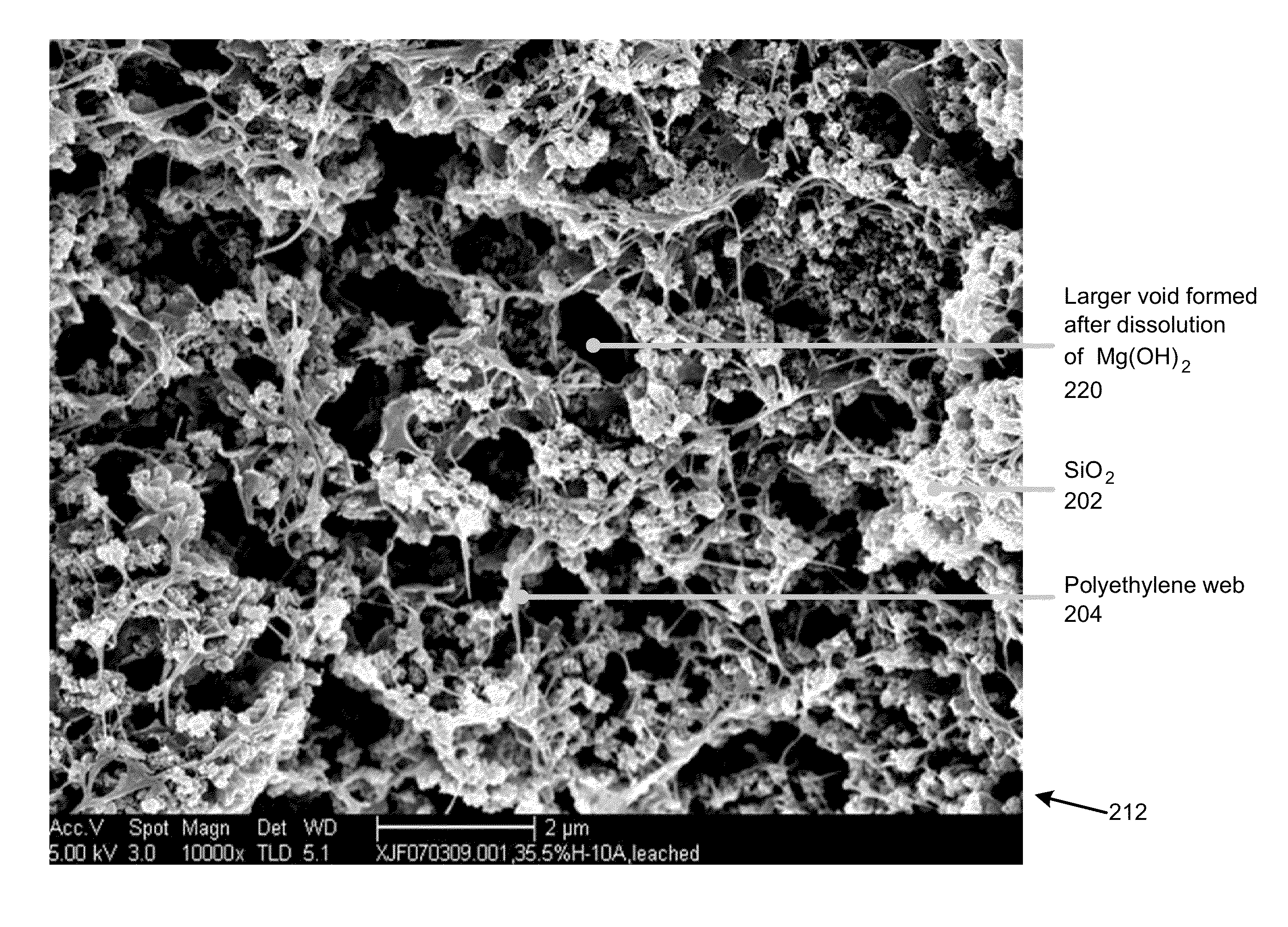

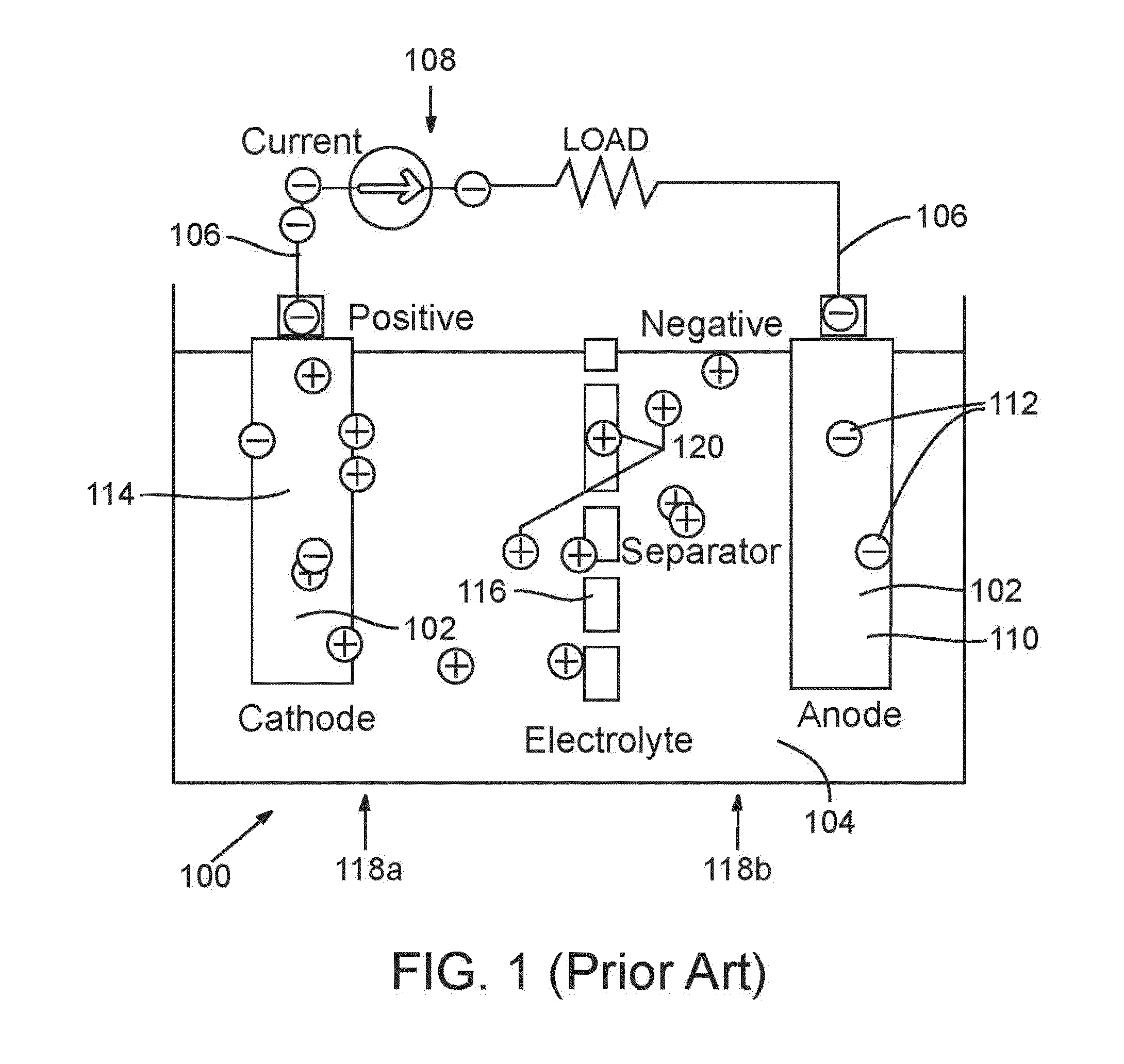

In-situ pore generation in lead-acid battery separator

ActiveUS20110045339A1High strength mechanical propertiesLow in electricalCell component detailsLead-acid accumulators constructionIonic diffusionPorosity

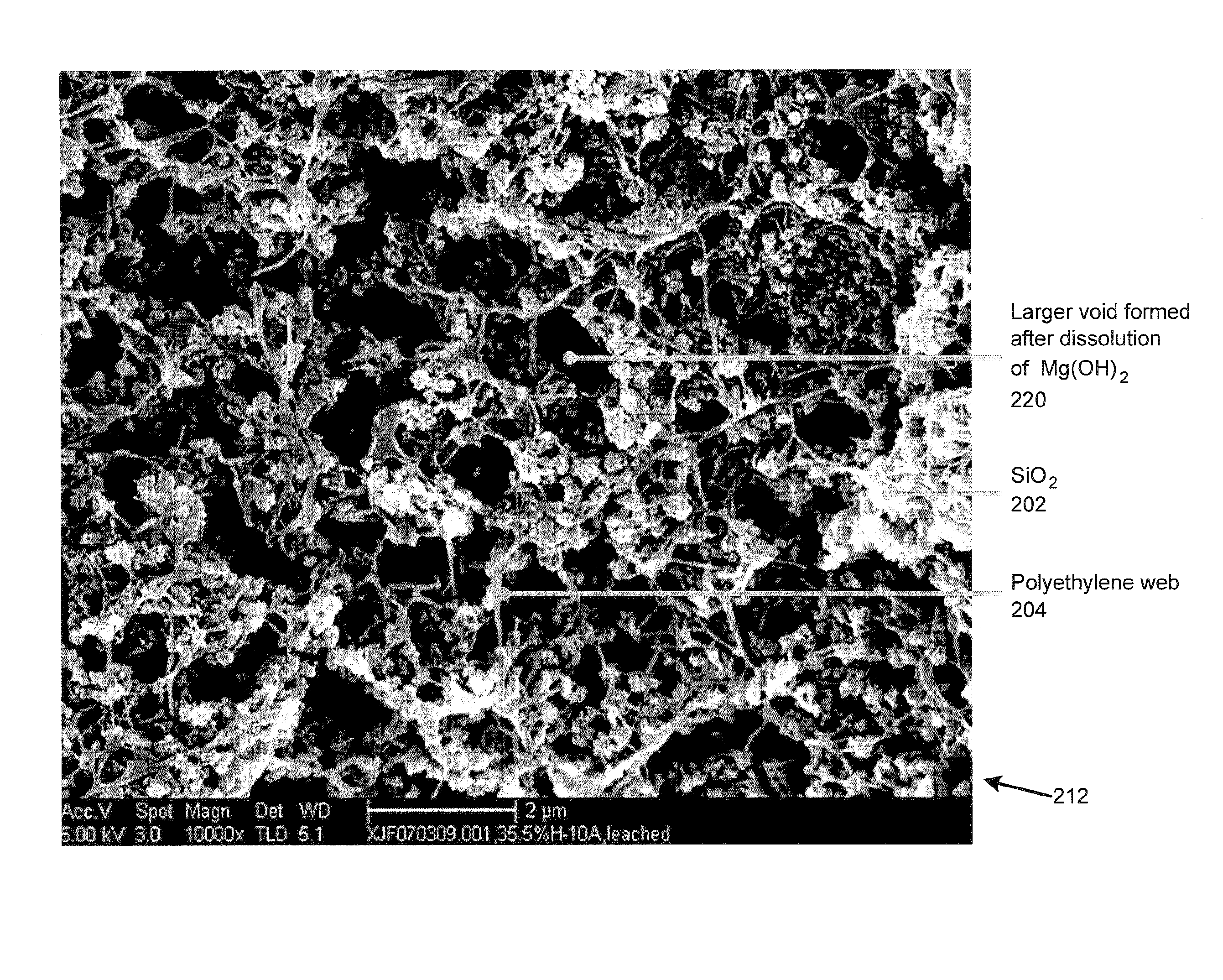

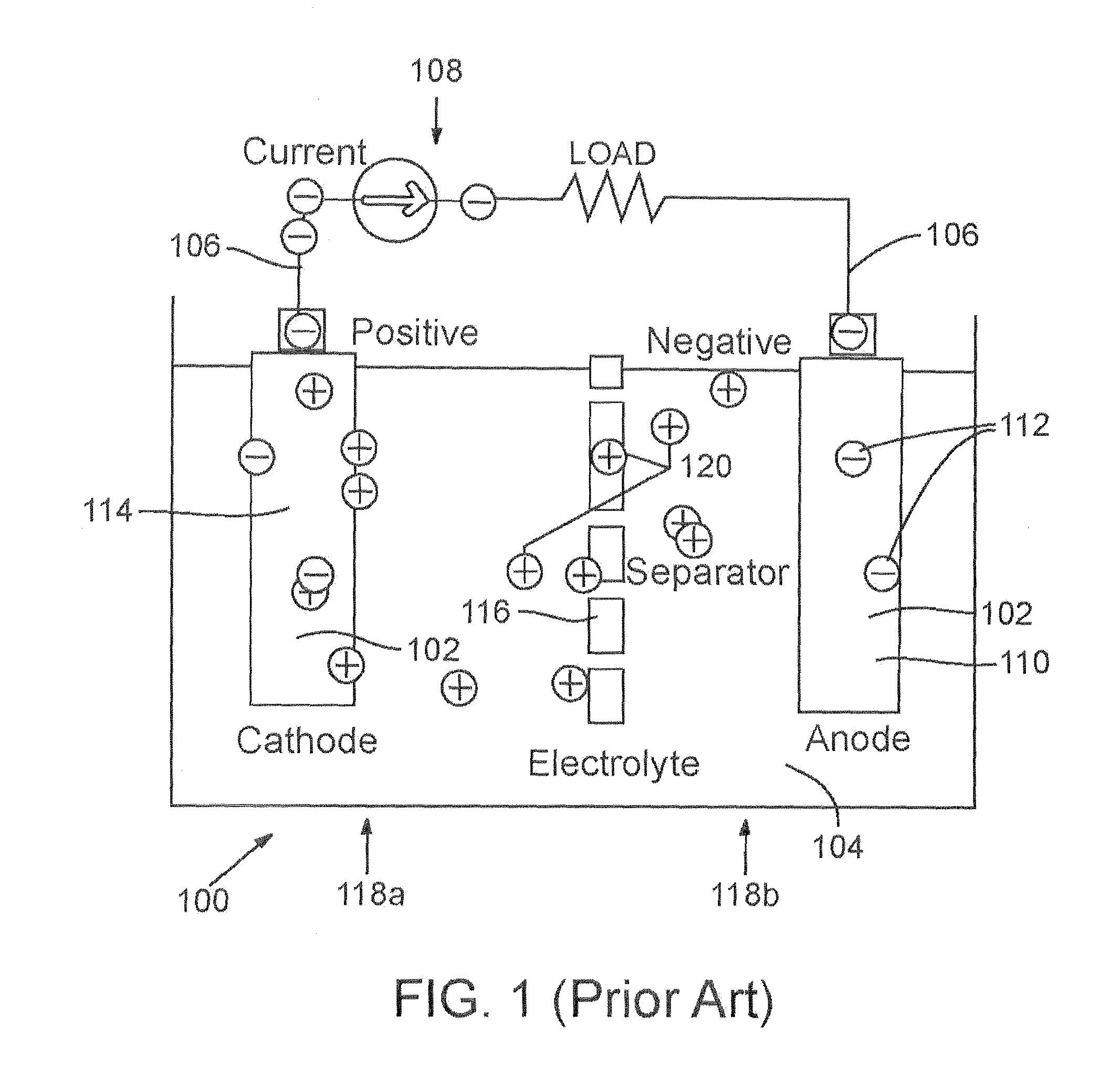

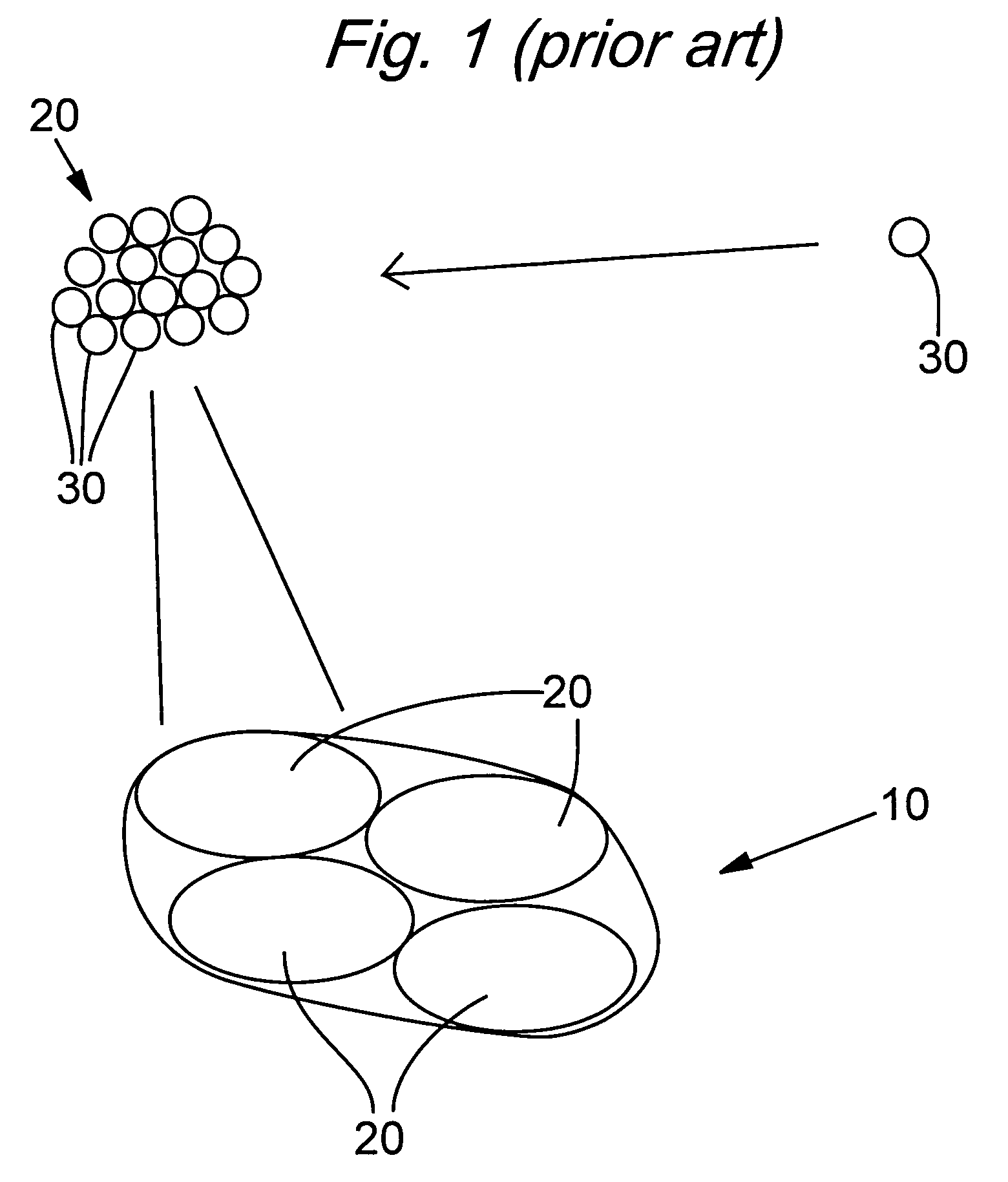

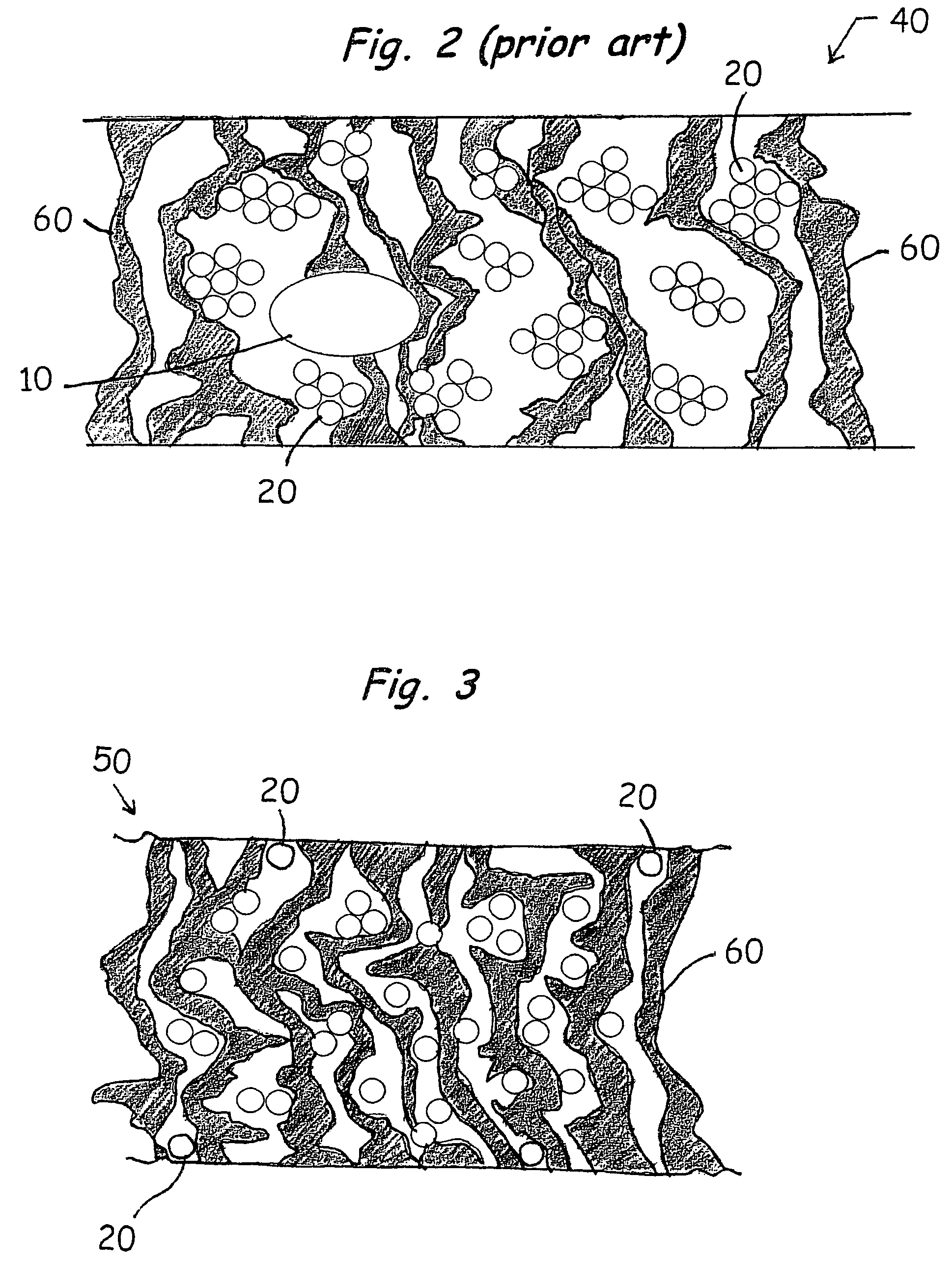

A microporous polyethylene battery separator material (212), for use in a flooded-cell type lead-acid battery, benefits from increased porosity, enhanced wettability, and exceptionally low electrical resistance when an electrolyte-soluble pore former is employed in the manufacturing process. The pore former (210) is soluble in electrolytic fluid and therefore dissolves in-situ in sulfuric acid during battery assembly. The dissolution of the pore former leaves behind additional, larger voids (220) in the separator material and thereby enhances ionic diffusion and improves battery performance.

Owner:AMTEK RES INT

Manufacturing method of 17-4PH steel pipe

InactiveCN101007384ASolve the unclear picklingSolve the problem of overacidFurnace typesOther manufacturing equipments/toolsAcid washingHeating temperature

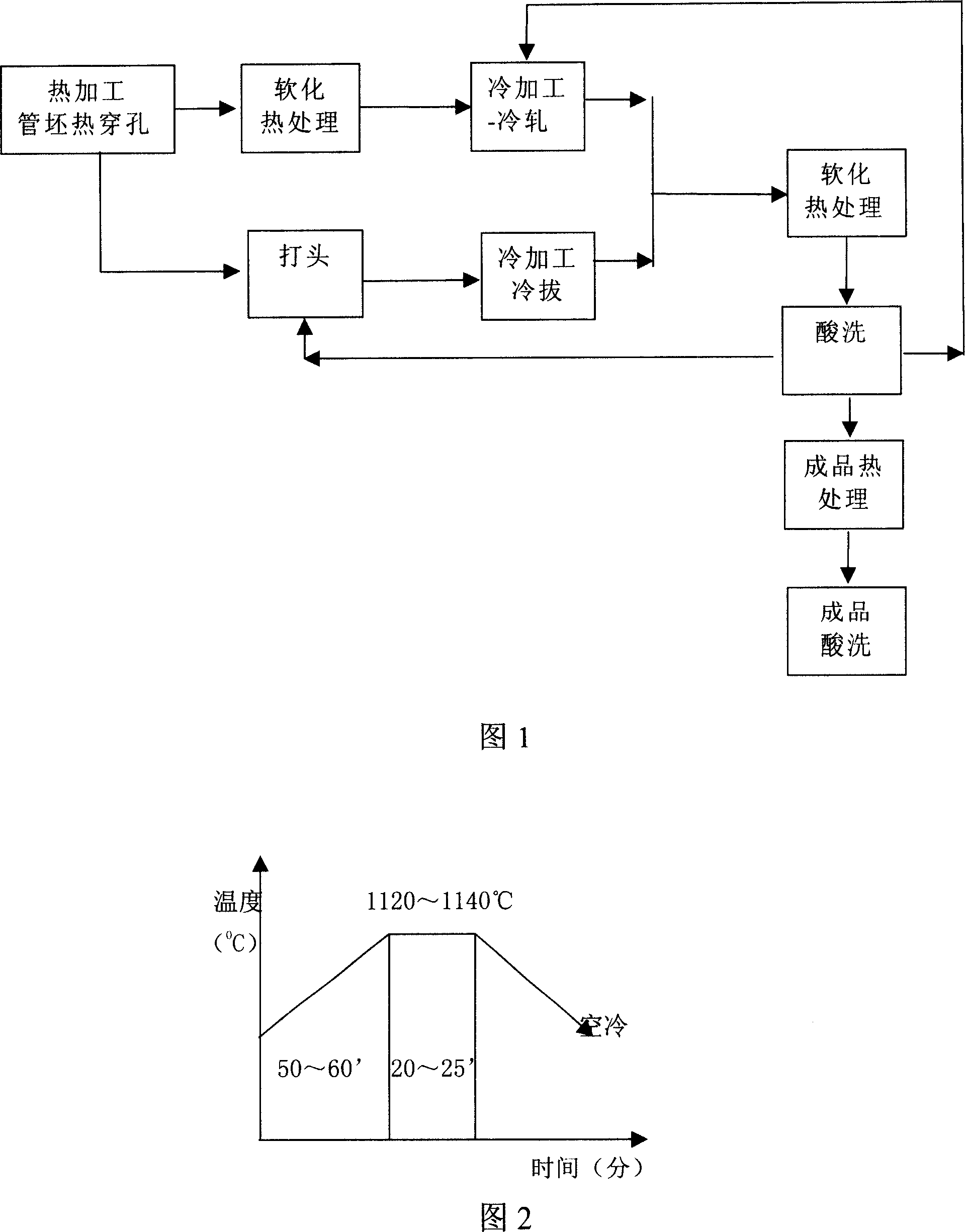

17-4PH steel pipe manufacturing method includes the following steps: a. thermal processing and pipe blank heat perforating: heating temperature is 1090 ~ 1150 degree C and insulation time is 15 ~ 35 minutes; b. softening heat treatment: temperature is 650 ~ 700 degree C, insulation time is 4~5.5 hours; c. cold-working: cold rolling; d. softening heat treatment: temperature is 650 ~ 700 degree C, insulation time is 4 ~ 5.5 hours; e. acid-washing; f. repeating steps c ~ e cycles rolling until finished product size; g . finished product heat treatment: solid solution treatment 1020 ~ 1050 degree C +15 ~30 minutes, precipitation hardening treatment 450-630DEG C+3.5-4.5 hours, the finished product forms precipitation hardening martensitic structure with high strength and excellent corrosion resistance; h. finished product acid-washing. The invention replaces the original pipe elements art through boring and turning the pipe elements to reaching the required diameter and wall thickness with the technology of cold-working to getting the required diameter and wall thickness after heat perforating, it shortens production cycles, reduces production costs, improves product metal yield rate and increases economic efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

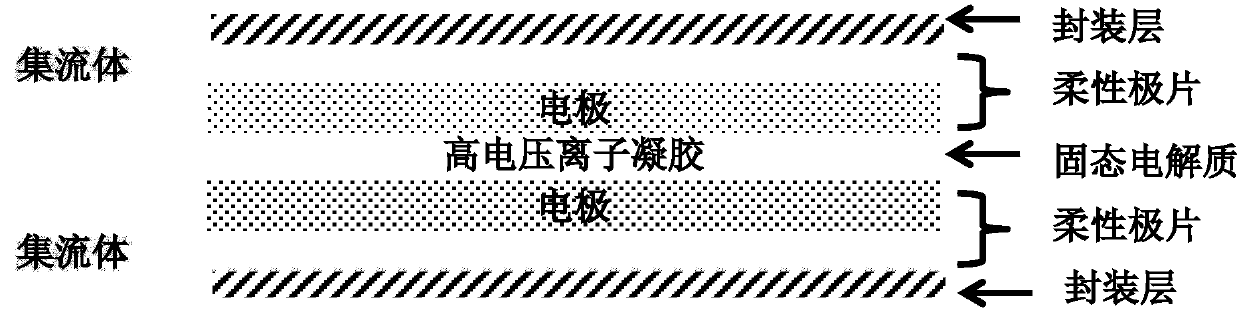

High-voltage flexible solid super capacitor and preparation method thereof

ActiveCN107919233AHigh voltageIncrease energy densityHybrid capacitor electrolytesHybrid capacitor electrodesEngineeringActive electrode

The invention relates to a high-voltage flexible solid super capacitor and a preparation method thereof. The super capacitor comprises a gel electrolyte film, flexible current collectors, electrodes and packaging layers, the surfaces of the flexible current collectors are coated with the electrodes to form flexible electrode slices respectively, one packaging layer, one flexible electrode slice, the gel electrolyte film, the other flexible electrode slice and the other packaging layer are stacked successively, and the packaging layers wrap the flexible electrode slice, the gel electrolyte filmand the other flexible electrode slice. Active electrode materials and the flexible electrode slices are prepared, ion gel is prepared and casted into the film, one flexible electrode slice, the gelfilm and the other electrode slice are stacked sequentially, and the flexible electrode slice, the gel electrolyte film and the other flexible electrode slice are packaged by thermoplastic high-molecular films to form the high-voltage flexible solid super capacitor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

High-performance prestressing duct grouting agent and preparation method thereof

The invention discloses a high-performance prestressing duct grouting agent which is prepared by the following components, by weight, 1-10% of water reduction component, 15-40% of water retention component, 1-10% of plastic-reserving component, 0.03-0.3% of tackifying component, 0-0.5% of delayed coagulation component, 0.1-1% of plasticity expansion component and 50-70% of later-stage volume expansion component. By mixing the high-performance prestressing duct grouting agent into cement according to a ratio of 10%, grout can obtain high mobility and high plasticity stability, a segregation layering phenomenon is greatly reduced, bleeding is avoided, and grouting is full. Whole-process volume stability of the prepared grout is high, micro expansion of plasticity and hardening stages can effectively compensate various contractions. Early strength and high-strength performance of the grout are prominent, durability is good, and the grout is applicable to various prestressing duct constructions. Simultaneously, bag-packaged additives are even in composition compared with additives prepared on the spot, transportation and comprehensive cost is low, and technical economical benefit is remarkable.

Owner:WUHAN UNIV OF TECH

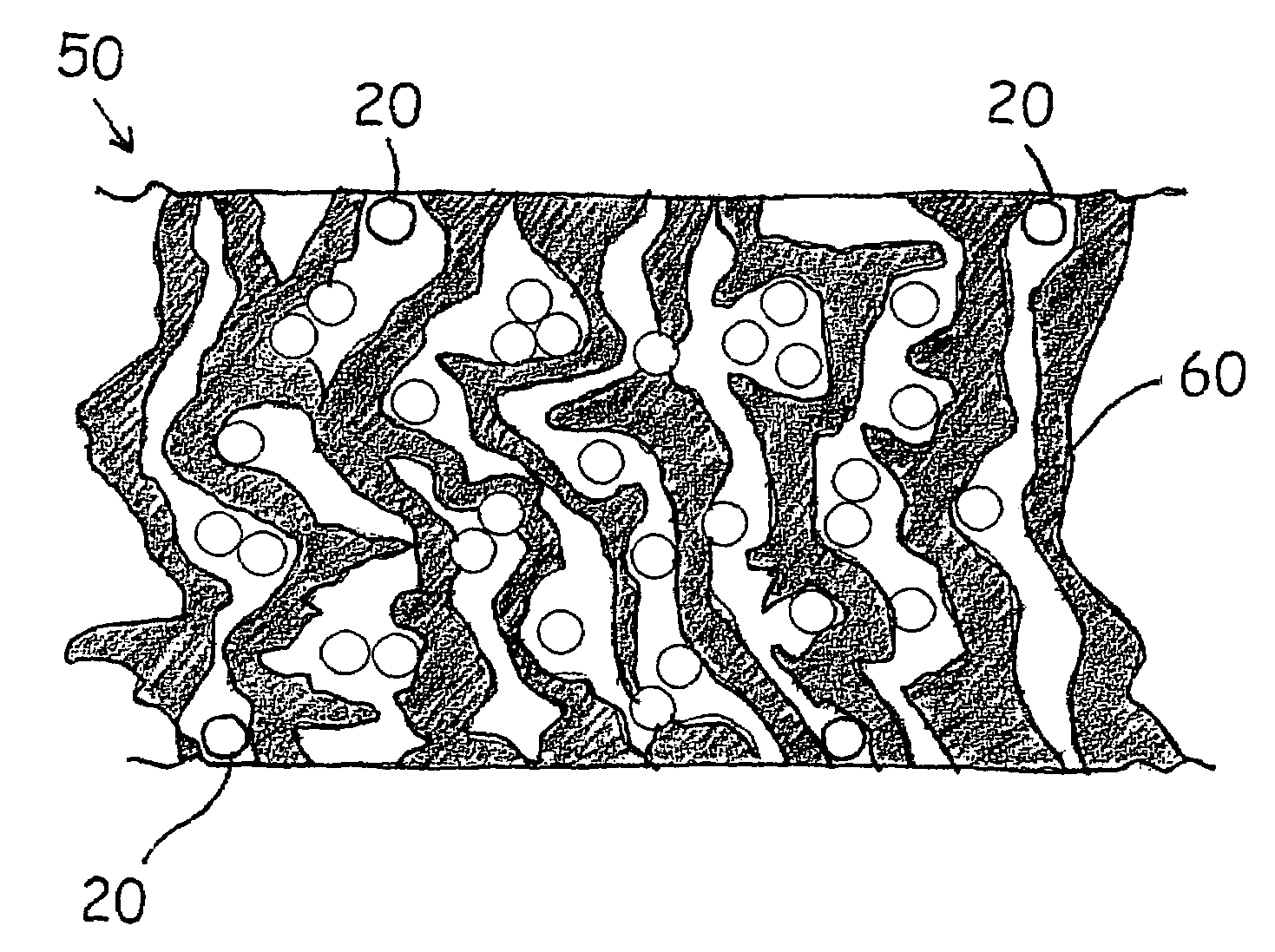

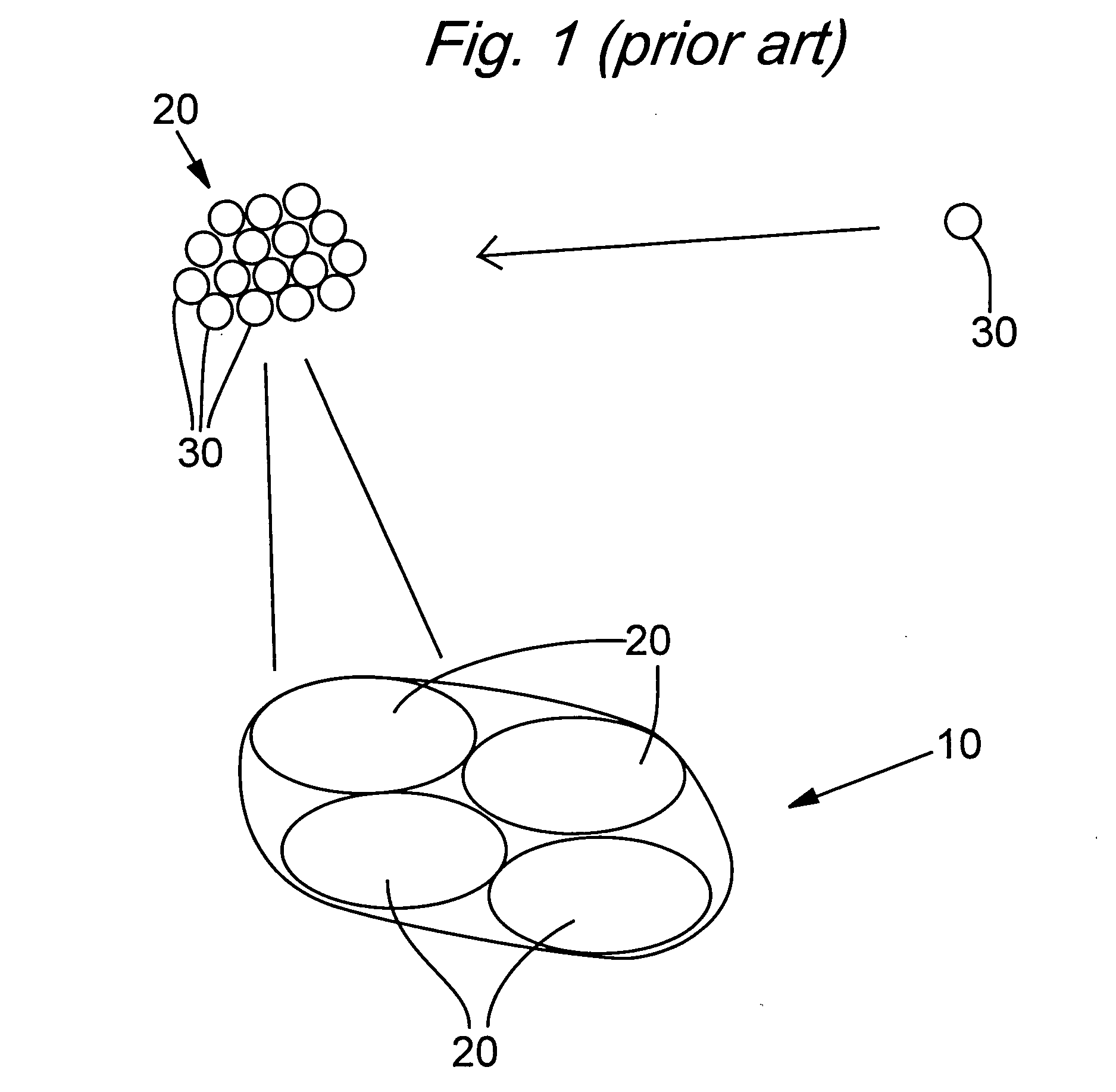

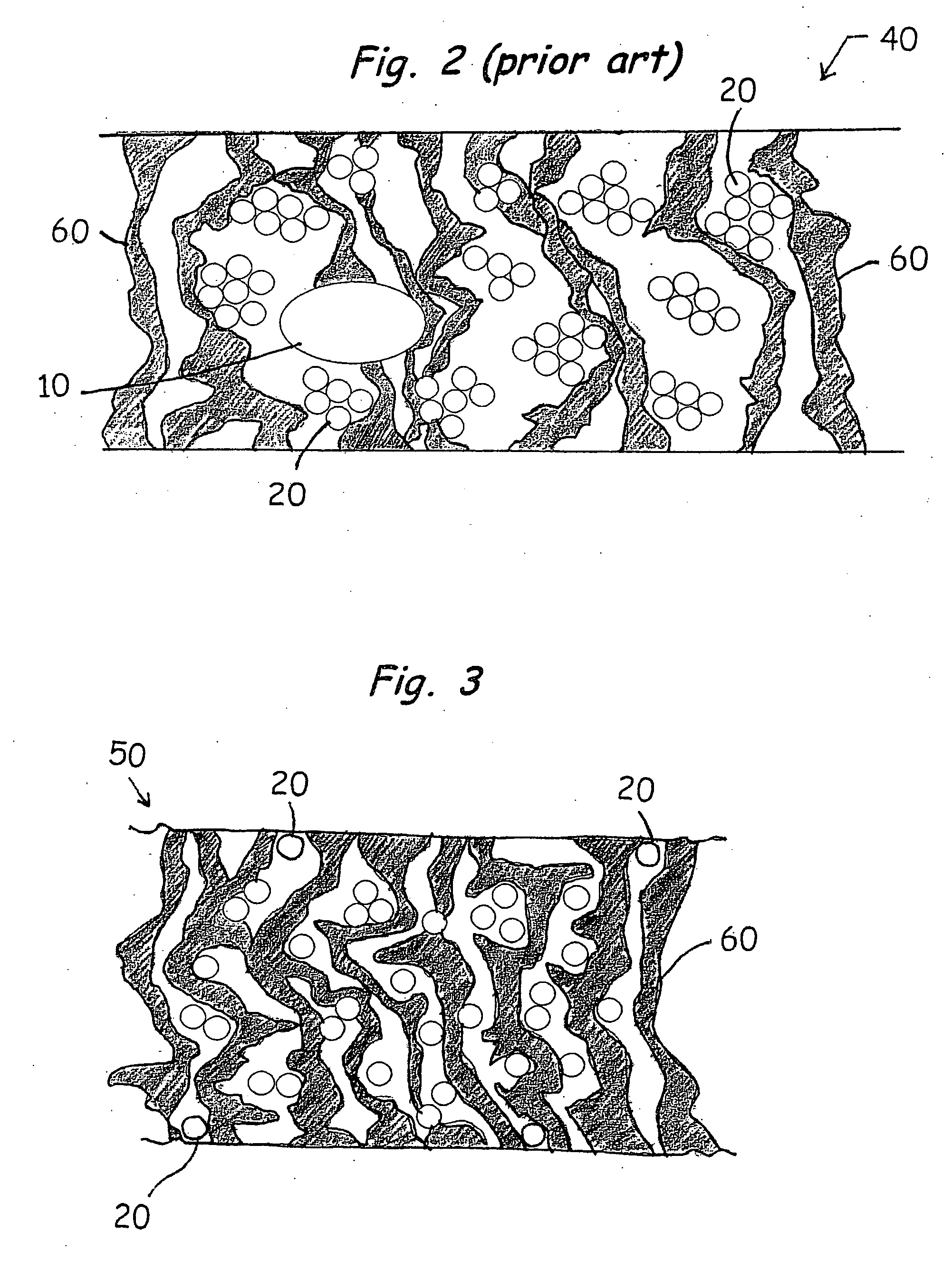

Lead acid battery separator with improved electrical and mechanical properties

InactiveUS7211322B2High resistivityHigh strengthLayered productsFinal product manufacturePolyolefinPolymer science

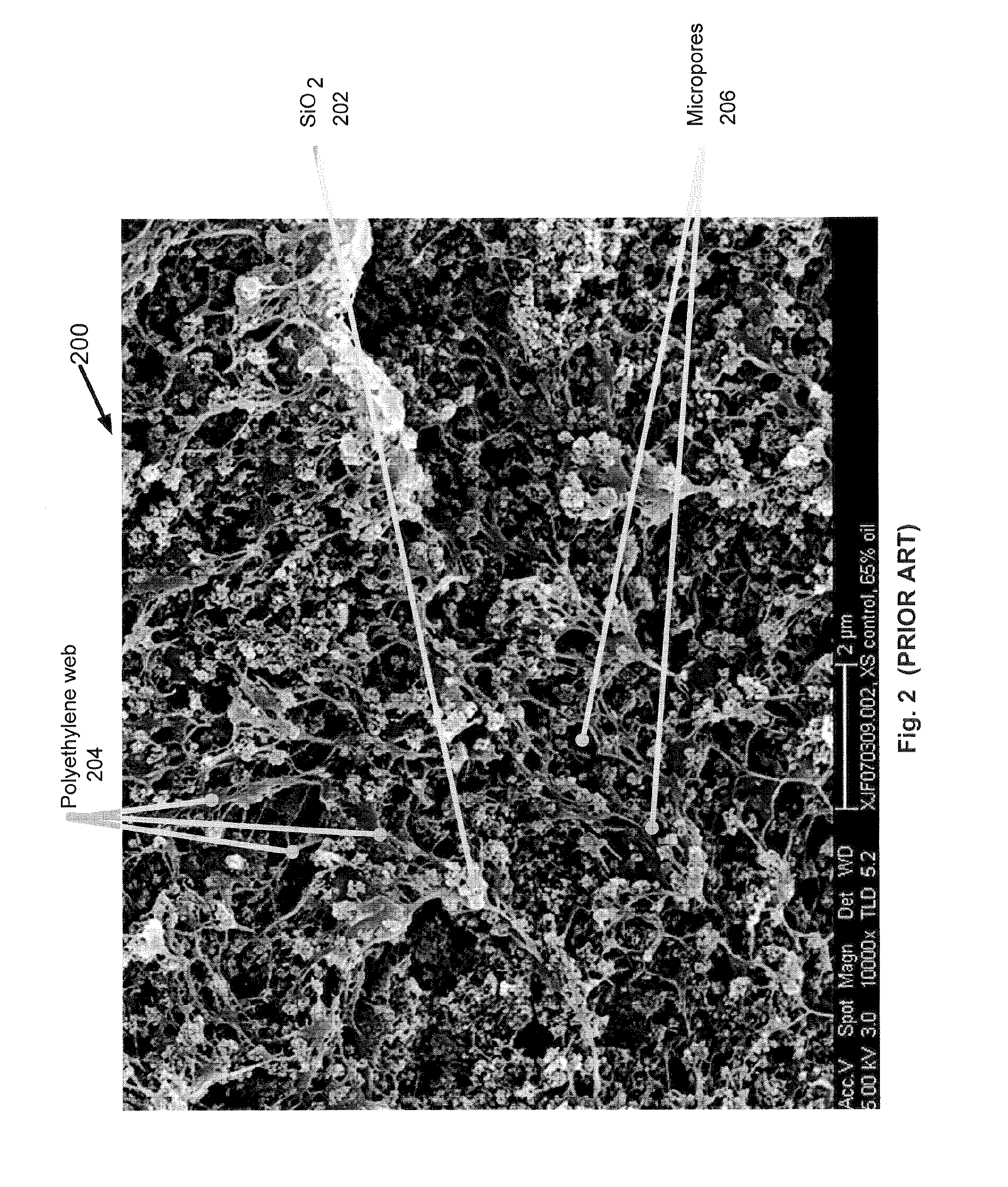

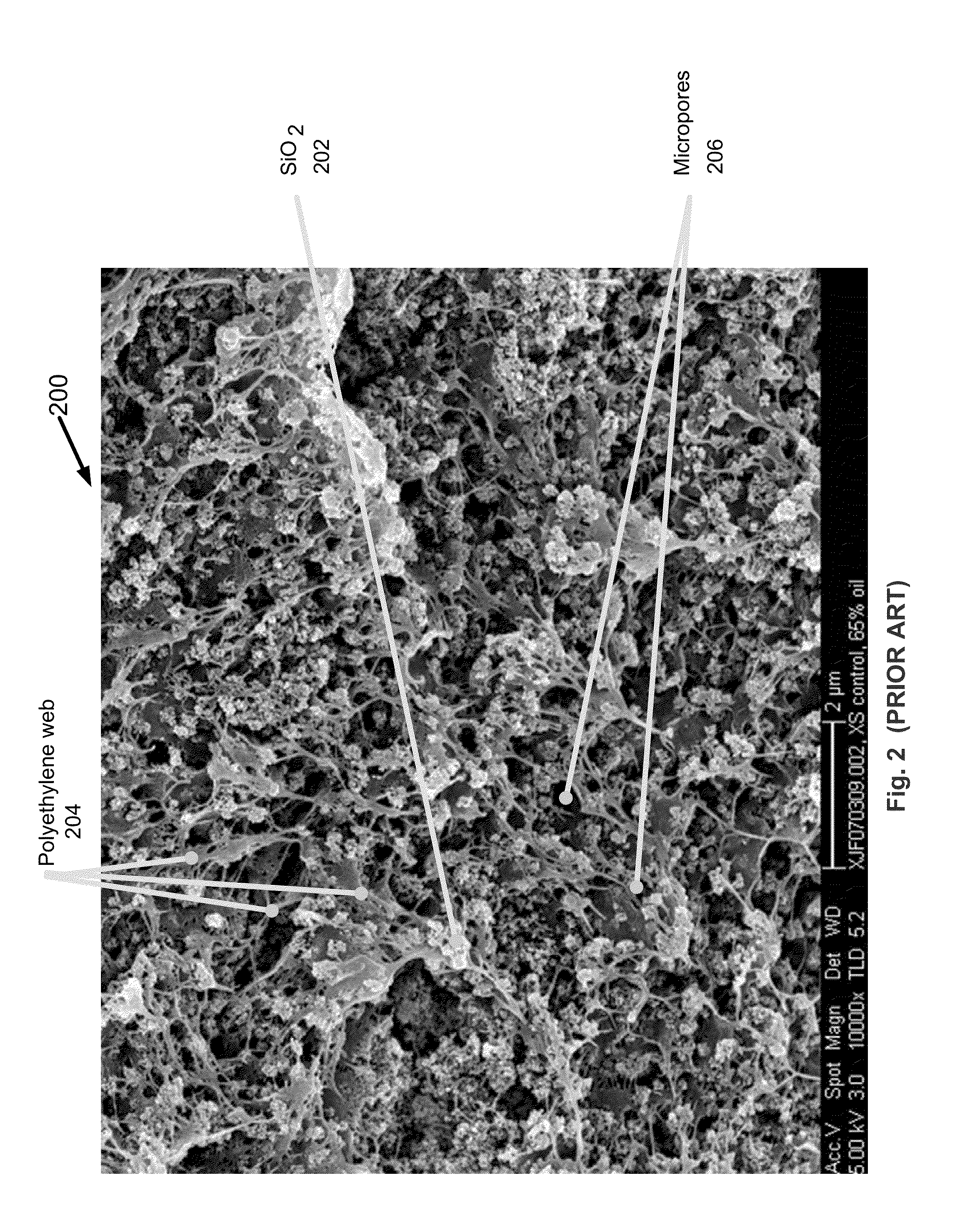

An oxidation resistant, microporous polyolefin web exhibiting high-strength mechanical and low electrical resistance properties is a solid matrix that includes an ultrahigh molecular weight polyolefin component and a friable precipitated silica component. The ultrahigh molecular weight polyolefin component provides high-strength mechanical properties to the web. The friable precipitated silica component is broken down into predominately discrete silica aggregates dispersed throughout the microporous web to maintain a low electrical resistance in the presence of an electrolyte. In an alternative preferred embodiment, a polyethylene web includes an antioxidant coating that is applied to the separator web following extraction of the majority of the process oils and drying of the extraction fluid from the separator pores. The resultant “sheath” of antioxidant protects the mechanical integrity of the polyethylene separator by suppressing polyethylene degradation.

Owner:ENTEK INT

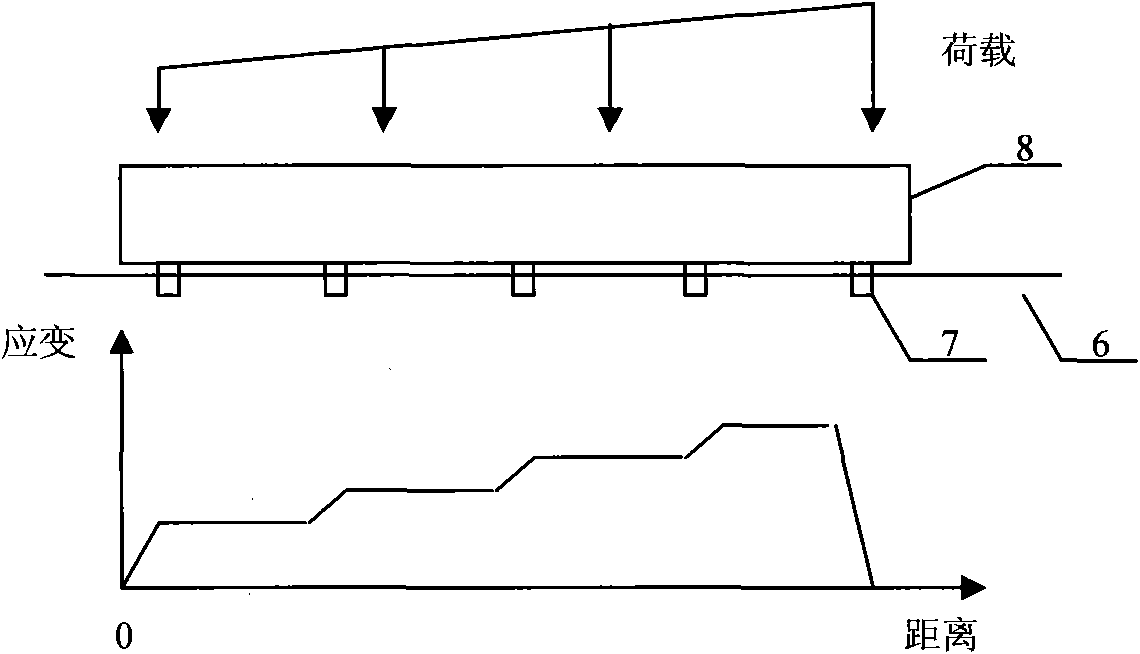

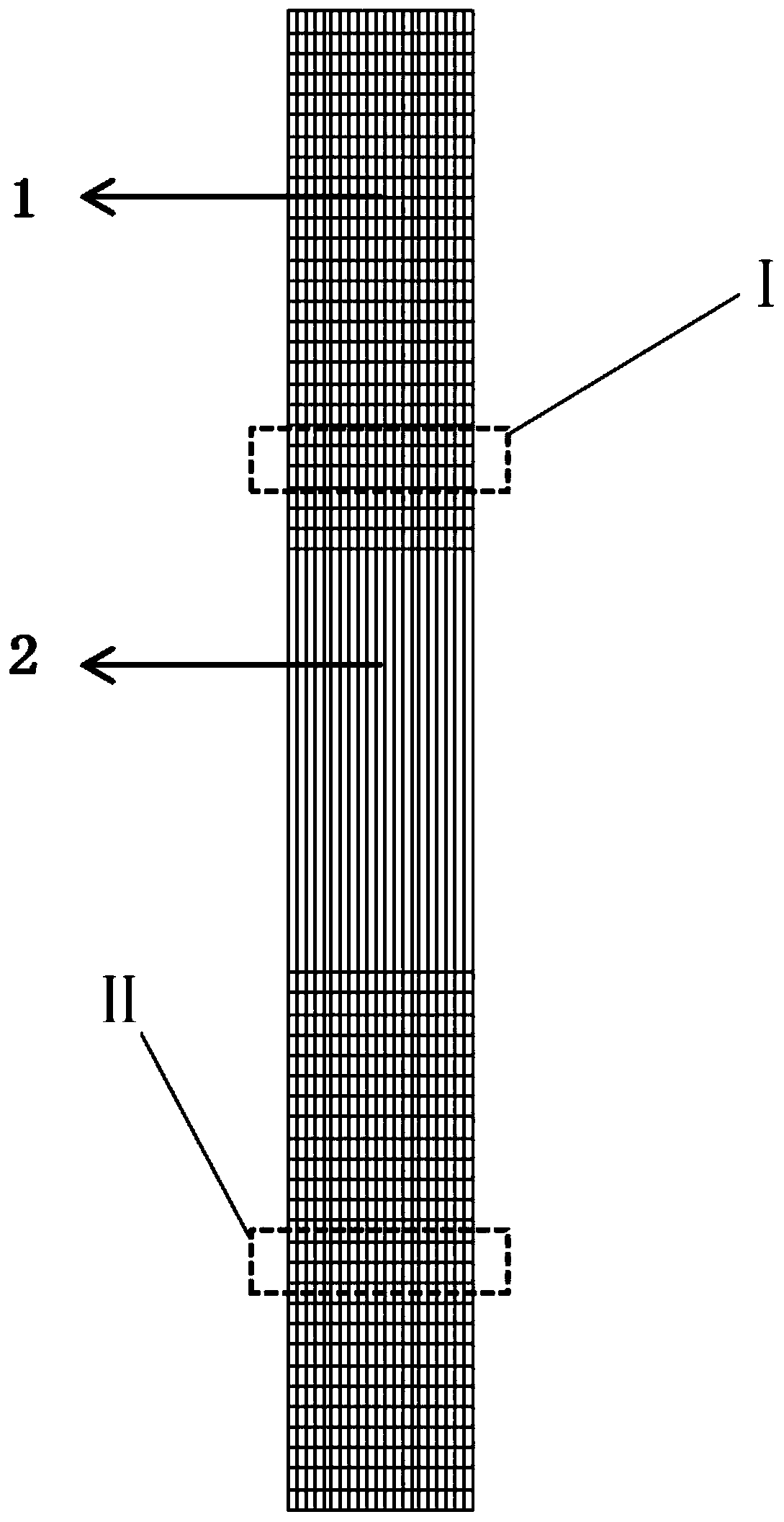

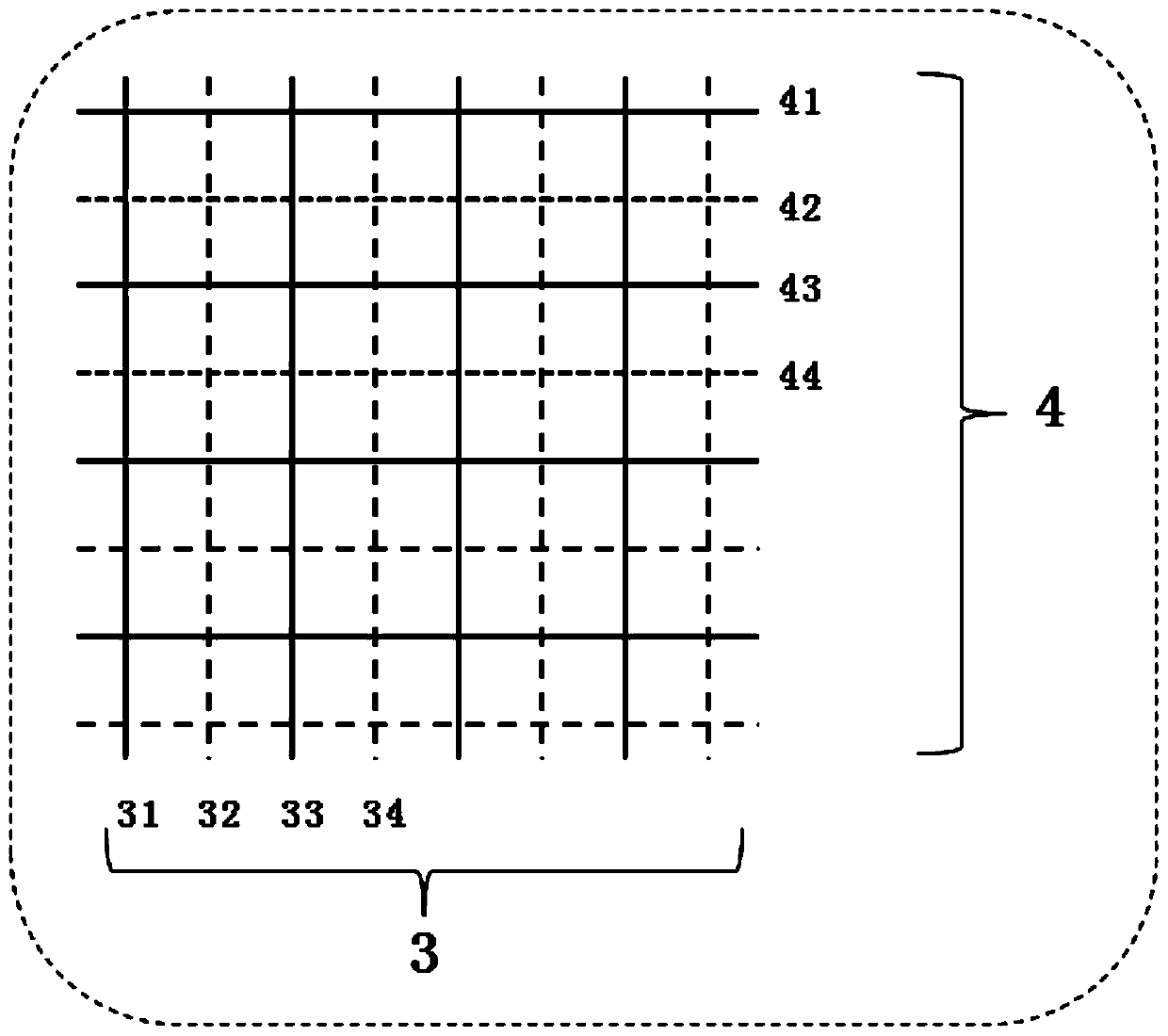

Process for mass-producing distributed high-accuracy self-monitoring fiber reinforced polymer (FRP) bars/cables on the basis of fiber-optic sensing

ActiveCN101598676AImprove survival rateReduce scrap rateCladded optical fibreOptically investigating flaws/contaminationCouplingEngineering

The invention provides a process for mass-producing distributed high-accuracy self-monitoring FRP bars / cables on the basis of fiber-optic sensing technology. The process mainly comprises the following procedures: (1), preparing and packaging an optical fiber sensor, that is, improving the sensing accuracy of the existing common single-mode communication optical fiber by the non-slip and long-gauge processing technology and reinforcing and strengthening the single-mode communication optical fiber by braiding / winding fiber around the single-mode communication optical fiber in a non-adhesive manner, thereby adapting to the mechanized production of the FRP bars / cables; and (2), the extrusion-forming process of the self-monitoring FRP bars / cables with controllable solidifying length (namely the length of a single FRP bar / cable), that is, a mass-production flow for introducing the packaging product of the high-accuracy optical fiber sensor into the modified FRP bars / cables. The process can ensure that the resin is fully solidified within the use length range of the bar / cable, while the resin at the end zone is not solidified, so that the fiber-optic interface can be led out. The process mainly comprises the key processes for controlling the optical fiber compounding state, the appearance and the length of the bars / cables, the coupling of temperature and pulling speed and the like.

Owner:SOUTHEAST UNIV +2

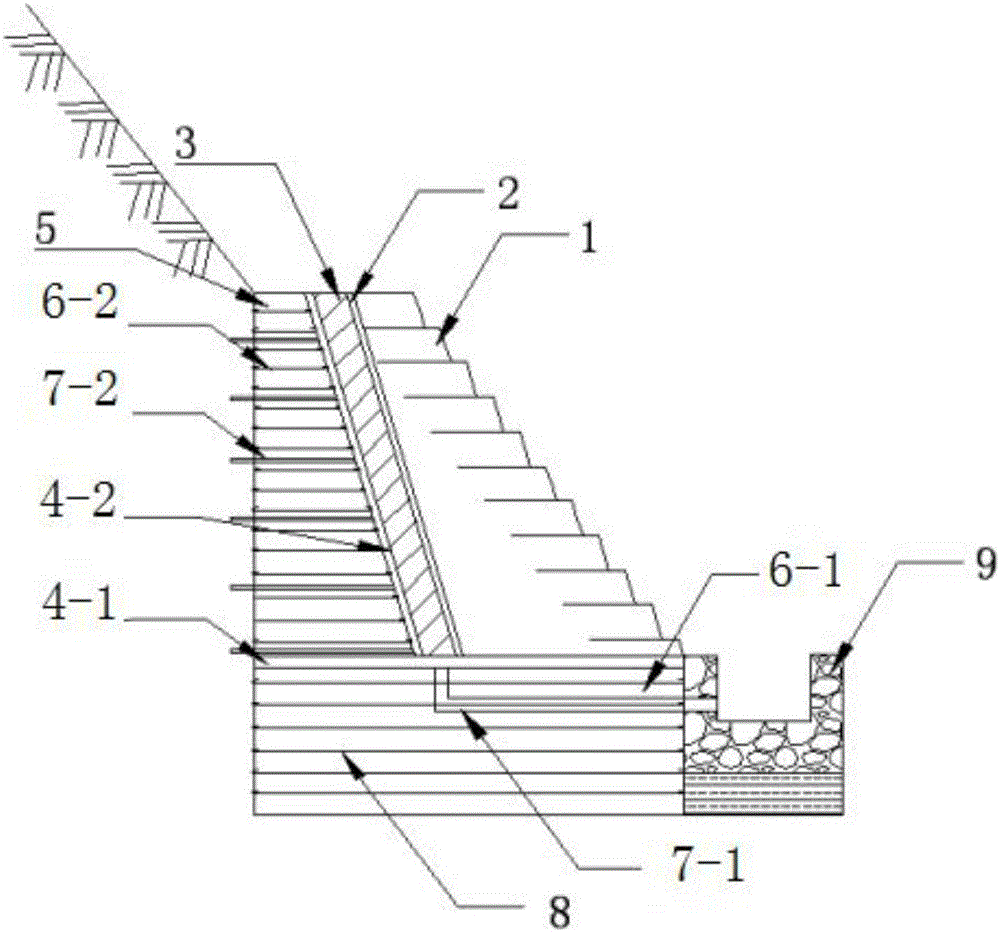

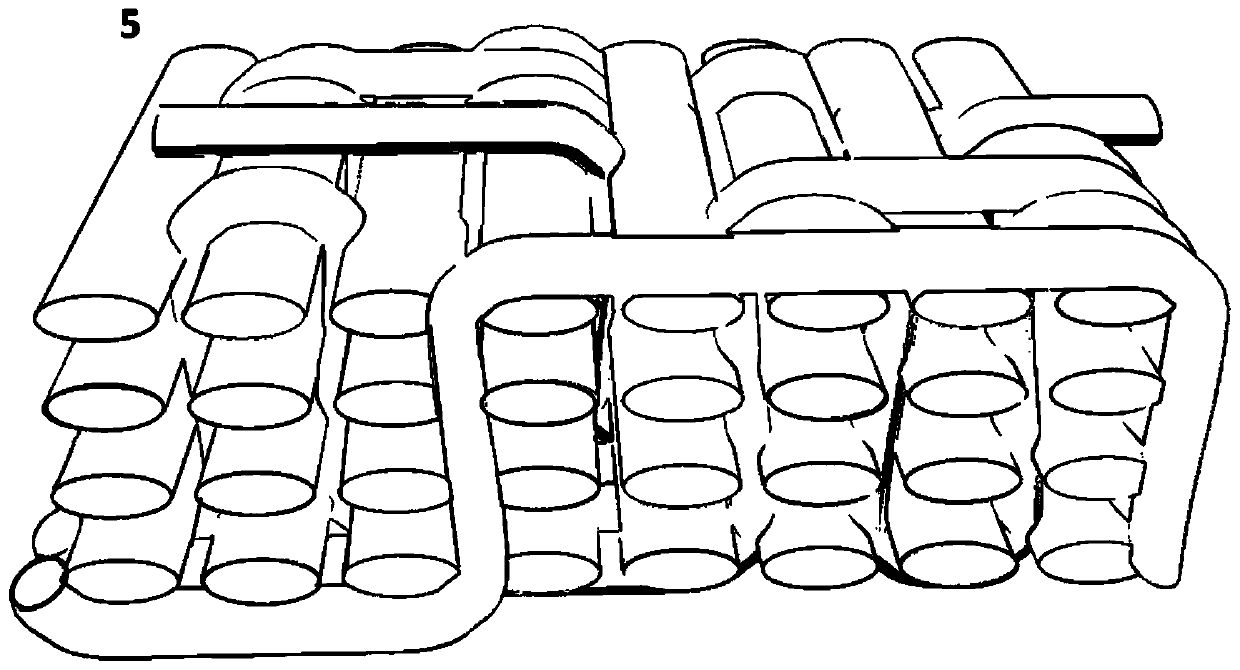

Honeycomb geocell earth retaining wall with ecological restoration function and construction method thereof

InactiveCN106368238AWith ecological restoration functionPrevent infiltrationArtificial islandsExcavationsCrushed stoneEngineering

The invention provides a honeycomb geocell earth retaining wall with an ecological restoration function and a construction method thereof. The honeycomb geocell earth retaining wall comprises a foundation arranged on the ground and a wall body arranged on the foundation; the wall body comprises a reinforced bed course, a composite geo-membrane, reinforced polypropylene water storing and draining modules, a filament geotextile and honeycomb geocells, wherein the reinforced bed course, the composite geo-membrane, the reinforced polypropylene water storing and draining modules, the filament geotextile and the honeycomb geocells are sequentially arranged on the surface of a slope in a paving mode; the foundation and the reinforced bed course each comprise reinforced lime earth improving loess, polypropylene two-way geogrids and a drain pipe; the multiple polypropylene two-way geogrids are parallelly arranged in the reinforced lime earth improving loess; and the drain pipe in the reinforced bed course and the drain pipe in the foundation are connected with the reinforced polypropylene water storing and draining modules correspondingly. The provided honeycomb geocell earth retaining wall with the ecological restoration function is high in bearing capacity, dynamics performance, slide resistance and erosion resistance and can be filled with a gravel soil layer, grass is planted in the gravel soil layer, not only can water and soil erosion be effectively prevented, but also a greening function is achieved, and accordingly, effective combination of ecological restoration and engineering management is achieved; and the construction method is simple, construction is convenient, and the cost is low.

Owner:NORTHWEST UNIV(CN)

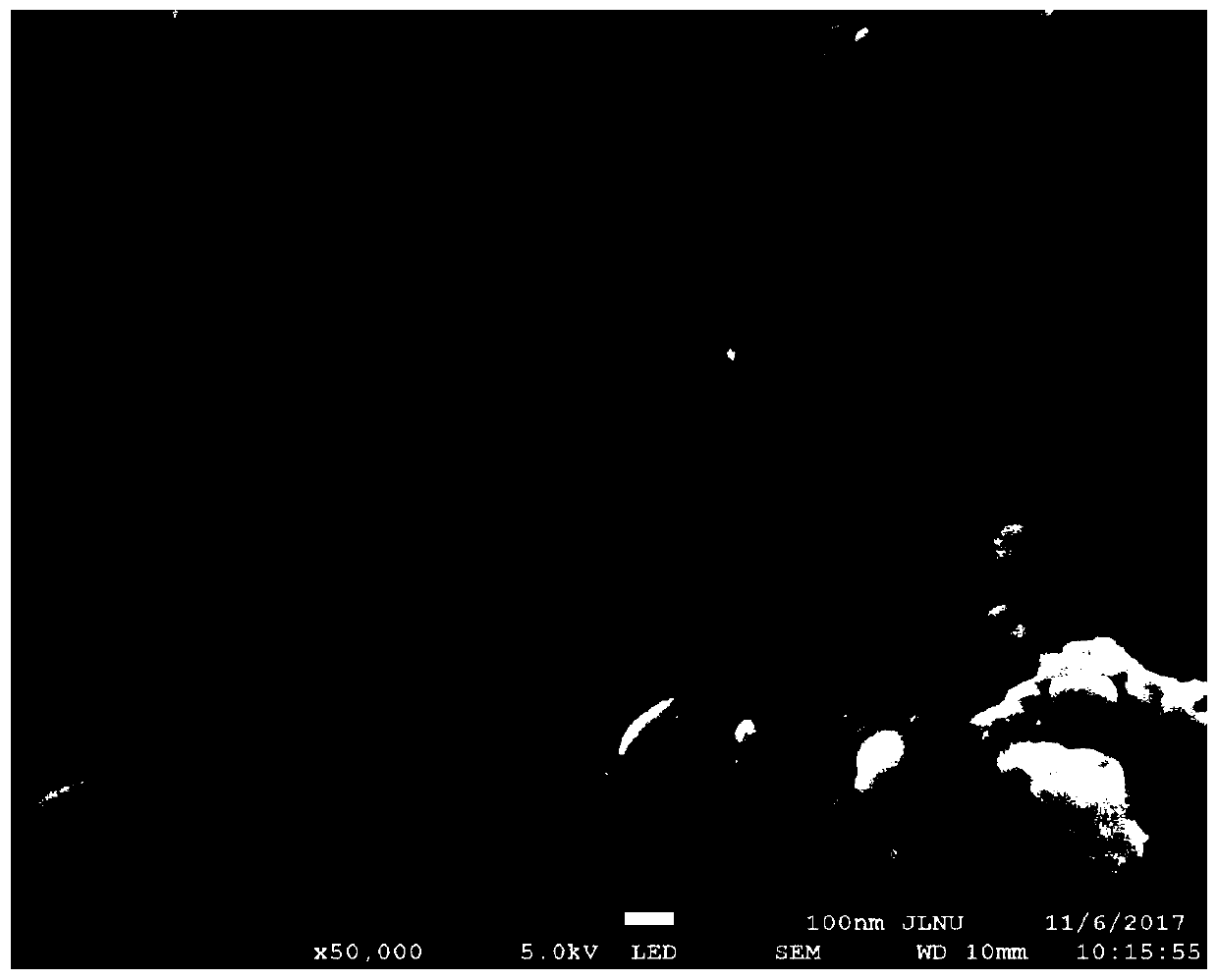

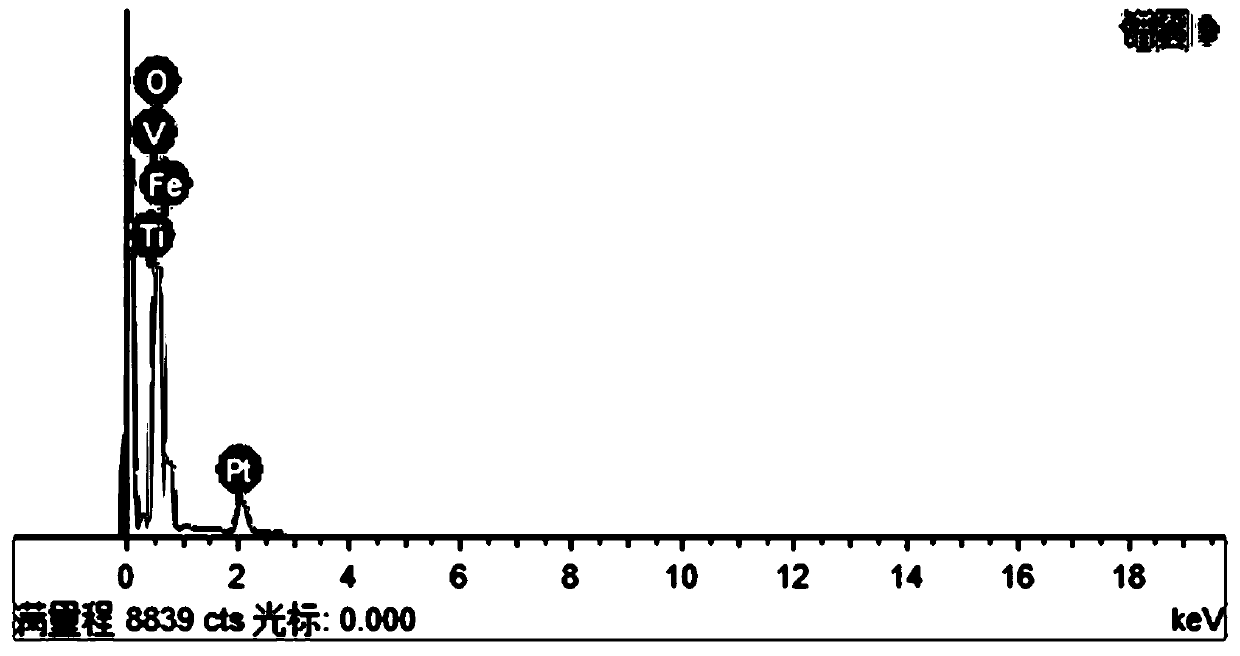

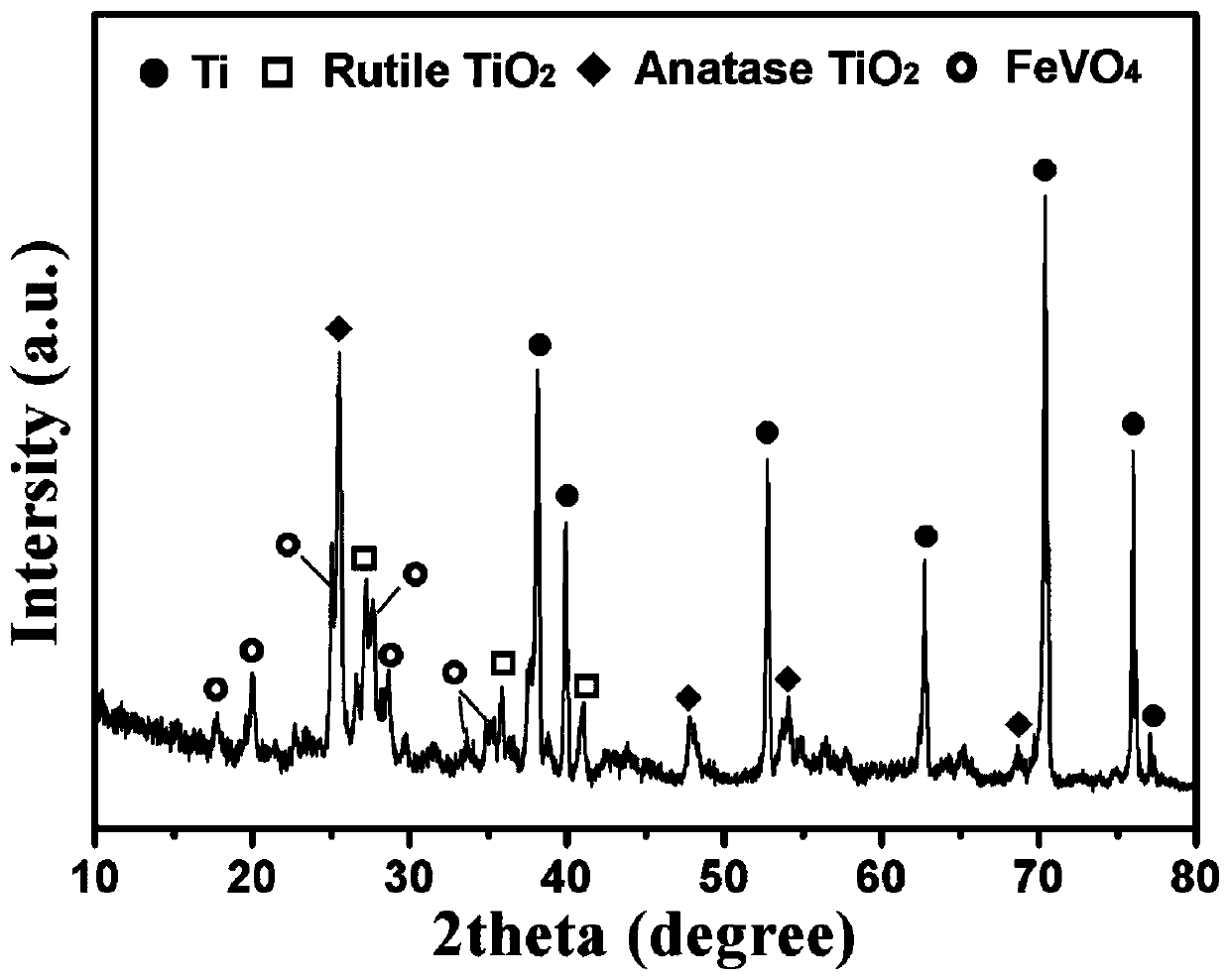

FeVO4/TiO2 porous catalyst film layer material for photo-Fenton combined catalysis and preparation method of FeVO4/TiO2 porous catalyst film layer material

ActiveCN110624560ARealize industrial productionEasy to operateWater/sewage treatment by irradiationWater treatment compoundsMaterials preparationFenton reaction

The invention discloses a FeVO4 / TiO2 porous catalyst film layer material for photo-Fenton combined catalysis and a preparation method of the FeVO4 / TiO2 porous catalyst film layer material, belongs tothe technical field of photo-Fenton combined catalytic material preparation. Aiming at the lack of a method and a catalyst capable of efficiently combining photocatalysis and Fenton reaction at present, a micro-arc oxidation method is utilized; a TiO2 film layer containing Fe and V is generated on the surface of a titanium substrate, then the FeVO4 / TiO2 porous catalyst film layer material is obtained through roasting in a protective atmosphere, photocatalysis and Fenton reaction are successfully and efficiently combined together, and the efficient catalyst capable of being used for degrading organic pollutants is obtained.

Owner:哈尔滨规格科技有限公司

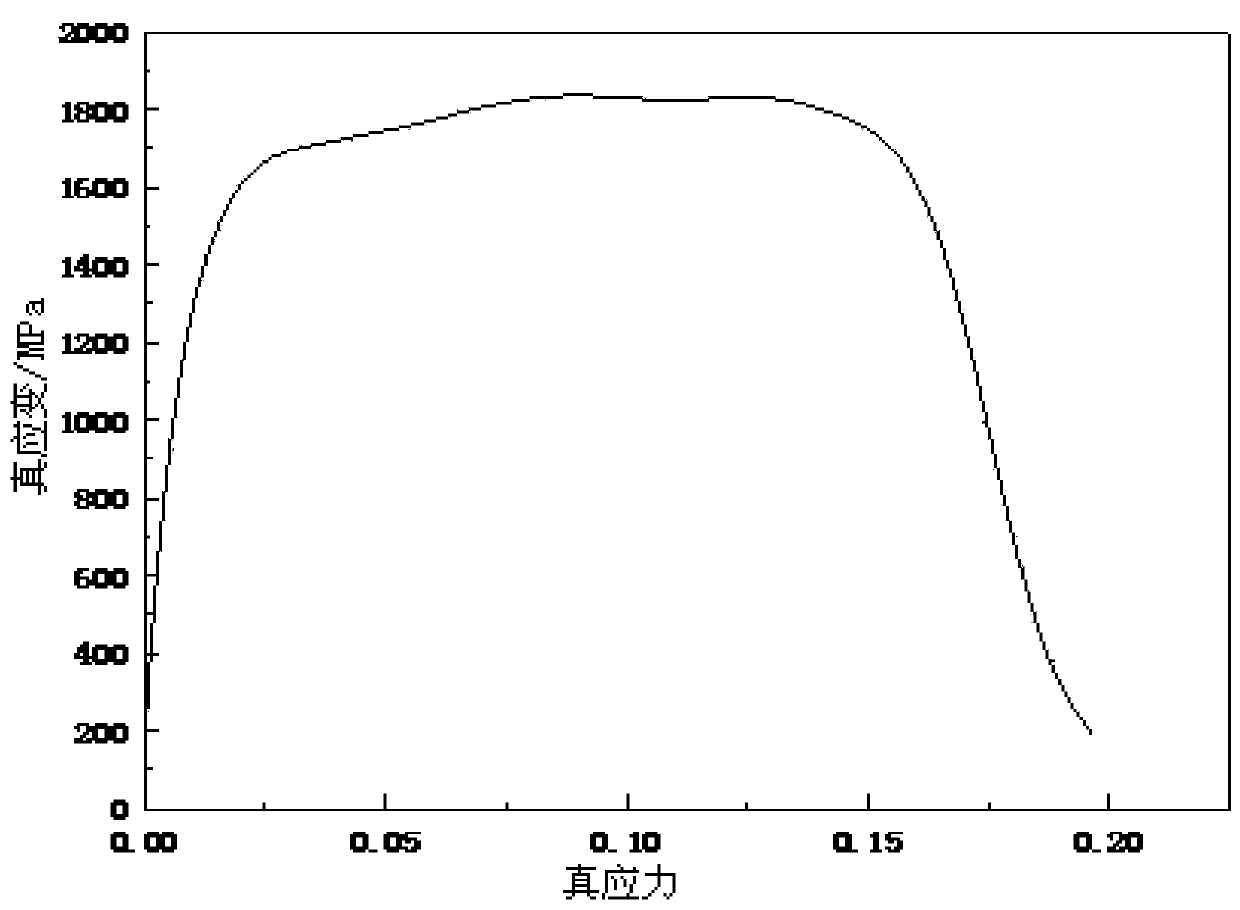

High-performance and low-cost titanium alloy

The invention discloses a high-performance and low-cost titanium alloy. The high-performance and low-cost titanium alloy is composed of the following components of, in percentage by mass, 4.3%-6.6% of Al, 2.0%-3.0% of V, 2.6%-3.2% of Mo, 1.6%-2.1% of Fe and the balance Ti and inevitable impurities, wherein the titanium alloy takes 1-grade titanium sponge, iron-molybdenum alloy, pure aluminum and TC4 recycled materials as raw materials and is obtained through a method of electron beam cold bed smelting. According to the high-performance and low-cost titanium alloy, the electron beam cold bed smelting method is adopted, and through the adding of the raw materials such as titanium sponge and the iron-molybdenum alloy which are not prone to causing high-density sinking and low-density volatilizing, so that non-uniformity of elements in the titanium alloy during the smelting process is avoided; meanwhile, large-scale utilization of the TC4 recycled material is realized, and the raw material cost is greatly reduced; in addition, the performance of the titanium alloy meets requirements of high strength and high dynamic bearing capacity of titanium alloy structural members in the military and civilian fields.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

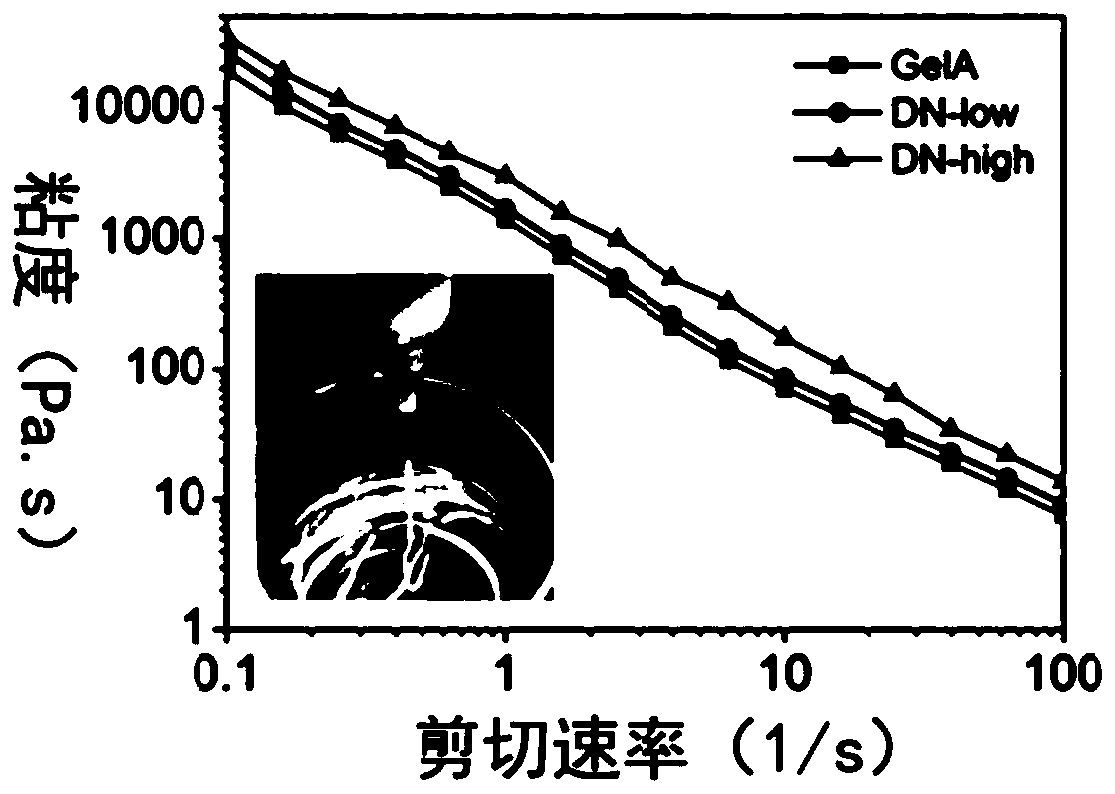

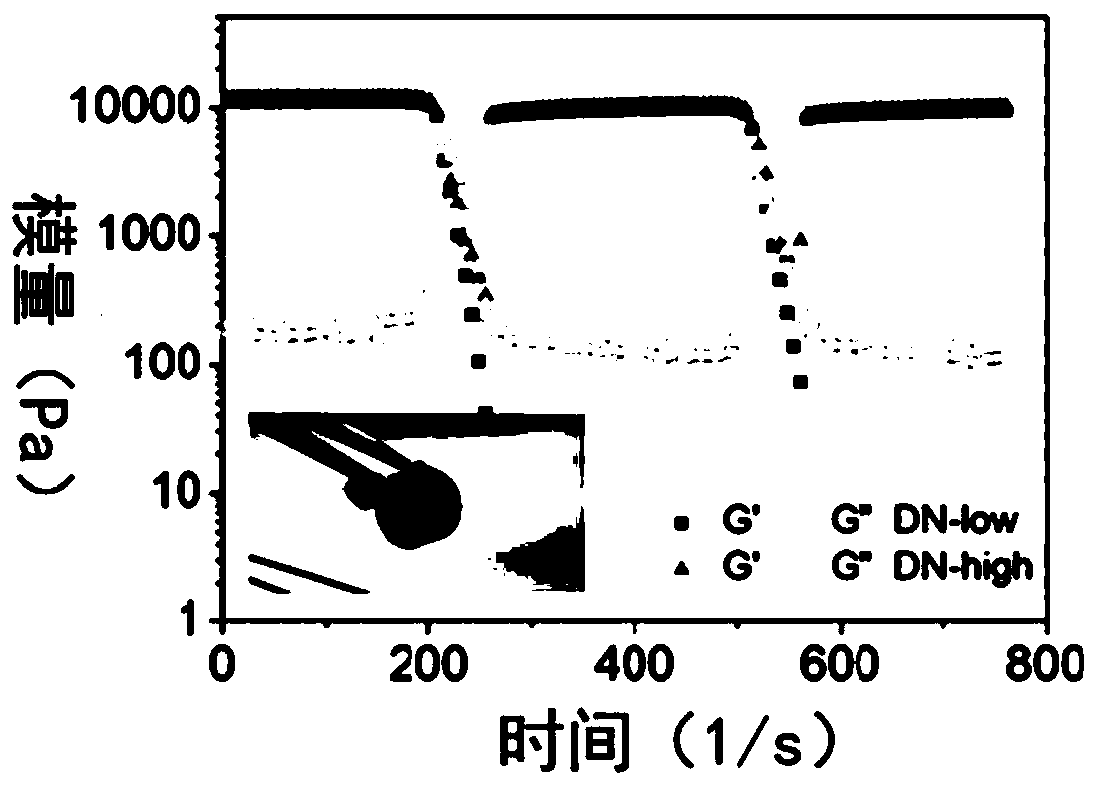

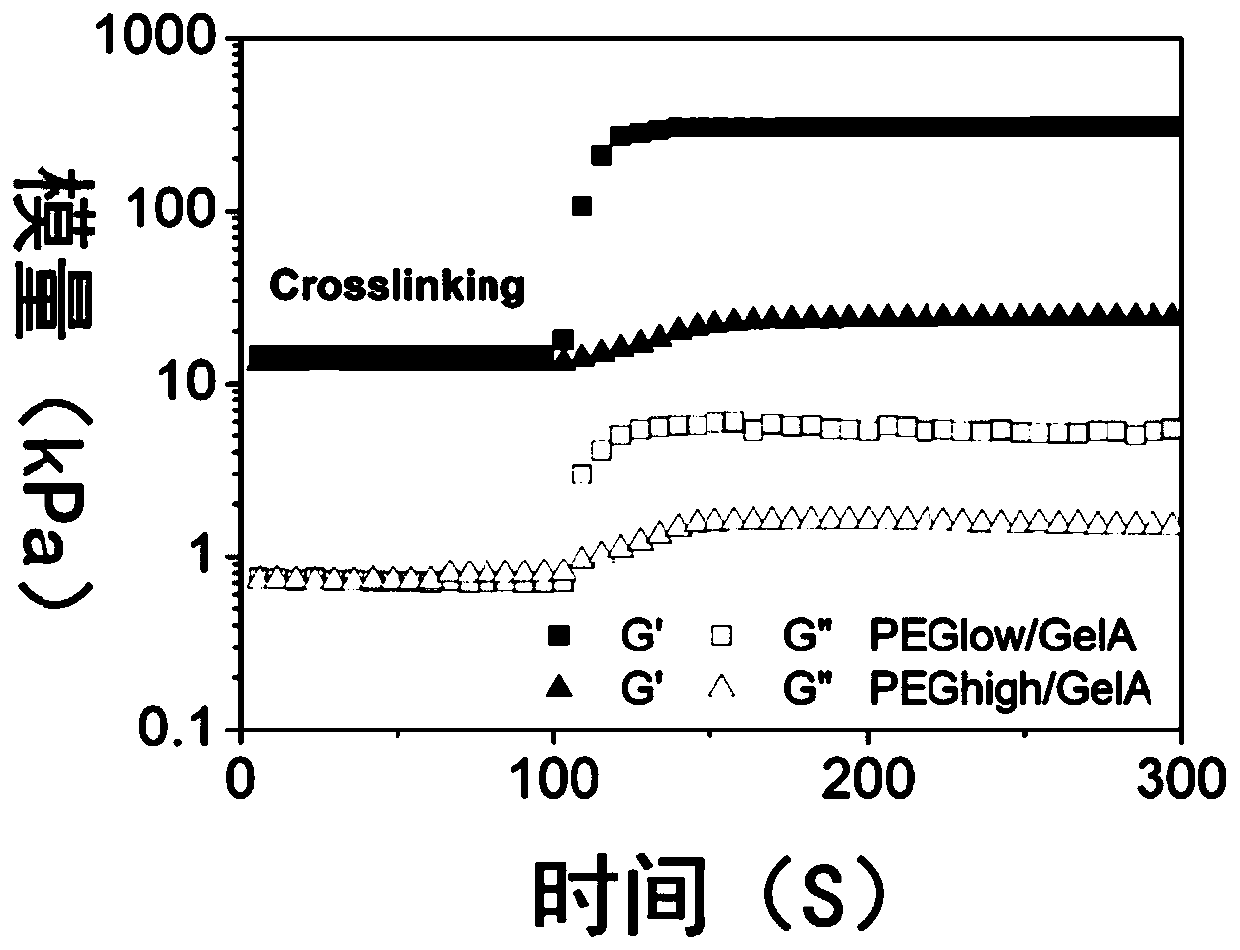

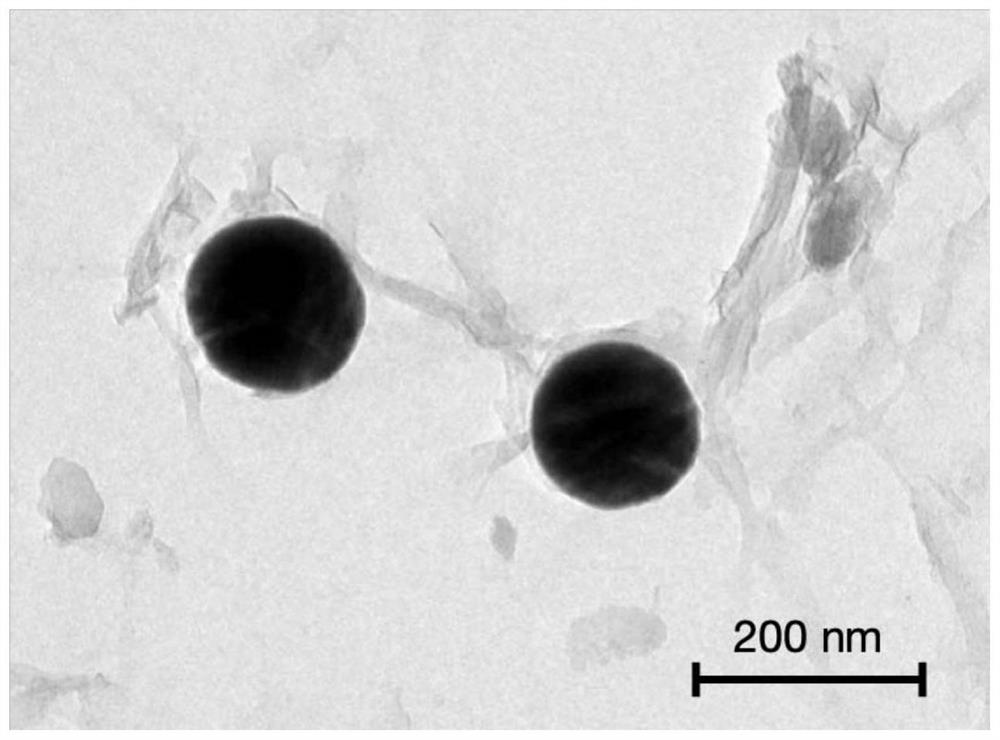

Double-network hydrogel based on polyethylene glycol/gelatin particles and preparation method and application thereof

InactiveCN111040205AGood biocompatibilityInfluence structureAerosol deliveryOintment deliveryPolymer sciencePolyethylene glycol

The invention discloses polyethylene glycol / gelatin particle dual-network hydrogel based on dual-network design and a preparation method thereof. Gelatin particles capable of dissipating energy of a network and polyethylene glycol macromolecules capable of keeping the structural integrity of the hydrogel are used, and the hydrogel material with high mechanical properties is formed on the basis ofa double-network design, when the polymer network is not formed, the reversible physical interaction between the colloidal gel materials endows the hydrogel with excellent shear thinning and self-repairing properties, and after the polymer network is formed, the mechanical properties of the hydrogel are obviously enhanced, and the hydrogel has printability and biocompatibility and has huge application potential in tissue engineering and regenerative medicine.

Owner:DALIAN UNIV OF TECH

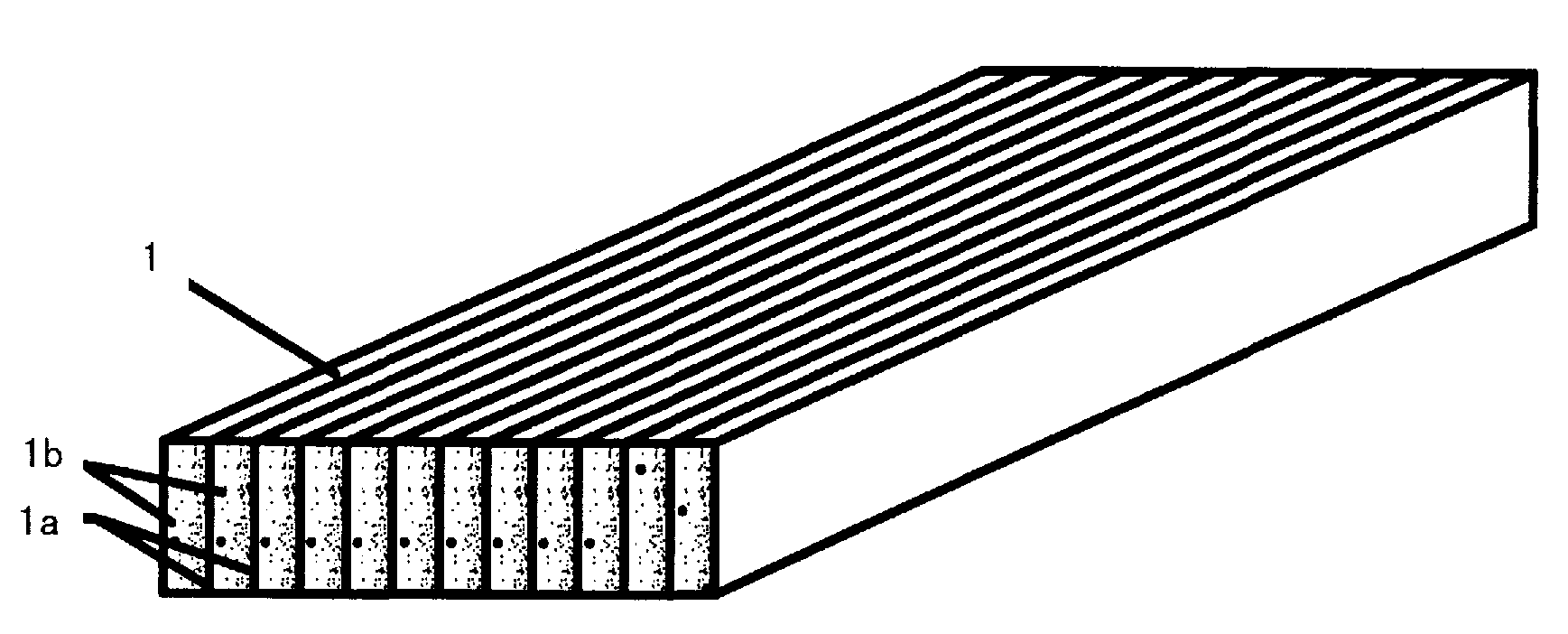

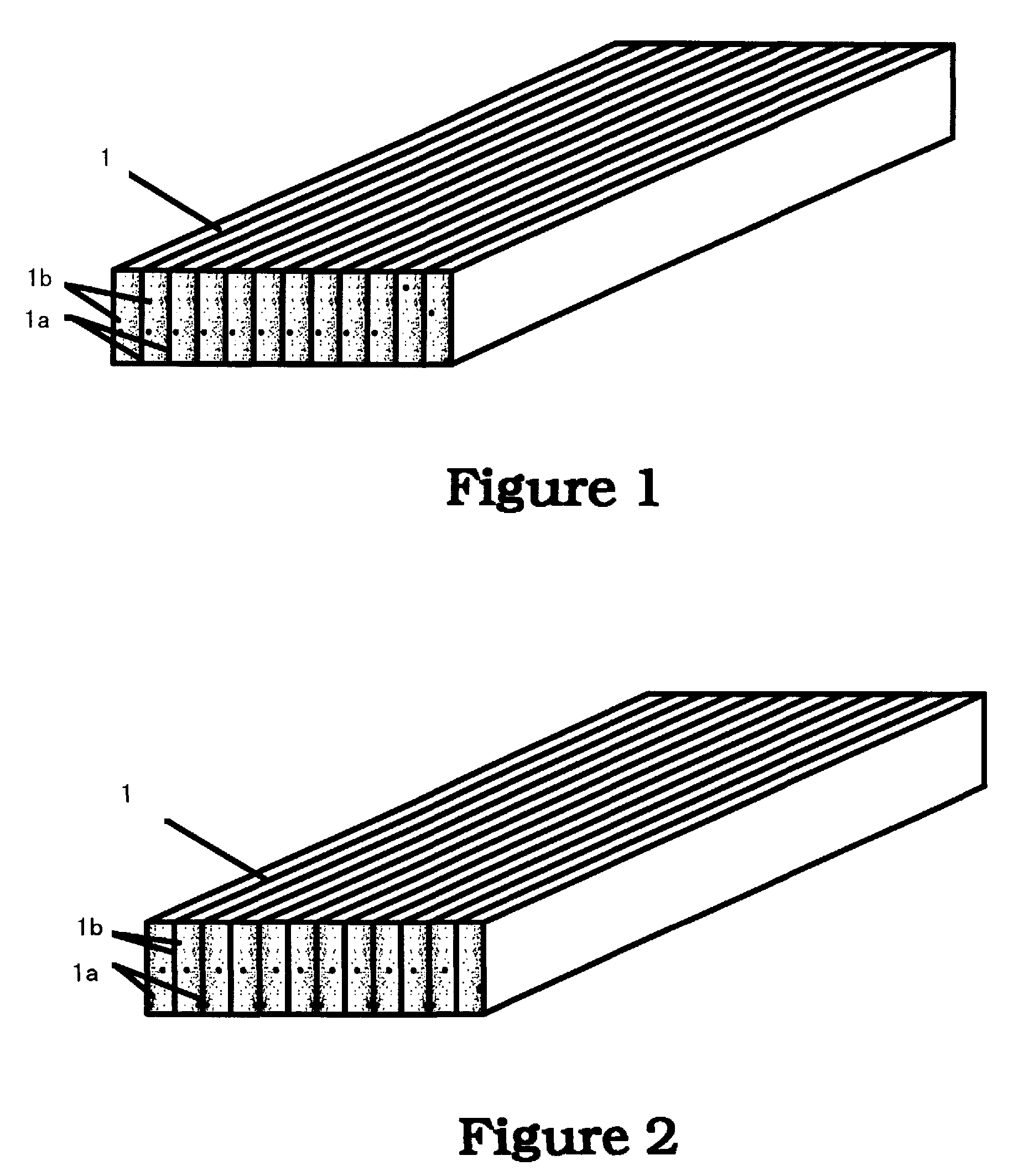

Method of manufacturing laminated bamboo sliver lumber

ActiveUS8231757B2High strengthImprove mechanical propertiesLamination ancillary operationsCane mechanical workingEngineeringMildew

A method of manufacturing laminated bamboo sliver lumber comprises steps of: preparing bamboo slivers; performing moth-proofing, mildew-proofing, and antiseptic treatments to the bamboo slivers and then drying the bamboo slivers to a moisture content of about 6-15%; machining each dried bamboo sliver to a thickness of about 0.5-3.5 mm (0.02-0.14 in) and a width of about 5-22 mm (0.20-0.87 in) and then dehumidifying the machined bamboo slivers to a moisture content of about 3-10%; applying a glue to the bamboo slivers by glue-coating or “immerging” process, in which a ratio of the glue to an absolute dry weight of the bamboo slivers is about 3-16%; and arranging the glued bamboo slivers with their “width” direction consistent with the “vertical” direction and then pressing the arranged bamboo slivers and curing the glue under a “side” pressure of about 3-15 MPa (0.44-2.18 ksi) and a “top” pressure of about 1-6 MPa (0.15-0.87 ksi) so as to form the laminated bamboo sliver lumber.

Owner:DASSO INDASTRIAL GRUP KO LTD

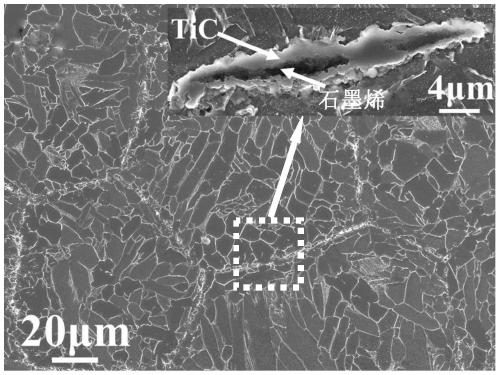

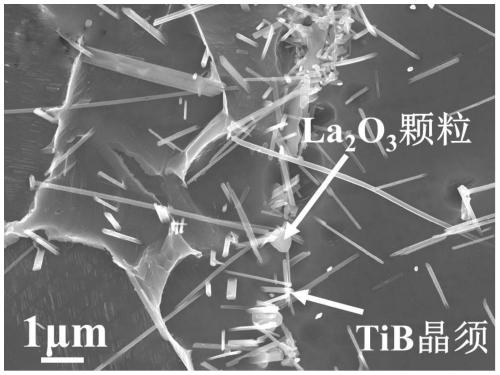

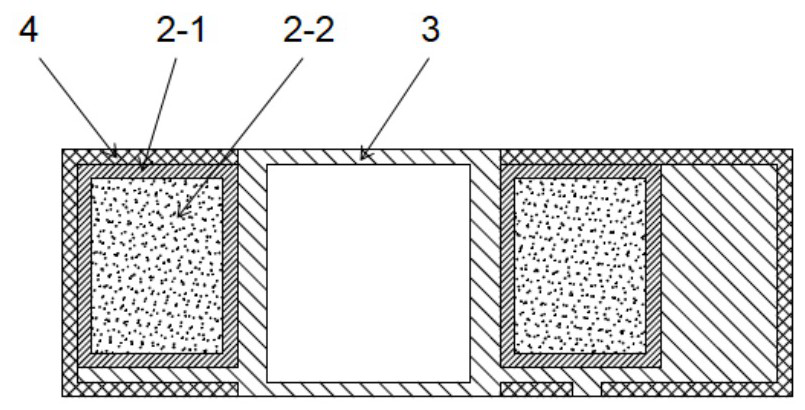

Preparation method for titanium-based composite material with graphene-rare earth mixed micro-structure

ActiveCN110434347AHigh strength mechanical propertiesInhibit growthTransportation and packagingMetal-working apparatusRare-earth elementCvd graphene

The invention discloses a preparation method for titanium-based composite material with a graphene-rare earth mixed micro-structure. The method comprises the following steps: firstly, preparing graphene dispersion liquid; secondly, mixing a substance containing a rare earth element with titanium-based powder to obtain rare earth-titanium-based mixed powder; thirdly, adding the graphene dispersionliquid to the rare earth-titanium-based mixed powder, and drying the mixture to obtain three-element mixed powder; fourthly, performing sinter molding on the three-element mixed powder to obtain the titanium-based composite material with the graphene-rare earth mixed micro-structure. According to the method, the three-element mixed powder with the graphene-rare earth mixed micro-structure is prepared by two-step mixing, and the titanium-based composite material with the graphene-rare earth mixed micro-structure is prepared by sintering. Spherical particles of the substance containing the rareearth element play roles in dispersion strengthening and crystal boundary strengthening; in-situ synthesis titanium carbide plays a dispersion strengthening role; the graphene plays a load transmitting role; through collaboration of the three elements, the strength mechanical property of the titanium-based composite material with the graphene-rare earth mixed micro-structure are greatly improved.

Owner:西安稀有金属材料研究院有限公司

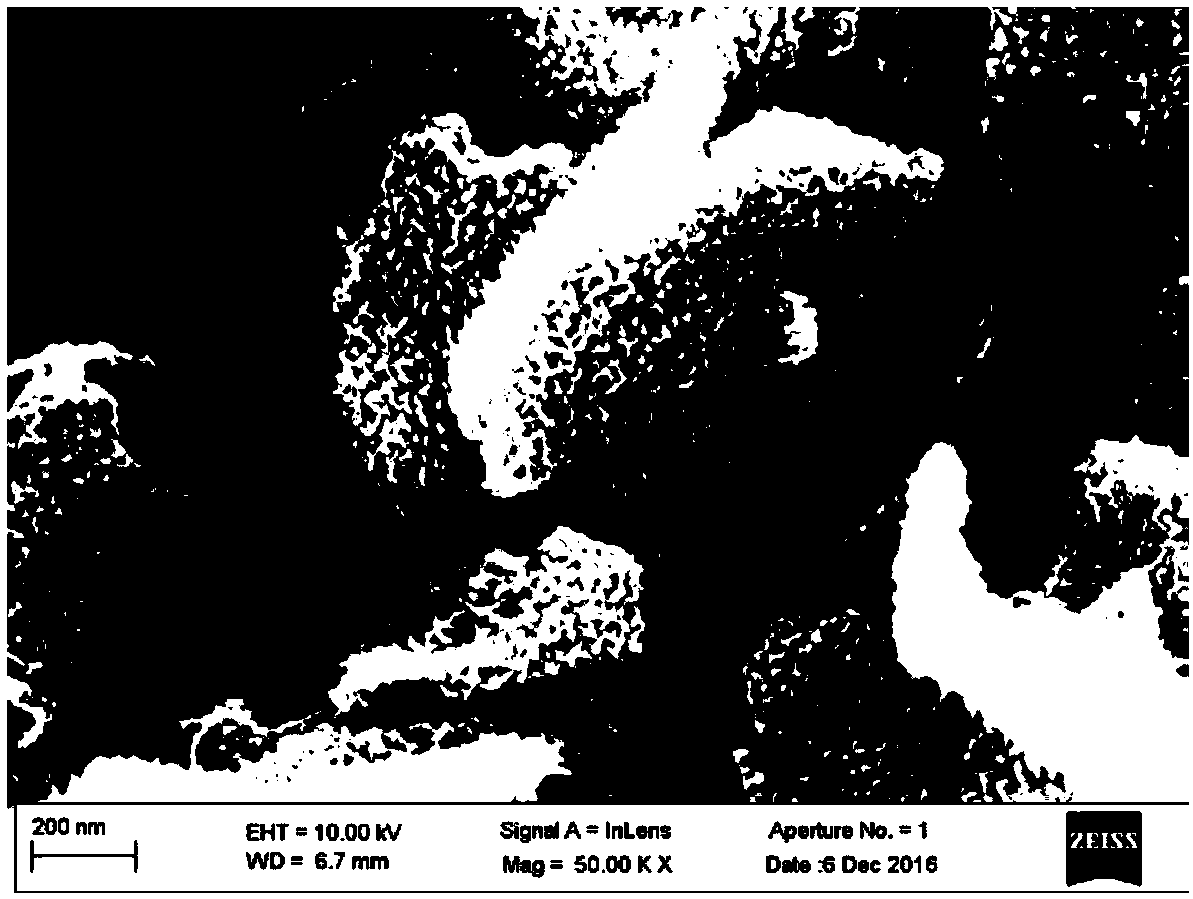

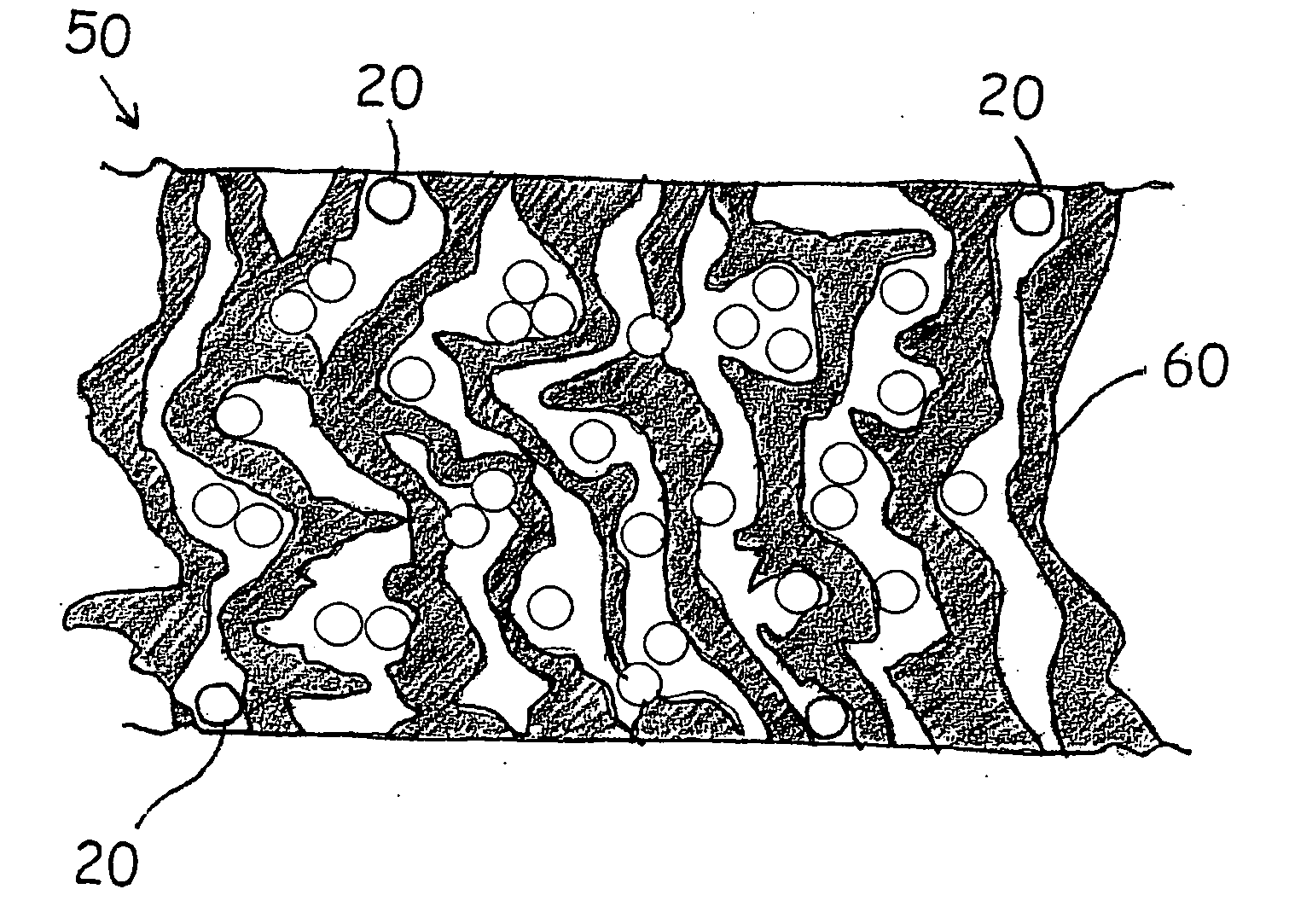

In-situ pore generation in lead-acid battery separator using electrolyte-soluble pore former

ActiveUS8592089B2High strength mechanical propertiesLow in electricalCell component detailsLead-acid accumulators constructionIonic diffusionPorosity

A microporous polyethylene battery separator material (212), for use in a flooded-cell type lead-acid battery, benefits from increased porosity, enhanced wettability, and exceptionally low electrical resistance when an electrolyte-soluble pore former is employed in the manufacturing process. The pore former (210) is soluble in electrolytic fluid and therefore dissolves in-situ in sulfuric acid during battery assembly. The dissolution of the pore former leaves behind additional, larger voids (220) in the separator material and thereby enhances ionic diffusion and improves battery performance.

Owner:AMTEK RES INT

Biomedical electric activity water gel and preparation method thereof

InactiveCN108864443AHigh strength mechanical propertiesGood biocompatibilityTissue regenerationProsthesisIonNerves tissue

The invention discloses biomedical electric activity water gel and a preparation method thereof, and relates to the field of high molecular materials, in particular to the biomedical electric activitywater gel and the preparation method thereof. The biomedical electric activity water gel can be prepared by the method with steps of using natural and non-toxic compounds of glycine and choline to form ion liquid; then using acrylic acid to modify ion liquid; forming vinyl choline-glycine ion liquid monomers; using N, N-methylene bisacrylamide (MBAA) as crosslinking agents; using potassium peroxodisulfate (KPS) as initiators; preparing polyionic liquid gel through free radical polymerization; using the polyionic liquid gel as a first gel network; using American FDA authenticated polyethyleneglycol (PEG) as reaction monomers of a second gel network; using N, N-methylene bisacrylamide (MBAA) as the crosslinking agents; uisng potassium peroxodisulfate (KPS) as the initiators; forming the electric activity gel with the high mechanical strength with the first gel network. The gel has good biocompatibility and biodegradability and can be used in the fields of nerve tissue engineering, myocardiac tissue engineering and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Refractory material with high strength and mechanical property

InactiveCN108033796AImprove mechanical propertiesHigh Strength Mechanical PropertiesCeramic materials productionClaywaresRare-earth elementSilicon dioxide

The invention relates to the technical field of researches and developments of refractory materials, and discloses a refractory material with high strength and mechanical property. A large number of non-clay silicate components in iron pyrite are used; zirconium oxide and silicon dioxide are used as skeleton structures and raw materials; aluminum oxide, ferric oxide and the like are used as combustion aids; a multiphase material is sintered to be compact by using a toughening mechanism of a rare earth element to a zirconium oxide material through a liquid phase sintering mechanism of the rareearth element under a reducing atmosphere, so that the mechanical property of the refractory material is improved; furthermore, an optimal raw material proportion, an optimal granularity and an optimal sintering temperature are researched to improve the compaction degree and the physical property of the material, so that the refractory material with high strength and mechanical property is prepared; furthermore, the recycling and utilization rate is high.

Owner:安徽雷萨重工机械有限公司

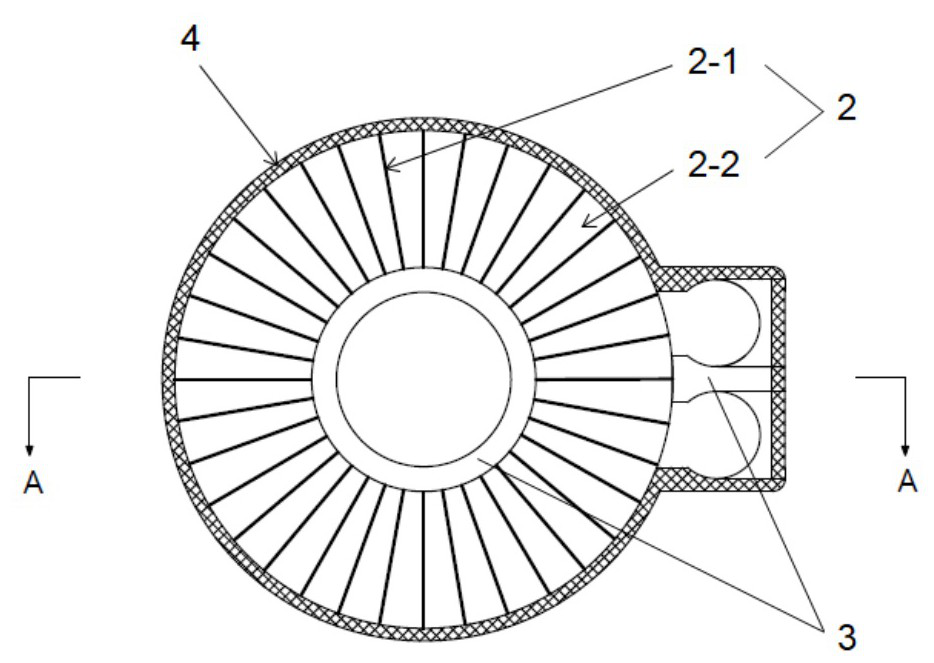

Preparation method and device of special membrane material for mining air drum

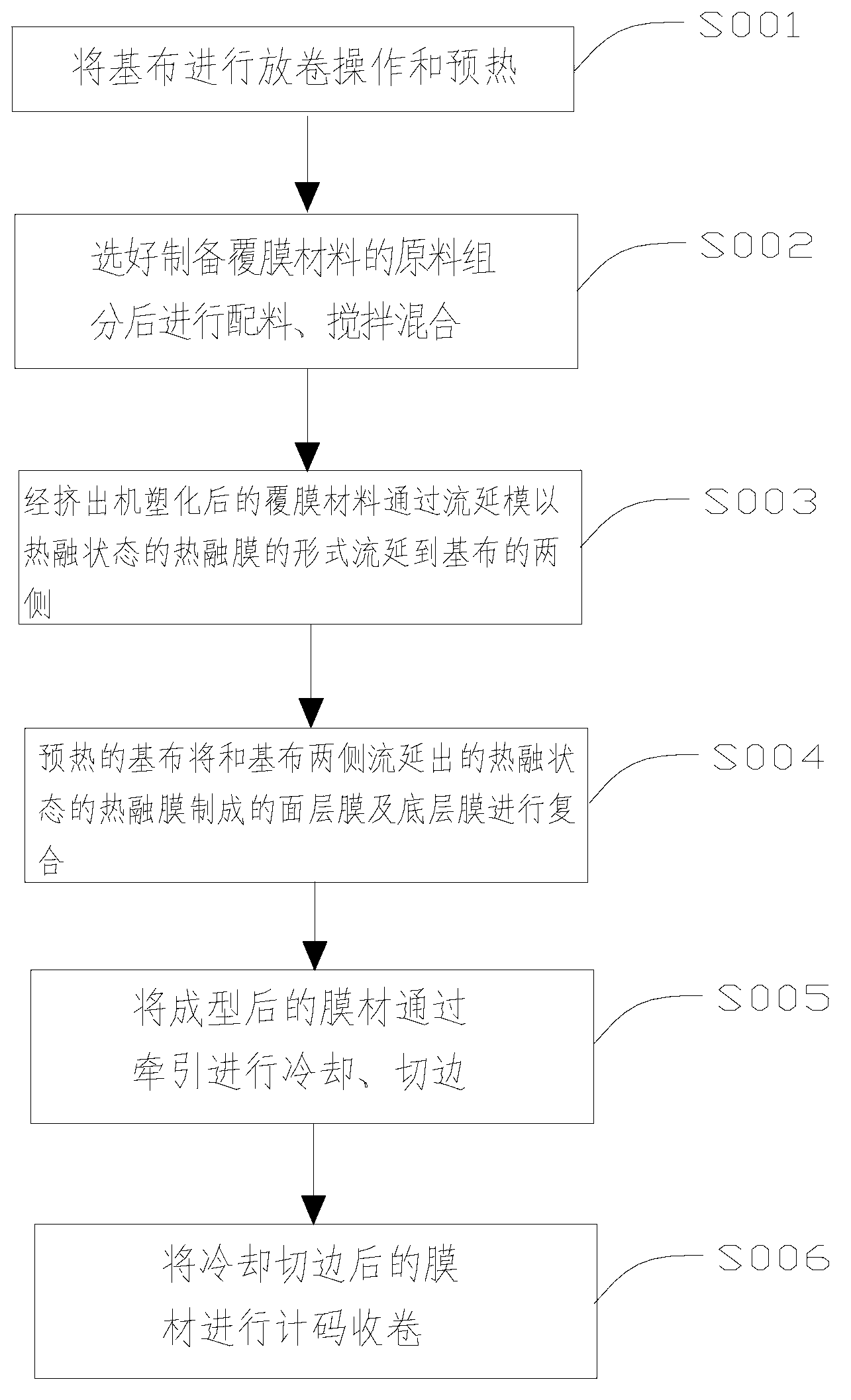

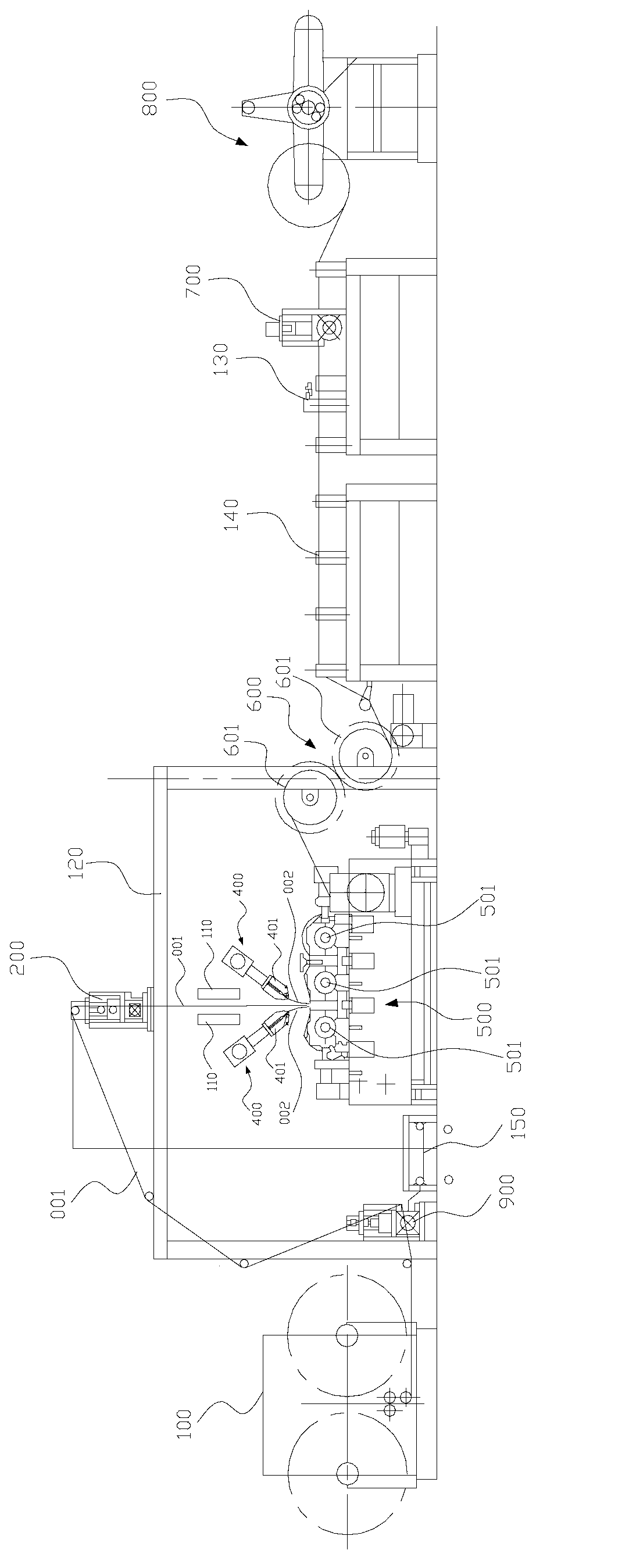

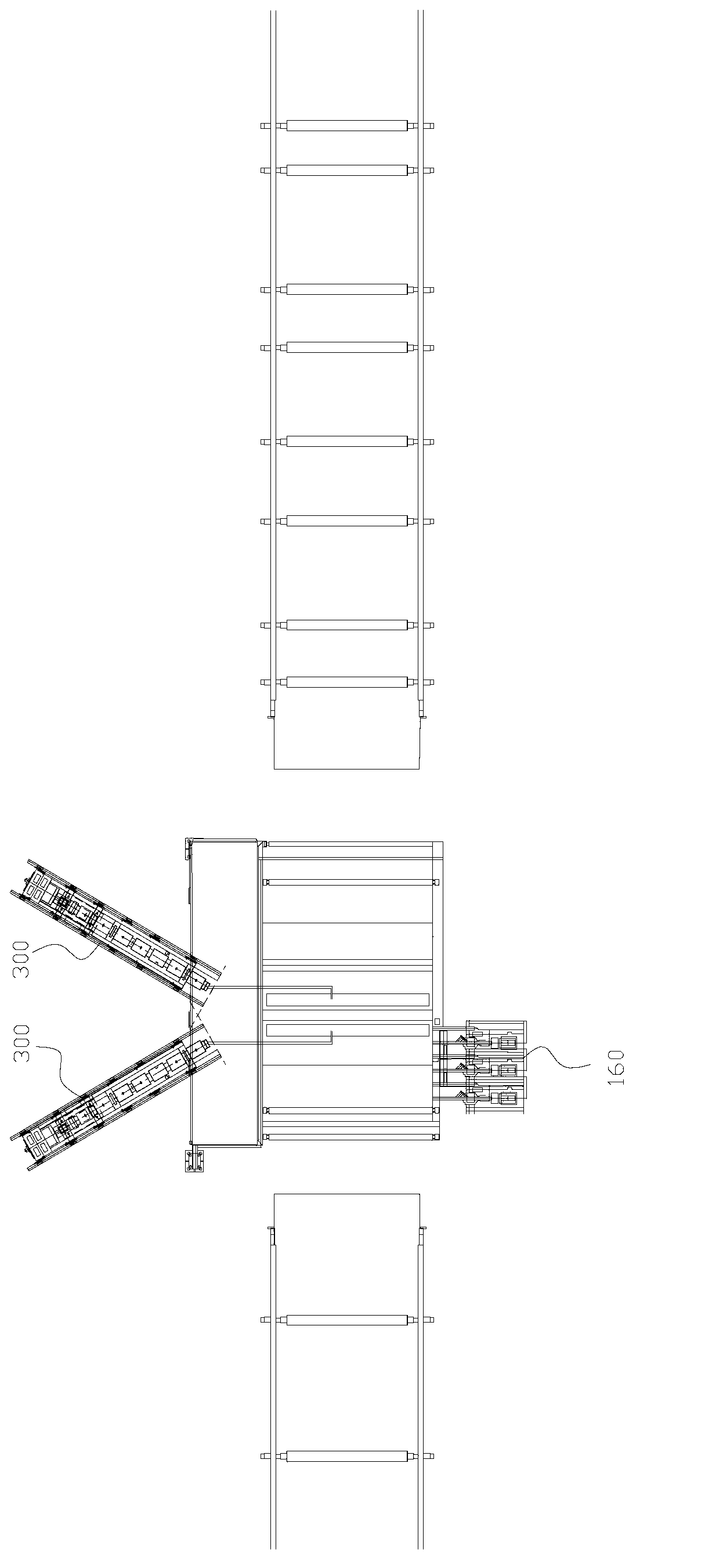

InactiveCN103192584ALess investmentRealize the purpose of energy savingLaminationLamination apparatusCasting moldHot melt

The invention discloses a preparation method of a special membrane material for a mining air drum. The preparation method comprises the following steps of: unreeling base cloth; selecting raw material components for preparing the covering membrane material, and then burdening and mixing; respectively plasticizing the covering membrane material through two extruders, then outflowing from two tape casting molds to form hot melt membrane, simultaneously casting the hot melt membrane on the two sides of the base cloth by the two tap casting molds, and carrying out hot melt composition by a hot melt composition device; and drawing and cooling the membrane material subjected to hot melt composition to obtain the finished product. Simultaneously, the invention discloses a device for preparing the special membrane material for the mining air drum. Compared with the prior art, the method and the device have the characteristics of little investment and energy saving. The covering membrane material is simultaneously cast on the two sides of the preheated base cloth, so that one-time molding is realized, heating composition only needs to be carried out once, and the operation of repeated heating and cooling is omitted, thus lots of heat and manual labor are saved, the cost is also saved, and moreover, the purpose of energy saving is realized.

Owner:JIANGSU SULONG ENVIRONMENTAL PROTECTION TECH

Multi-element composite anti-oxidation Ti2AlNb alloy and preparation method thereof

ActiveCN111647771AImprove antioxidant capacityHigh Strength Mechanical PropertiesTemperature control deviceExtrusion control devicesSmelting processChemical element

The invention provides a multi-element composite anti-oxidation Ti2AlNb alloy and a preparation method thereof. The alloy contains chemical elements by weight percentage: Al: 20%-25%, Nb: 20%-23%, W:0.1%-1.5%, Zr: 1%-3%, Si: 0.1%-1%, Ta: 0.1%-2%, W + Zr + Si + Ta: 1.5%-7.5%, and the balance of Ti. The preparation method comprises courses of alloy proportioning, smelting, cogging and forging, wherein a method for arranging a piezoelectric electrode on an alloy with high-melting-point alloy elements in a distributed manner is used for alloy proportioning; a three-vacuum self-consumption smelting technology is used for the smelting process; a method of homogenizing thermal treatment + extrusion clogging is used for the clogging process; and multi-phase area alternate forging method is adopted for the forging process. According to the invention, alloy elements such as W, Zr, Si and Ta are added in a Ti-Al-Nb system; the smelting and forging technologies with alloy composition homogenization and organizational homogenization are combined; high-temperature oxidation resistance of the Ti2AlNb alloy is enhanced obviously; and high-strength mechanical performance is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Environment-friendly wood optimization solution

InactiveCN106142259AIncrease profitExtended service lifeWood treatment detailsWood impregnation detailsEmulsionLower grade

The invention relates to an environment-friendly wood optimization liquid, which comprises the following components in parts by weight: 10%-50% of alkaline silica sol, 10%-30% of sodium octaborate, and 2%-vinyl acetate-ethylene monomer emulsion copolymer 10%, magnesium chloride 1%‑2%, catalyst 1.5%‑2%, and water 30%‑60%. This wood optimization solution is compounded with organic and inorganic materials, combining the characteristics of inorganic and organic materials, so that the modified wood has significant advantages such as flame retardancy, loss resistance, and dimensional stability, and realizes the high-grade of low-grade wood. Improve the utilization rate and service life of wood. The formulation of the optimized solution is non-toxic, halogen-free, and has good environmental protection performance. It belongs to an environment-friendly optimized solution for wood modification treatment, and does not pollute the environment during production and use.

Owner:NANJING BOJUN NEW MATERIAL CO LTD +1

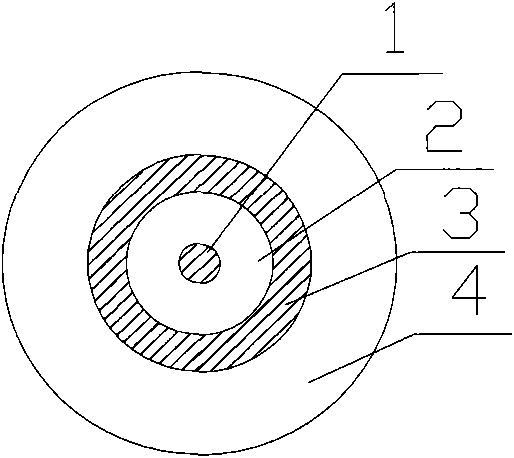

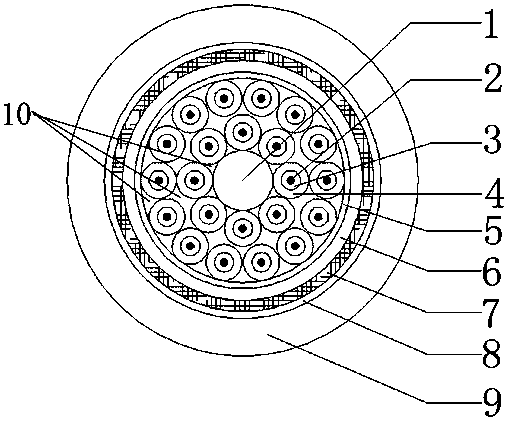

High-flexibility tensile flame-retardant fireproof shielding towline cable

InactiveCN108133771AMove fastHigh strength mechanical propertiesInsulated cablesDetails of conductive coresPolyesterCopper foil

The invention discloses a high-flexibility tensile flame-retardant fireproof shielding towline cable comprising a tensile element which is arranged at the center of the cable. The tensile element is externally provided with a first cable core layer and a second cable core layer in turn. The second cable core layer is externally wrapped by a first smooth polyester film isolation layer. The smooth polyester film isolation layer is externally extruded by a fireproof lining layer. The fireproof lining layer is externally provided with a copper foil wire braided shielding reinforced layer. The copper foil wire braided shielding reinforced layer is externally wrapped by a second smooth polyester film isolation layer. The second smooth polyester film isolation layer is externally extruded by a composite TPU elastomer sheath layer. The gap between the tensile element, the first cable core layer and the second cable core layer is filled with fibers. The high-flexibility tensile flame-retardantfireproof shielding towline cable has the characteristics of being high-flexibility, tensile, fireproof, long in service life and high in reliability so that the use requirements of the modern intelligent industrial electronic system can be met.

Owner:WUXI MINGZHU CABLE

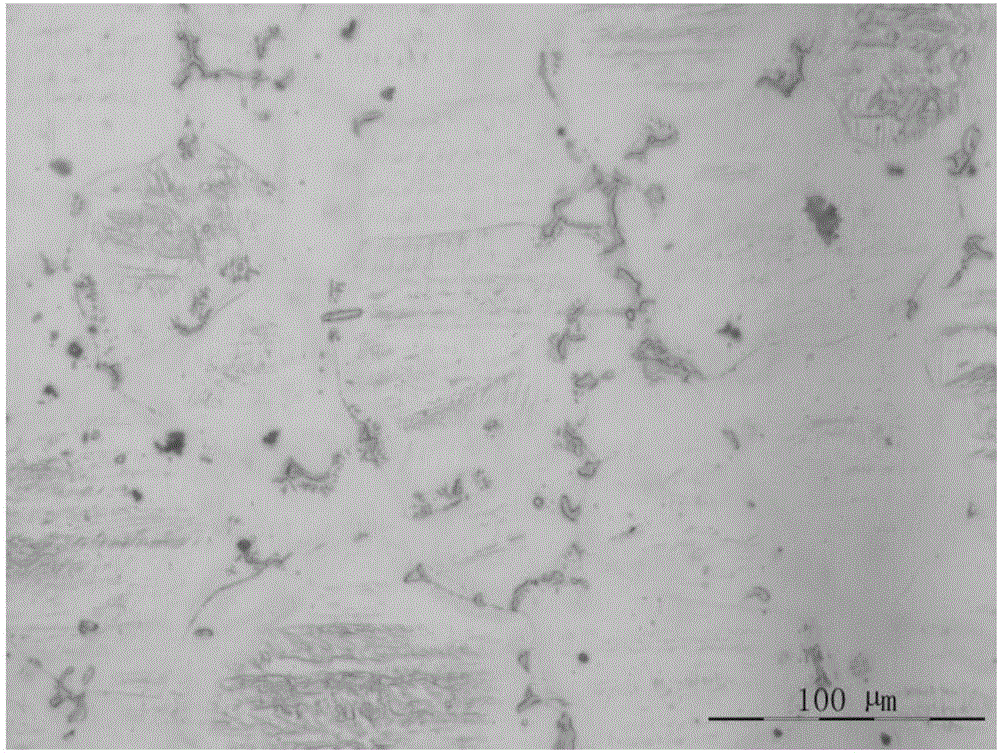

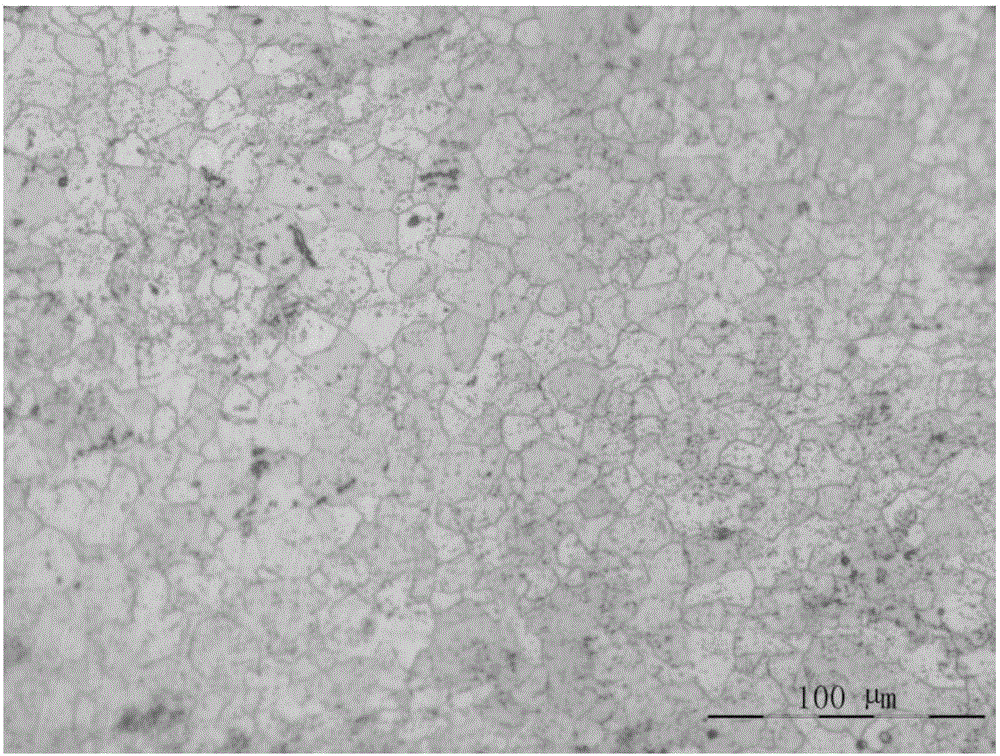

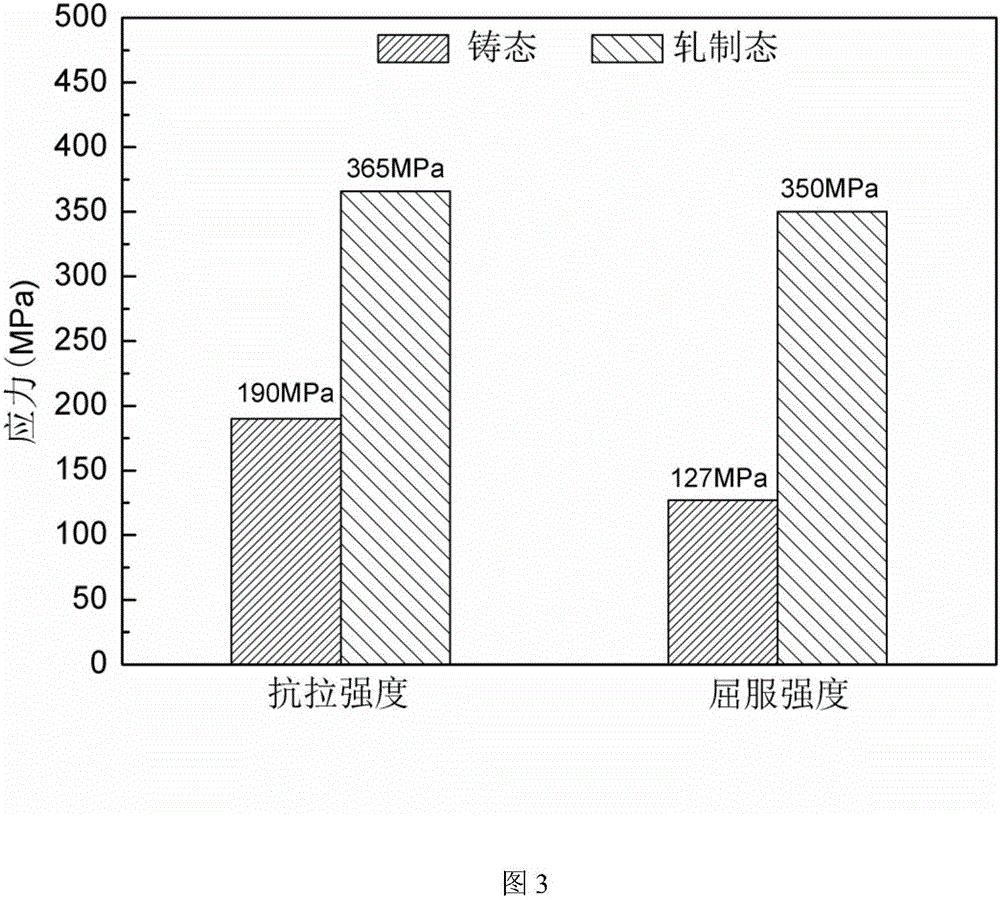

Low-cost short-process manufacture technique for high-strength rare earth magnesium alloy plate

The invention discloses a low-cost short-process manufacture technique for a high-strength rare earth magnesium alloy plate, belonging to the field of metal material machining. The manufacture technique is characterized in that a low-rare earth-content Mg-Gd-Er-Zr alloy ingot casting is directly subjected to hot rolling with the total pressing amount of 85-97%, so that the high-strength magnesium alloy plate with uniformly and dispersedly distributed strengthening phase Mg5 (Gd, Er) and refined grain structures (with the grain size smaller than 10 mu m) is obtained. The manufacture technique has the characteristics that cost is low; efficiency is high; and alloy strength is high. The manufacture technique can be practically applied to various bearing structure components in the fields of automobiles, aerospace and the like.

Owner:BEIJING UNIV OF TECH

Lead acid battery separator with improved electrical and mechanical properties

InactiveUS20060127661A1High resistivityHigh strengthFinal product manufactureLayered productsPolymer sciencePolyolefin

An oxidation resistant, microporous polyolefin web exhibiting high-strength mechanical and low electrical resistance properties is a solid matrix that includes an ultrahigh molecular weight polyolefin component and a friable precipitated silica component. The ultrahigh molecular weight polyolefin component provides high-strength mechanical properties to the web. The friable precipitated silica component is broken down into predominately discrete silica aggregates dispersed throughout the microporous web to maintain a low electrical resistance in the presence of an electrolyte. In an alternative preferred embodiment, a polyethylene web includes an antioxidant coating that is applied to the separator web following extraction of the majority of the process oils and drying of the extraction fluid from the separator pores. The resultant “sheath” of antioxidant protects the mechanical integrity of the polyethylene separator by suppressing polyethylene degradation.

Owner:ENTEK INT

Integrated micro-molding gradient degradation woven artificial ligament and preparation method thereof

ActiveCN110755175AHigh Strength Mechanical PropertiesStable structureLigamentsMusclesFemoral boneJoint cavity

The invention discloses an integrated micro-molding gradient degradation woven artificial ligament. The integrated micro-molding gradient degradation woven artificial ligament is characterized in thatthe artificial ligament is of an integrally molded structure and is a three-section type woven artificial ligament provided with thighbone and shinbone bone tunnel sections at the two ends and provided with a joint cavity free section in the middle, wherein the thighbone and shinbone bone tunnel sections are constituted by 2-10 layers of tubular or sheet-like jointing tissue; the thighbone and shinbone bone tunnel sections are each of an interwoven structure constituted by multiple layers of warp yarn and weft yarn, and all the layers are connected through the jointing tissue; and parallellyarrayed warp yarn serves as the joint cavity free section. The preparation method comprises the steps of determining of an organization chart of a multi-layer fabric, determining of a looming draft, looming weaving, post-processing and the like. Based on regulation and control over weaving parameters and arrangement of the yarn with different degradation characteristics, gradient degradation of the ligament is achieved, the stress shielding effect at the later stage of implantation is reduced, and a three-dimensional topological structure of the artificial ligament synergistically responds with the biomechanical property, degradation property and tissue induction property of the artificial ligament.

Owner:DONGHUA UNIV

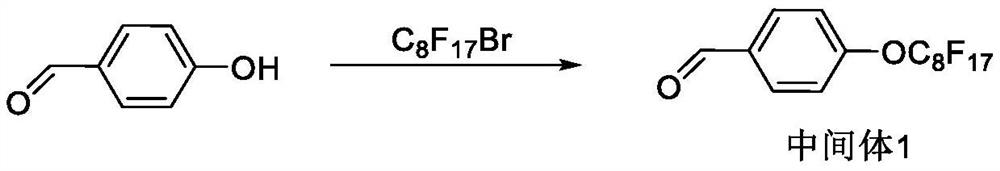

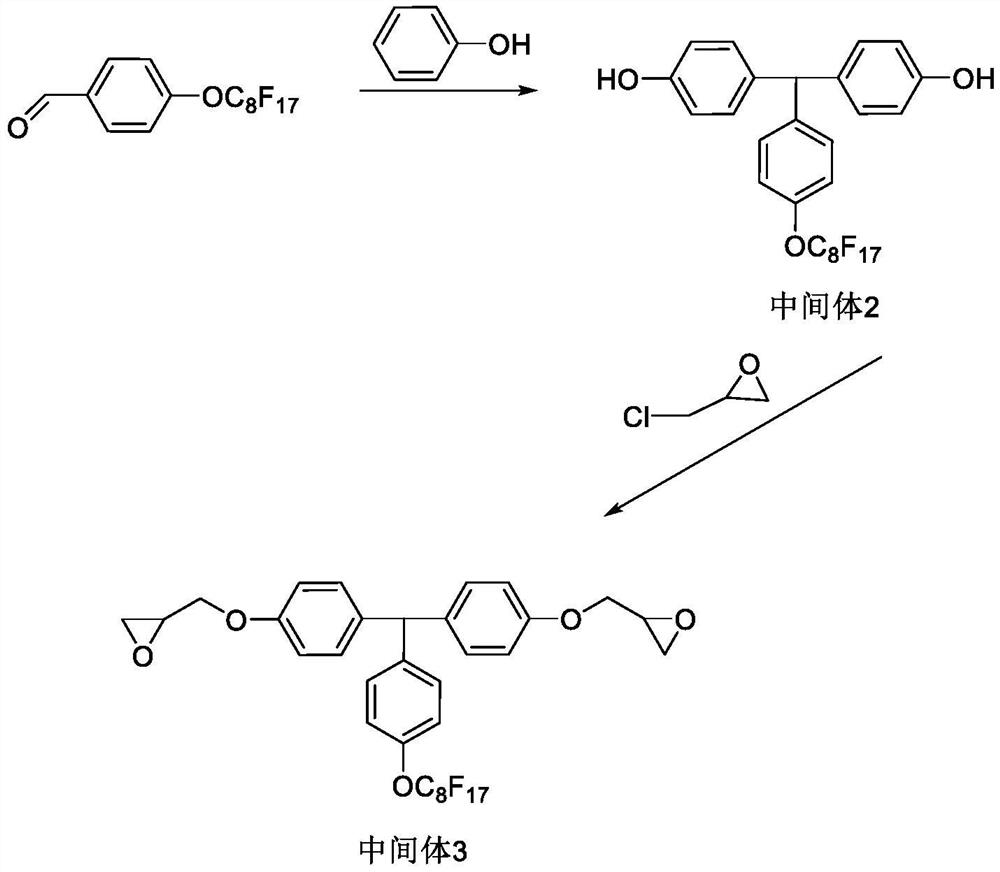

Power cable sheath tube with high insulativity

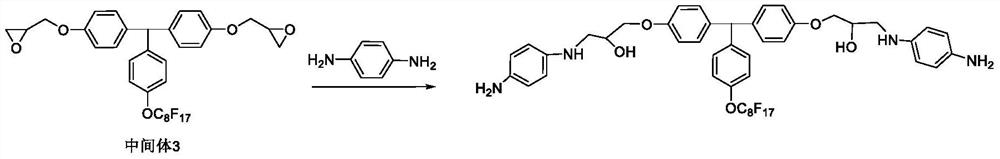

ActiveCN113337041AGood chemical resistanceImprove heat resistanceClimate change adaptationGlass fiberPower cable

The invention discloses a power cable sheath tube with high insulativity, and belongs to the technical field of sheath tube production. The power cable sheath tube comprises the following raw materials by weight: 90-150 parts of polypropylene, 8-17 parts of calcium carbonate, 3-12 parts of glass fiber, 5-12 parts of talcum powder, 1-3 parts of carbon black, 0.5-1.5 parts of a coupling agent, 0.3-0.8 part of an antioxidant, 0.3-1.2 parts of a lubricant, and 1.5-3.5 parts of an anti-corrosion auxiliary agent. And the corrosion-resistant auxiliary agent is introduced into the polypropylene base material, and the corrosion resistance and high insulativity of the power cable sheath tube are further improved through the special molecular structure of the corrosion-resistant auxiliary agent. Due to the fact that molecules of the corrosion-resistant auxiliary agent have long fluorine-containing alkyl chains, the fluorine-containing alkyl chains are easy to gather on the surface of the sheath tube to form a fluorine chain layer, and the fluorine-fluorine chain has high bond energy, so that the corrosion-resistant auxiliary agent has high corrosion resistance, mechanical property and insulating property.

Owner:安庆市悦发管业有限公司

Preparation method of rare earth modified high-intensity non-woven fabrics

InactiveCN108998854AImprove mechanical propertiesHigh Strength Mechanical PropertiesNon-woven fabricsMonocomponent polyesters artificial filamentPolytetramethylene terephthalateMass ratio

The invention discloses a preparation method of rare earth modified high-intensity non-woven fabrics. The preparation method comprises the following operating steps of (1) adding lutecium chloride andthulium chloride to water, then continuing adding sodium napthionate to the water, performing uniform mixing and stirring so as to obtain a mixture, raising the temperature of the mixture, and performing heat preservation so as to obtain rare earth naphthenates; (2) uniformly mixing the rare earth naphthenates with nanometer lutecium oxide, nanometer thulium oxide, sodium methallyl sulfonate andethylenediamine base propanesulfonate so as to obtain resin modifying agents; and (3) uniformly mixing polybutylene terephthalate slices with the resin modifying agents and a flow modifier to obtain anew mixture, adding the new mixture to a slice pelleting machine, performing co-mixing and granulation to obtain PBT master batches, adding the PBT master batches and the polybutylene terephthalate slices to dissolving and spraying equipment in the mass ratio of the PBT master batches to the polybutylene terephthalate slices being 1 to (15-20), and performing melt spinning and knitting so as to obtain the rare earth modified high-intensity non-woven fabrics. The non-woven fabrics prepared by the preparation method disclosed by the invention have good mechanical properties, and can be used under various high-intensity conditions.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

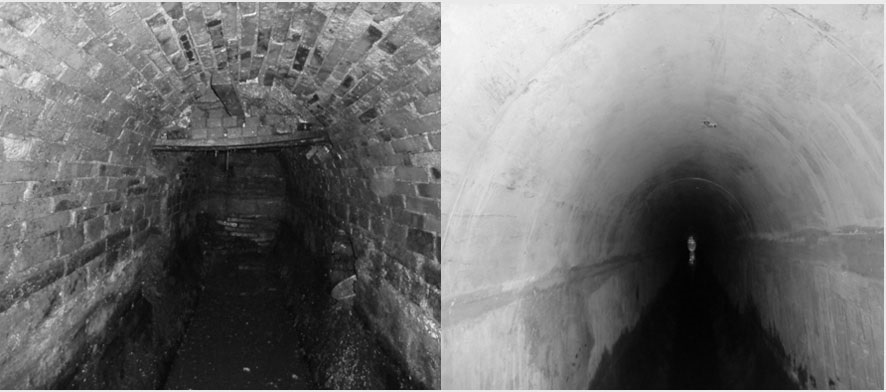

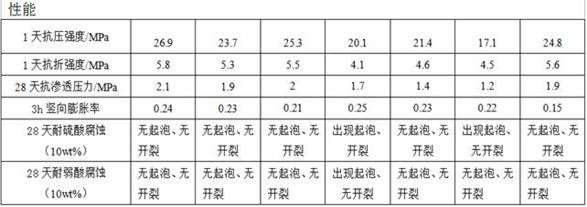

In-service drainage pipeline trenchless plastic spraying repair material and preparation method thereof

ActiveCN112500038AWith micro-expansionPrevent microcrackingSolid waste managementSewer pipelinesFiberPolyvinyl alcohol

The invention relates to an in-service drainage pipeline trenchless plastic spraying repair material and a preparation method thereof. The preparation method comprises the following steps of: mixing acementing material, quartz sand, modified zeolite powder, latex powder, polyvinyl alcohol, a fiber material, a water-retaining agent, epoxy resin and a retarder, and then mixing the mixture with a mixture of a wetting agent, a curing agent and water to obtain the in-service drainage pipeline trenchless plastic spraying repair material. The plastic spraying repair material can be used under the condition of normal drainage of a pipeline, the repair efficiency is ensured, the construction quality is improved, and the effectiveness and reliability of trenchless repair of an in-service defectivedrainage pipeline are ensured. The problems of leakage, corrosion and damage of underground pipelines can be efficiently solved, and the situation that the pipelines are shut down is avoided. The construction cost in drainage pipeline repair is effectively reduced. The repaired pipeline is smooth and flat in surface and uniform in thickness, the impermeability and the corrosion resistance are effectively improved, and actual operation of the underground pipeline can be met.

Owner:堡森(上海)新材料科技有限公司

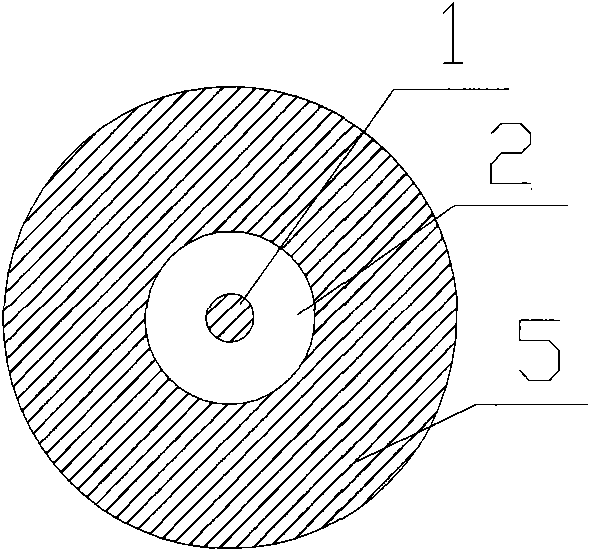

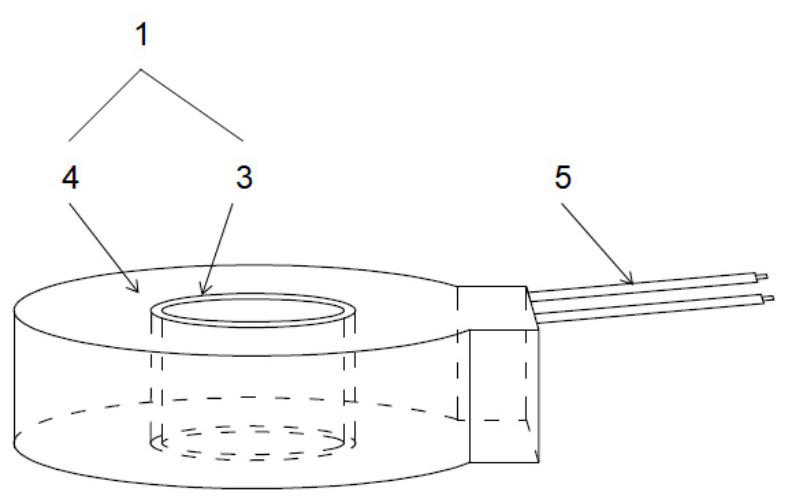

Injection-molded current transformer and preparation method thereof

PendingCN112904069AQuality improvementGood appearance consistencyCurrent measurements onlyVoltage/current isolationStructural engineeringInductor

The invention provides an injection-molded current transformer and a preparation method thereof. The current transformer comprises a winding magnetic core, a lead and a shell, the shell comprises a supporting body and a plastic layer surrounding the outer surface of the mutual inductor, the supporting body is composed of a fixing plate, a boss with a through hole, a lead fixing groove and a positioning column, the fixing plate is used for supporting a winding magnetic core, the boss is used for assembling and fixing the winding magnetic core, and the through hole of the boss is used for installing a primary winding; the lead fixing groove and the fixing plate are formed into a whole and are used for fixing the lead; the positioning column is arranged at the bottom of the fixing plate and used for being connected and positioned with an injection mold ejector pin. The winding magnetic core and the supporting body are both arranged in the plastic layer in an injection molding mode. The current transformer is stable and reliable in quality and good in toughness, insulativity and sealing performance, the preparation method of the current transformer comprises the five steps of coil winding, lead connection, supporting body preparation, winding magnetic core assembly and injection molding, the preparation process is simple, and the production efficiency is high.

Owner:NINGBO ZHONGKE BIPULASI NEW MATERIAL TECH CO LTD

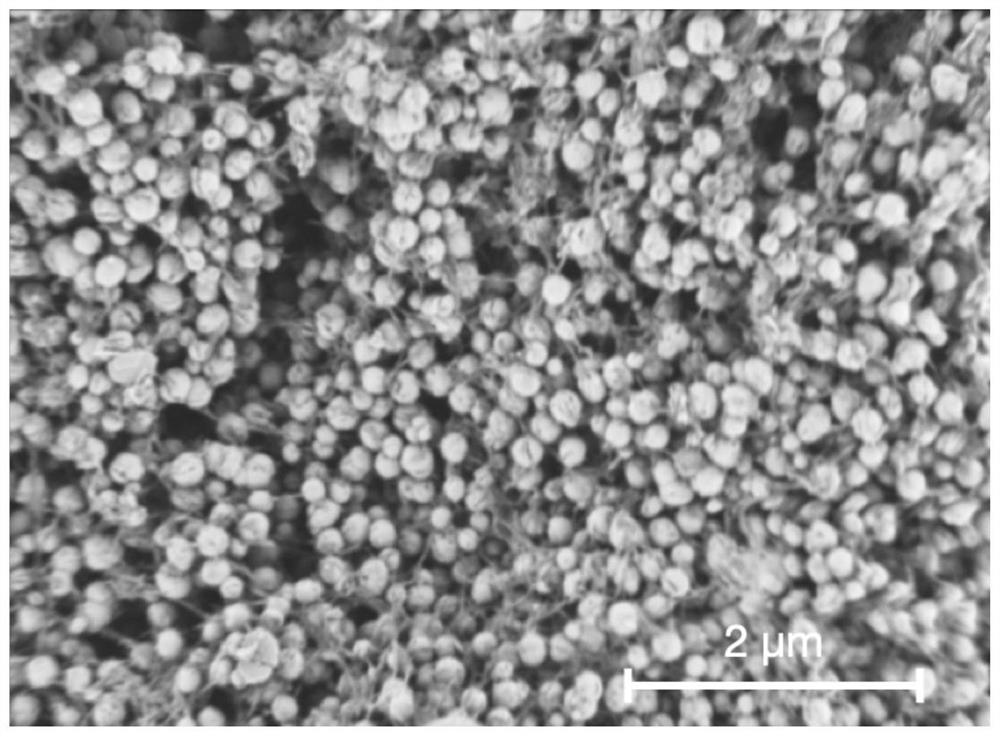

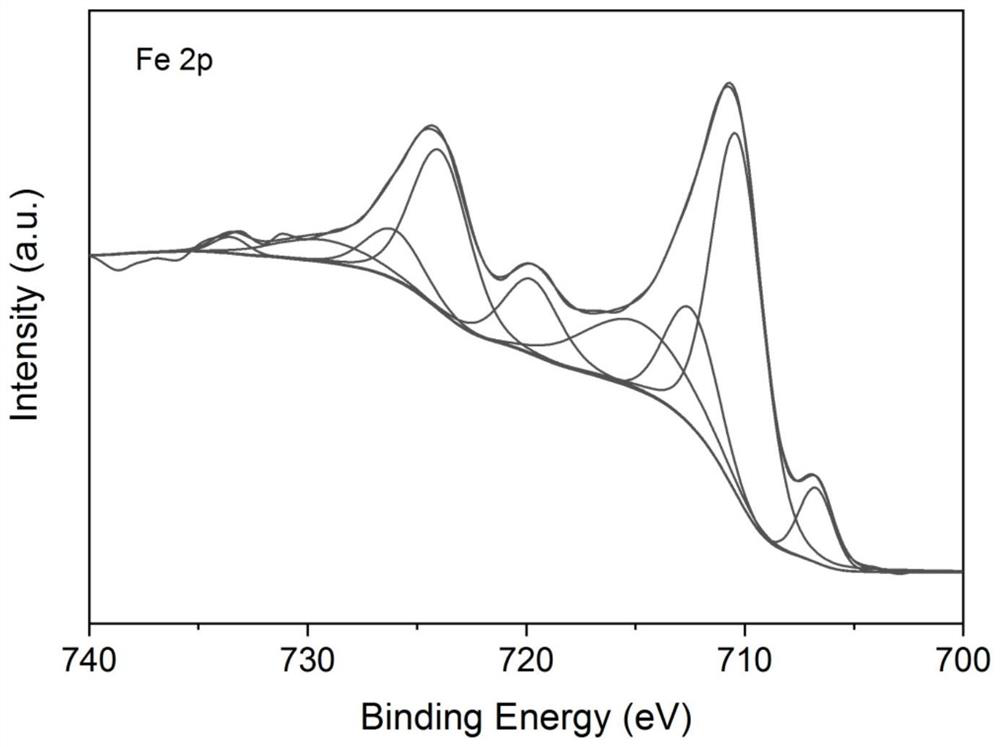

Application of iron-based cellulose nano composite material in water environment

InactiveCN113262764AHigh strengthHigh strength mechanical propertiesOther chemical processesWater contaminantsNanocompositeMaterials science

The invention provides application of an iron-based cellulose nano composite material in a water environment. The iron-based cellulose nano composite material is used for adsorbing and reducing heavy metal ions in a water environment; and the iron-based cellulose nano composite material is of a three-dimensional network structure composed of nano cellulose and nano zero-valent iron, wherein the diameter of the iron-based cellulose nano composite material is 5-70 nm, and the particle size of the iron-based cellulose nano composite material is 300-1000 nm. The iron-based cellulose nano composite material provided by the invention has the advantages of large specific surface area and high heavy metal adsorption and reduction capability, the dispersity of nano zero-valent iron in a water environment is effectively improved, and the in-situ synthesis method is simple to operate and can be recycled, so that heavy metal ions in the water environment can be efficiently removed.

Owner:TONGJI UNIV

Halogen-free phosphorus-free flame-retardant thermoplastic alloy and preparation method thereof

PendingCN110982155AImprove mechanical propertiesImprove flame retardant performanceElastomerThermoplastic

The invention discloses a halogen-free phosphorus-free flame-retardant thermoplastic alloy and a preparation method thereof. The halogen-free phosphorus-free flame-retardant thermoplastic alloy is prepared from the following components in parts by weight: 50 to 70 parts of polyolefin, 25 to 40 parts of a thermoplastic elastomer, 5 to 10 parts of a compatilizer, 30 to 50 parts of calcium gluconate,10 to 15 parts of melamine cyanuric acid, 5 to 10 parts of hydrotalcite, 3 to 5 parts of zinc stannate, 0.1 to 0.5 part of an antioxidant and 3 to 5 parts of a silicone lubricant. According to the invention, the thermoplastic alloy is prepared by adding calcium gluconate; after combustion of calcium gluconate, calcium carbonate and carbon dioxide are produced, calcium carbonate can rapidly expandto form porous calcium carbonate under the action of carbon dioxide, the good flame-retardant synergistic effect is achieved, the high mechanical property and the high flame-retardant effect of the thermoplastic alloy are ensured, meanwhile, the smoke generation amount can be reduced, emission of toxic substances is effectively reduced, the environment is protected, and the mechanical property and the chemical property of the alloy are not affected.

Owner:FAR EAST CABLE +1

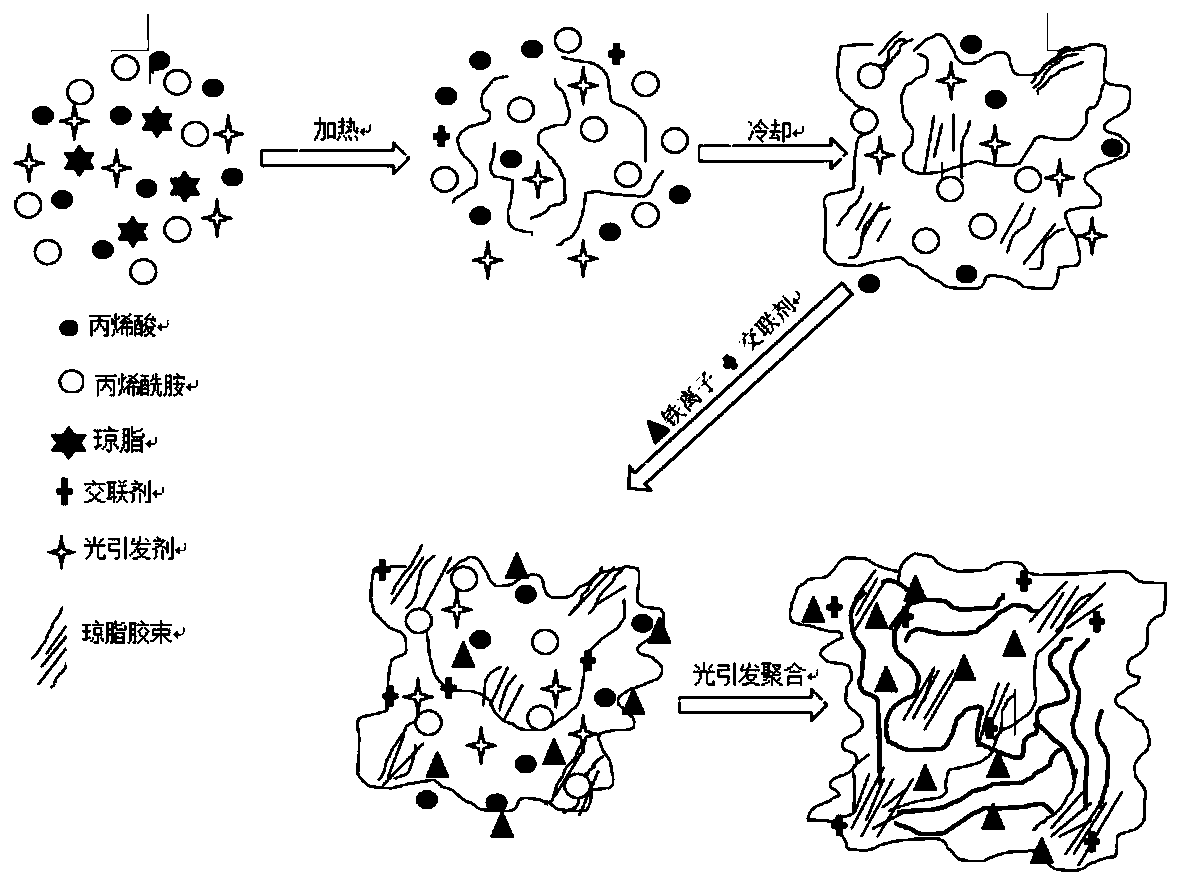

Preparation method of double-network hydrogel

InactiveCN110078939AHigh Compression Mechanical PropertiesHigh strength mechanical propertiesIonPhotoinitiator

The invention discloses a preparation method of double-network hydrogel. The preparation method comprises steps as follows: firstly, agar, acrylamide and a photoinitiator are added to a first reactor,then acrylic acid and first raw water accounting for 90% of total amount of water are added, agar is taken as a first layer and combined by hydrogen bonds, and a first-layer network is formed. Synergistic coordination of ions is realized while free radical polymerization of the double-network hydrogel is performed, the synergistic coordination effect is realized by introducing iron ions on the basis of the optimal second-layer network, one novel second-layer network with chemical and physical joint interaction is synthesized to obtain the hydrogel by polymerization, the synergistic coordination of the ions is realized while free radical polymerization of the double-network hydrogel is performed, and the hydrogel has mechanical properties such as fatigue resistance, self-recovery, high tensile strength and high compression.

Owner:YANSHAN UNIV

Alloy microscopy vascular clamp with antiallergic function

InactiveCN104367362AHigh strength mechanical propertiesStrong biophiliaWound clampsBiophysicsBiomedical engineering

The invention discloses an alloy microscopy vascular clamp with the antiallergic function. The alloy material comprises, by weight, 100 parts of Fe, 15-30 parts of Pd, 15-20 parts of Ru, 3-10 parts of Zr, 2-6 parts of Mo, 1-5 parts of Ge, 0.5-2 parts of Sn and 0.2-2 parts of tungsten. According to the alloy microscopy vascular clamp with the antiallergic function, the needed high precision and high-strength mechanical performance is guaranteed, the very strong biological affinity is achieved, the irritation to the vessels and other cell tissues of the human body is weak, and using is safer.

Owner:WUXI HEBANG METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com