Manufacturing method of 17-4PH steel pipe

A manufacturing method and technology for steel pipes, applied in the direction of manufacturing tools, other manufacturing equipment/tools, metal rolling, etc., can solve the problems of large investment in extruder equipment, long cycle, huge tooling and dies, etc., and achieve obvious economic benefits and social benefits. The effect of benefit, low production cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

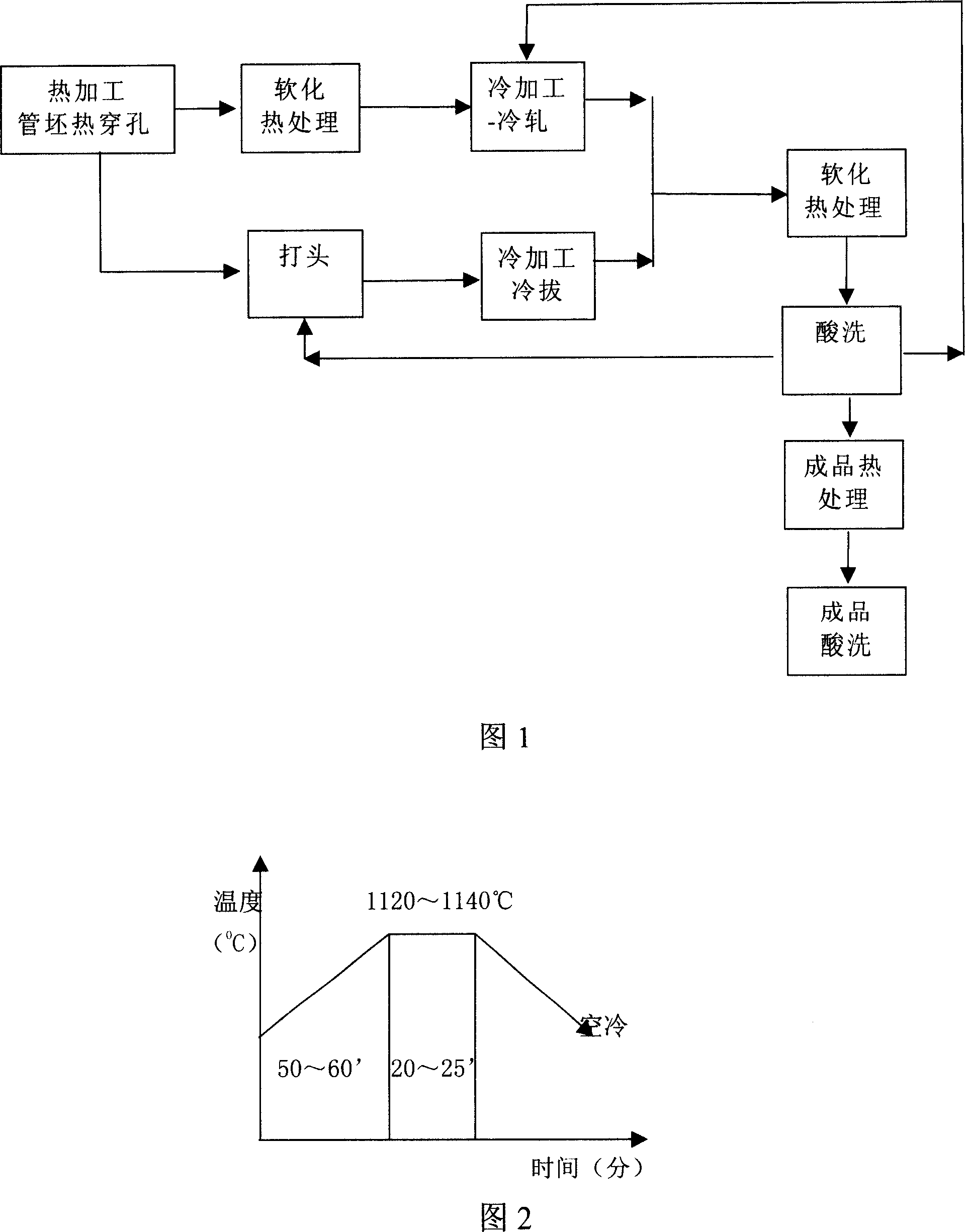

[0056] Referring to Fig. 1, process flow chart of the present invention. Now take the production of Φ21×6mm finished products with Φ85mm tube blank as an example:

[0057] 1. Thermal processing

[0058] See Figure 2, the heating system of 85mm tube blank, 1120~1140℃ is the heating temperature of tube blank, 50~60' is the heating period of tube blank, 20~25' is the average temperature of tube blank kept in the range of 1120~1140℃ The heating time, while the preheating speed of the tube blank from room temperature is not limited by uncertain factors.

[0059] As the size of the tube blank changes, its heating temperature and holding time should be adjusted appropriately.

[0060] The thermal perforation technical parameters are shown in Table 2:

[0061] Table 2

[0062]

Specifications (mm)

(A)

roll

Rotating speed

two rolls

spacing

(mm)

the head

the head

stick out

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com