Process for mass-producing distributed high-accuracy self-monitoring fiber reinforced polymer (FRP) bars/cables on the basis of fiber-optic sensing

A technology of optical fiber sensing and production technology, which is applied in the direction of optical testing flaws/defects, cladding optical fibers, optical waveguides and light guides, etc. The sensor interface leads to problems such as difficulties, and achieves the effect of improving market competitiveness, high cost performance, and improving the degree of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

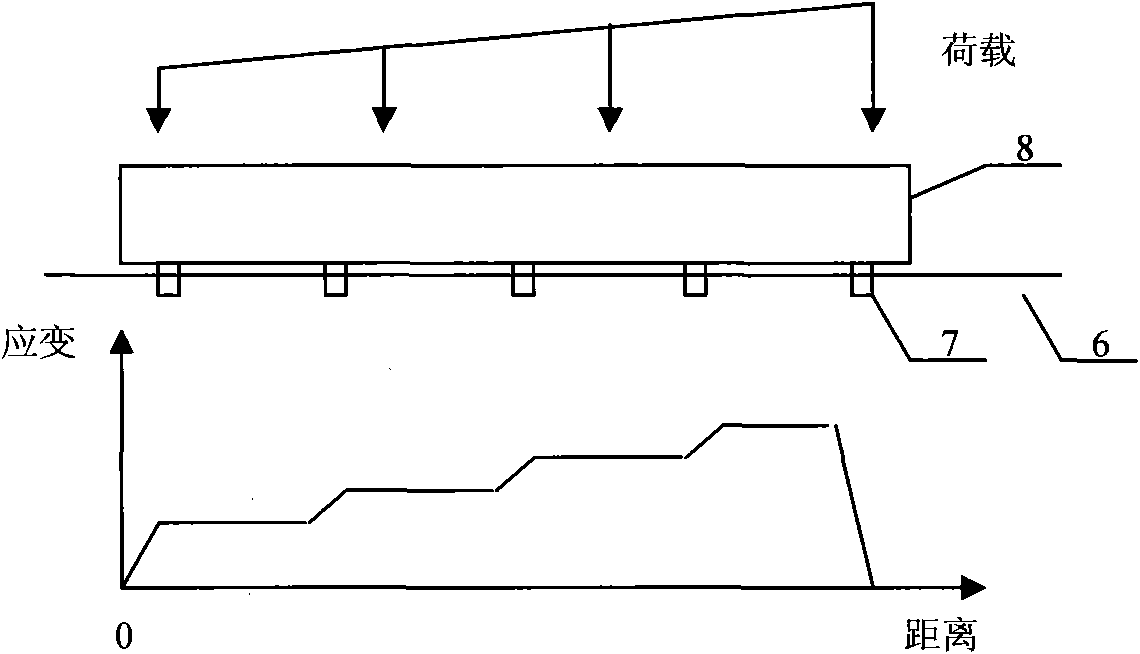

[0032]In conjunction with the legend, the specific implementation process of the present invention is described in more detail:

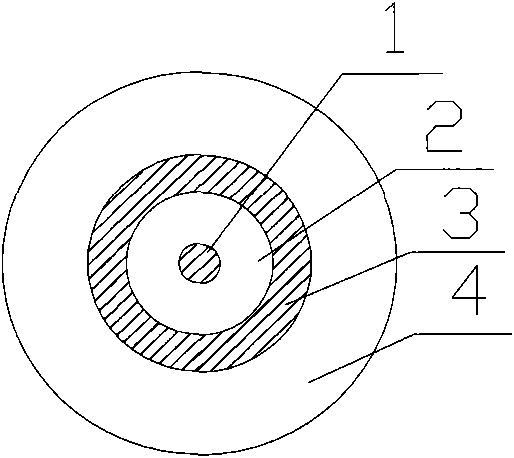

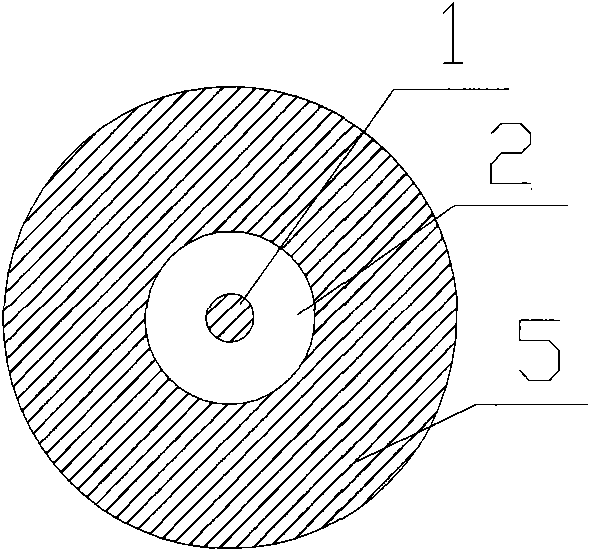

[0033] The technical solution of the present invention mainly includes the following three parts: (1) industrialized preparation of high-precision optical fiber sensors; (2) dry-type composite enhanced optical fiber sensors of optical fiber-fiber; (3) self-monitoring FRP tendons with controllable curing length / Cable pultrusion process.

[0034] (1) Industrial preparation of high-precision optical fiber sensors

[0035] At present, the commercial optical fibers that can be used for large-scale monitoring are generally communication optical fibers. Due to the inconsistency of uses, the methods of optical fiber structure design are different, and this difference will reduce the accuracy when used for sensing and measurement. At the same time, the existing distributed optical fiber sensing technology has spatial resolution energy, which requires the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com