Preparation method for titanium-based composite material with graphene-rare earth mixed micro-structure

A technology of titanium-based composite materials and graphene, which is applied in metal processing equipment, improvement of process efficiency, transportation and packaging, etc., to achieve the effect of improving strength and mechanical properties, simple process and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

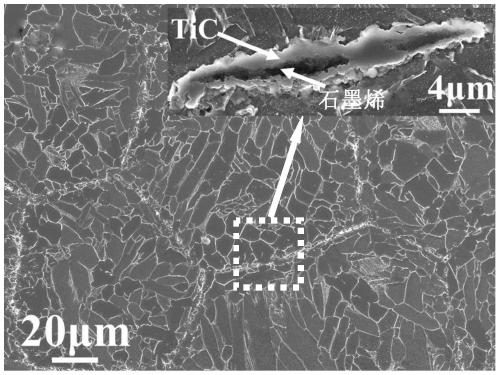

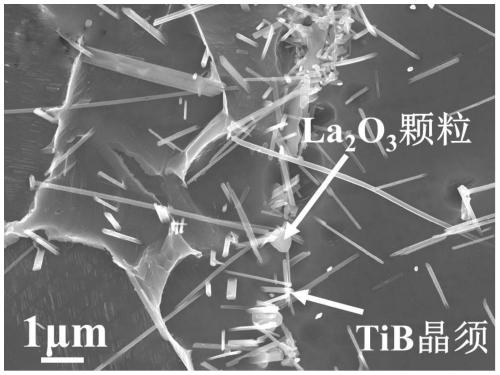

Image

Examples

Embodiment 1

[0028] The method of the present embodiment comprises the following steps:

[0029] Step 1, the preparation of graphene dispersion liquid: adopt the method for ultrasonic pre-dispersion assisted mechanical stirring to disperse 0.1g graphene in 100mL solvent at room temperature, obtain graphene dispersion liquid; The time of described ultrasonic pre-dispersion is 5min, so The rotating speed of described mechanical stirring is 50r / min; Described solvent is mixed according to the volume ratio of 1:4 by ethanol and Virahol;

[0030] Step 2, preparation of rare earth-titanium-based mixed powder: 0.3g of LaB 6 Perform high-energy ball milling and mixing with 200g of TC4 titanium alloy powder to obtain rare earth-titanium-based mixed powder; the high-energy ball milling speed is 300r / min, the time is 3h, and the ball-to-material ratio is 8:1;

[0031]Step 3. Preparation of ternary mixed powder: add the graphene dispersion obtained in step 1 to the rare earth-titanium-based mixed pow...

Embodiment 2

[0037] The method of the present embodiment comprises the following steps:

[0038] Step 1, the preparation of graphene dispersion liquid: adopt the method for ultrasonic pre-dispersion assisted mechanical stirring to disperse 0.5g graphene in 100mL solvent at room temperature, obtain graphene dispersion liquid; The time of described ultrasonic pre-dispersion is 10min, so The rotating speed of described mechanical stirring is 200r / min; Described solvent is mixed according to the volume ratio of 1:4 by ethanol and Virahol;

[0039] Step 2. Preparation of rare earth-titanium-based mixed powder: 0.5g of La and 200g of Ti-1400 titanium alloy powder were mixed by high-energy ball milling to obtain rare-earth-titanium-based mixed powder; min, the time is 5h, the ball-to-material ratio is 8:1

[0040] Step 3. Preparation of ternary mixed powder: add the graphene dispersion obtained in step 1 to the rare earth-titanium-based mixed powder obtained in step 2, and perform mechanical she...

Embodiment 3

[0044] The method of the present embodiment comprises the following steps:

[0045] Step 1, preparation of graphene dispersion liquid: 1.0g graphene is dispersed in 100mL solvent at room temperature by adopting the method for ultrasonic pre-dispersion assisted mechanical stirring, obtains graphene dispersion liquid; The time of described ultrasonic pre-dispersion is 10min, so The rotating speed of described mechanical stirring is 200r / min; Described solvent is mixed according to the volume ratio of 1:4 by ethanol and Virahol;

[0046] Step 2, preparation of rare earth-titanium-based mixed powder: 0.5g of La, 0.5g of La 2 o 3 Perform high-energy ball milling and mixing with 200g of TC4 titanium alloy powder to obtain a rare earth-titanium-based mixed powder; the high-energy ball milling speed is 500r / min, the time is 5h, and the ball-to-material ratio is 8:1

[0047] Step 3. Preparation of ternary mixed powder: add the graphene dispersion obtained in step 1 to the rare earth-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com