Preparation method of double-network hydrogel

A hydrogel and double network technology, which is applied in the field of polymer material preparation, can solve the problems of unstable gel performance and long time consumption, and achieve the effect of high compression mechanical properties and high strength mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

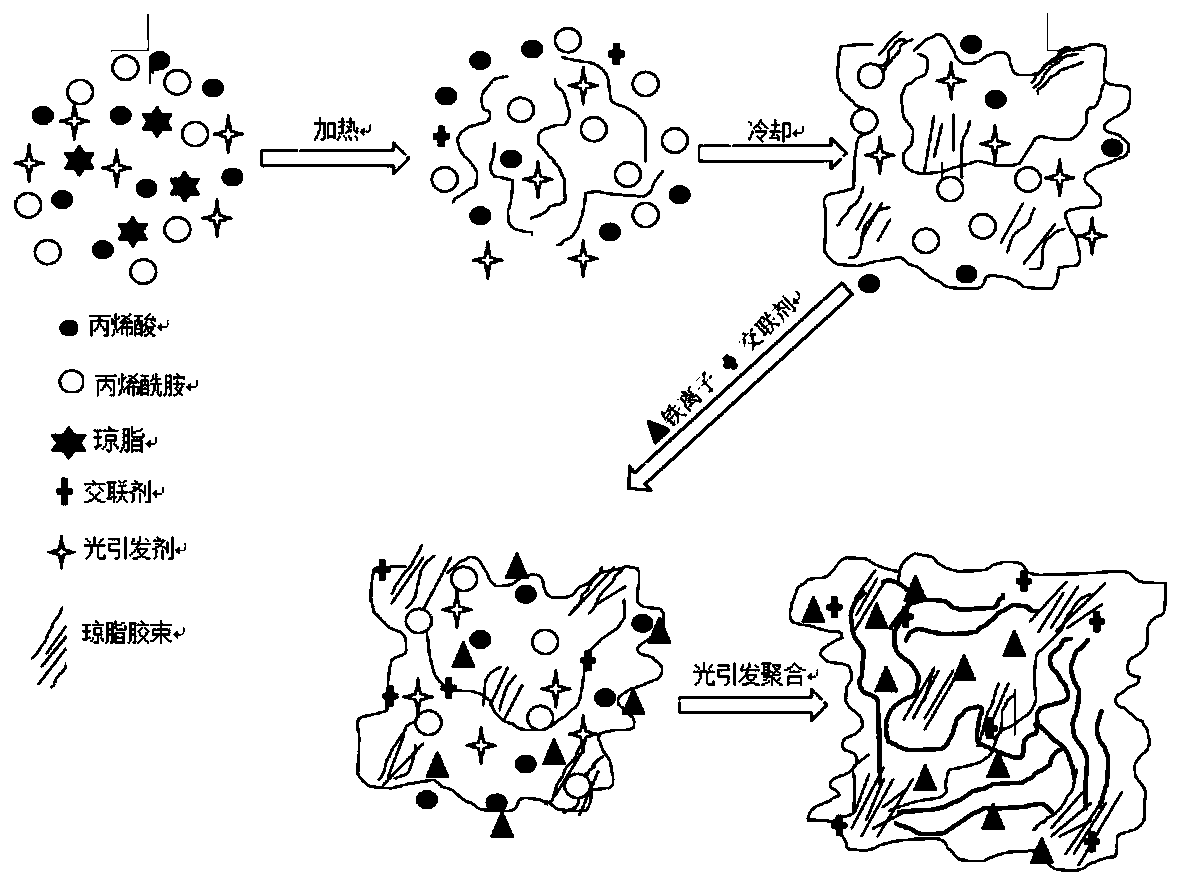

[0022] Such as figure 1 As shown, the present invention provides a kind of preparation method of double-network hydrogel, first uses agar as the first layer to combine with hydrogen bond, forms tight, brittle and strong network structure, and then through the optimal network structure in the second layer Based on the introduction of iron ions to achieve synergistic coordination, a new type of chemically and physically interacting second-layer network is synthesized to polymerize into a hydrogel, and the synergistic coordination of ions is achieved while the double-network hydrogel undergoes free radical polymerization. position, so that the hydrogel has the mechanical properties of fatigue resistance, self-recovery, high tensile and high compression.

[0023] The raw materials used in the preparation of the double network hydrogel in the present invention include the following components: monomers, crosslinking agents, photoinitiators, ferric nitrate nonahydrate, agar and wate...

Embodiment 1

[0033] First configure the crosslinking agent aqueous solution with a concentration of 10mg / ml, and then start to prepare the double network hydrogel:

[0034] S1. Add 70mg agar, 2.0574g acrylamide, 0.0665g photoinitiator to the first reactor, then add 41uL acrylic acid and 6.3ml water; add 0.0119g iron nitrate nonahydrate, 0.7ml water and 137uL cross-link The aqueous solution of the agent is stirred and mixed uniformly in the second reactor;

[0035] S2, the first reactor is charged and discharged under the protection of nitrogen to remove the air inside, and the first reactor is placed in an oil bath at 90° C. and heated for 5 minutes to form a uniform solution in a sealed state;

[0036] S3. Take the first reactor out of the oil bath, cool it down to room temperature and store it at -3°C for 5 minutes to form the first network of the double network hydrogel, and keep the solution mixing process under low temperature protection Preventing its polymerization; adding the mixe...

Embodiment 2

[0039] First configure the crosslinking agent aqueous solution with a concentration of 10mg / ml, and then start to prepare the double network hydrogel:

[0040]S1. Add 105mg agar, 2.0362g acrylamide, 0.0665g photoinitiator to the first reactor, then add 61uL acrylic acid and 6.3ml water; add 0.0358g iron nitrate nonahydrate, 0.7ml water and 137uL cross-link The aqueous solution of the agent is stirred and mixed uniformly in the second reactor;

[0041] S2, the first reactor is charged and discharged under the protection of nitrogen to remove the air inside, and the first reactor is placed in an oil bath at 85° C. and heated for 8 minutes to form a uniform solution in a sealed state;

[0042] S3. Take the first reactor out of the oil bath, cool it down to room temperature and store it at -3°C for 3 minutes to form the first network of the double network hydrogel, and keep the solution mixing process under low temperature protection Prevent its polymerization; add the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com