Patents

Literature

155results about How to "Good appearance consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

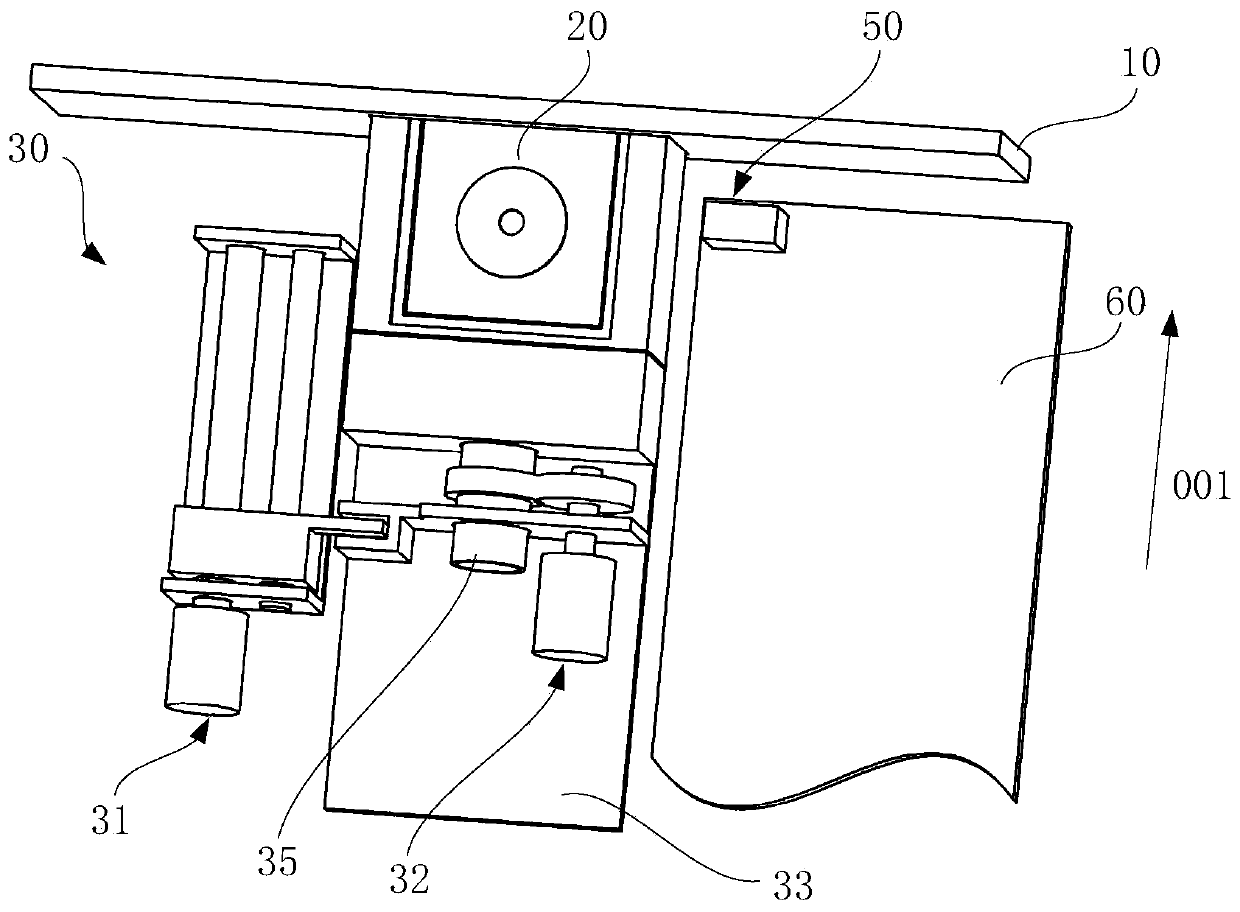

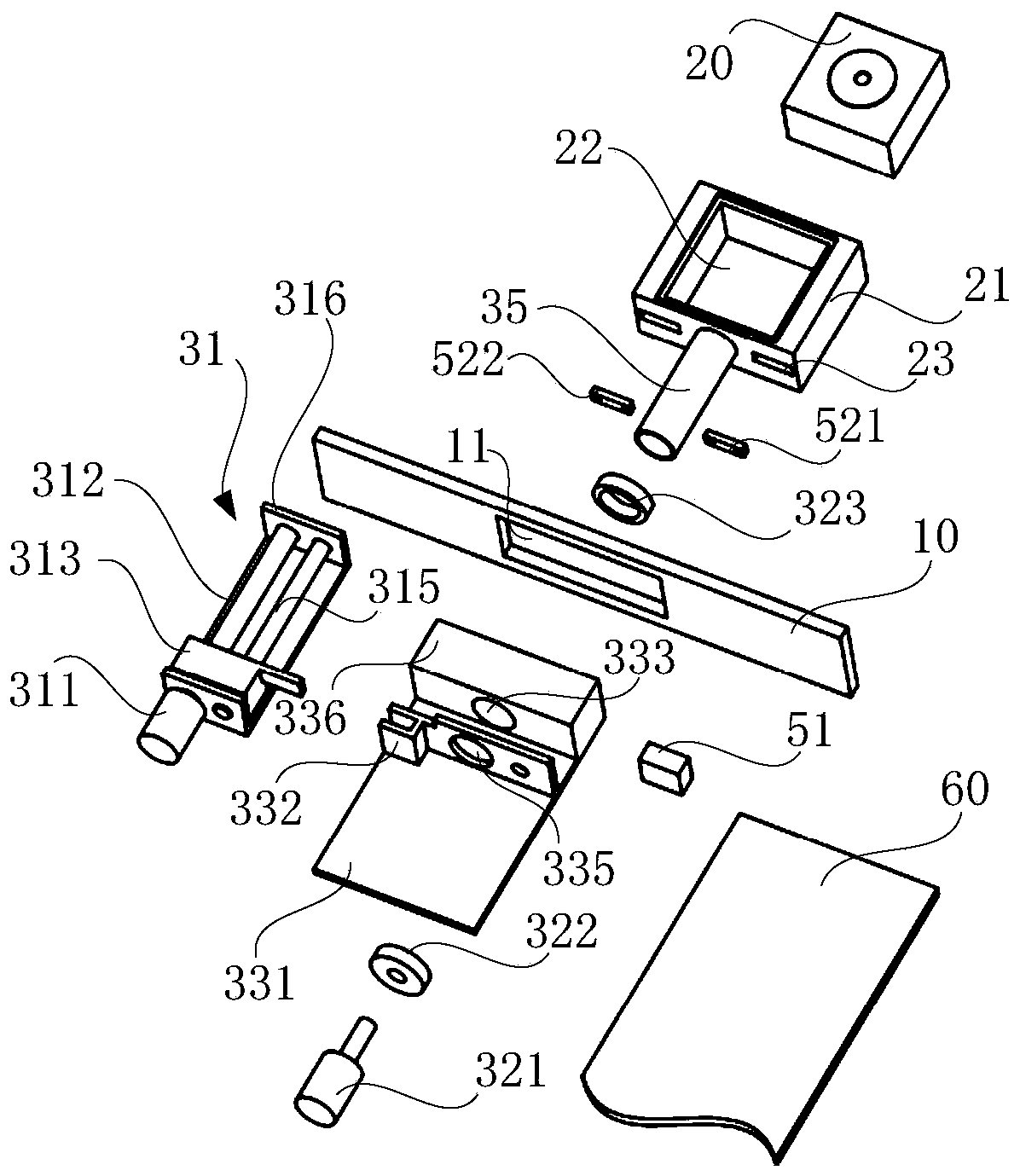

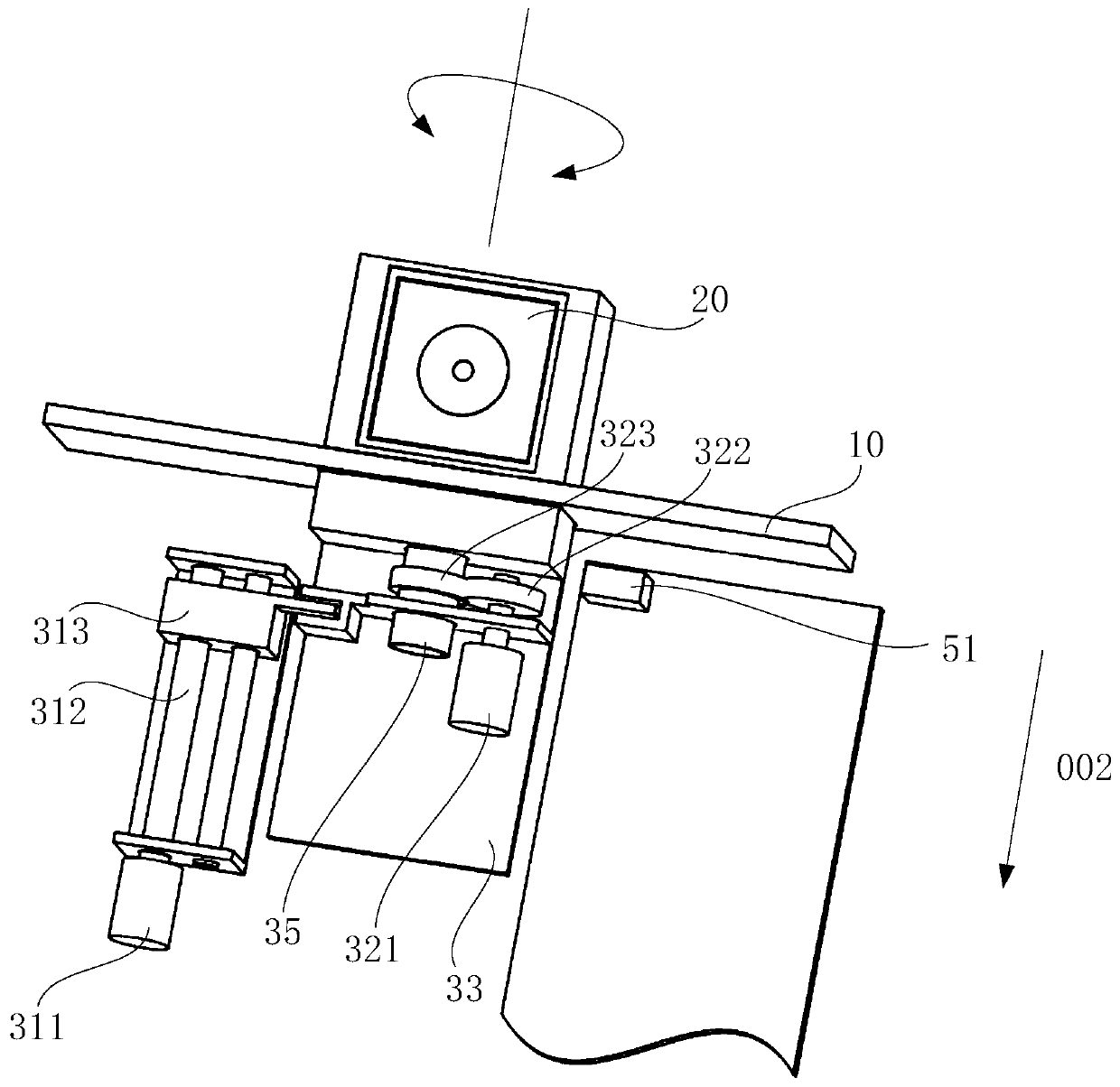

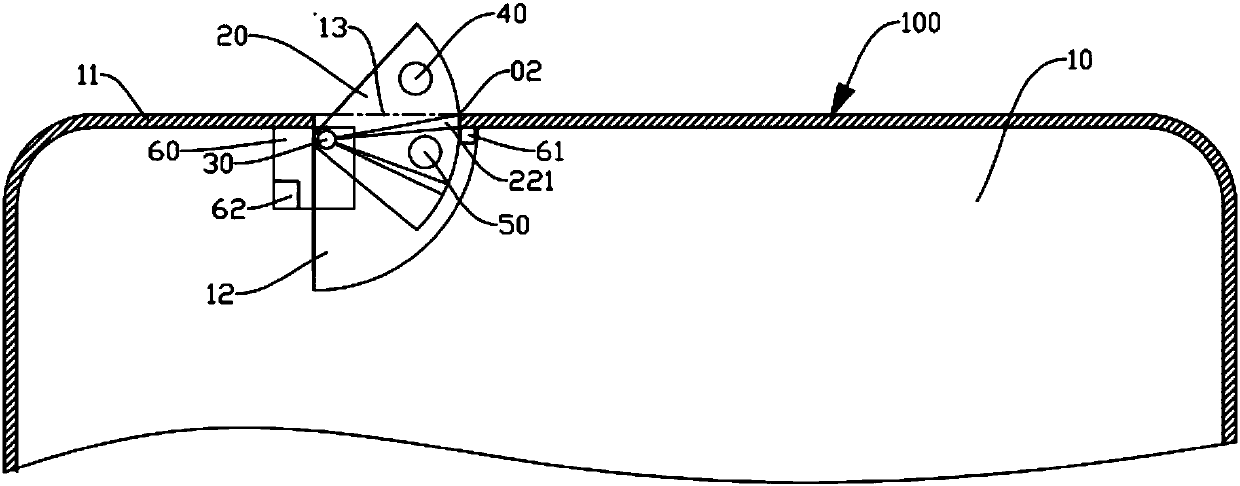

Mobile terminal, mobile terminal control method and computer storage medium

PendingCN110581938AIncrease the screen ratioGood appearance consistencyTelevision system detailsColor television detailsComputer graphics (images)Computer terminal

The mobile terminal of the present application comprises: a shell; a camera which is accommodated at a first position in the shell and can be driven to move from the first position to a second position so as to protrude out of the shell, wherein at the second position, the camera can be driven to a fixed angle or different angles so as to shoot; and a detection assembly which is used for detectingdata representing the position state of the camera, wherein the position state comprises a moving position and / or a rotating angle. By controlling stretching and rotation of the camera on the mobileterminal, the functions of front shooting, rear shooting, moving target tracking shooting and the like can be achieved, the screen-to-body ratio and the appearance consistency of the mobile terminal can be improved, data representing the position state of the camera is detected through the detection assembly, and the control precision can be improved.

Owner:SHENZHEN TRANSSION HLDG CO LTD

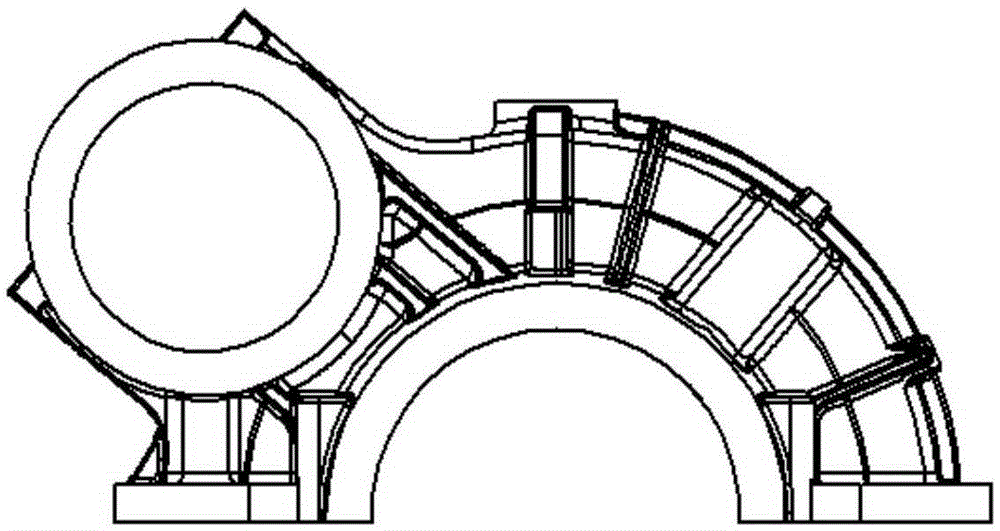

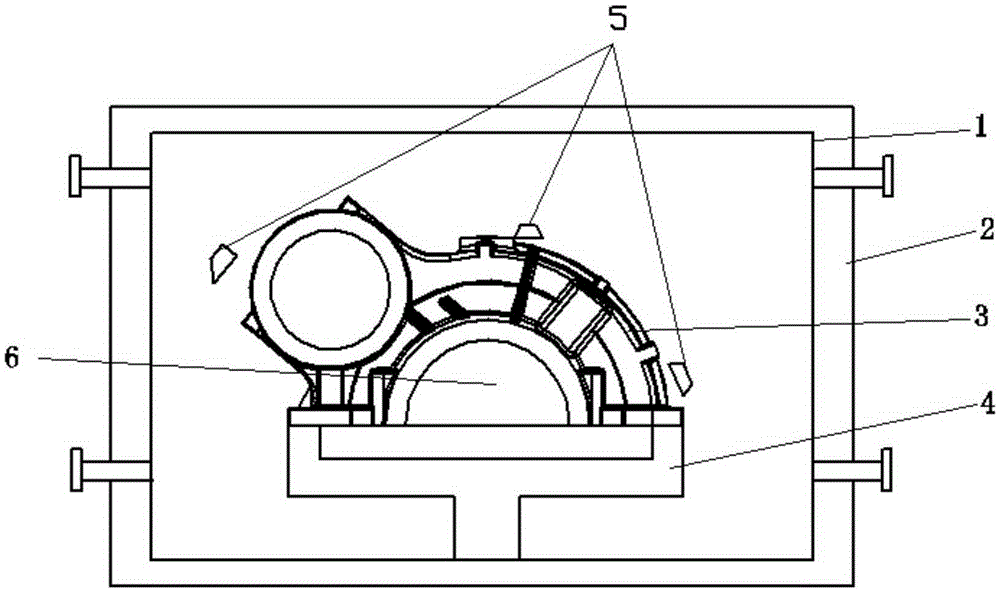

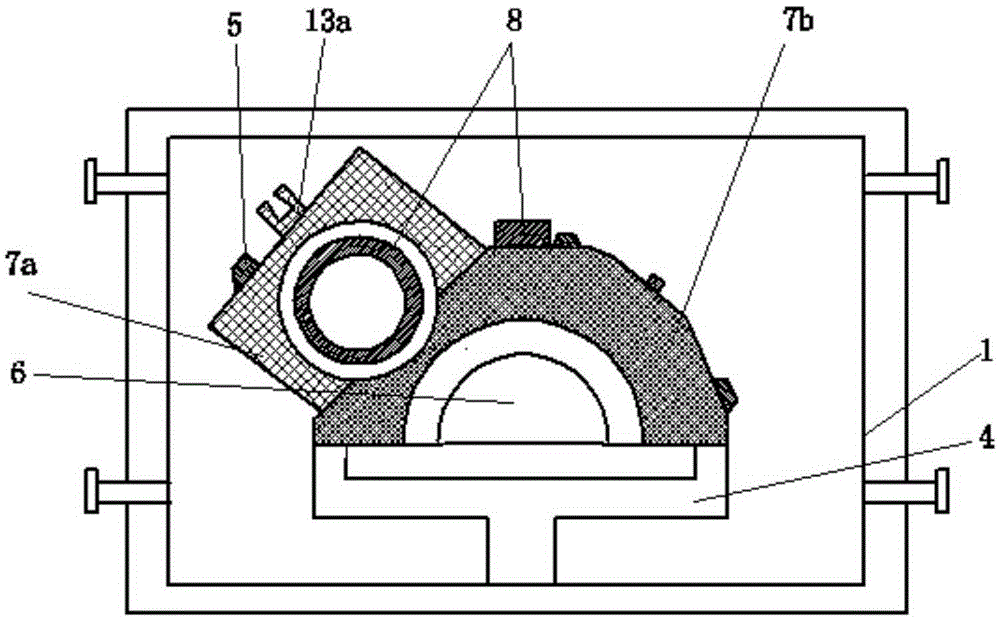

Casting mold and forming method for box body of gearbox

ActiveCN105382206AClear outlineFilled tightlyFoundry mouldsFoundry coresCasting moldMaterials science

The invention provides a casting mold and forming method for a box body of a gearbox and belongs to the technical field of liquid formation of metal. The forming method comprises the following steps that precoated sand is used for core shooting, so that precoated sand blocks are manufactured, then an outer precoated sand mold layer is formed by splicing the precoated sand blocks, and the outer precoated sand mold layer and a sand core are used for forming a casting cavity of the box body of the gearbox; and finally the box body of the gearbox is manufactured through the casting mold in a low-pressure casting way. According to the specific structure of the casting mold, the sand core is located in the center of the casting mold; the casting cavity is formed in the outer layer of the sand core and mainly formed by the sand core and the outer precoated sand mold layer; an outer resin sand mold layer is arranged on the outer layer of the outer precoated sand mold layer, and the outer precoated sand mold layer and a sand box are connected through the outer resin sand mold layer, so that the casting mold is formed. According to the casting mold and forming method for the box body of the gearbox, the cavity which is formed by the precoated sand and used for large complicated castings is used for low-pressure casting for the first time, the precoated sand blocks are subjected to core shooting under pressure, high-temperature sintering formation is conducted, filling is compact, and the situations that sand filling is incompact and sand adhesion defects are caused due to human factors during resin sand molding are avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

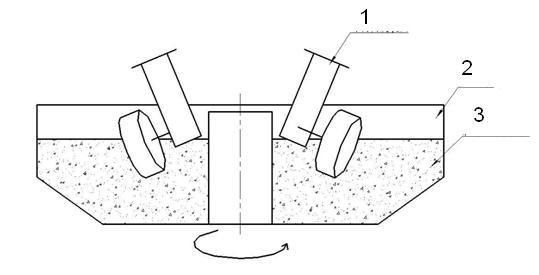

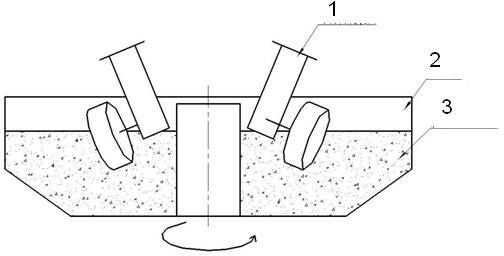

Aluminum wheel finishing process

InactiveCN102430974AOvercoming qualityOvercome efficiencyEdge grinding machinesPolishing machinesAlloy wheelAluminium alloy

The invention discloses an aluminum alloy wheel finishing process, which comprises the steps of: aslant pouring and immersing aluminum alloy blank subjected to thermal processing in a rotating container filled with a grinding material and a grinding agent, forming a medium flow in the front of the wheel through the rotation of the wheel and the relative movement of the container, and carrying out regular and efficient grinding and polishing processing on the front of the wheel and window parts by the medium flow, and finally realizing a mirror polishing effect with extremely excellent surface consistency. By adopting the process, the problems of poor appearance quality in tradition mechanical polishing and low efficiency of a vibration finishing process are overcome, the labor intensity of workers is greatly reduced, the labor environment of the workers is improved, the efficiency is 5-6 times that of the tradition polishing process and vibration finishing, and great cost advantage is achieved.

Owner:CITIC DICASTAL +1

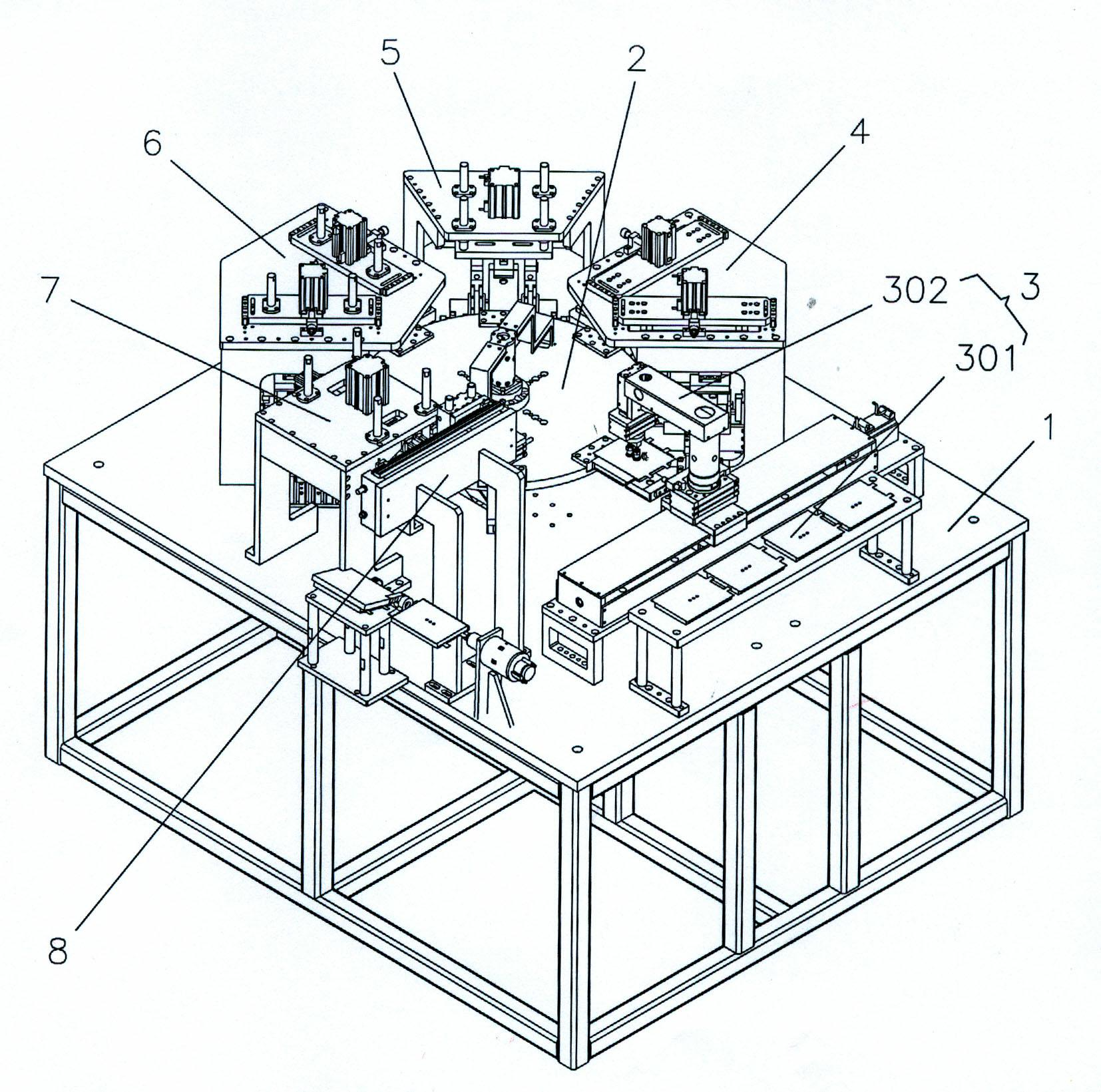

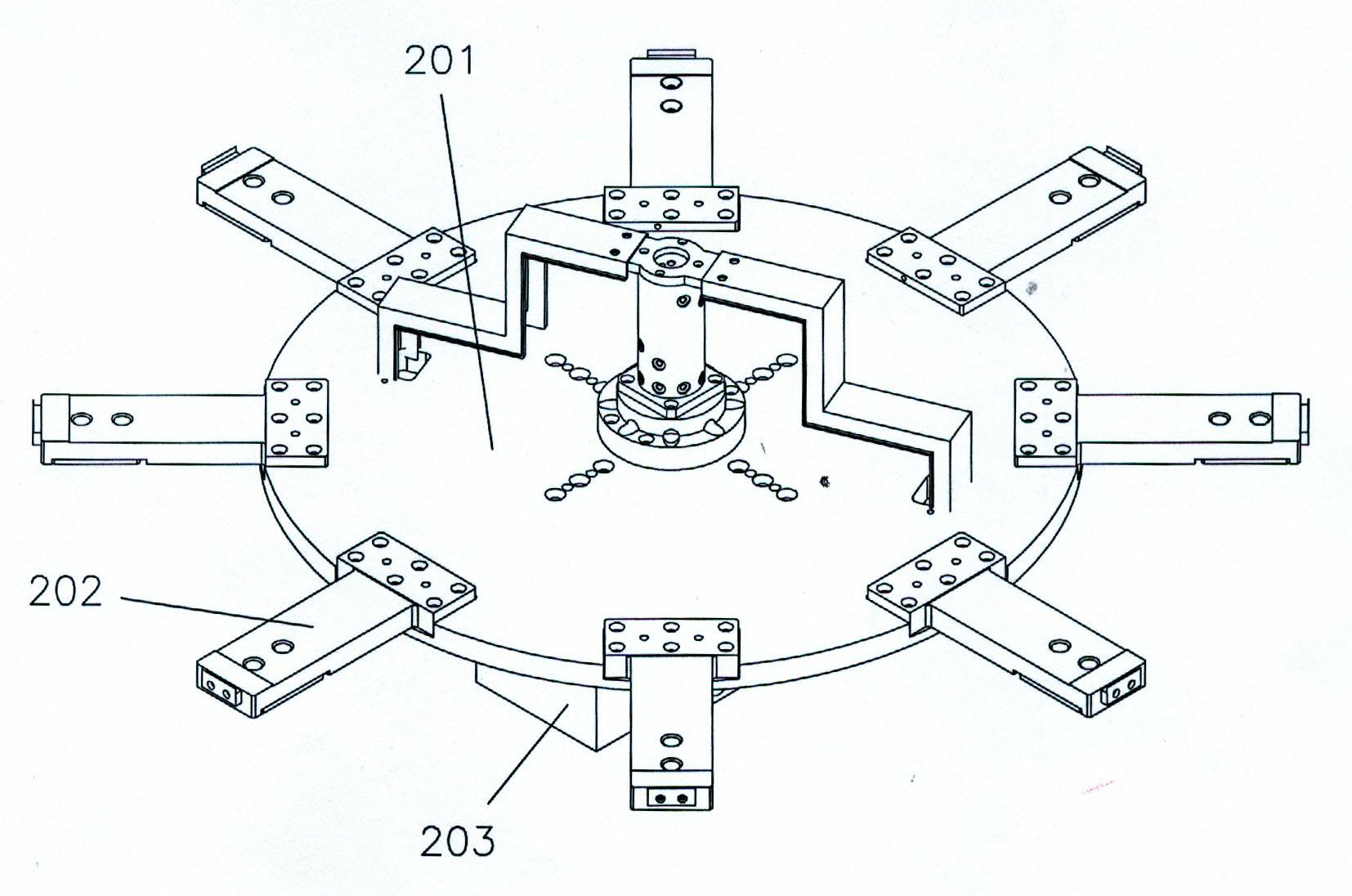

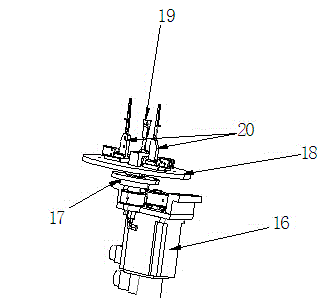

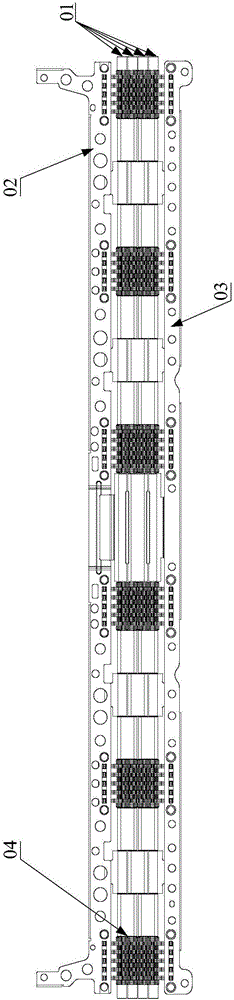

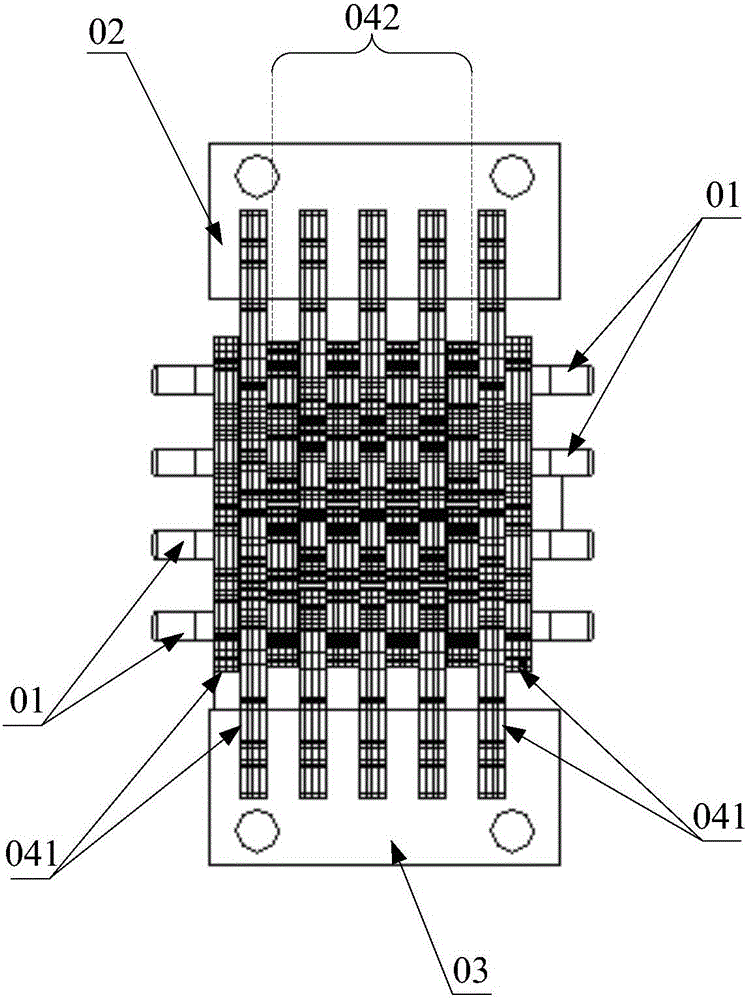

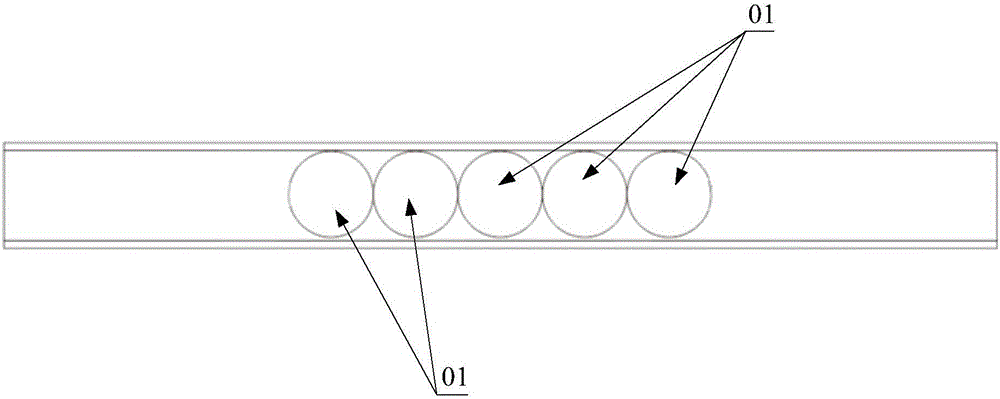

Battery core shaping mechanism and fully-automatic battery core liquid-extracting, packaging and shaping packing machine

The invention discloses a fully-automatic battery core liquid-extracting, packaging and shaping packing machine used for extracting liquid from a flexibly packed lithium battery and packaging and shaping the flexibly packed lithium battery, and a battery core shaping mechanism thereof. The key point of the invention lies in the design of the battery core shaping mechanism. The mechanism comprisesa turntable device, wherein an edge-cutting device, a preheating device, an edge-folding device and an edge-ironing device are sequentially arranged along the outer edge of the turntable device. Due to the design, the structure of the battery core shaping mechanism is compact. More importantly, the preheating device is arranged in front of a folded edge device, so an aluminum-plastic membrane corner can be prevented from being broken when the edge of a flexibly packed battery core is folded; and the quality and the forming rate of the product are guaranteed. A correcting device with a pressure sensor is also arranged beside the edge-cutting device and the edge-folding device, so the consistency of forming the flexibly packed lithium battery is guaranteed and the battery core is not damaged by correcting the position of the battery core before the edge of the battery core is cut and folded.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

Electronic equipment

InactiveCN111405413AReduce the number of openingsGood appearance consistencyFrequency/directions obtaining arrangementsTelephone set constructionsEngineeringAcoustics

The invention discloses electronic equipment. The electronic equipment comprises a first shell, a first functional module and a second functional module, wherein the first shell and the first functional module form an accommodating space, the second functional module is arranged in the accommodating space, the second functional module comprises an acoustic device, an assembly gap is formed betweenthe first shell and the first functional module, a sound guide channel is formed in the first shell, and the acoustic device is communicated with the assembly gap through the sound guide channel. According to the scheme, the sound information can be transmitted through the assembly gap between the first shell and the first functional module, so that a sound guide hole does not need to be formed in the shell, the number of the holes of the shell is reduced, the integrity of the shell is improved, the consistency of the appearance quality of the shell is enhanced, the assembly gap is narrower than the sound guide hole, water vapor and dust in the environment can be effectively prevented from entering the shell, and the waterproof performance and the dustproof performance of the electronic equipment are improved.

Owner:VIVO MOBILE COMM CO LTD

Solar cell front sliver paste powder adaptable to high sheet resistance and shallow junction

ActiveCN103000248ACompact structureGood appearance consistencyNon-conductive material with dispersed conductive materialSemiconductor devicesHigh resistanceMicrometer

The invention relates to solar cell front sliver paste powder adaptable to high sheet resistance and shallow junction. The powder comprises, by weight percent, 50-75% of coarse sliver powder 2-5 micrometers in average particle size, 20-45% of fine sliver powder 0.5-2 micrometers in average particle size, 1-9% of glass powder, and 0.1-3% of additive. The components are added up to 100% by weight percent. Both the glass powder and the additive are in twin-peak particle size distribution. Compared with the prior art, the front sliver paste powder is optimized by powder gradation. The glass powder and the additive are proper in particle size. Voids between the coarse and fine sliver powders can be effectively filled with the glass powder and the additive. After sintering, silver islands are small and evenly distributed, can form fine orphic contacts and are fine in appearance. The glass powder has moderate activity and does not disrupt P-N junctions. The front sliver paste made from the powder is suitable for sintering on shallow-junction silicon cells.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Antenna apparatus and terminal

ActiveCN106129621ALow costImprove reliability and appearance consistencySimultaneous aerial operationsAntenna supports/mountingsRadio frequencyComputer module

The invention relates to the technical field of terminal, and concretely relate to an antenna apparatus and a terminal. The antenna apparatus comprises a metal frame. A clearance area is between one end of the metal frame and the circuit board of the terminal. A radio frequency module arranged on the circuit board is connected to a feeding point which is connected to a feed metal wire. One end of the feed metal wire is connected to the metal frame. One side of the clearance area is also provided with an impedance loading device, and two ends of the impedance loading device are connected to the circuit board and the metal frame. According to the antenna apparatus and the terminal, a part of the metal frame is flexibly used as an antenna, by using the impedance loading device, the metal frame can be used as the antenna without opening a gap and cutting, the impedance loading device can be used for adjusting loading impedance so as to facilitate the tuning of the antenna, thus a multiple-communication-frequency-range antenna is realized, the cost can be reduced, and the reliability and appearance consistency of a product are improved.

Owner:MEIZU TECH CO LTD

Quasi-monocrystalline silicon etching method

InactiveCN102306681AGood appearance consistencyAvoid the shortcomings of large color differenceFinal product manufactureSemiconductor devicesAcid etchingAlkaline etching

The invention relates to the solar energy cell production technology method field, concretely relating to a quasi-monocrystalline silicon etching method which comprises an alkaline etching operation on a quasi-monocrystalline silicon which mainly is (100) crystal grain and an acid etching operation on the quasi-monocrystalline silicon. Compared with simple acid etching, according to the invention, photoelectric conversion efficiency of a quasi-monocrystalline cell is obviously raised, a shiny phenomenon of part etching face caused by adopting simple alkaline etching can be obviously eliminated, and a whole process can be accurately adjusted according to an area the (100) crystal grain occupies. The quasi-monocrystalline silicon etching method has the characteristics of a fully controllable processing process, a good integral etching effect, qualified appearance and simple technology, and is suitable for quasi-monocrystalline silicon large scale production.

Owner:浙江向日葵大健康科技股份有限公司

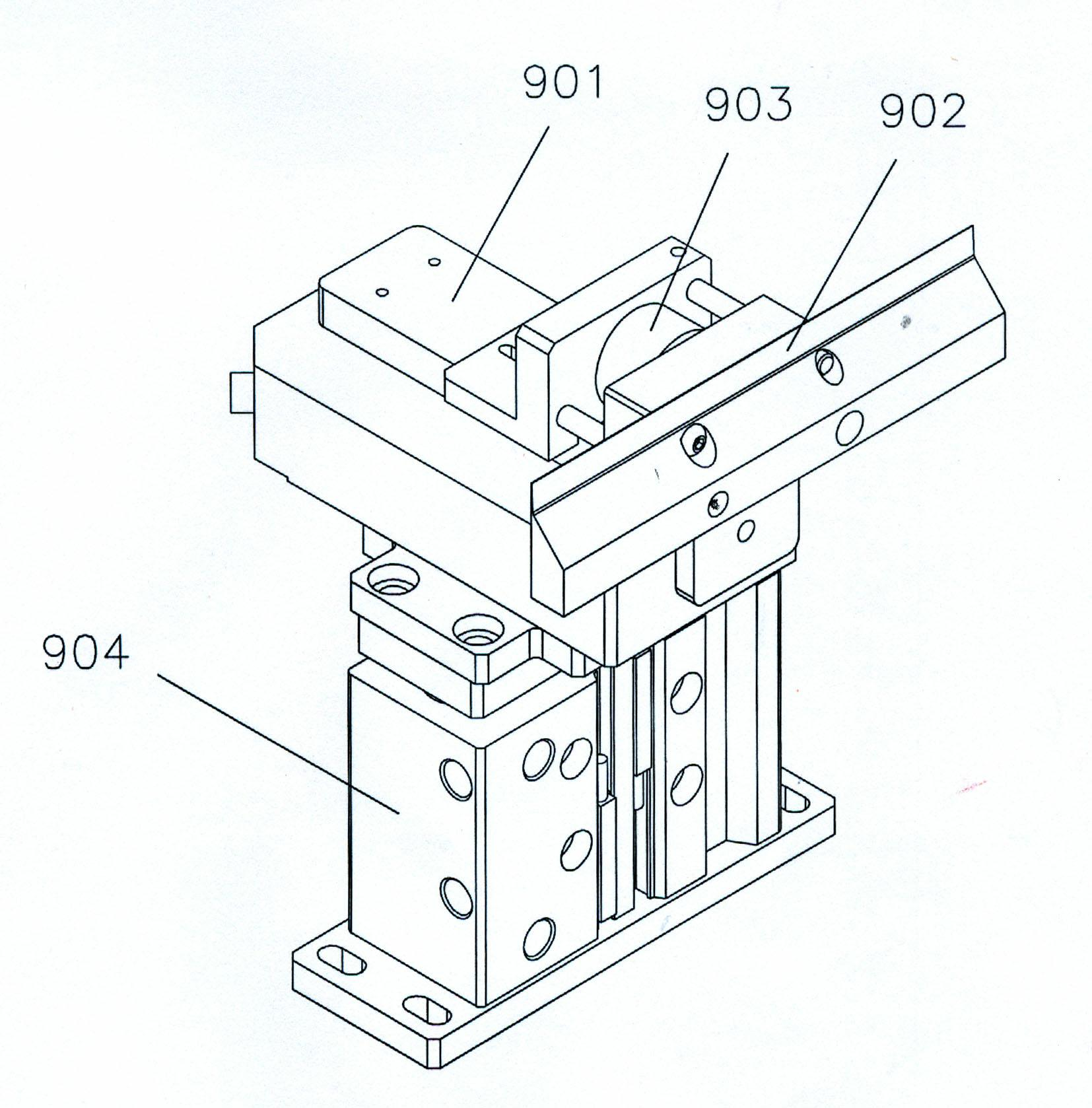

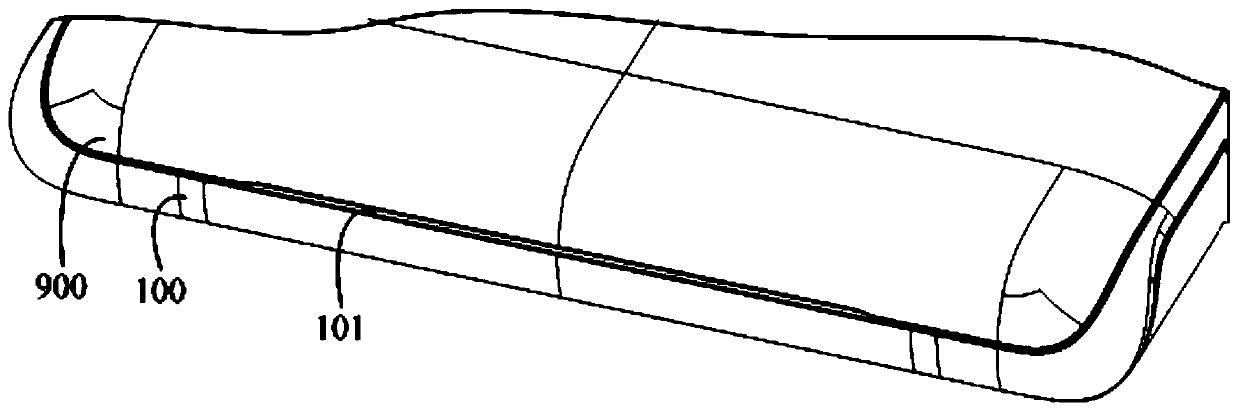

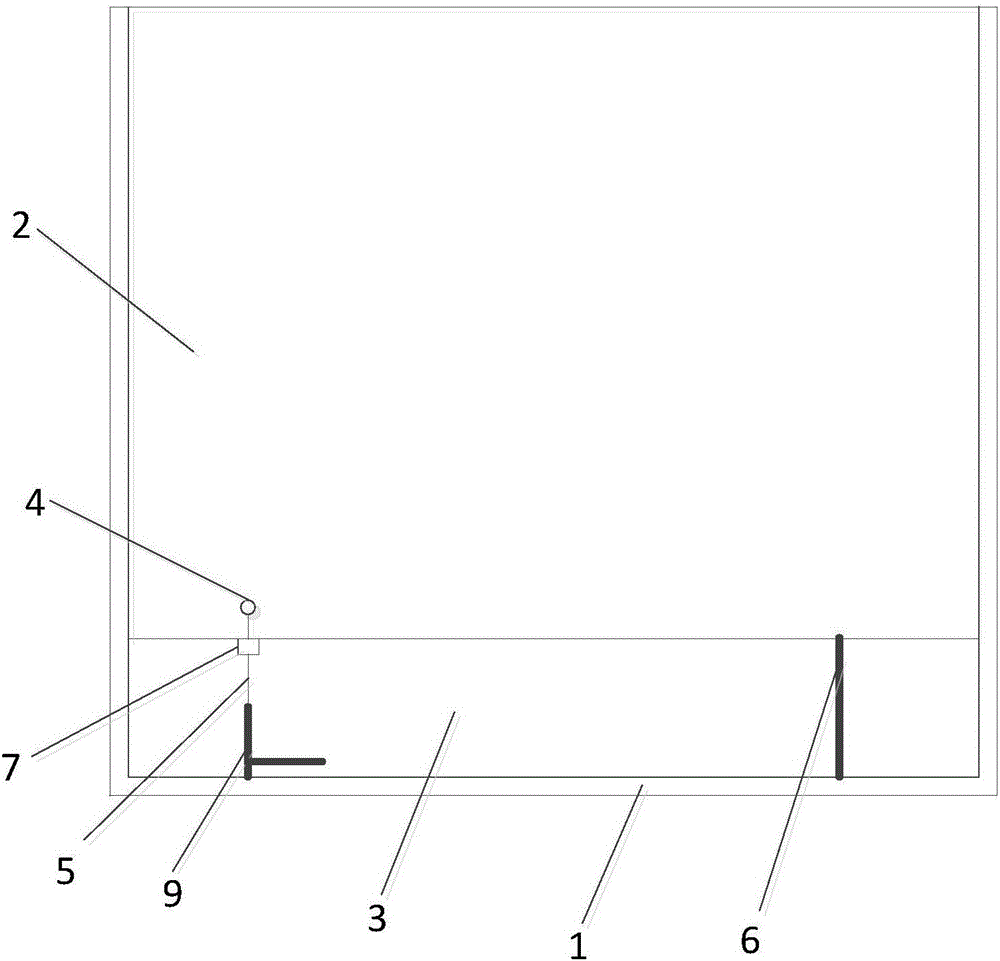

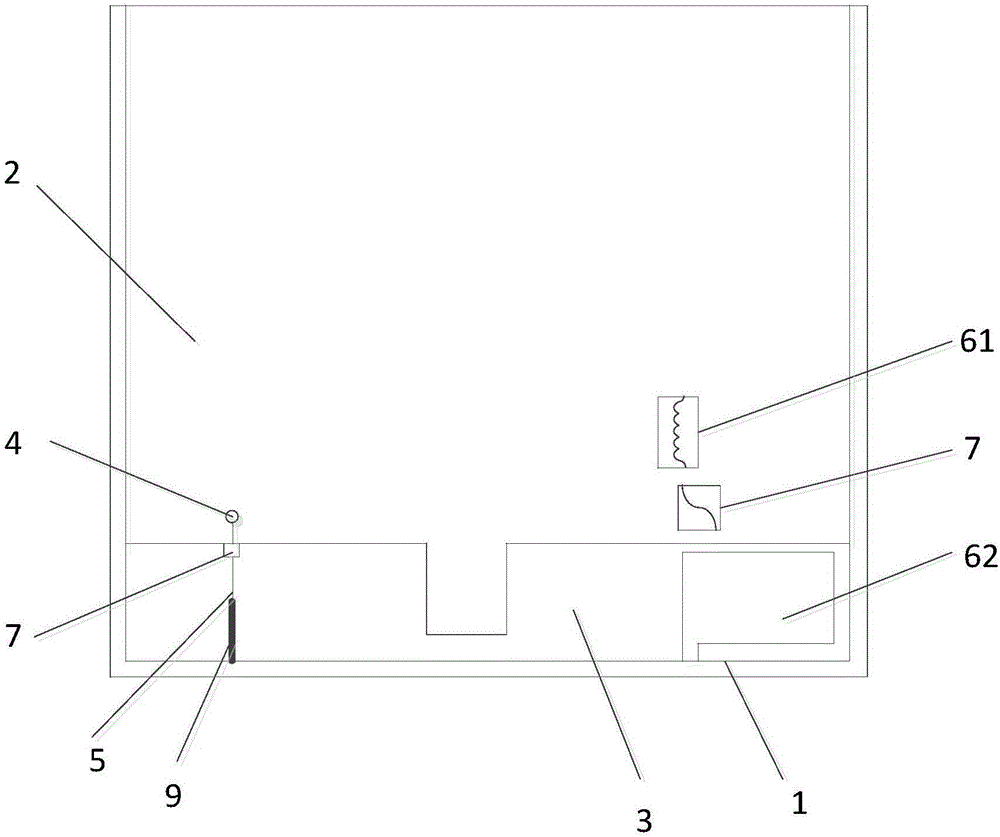

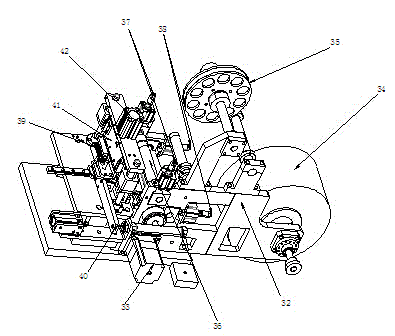

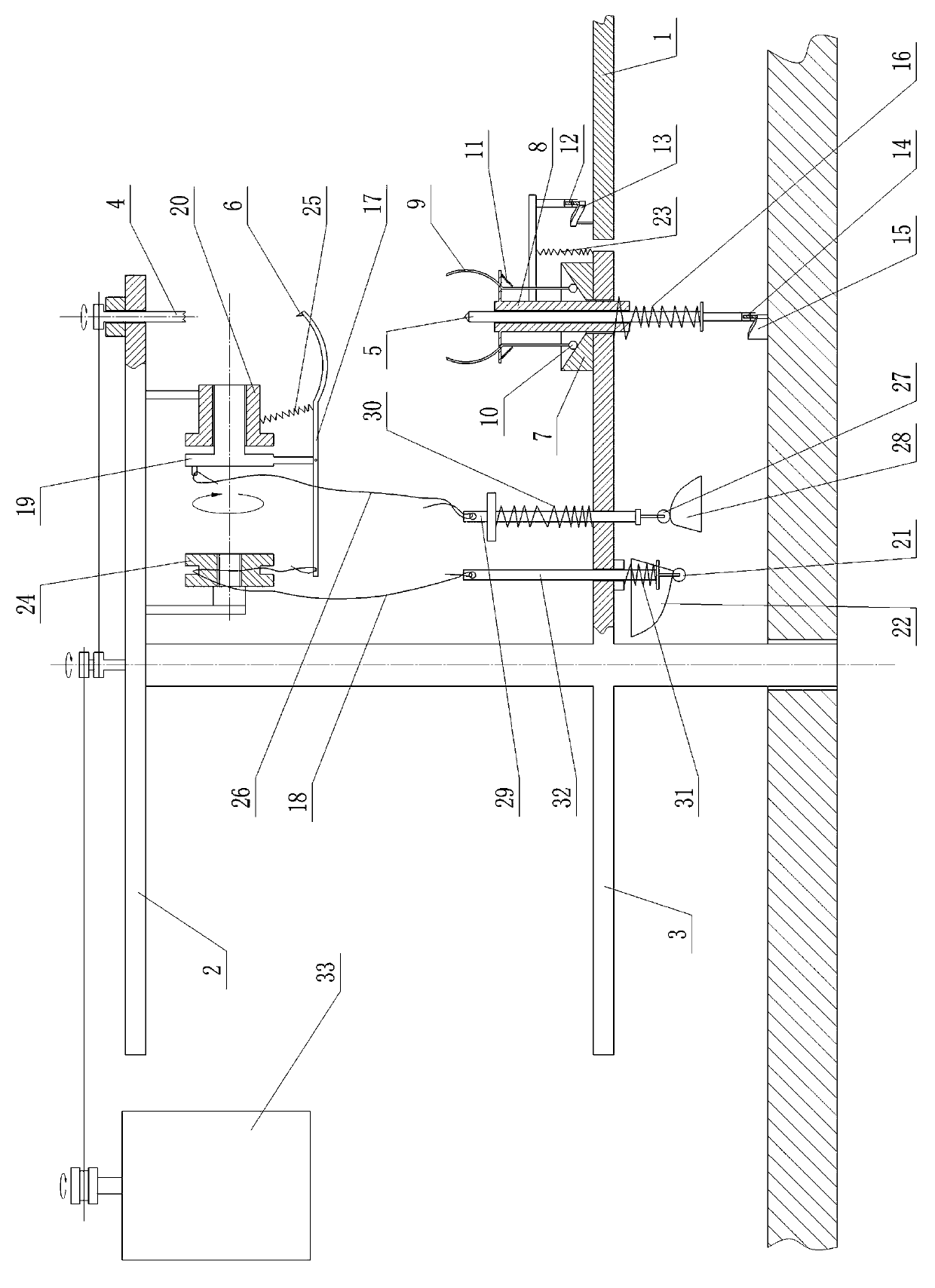

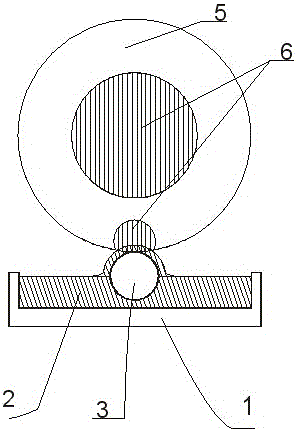

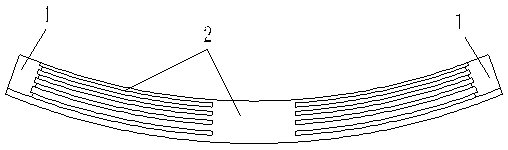

Wrapping type wire winding and bundling machine

InactiveCN104443504AIncrease productivityImprove yieldFilament handlingPackagingEngineeringAutomation

The invention discloses a wrapping type wire winding and bundling machine. The wrapping type wire winding and bundling machine comprises a machine frame 1 and a wire winding operating table 2 located on the upper surface of the machine frame 1, wherein a wrapping platform 3 is arranged at the center of the wire winding operating table 2, a wire winding mechanism 4 is arranged in front of the wrapping platform 3, a film feeding mechanism 5 and a film cutting mechanism 6 are arranged behind the wrapping platform 3, the film feeding mechanism is connected with the wrapping platform through the film cutting mechanism, an outer wrapping mechanism 7 is arranged on the left side of the wrapping platform 3, an inner wrapping mechanism 8 is arranged on the right side of the wrapping platform 3, and a horizontal movement mechanism 9 is arranged on the upper portion of the wrapping platform 3. The wrapping type wire winding and bundling machine has the advantages that the automation degree is high and manpower resources are saved.

Owner:东莞市林洋机械设备有限公司

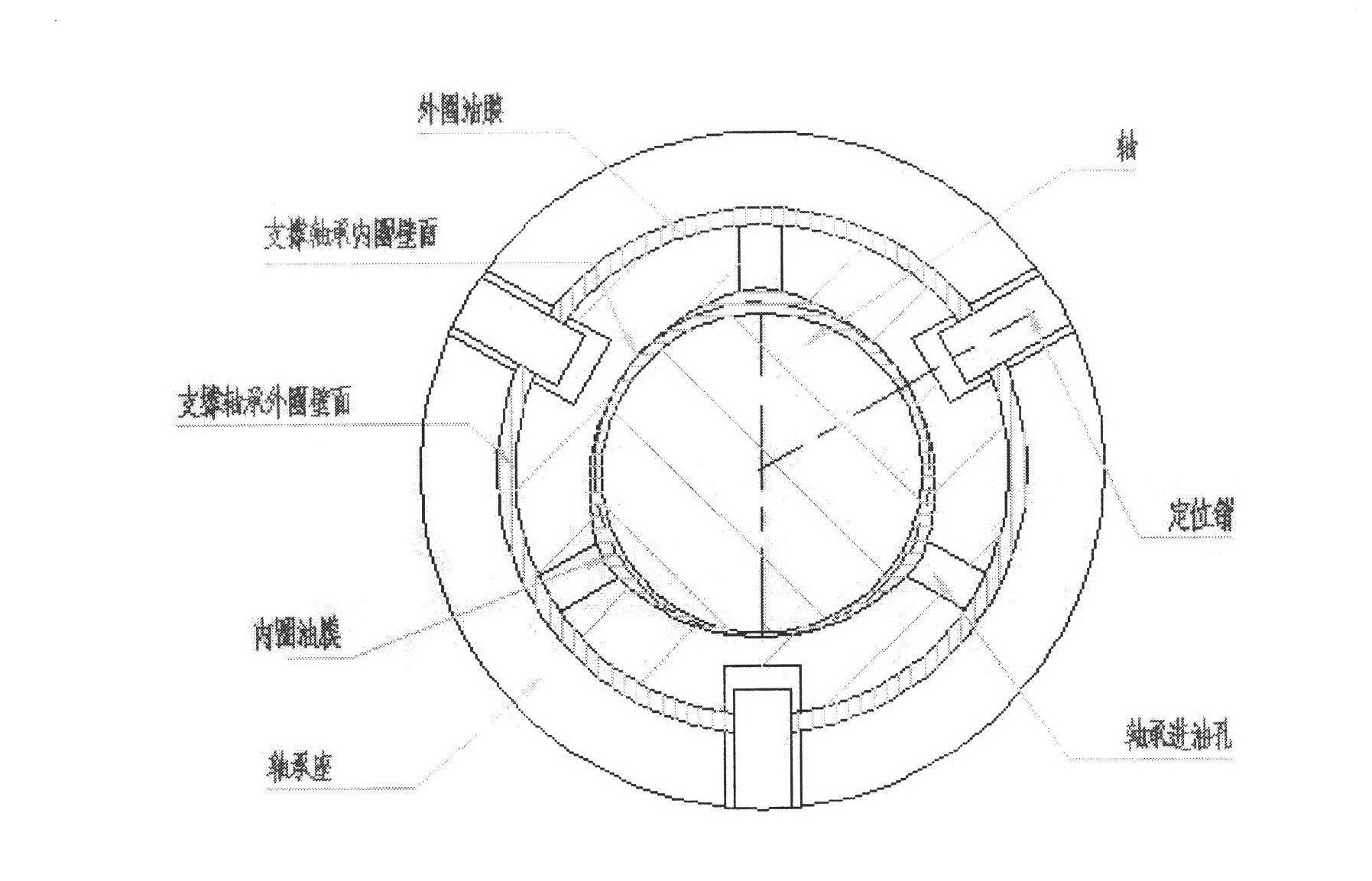

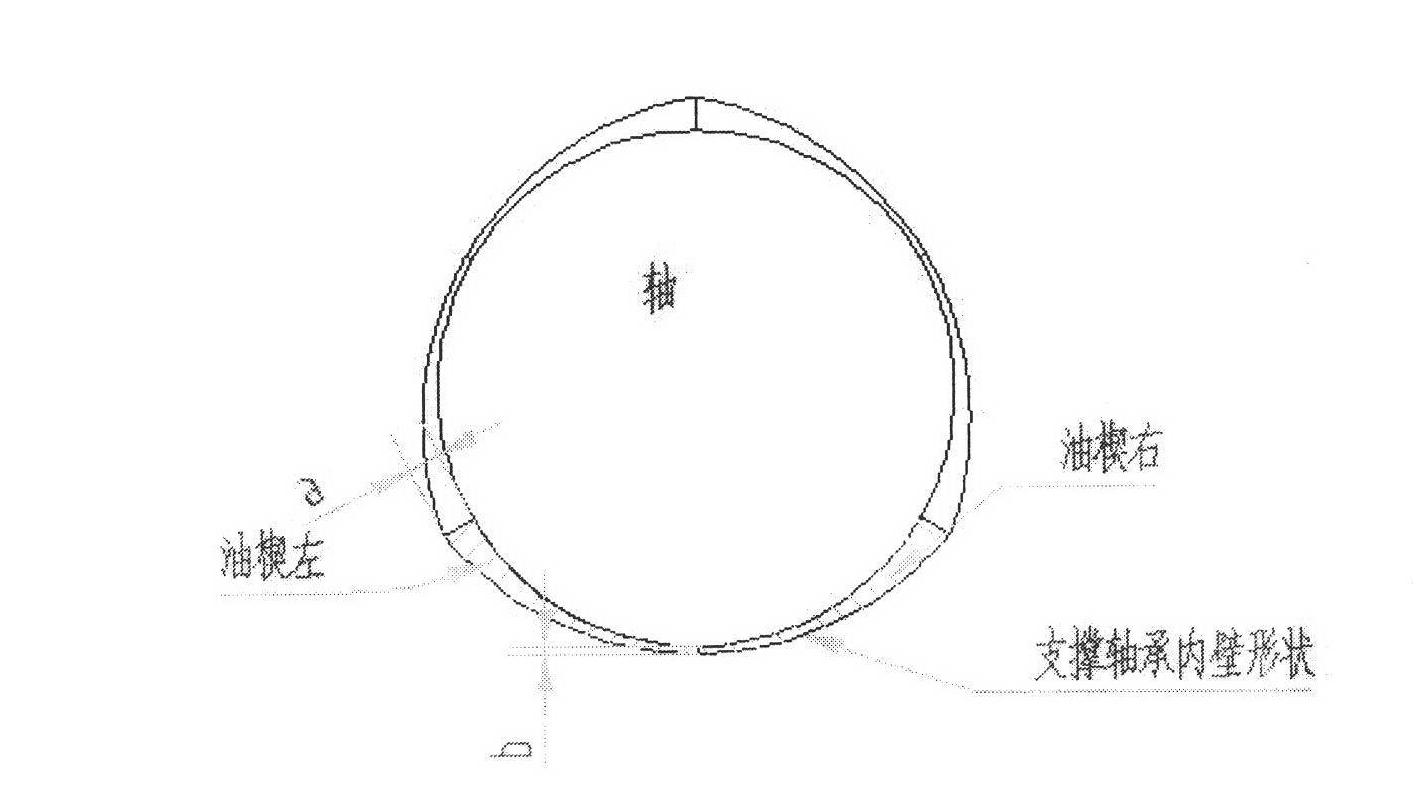

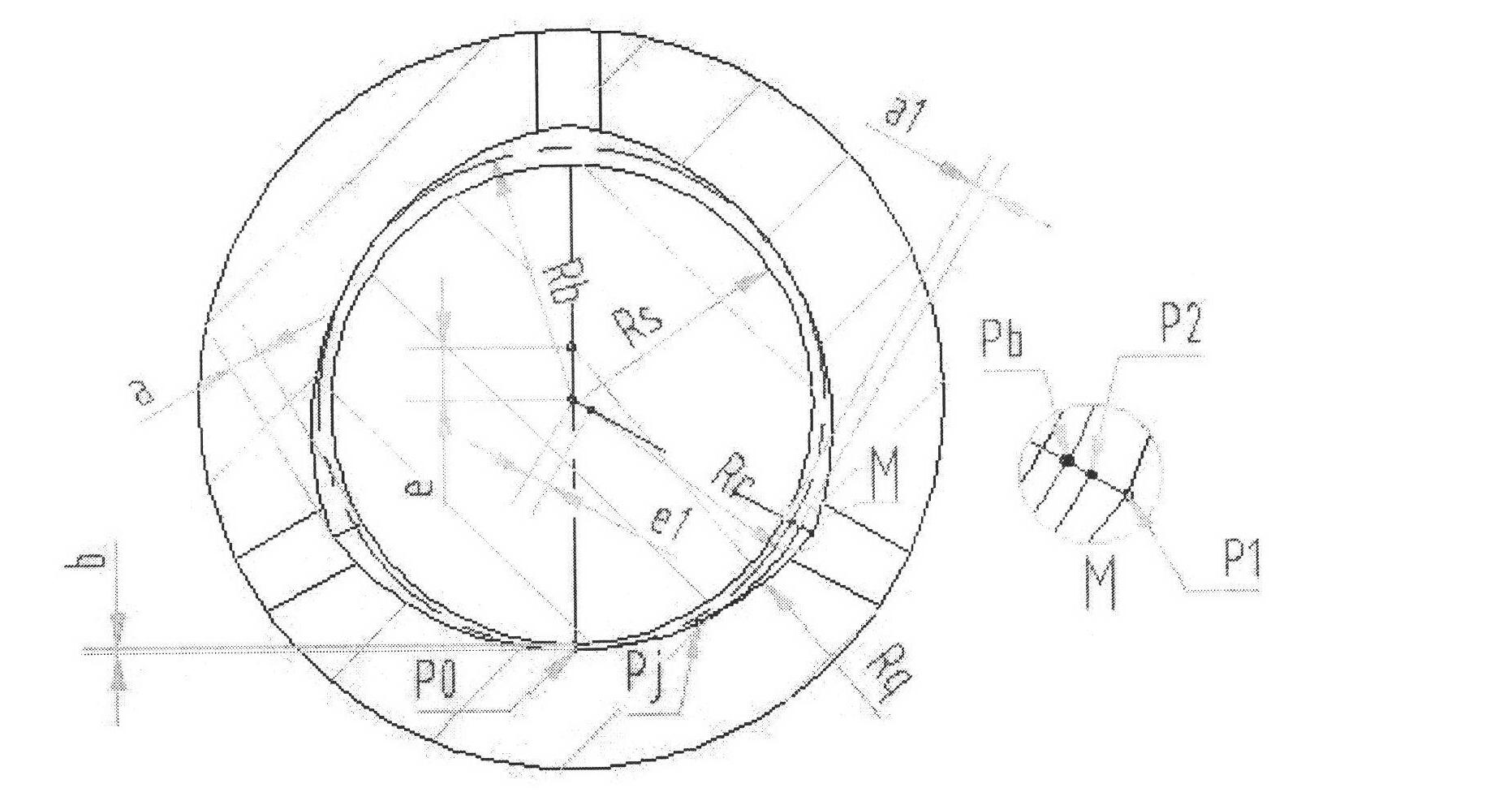

Method for determining shape of semi-floating supporting bearing inner bore oil wedge of supercharger

ActiveCN102192238ANo problem of inconsistent appearance qualityReduce processing requirementsShaftsBearing componentsEngineeringBearing design

The invention discloses a method for determining the shape of a semi-floating supporting bearing inner bore oil wedge of a supercharger. The method is characterized by comprising the following steps: drawing two concentric circles which are concentric with an axle with the radius of Rb and R2 according to the limited conditions of the value of a1 and b, and axle radius Rs, the base radius of the bearing inner bore (Rb=Rs+b), and the axis distance (R2=Rs+a1) of the deepest point distance axle manufactured on the inner wall of the supporting bearing; dividing the two concentric circles into n equal parts according to the number n of oil wedges; and connecting 2n along ents sequentially by virtue of a curve, wherein the polar equation of the curve is rho=Rm+e*sin(n*t) or rho=Rm+e*cos(n*t), and the curve is in the shape of the supporting bearing inner bore oil wedges. According to the invention, a more simple method is used for designing and describing the oil wedges of the bearing inner wall, not only can the limiting requirement of the bearing design be satisfied, but also the design and drawing difficulty is reduced, the drawing label is simplified, the manufacturing difficulty is reduced, and the consistency of the appearance of the product is ensured.

Owner:CHONGQING TURBO FLOW MACHINERY MFG

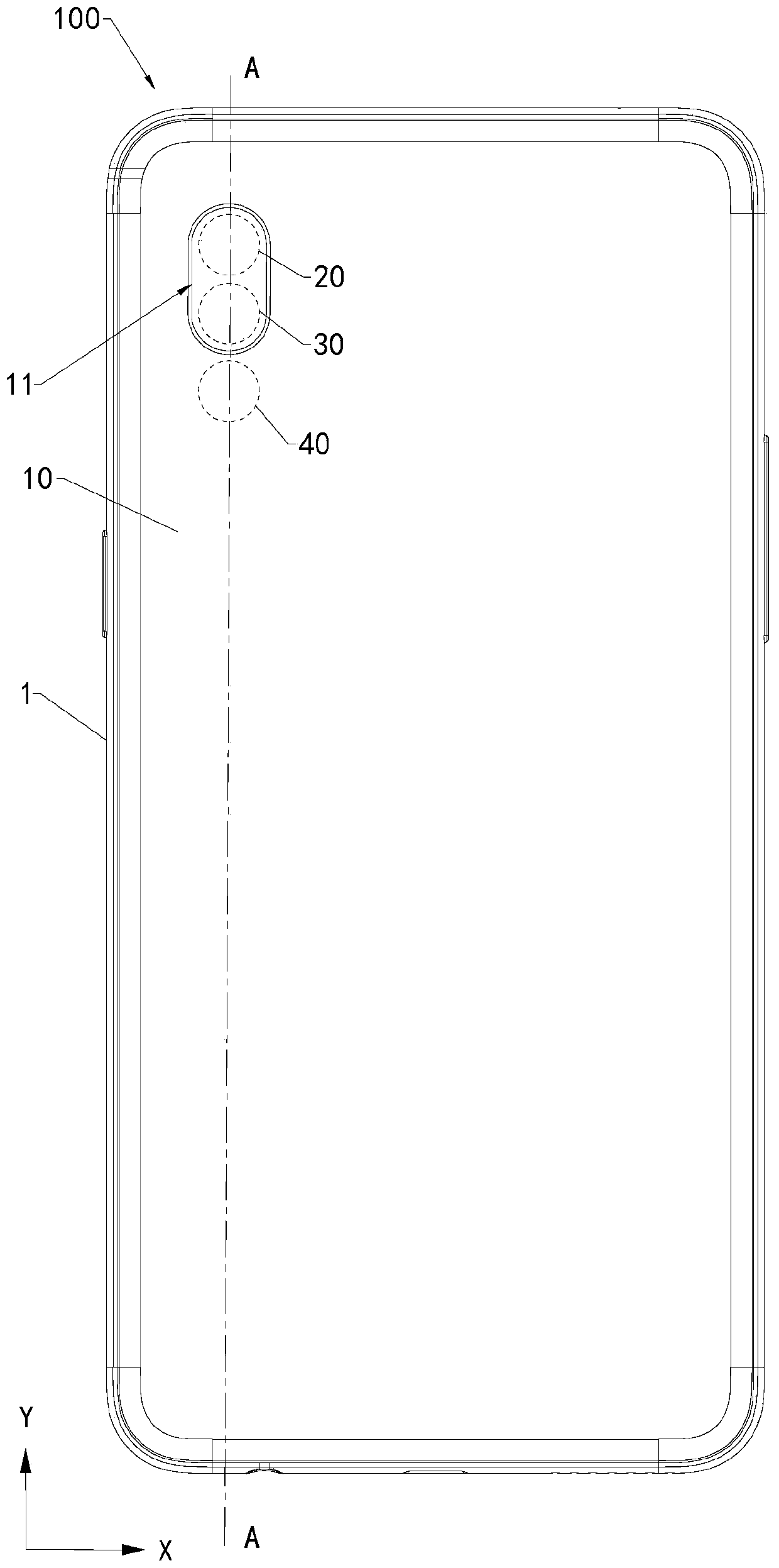

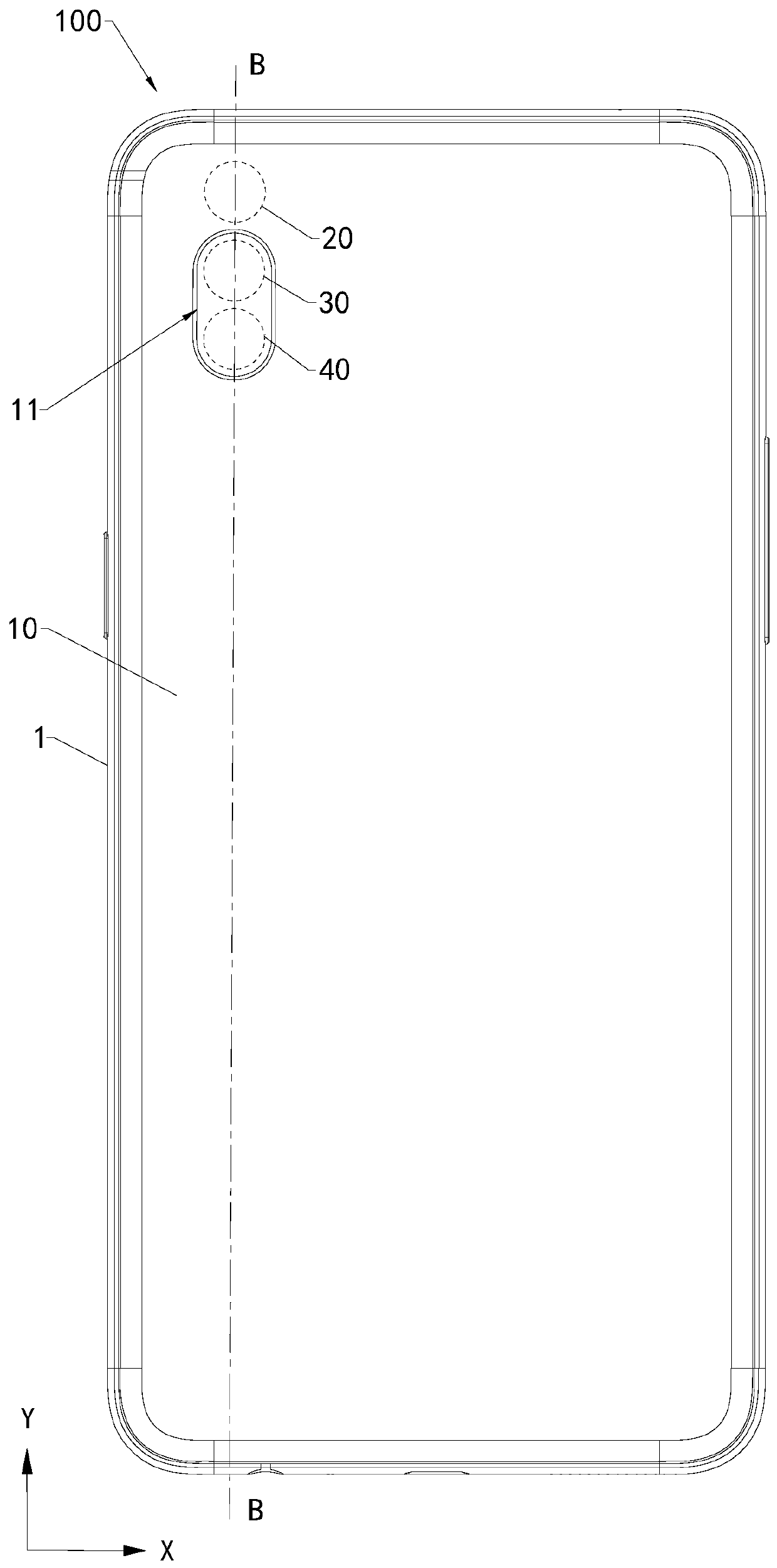

Electronic equipment and a shooting method of the electronic equipment

ActiveCN109714456AGood appearance consistencyReduce areaTelevision system detailsColor television detailsShooting methodComputer science

The invention discloses electronic equipment and a shooting method of the electronic equipment. Electronic equipment comprises a middle frame, a Rear cover, a first camera, a Second camera and a thirdcamera; the rear cover covers the middle frame so as to form a Containing space, The rear cover is provided with a light-transmitting part; the First camera, the second camera and the third camera are arranged in the accommodating space; the First camera, the second camera and the third camera are movably connected to the middle frameand are opposite to or far away from the light-transmitting part; When the electronic equipment is switched to the first shooting mode, the photosensitive surface of the first camera and the photosensitive surface of the second camera are opposite to the light transmitting part, and when the electronic equipment is switched to the second shooting mode and the photosensitive surface of the second camera and the photosensitive surface of the third camera are opposite to the light transmitting part, the first shooting mode is different from the second shooting mode. The electronic device is good in appearance consistency.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

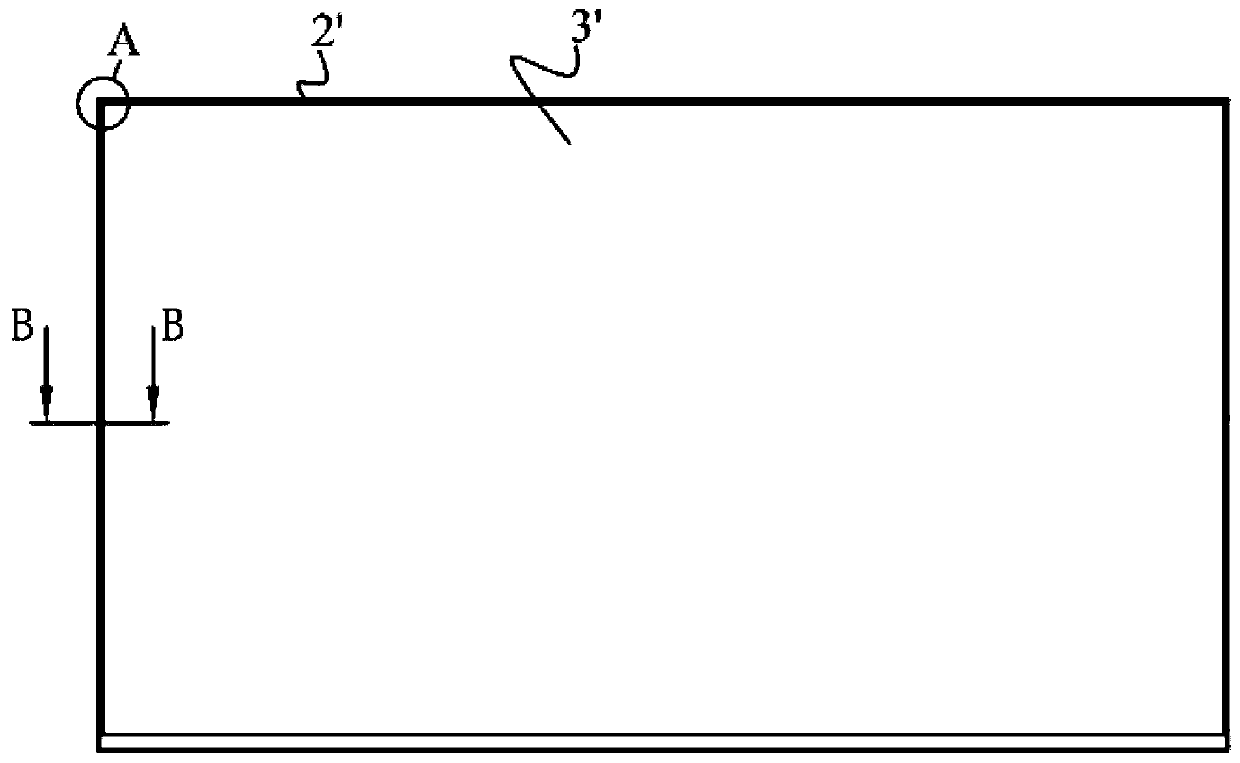

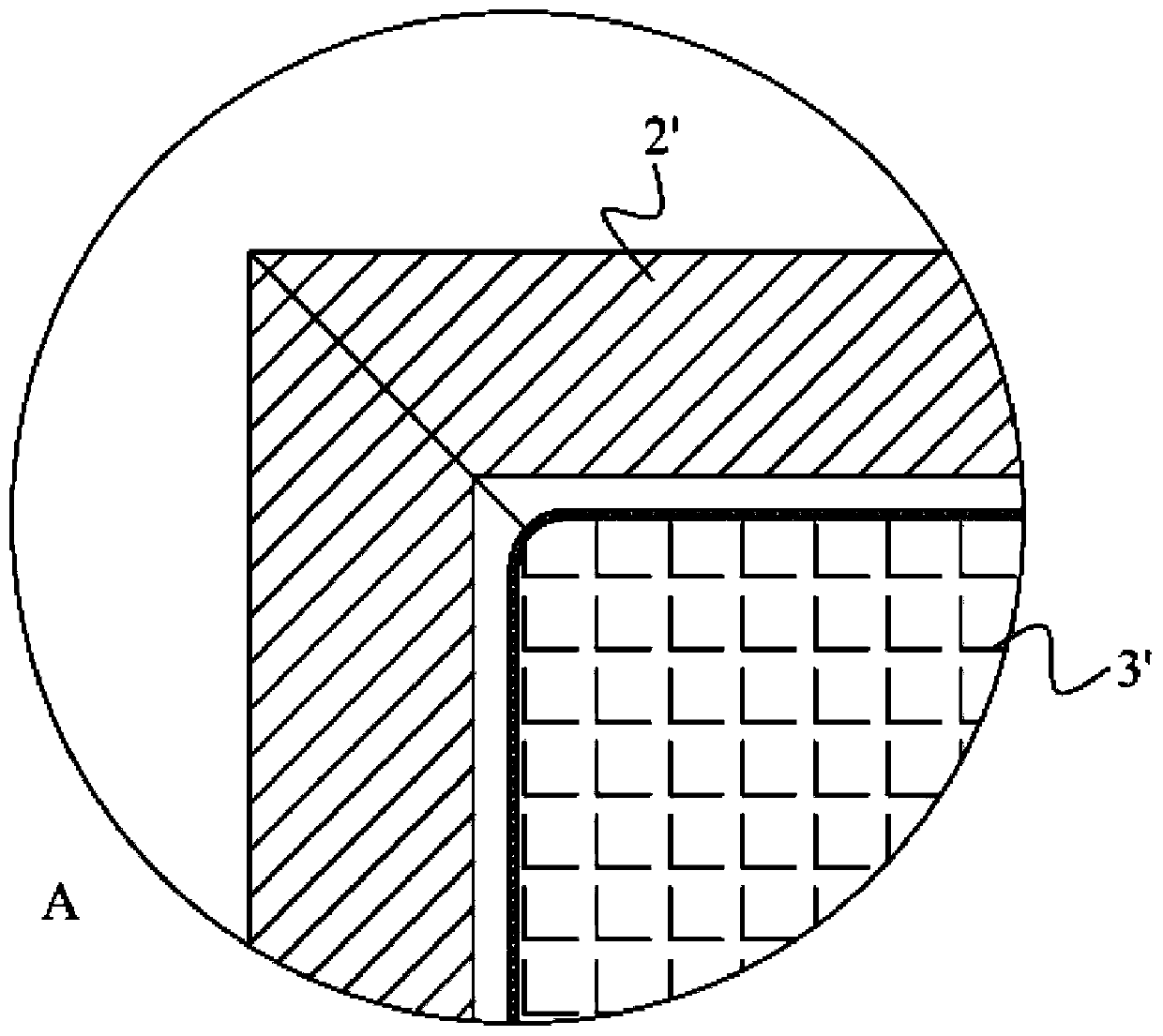

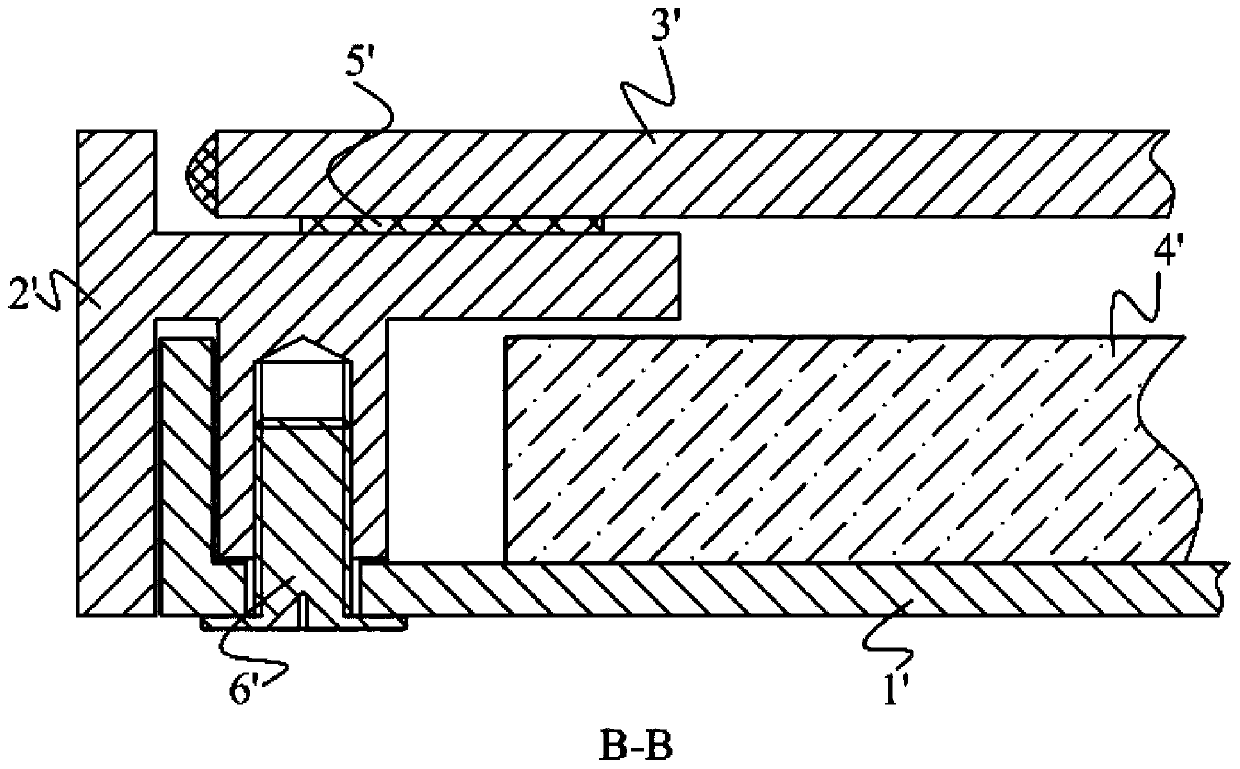

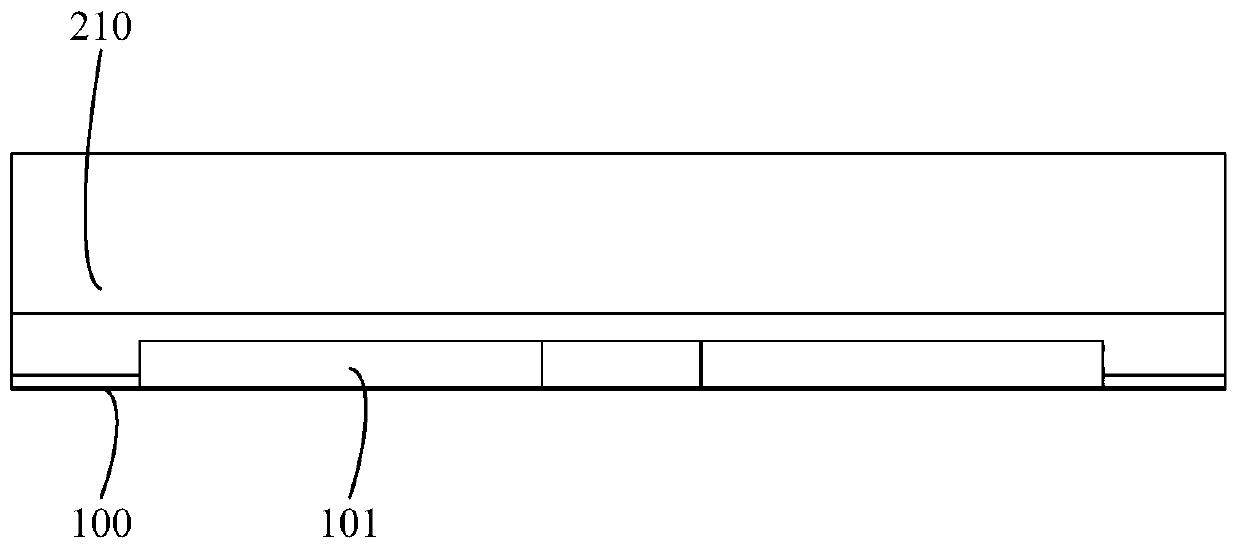

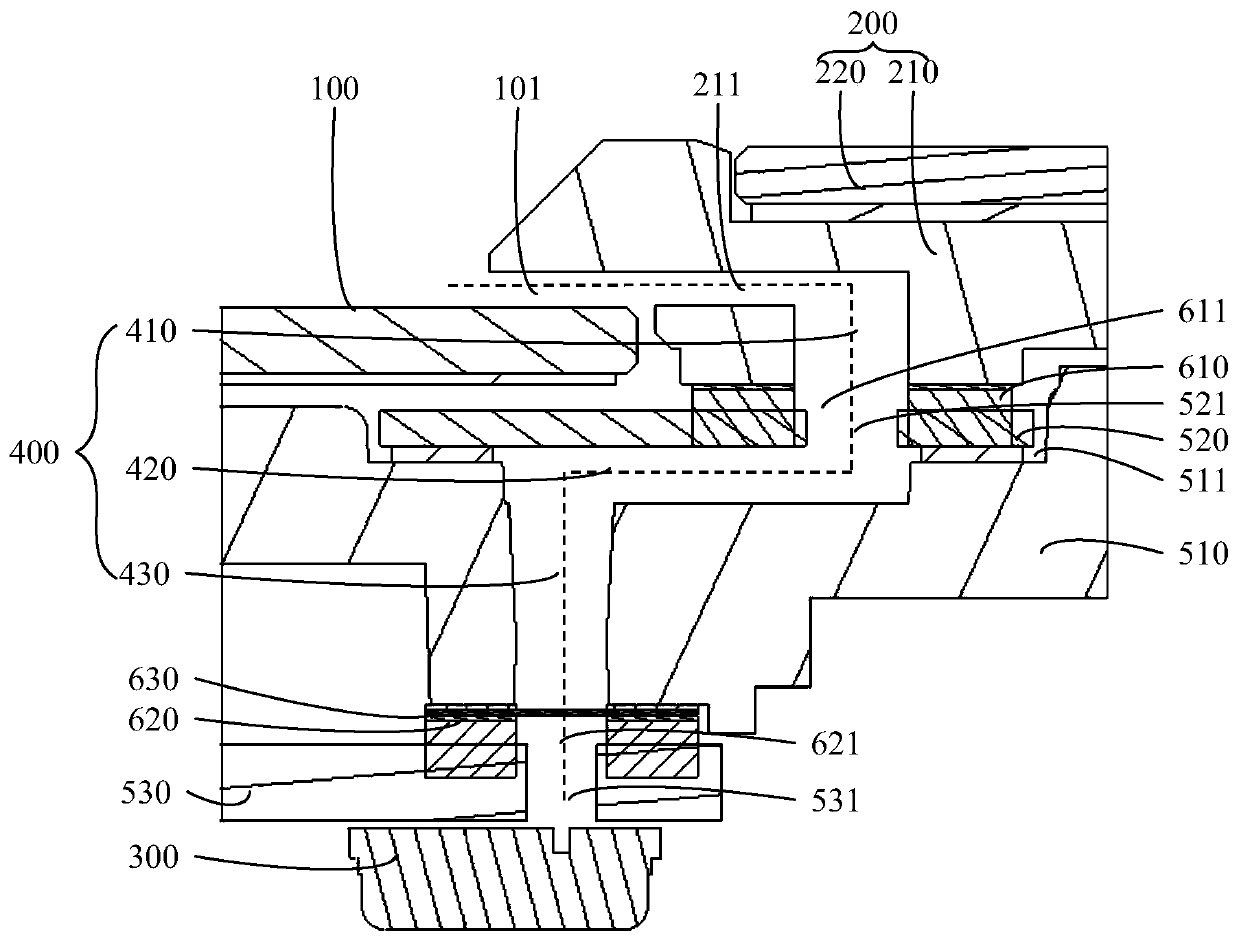

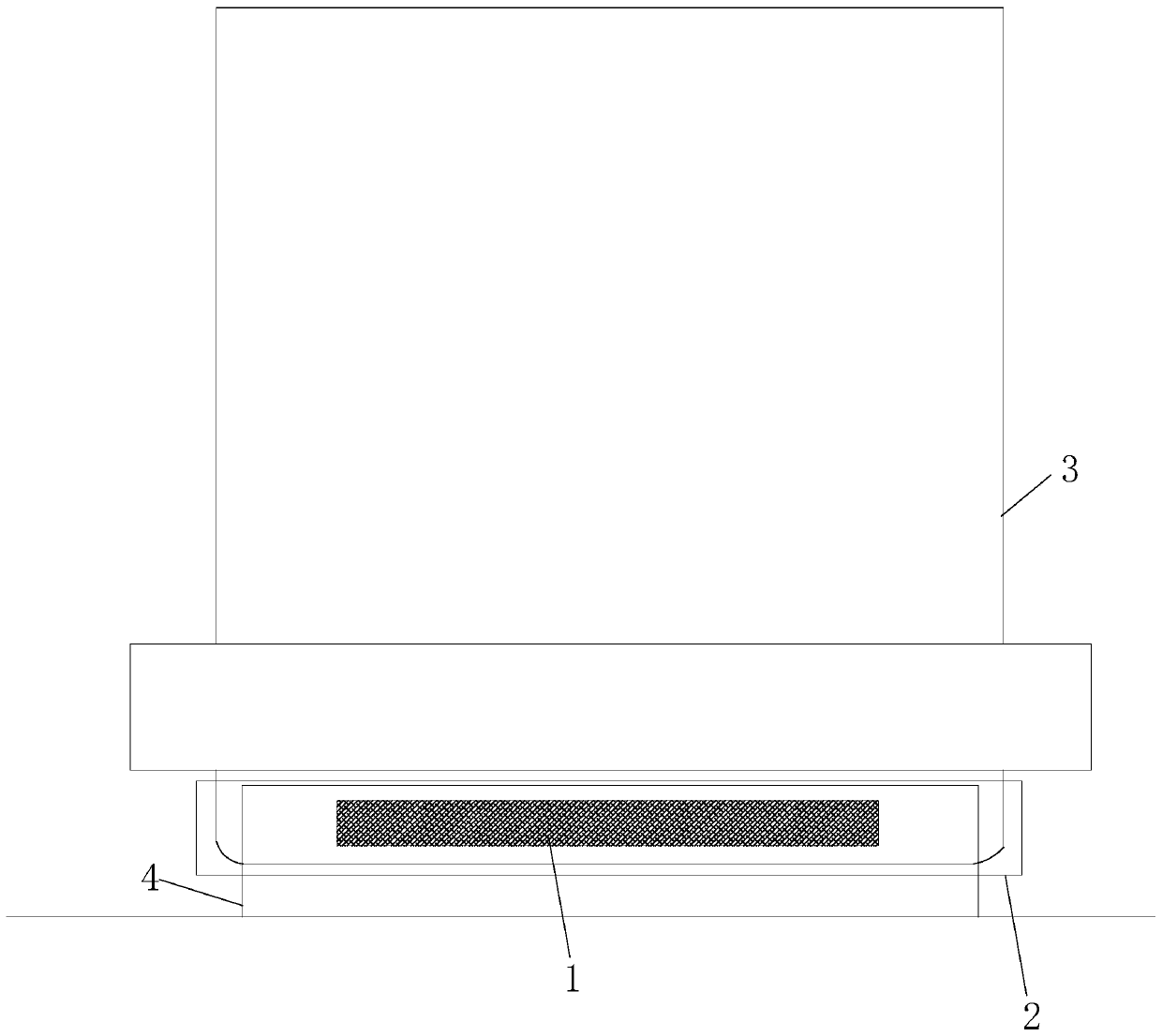

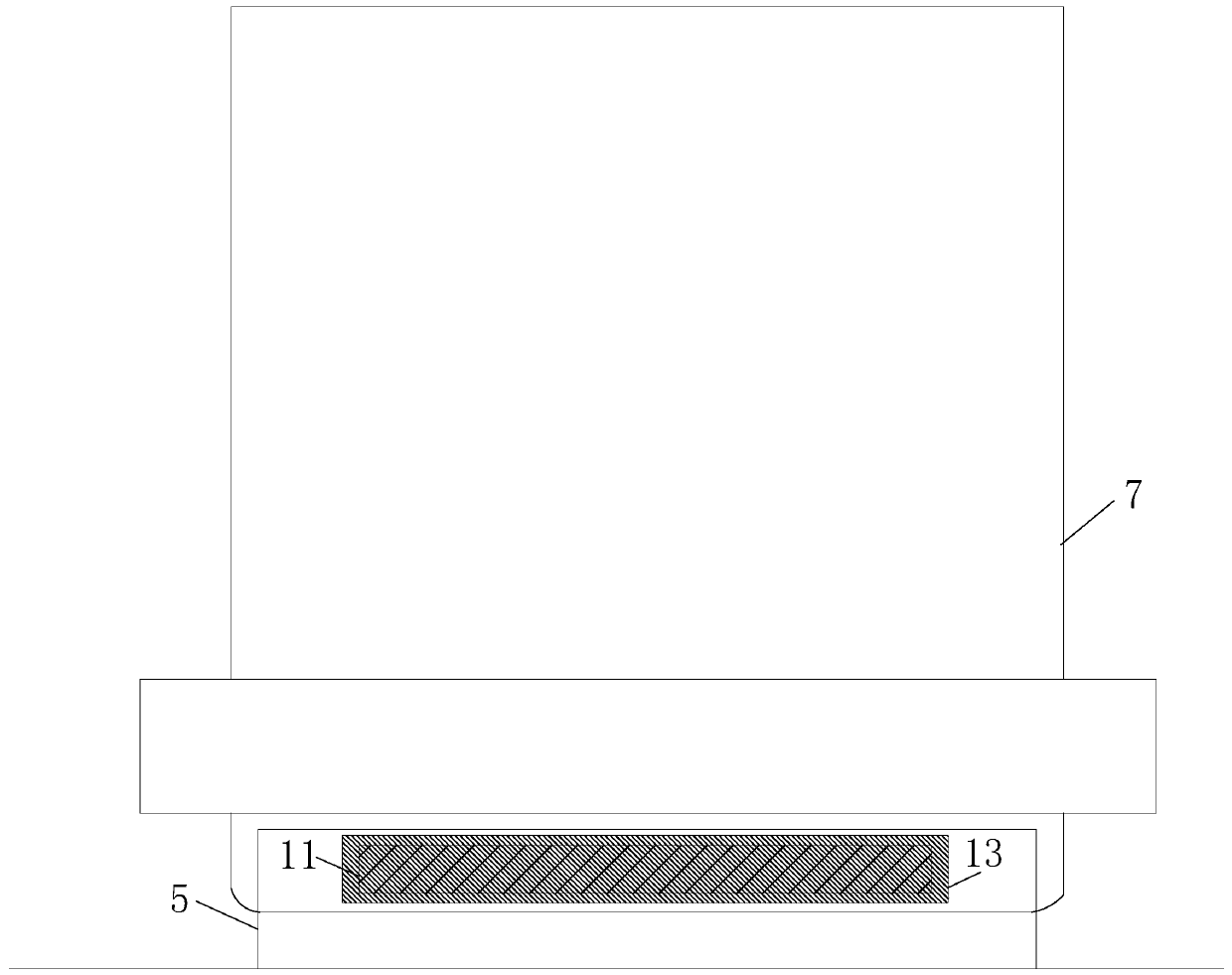

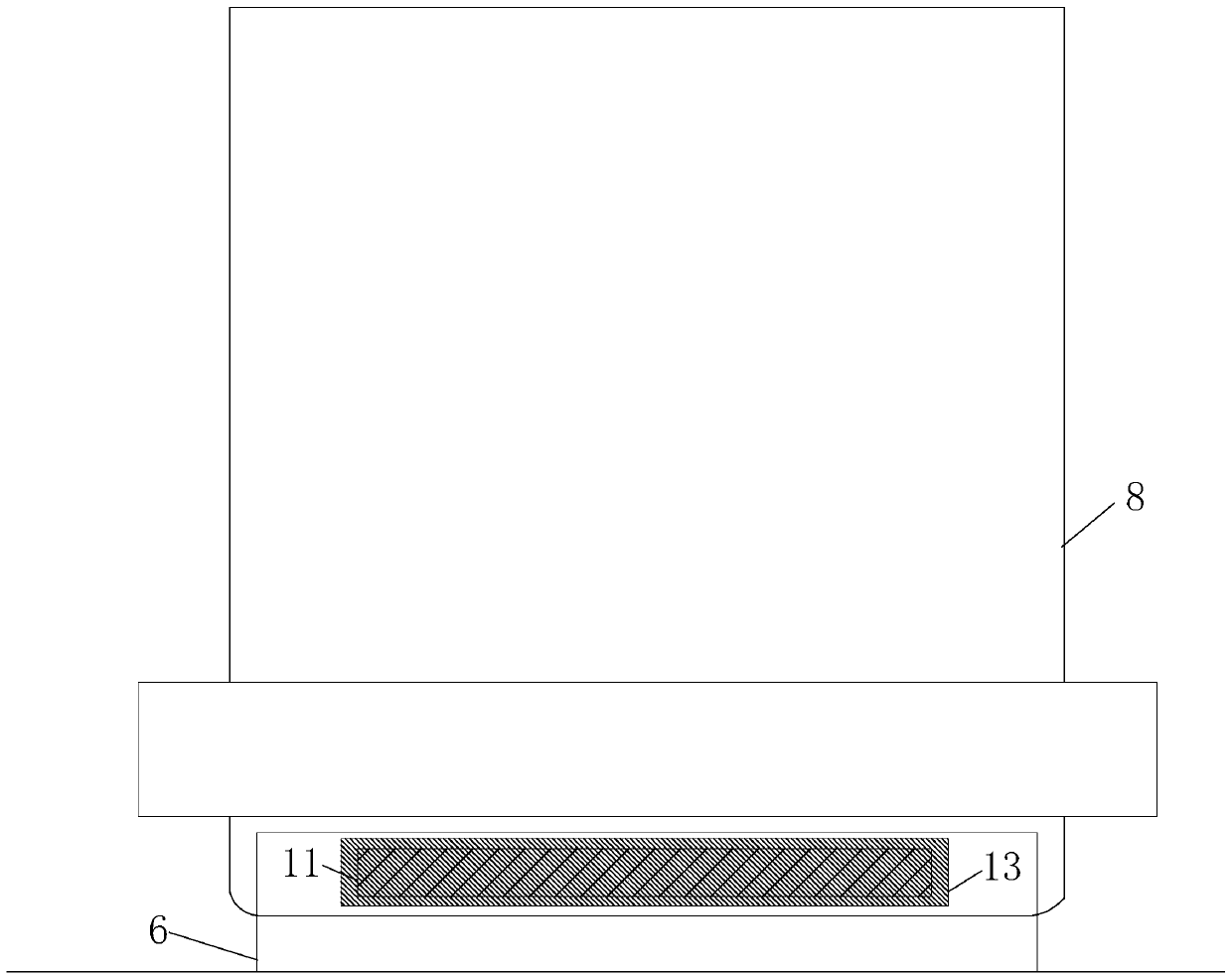

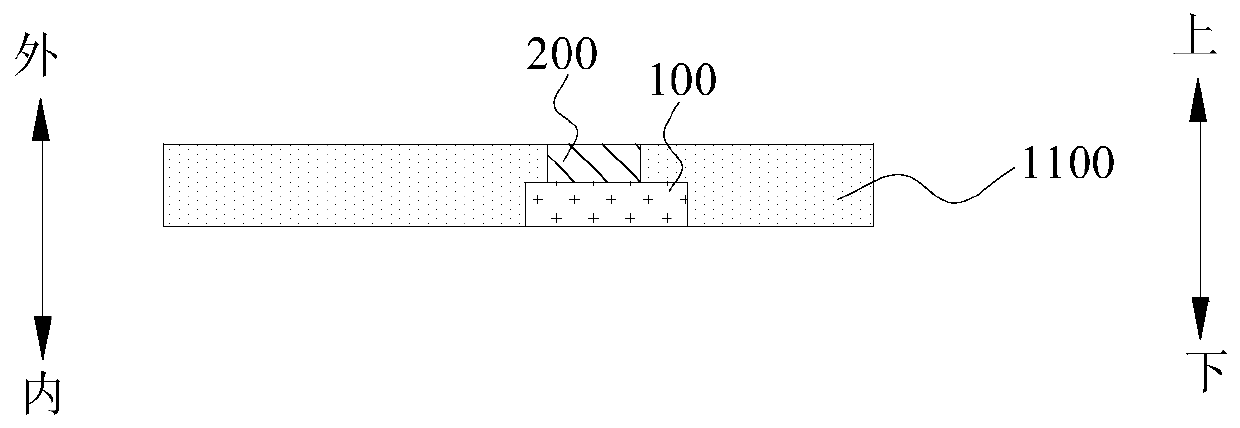

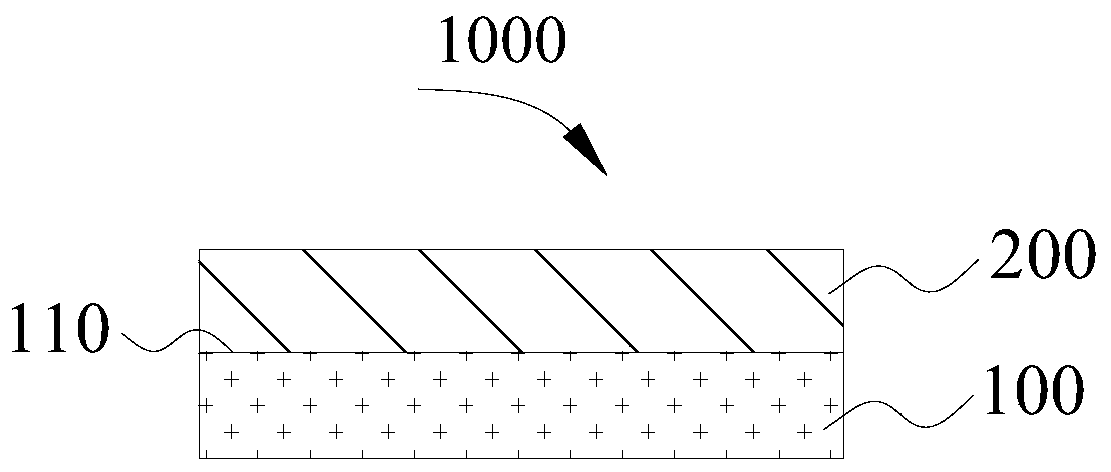

Display module and display equipment

InactiveCN109856838AGood appearance consistencySimple appearance treatment processNon-linear opticsEngineeringFlanging

The invention discloses a display module and display equipment, and relates to the technical field of the display equipment. The display module comprises a back plate and a middle frame; the edges ofthe three sides of the back plate are bent towards the front side to form first flanging, the end of the first flanging is bent towards the inner side to form an abutting part, and the edge of the remaining side of the back plate is bent towards the rear side to form second flanging; the middle frame comprises a U-shaped frame and a lower side frame, the U-shaped frame is arranged on the inner side of the first flanging, the abutting part abuts against the front side face of the U-shaped frame, and the inner side of the U-shaped frame is provided with a clamping groove for containing the edgeof an optical element; and the lower side frame is connected with the second flanging and shields an opening of the U-shaped frame. According to the display module, defects such as knife edges at theend of the back plate are hidden through the first flanging, the abutting part and the second flanging, the middle frame does not need to be used as an appearance piece at the edge of the display module, thus appearance faces of the display module are all provided by the back plate, and the appearance consistency is better; and when the back plate serves as the appearance piece, an appearance treatment process is simple, the cost is advantageously lowered, and the production efficiency is improved.

Owner:江门创维显示科技有限公司

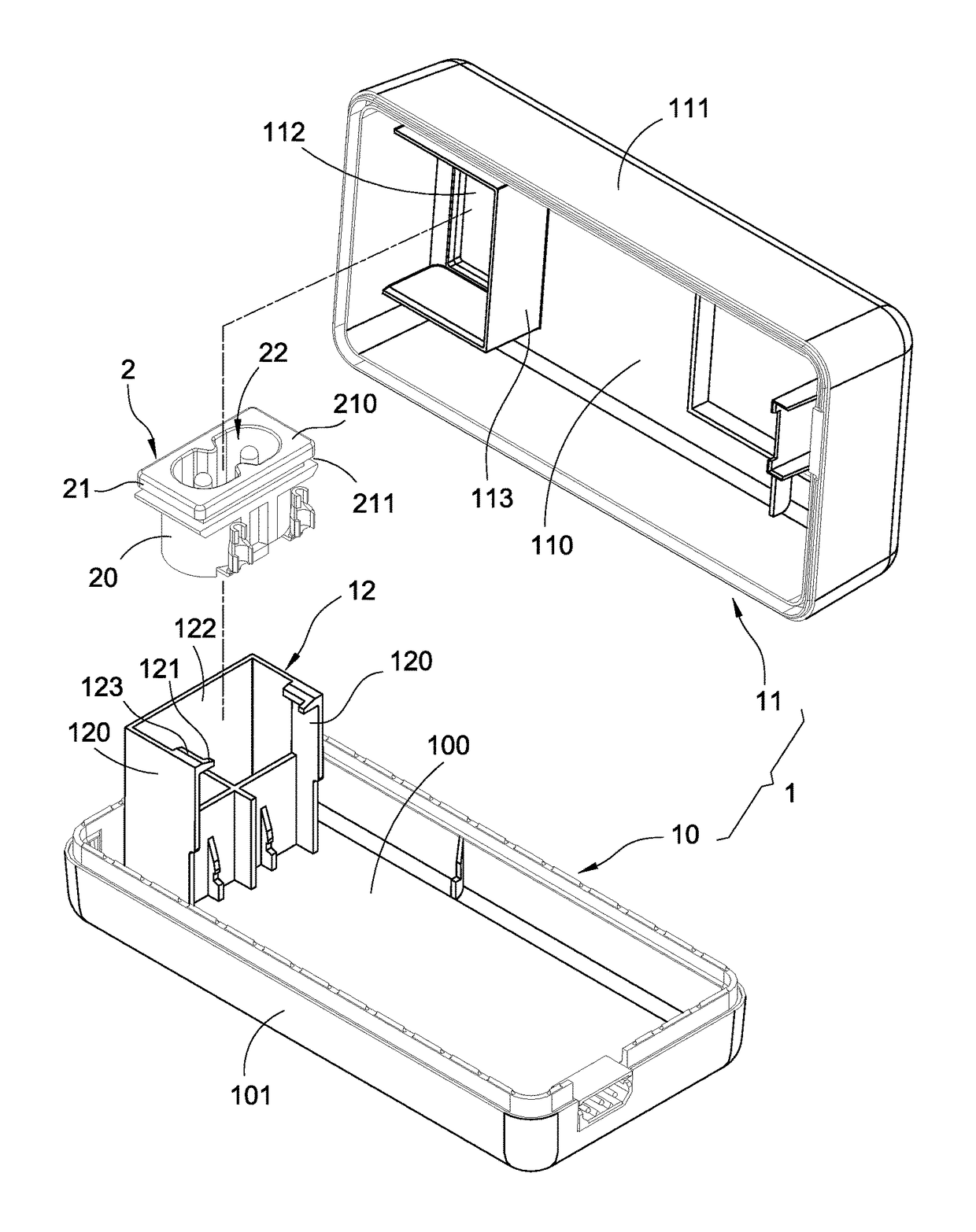

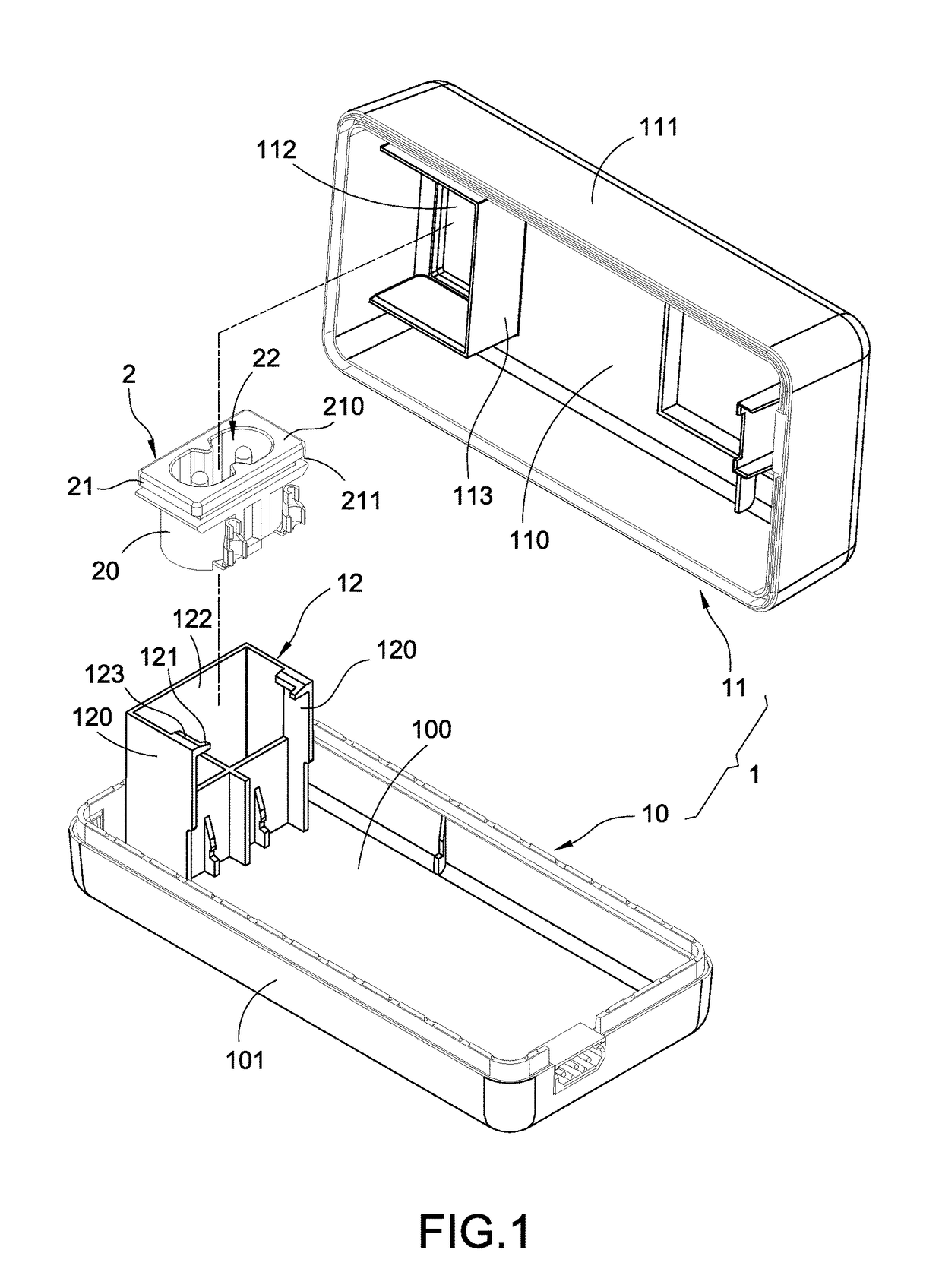

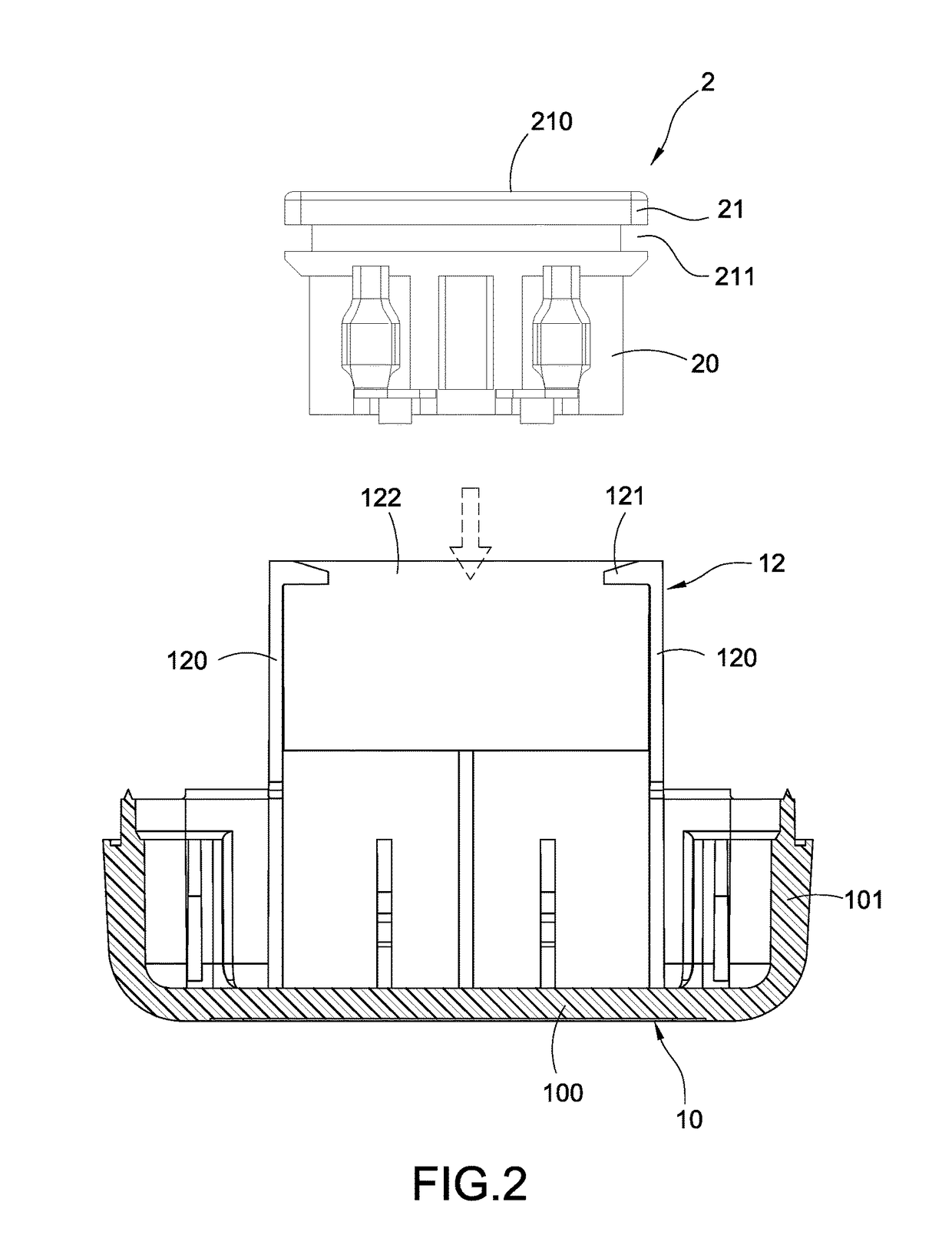

Adapter casing module for installing a power socket

ActiveUS9825415B1Easy to installGood appearance consistencyTwo pole connectionsCoupling device detailsEngineering

Owner:CHICONY POWER TECH CO LTD

Auxiliary metal machining process for CuCr contact surface treatment machining

ActiveCN112454013AProcess low consumptionAvoid Oxidation RiskEdge grinding machinesPolishing machinesGrindingPolishing

The invention discloses an auxiliary metal machining process for CuCr contact surface treatment machining. The process comprises the steps of magnetic grinding, abrasive matching, CuCr contact basketing, grinding and vacuum degreasing treatment; and number 10 industrial white oil is adopted as a grinding cooling wetting medium, mixed abrasive adopting a stainless steel needle is adopted as grinding polishing abrasive, a CuCr contact is subjected to magnetic grinding polishing, then vacuum degreasing, vacuum drying and vacuum packaging are conducted, and the technical requirement that "the surface of the CuCr contact is free of scratches, oxidation, stains and other defects" is met. The process is low in consumption, environment friendly and efficient, the oxidation risk of the polishing link is effectively avoided, the CuCr contact produced through the process is excellent in appearance quality, the surface appearance of the product is in inherent metallic luster, and the appearance consistency is high.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Electronic device and watch chain shaft mechanism thereof

ActiveCN106102368AImprove aestheticsNice appearanceCasings/cabinets/drawers detailsPivotal connectionsRelative displacementElectric equipment

The invention discloses a watch chain shaft mechanism. The watch chain shaft mechanism comprises a plurality of rotation shafts and a plurality of hinge mechanisms, wherein the plurality of rotation shafts are arranged in parallel, the plurality of hinge mechanisms are arranged on the rotation shafts, two arbitrary adjacent rotation shafts are connected through the hinge mechanism, and wrapping layers covers surfaces of all hinge mechanisms. In the watch chain shaft mechanism provided by the embodiment of the invention, the rotation shafts which are arranged adjacent to each other are connected in a pairwise manner by the hinge structures, so that the two rotation shafts which are connected to each other only rotate relative to each other, no displacement change is generated, the relative displacement change among the rotation shafts is generated only between different combinations, no interference is generated on normal working of the rotation shafts by the wrapping layers wrapping the external parts of the rotation shafts, all outer surfaces of the watch chain shaft mechanism can be covered and decorated on the premise of ensuring the normal working of the watch chain shaft mechanism, the appearance consistency of an electronic device can be improved, and the appearance of the electronic device is more attractive. The invention also provides the electronic device with the above watch chain shaft mechanism.

Owner:LENOVO (BEIJING) CO LTD

Process for producing magnetic ring

InactiveCN102856067AReduce investmentReduce water and electricity consumptionEdge grinding machinesInductances/transformers/magnets manufactureEngineeringEnergy consumption

The invention discloses a process for procuring a magnetic ring. The production process comprises the following operation steps: 1) pressing into a blank; 2) full-automatically chamfering the blank; and 3) sintering and moulding the blank, wherein the step 2) of full-automatically chamfering the blank is the process of chamfering the magnetic ring blank by using the full-automatic chamfering separator. The process for procuring the magnetic ring has the beneficial effects of simple technical route, few apparatus investment, and full-automatic chamfering process; the working efficiency can be effectively improved, the labour is saved, and the cost is reduced; the chips and dust are recycled, and the production process is green and environment-friendly, can reduce the hydroelectric energy consumption and save the cost and has excellent application foreground.

Owner:深圳市金核科技股份有限公司

Electronic device

ActiveCN111405414AReduce the number of openingsGood appearance consistencyFrequency/directions obtaining arrangementsTelephone set constructionsEngineeringAcoustics

The invention discloses electronic device. The device comprises a shell, a first functional module and a second functional module, wherein the second functional module is arranged in the shell, the second functional module comprises an acoustic device, a sound guide channel is formed in the shell, the first functional module at least partially protrudes out of the outer surface of the shell, an assembly gap is formed between the outer surface of the shell and the side wall of the first functional module, and the acoustic device is communicated with the assembly gap through the sound guide channel. According to the scheme, the sound information can be transmitted through the assembly gap between the first functional module and the shell, so that a sound guide hole does not need to be formedin the shell, the number of the holes of the shell is reduced, the integrity of the shell is further improved, the appearance consistency of the shell is enhanced, the assembly gap is narrower than the sound guide hole, water vapor and dust in the environment can be effectively prevented from entering the shell, and the waterproof performance and the dustproof performance of the electronic deviceare further improved.

Owner:VIVO MOBILE COMM CO LTD

Fruit peeling machine

InactiveCN103766472ASmooth peelingGood appearance consistencyFood preparationFruits/vegetable preservation by dehydrationMechanical engineering

The invention discloses a fruit peeling machine. The fruit peeling machine comprises an upper rotary disk and a lower rotary disk, wherein rotatable upper ejector pins are uniformly arranged on the upper rotary disk at equal intervals and respectively connected with a power mechanism; the lower rotary disk is arranged below the upper rotary disk; a material grasper corresponding to the upper ejector pins is arranged on the lower rotary disk; lower ejector pins which are corresponding to the upper ejector pins and can move up and down are arranged in the middle of the material grasper; cutter blades which can move according to arc-shaped tracks are arranged beside the lower end heads of the upper ejector pins; the upper rotary disk and the lower rotary disk are connected with the power mechanism and rotate synchronously. The fruit peeling machine is suitable for the peeling of various fruits, and particularly suitable for the peeling of persimmons. The fruit peeling machine is uniform in peeling thickness and good in appearance consistency; a cutter does not need to be held manually. Thus, the fruit peeling machine is high in safety and working efficiency.

Owner:胡禾村

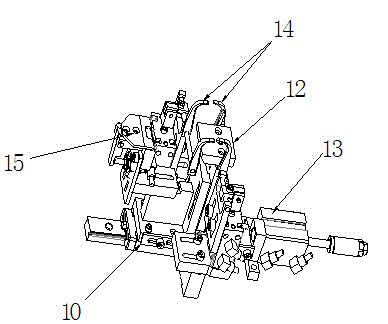

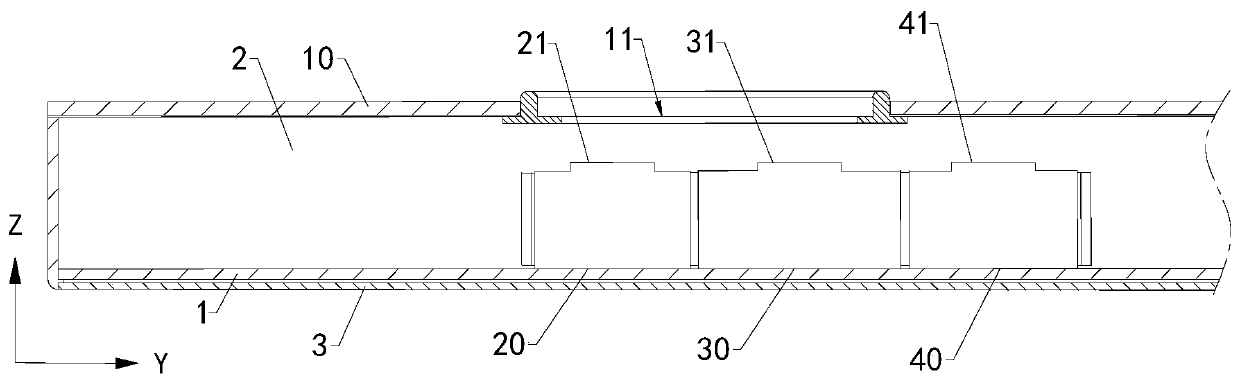

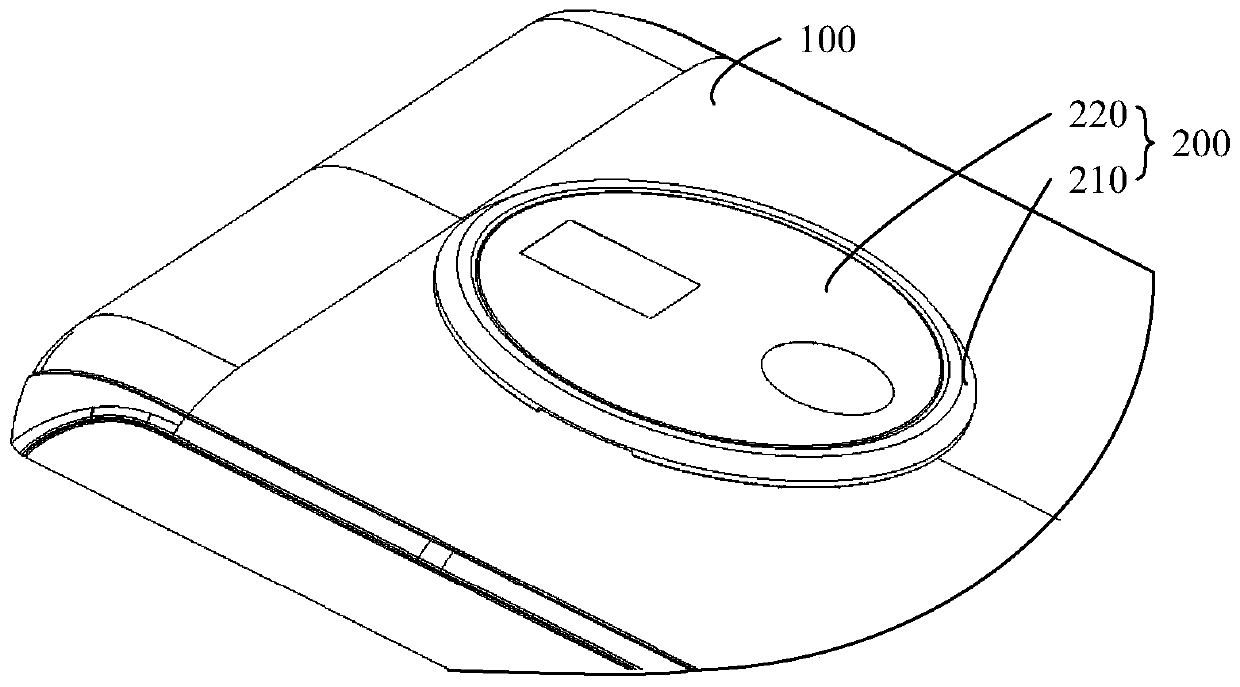

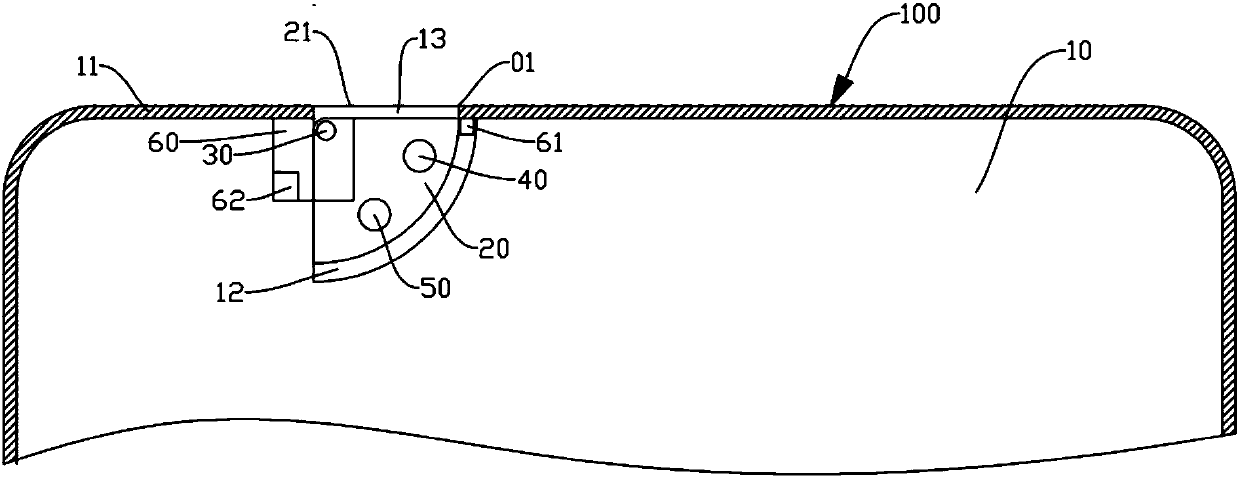

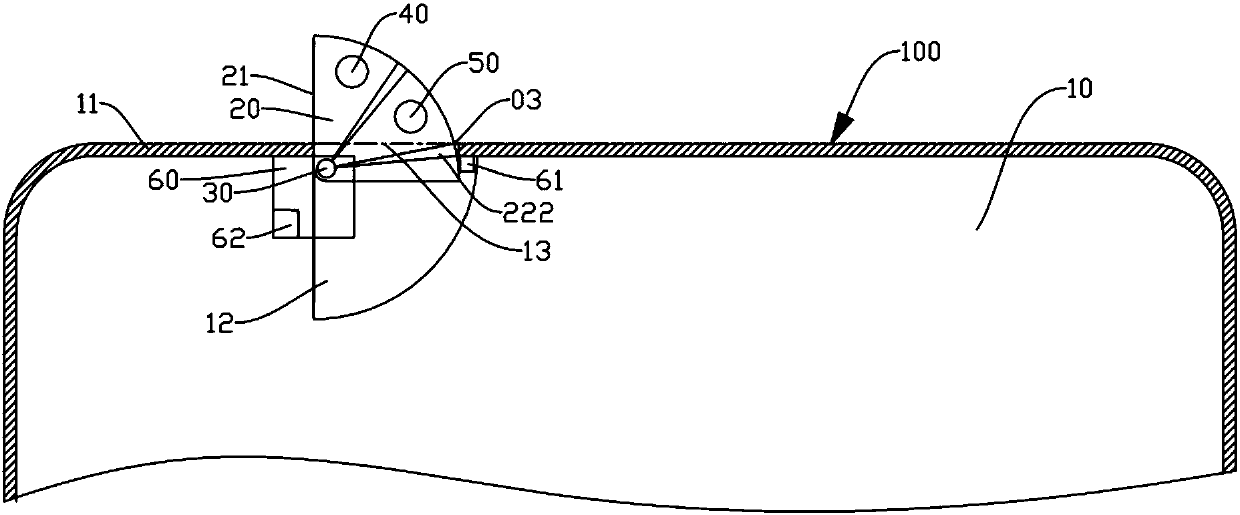

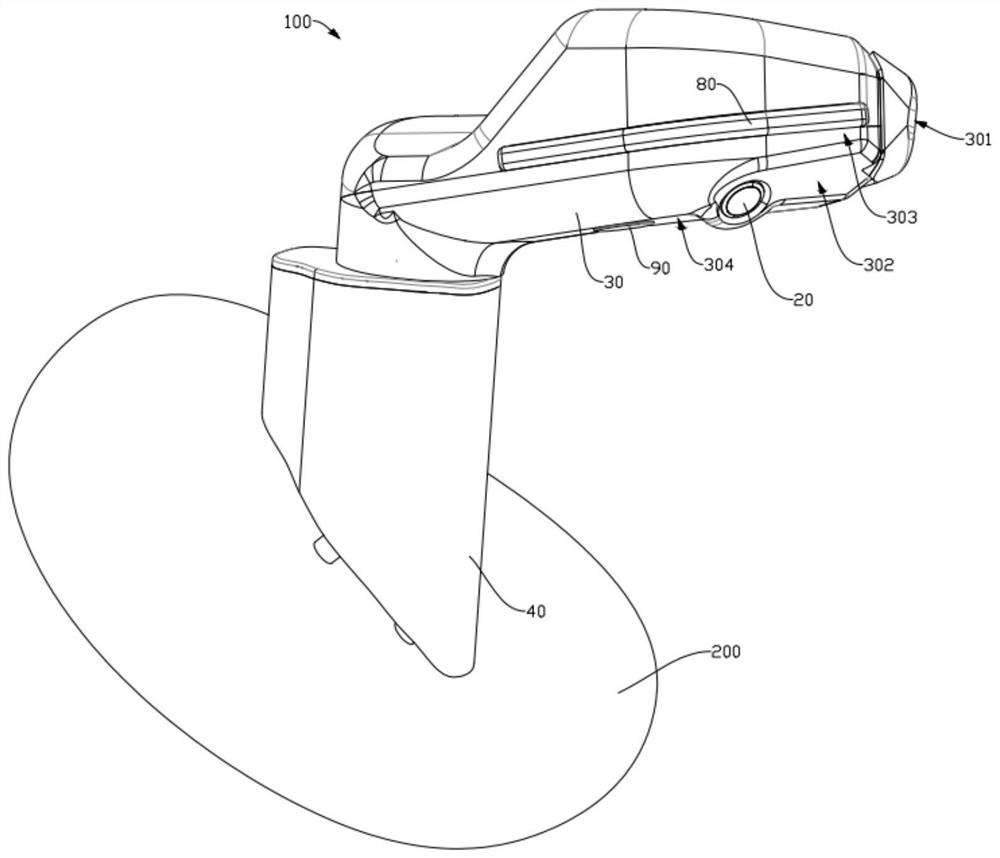

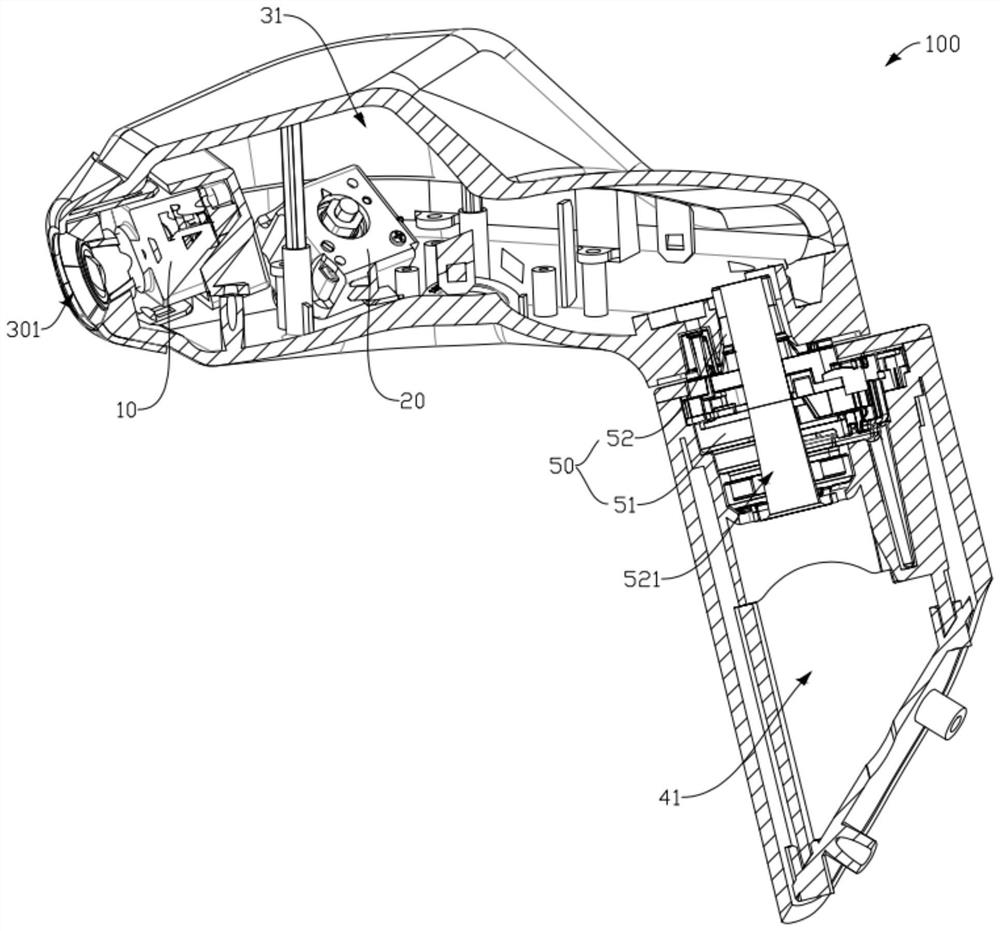

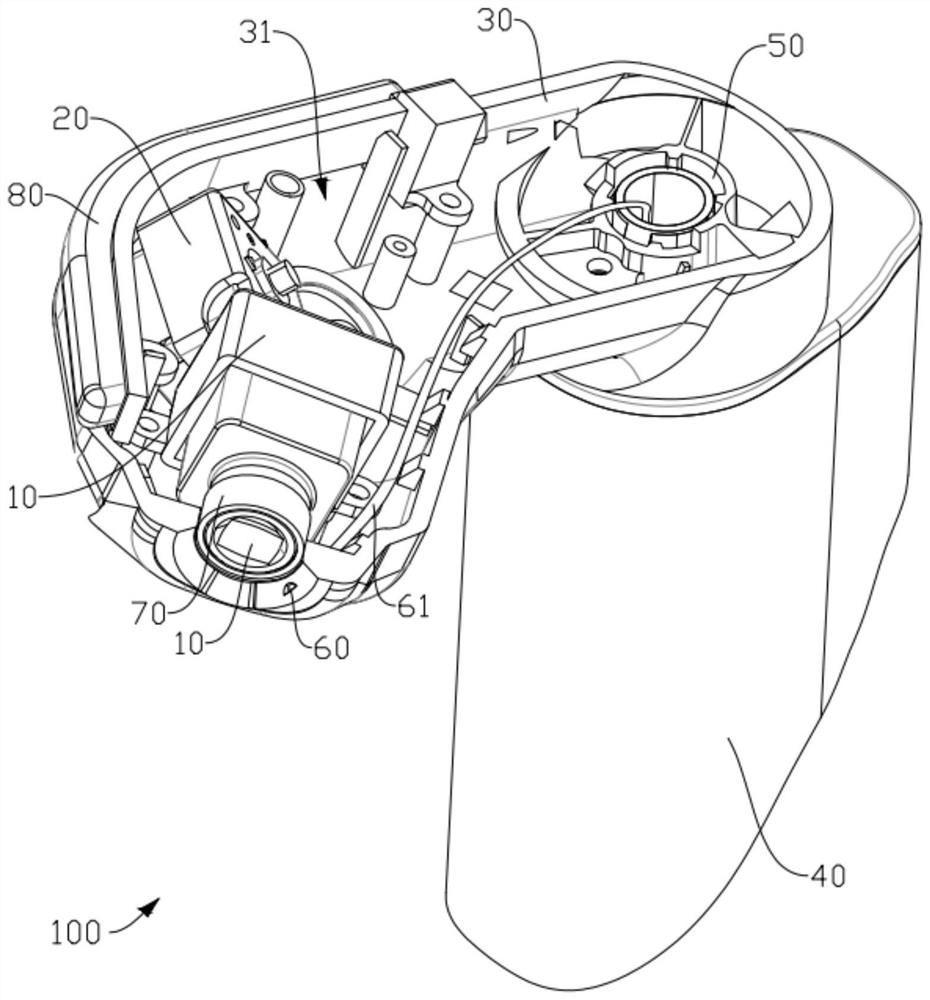

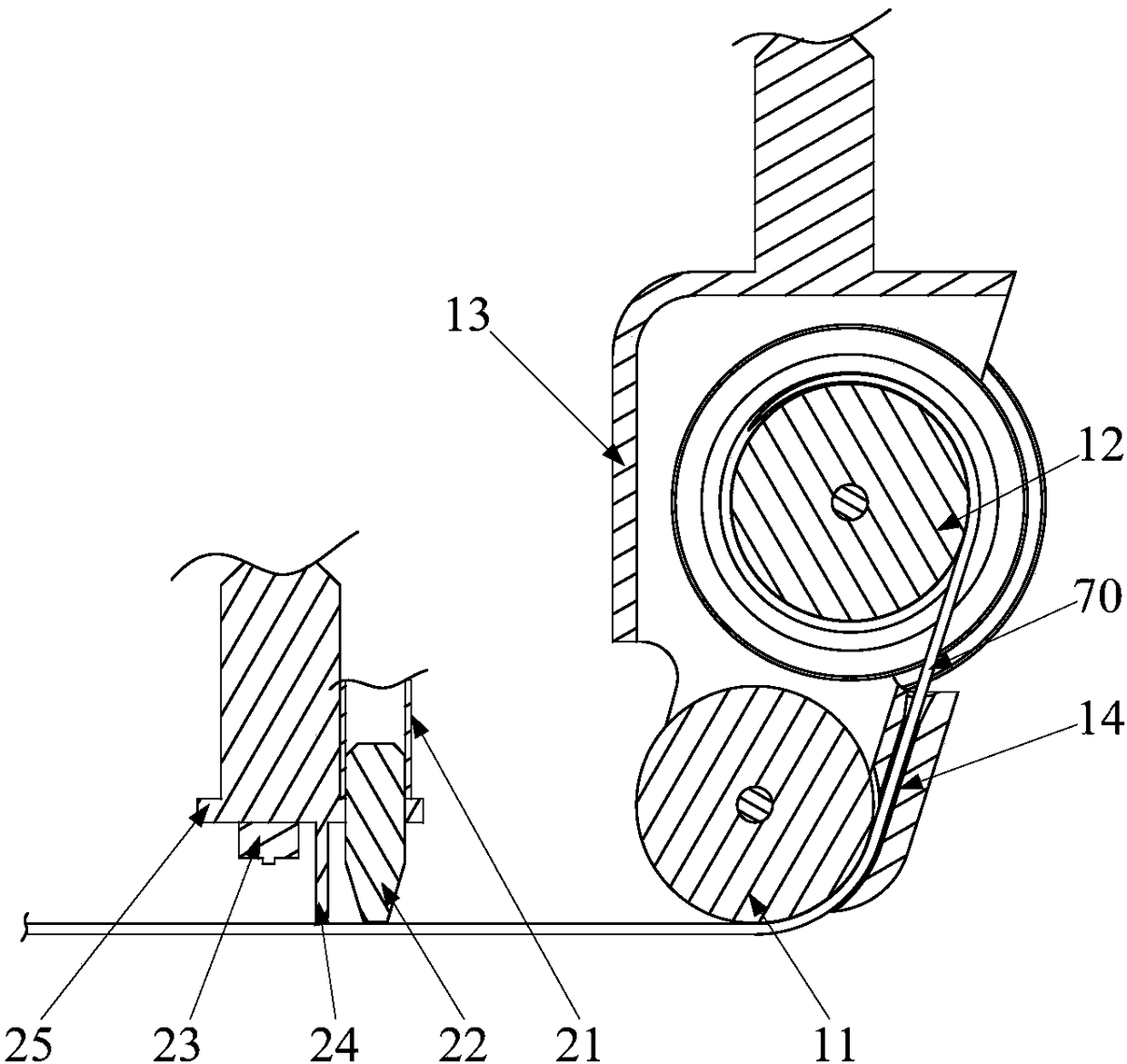

Functional component, mobile terminal and control method thereof

ActiveCN109861711AGood appearance consistencyImprove experienceTransmissionTelephone set constructionsFunctional requirementEmbedded system

The invention relates to the field of mobile terminals, and discloses a functional component of a rotary push-out functional device. The functional component includes a housing, a rotating disc, a rotating shaft, a first functional device and a second functional device, wherein the shell is provided with a containing cavity, the rotary disc is rotationally connected with the shell through a rotaryshaft, the first functional device and the second functional device are arranged on the rotary disc at intervals, and the rotary disc is provided with at least three stop positions so as to achieve containing in the shell or achieve combination of different functional devices outside the shell through rotation. The mobile terminal comprising the functional component can hide functional devices inthe shell, and the invention also relates to the combination of various functional devices correspondingly realized according to different functional requirements or use scenes, so as to improve theuser experience of the mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

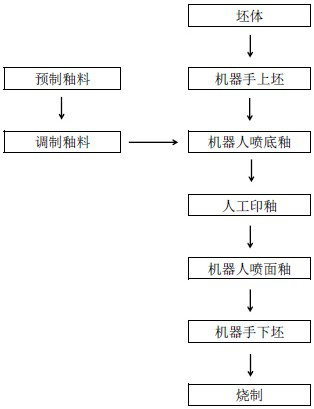

Glaze spraying process of robot glaze spraying circulation line and ceramic closestool prepared by glaze spraying process

The invention relates to the technical field of ceramic processing, in particular to a glaze spraying process of a robot glaze spraying circulation line and a ceramic closestool prepared by the glazespraying process. The robot glaze spraying circulation line comprises a robot glaze spraying line, the robot glaze spraying line is provided with a plurality of robots and further provided with a ballmill and a dispersion machine, the glaze spraying process of the robot glaze spraying circulation line comprises a glaze prefabricating step, a glaze blending step and a robot glaze spraying step, and the glaze prefabricating step comprises the following steps: S1) burdening according to set raw material components, S2) putting into the ball mill, adding a water reducing agent, and grinding to prepare glaze slurry, and S3) detecting that specific gravity, fluidity and fineness of glaze slip are all qualified, so as to obtain prefabricated glaze material. According to the glaze spraying process of the robot glaze spraying circulation line, the phenomenon that the glaze slip flows down from a green body is avoided after glaze spraying, the thickness of a glaze layer is uniform and consistent, the utilization rate of the glaze slip is high, and the prepared ceramic closestool is smooth in glaze surface, free of pores, low in defect rate and high in production efficiency.

Owner:JIANGXI DONGPENG BATHROOM CO LTD +1

Lithium ion battery core package, lithium ion battery and preparation method of lithium ion battery

PendingCN111129414AImprove appearance consistencyTechnical Issues Affecting Connection RobustnessFinal product manufactureCell component detailsSlag (welding)Engineering

The invention relates to the field of lithium ion battery preparation, and discloses a lithium ion battery core package, a lithium ion battery and a preparation method of the lithium ion battery. Thelithium ion battery comprises a core package, and the lithium ion battery comprises a positive plate, a negative plate and a diaphragm arranged between the adjacent positive plate and negative plate at interval; a positive tab welding part and a negative tab welding part extend out of the lithium ion battery core package; a positive tab and a negative tab are respectively welded on one surface ofthe positive tab welding part and one surface of the negative tab welding part; the surfaces of the positive tab and the negative tab and the welding areas of the positive tab welding part and the negative tab welding part are coated with a glue solution, the glue solution is cured into a glue body which is combined with the welding areas into a whole, and the welding areas are tightly wrapped inthe glue body. By applying the technical scheme, the protection on the welding mark area of the tab welding part is improved, welding slag at the welding mark area is prevented from corroding the welding mark area and piercing high-temperature glue, and short circuit caused by falling of the welding slag, piercing of an inner-layer aluminum-plastic film by the welding slag or burrs and the like isavoided, so the safety and the stability of the lithium ion battery are improved.

Owner:江苏丰盈科技有限公司

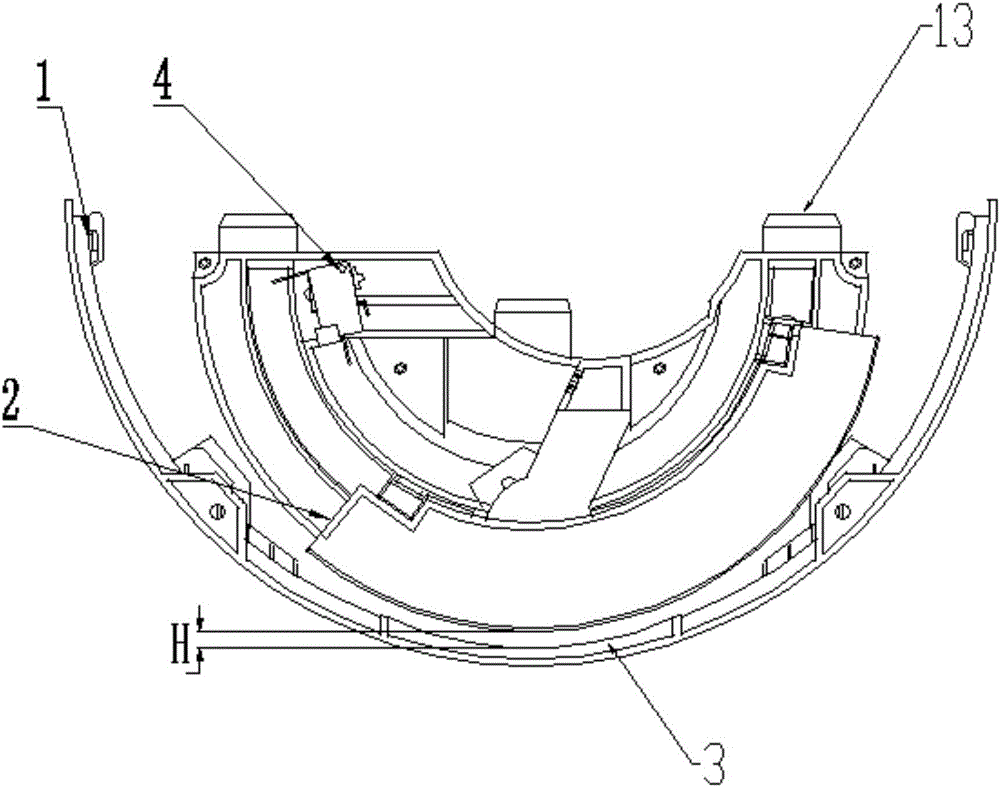

Electronic rearview mirror and automobile

InactiveCN112793511AImprove road passabilityReduce wind resistanceOptical viewingControl theoryMechanical engineering

The invention relates to an electronic rearview mirror which is installed on the side face of an automobile body and comprises a shell, a connecting base, a first camera and a second camera. The shell is rotationally connected with the automobile body through the connecting base, and the first camera and the second camera are both contained in an inner cavity of the shell. The connecting base drives the shell to rotate so that the electronic rearview mirror can have a first posture of being opened for use relative to the side face of the automobile body and a second posture of being folded and attached to the side face of the automobile body. When the electronic rearview mirror is in the first posture, the first end extends towards the rear portion of the automobile body, the included angle between the first side face and the side face of the automobile body ranges from 80 degrees to 105 degrees, the first camera collects images towards the rear portion of the automobile body, and the second camera collects images towards the side portion of the automobile body. The electronic rearview mirror is small in size, flexible in installation position and capable of improving the trafficability of the automobile and reducing oil consumption.

Owner:SHANGHAI OUFEI INTELLIGNET VEHICLE INTERNET TECH CO LTD

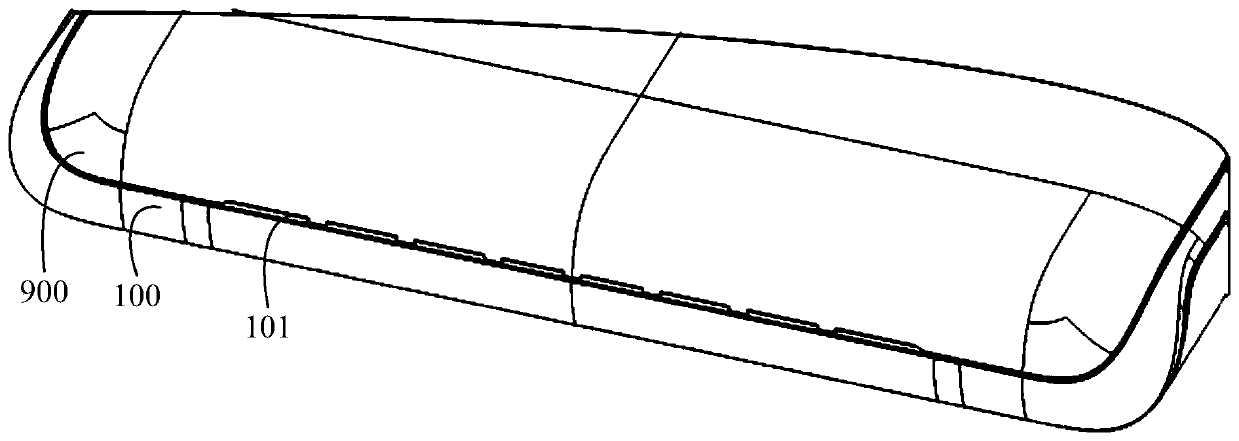

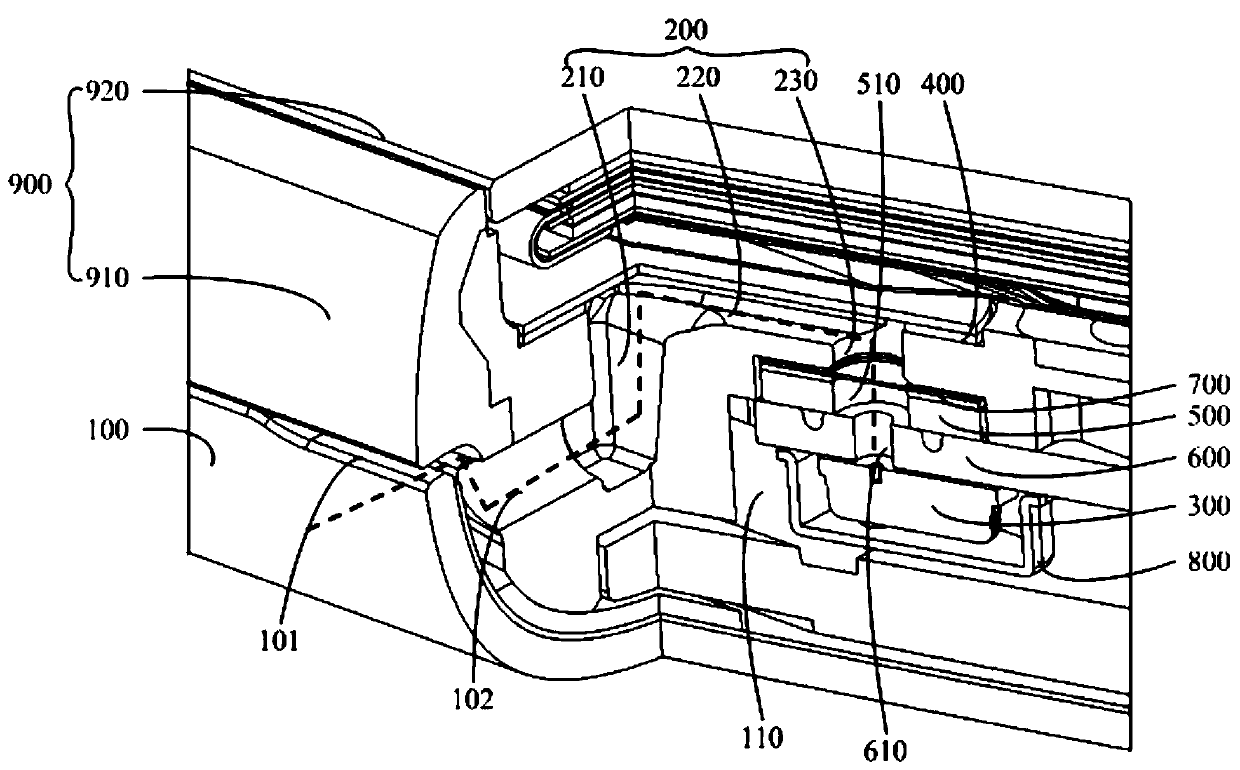

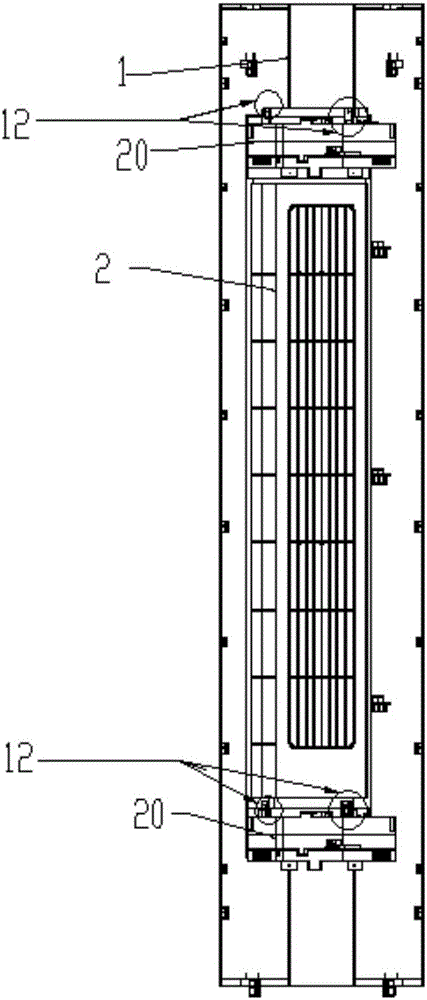

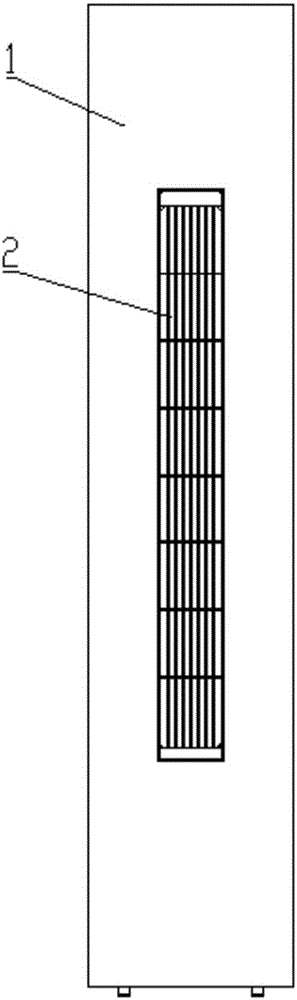

Driving structure achieving non-clearance closing of door plank, air outlet device and air conditioner

InactiveCN106052064AGood appearance consistencyPrevent dust from enteringMechanical apparatusSpace heating and ventilation safety systemsEngineeringClosed state

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

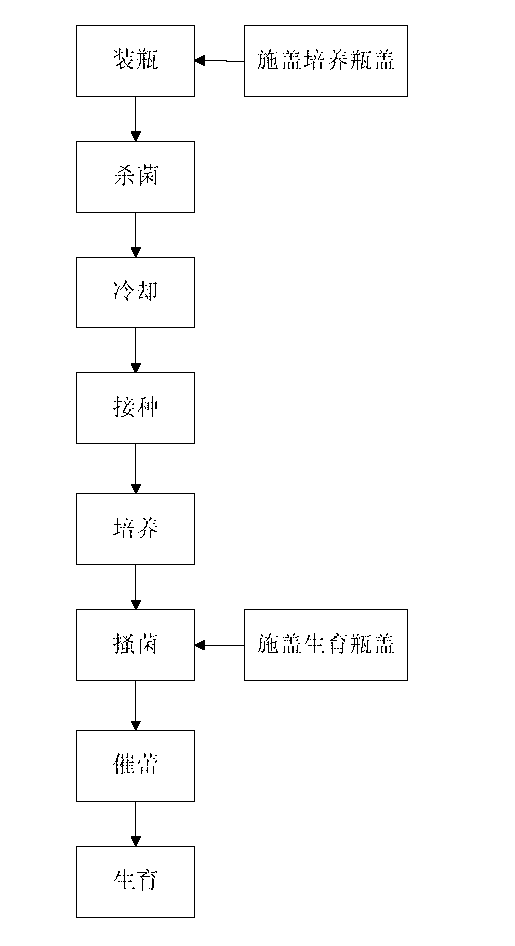

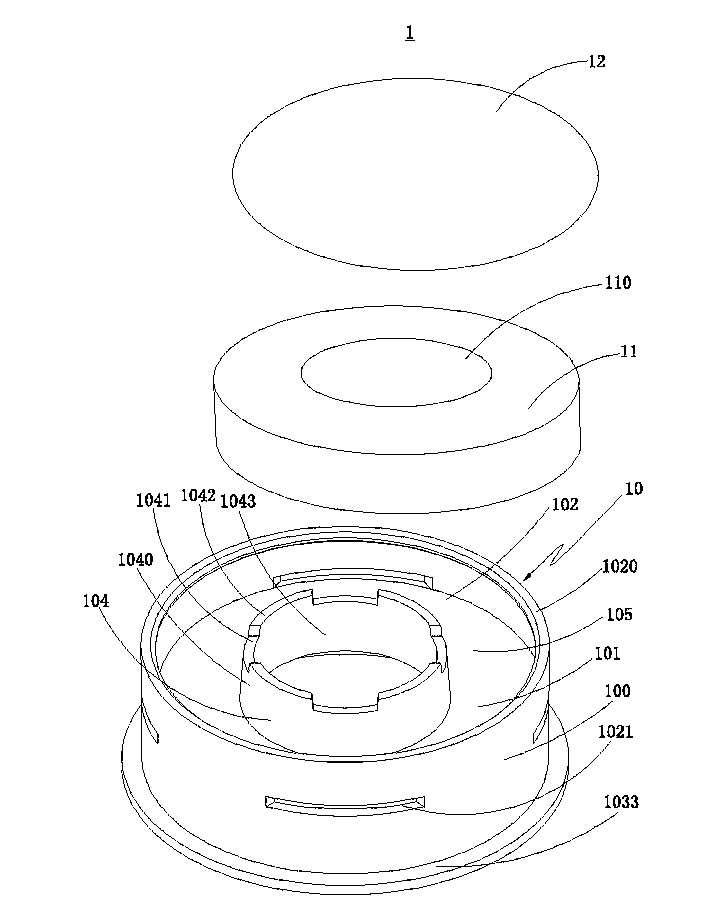

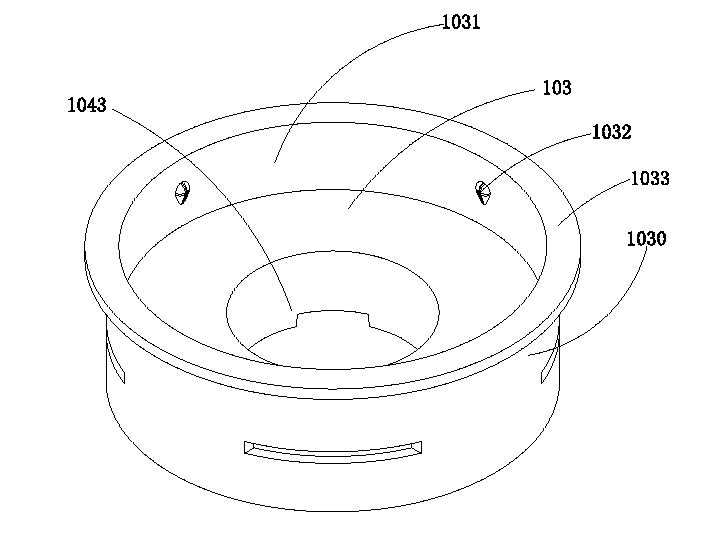

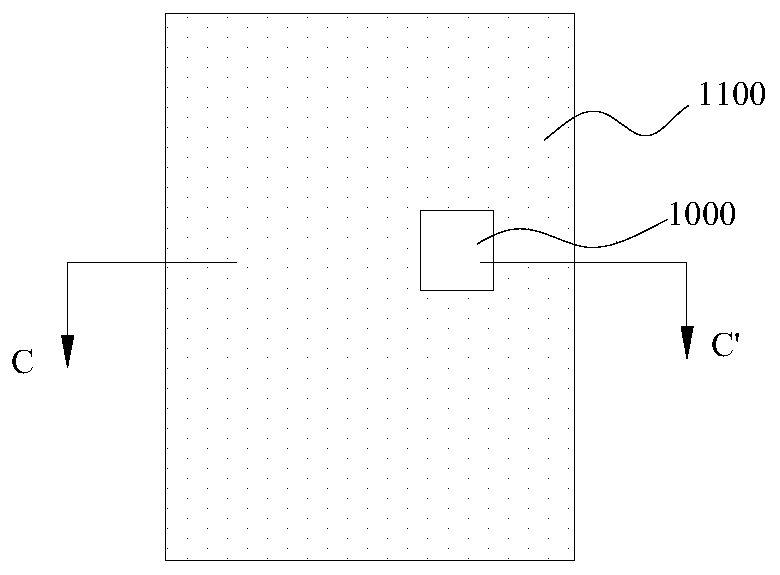

Grifola frondosa cultivation method

The invention relates to a grifola frondosa cultivation method, which comprises steps of bottling, sterilization, cooling and grafting. The grifola frondosa cultivation method is characterized by also comprising the following steps of: culturing: a culture bottle lid for fixed-point primordium generation is arranged on the opening of a culture bottle in a covering way, mycelium culturing is then performed so that a sporocarp primordium is limited in an expansion space formed on the culture bottle lid, and the culture bottle lid is removed after the sporocarp primordium is formed; mycelium stimulation: mycelium stimulation is performed in a ring shape on the periphery of the primordium of culture materials, and a growth bottle lid made of opaque material is arranged in a covering way; bud inducement: the culture bottle is moved into a bud inducement room for continuous development after mycelium stimulation, and the bud inducement is completed; and growth: the culture bottle is moved into a growth room for continuous development after bud inducement, and the growth is completed; wherein the structure and parameters of a growth bottle lid are set and controlled specially. While the consistency of the appearance of mature grifola frondosa is improved, the leaf differentiation rate of the grifola frondosa in the growth stage can be improved greatly, and thus the quality of the grifola frondosa can be improved.

Owner:SHANGHAI FINC BIO TECH INC

Housing, method for controlling test of photosensitive test module, and electronic equipment

InactiveCN109699133AGood appearance consistencyImprove integrityCasings/cabinets/drawers detailsNon-linear opticsTransmittanceEngineering

The invention discloses a housing, a method for controlling the test of a photosensitive test module, and a piece of electronic equipment. Specifically, the housing includes a substrate and a photosensitive test module arranged on the substrate. The photosensitive test module includes a photosensitive component which has a detection surface, and an electrochromic component which at least covers the detection surface of the photosensitive component and is configured to be switched between a high light transmittance state and a low light transmittance state. The light transmittance of the electrochromic module is not less than 85% in the high light transmittance state. Thus, the photosensitive test module has a good appearance effect and use performance, and the surface consistency and integrity of the housing can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

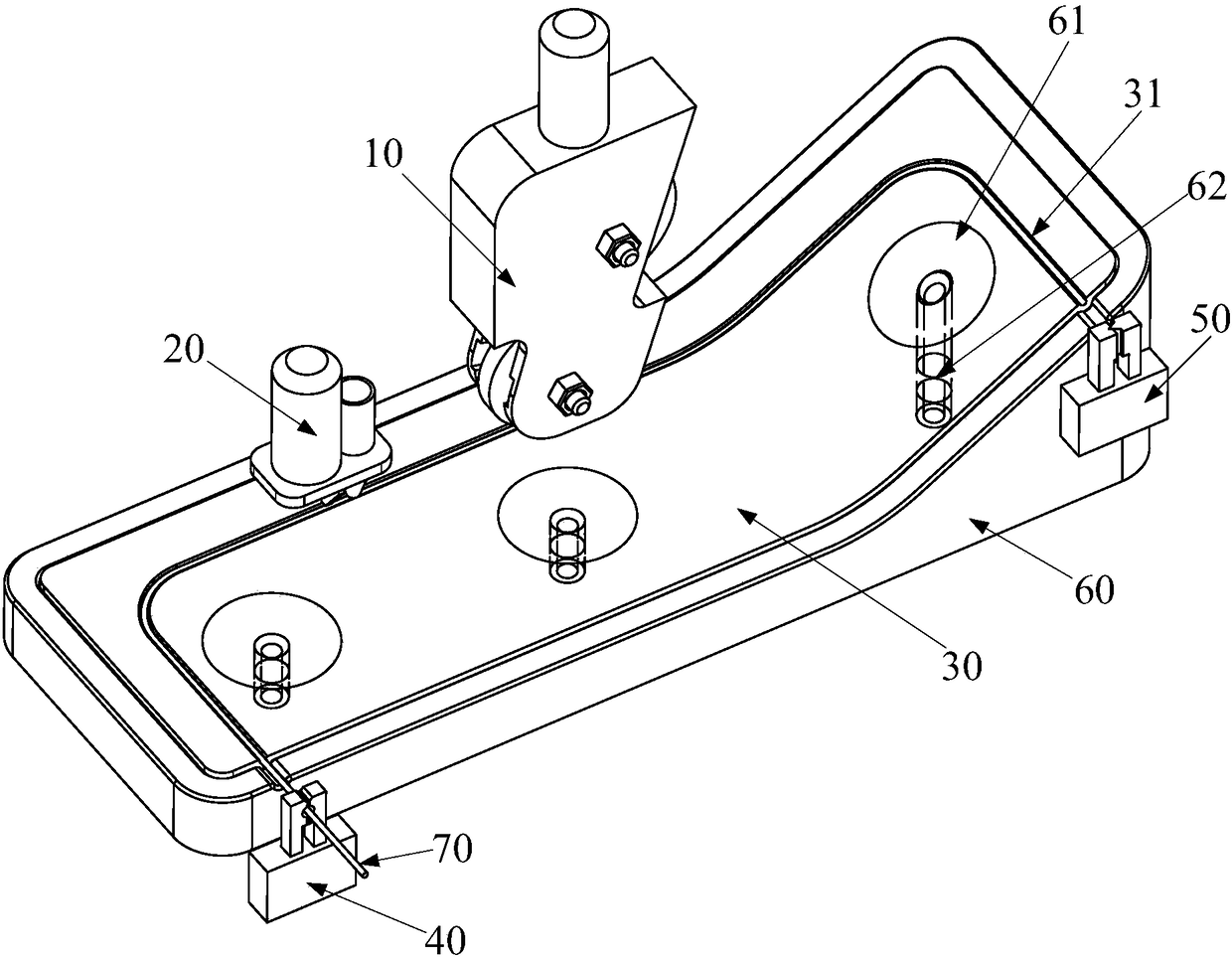

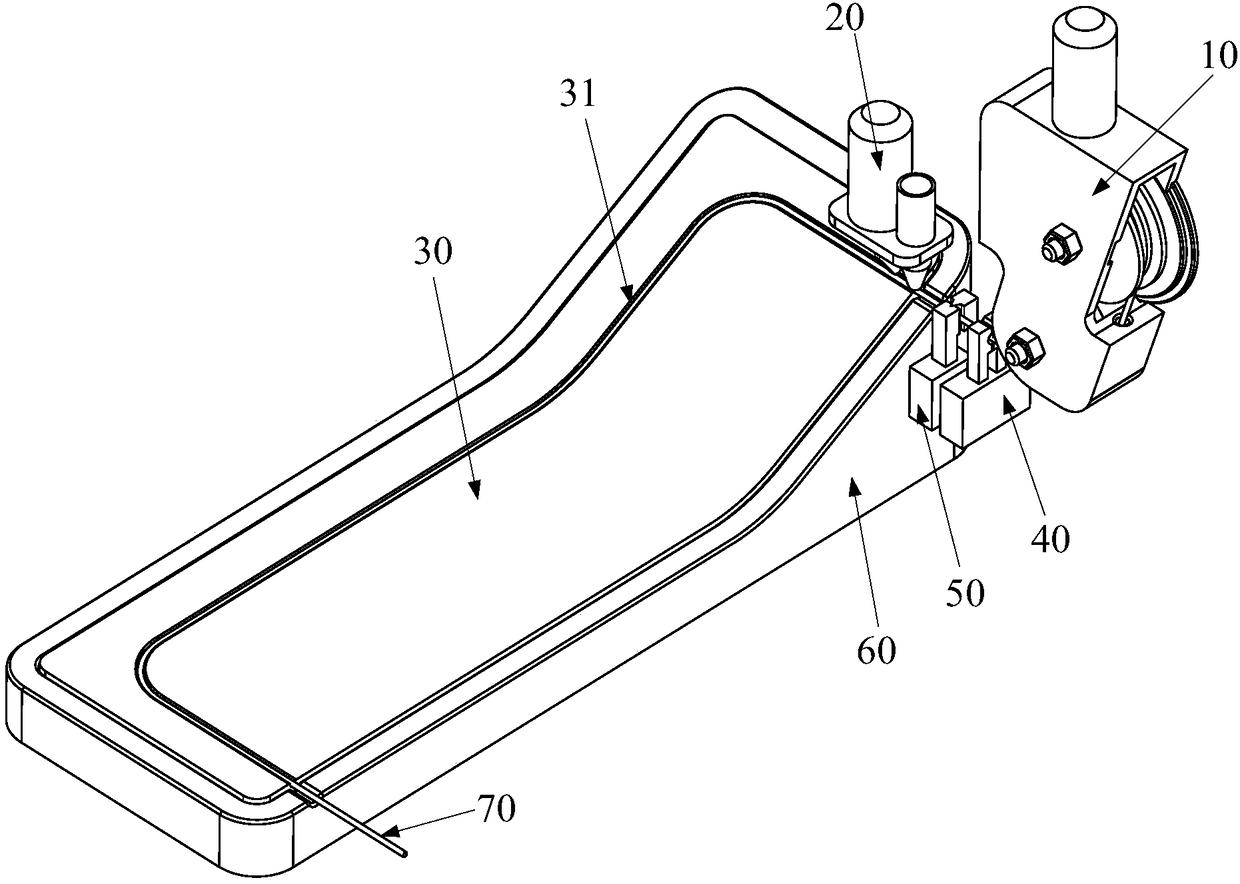

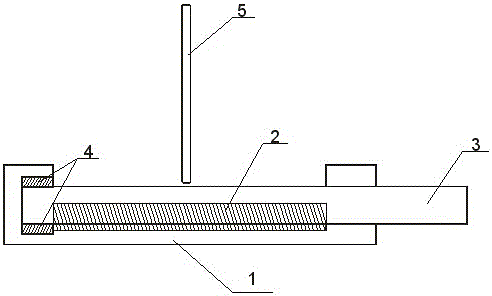

Optical fiber installation device and vehicle lamp assembly system

PendingCN108508560ATension is easy to controlAvoid breakingOptical fibre/cable installationFiberEngineering

The invention provides an optical fiber installation device and a vehicle lamp assembly system, relates to the technical field of vehicle lamp assembly systems and aims to solve the problem of difficult mounting and fixing of optical fibers. The optical fiber installation device comprises a laying mechanism, a gluing mechanism and a driving mechanism, wherein the optical fiber is arranged in the laying mechanism, an optical fiber placing groove is arranged on the optical fiber fixing carrier, the driving mechanism is respectively connected with the laying mechanism and the gluing mechanism todrive the laying mechanism and the gluing mechanism to move along the optical fiber placing groove, and the laying mechanism is used for placing the optical fiber in the optical fiber placing groove.The optical fiber installation device is used for installing the optical fiber into the optical fiber fixing carrier, and fixing the optical fiber in the optical fiber fixing carrier through the glueliquid. The device has the advantages of high efficiency, small manual labor amount, high yield, high reliability and good appearance consistency, and the fiber track can be space three-dimensional.

Owner:HASCO VISION TECHNOLOGY CO LTD

Piezoelectric ceramic piece positive and negative electrode electrical connection device

ActiveCN104993044AReduce consumptionGood appearance consistencyPiezoelectric/electrostrictive/magnetostrictive devicesElectricityMetallurgy

A piezoelectric ceramic piece positive and negative electrode electrical connection device comprises a silver slurry tank, conductive silver slurry, a cylindrical rod, bearings, a piezoelectric ceramic piece, and electrodes. The silver slurry tank contains the conductive silver slurry. The bearings are mounted at one end of the silver slurry tank. One end of the cylindrical rod passes through one end of the silver slurry tank, and the other end of the cylindrical rod is fixed to the bearings at the other end of the silver slurry tank. The piezoelectric ceramic piece is arranged on the cylindrical rod, and the circular surface of the piezoelectric ceramic piece is perpendicular to the length direction of the cylindrical rod. The electrodes are arranged on the piezoelectric ceramic piece. By using the device, the width and depth of electrode connection can be controlled, the appearance consistency of connection is good, the electrical reliability of connection is high, and the consumption of silver slurry is reduced by about 2 / 3.

Owner:HUNAN JIAYEDA ELECTRONICS

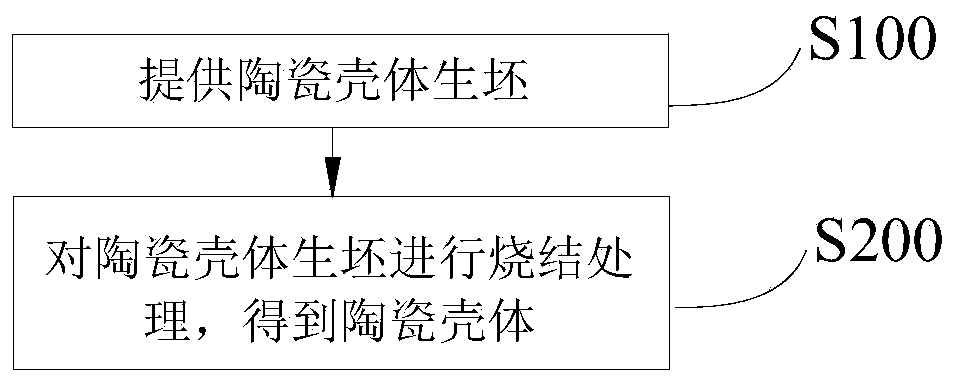

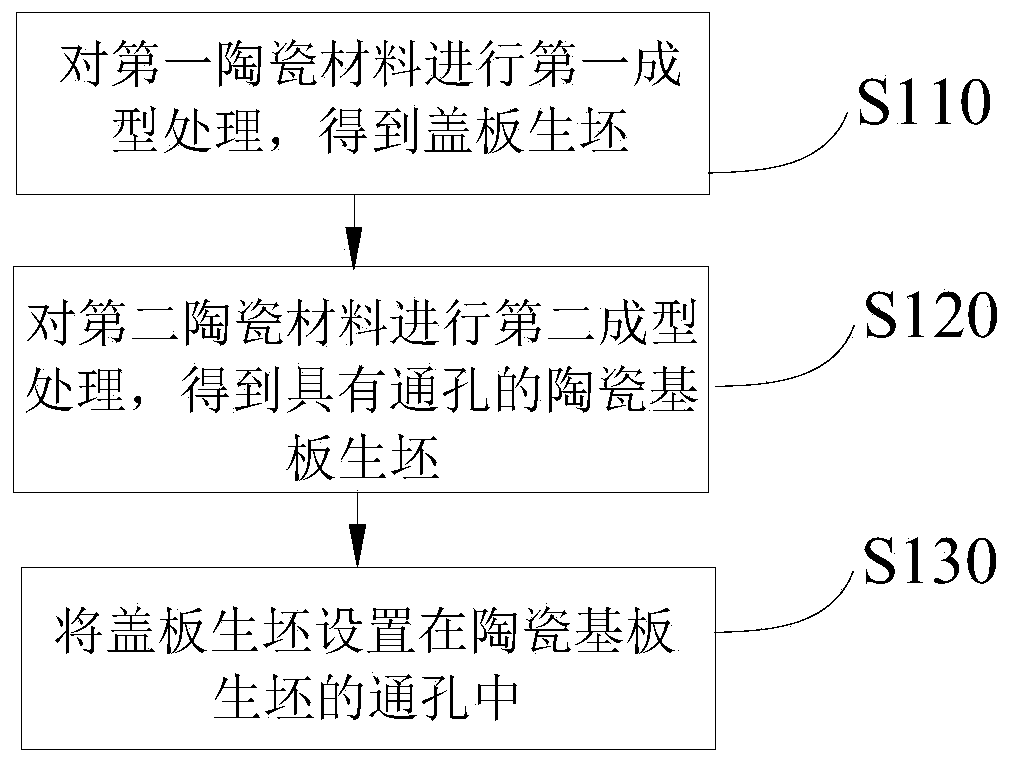

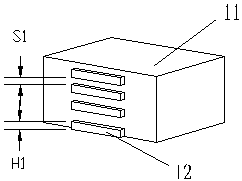

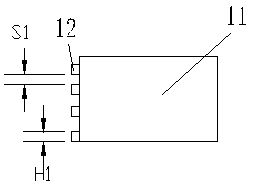

Ceramic casing and preparation method thereof as well as electronic equipment

The application discloses a ceramic casing and a preparation method thereof as well as electronic equipment. Specifically, the application provides the ceramic casing. The ceramic casing comprises a ceramic substrate with a through hole and a cover plate which is positioned at the through hole and is integrated with the ceramic substrate; the cover plate is made of a first ceramic material; the light transmission rate of the cover plate is not smaller than 70 percent. Therefore, the bonding strength of the ceramic substrate and the cover plate is higher; in addition, the sealing property and the consistency of the ceramic substrate and the cover plate are better; the ceramic casing has good attractive effects and better use performance.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Filling method of damping layers of wheel noise reduction block, positioning structure and wheel noise reduction block

PendingCN107584705AGuaranteed bonding strengthGuaranteed uniformityRail-engaging wheelsVulcanizationEngineering

The invention provides a filling method of damping layers of a wheel noise reduction block. A damping material is filled into gap layers of an interlayer structure of the wheel noise reduction block by using a vulcanizing and bonding manner to form damping layers; positioning blocks are used for positioning constraining layers of the interlayer structure during vulcanizing and bonding so as to prevent the constraining layers from deforming in the vulcanizing process; the positioning blocks are arranged at the edges of the interlayer structure and one part of each positioning block stretches into the gap layers to support and position the constraining layers during vulcanizing, so that the deformation of the interlayer structure in the vulcanizing process is avoided. According to the filling method, a vulcanization molding manner is adopted; the bonding strength between the damping layers and the interlayer structure is ensured; the uniformity degree and the beautiful degree of the damping layers are ensured; the positioning blocks are used for positioning and controlling the constraining layers of the interlayer structure during vulcanizing and filling; the problem of deformation of the constraining layers and mounting plates caused by high freedom degree of the ends in the vulcanizing process can be avoided, so that the non-uniform thickness of the damping layers can be avoided; the production quality and the size deviation of the wheel noise reduction block are ensured; and the effect of reducing vibration and noise can be improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Microwave curing process of bonded NdFeB magnet

InactiveCN102982995AImprove curing efficiencyIncrease productionMaintainance of heating chambersFurnace typesHigh energyUltimate tensile strength

The invention discloses a microwave curing process of a bonded NdFeB magnet, aiming at solving the problems of low efficiency and high energy consumption of the traditional electrothermal curing process. The microwave curing process comprises the following steps of: (1) putting a green body of the bonded NdFeB magnet on a ceramic substrate, and putting the ceramic substrate into a microwave kiln; (2) starting an exhaust system of the microwave kiln, heating to 135-145 DEG C at a heating speed of 15 DEG C / min-20 DEG C / min, and maintaining the temperature for 10-15min; and (3) powering off the exhaust system after the temperature preservation is ended, and taking the bonded NdFeB magnet out. The microwave curing process disclosed by the invention is short in curing time, low in energy consumption, small in curing deformation rate, uniform in product quality and greatly improved in curing strength and yield of the bonded NdFeB magnets.

Owner:湖南航天有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com