Method for determining shape of semi-floating supporting bearing inner bore oil wedge of supercharger

A technology for supporting bearings and determining methods, applied in sliding contact bearings, bearings for rotating motion, bearings, etc., can solve the problems of uneven comparison of three oil wedges, sacrifice of design life, poor control of appearance quality, etc., to achieve convenience Turning tool vibration control strategy, design description is simple and easy to use, and design changes are simple and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

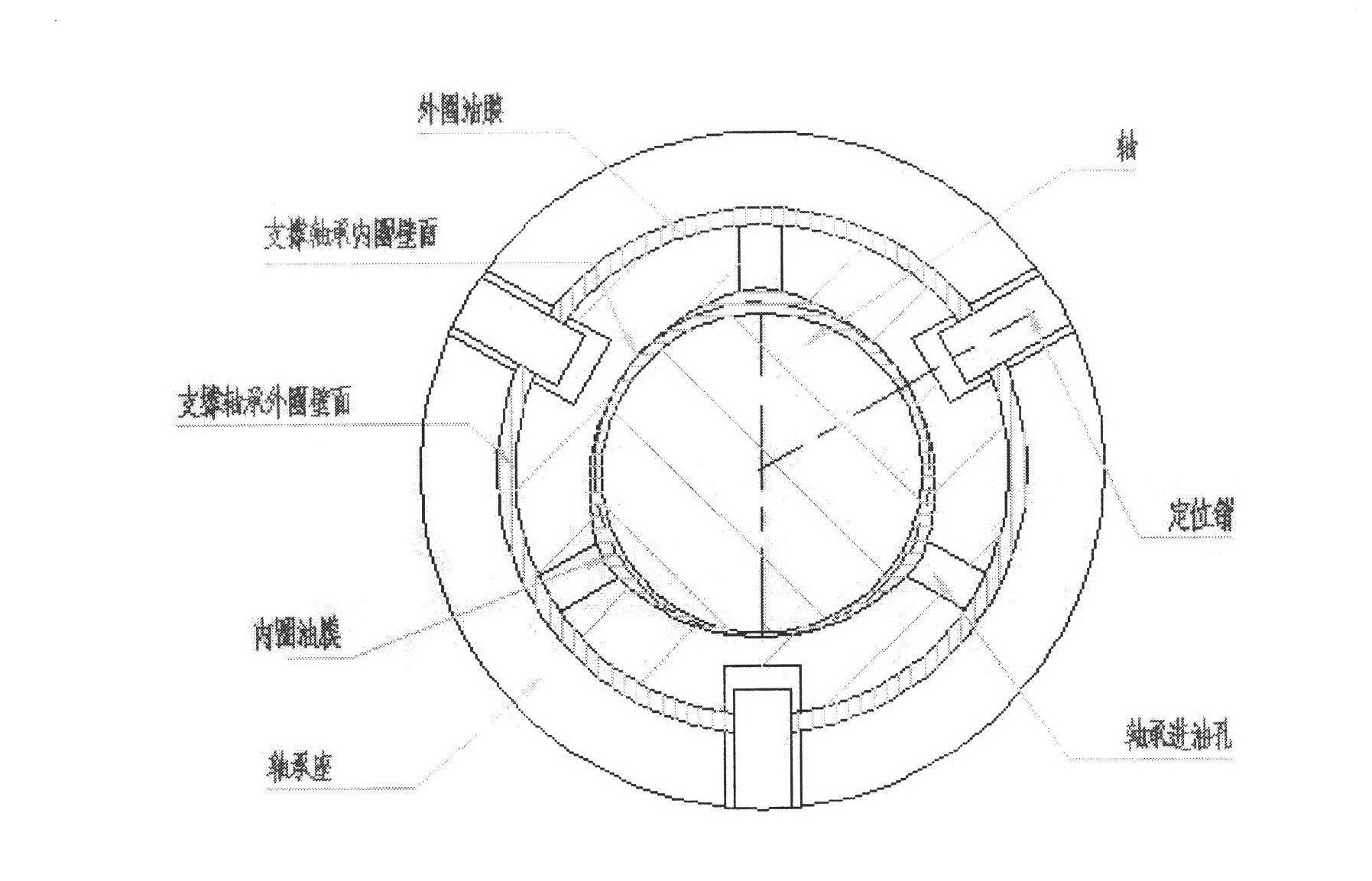

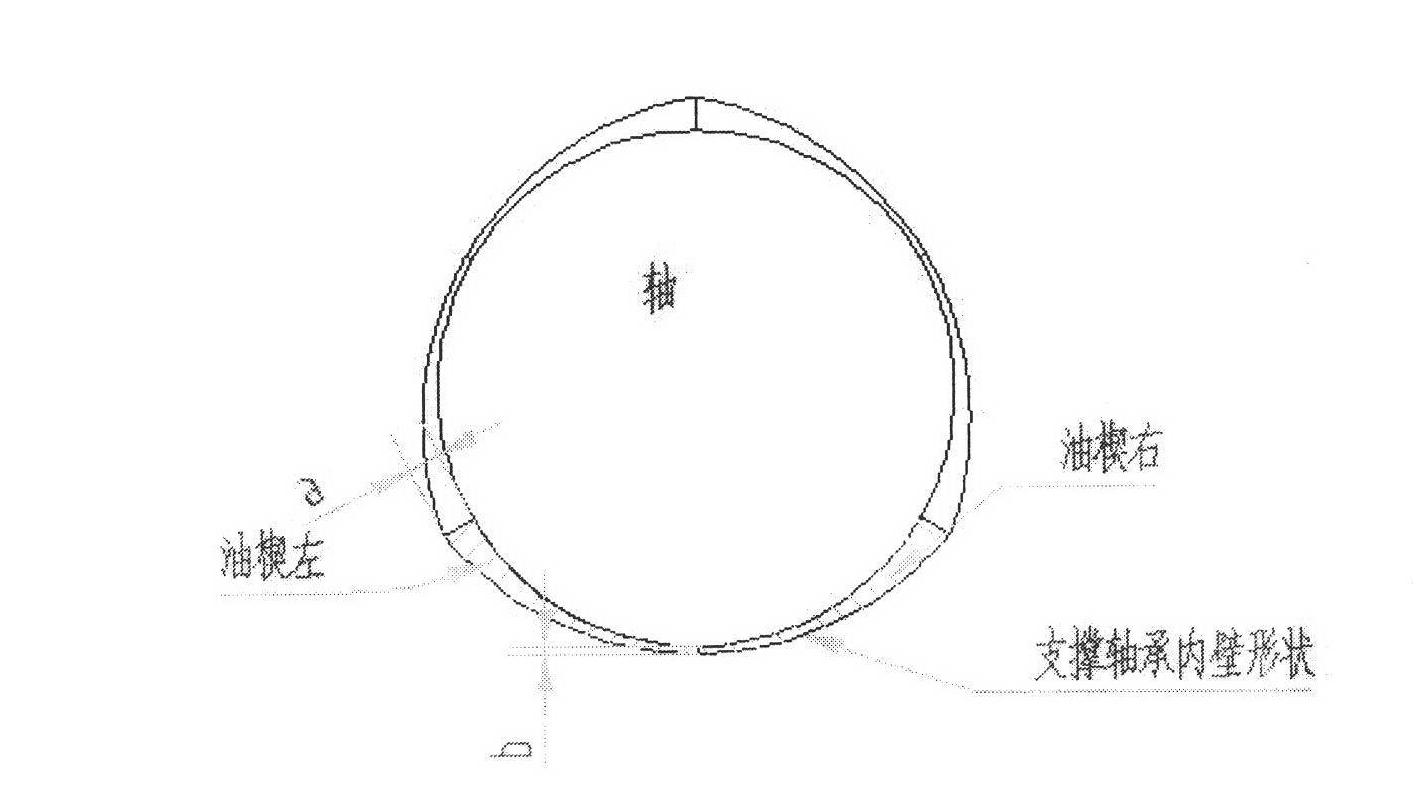

[0032] The present invention will be further described below in conjunction with accompanying drawing.

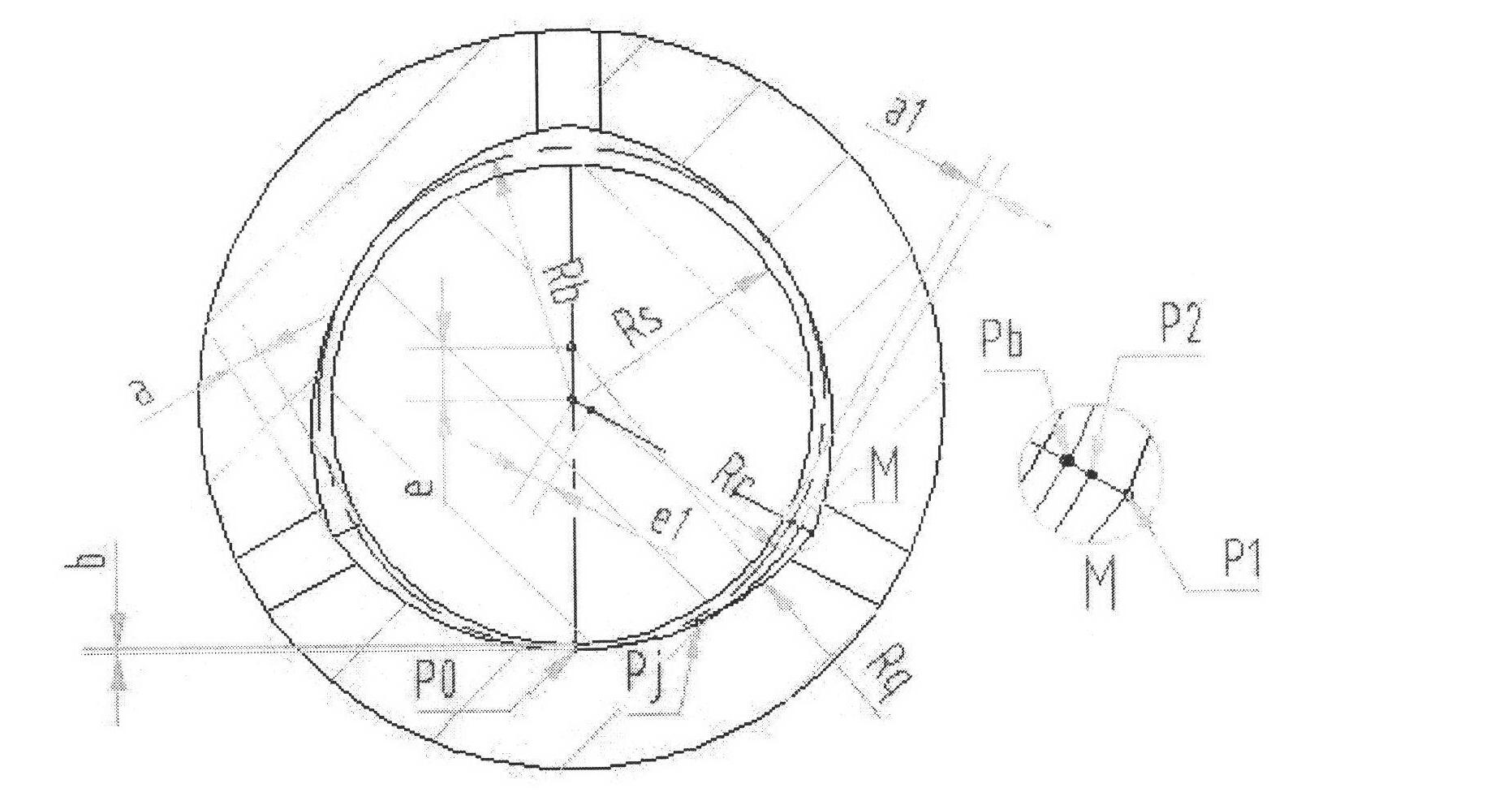

[0033] The method for determining the shape of the oil wedge in the inner hole of the supercharger semi-floating support bearing according to the present invention, the determination steps are as follows, and the details can be referred to at the same time Figure 4 :

[0034] 1) According to the limited conditions a1 and b values proposed in the design of the support bearing, assuming that the shaft radius is Rs, then the base circle radius of the inner hole of the support bearing Rb=Rs+b, and the distance R2 between the deepest point of the inner wall of the support bearing and the center of the shaft =Rs+a1;

[0035] 2) Draw two concentric circles concentric with the axis with the radii Rb and R2 respectively;

[0036] 3) According to the number n of oil wedges, divide the two concentric circles obtained in step 2 into n equal divisions, and obtain n equal division p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com