Patents

Literature

31results about How to "Tension is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

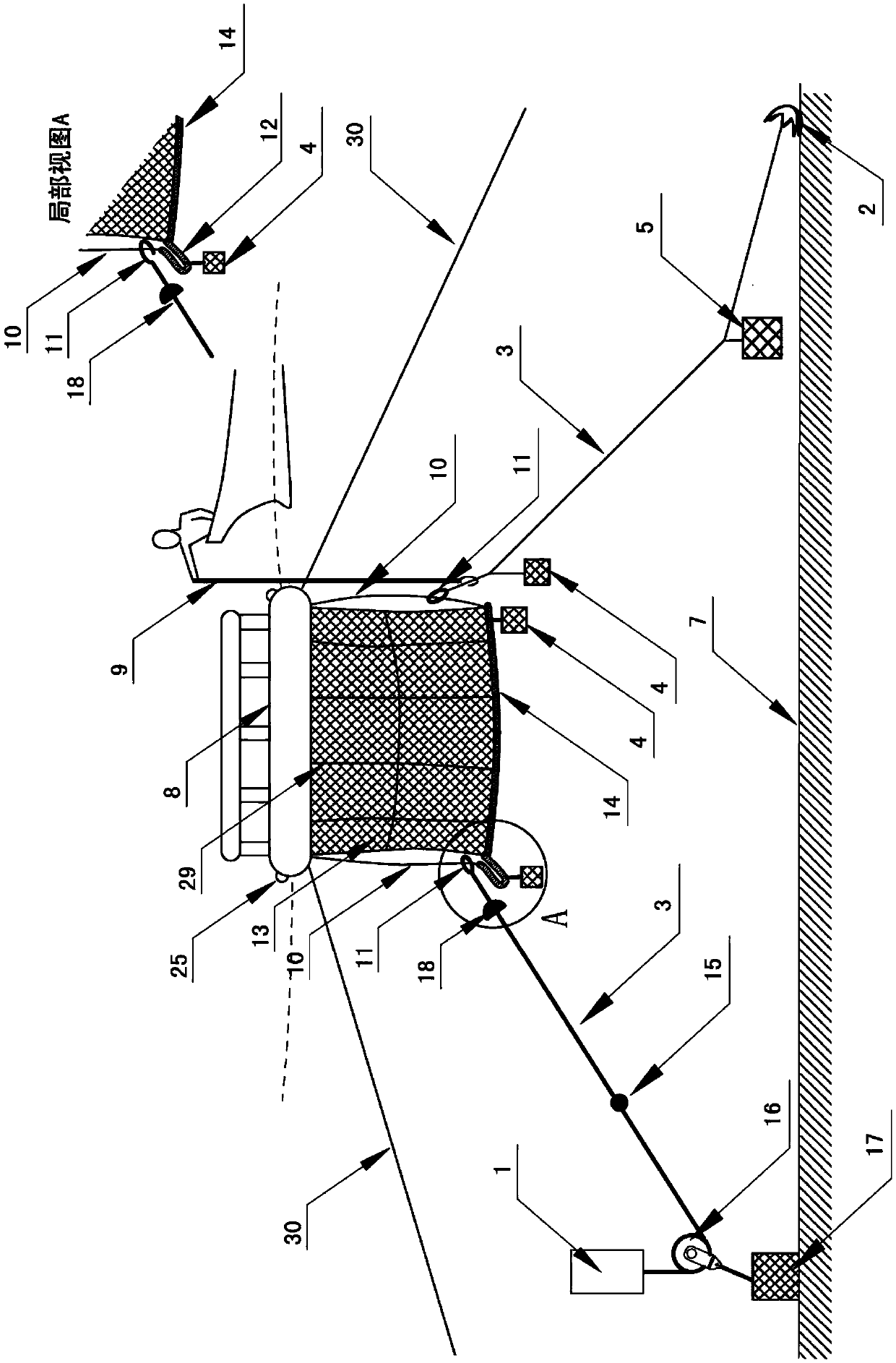

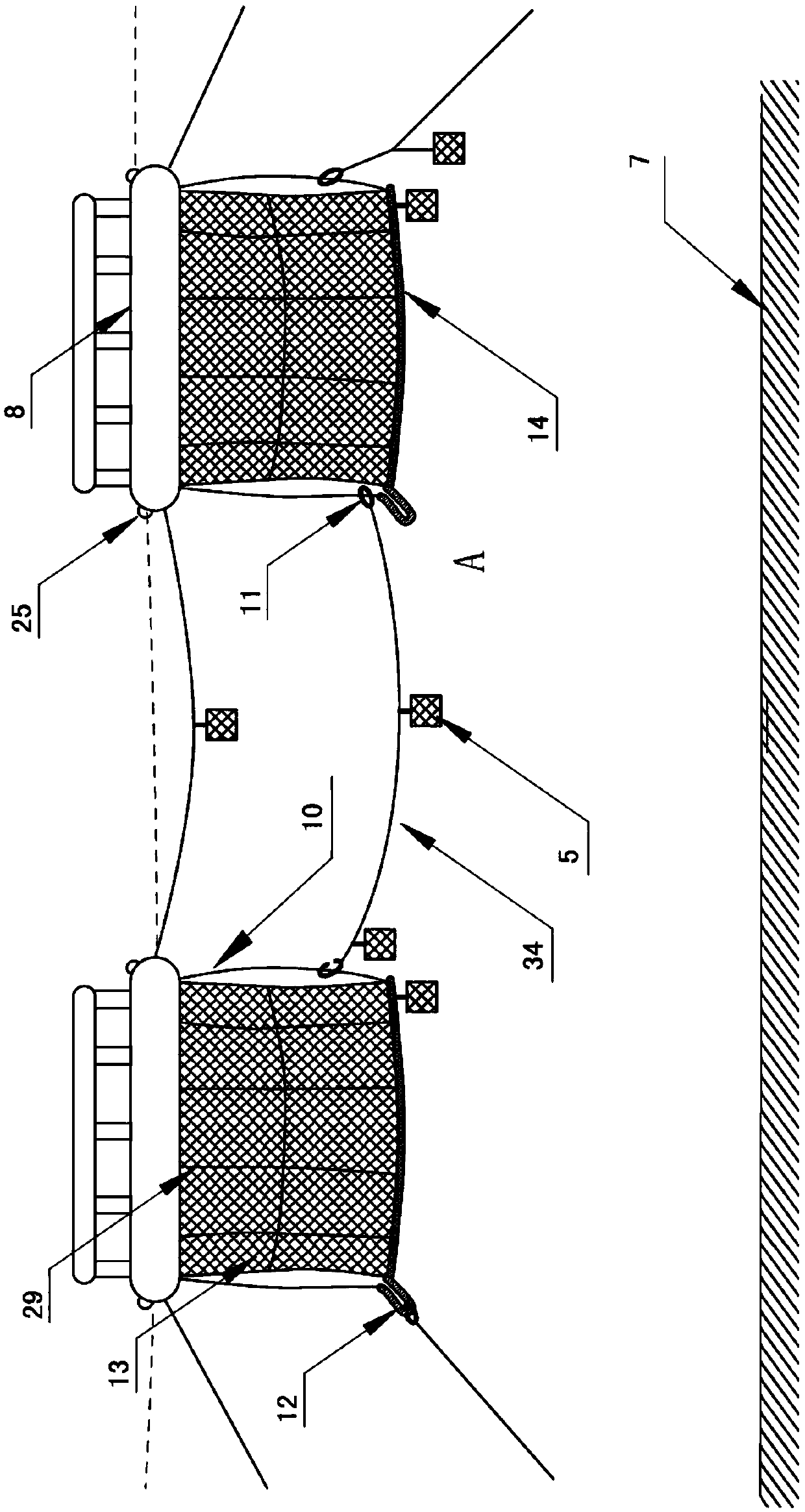

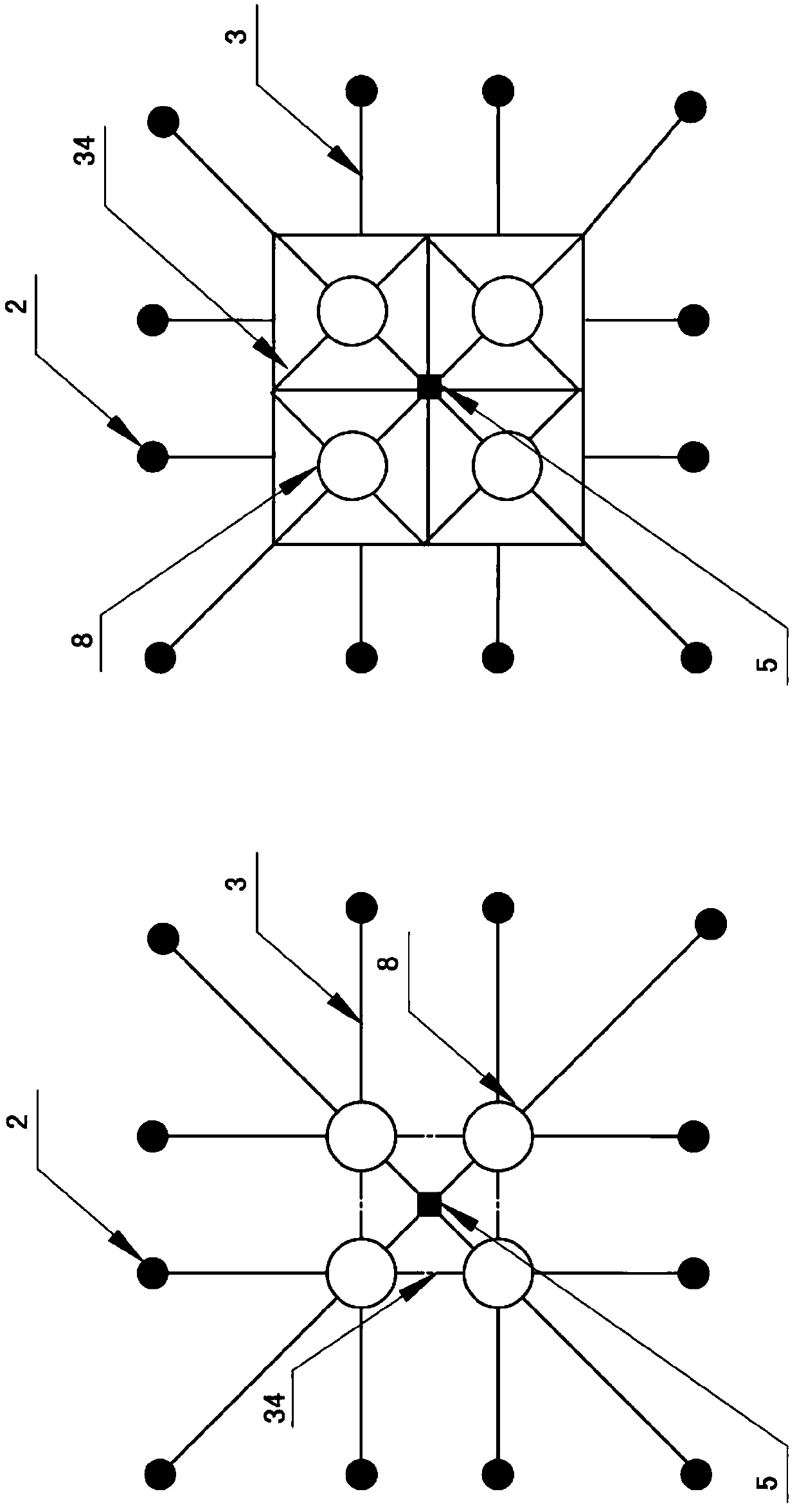

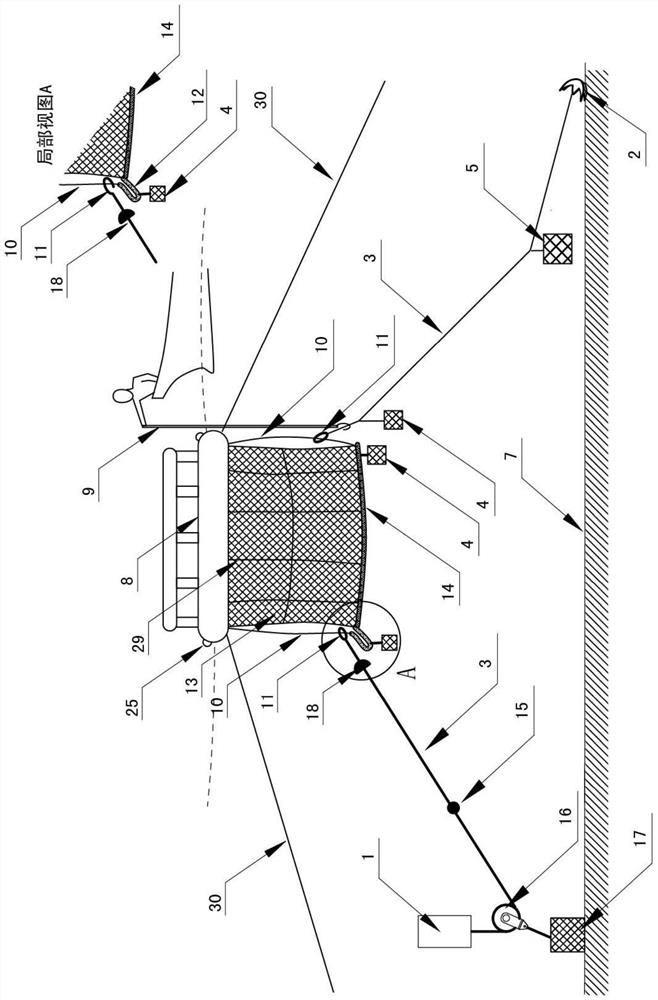

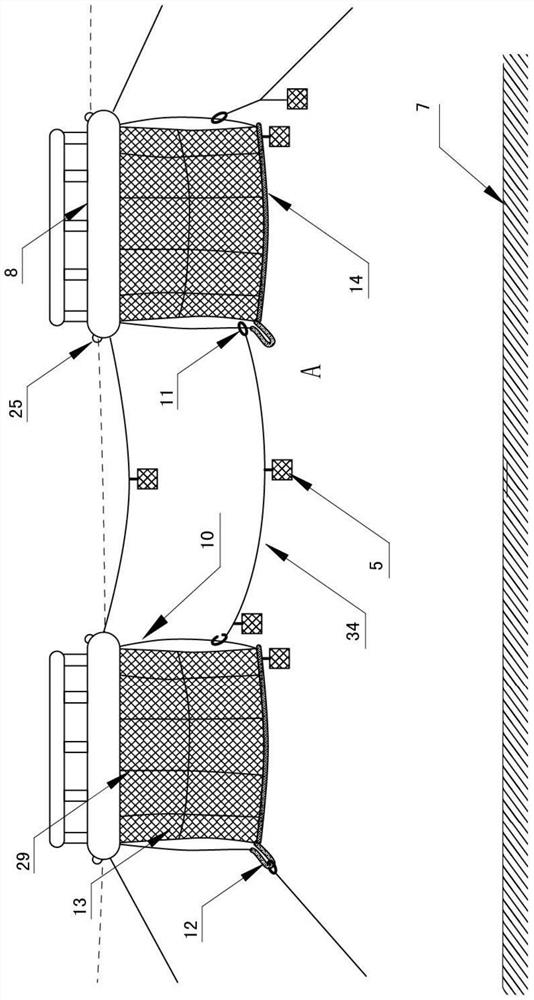

Floating type net cage underwater quick detachable binding structure

ActiveCN105494178AEasy to operateEasy to break awayClimate change adaptationPisciculture and aquariaMooring systemUnderwater

The invention provides a floating type net cage underwater quick detachable binding structure and belongs to the field of net cages. Concretely, a guide rope is arranged outside the net cage; one end of the guide rope is tied to a floating pipe or a net rib on the upper end of the net cage and the other end is tied to a net rib on the bottom end of a mesh; the end part of a mooring cable of a mooring system is provided with a lifting hook sleeved on the guide rope; the bottom end net rib close to the guide rope is tied with a sinker; and a position on the mooring cable and close to the lifting hook is provided with a sinker or a gravity rope knot. When unfixation is required, a user on the water can insert a hook rod into the water to hook the mooring cable, so the mooring cable can be hooked to the water surface; and the net cage can be unfixed.

Owner:威海晟龙明科机电设备有限公司

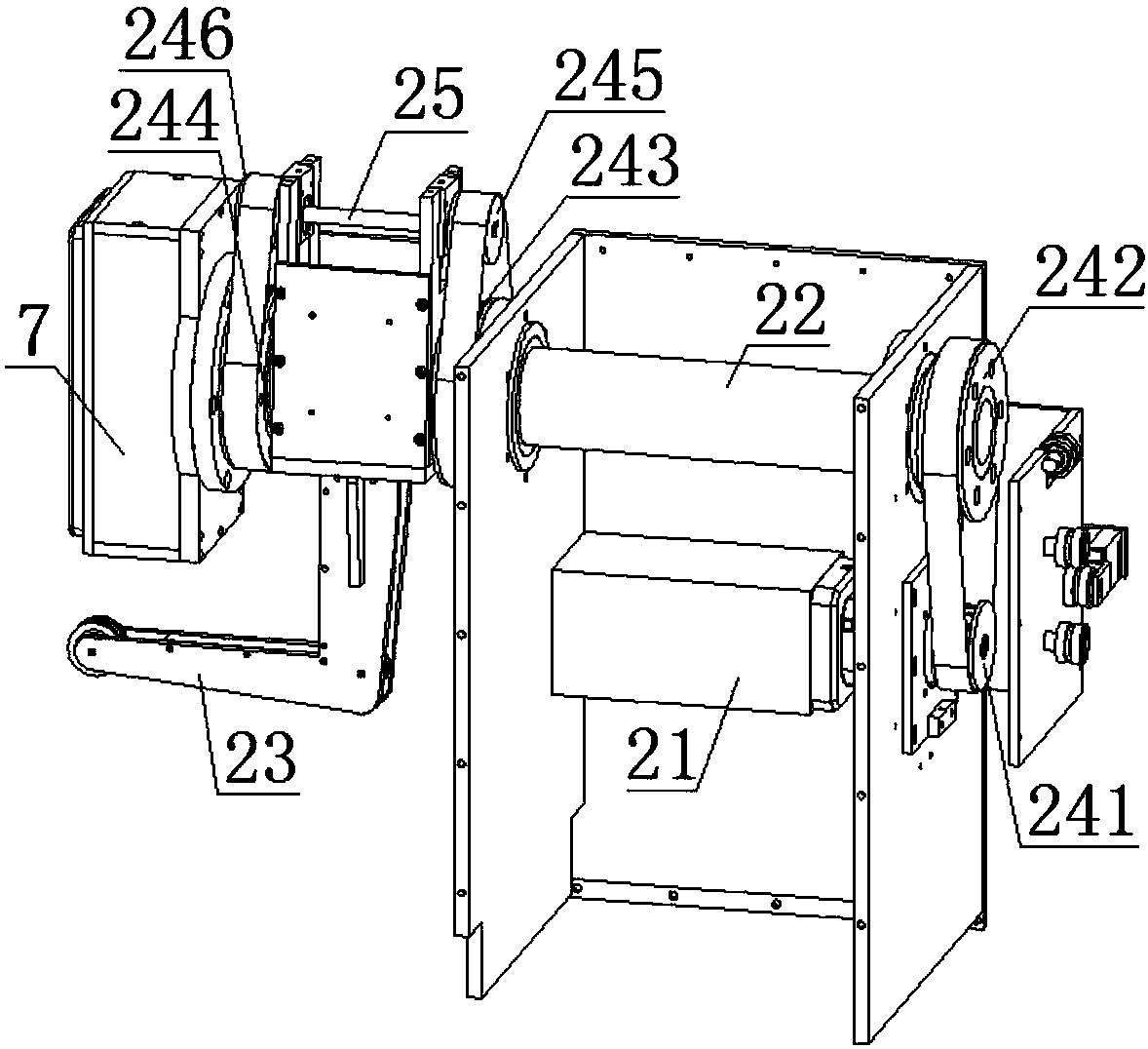

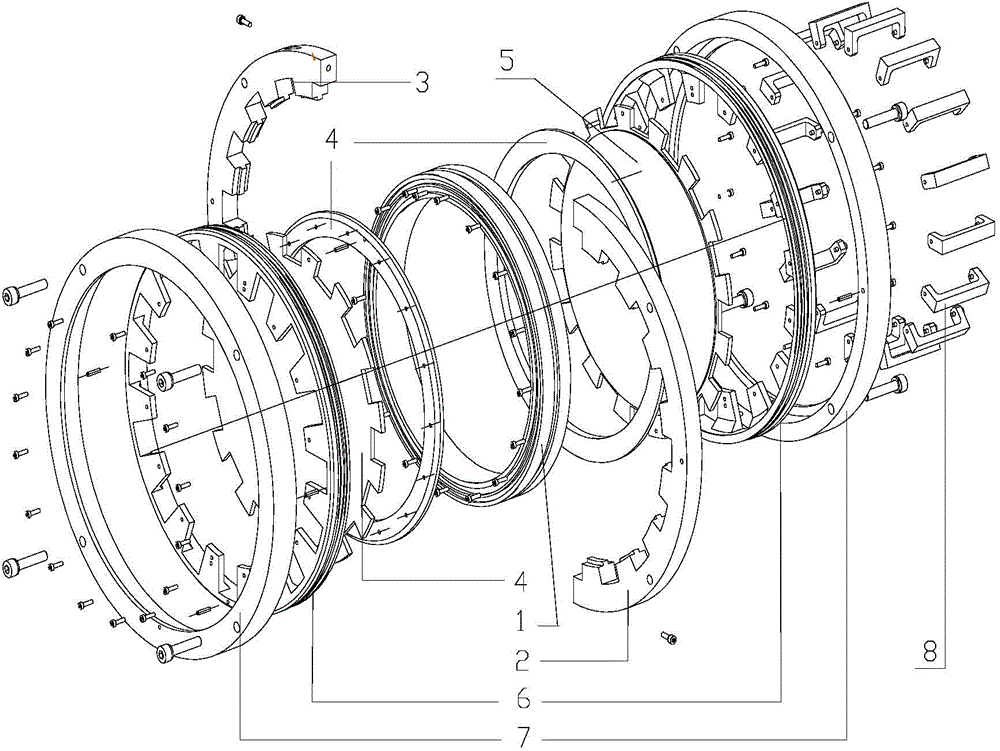

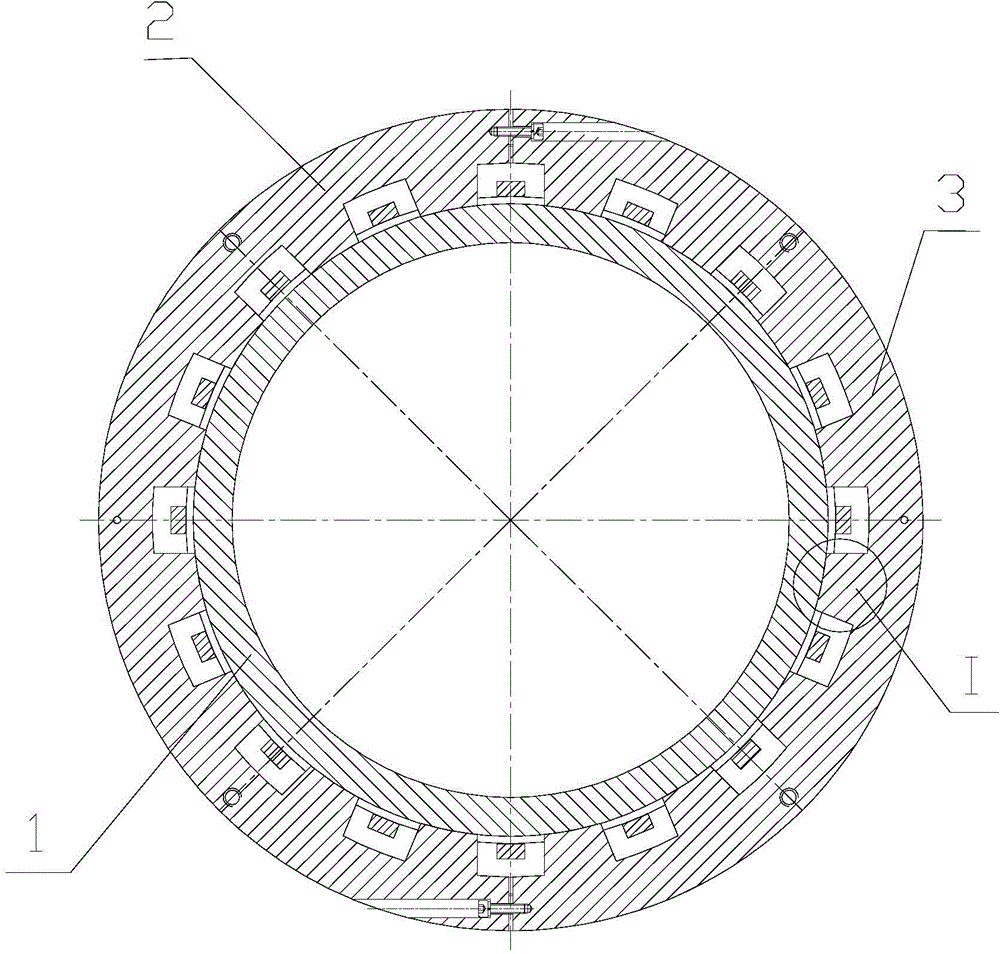

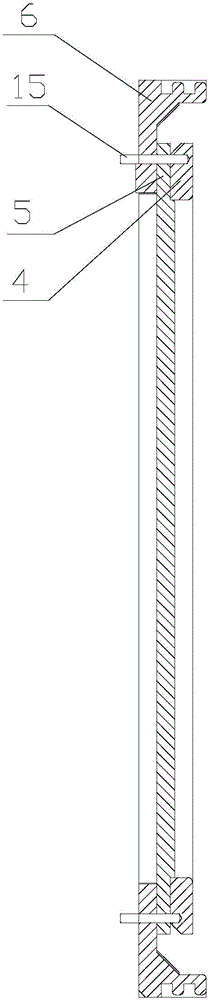

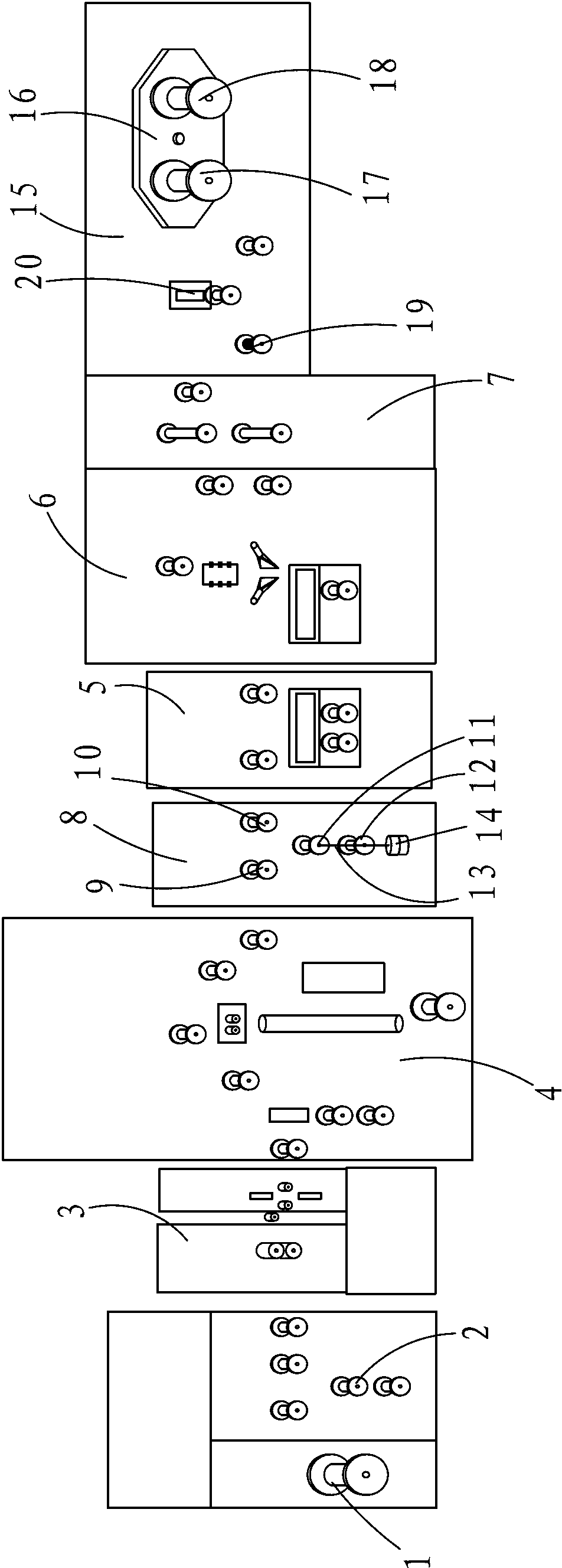

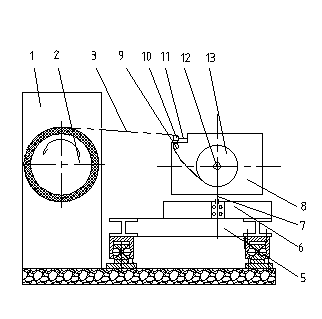

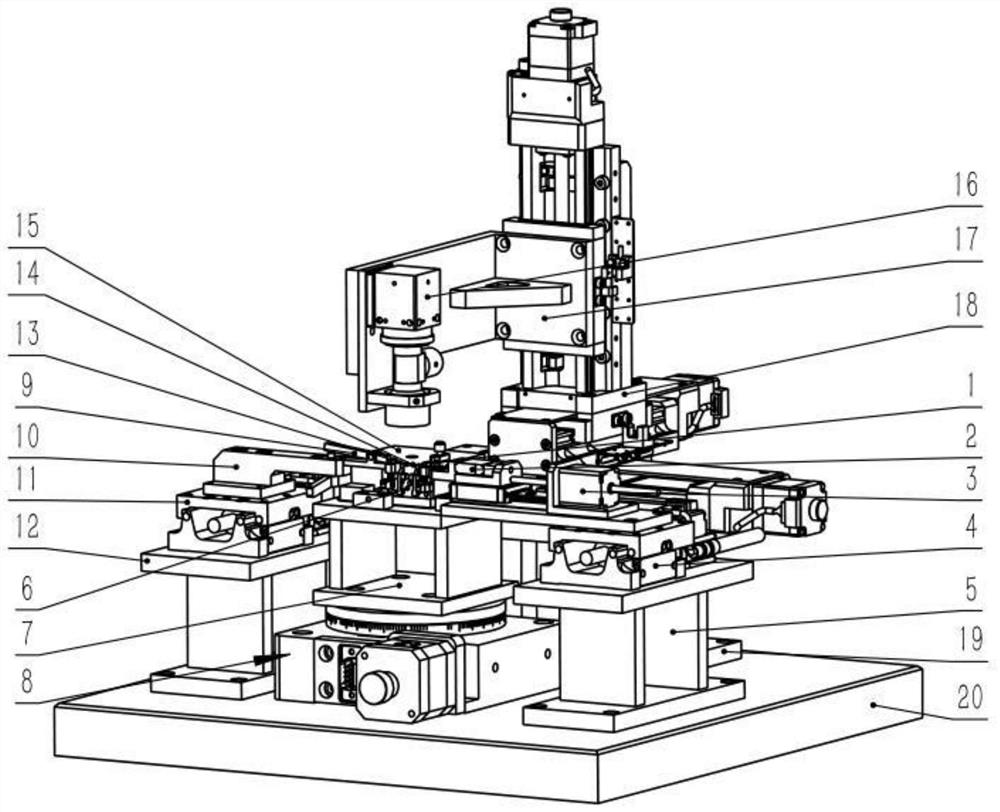

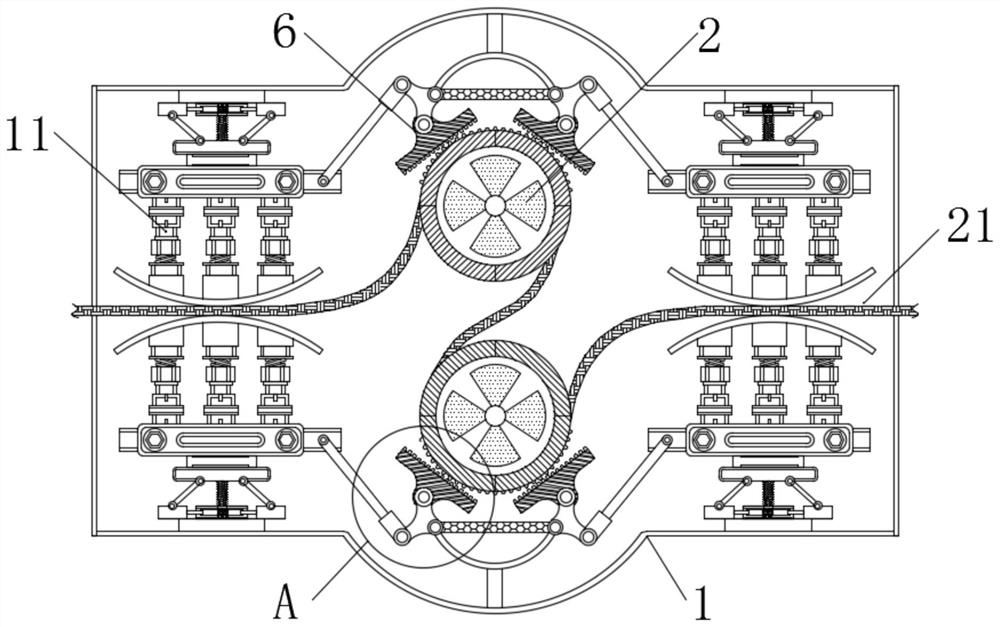

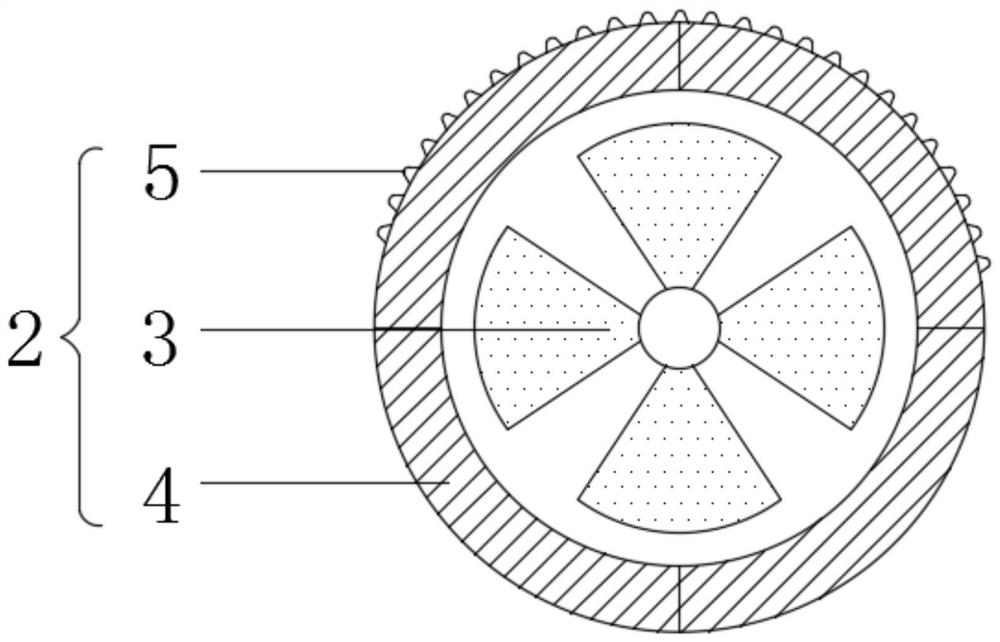

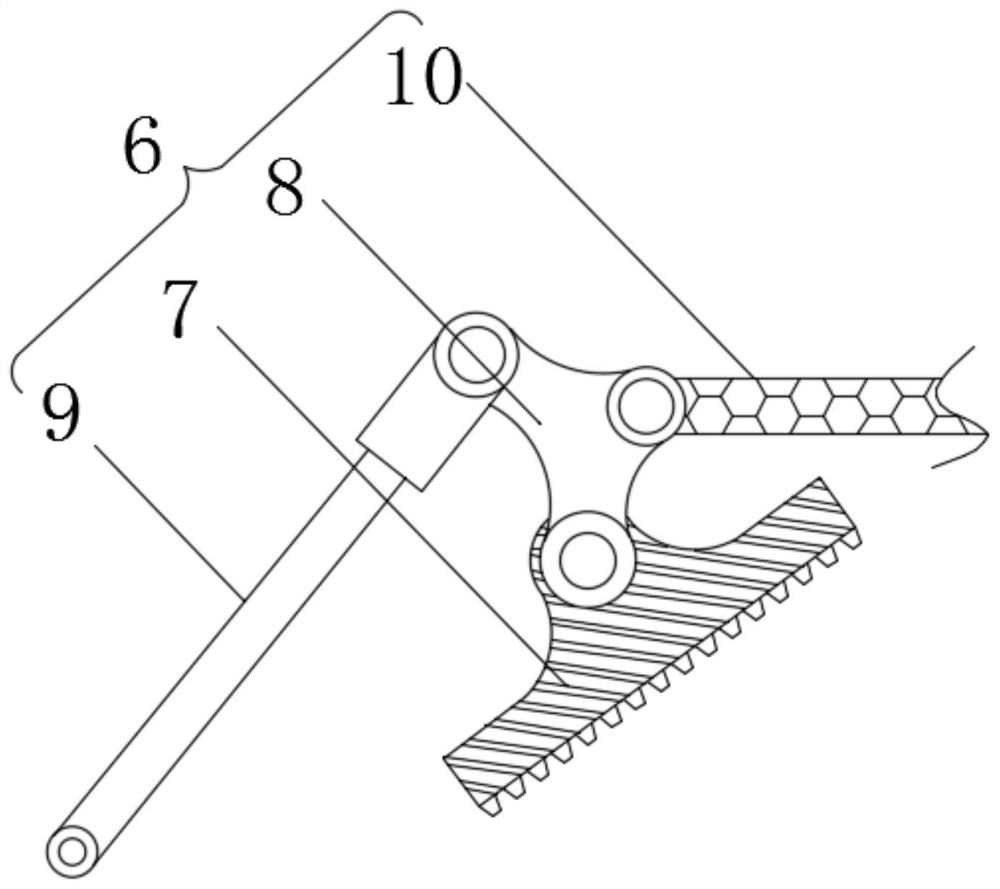

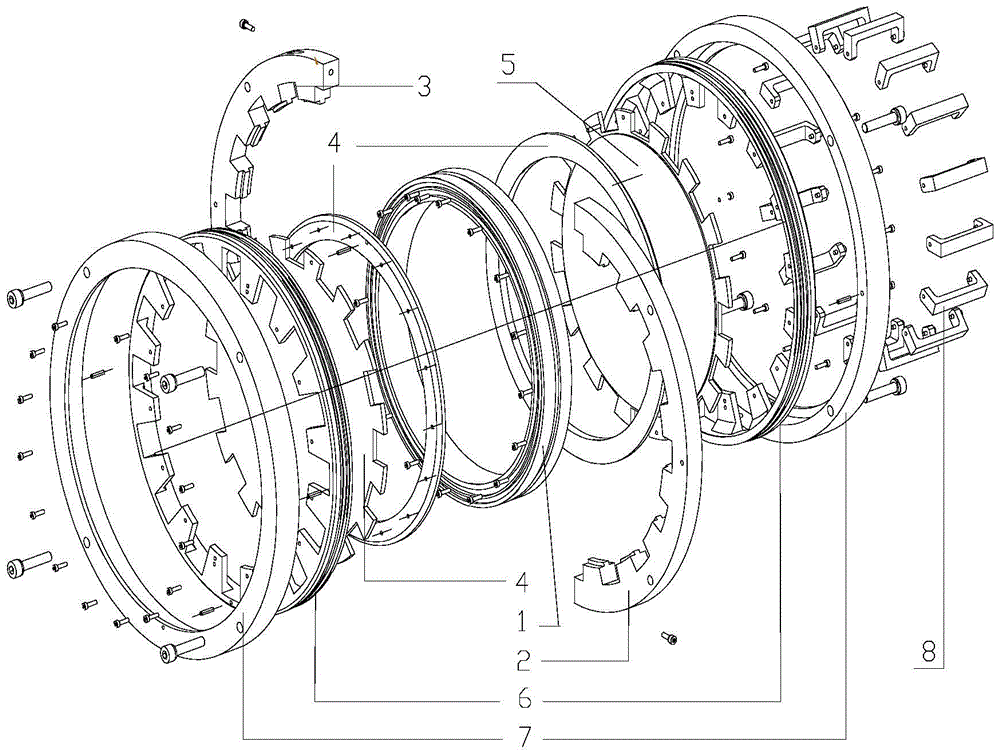

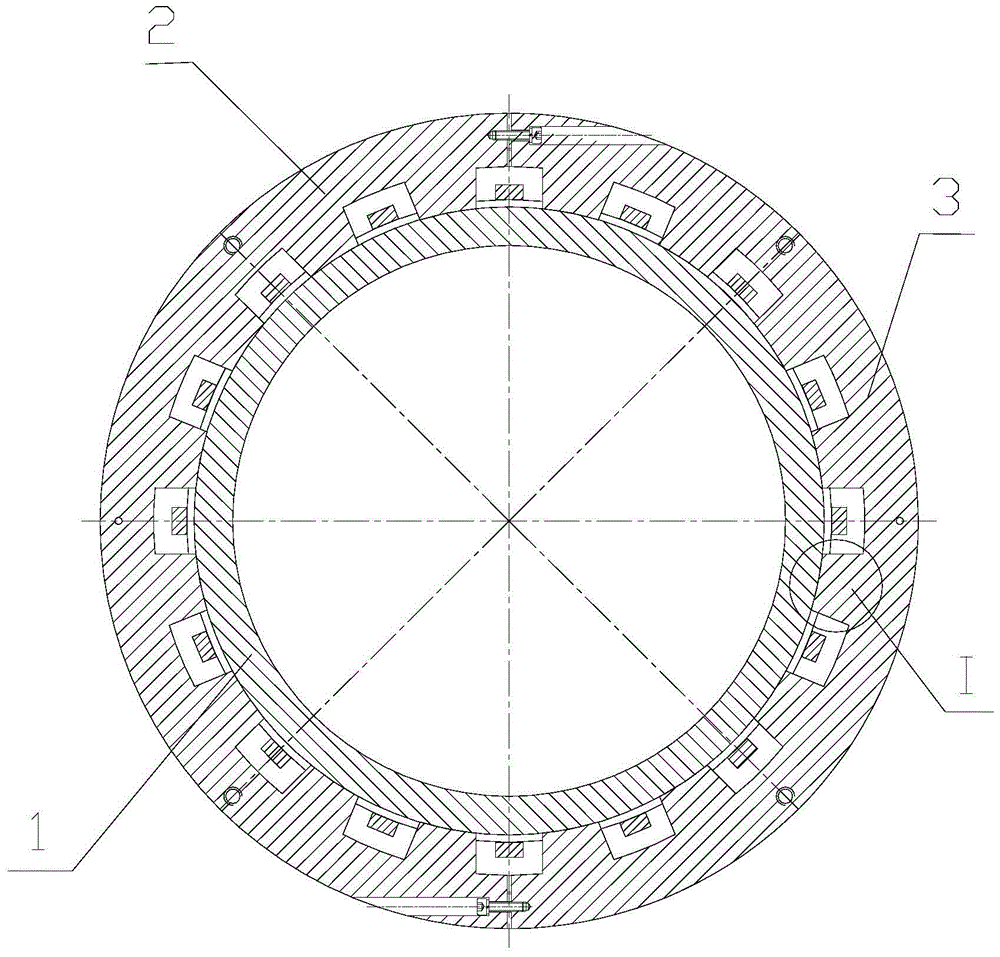

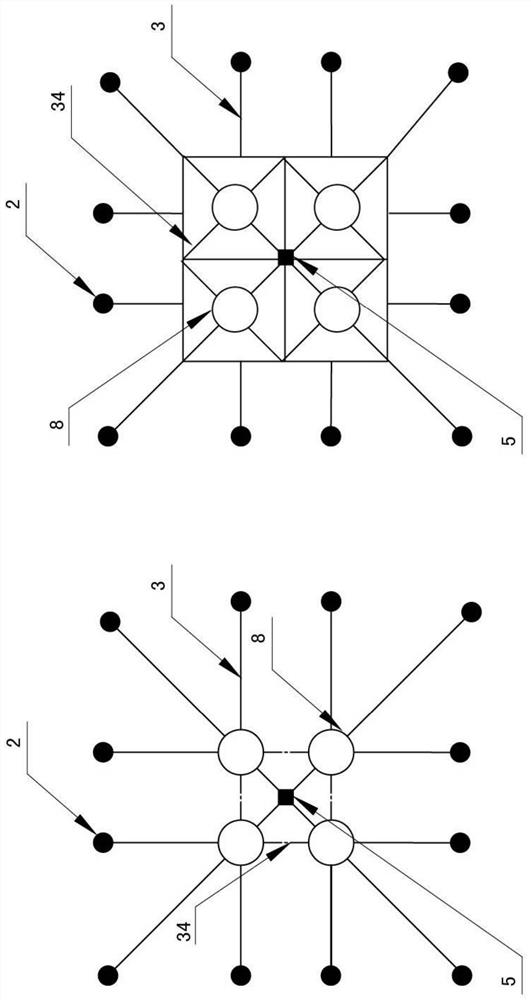

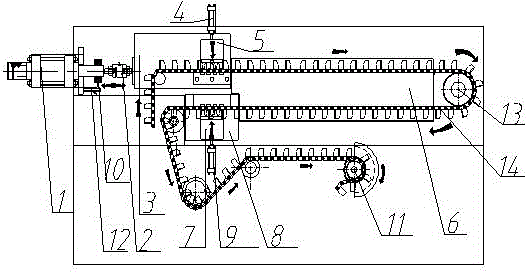

AC synchronous generator rotor full-automatic winding machine

PendingCN107707088ARealize automatic reversal of magnetic polesImprove work efficiencyManufacturing dynamo-electric machinesWinding machineTransducer

The invention relates to an AC synchronous generator rotor full-automatic winding machine which comprises a base, a winding device which can rotate forwardly or reversely, and a pole changing device.The winding device and the pole changing device are oppositely arranged and are installed on the base. A rotor is fastened in the pole changing device. The pole wings of the rotor are aligned with thewinding direction of the winding device. The winding device carries out winding on the pole wings of the rotor. The pole changing device drives the rotor to rotate. The rotor is fastened to the polechanging device, and the winding device carries out winding on the pole wings of the rotor. After winding on one pole wing is completed, the pole changing device drives the rotor to rotate to make next pole wing aligned with the winding direction of the winding device and to continue winding on the pole wing. At the moment, the winding device rotates reversely to reverse an enameled wire coil, andthus, the magnetic poles of the rotor are automatically reversed. The whole winding machine automatically completes all work of rotor winding. There is no need for manual pole changing, there is no need to cut off enameled wire ends, and there is no need to weld enameled wire ends. The work efficiency of generator rotor production and the quality of products are improved.

Owner:王江锋

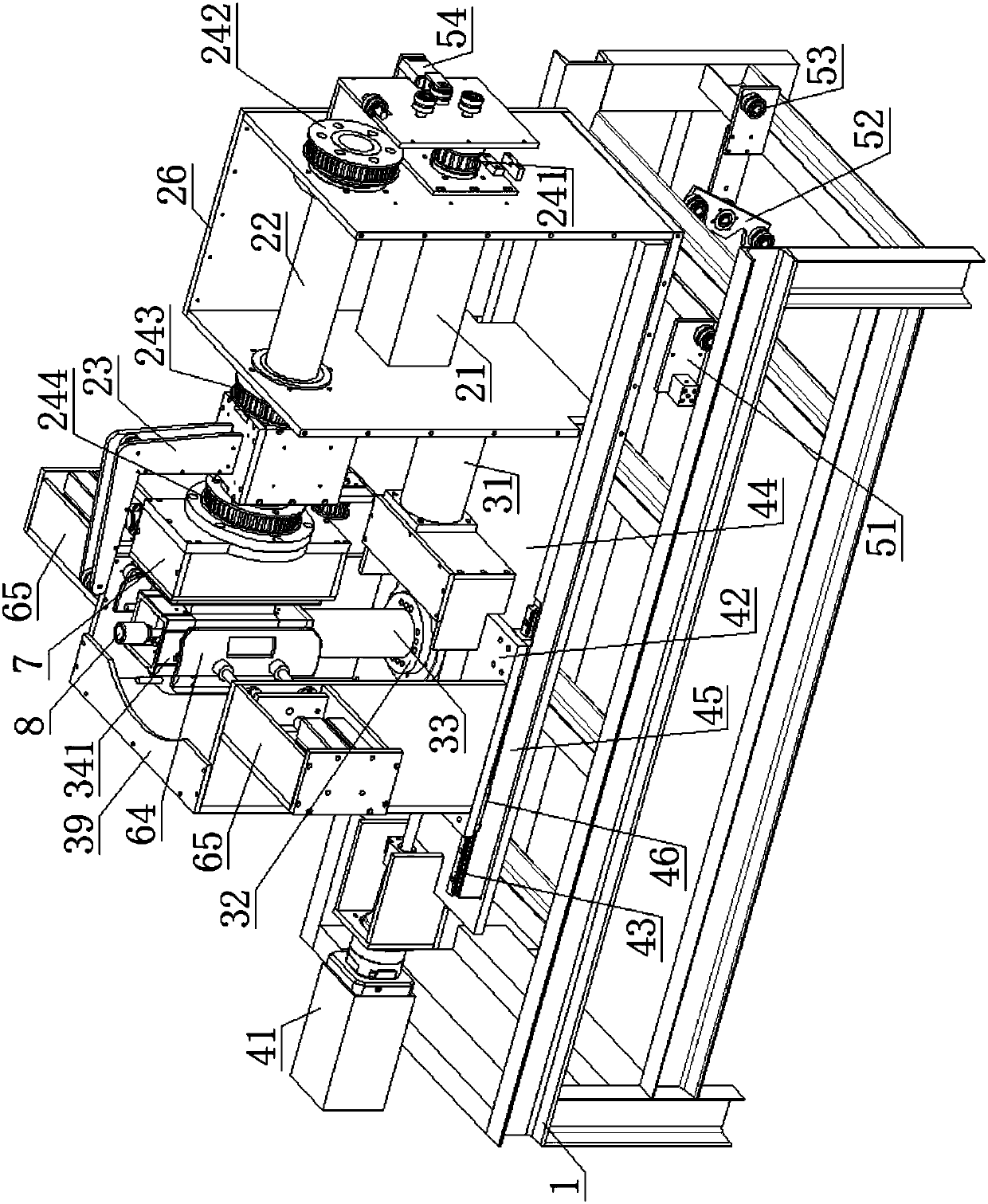

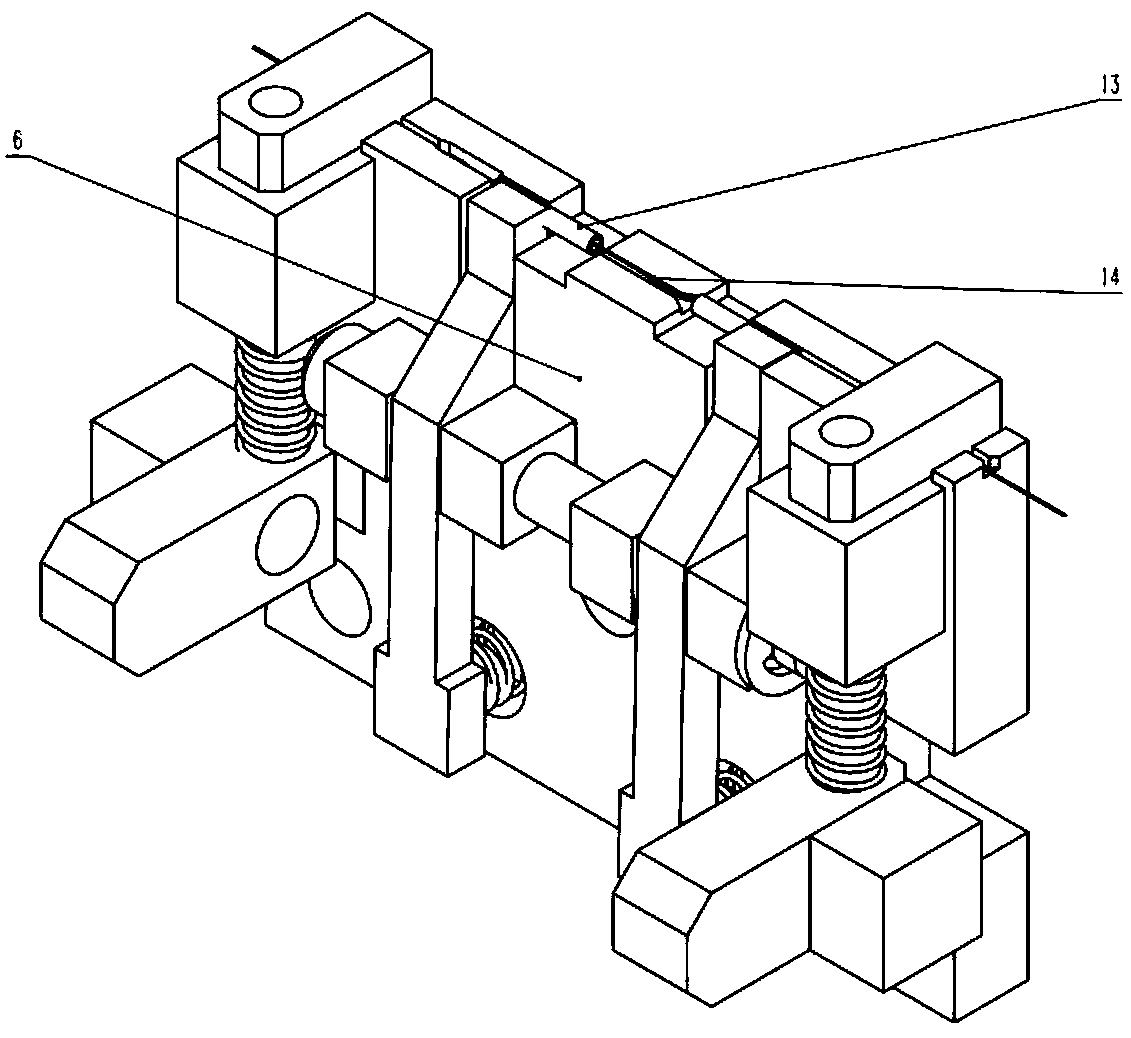

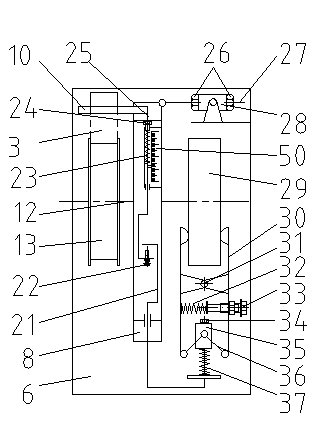

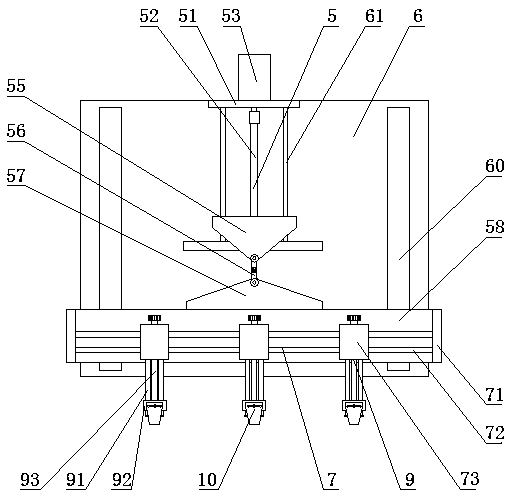

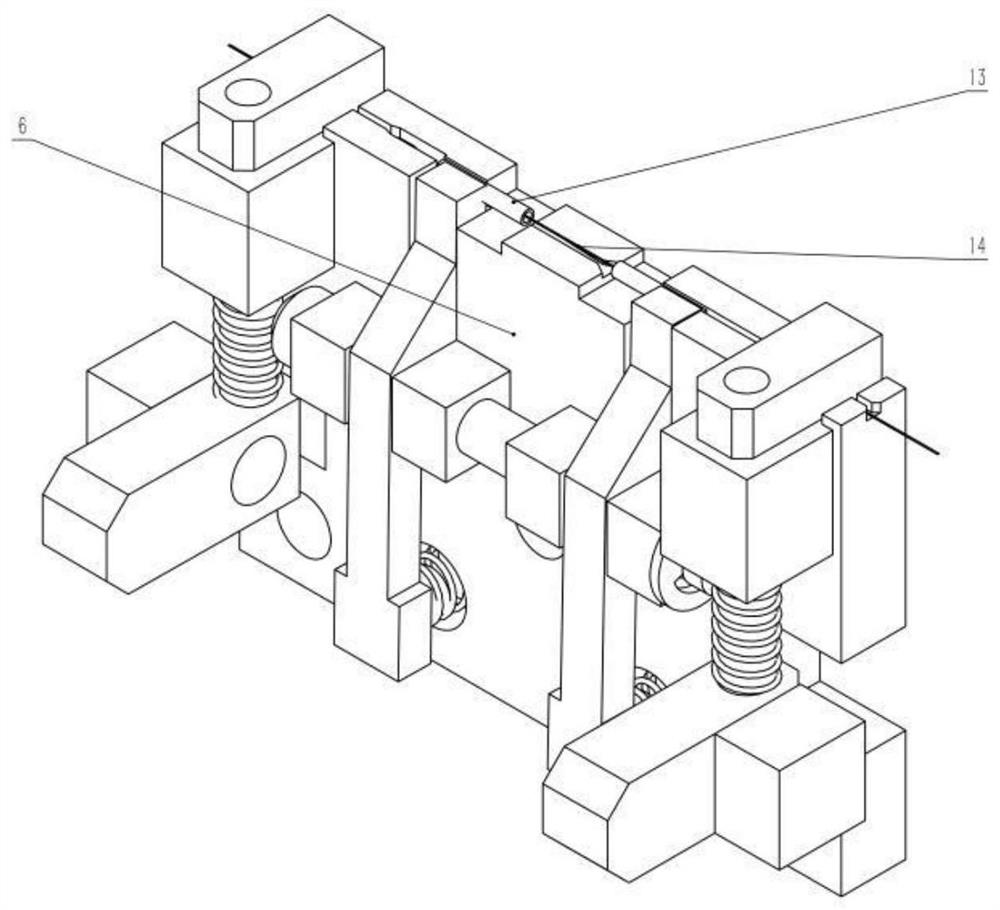

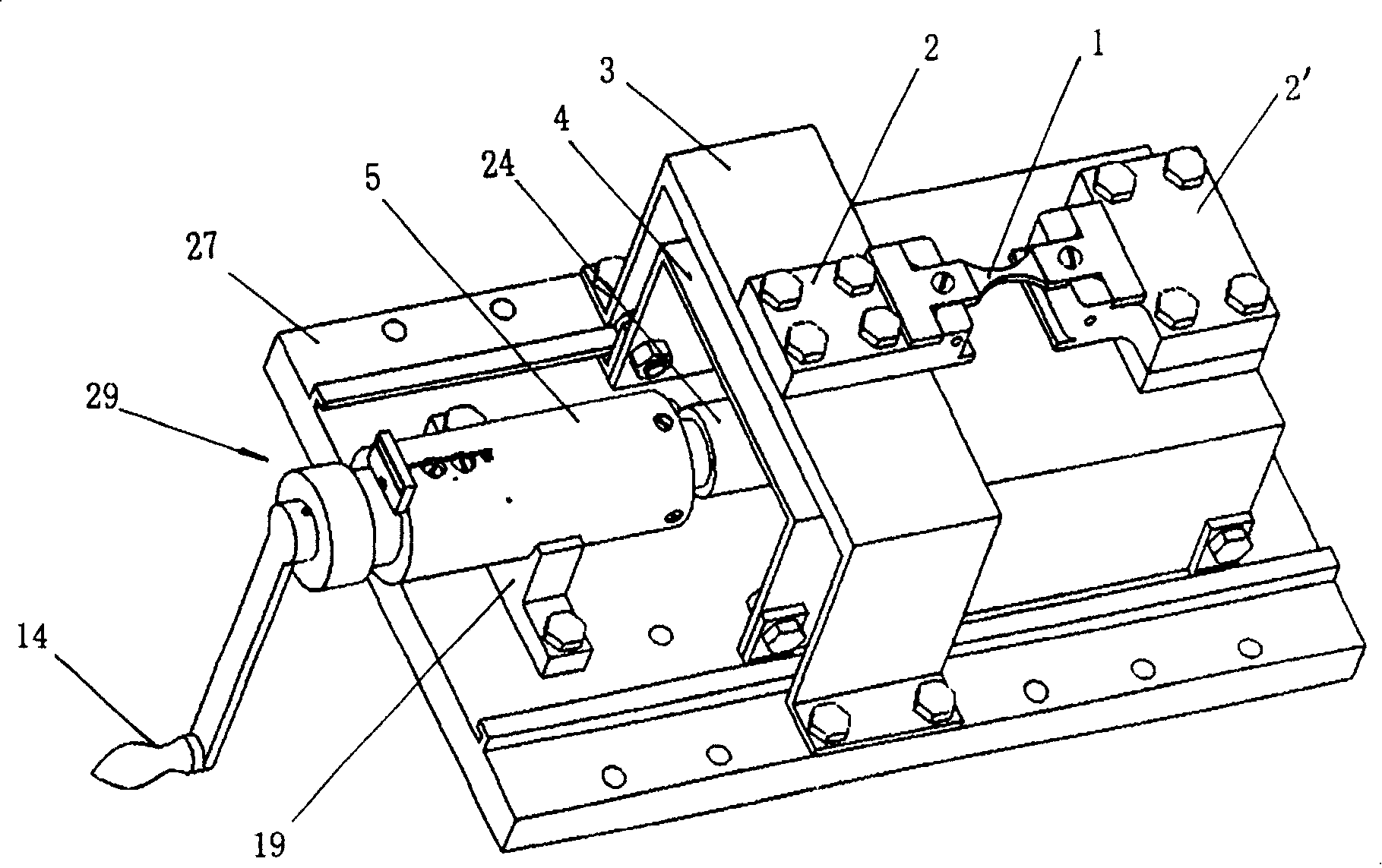

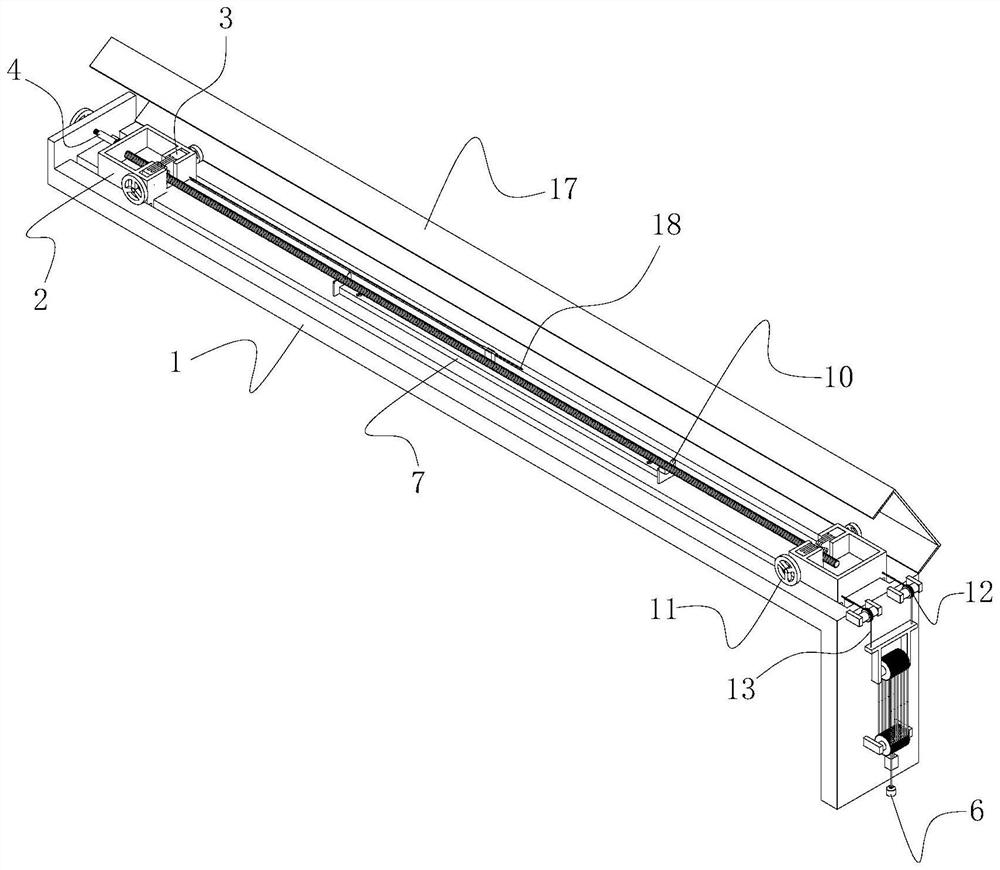

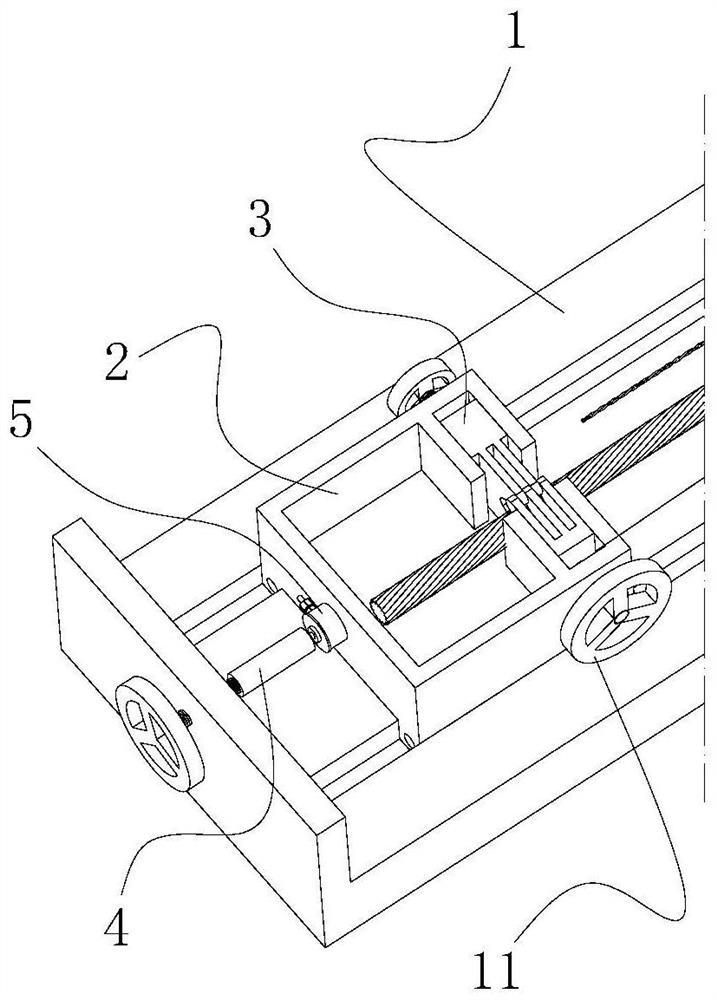

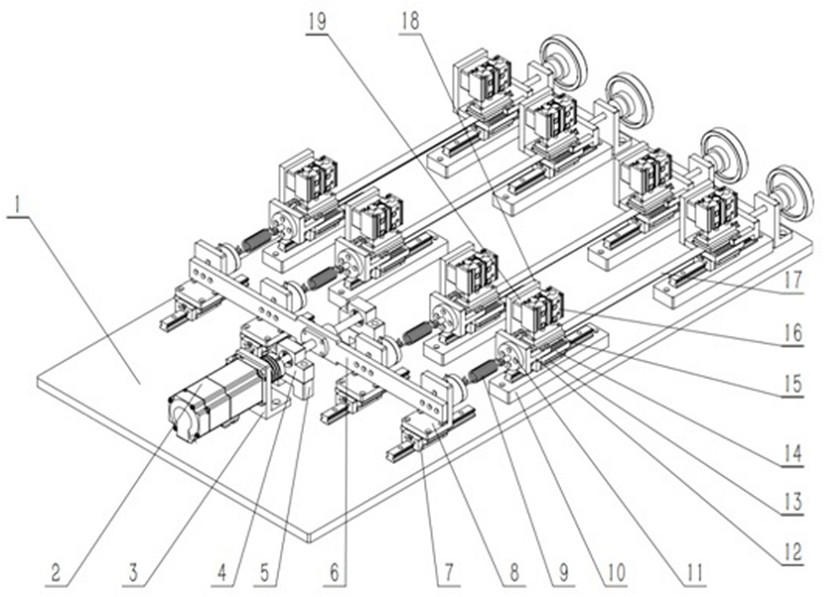

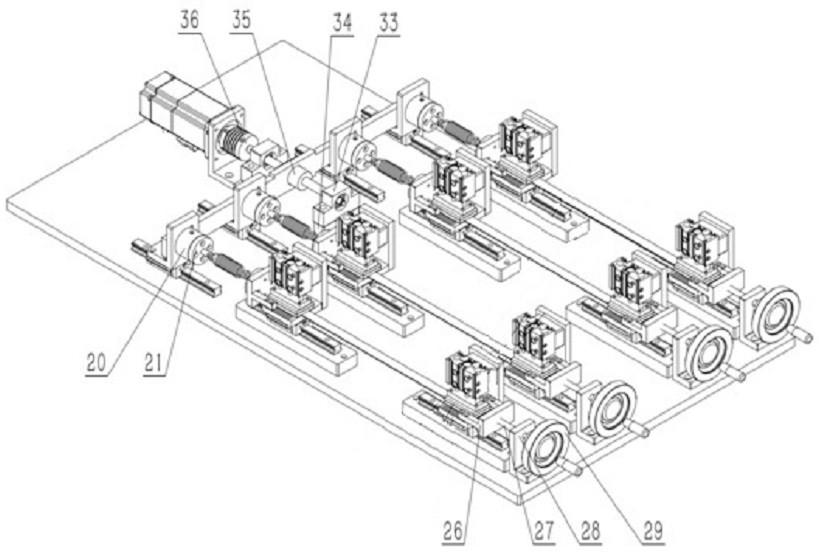

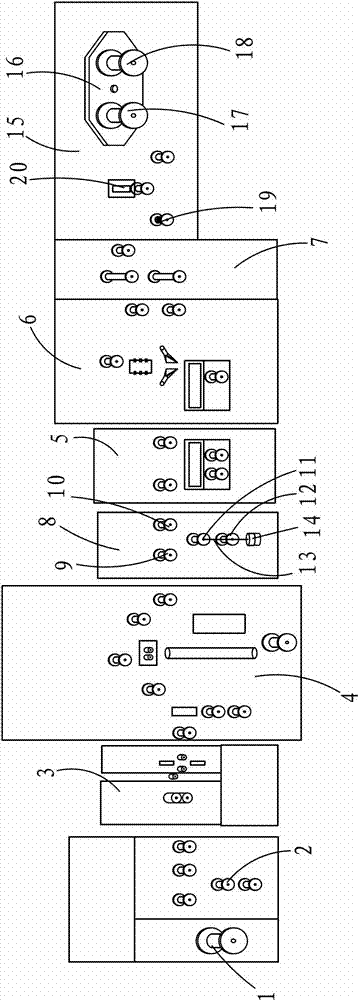

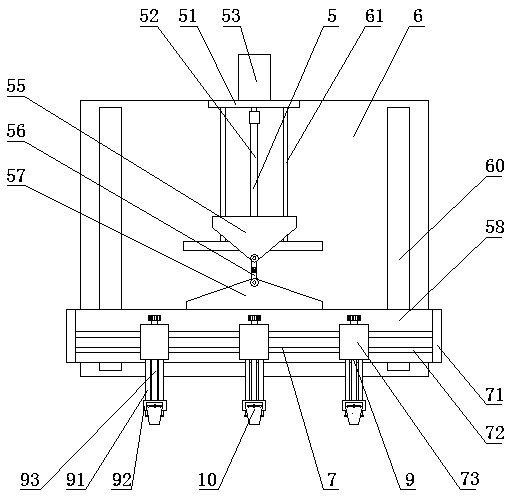

Automatic wire passing and aligning device and method for micro glass tube

ActiveCN109664241AImprove assembly efficiencyAvoid errorsMetal-working hand toolsAccelerometerAutomatic control

The invention belongs to the technical field of automatic assembly of precision micro parts, and relates to an automatic wire passing and aligning device and method for a micro glass tube. The deviceuses a technology of automatically wire passing and aligning for a micro-miniature accelerometer inertia pendulum part suspension wire and the glass tube. The middle part of the device is a glass tubeclamp installing and adjusting mechanism, a suspension wire aligning mechanism and a wire passing and aligning mechanism are arranged at the two sides of the glass tube clamp installing and adjustingmechanism respectively, a visual measurement module is at the rear side, the bottoms of the four parts are all installed on a platform, the wire passing and aligning mechanism and the visual measurement module are connected with a PC respectively, and therefore automatic control is realized. The device can realize the automatic wire passing and aligning function of the micro glass tube with visible assembly process and controllable passing wire tension.

Owner:DALIAN UNIV OF TECH

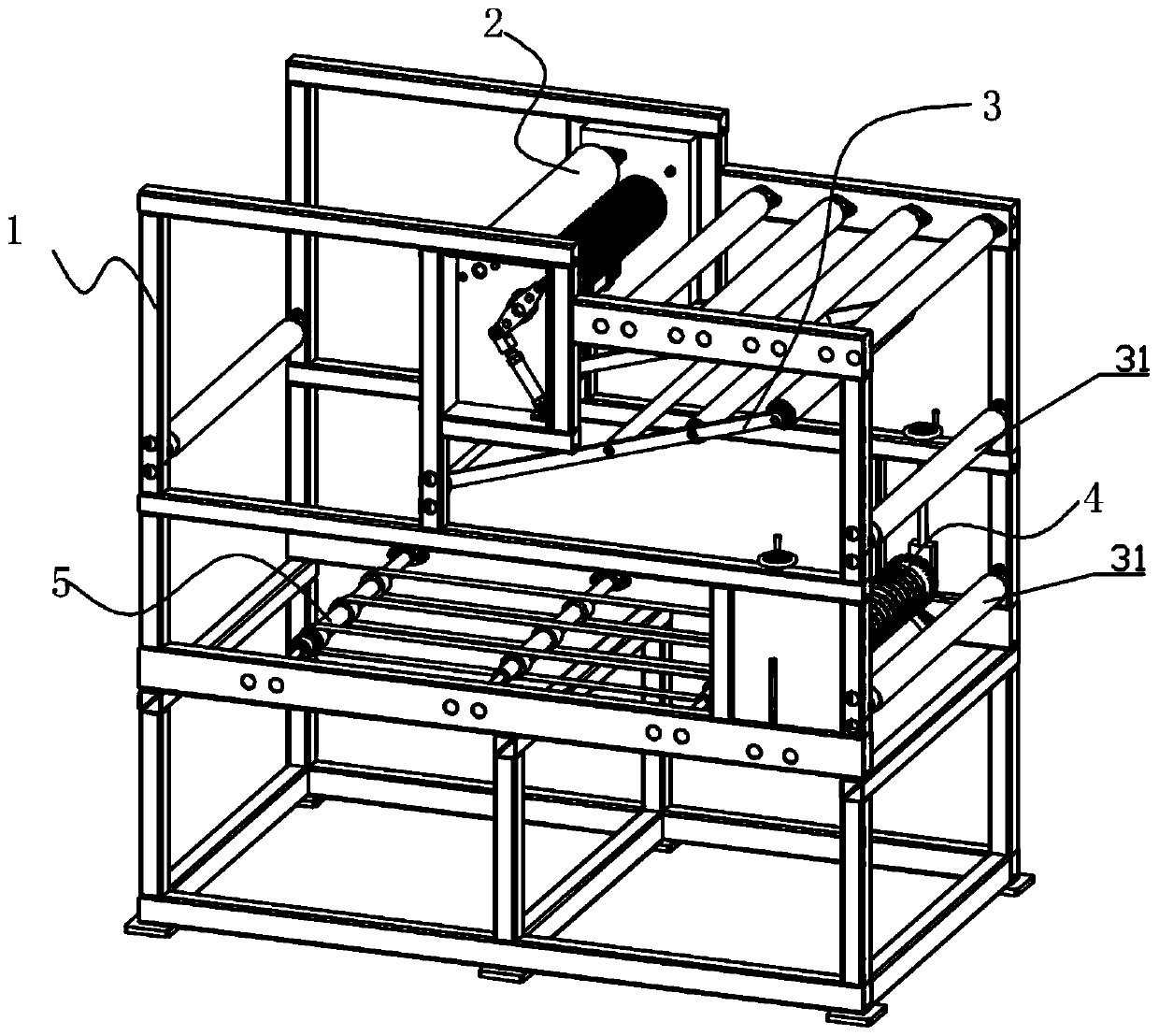

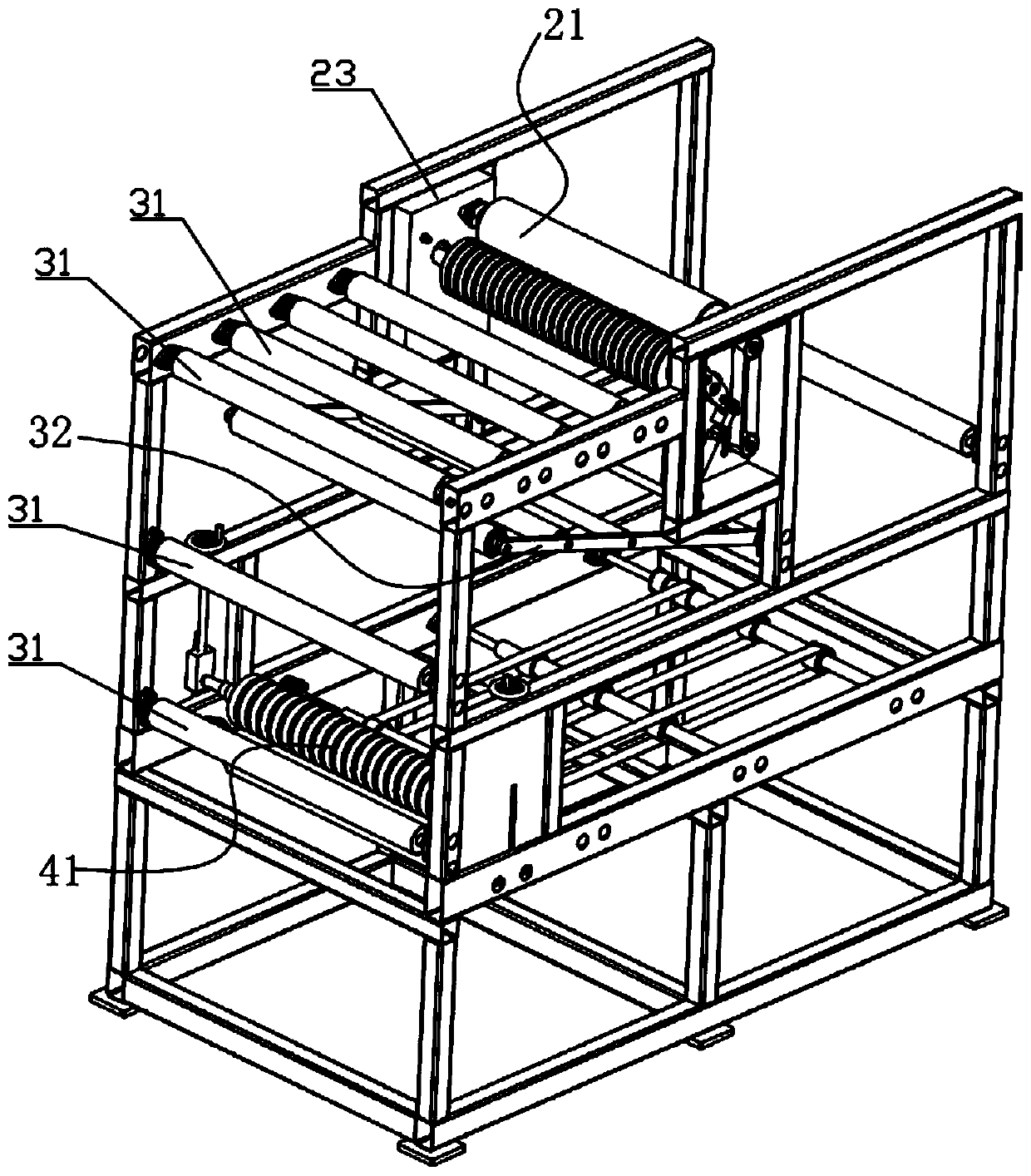

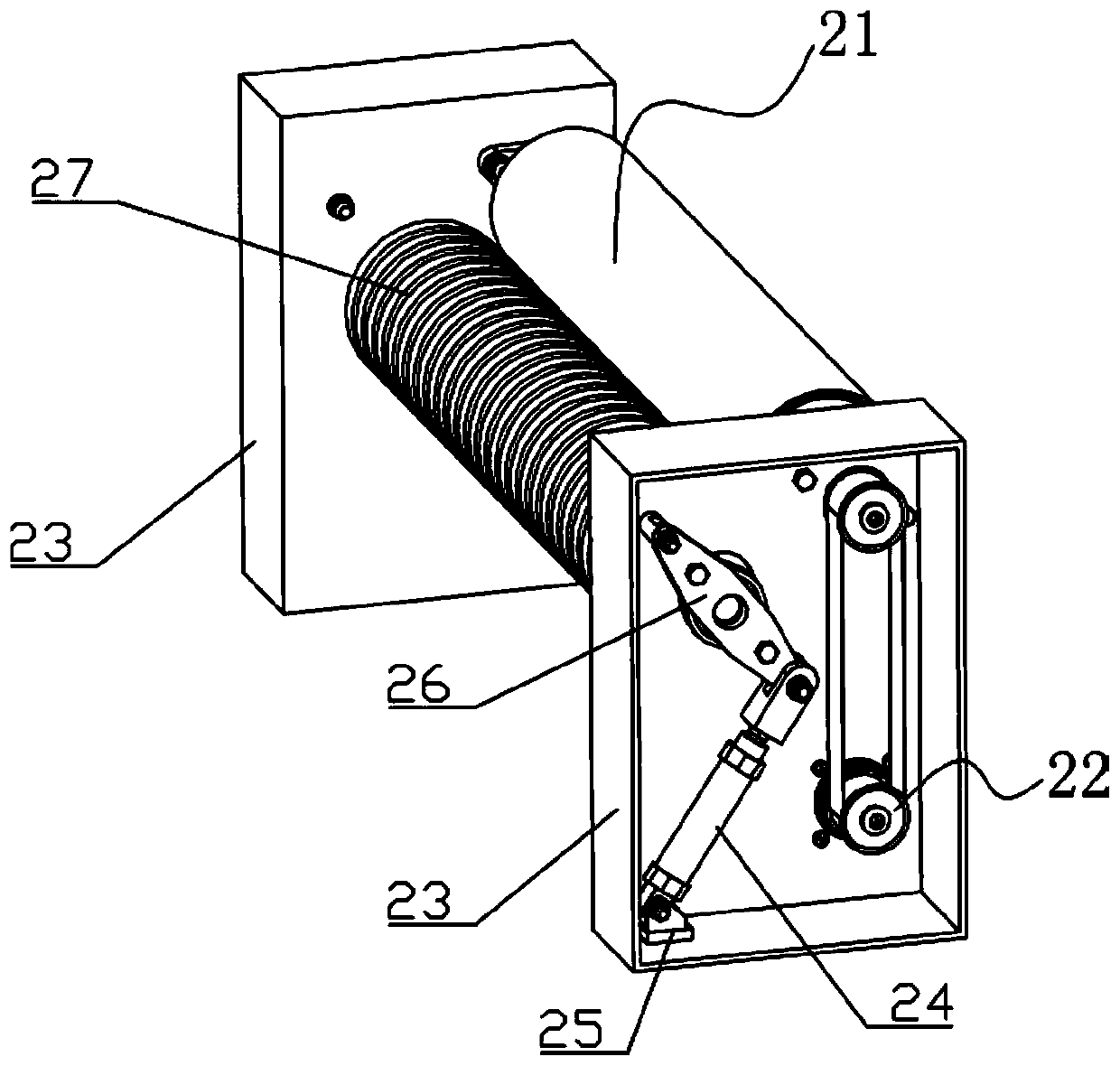

Woven bag feeding and conveying device

InactiveCN110615305AReduce traction differenceSimple structureBag making operationsPaper-makingEngineeringDrive motor

The invention discloses a woven bag feeding and conveying device. The woven bag feeding and conveying device comprises a rack, a first active conveying assembly, a tensioning assembly, a second activeconveying assembly and a conveyor belt assembly, wherein the first conveying assembly is arranged on the upper portion of the rack; the first active conveying assembly comprises a first press roll set and a driving motor connected with the first press roll set to drive the first press roll set to rotate; the tensioning assembly is arranged on the rack; the tensioning assembly comprises a plurality of conveying rolls horizontally and rotatably arranged on the top of the rack side by side and a tensioning frame located below the conveying rolls; the tensioning frame is arranged obliquely in themanner that the end located below the first press roll set is lower than the end far away from the first press roll set; the end, located below the first press roll set, of the tensioning frame is rotatably mounted on the rack, and the other end of the tensioning frame is arranged in a suspended mode; the plurality of conveying rolls are rotatably mounted on the tensioning frame in the width direction of the tensioning frame; the second active conveying assembly is arranged below the tensioning frame; the second active conveying assembly comprises a second press roll set connected with an external motor; and the conveyor belt assembly is arranged on the discharge side of the second press roll set.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

Method for manufacturing spring steel wire with excellent stability and stress resistance

ActiveCN112453080AHigh stability and stress resistanceHigh tensile strengthFurnace typesProcess efficiency improvementWire rodSpring steel

The invention discloses a method for manufacturing a spring steel wire with excellent stability and stress resistance. The method comprises the following steps of selecting raw materials, namely selecting a high-carbon steel hot-rolled high-quality wire rod for production; descaling the high-carbon steel hot-rolled wire rod through a stripping wheel, drawing the high-carbon steel hot-rolled wire rod to the diameter of a pre-drawn semi-finished steel wire required by process design through a tungsten steel wire drawing die by adopting a pre-drawing machine, and then conducting primary drawing treatment; and conducting continuous heat treatment on the semi-finished steel wire, namely conducting lead bath quenching treatment on the pre-drawn semi-finished steel wire through a heat treatment furnace, wherein the tensile strength of the semi-finished steel wire obtained after heat treatment is 880-1100 MPa. According to the method, the steel wire is high in stability and stress resistance,drawing tension and tension can be conveniently controlled to produce carbon thin spring steel wires of different sizes and standards, the tensile strength of the steel wire can be continuously improved, the requirements for the appearance, the surface quality, the mechanical property and the toughness of a steel wire product are met, meanwhile, batch production is achieved, and the product quality requirement is met.

Owner:德清林缘金属制品有限公司

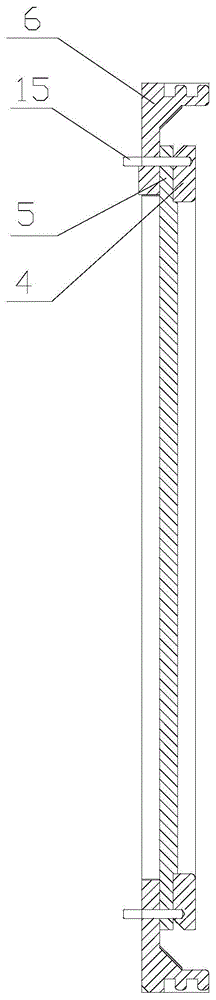

Inflatable membrane reflector, and assembly tool and assembly method thereof

InactiveCN104570176AEasy to operateImprove controllabilityMirrorsMountingsPolyimide membraneEngineering

The invention provides an inflatable membrane reflector, and an assembly tool and an assembly method thereof. A membrane reflector is composed of a clip, a main mirror frame, a main mirror pressure plate, a polyimide membrane and a seal ring, wherein the assembly tool comprises a connecting frame, a pressure plate, a membrane frame, a pressure cover and nylon ropes; the assembly method of the assembly tool comprises the following steps: fixing the connecting frame on the main mirror frame; fastening the positions of the main mirror pressure plate, the pressure plate and the membrane frame; respectively binding two membranes on the membrane frame through the nylon ropes; controlling the tightening degree of the membranes by tightening the nylon ropes, and simultaneously, uniformly tightening the membranes; and fastening the membrane frame and the pressure cover, then fastening the pressure cover and the connecting frame, and finally pressing the pressure plate, the main mirror pressure plate and the membranes on the main mirror frame. Effective control on an ideal surface shape of the membrane is finished by the assembly tool; and the surface shape accuracy of the membrane reflector is improved.

Owner:BEIJING SIMULATION CENT

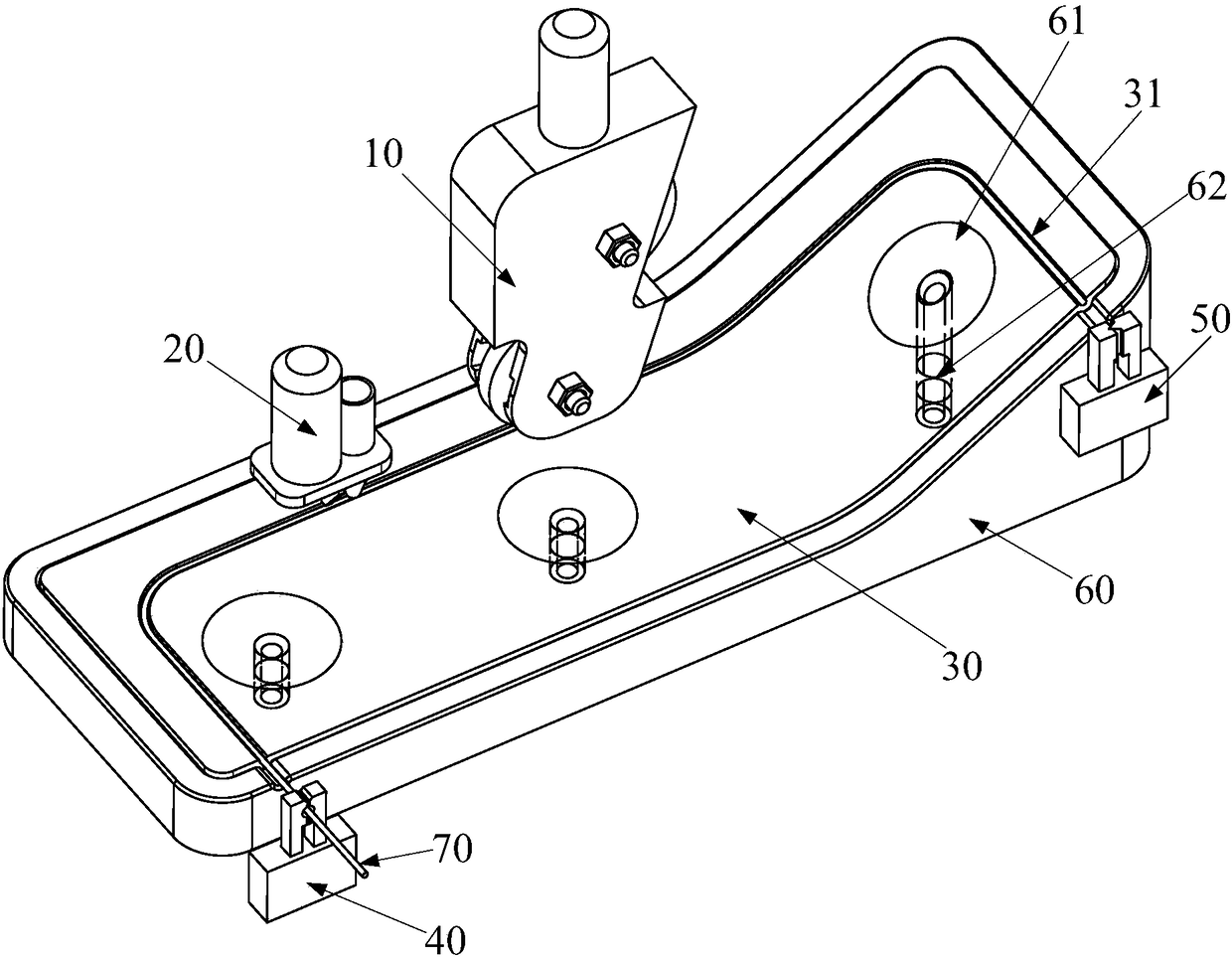

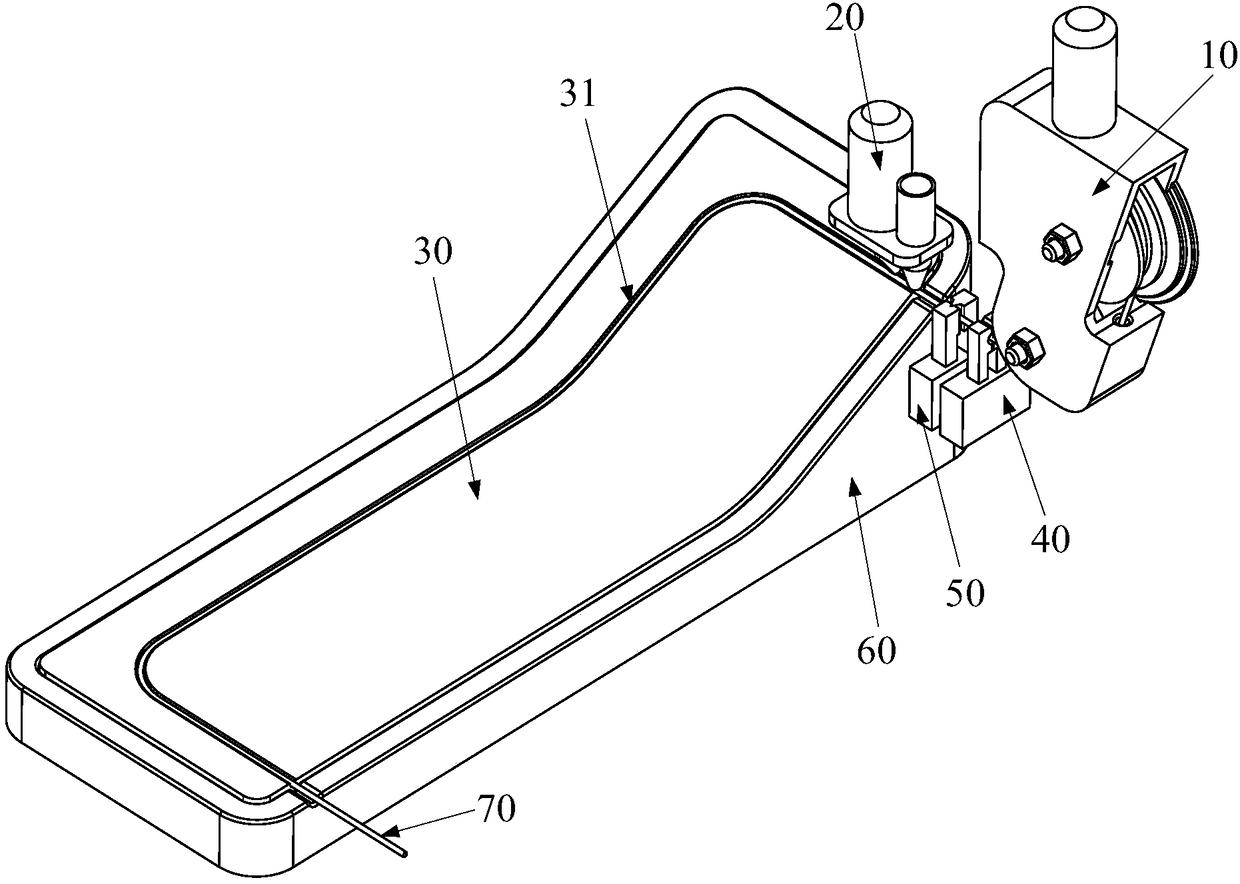

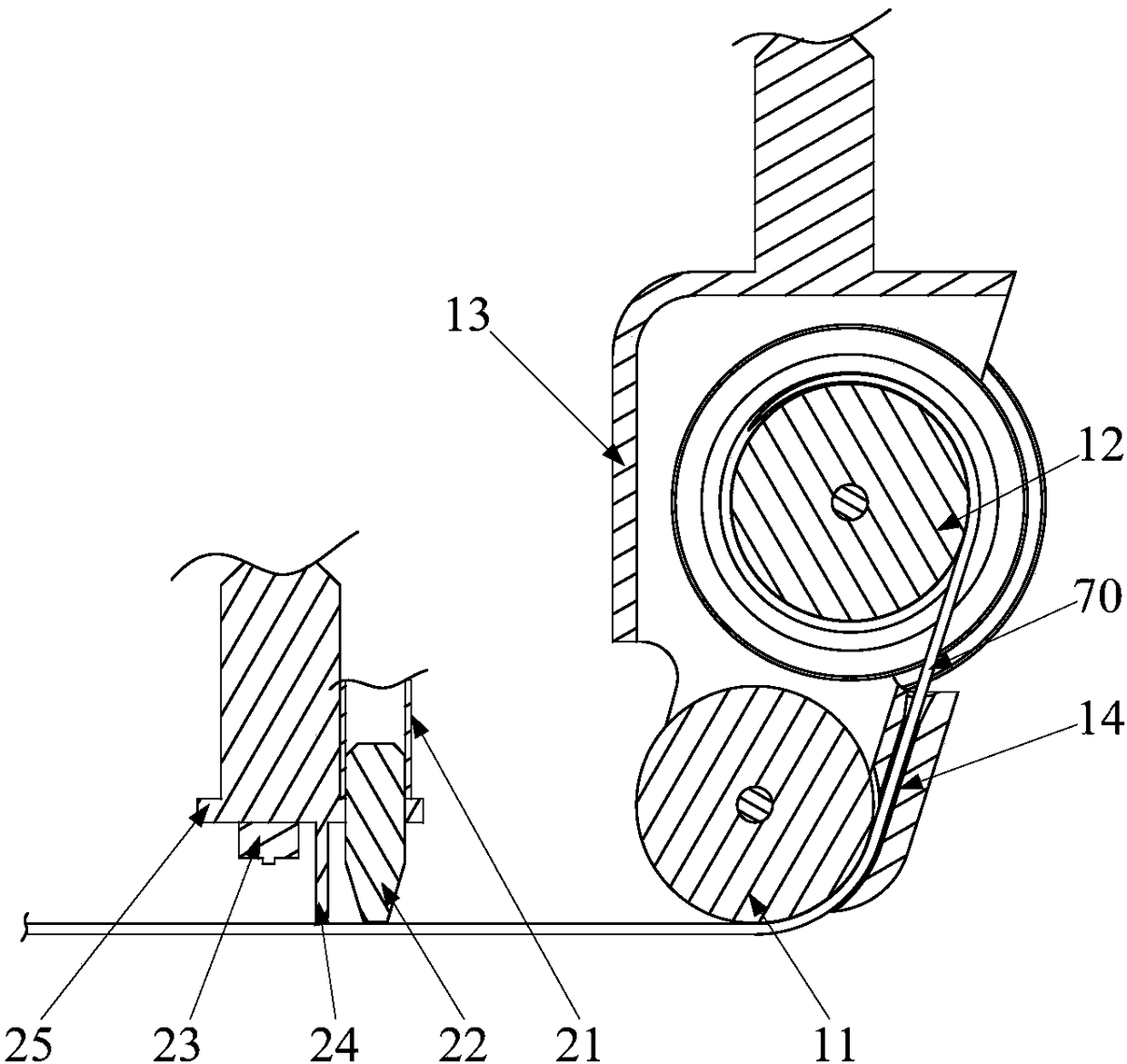

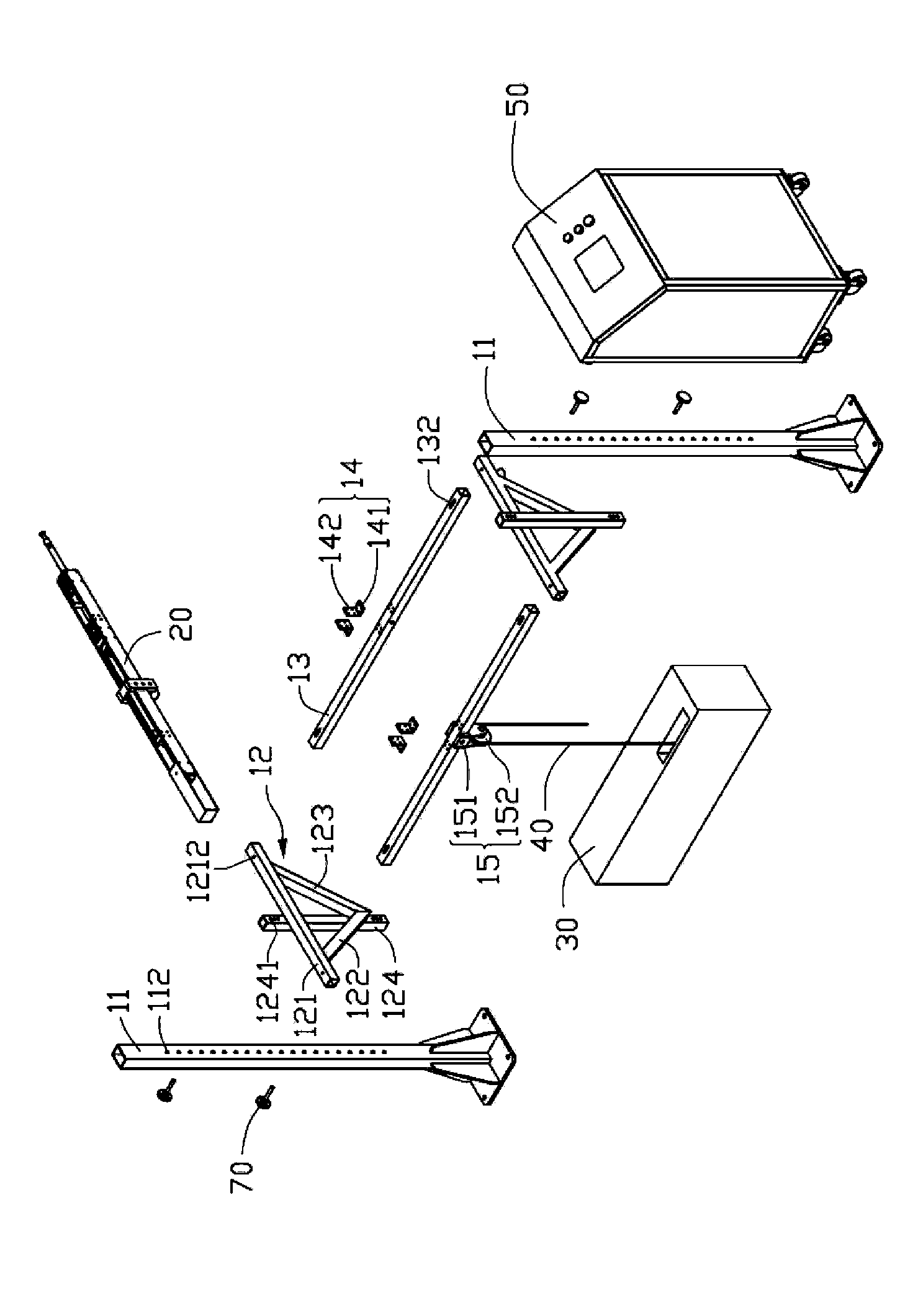

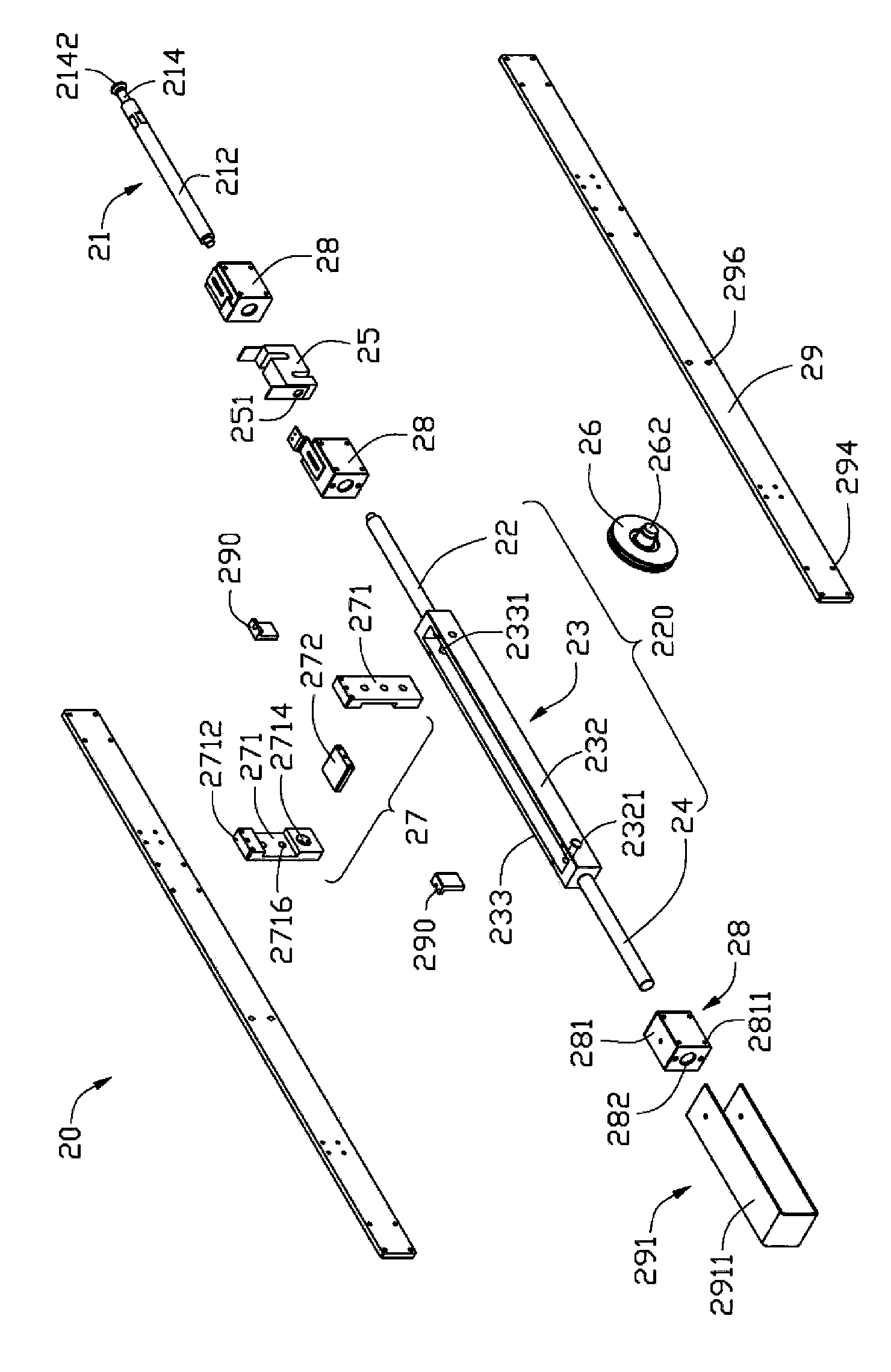

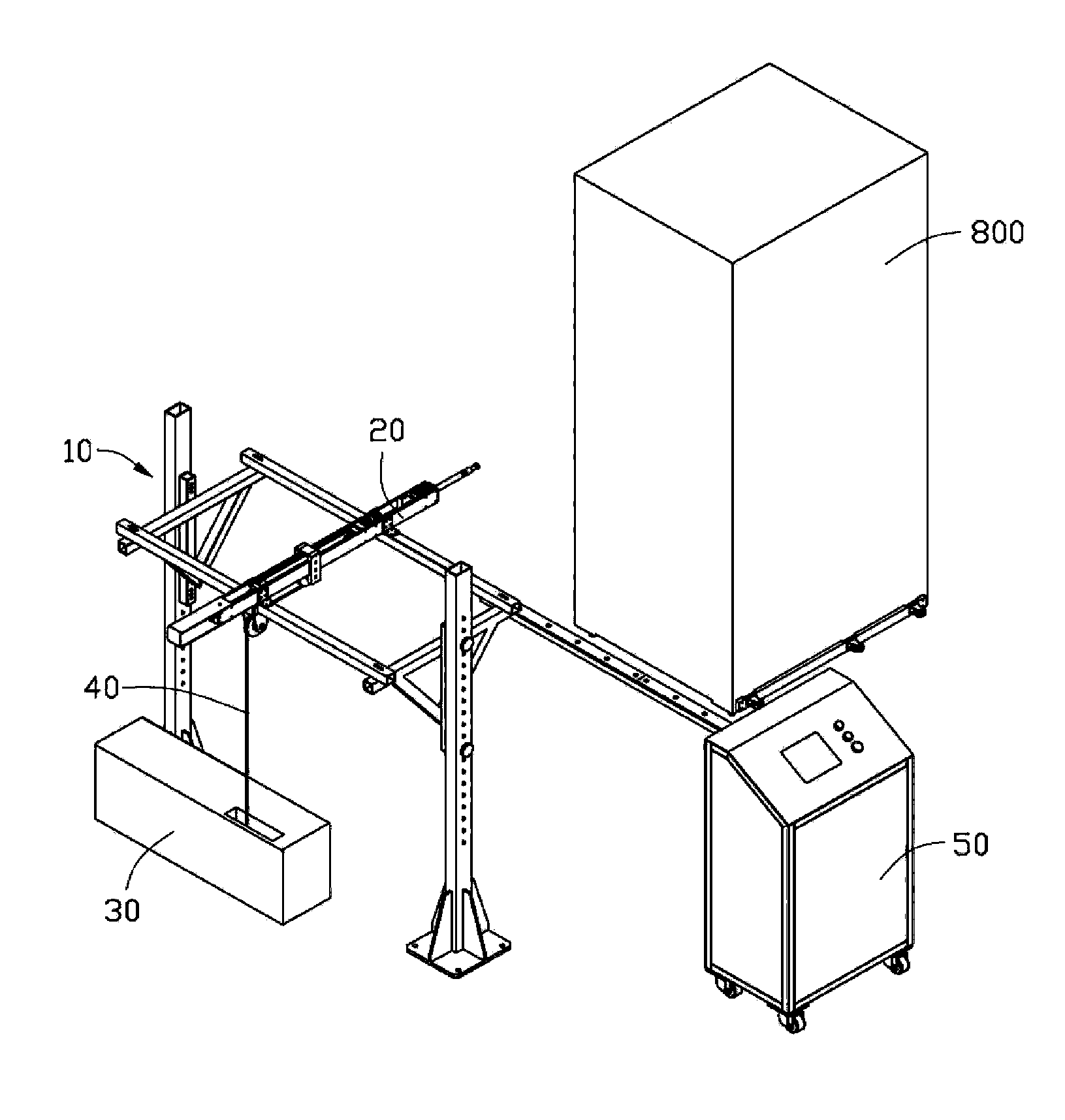

Optical fiber installation device and vehicle lamp assembly system

PendingCN108508560ATension is easy to controlAvoid breakingOptical fibre/cable installationFiberEngineering

The invention provides an optical fiber installation device and a vehicle lamp assembly system, relates to the technical field of vehicle lamp assembly systems and aims to solve the problem of difficult mounting and fixing of optical fibers. The optical fiber installation device comprises a laying mechanism, a gluing mechanism and a driving mechanism, wherein the optical fiber is arranged in the laying mechanism, an optical fiber placing groove is arranged on the optical fiber fixing carrier, the driving mechanism is respectively connected with the laying mechanism and the gluing mechanism todrive the laying mechanism and the gluing mechanism to move along the optical fiber placing groove, and the laying mechanism is used for placing the optical fiber in the optical fiber placing groove.The optical fiber installation device is used for installing the optical fiber into the optical fiber fixing carrier, and fixing the optical fiber in the optical fiber fixing carrier through the glueliquid. The device has the advantages of high efficiency, small manual labor amount, high yield, high reliability and good appearance consistency, and the fiber track can be space three-dimensional.

Owner:HASCO VISION TECHNOLOGY CO LTD

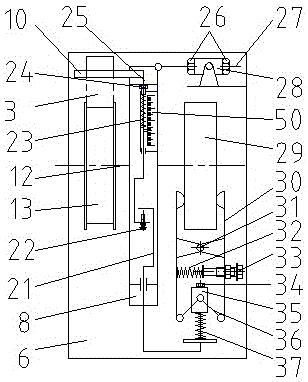

Rotary spraying purification equipment for implementing spaced and cross disinfection of sewage

InactiveCN107381736AEasy to handleImprove efficiencySpecific water treatment objectivesMovable spraying apparatusDisinfectantWater quality

The invention discloses rotary spraying purification equipment for implementing spaced and cross disinfection of sewage. The equipment comprises a water collecting tank, a disinfectant storage tank, a rotary disinfection purification cabin and a control box. The equipment is applied to a sewage treatment process, the rotary disinfection purification cabin is redesigned with two parts, i.e., an upper-layer cabin body and a lower-layer cabin body, a rotary disinfection purification spraying component is arranged in the lower-layer cabin body, and a disinfectant is sprayed in a rotary manner through the spraying component, so that the problems of non-uniform medicament spraying and the like of existing equipment are solved, quick and complete disinfection is implemented, and the sewage treatment capability and efficiency are improved; the sewage and a medicament are fed and sprayed in a spaced manner in an implementation process, and a spaced and cross disinfection manner is adopted to implement treatment and purification of the sewage, so that the problem of incomplete disinfection purification of the existing equipment due to relatively more sewage in a sewage tank during treatment is solved, and in addition, the spaced and cross disinfection manner is favorable for keeping the water quality stable.

Owner:初丽萍

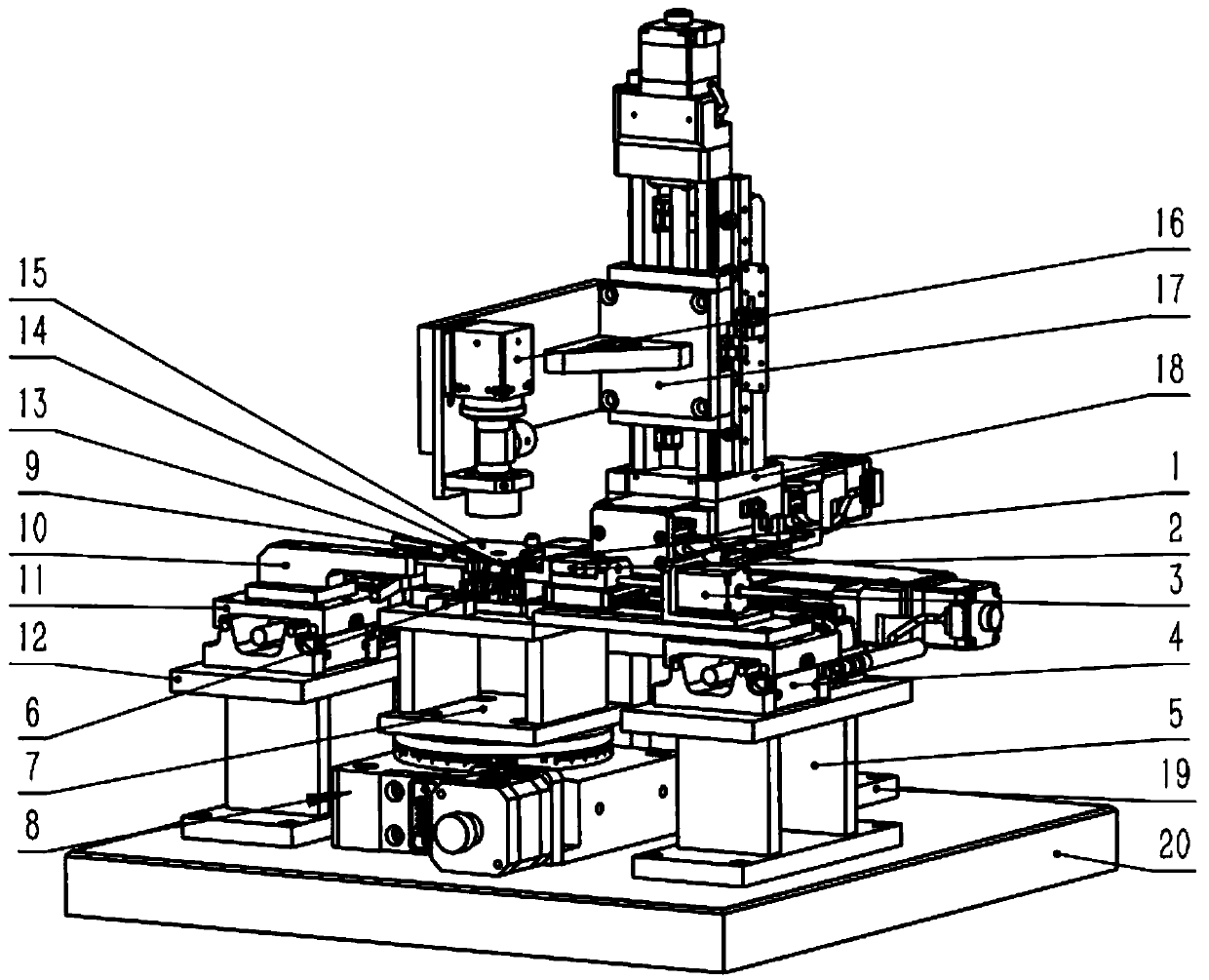

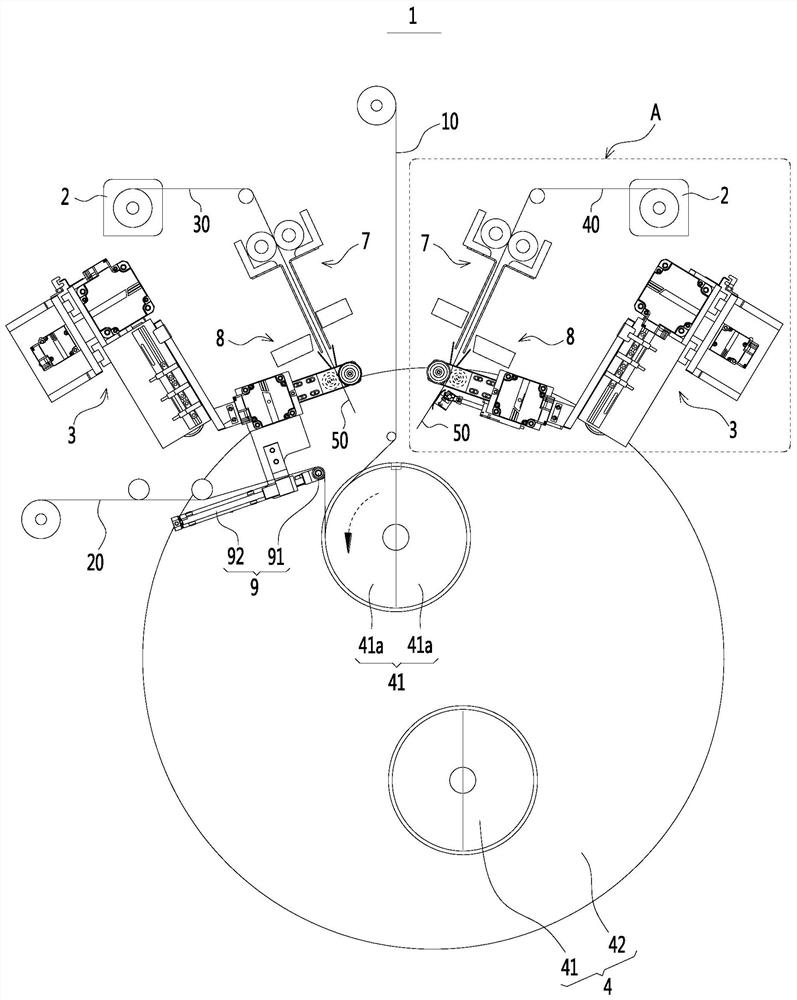

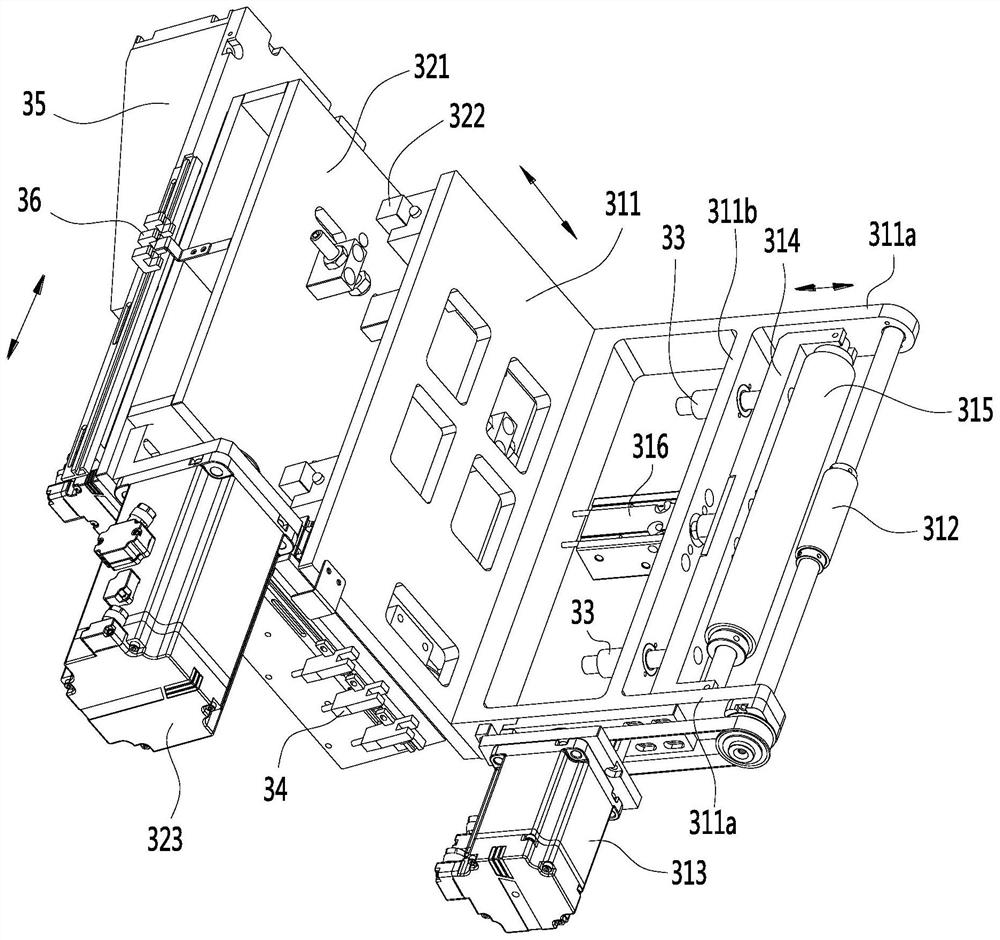

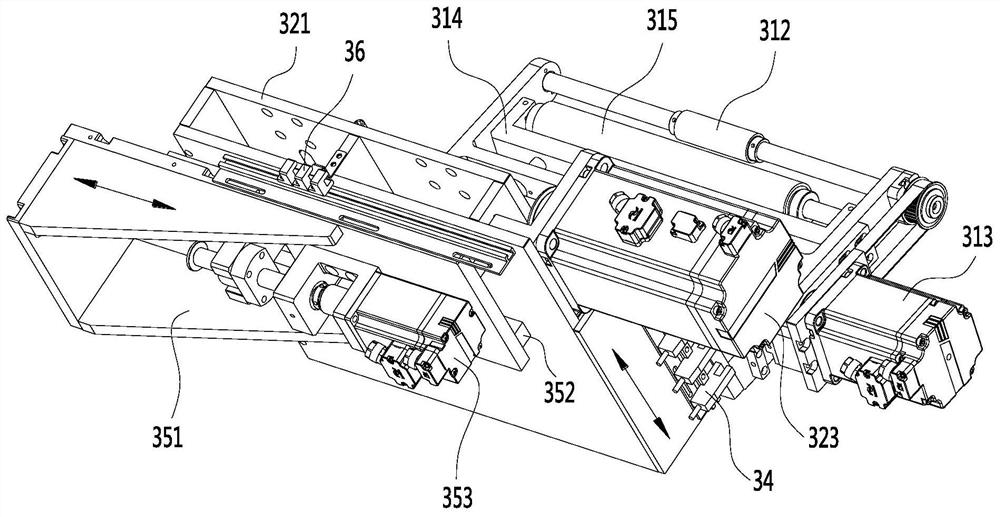

Electrode sheet winding equipment

PendingCN112234260AImprove winding qualityTension is easy to controlFinal product manufactureWound/folded electrode electrodesStructural engineeringMechanical engineering

The invention relates to electrode sheet winding equipment, which comprises: an electrode sheet unwinding device used for driving a material roll to output an electrode sheet to a material receiving position; an electrode sheet feeding device arranged at the downstream of the electrode sheet unwinding device, wherein the electrode sheet feeding device comprises an electrode sheet clamping assemblyand a driving assembly, the electrode sheet clamping assembly is connected with the driving assembly, and the electrode sheet feeding device can clamp the roll-in section of the electrode sheet at the material receiving position through the electrode sheet clamping assembly; and drives the electrode sheet clamping assembly to reciprocate between the material receiving position and the material feeding position through the driving assembly; and an electrode sheet winding device arranged at the downstream of the electrode sheet feeding device, wherein the electrode sheet winding device comprises a winding needle for winding the electrode sheet, and at the feeding position, the electrode sheet feeding device can directly convey the roll-in section to the winding needle. According to the electrode sheet winding equipment, it can be guaranteed that the roll-in section of the electrode sheet has controllable tension force, and the possibility that the roll-in section is prone to displacement, bending, folding and the like when entering a winding needle is reduced.

Owner:CONTEMPORARY AMPEREX TECH CO

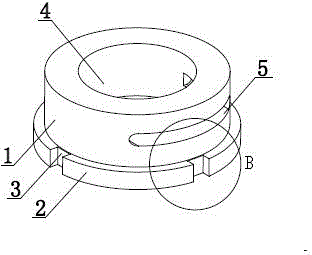

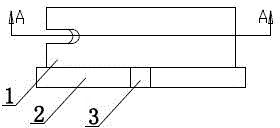

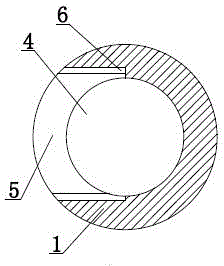

Transmission adjustment device for printing machine

InactiveCN104691090ATension is easy to controlEasy to installRotary pressesTitanium metalEngineering

The invention discloses a transmission adjustment device for a printing machine. The transmission adjustment device comprises a driving cap body made of titanium metal materials, and the driving cap body is in a cylindrical shape; a mounting hole is formed in the middle of a shaft of the driving cap body and is in a cylindrical shape; an adjusting ring is arranged on the peripheral surface of the bottom of the driving cap body; a plurality of tooth grooves which are formed at equal intervals are formed in the peripheral surface of the adjusting ring, and the cross sections of the tooth grooves are in a U shape; and an open groove is formed in the middle position of the peripheral surface of the driving cap body and is communicated with the mounting hole. The transmission adjustment device can be conveniently arranged at the shaft ends of transmission rollers in a sleeving manner, and through matching of the tooth grooves and protruding teeth of the adjacent transmission rollers, meshing is achieved; the tension force between the transmission rollers is adjusted by adjusting the meshing distance between the tooth grooves and the protruding teeth.

Owner:袁国梁

Soldering strip production line

InactiveCN102994933AControl tensionTension is easy to controlHot-dipping/immersion processesMolding machineTin plating

The invention discloses a soldering strip production line. The production line comprises a soldering strip forming mechanism and a soldering strip tin-plating mechanism; the soldering strip forming mechanism comprises a wire outlet device, a first tension adjusting device, a strip pressing device and an annealing device in turn; the soldering strip tin-plating mechanism comprises a solvent coating device, a tin-plating device, a second tension adjusting device and a winding device in turn and further comprises a connection device arranged between the annealing device and the tin-plating device; the connection device comprises a connection bracket, a first and a second rotating roller rotationally arranged on the connection bracket, a sliding roller arranged on the connection bracket in a sliding manner, a tension control device and an induction device arranged on the connection bracket. The soldering strip forming mechanism and the soldering strip tin-plating mechanism are directly connected through the connection device, so that original wire winding devices and wire unwinding devices are omitted, the production efficiency is enhanced and the production cost is reduced; and meanwhile, the connection device is provided with the tension control device, so that the tension of the copper strips is conveniently controlled and the quality of the products is enhanced.

Owner:江苏亿欣新材料科技股份有限公司

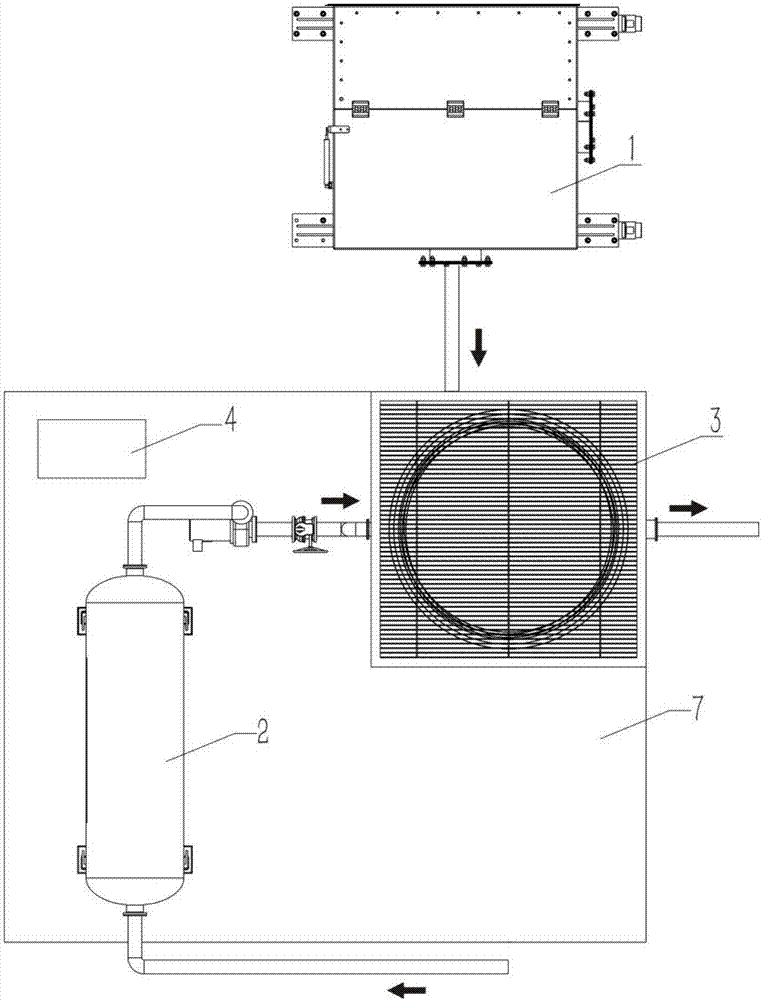

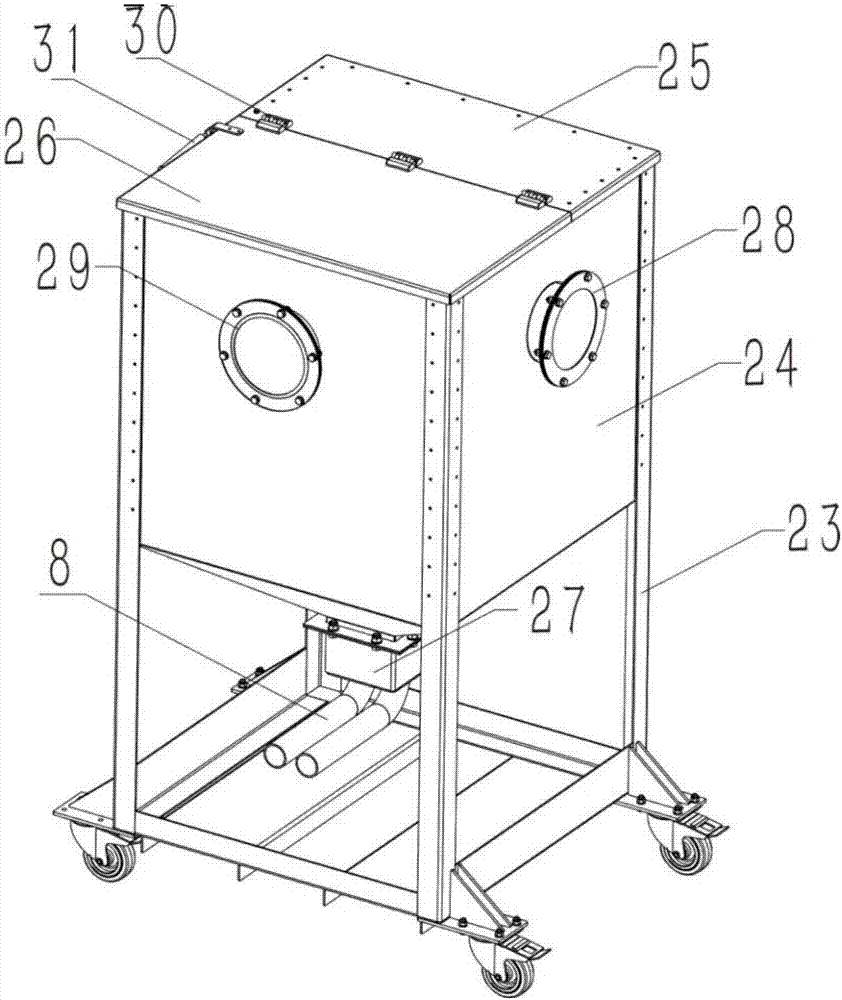

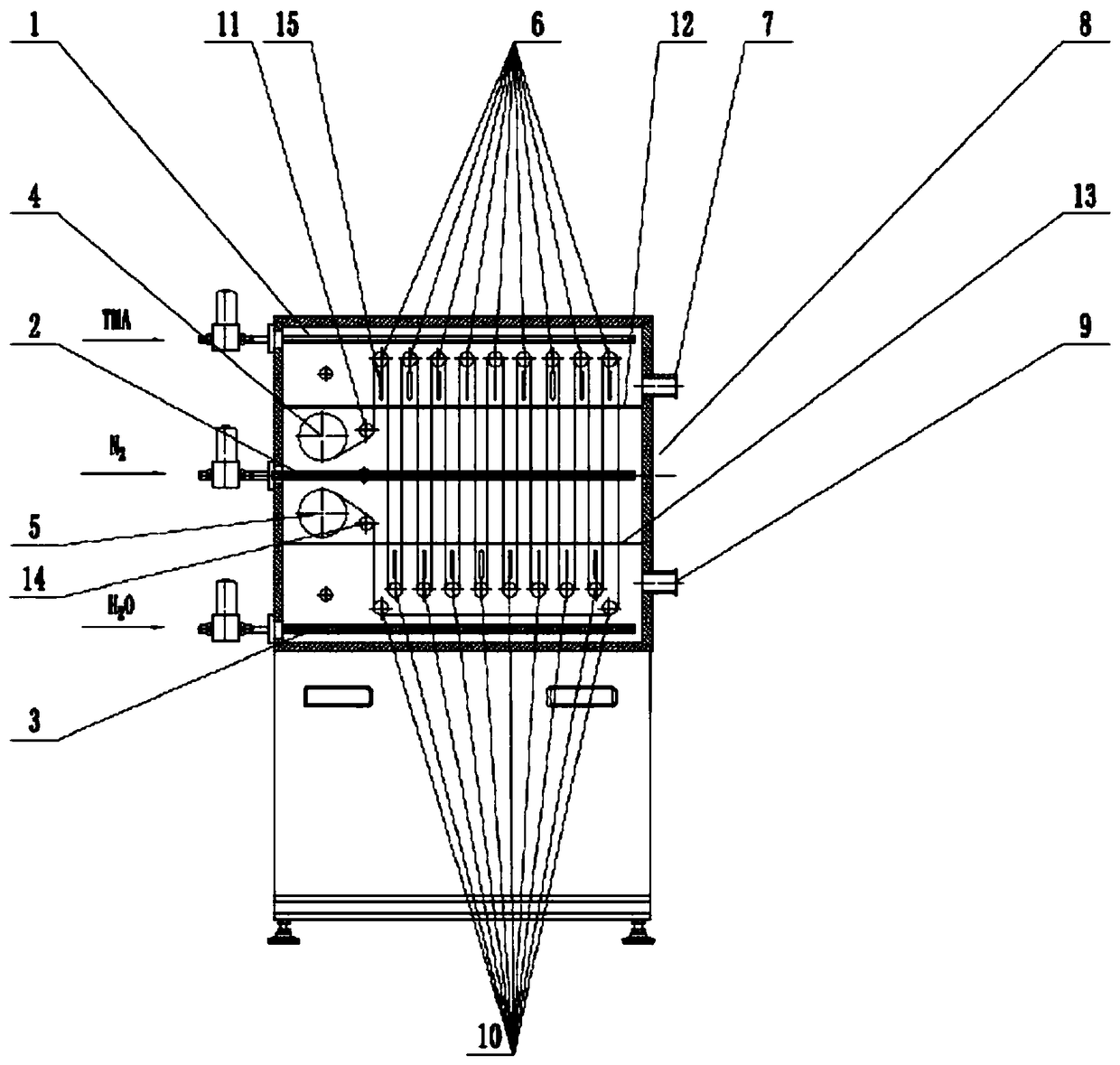

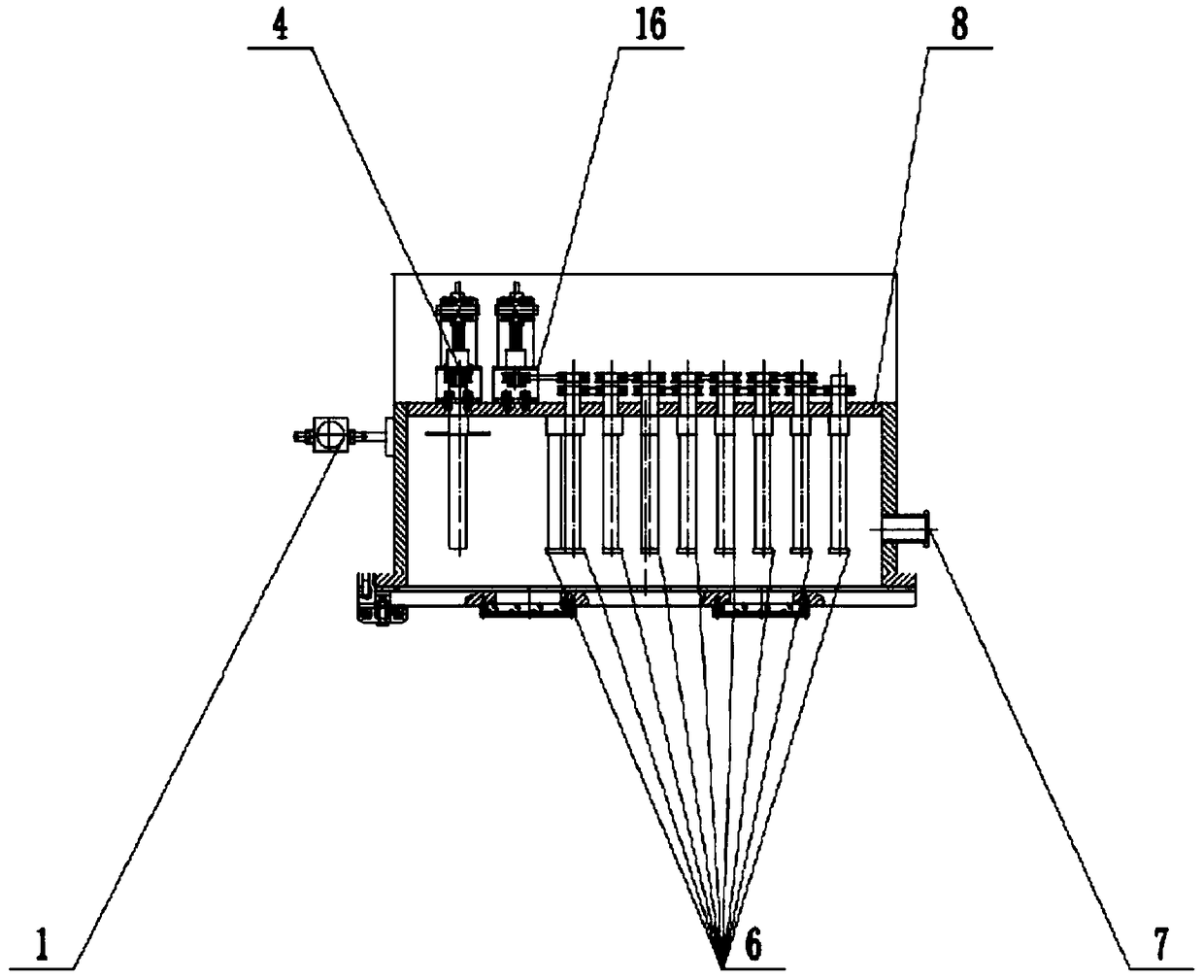

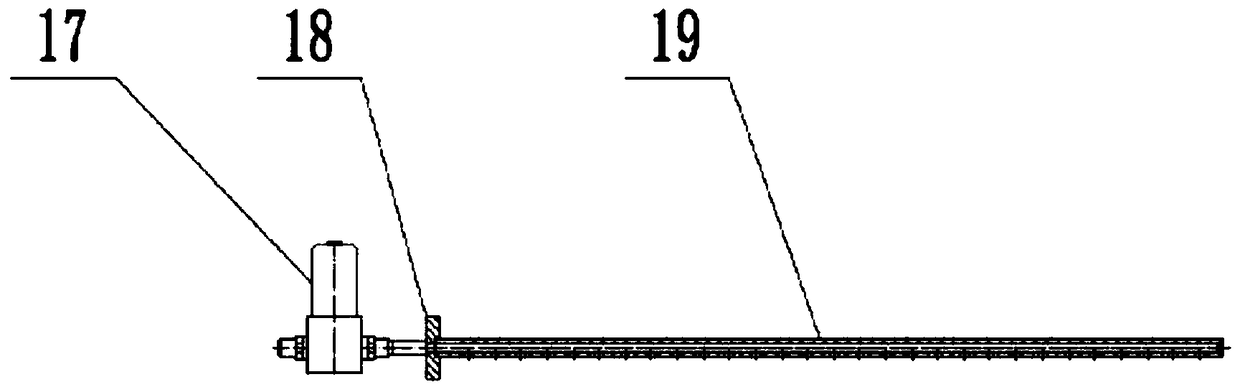

Reeling device for atomic layer deposition based continuous double-sided coating film

PendingCN109082648AEvenly distributedUniform depositionChemical vapor deposition coatingEngineeringChange positions

The invention discloses a reeling device for atomic layer deposition based continuous double-sided coating film. The reeling device comprises a box body divided into a first area, a second area and athird area inside sequentially; unreeling rolls, first transitional rolls, a first gas inlet system and a first heater are arranged in the first area, a second gas inlet system is arranged in the second area, reeling rolls, second transitional rolls, a third gas inlet system and a second heater are arranged in the second area; the unreeling rolls and the reeling rolls are respectively used for unreeling and reeling a base band; the first transitional rolls and the second transitional rolls are used for supporting direction-changing position of the base band; the first gas inlet system, the second gas inlet system, and the third gas inlet system all extend into an gas homogenizing pipe; and the first area, the second area and the third area in the box body are provided with gas outlets respectively. With the gas homogenizing pipe, gas is distributed uniformly when introducing into the box body, so that reaction efficiency is improved and the atomic layer deposition is more uniform.

Owner:BEIJING UNIV OF TECH

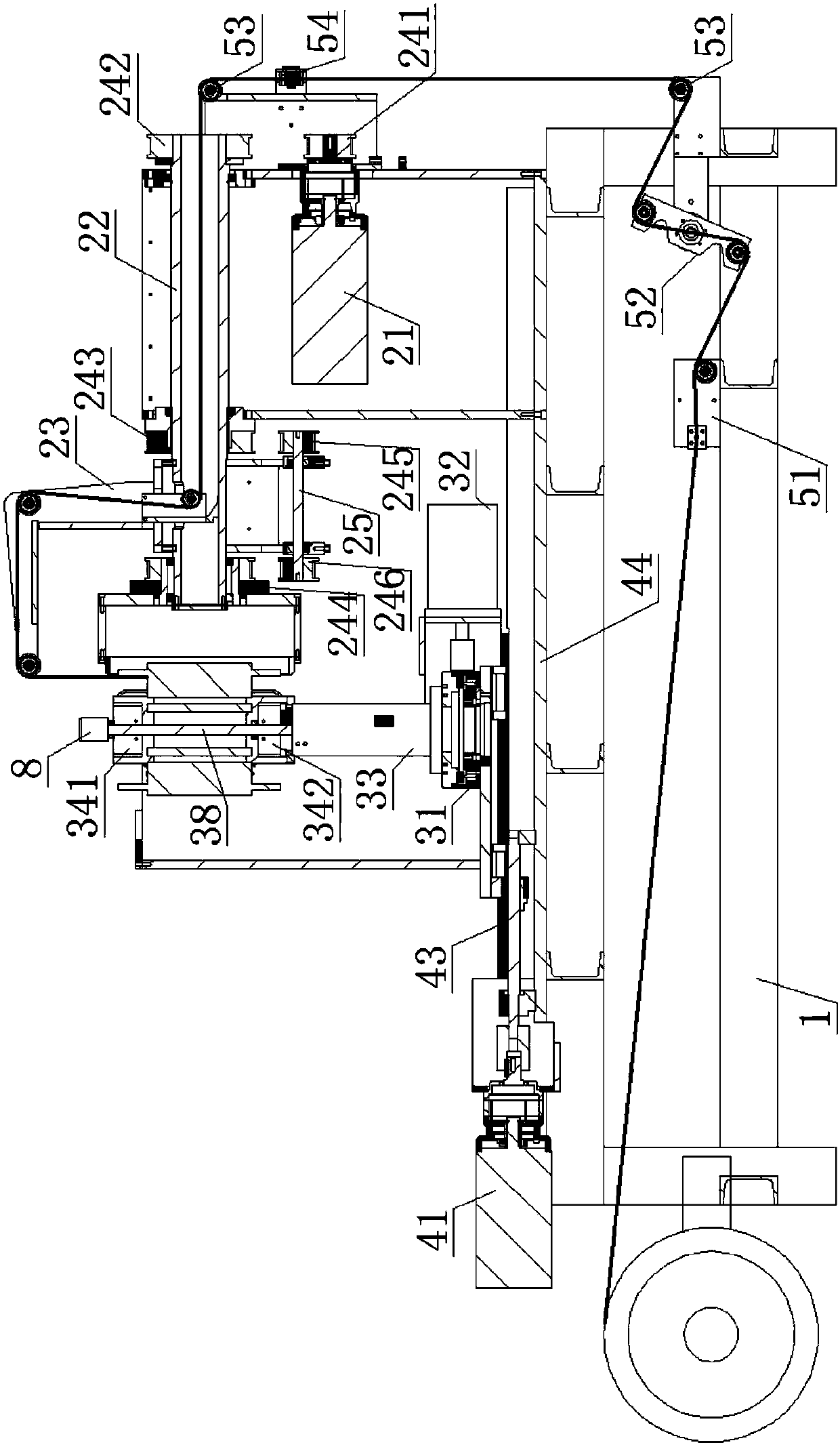

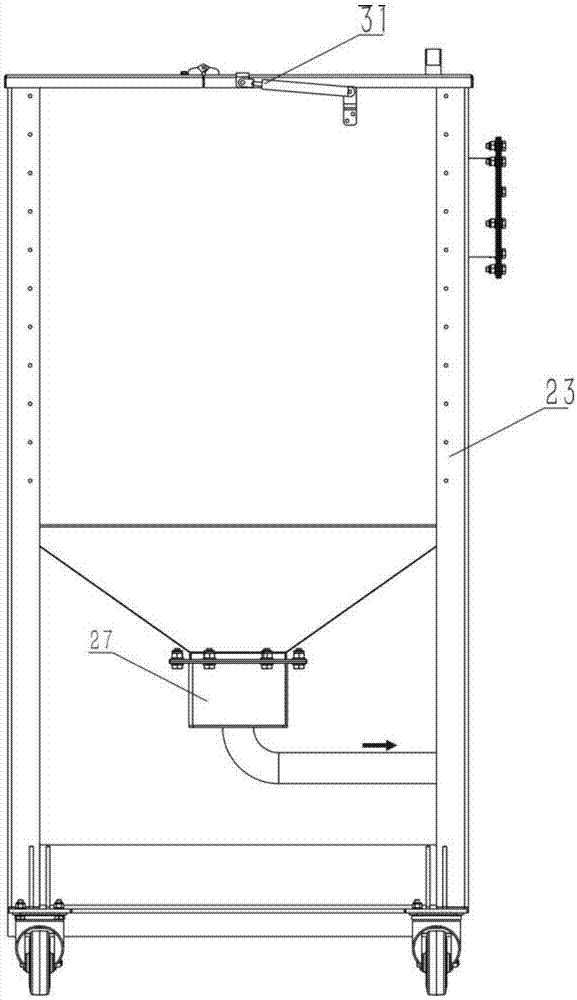

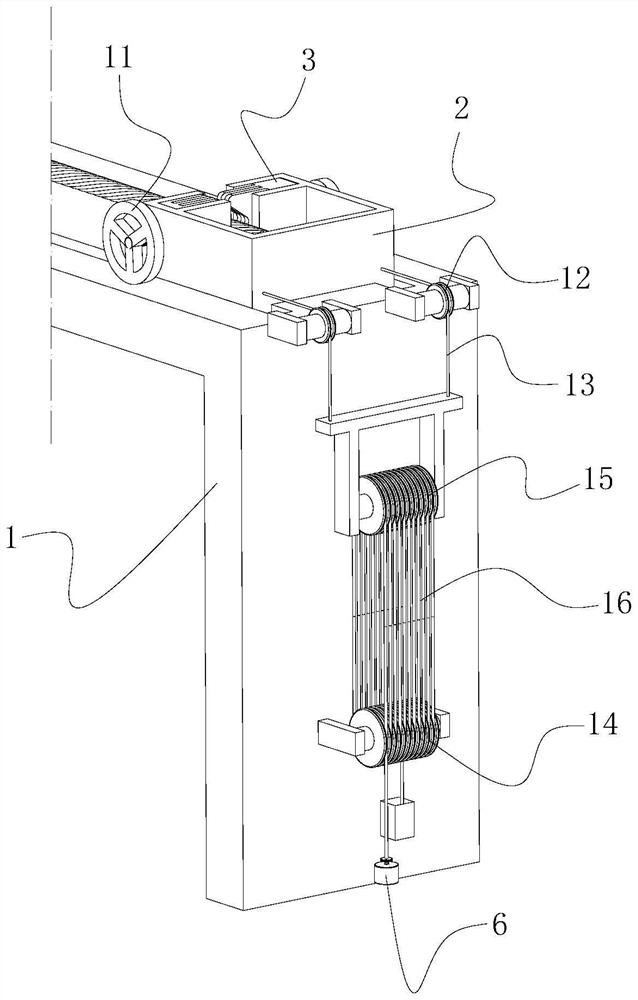

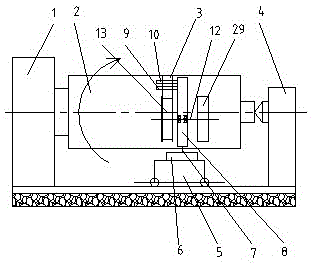

Floating pipe water-cloth binding equipment

The invention relates to manufacturing equipment of a floating pipe in the field of pipeline manufacture and particularly relates to floating pipe water-cloth binding equipment which is used for binding water cloth on the surface of a floating pipe. According to an existing manufacturing process of the floating pipe, especially before the vulcanization is carried out, stuck raw rubber needs to be fixed and pressed, water-cloth binding is adopted as a generally-adopted method, a used device is a simple device, tension is controlled by manual operation in binding of the water cloth, since the tension is perceived by hand feeling of workers in manual operation, the error is large, and the thickness error of the vulcanized rubber is large, so that the quality of the floating pipe is seriously influenced. The water-cloth binding equipment overcomes the defects in an existing process, and has the advantages that the continuous mechanical production in the binding of the water cloth can be well realized, the productivity is high, the operation is convenient, the labor intensity of the workers is low, and the tensioning force of the water cloth is controllable, adjustable and perceived.

Owner:ZHENJIANG COLLEGE

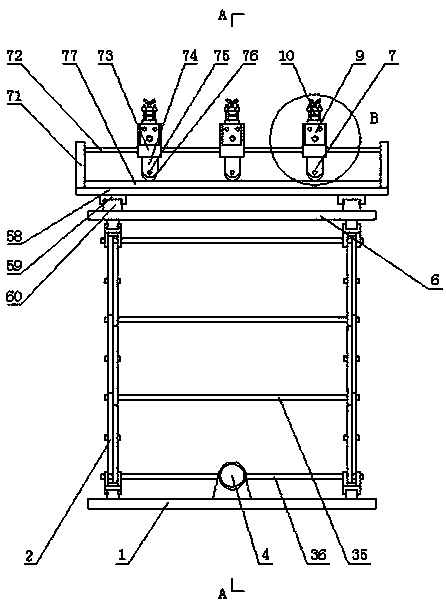

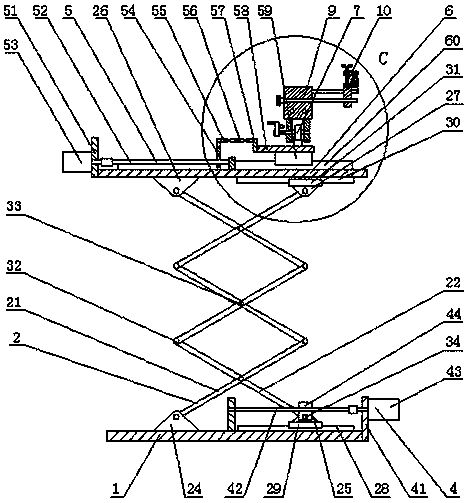

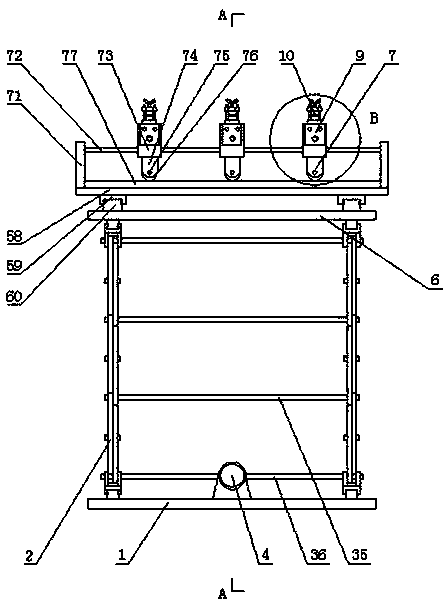

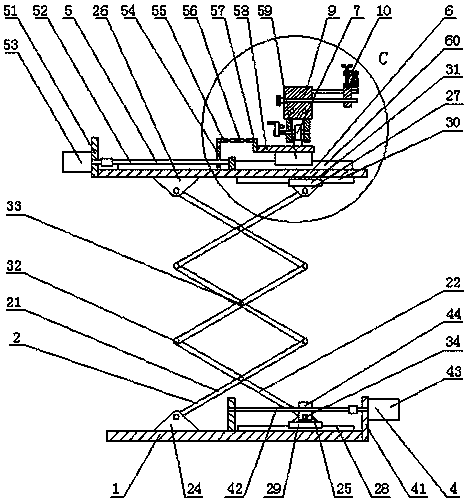

Building membrane traction device and using method thereof

ActiveCN110924609ASolve the dangerSolve efficiency problemsRoof toolsArchitectural engineeringStructural engineering

The invention discloses a building membrane traction device and a using method thereof. The building membrane traction device comprises a bottom plate, wherein a lifting frame is mounted on the uppersurface of the bottom plate; a driving mechanism is connected with the bottom of the lifting frame and drives the lifting frame to go up and down; a lifting platform is connected with the upper part of the lifting frame; a traction mechanism is mounted on the upper surface of the lifting platform; a transverse adjusting mechanism is mounted above the traction mechanism and is used for adjusting the transverse position of a building membrane clamping point; a plurality of boundary adjusting mechanisms are mounted above the transverse adjusting mechanism and are used for adjusting the front-backposition of the building membrane clamping point to meet the clamping requirement of building membranes with irregular boundary shapes; and a clamping mechanism is mounted above the boundary adjusting mechanisms. The building membrane traction device aims to solve the problems that manual traction is needed when the building membrane is mounted at present, as a result, dangers are likely to takeplace, the working efficiency is low, and the building membrane has an irregular shape and is difficult to be clamped.

Owner:LUDONG UNIVERSITY

A micro-glass tube automatic threading and centering device and method

ActiveCN109664241BImprove assembly efficiencyAvoid errorsMetal-working hand toolsAccelerometerAutomatic control

The invention belongs to the technical field of automatic assembly of precision micro parts, and relates to an automatic wire passing and aligning device and method for a micro glass tube. The deviceuses a technology of automatically wire passing and aligning for a micro-miniature accelerometer inertia pendulum part suspension wire and the glass tube. The middle part of the device is a glass tubeclamp installing and adjusting mechanism, a suspension wire aligning mechanism and a wire passing and aligning mechanism are arranged at the two sides of the glass tube clamp installing and adjustingmechanism respectively, a visual measurement module is at the rear side, the bottoms of the four parts are all installed on a platform, the wire passing and aligning mechanism and the visual measurement module are connected with a PC respectively, and therefore automatic control is realized. The device can realize the automatic wire passing and aligning function of the micro glass tube with visible assembly process and controllable passing wire tension.

Owner:DALIAN UNIV OF TECH

A method of manufacturing steel wire for spring with excellent stability and stress resistance

ActiveCN112453080BHigh stability and stress resistanceHigh tensile strengthFurnace typesProcess efficiency improvementProcess designIndustrial engineering

The invention discloses a method for manufacturing steel wires for springs with excellent stability and stress resistance, comprising the following steps: raw material selection: selecting high-carbon steel hot-rolled high-quality wire rods for production; Scale treatment, and use a pre-drawing machine to draw it to the diameter of the pre-drawn semi-finished steel wire required by the process design through a tungsten steel wire drawing die, and then perform preliminary drawing treatment; continuous heat treatment of the semi-finished steel wire: heat the pre-drawn semi-finished steel wire The furnace is subjected to lead bath quenching treatment, and the tensile strength of the semi-finished steel wire after heat treatment is 880-1100MPa. The invention can make the steel wire have high stability and stress resistance, and it is convenient to control the pulling force and tension of drawing to produce carbon fine spring steel wires of different sizes and standards. Mechanical properties and toughness requirements, but also meet mass production and ensure product quality requirements.

Owner:德清林缘金属制品有限公司

A body manufacturing method of an oil-immersed amorphous alloy transformer

ActiveCN104465058BReduce lossGood effectTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLap jointAlloy

The invention discloses a manufacturing method of a transformer body of an oil immersion type amorphous alloy transformer. The manufacturing method includes the following steps: (1) annealing treatment is carried out on iron cores; (2) the iron cores are pushed to the testing position for testing according to the furnace exiting sequence; (3) coils for forming the transformer body of the transformer draw close; (4) iron core jackets are drawn off after the iron cores are pushed into the testing position; (5) packing is carried out; (6) binding is carried out, wherein the binding belt tension ranges from 1500 N to 2500 N according to different weights of the transformer body; (7) after an amorphous sheet layer on the outmost face is closed, a shock pad is placed on the outer face of the amorphous sheet layer, a silicon steel sheet hasp on the outer layer is tightened, the hasp part is firmly glued through adhesive tape, and the adhesive tape is used for firm gluing if the hasp is damaged; (8) the coils are cleaned; (9) the lap joint position is coated with glass cement; (10) upper clamp insulation is arranged, and an upper clamp is installed in place. By means of the manufacturing method, stable-performance annealing parameters can be guaranteed, the fixing effect is improved through an elastic insulation binding belt, and the sound insulation effect and the sound absorption effect can be improved.

Owner:NINGBO AUX HIGH TECH

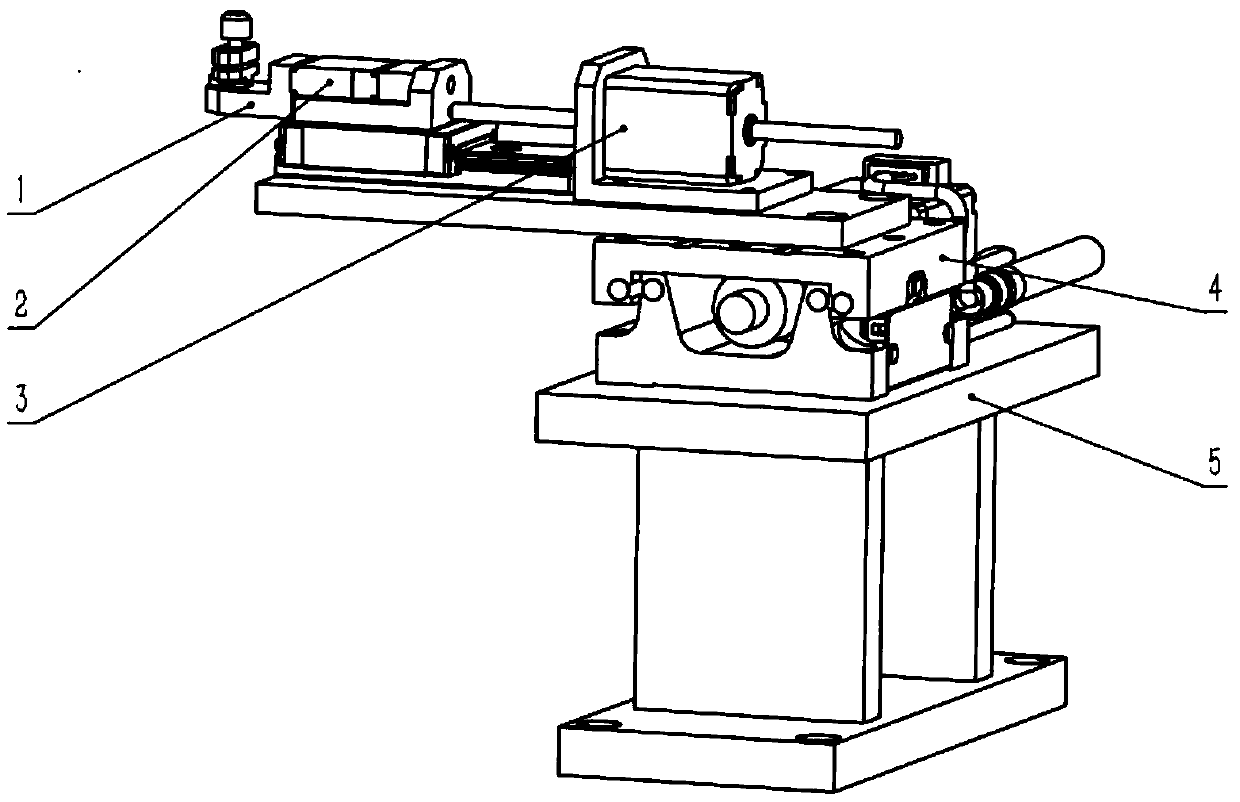

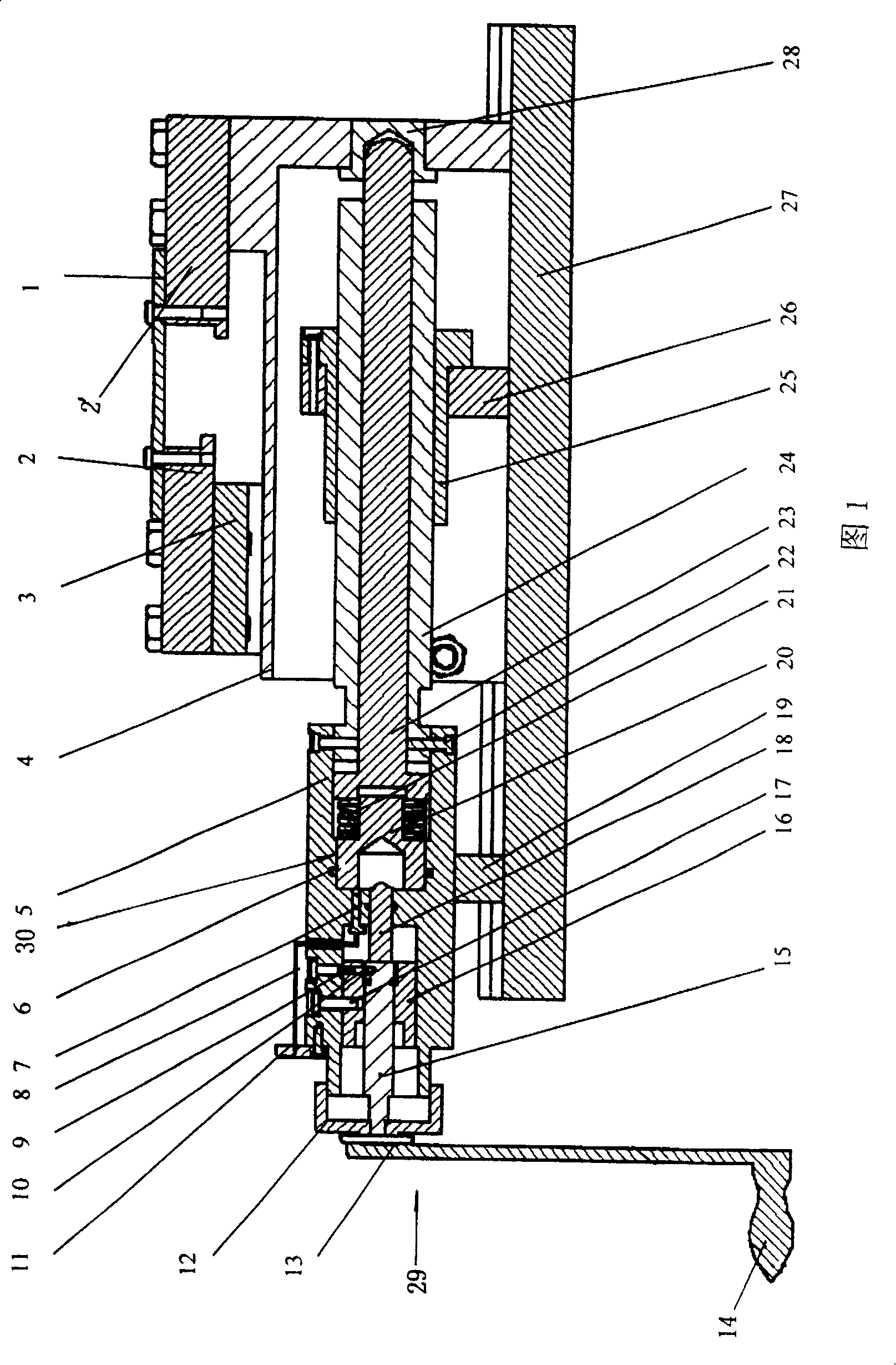

Drawing force controllable manual hydraulic drawing tool

InactiveCN100389931CSolve processing problemsEasy and accurate measurementMetal working apparatusPull forceMachine tool

A stretch force controllable hand operated hydraulic pull tool use as the attachment of machine-tool for applying a stretch force to workpiece is disclosed. It features the combination of mechanical advancing with hydraulic loading.

Owner:NANJING TOOLING

Cloth wrinkle removing treatment device for garment making

InactiveCN114182469AInhibit sheddingImprove the efficiency of leveling and wrinkle removalStretchingMechanical engineeringCotton material

The invention relates to the technical field of garment making, and discloses a cloth wrinkle removing treatment device for garment making, which comprises a shell, a cloth winding mechanism is movably connected in the shell, the cloth winding mechanism comprises a rotating handle, a roller shaft is fixedly connected to the outer surface of the rotating handle, and a rack plate is fixedly connected to one side of the outer surface of the roller shaft. Pressure mechanisms are meshed with the outer surfaces of the rack plates and located on the two sides of the roller shafts, the cloth is wound on the outer surfaces of the roller shafts in a zigzag mode, the length of the cloth leveled at a time can be increased, the number of the roller shafts is two or more, and therefore the cloth is wound on the outer surfaces of the roller shafts in a long length, and the cloth leveling efficiency is improved. By means of the cloth flattening device, long cloth can be flattened at a time, the cloth does not need to be taken down from the device after being stretched, follow-up cloth flattening work can not be completed after position adjustment, the cloth flattening and wrinkle removing efficiency is improved, the time and energy of an operator are saved, and meanwhile the tension of the cloth is easy to control.

Owner:浙江山海数字信息科技有限公司

Kelvin double-arm bridge clamp for cable conductor resistance test

PendingCN114740233ATension is easy to controlReal-time display of tension valueResistance/reactance/impedenceMeasurement instrument housingElectrical resistance and conductanceElectrical conductor

The invention discloses a Kelvin double-arm bridge clamp for cable conductor resistance testing, and belongs to the technical field of cable detection equipment. A horizontal linear guide rail is arranged on a substrate; the two sliding seats are installed on the base plate through horizontal linear guide rails and are arranged close to the two ends of the base plate respectively. Current chucks are respectively arranged on the sliding seats; the pull rod is connected with one end of the substrate and a sliding seat; the tension sensor is arranged between the pull rod and the sliding seat; the balancing weight is connected with the other sliding seat through a stay wire; the insulating cross beam is a beam frame parallel to the horizontal linear guide rails, and the insulating cross beam is arranged between the two sliding seats; the upper end of the vertical pin rod is connected with the insulating cross beam, and the lower end of the vertical pin rod is mounted on the substrate; the vertical pin rod is sleeved with the spring, and the spring transversely applies upward elastic force to the insulator. The potential contact heads are provided with V-shaped contact grooves, and the two potential contact heads are arranged on the two sections of the insulating cross beam respectively. According to the device, the traction tension of the sample conductor can be adjusted and controlled, and the cable cannot be damaged.

Owner:天津福尔欣汽车线缆有限公司

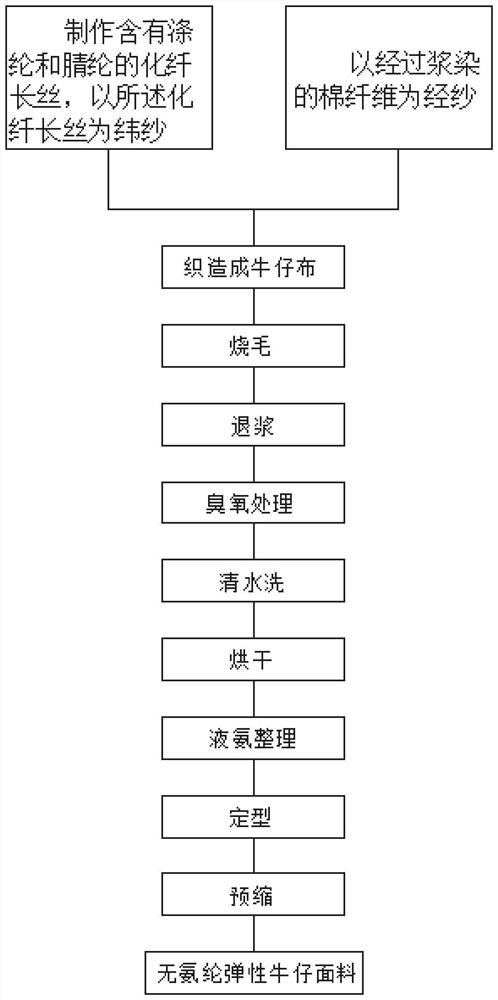

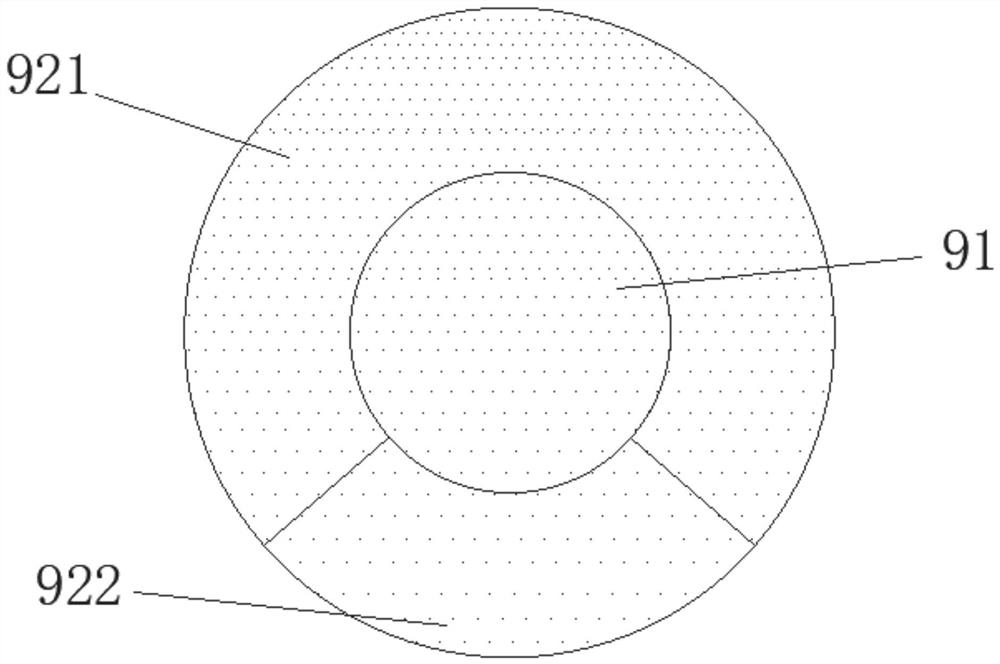

Spandex-free elastic denim fabric manufacturing method and denim fabric

PendingCN114717717AImprove water absorptionTension is easy to controlFilament/thread formingArtificial filament heat treatmentPolyesterCotton fibre

The invention discloses a spandex-free elastic denim fabric manufacturing method and denim fabric, and belongs to the field of spinning, the manufacturing method comprises the following steps: manufacturing chemical fiber filaments containing terylene and acrylic fibers, using the chemical fiber filaments as weft yarns, using sizing-dyed cotton fibers as warp yarns, and weaving into denim, denim is sequentially subjected to singeing, desizing, ozone treatment, clean water washing, drying, liquid ammonia finishing, shaping and preshrinking, and the spandex-free elastic denim fabric is obtained. According to the manufacturing method, covering yarns are not used as raw materials, spandex is not used, chemical fiber filaments containing polyester and acrylic fibers are used as weft yarns with certain elasticity, cotton fibers are used as warp yarns, and after ozone treatment, the spandex-free elastic denim fabric is obtained. After liquid ammonia finishing, the cotton fibers also have elasticity, acrylic fibers in the chemical fiber filaments are curled to form water guide channels, polyester provides certain elasticity, the fabric has certain elasticity in the warp direction and the weft direction, and the fabric has the advantages of being breathable and slightly elastic.

Owner:GUANGDONG FORWARD DENIM

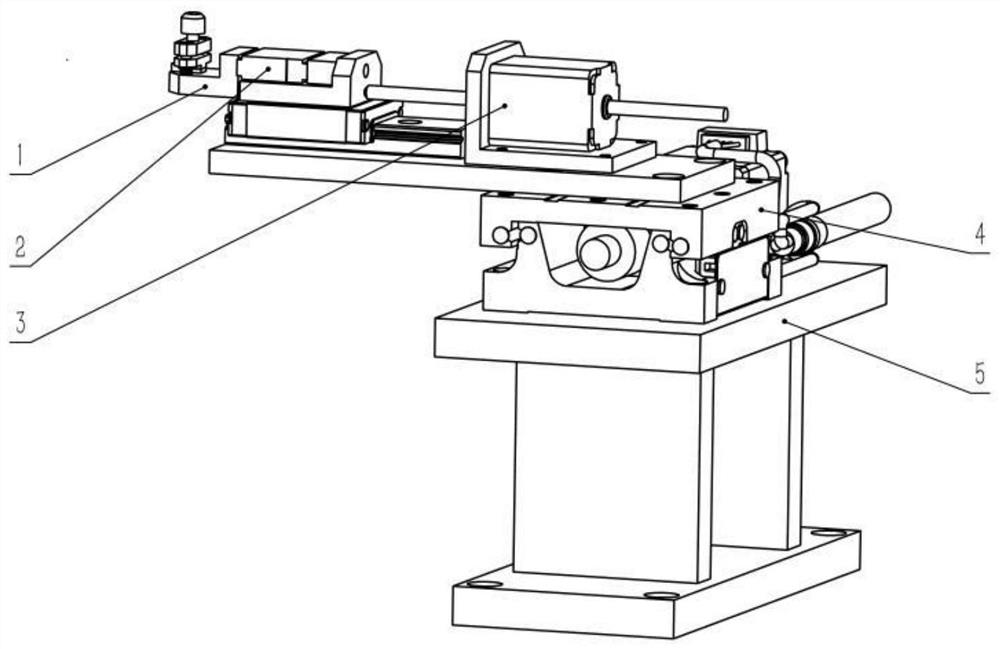

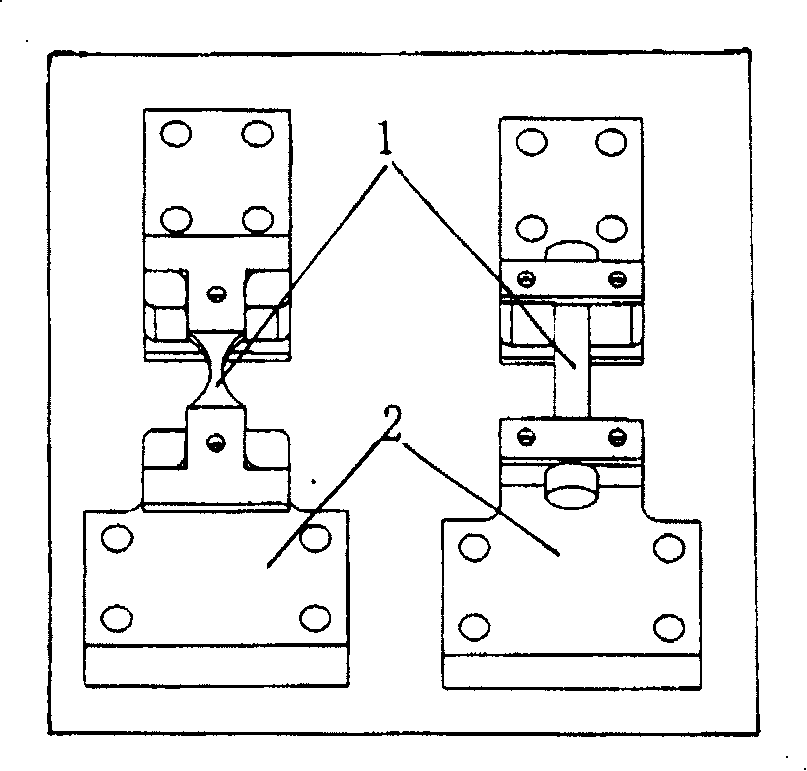

Sample preparing and tensioning equipment for performance testing of tensile sample strip of carbon fiber multifilament

PendingCN113495026AAchieve tensionReduce tensionPreparing sample for investigationMaterial strength using tensile/compressive forcesFiberCarbon fibers

The invention relates to sample preparing and tensioning equipment for performance testing of a tensile sample strip of a carbon fiber multifilament. The equipment comprises a horizontally arranged bottom plate, wherein a stretching module is arranged on the bottom plate and comprises a first pressing assembly and a second pressing assembly which are used for fixing a carbon fiber tow; a sliding assembly is arranged below at least one of the first pressing assembly and the second pressing assembly so as to allow the pressing assembly provided with the sliding assembly to move in the extending direction of the carbon fiber tow, and the end, where the movable pressing assembly is located, of the stretching module is a stretching end; a transmission structure and a driving device are arranged on the bottom plate, and the transmission structure is in transmission connection with the stretching end of the stretching module; and the output end of the driving device is in transmission connection with one end of the transmission structure. According to the equipment provided by the invention, the carbon fiber tow can be conveniently tensioned, and the tensioned carbon fiber tow can be conveniently subjected to dipping treatment, so the standard of a manufactured test sample piece is ensured, and the accuracy of a test result of the test sample piece is ensured.

Owner:大工碳鼎科技洛阳有限公司

A kind of inflatable film reflector and its assembly tooling and assembly method

InactiveCN104570176BEvenly tautTension is easy to controlMirrorsMountingsThin membraneMechanical engineering

The invention provides an inflatable film reflector and its assembly tool and assembly method. The film reflector is composed of a clip, a main mirror frame, a main mirror pressure plate, a polyimide film and a sealing ring: the assembly tool includes a connecting Frame, pressing plate, film frame, gland, nylon rope; the assembly method steps of described assembly tooling are as follows: the connection frame is fixed on the main mirror frame; The position of the main mirror pressing plate, pressing plate and film frame is fastened; The two films are tied to the film frame respectively, and the tension of the film is controlled by tightening the nylon rope, and the film is evenly tightened; the film frame is fastened to the gland, and then the gland is fastened to the connecting frame; finally Press the pressing plate, the main mirror pressing plate and the film tightly on the main mirror frame. The invention realizes the effective control of the ideal surface shape of the thin film by using the assembly tool, and improves the surface shape precision of the thin film reflector.

Owner:BEIJING SIMULATION CENT

Pushing and drawing force testing machine

InactiveCN101871830BTension is easy to controlEasy to operateStatic/dynamic balance measurementShock testingPull forceElectronic equipment

The invention relates to a pushing and drawing force testing machine which is used for testing pushing force or drawing force for electronic equipment. The pushing and drawing force testing machine comprises a supporting device, a pushing and drawing force switching mechanism, a force application device and a rope, wherein the pushing and drawing force switching mechanism is fixed on the supporting device; the force application device is used for controlling the magnitude of output acting force; the rope is connected with the force application device and the pushing and drawing force switching mechanism; the pushing and drawing force switching mechanism comprises an actuating rod and a connecting component, wherein the actuating rod is butted with the electronic equipment or is connected with the electronic equipment through a connecting piece, and the connecting component is connected with the actuating rod and is provided with a first clamping column; and the force application device draws the rope to enable the actuating rod of the pushing and drawing force switching mechanism to push or draw the electronic equipment in a sliding way. The pushing and drawing force testing machine has the advantages of convenient operation and high reliability of test results.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Floating net cage underwater easily disassembled binding structure

ActiveCN105494178BEasy to operateEasy to break awayClimate change adaptationPisciculture and aquariaMooring systemUnderwater

The invention provides a floating type net cage underwater quick detachable binding structure and belongs to the field of net cages. Concretely, a guide rope is arranged outside the net cage; one end of the guide rope is tied to a floating pipe or a net rib on the upper end of the net cage and the other end is tied to a net rib on the bottom end of a mesh; the end part of a mooring cable of a mooring system is provided with a lifting hook sleeved on the guide rope; the bottom end net rib close to the guide rope is tied with a sinker; and a position on the mooring cable and close to the lifting hook is provided with a sinker or a gravity rope knot. When unfixation is required, a user on the water can insert a hook rod into the water to hook the mooring cable, so the mooring cable can be hooked to the water surface; and the net cage can be unfixed.

Owner:威海晟龙明科机电设备有限公司

Floating pipe water cloth equipment

InactiveCN103640238BRealize continuous mechanized productionTension is easy to controlTubular articlesProduction ratePipe water

The invention relates to manufacturing equipment of a floating pipe in the field of pipeline manufacture and particularly relates to floating pipe water-cloth binding equipment which is used for binding water cloth on the surface of a floating pipe. According to an existing manufacturing process of the floating pipe, especially before the vulcanization is carried out, stuck raw rubber needs to be fixed and pressed, water-cloth binding is adopted as a generally-adopted method, a used device is a simple device, tension is controlled by manual operation in binding of the water cloth, since the tension is perceived by hand feeling of workers in manual operation, the error is large, and the thickness error of the vulcanized rubber is large, so that the quality of the floating pipe is seriously influenced. The water-cloth binding equipment overcomes the defects in an existing process, and has the advantages that the continuous mechanical production in the binding of the water cloth can be well realized, the productivity is high, the operation is convenient, the labor intensity of the workers is low, and the tensioning force of the water cloth is controllable, adjustable and perceived.

Owner:ZHENJIANG COLLEGE

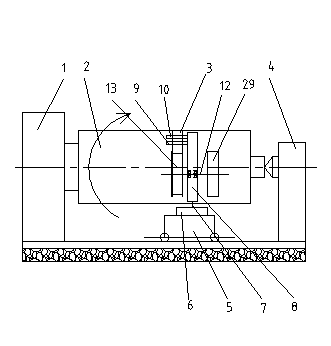

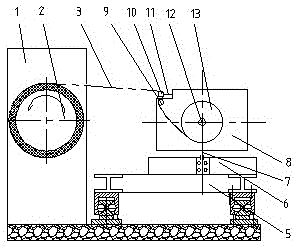

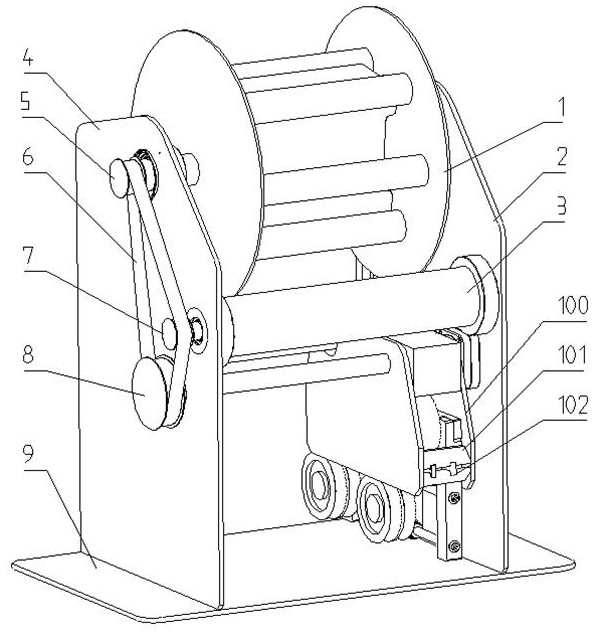

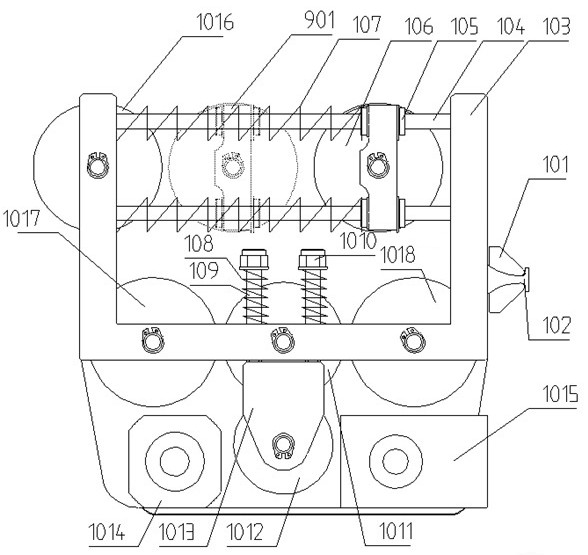

Controllable tension take-up and pay-off device and take-up and pay-off method

The invention discloses a controllable tension take-up and pay-off device and a take-up and pay-off method. The controllable tension take-up and pay-off device comprises a support, an electric slip ring cable roller (1), a cable arranging assembly (100) and a servo motor set (3); the support comprises a bottom plate (9), and a left mounting plate (2) and a right mounting plate (4) are mounted on the bottom plate (9); the electric slip ring cable roller (1) is installed on the top of the support through a spool belt wheel (5); the cable arranging assembly (100) is installed at the bottom of the support, and the right side of the cable arranging assembly (100) is fixedly connected with a cable arranging belt wheel (8); and the servo motor set (3) is installed in the middle of the support, the right side of the servo motor set (3) is fixedly connected with a driving belt wheel (7), and the driving belt wheel (7), the spool belt wheel (5) and the cable arranging belt wheel (8) are connected together through a transmission belt (6) to be in linkage. The tension on a cable can be kept stable, the state of the cable is controllable during paying-off, the paying-off speed on a cable disc can be sensed, and the situation that the rotating speed of a motor on a spool cannot be accurately controlled to be matched with the paying-off speed due to the fact that the winding radius of a cable on the spool changes all the time in the take-up and paying-off process is avoided.

Owner:北京军立方机器人科技有限公司

Soldering strip production line

InactiveCN102994933BControl tensionTension is easy to controlHot-dipping/immersion processesProduction lineTin plating

The invention discloses a soldering strip production line. The production line comprises a soldering strip forming mechanism and a soldering strip tin-plating mechanism; the soldering strip forming mechanism comprises a wire outlet device, a first tension adjusting device, a strip pressing device and an annealing device in turn; the soldering strip tin-plating mechanism comprises a solvent coating device, a tin-plating device, a second tension adjusting device and a winding device in turn and further comprises a connection device arranged between the annealing device and the tin-plating device; the connection device comprises a connection bracket, a first and a second rotating roller rotationally arranged on the connection bracket, a sliding roller arranged on the connection bracket in a sliding manner, a tension control device and an induction device arranged on the connection bracket. The soldering strip forming mechanism and the soldering strip tin-plating mechanism are directly connected through the connection device, so that original wire winding devices and wire unwinding devices are omitted, the production efficiency is enhanced and the production cost is reduced; and meanwhile, the connection device is provided with the tension control device, so that the tension of the copper strips is conveniently controlled and the quality of the products is enhanced.

Owner:江苏亿欣新材料科技股份有限公司

A construction film traction device and method of using the same

ActiveCN110924609BTension is easy to controlAvoid damageRoof toolsExtraordinary structuresArchitectural engineeringStructural engineering

The invention discloses a building membrane traction device and a using method thereof. The building membrane traction device comprises a bottom plate, wherein a lifting frame is mounted on the uppersurface of the bottom plate; a driving mechanism is connected with the bottom of the lifting frame and drives the lifting frame to go up and down; a lifting platform is connected with the upper part of the lifting frame; a traction mechanism is mounted on the upper surface of the lifting platform; a transverse adjusting mechanism is mounted above the traction mechanism and is used for adjusting the transverse position of a building membrane clamping point; a plurality of boundary adjusting mechanisms are mounted above the transverse adjusting mechanism and are used for adjusting the front-backposition of the building membrane clamping point to meet the clamping requirement of building membranes with irregular boundary shapes; and a clamping mechanism is mounted above the boundary adjusting mechanisms. The building membrane traction device aims to solve the problems that manual traction is needed when the building membrane is mounted at present, as a result, dangers are likely to takeplace, the working efficiency is low, and the building membrane has an irregular shape and is difficult to be clamped.

Owner:LUDONG UNIVERSITY

Chain Pretensioner

The invention discloses a chain pre-tensioning device, which comprises a bottom plate, a pre-tensioning oil cylinder, a tension sensor, a movable insertion plate fixing seat, a movable insertion plate oil cylinder, a movable insertion plate, a pre-tensioning runway, a fixed insertion plate, a fixed insertion plate seat, a fixed insertion plate oil cylinder, a pre-tensioning oil cylinder position limiting sleeve, a pre-tensioning material guiding chain wheel and a displacement sensor. The movable insertion plate and the fixed insertion plate are inserted into a chain, and the pre-tensioning oil cylinder is tensioned, so the chain is tensioned, and the chain is enabled to maintain the tensioning state in the use process. Through adopting the mode, the chain pre-tensioning device has the advantages that the reliability performance is high, the positioning is precise, the structure is compact, the stretching effect is good, the tension force is controllable, the finished product quality is stable, the process is simple, the adaptability is good, and wide market prospects are realized in chain transmission manufacturing industry.

Owner:SUZHOU SHUNGE INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com