Drawing force controllable manual hydraulic drawing tool

A controllable, tensile force technology, applied in metal processing and other directions, can solve the problem that the puller cannot meet the use requirements, and achieve the effect of compact structure, uniform and stable tensile stress, and easy control of the tensile force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

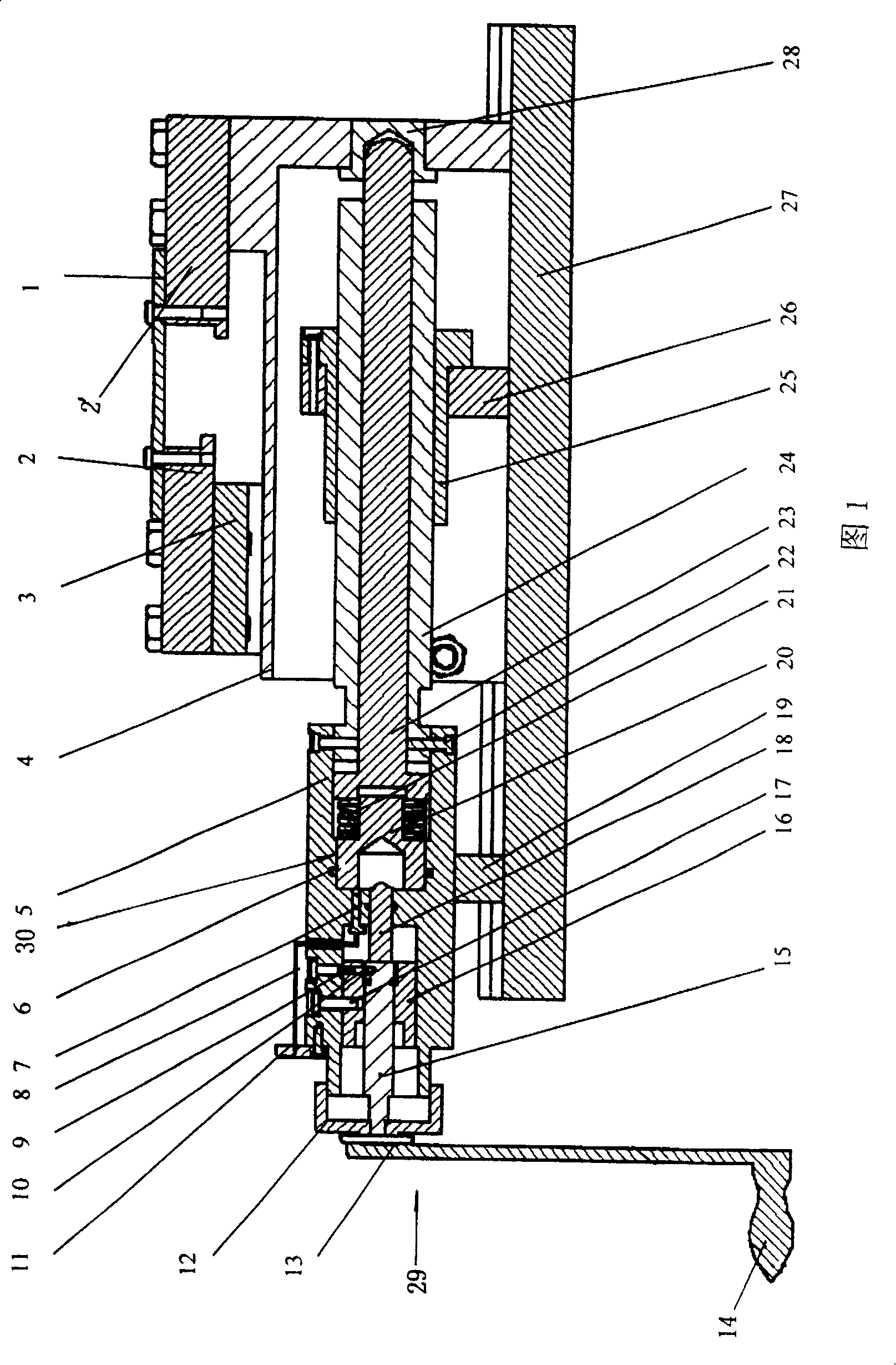

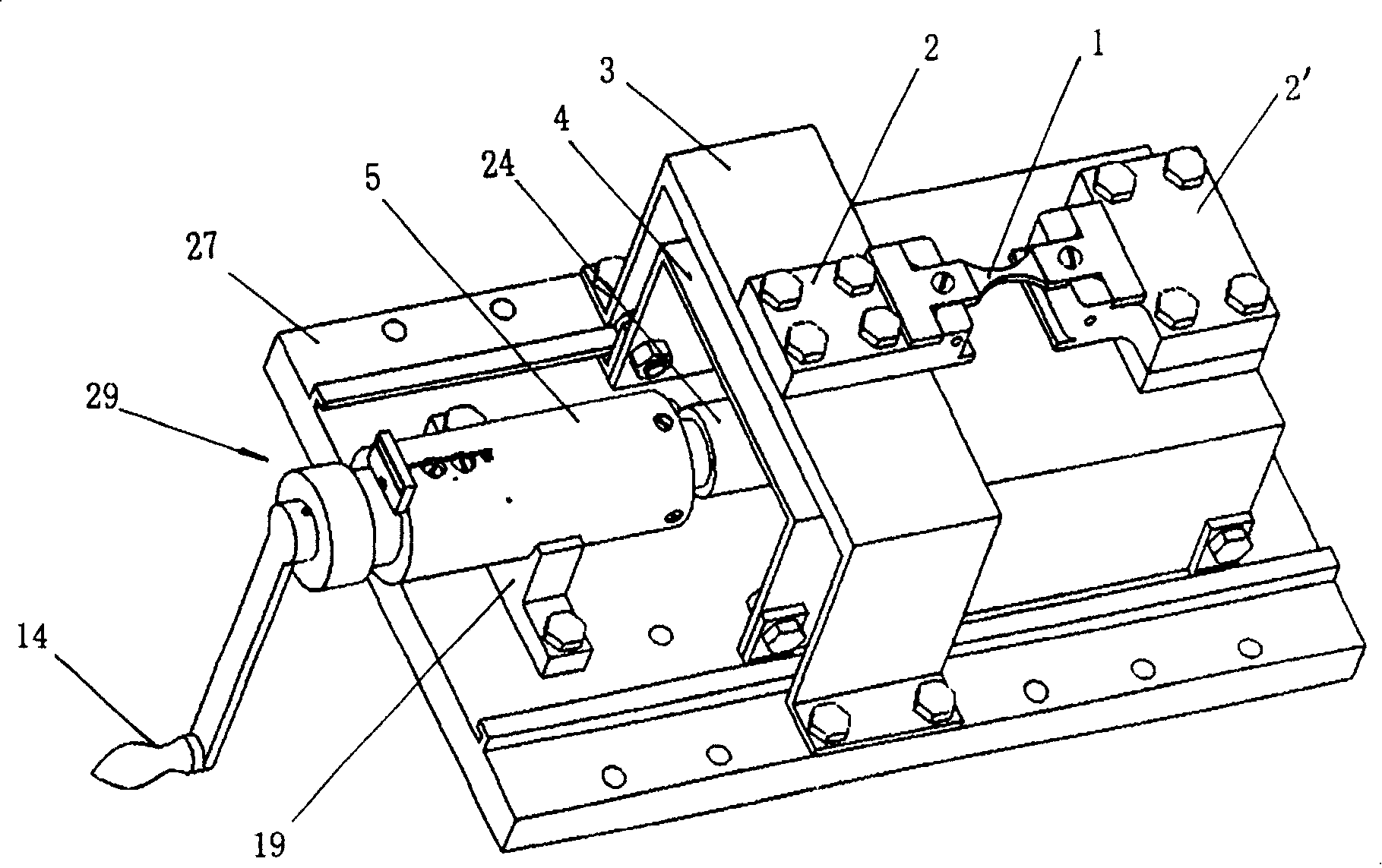

[0028] The following structural drawings and embodiments further illustrate the present invention.

[0029] As shown in Figures 1 and 3.

[0030] A tension controllable manual hydraulic puller, which mainly consists of the following components:

[0031] A base 27, which can be fixedly connected to the machine tool workbench by bolts;

[0032] A fixed clamp body 3 connected to the base 27, the fixed clamp body 3 can be integrally connected with the base 27, and can also be connected by connecting bolts;

[0033] A movable pliers body 4 that can move linearly under the guidance of the base 27 and the fixed pliers body 3;

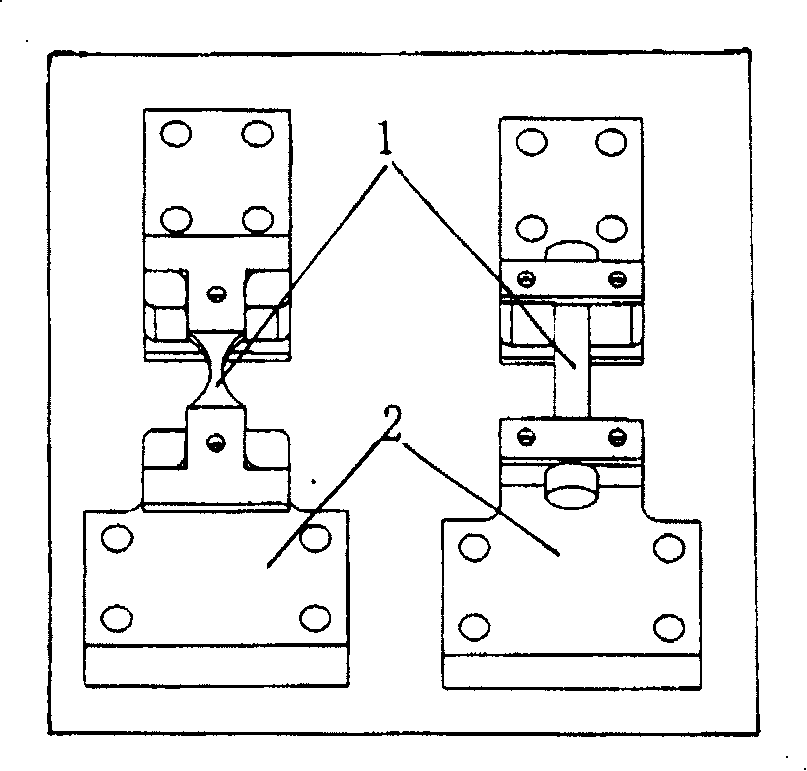

[0034] Two positioning blocks 2, 2' connected to the fixed pliers body 3 and the movable pliers body 4 respectively for clamping the workpiece 1, the shape of the positioning blocks 2, 2' is related to the shape of the workpiece, image 3 Shown are positioning blocks of two structures, one of which is a positioning block for a plate-shaped workpiece, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com