AC synchronous generator rotor full-automatic winding machine

A fully automatic winding machine and synchronous generator technology, which is applied in the manufacture of motor generators, electric components, electrical components, etc., can solve the problems of inability to automatically change poles, inability to automatically reverse magnetic poles, etc., to improve work efficiency It is related to product quality, solves the problem of poor winding quality, and ensures the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

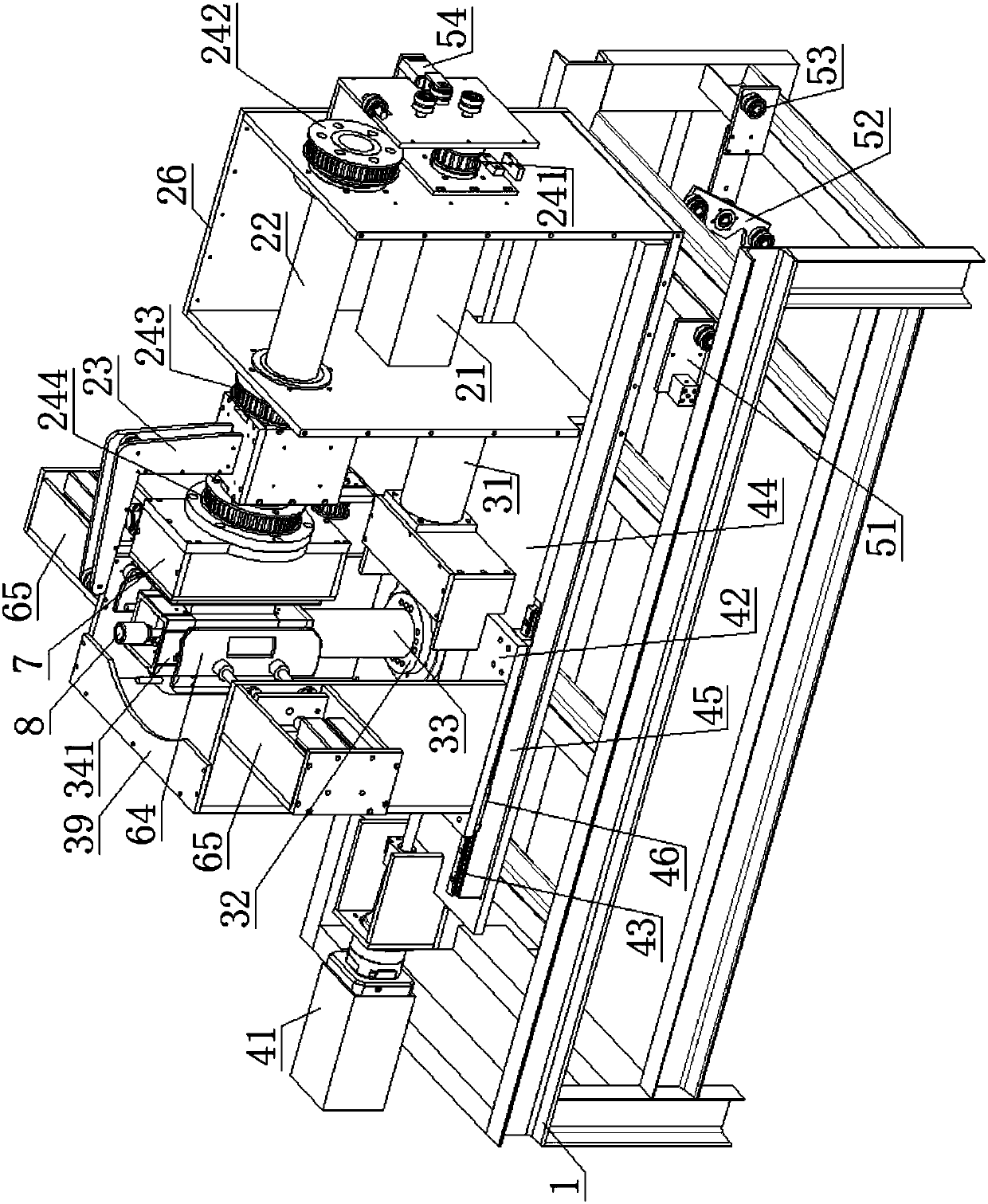

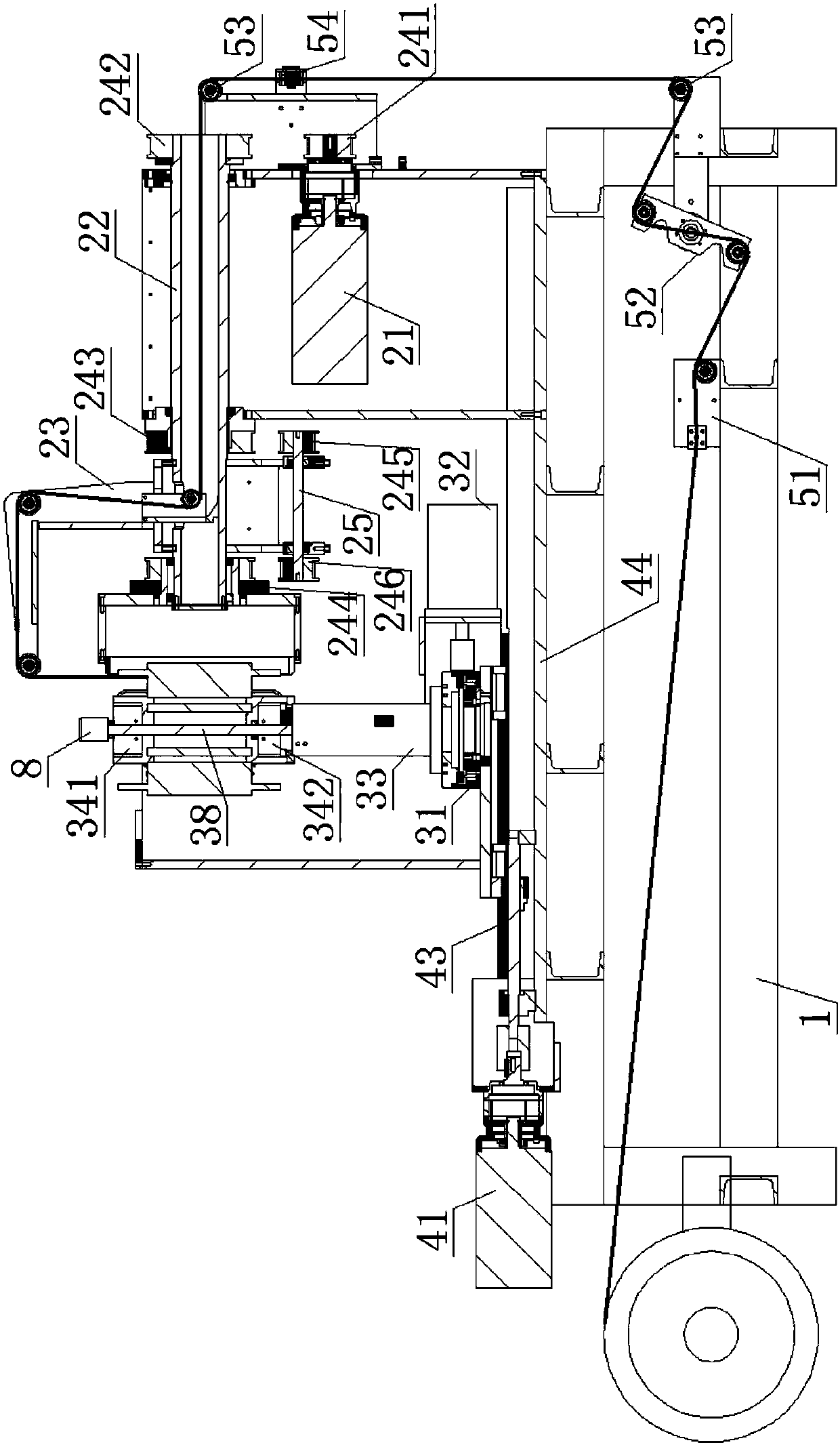

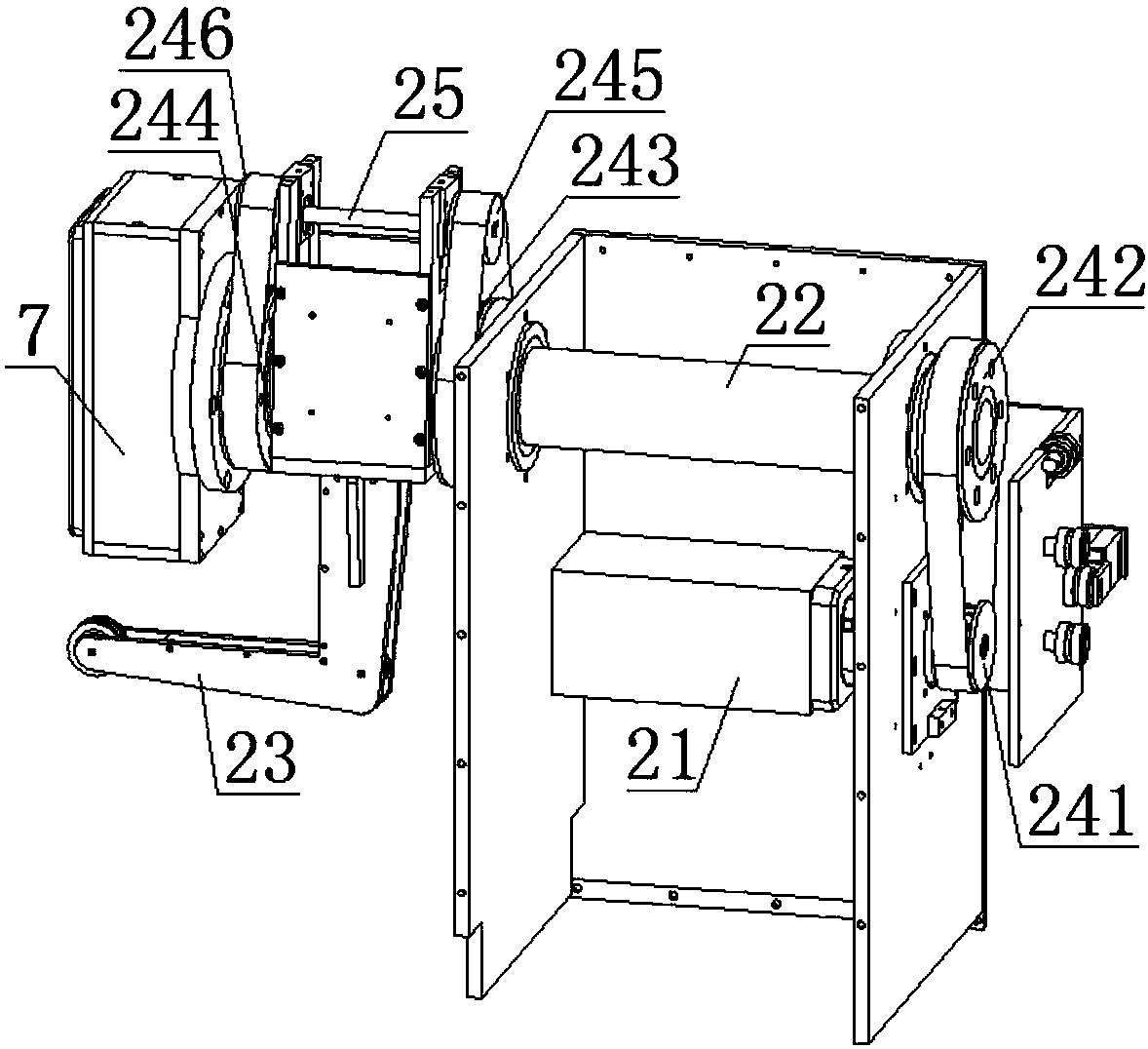

[0037] A fully automatic winding machine for the rotor of an AC synchronous generator, such as Figure 1 to Figure 5 As shown, it includes a base 1 welded by channel steel, a reversible winding device and a pole changing device capable of switching rotor blades. Such as Figure 6Shown is a schematic diagram of the structure of the generator rotor. The rotor has pole wings 9, and the rotor is fastened in the pole changing device. Wherein, winding device comprises winding motor 21, hollow shaft 22, winding rod 23 and winding housing 26, and winding rod 23 is installed on the outside of winding housing 26, and winding motor 21 and hollow shaft 22 are installed in parallel Inside the wire casing 26 , the winding casing 26 is fixedly installed on the base 1 . The output shaft of the winding motor 21 is connected with the a synchronous wheel 241 positioned at the outside of the winding shell 26, and one end of the hollow shaft 22 is connected with the b synchronous wheel 242 positi...

Embodiment 2

[0042] As preferably, in order to realize the present invention better, optimize further on the basis of above-mentioned embodiment, especially adopt following setting structure:

[0043] Such as figure 1 , figure 2 As shown, in order to arrange the enameled wires wound on the rotor pole wings 9 evenly and tightly, the present invention also adds a cable arrangement device, which includes a cable arrangement motor 41 installed on the base 1 and a slide table main board 44. Main beams 45 are provided on both sides of the platform main board 44, and slide rails 43 are provided on the main beams 45; a slide table 42 is fixed on the bottom of the pole-changing shell 39, and the four corners of the bottom of the slide table 42 are respectively provided with sliding rails 43. The chute 46, the cable motor 41 drives the slide table 42 to move on the slide table main board 44 through the cooperation of the slide rail 43 and the chute 46, so that the pole wing 9 of the rotor can mov...

Embodiment 3

[0045] As preferably, in order to realize the present invention better, optimize further on the basis of above-mentioned embodiment, especially adopt following setting structure:

[0046] Such as figure 1 , figure 2 As shown, in order to tighten the enameled wire and make the tension force of the enameled wire to be wound controllable, the present invention also adds a tensioning device, which includes a motor-driven clamping plate 51, a plurality of rollers 53 forming the path of the enameled wire, Torsion spring 52 and tension sensor 54, clamping plate 51 is installed on the enameled wire path, and torsion spring 52 is installed on the enameled wire path between tensioning clamping plate 51 and winding rod 23, and tension sensor 54 is installed on torsion spring 52 and winding rod 23 The enameled wire path between them, and the tension sensor 54 is electrically connected with the drive motor of the splint 51 .

[0047] The stretching splint 51 clamps the enameled wire, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com