Floating pipe water-cloth binding equipment

A floating tube and water cloth technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of high labor intensity, low product quality, low productivity, etc., and achieve low labor intensity, convenient operation and high productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

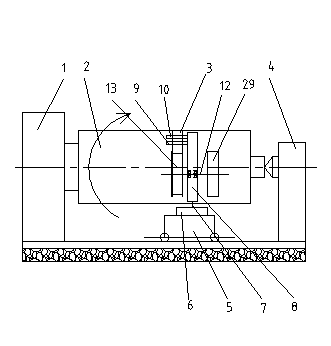

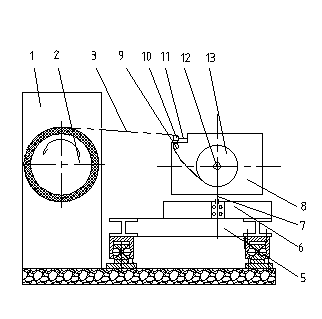

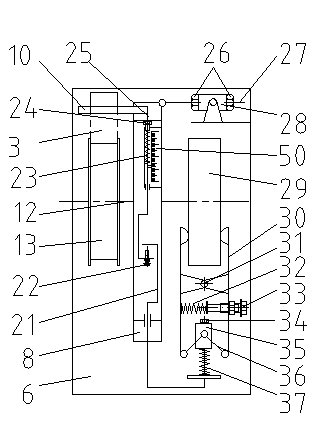

[0020] A kind of floating pipe water cloth equipment used in the floating pipe manufacturing process, said equipment includes, power box 1, floating pipe 2, water cloth 3, floating pipe water cloth device, tailstock 4 and trolley 5, floating pipe 2 Clamped between the power box 1 and the tailstock 4, it can rotate with its axis. The trolley 5 is located on one side of the floating tube 2. The trolley 5 is equipped with a floating tube water cloth device. The floating tube water cloth device is a floating tube 2 Provide the water cloth 3, the power box 1 and the tailstock 4 are installed on the ground, the trolley 5 can move along the direction parallel to the axis of the floating tube 2. , stand 8, water cloth roll 13, main shaft 12, friction wheel 29, angle adjustment device, tension device and brake device, bottom frame 6 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com