Patents

Literature

51results about How to "Controllable tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

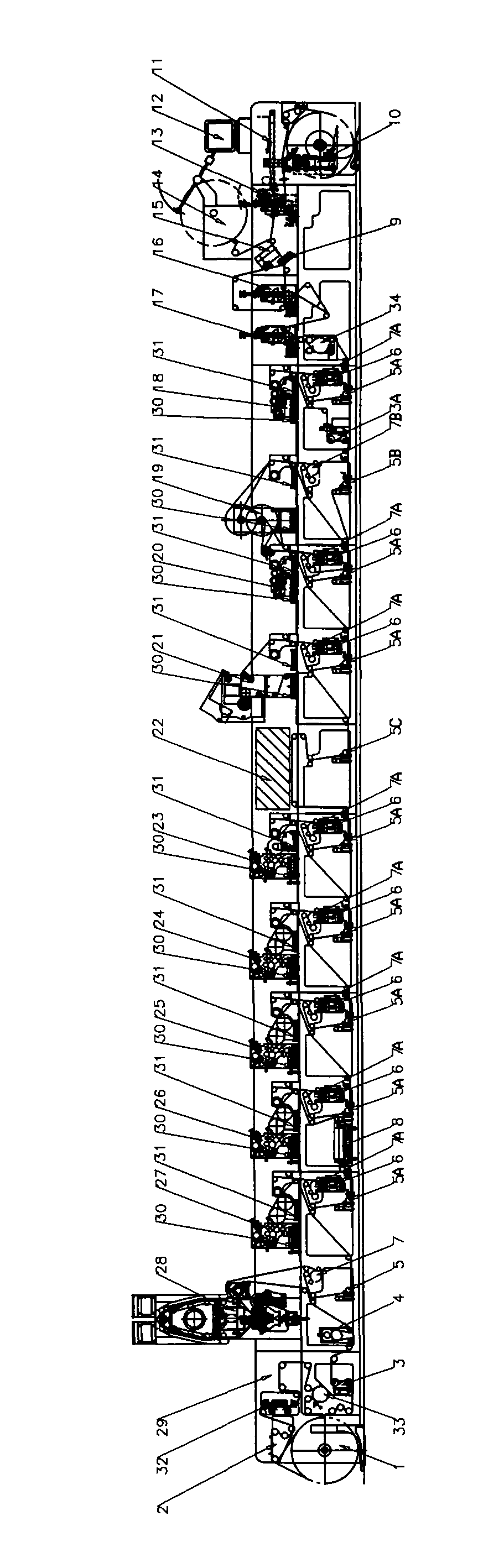

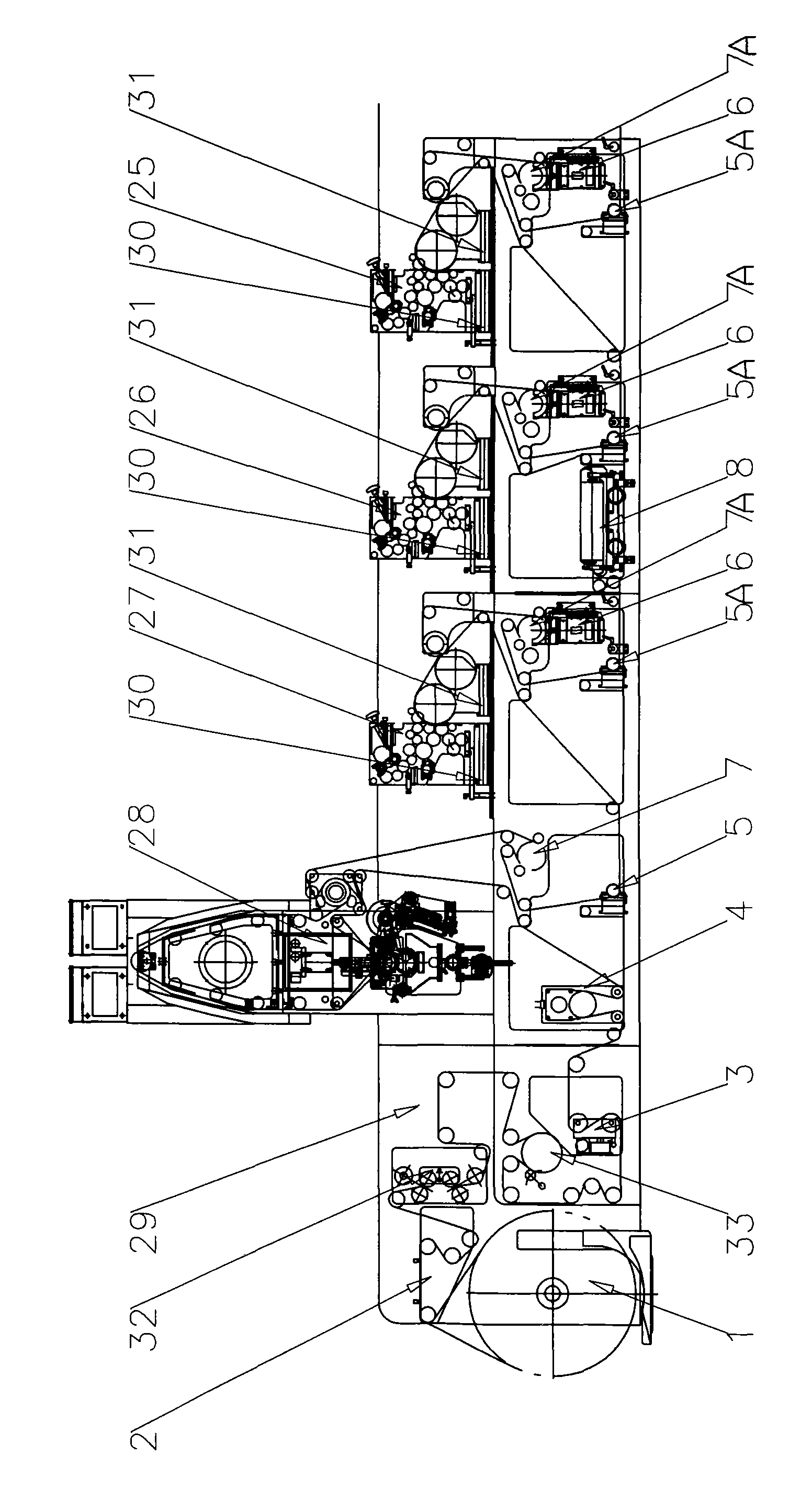

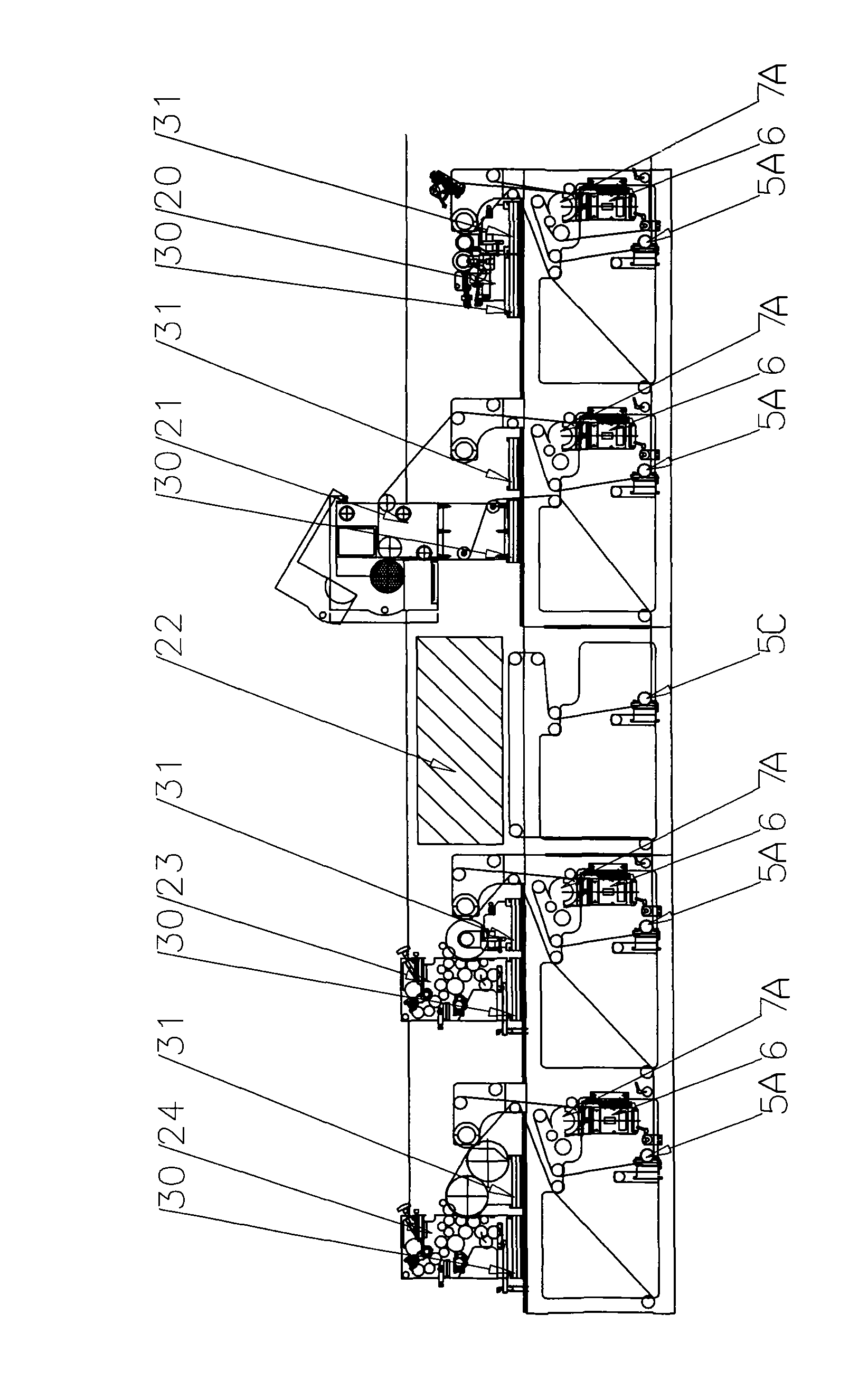

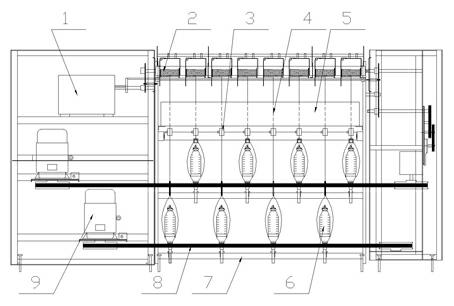

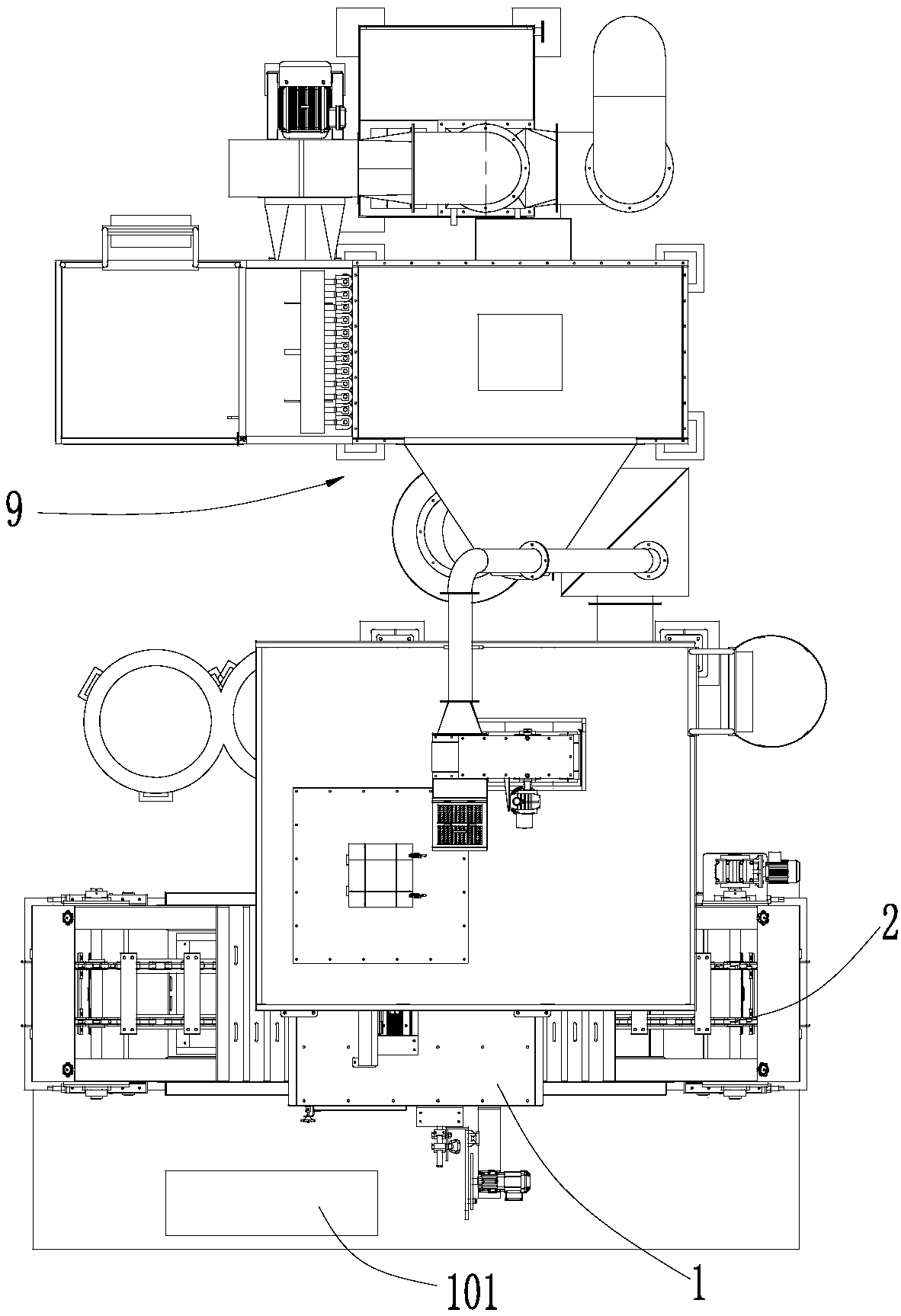

Multifunctional complex printer

InactiveCN101524912AControllable tensionHigh sensitivityTypewritersRotary pressesScreen printingLetterpress printing

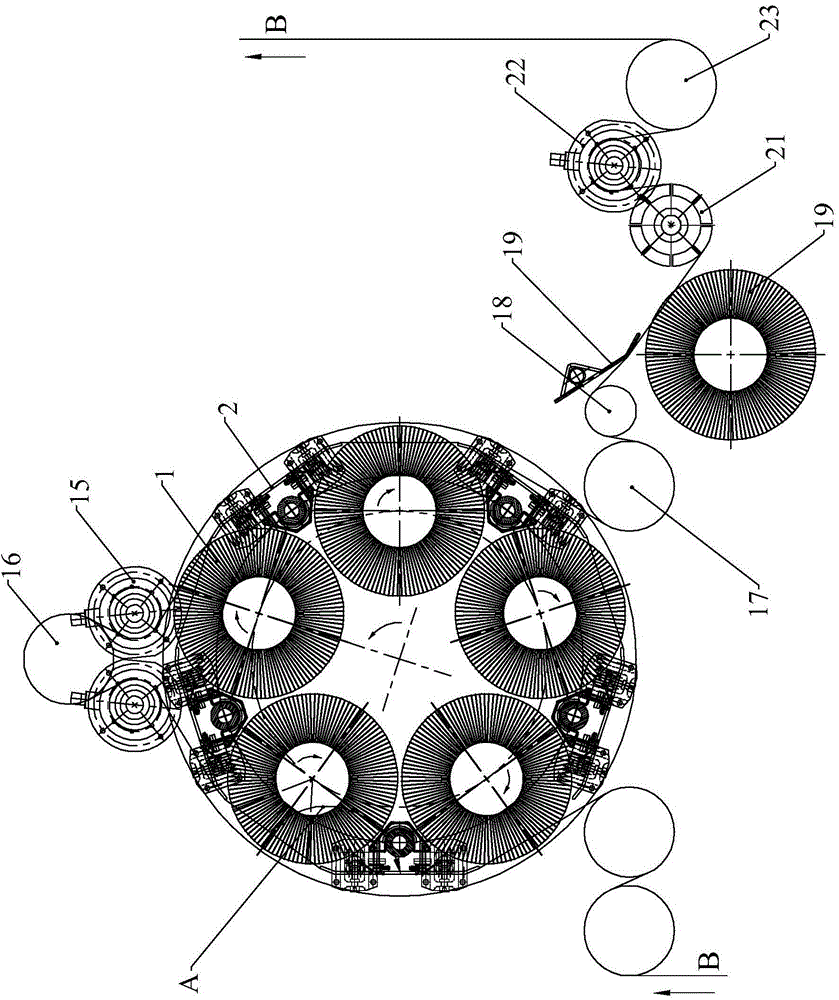

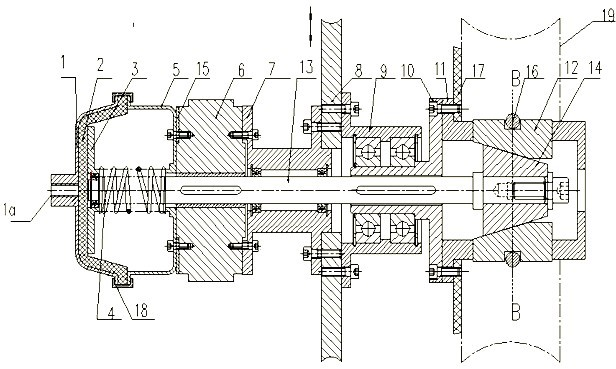

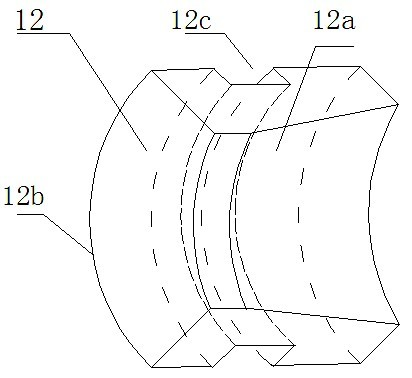

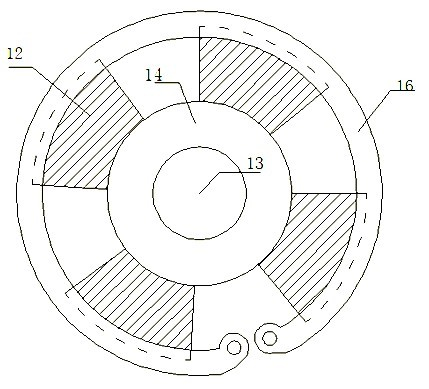

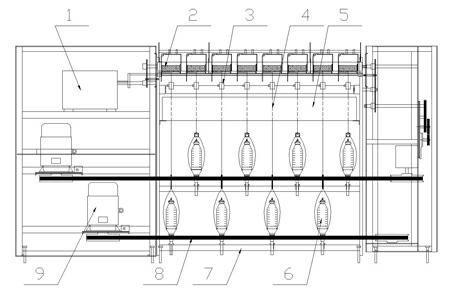

The invention relates to a multifunctional complex printer. The multifunctional complex printer comprises a lifting device of a paper feed part. The multifunctional complex printer is characterized in that a corona device, a first AC servo tension detection device and a first cooling pull roll device are sequentially arranged at right side of a first deviation correction device, an intaglio printing unit is arranged above the corona device, the first AC servo tension detection device and the first cooling pull roll device, a first interchangeable hectograph unit, a second interchangeable hectograph unit, a third interchangeable hectograph unit, a fourth interchangeable hectograph unit, an interchangeable letterpress printing unit, an interchangeable screen printing unit and a first interchangeable flexography printing unit are sequentially arranged at the right side of the intaglio printing unit, a fourth AC servo tension detection device is arranged below a reserved platform of an inkjet device, and a second two-cylinder die cutting device, a back cutting device and a television monitoring camera are sequentially arranged at the right side of a first two-cylinder die cutting device. The multifunctional complex printer has the advantages of flexibly combining various printing modes according to pluralism of products and optionally exchanging printing modes of various color classes.

Owner:SHANGHAI XINMIN TAIYO KIKAI

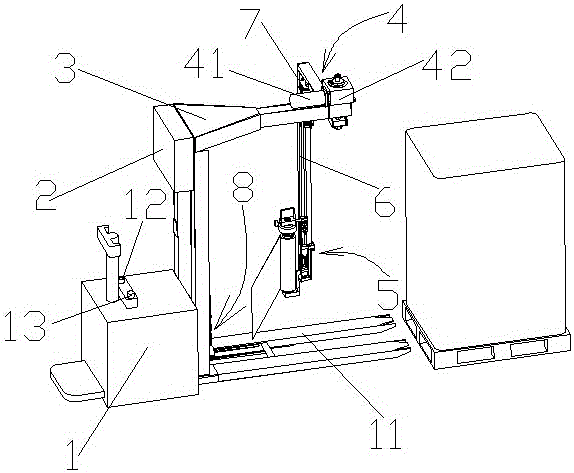

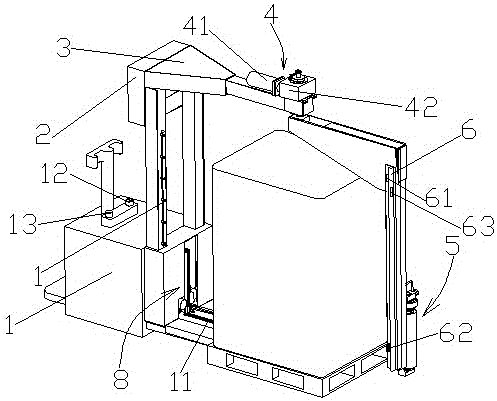

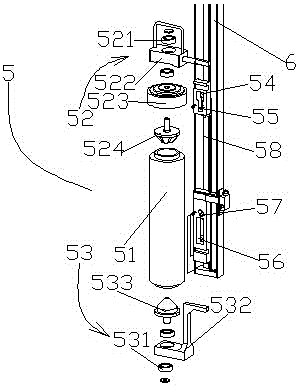

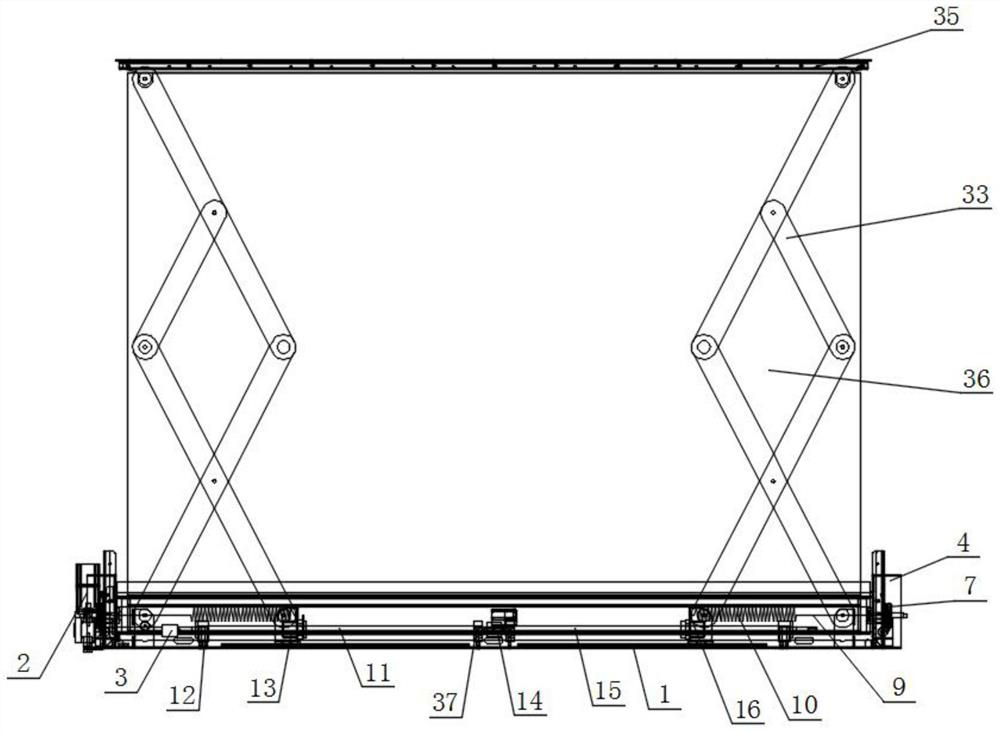

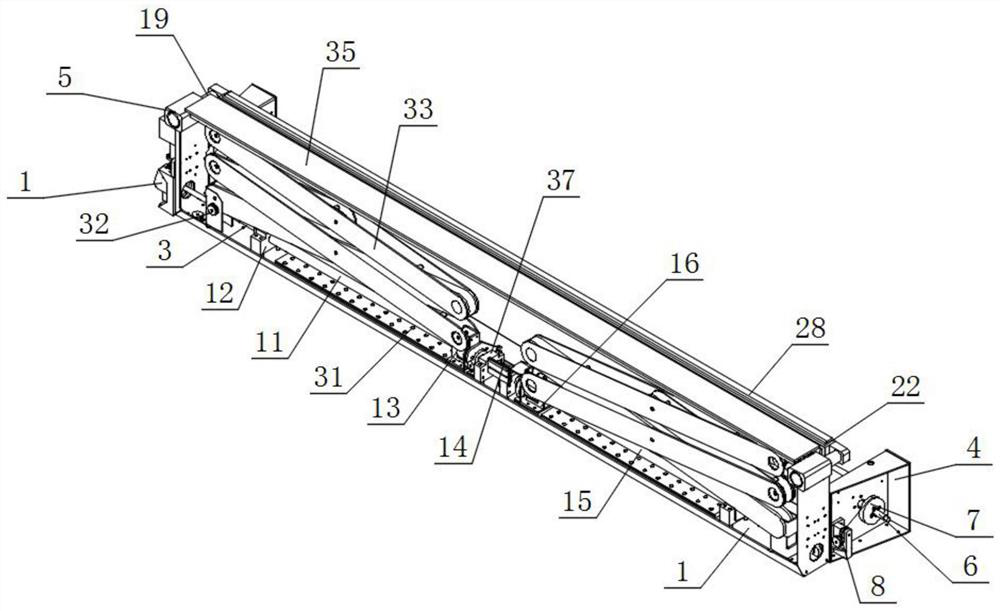

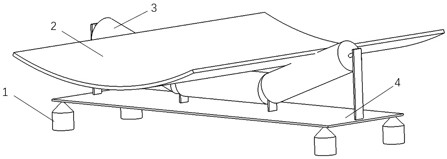

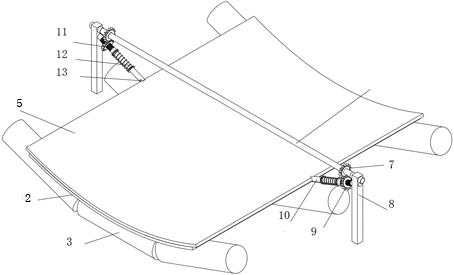

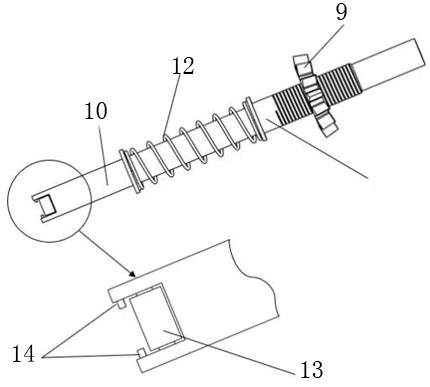

Mobile film winding machine

PendingCN105775196AControllable tensionIncrease profitWrapping material feeding apparatusWeb rotation wrappingWinding machineMotor drive

The invention discloses a mobile film winding machine which comprises a forklift body, an electric cabinet, a fixed support frame, a rotating mechanism, a film tension control mechanism, a film up-and-down moving frame, a film up-and-down moving motor and a film cutting and pressing mechanism, wherein the rotating mechanism is arranged at the tail end of the fixed support frame; the film up-and-down moving frame is movably arranged on the fixed support frame; the film tension control mechanism is arranged on the film up-and-down moving frame; the film up-and-down moving motor drives the film up-and-down moving frame to rise and fall; and the film cutting and pressing mechanism is arranged on the fixed support frame. According to the mobile film winding machine, a mobile forklift is adopted, a film is rotated upwards and wound around cargo through the rotating mechanism and a lifting mechanism, the winding efficiency is high, and the use of the mobile film winding machine is not limited and is convenient; manual operation is not needed, so that the labor intensity of workers is low, and the labor cost is saved; the film tension is controllable, the packing effect is better, and the cargo cannot become loose easily; the cargo does not need to be rotated, so that a great amount of electric energy is saved; and meanwhile, the height of the cargo is detected through photoelectricity, the utilization ratio of the film is high, and the use cost of the film is low.

Owner:北京小棉医药有限公司

Process for processing full polyester superfine fiber blanket

InactiveCN1858318AReduce fuzzFeed and feed tension of wool is easy to controlWeft knittingMicrofiberPolyester

The process of producing superfine full polyester fiber blanket includes the following steps: preparing DTY yarn material, weft knitting, dyeing or printing, opening and stoving, fixing color, finishing, heat setting, back pilling and finishing, clipping, and sewing to form the blanket. The production process features the re-networking of DTY yarn before weft knitting to constitute single strand high F superfine denier yarn, and this can reduce broke filament, and result in easy control of feeding tension, homogeneous tension and density. The present invention can produce high quality full polyester fiber blanket with fluff height of 4.5-12 mm, unit area weight of 300-500 g / sq m, plumpy fluff.

Owner:常熟市锦绣经纬编有限公司

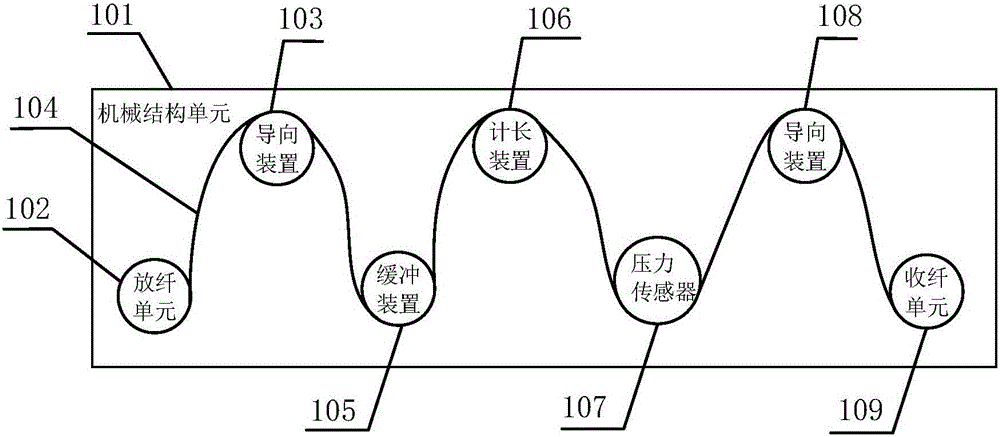

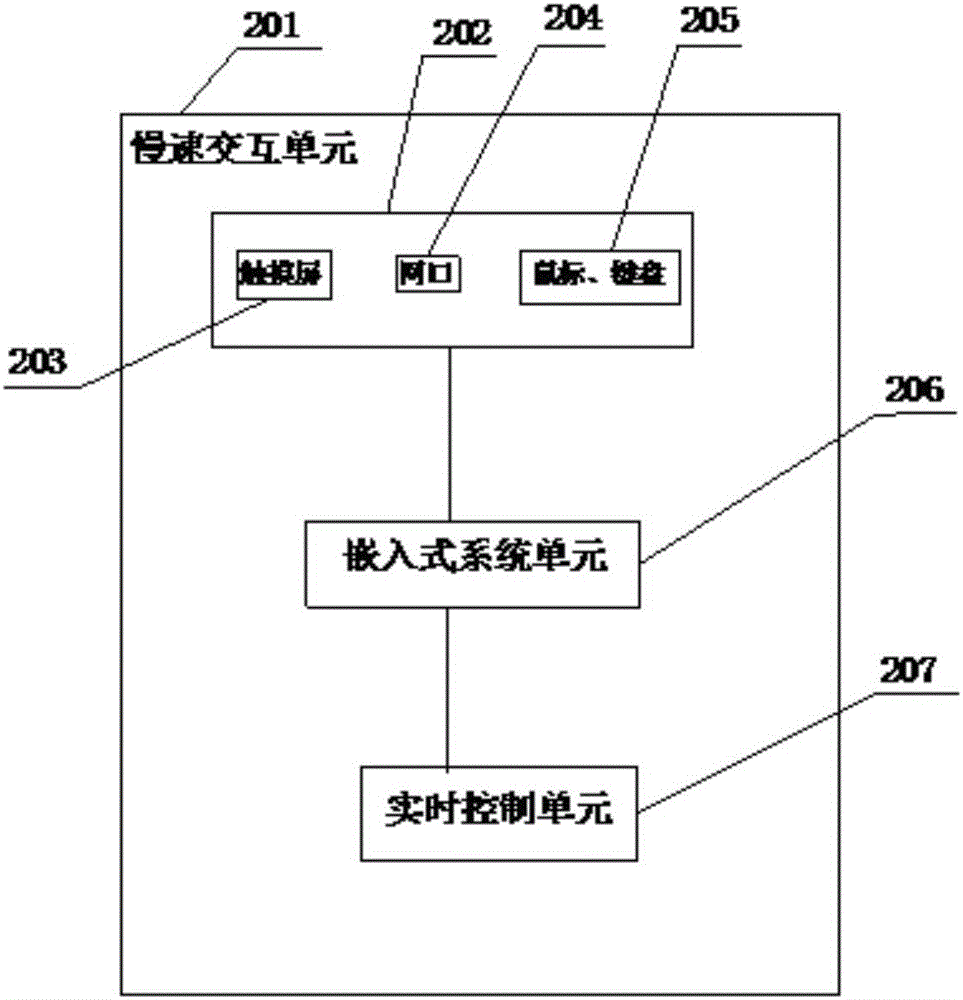

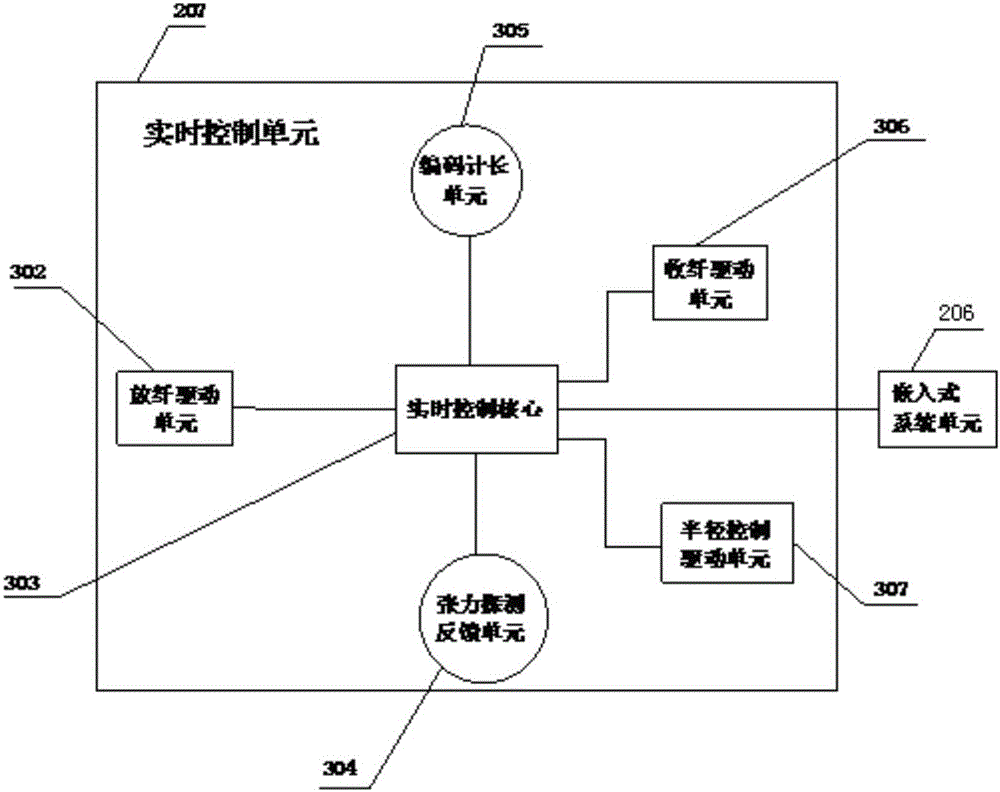

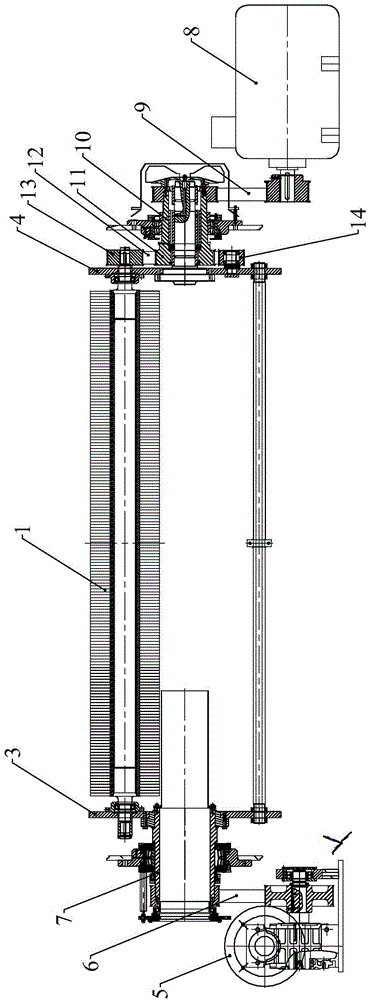

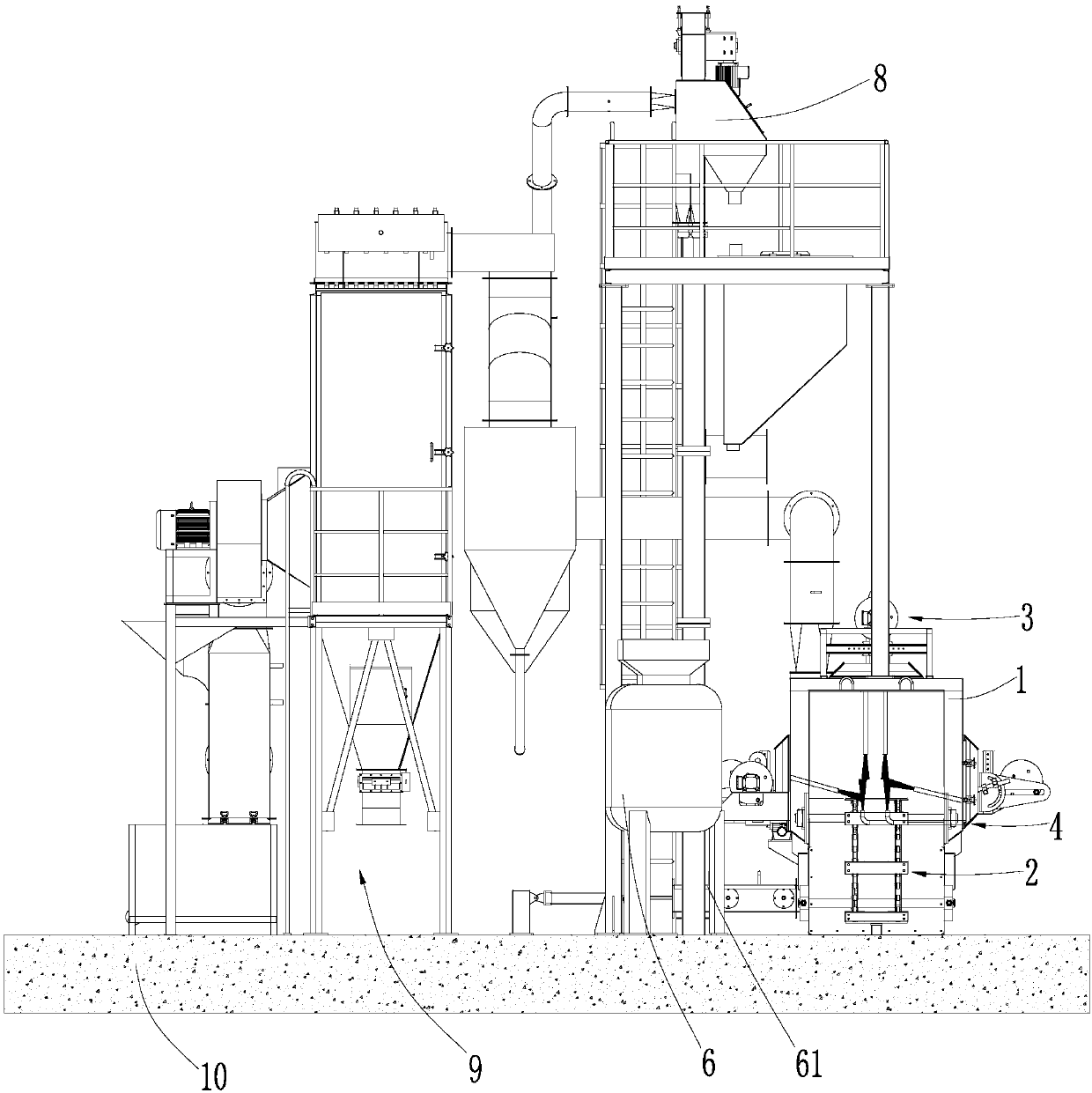

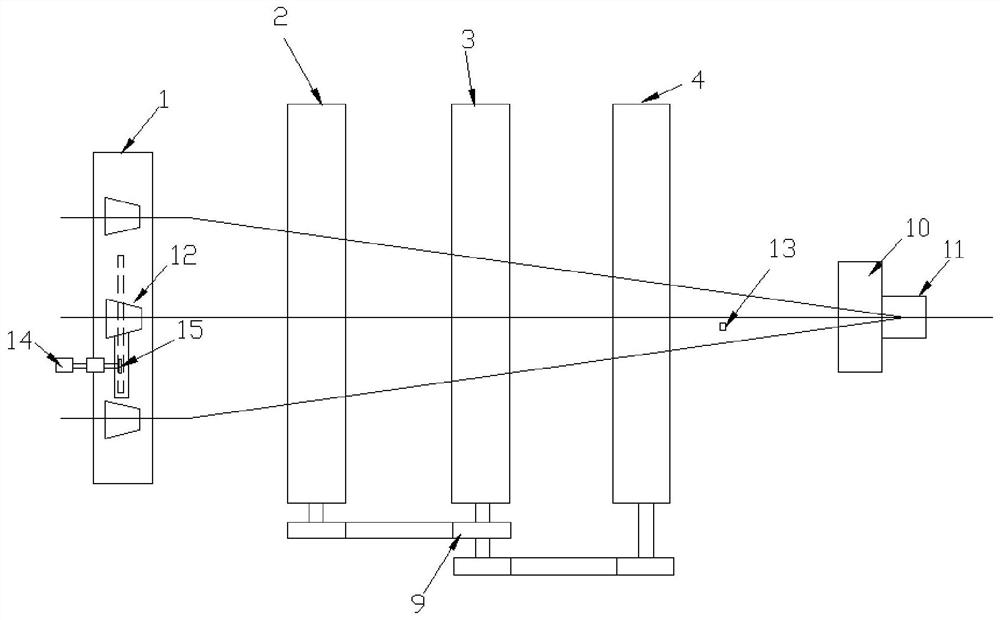

Fiber winding system and automatic control method

InactiveCN106054692AGuaranteed uptimeReal-time adjustment of operating speedProgramme controlComputer controlFiberLoop control

The invention discloses a fiber winding system, which comprises a mechanical structure unit and a low-speed interaction unit, and is characterized in that the mechanical structure unit is composed of a fiber releasing unit, a first guiding device, a buffer device, a length metering device, a pressure sensor, a second guiding device and a fiber collecting unit, the slow-speed interaction unit is composed of a man-machine interaction unit, an embedded system unit and a real-time control unit, and the real-time control unit is composed of a fiber release driving unit, a fiber collection driving unit, a radius control driving unit, a code length metering unit, a tension detection feedback unit and a real-time control core. The invention further relates to an automatic control method of a fiber winding machine, which comprises a tension closed-loop control method and a length metering automatic stop control method. The fiber winding system is simple in structure, low in cost and high in fiber winding efficiency, can ensures that optical fiber tension control is enabled to be sable and that system operation is enabled to be steady when the system is in high-speed operation, and can wind optical fiber loops with different radiuses very conveniently at the same time.

Owner:GUANGXUN SCI & TECH WUHAN

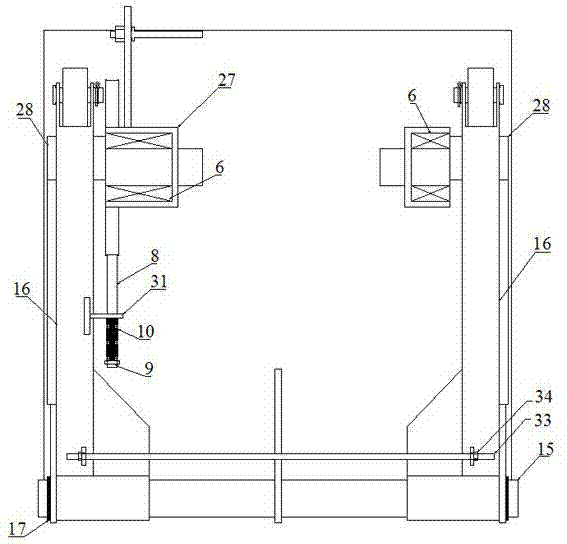

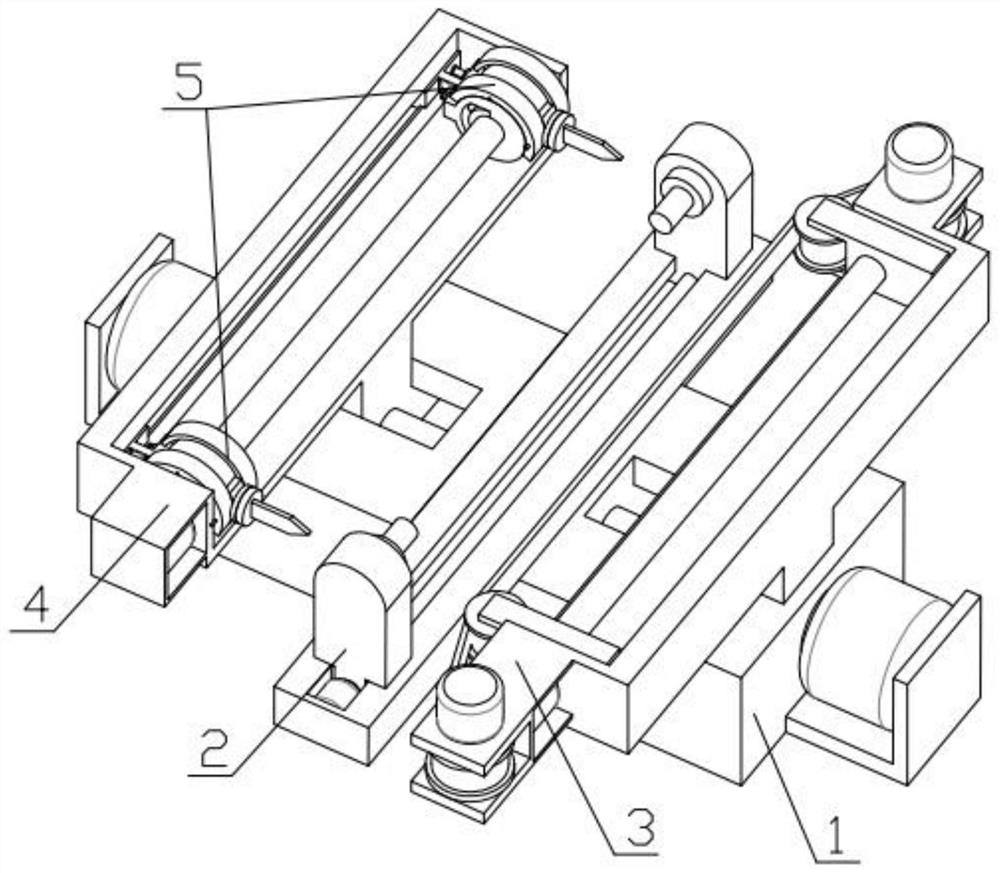

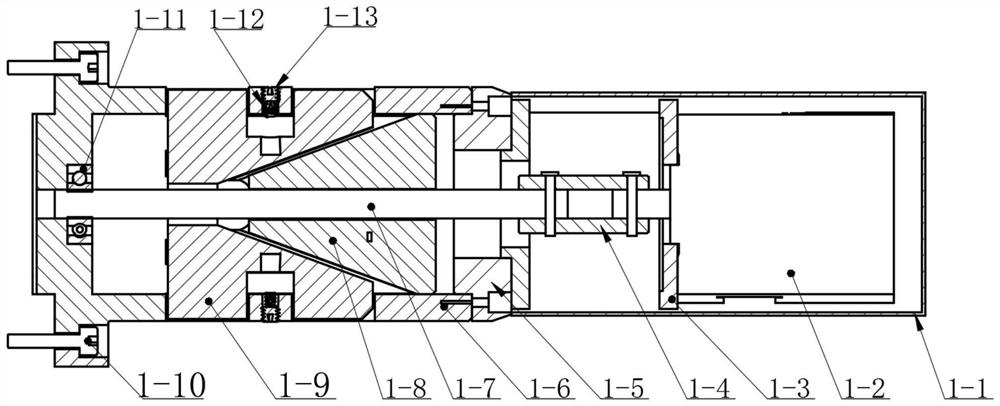

Coil winding paying-off device

ActiveCN104779049AEasy to crossControllable tensionFilament handlingCoils manufactureEngineeringMechanical engineering

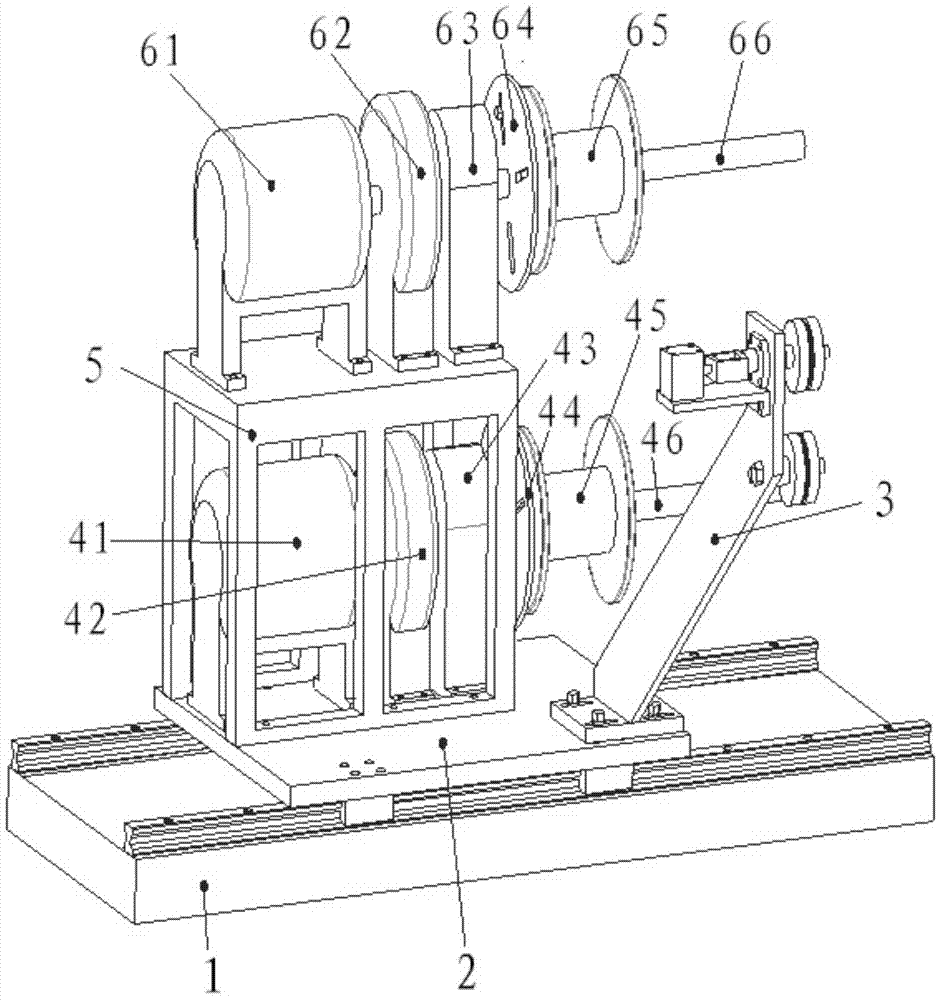

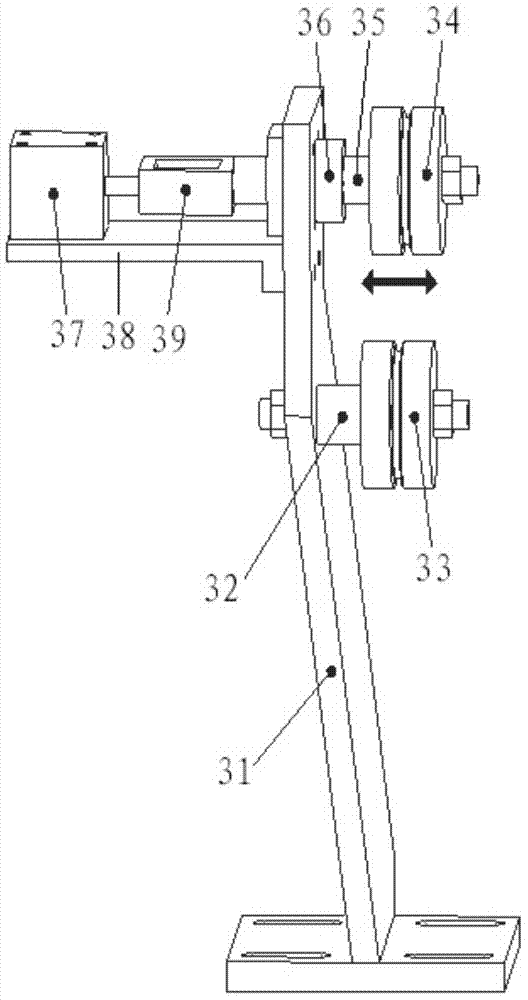

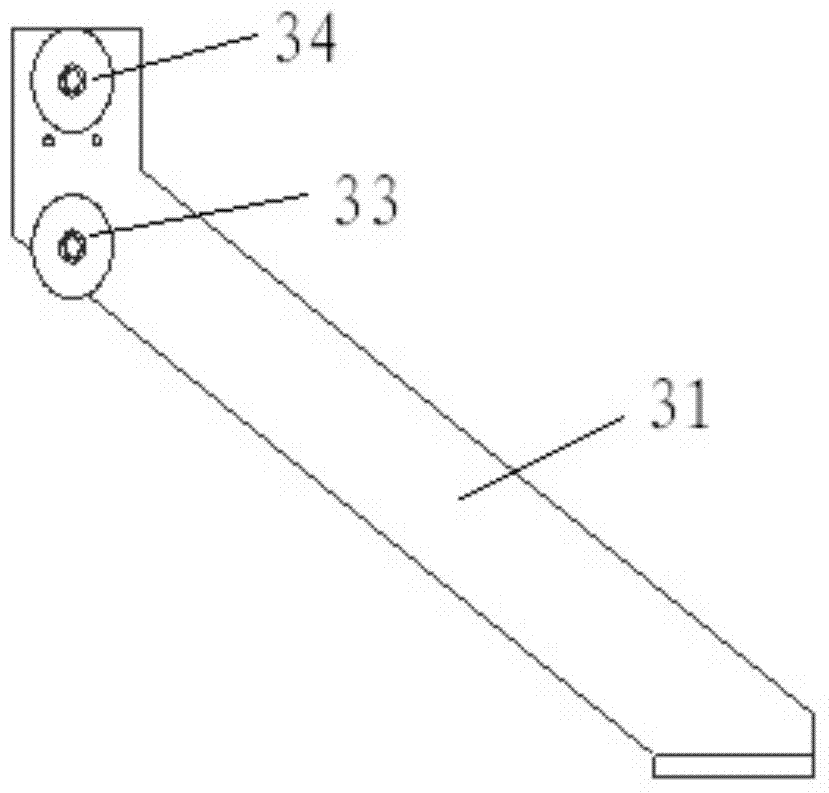

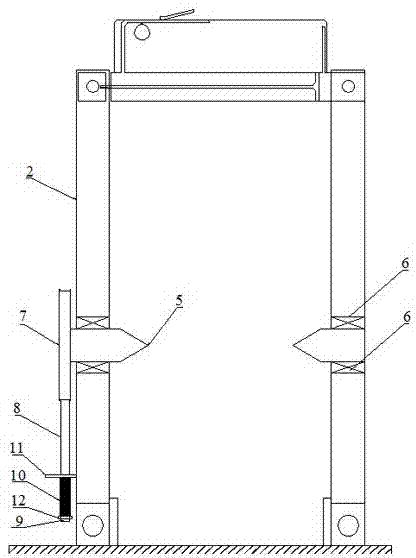

A coil winding paying-off device comprises a workbench, an upper tension paying-off mechanism, a lower tension paying-off mechanism, a rack and a wire crossing and reversing mechanism. The upper tension paying-off mechanism is installed on the rack which is installed on the workbench, the lower tension paying-off mechanism is installed on the workbench and located below the upper tension paying-off mechanism, the wire crossing and reversing mechanism is installed on the workbench, and the workbench is installed on a horizontal moving sliding table. According to the coil winding paying-off device, the upper tension paying-off mechanism and the lower tension paying-off mechanism provide independent tension output for two sets of paying-off coils respectively, the wire crossing and reversing mechanism conducts left and right crossing and reversing on wires of each layer in the coil winding process, and the horizontal moving sliding table adjusts the double tension paying-off mechanisms and the wire crossing and reversing mechanism to move left and right in the coil winding process; by means of the coil winding paying-off device, the tension of all the wires in the coil winding process is more controllable, crossing of the wires among the layers is more convenient, and the operation is easier.

Owner:ALLTECH MEDICAL SYST

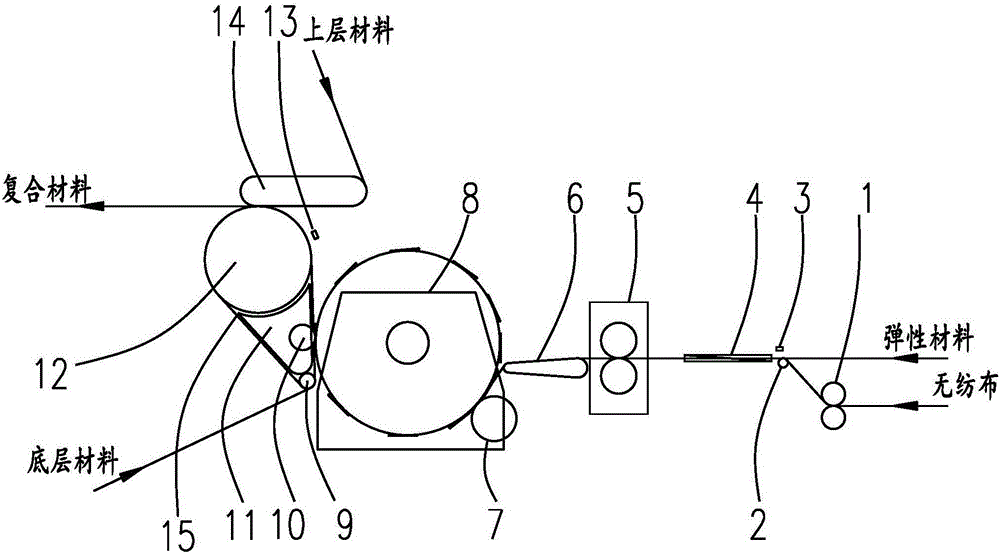

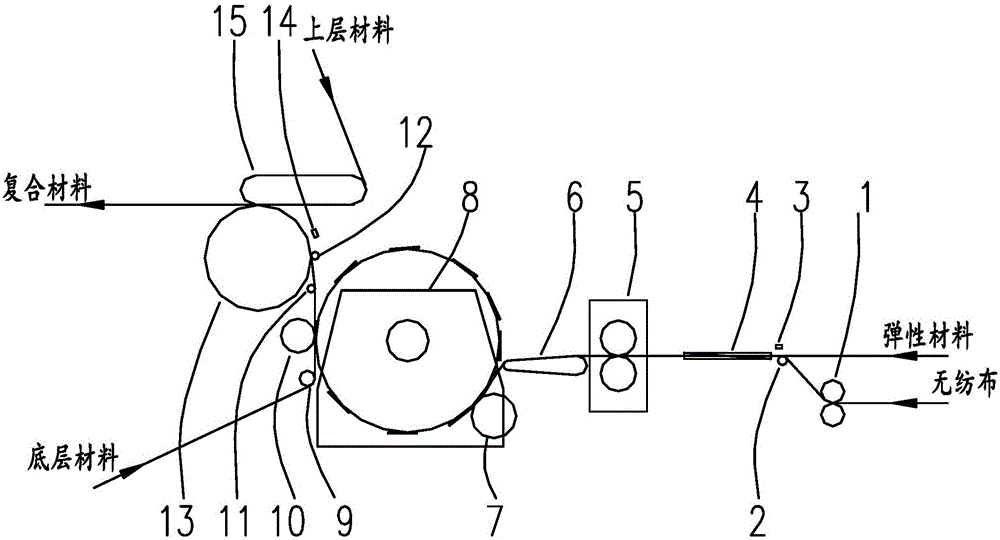

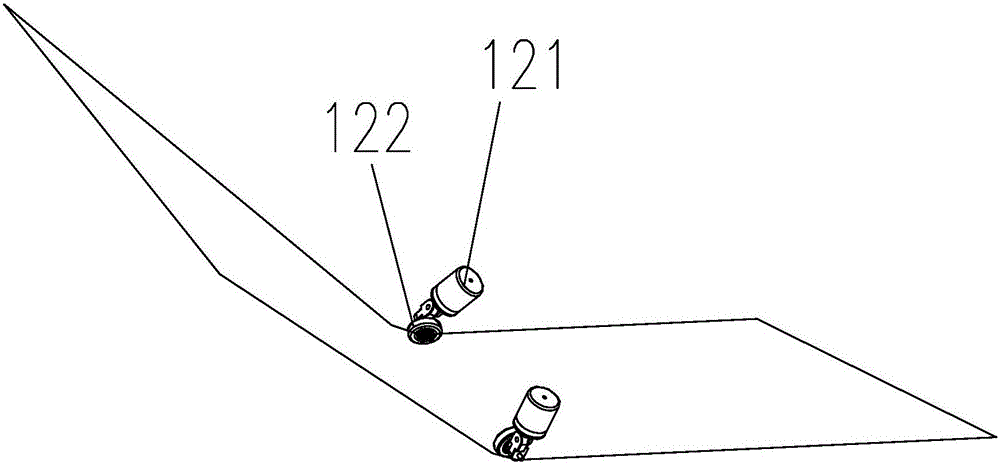

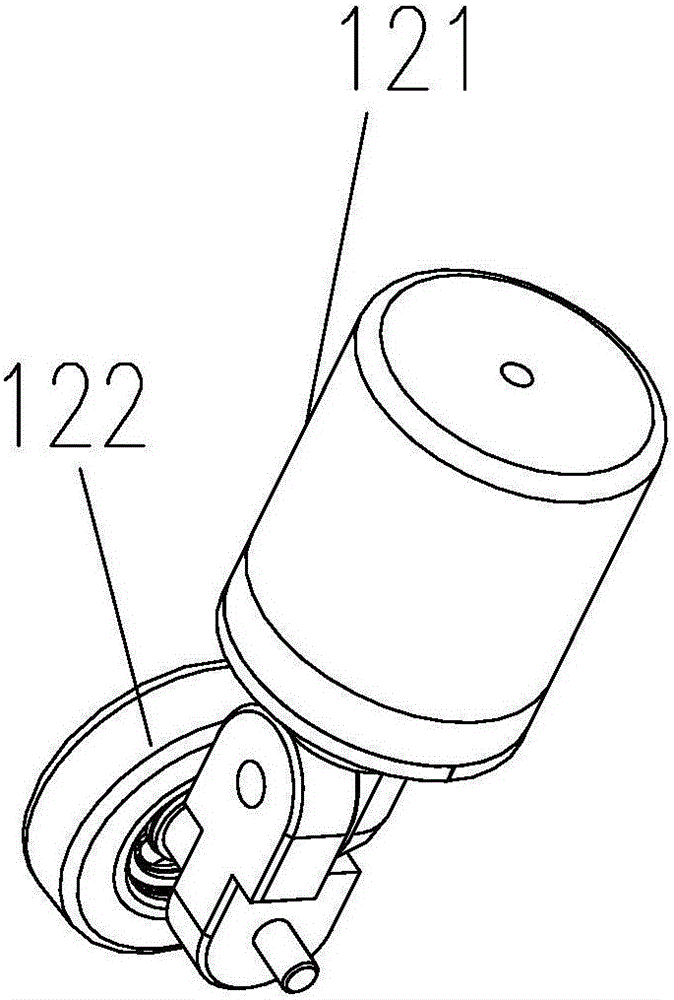

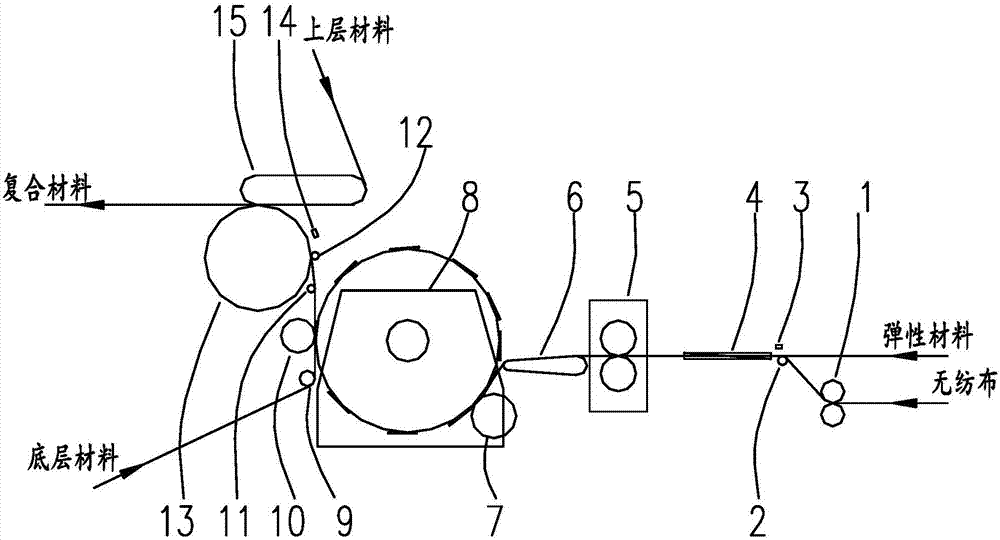

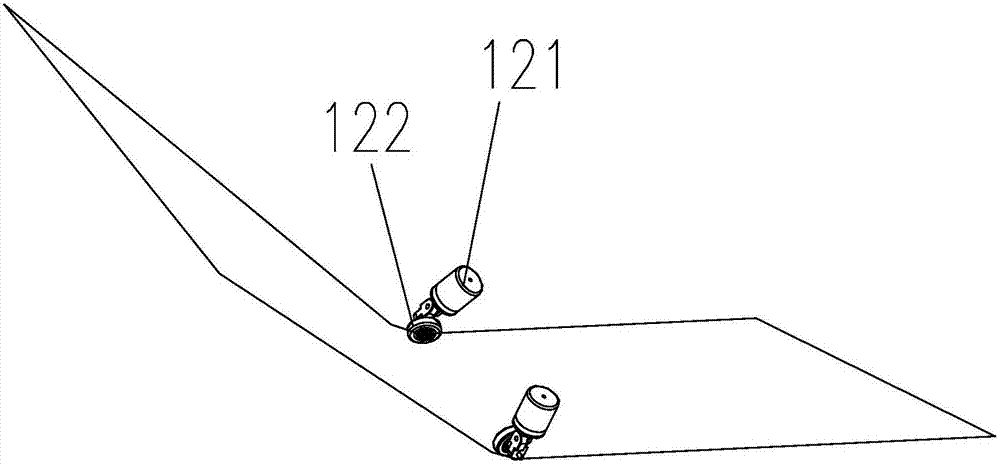

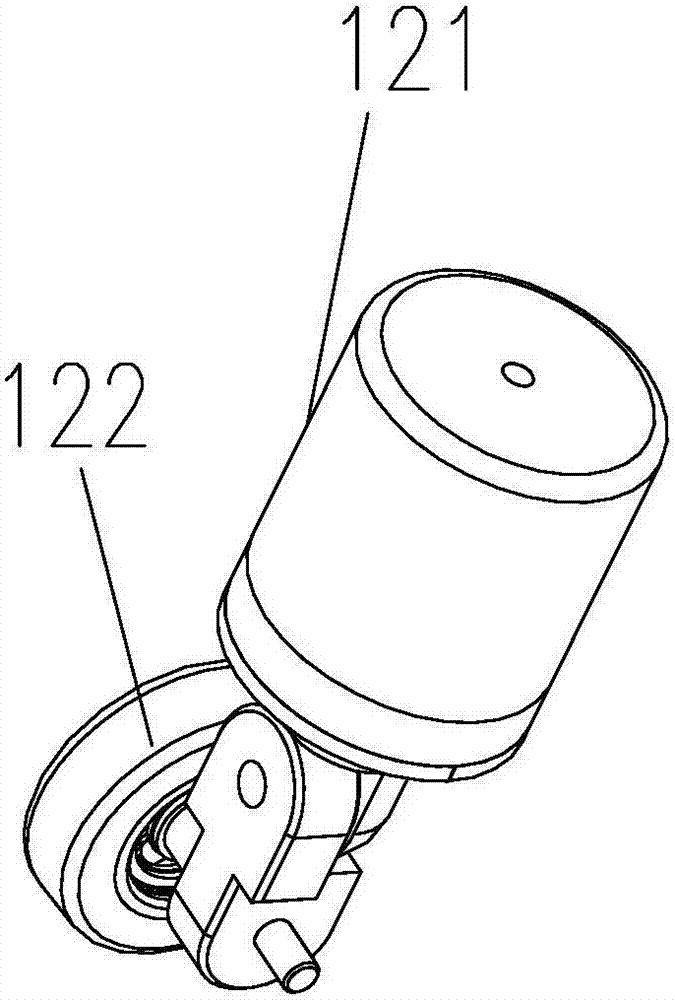

Apparatus and technology for compounding material

ActiveCN106064518AControllable tensionNice appearanceLamination ancillary operationsLaminationCompound aPunching

The invention belongs to the field of machinery, and provides an apparatus for compounding a material. The apparatus comprises the following components: a traction mechanism, a first gluing mechanism, a folding mechanism, a partial cutting and punching unit, a cutting and rotating mechanism, a guide roller, a beating mechanism, a second gluing mechanism, and a transferring wheel; the beating mechanism comprises a cam, when the cam as well as the cutting and rotating mechanism are attached, the cam beats the material, and a first negative pressure conveying mechanism is arranged between the transferring wheel and the cutting and rotating mechanism. A piece of non-woven fabric and an elastomeric material are compounded on line, the elastomeric material in a compounded body is partially treated, in order to reach the requirements of beautiful shape and comfortable usage. In a production process of the compounding technology, the tension force of the material is easy to control, the comfort level is guaranteed, and the same kinds of raw materials can be used for producing a plurality of products with reduced cost. After the bottom material and the elastic composite material are compounded, negative pressure fixing and conveying are used, in order to guarantee that deformation and folding of the bottom material are not generated in the effects of elasticity.

Owner:ANQING HENG CHANG MACHINERY

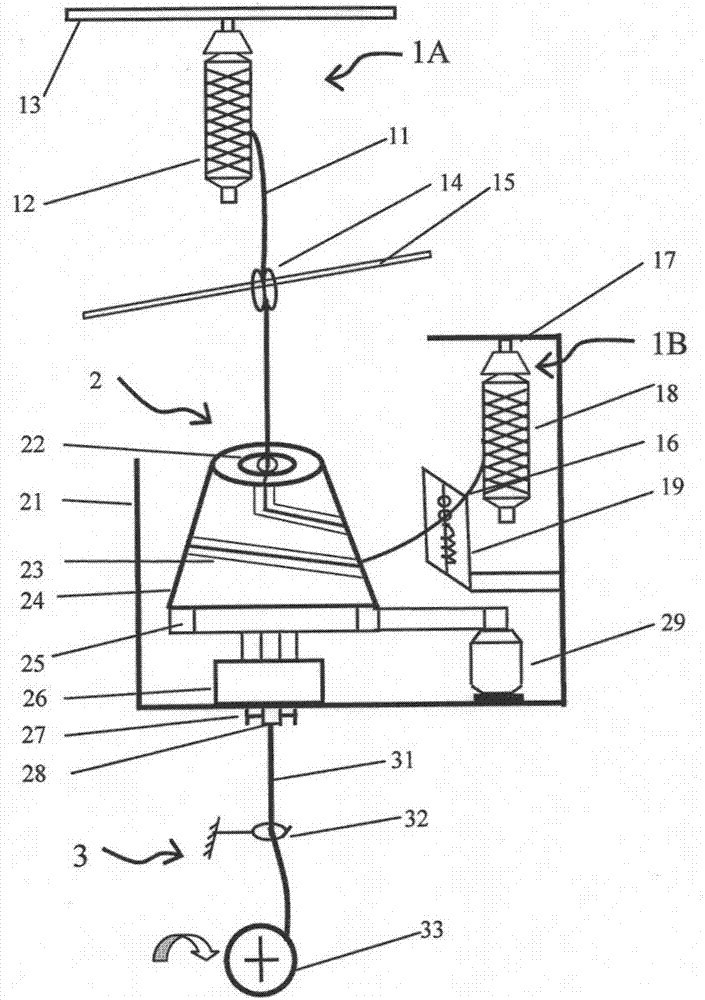

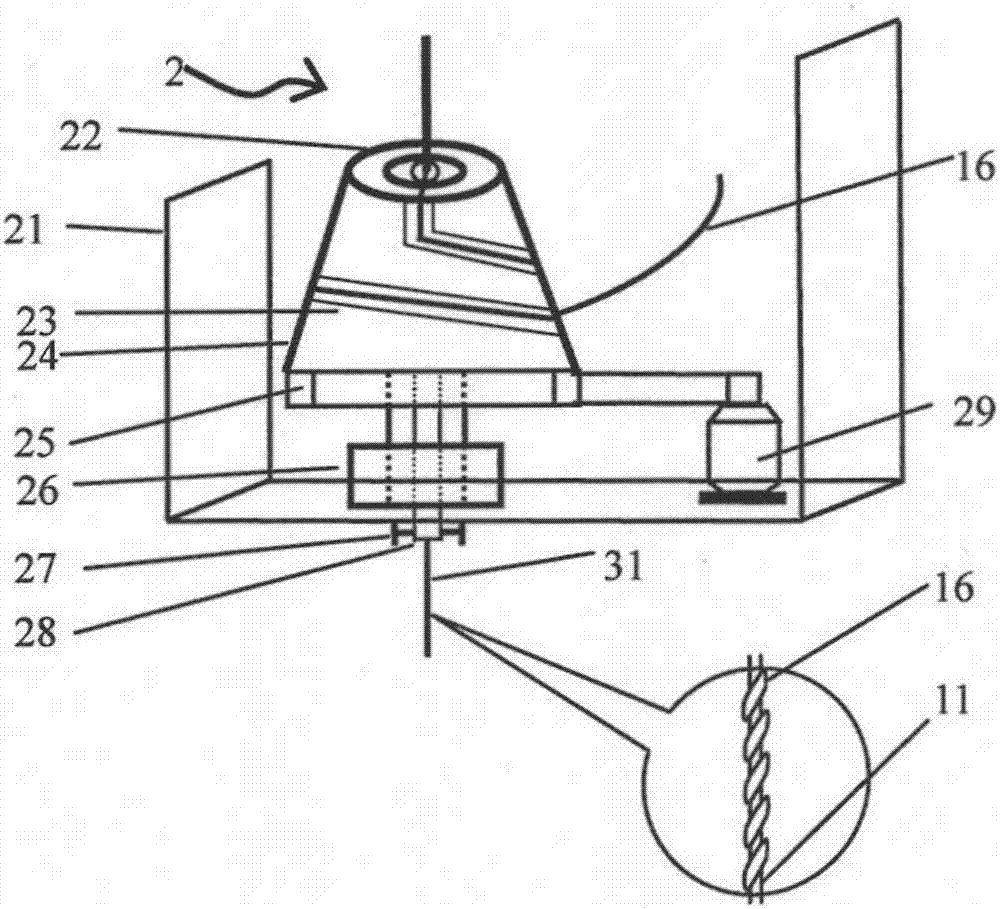

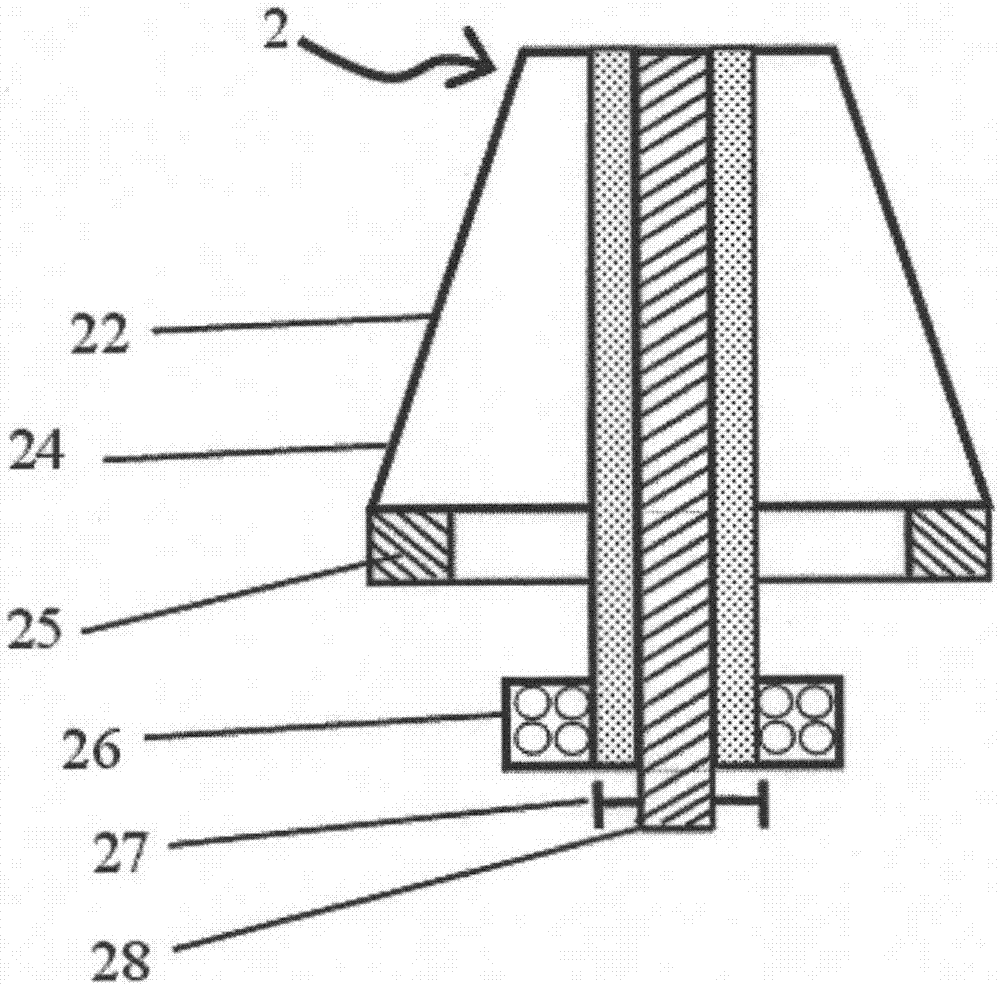

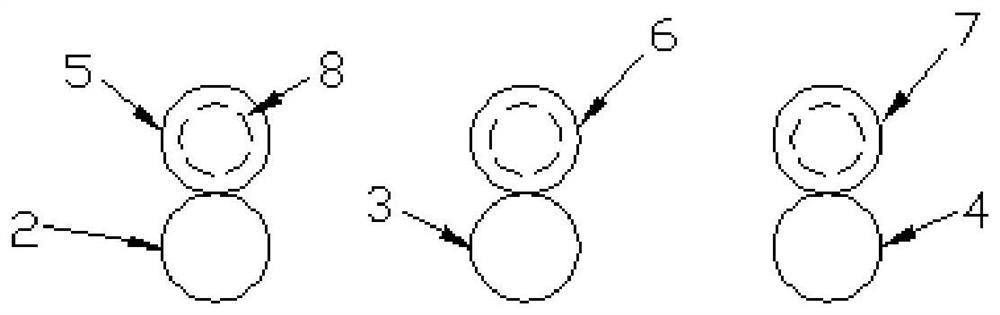

A device for preparing auxetic composite yarn through active wrapping of fine and hard low-elasticity yarn around thick and soft high-elasticity yarn

The invention relates to a device for preparing auxetic composite yarn through active wrapping of fine and hard low-elasticity yarn around thick and soft high-elasticity yarn and a method and use thereof. The device comprises yarn component supply and feeding control mechanisms, an active wrapping forming mechanism and a winding mechanism. The method is characterized in that thick and soft high-elasticity yarn unwound from bobbins passes through a tension disk and passes through a hollow pipe through pulling of certain tension; fine and hard low-elasticity yarn passes through a telescopic location yarn guide and is output to a head end of the hollow pipe along a spiral yarn guide groove of a speed-controllable rotor via rotation of the rotor, and then meets the thick and soft high-elasticity yarn and is wound around the thick and soft high-elasticity yarn actively to form auxetic composite yarn with a spiral wrapping structure. The device is easy to operate, low in cost, and suitable for continuous production, promotion and application, and can be installed on spinning machines for ring spinning, friction spinning, rotor spinning and electrostatic spinning. Auxetic composite yarn manufactured with the device is uniform in structure and unique in performance and can be used for buffering ropes, bulletproof and stab-resistant yarn, yarn for heat preservation fabric and sewing threads for medical surgery.

Owner:DONGHUA UNIV

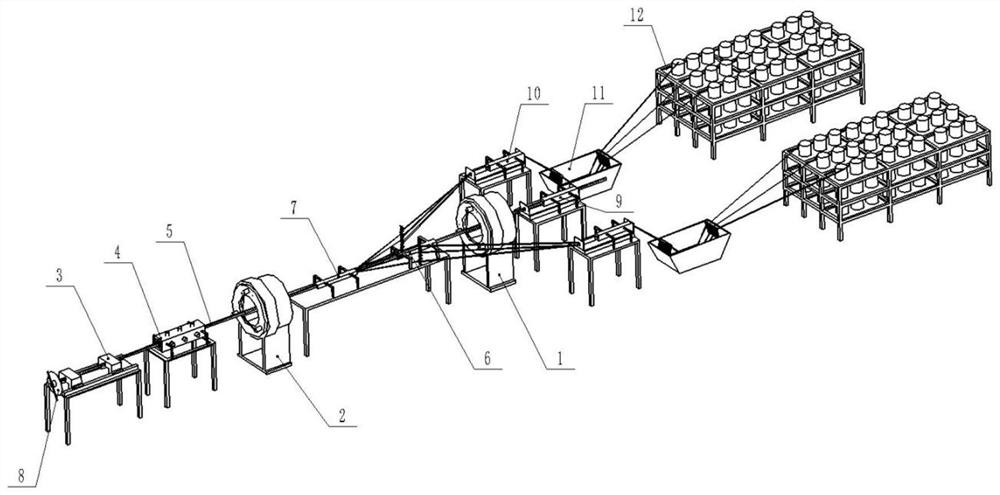

Sanding system of sanding machine

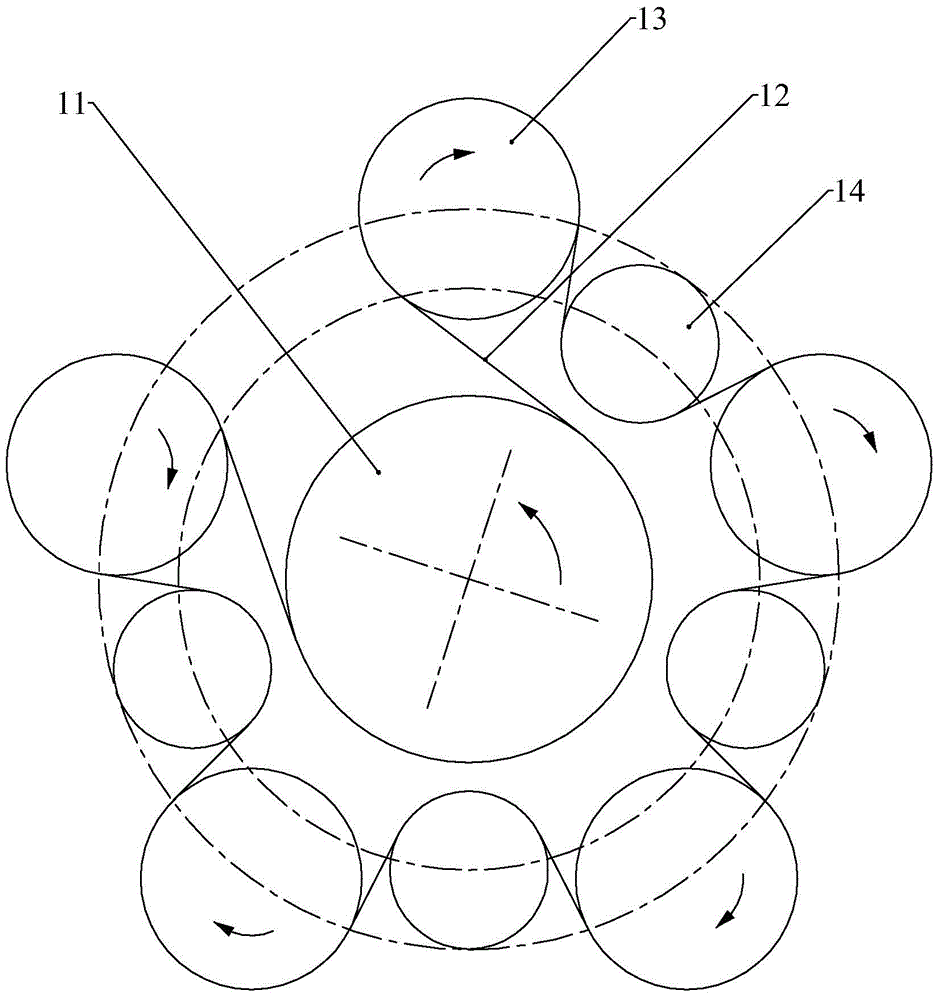

The invention relates to a sanding system of a sanding machine. The sanding system comprises a brush drum, a brush drum drive device, a brush roller drive device, a brush roller synchronous rotation device and a sanding arrangement device. The brush drum comprises five brush rollers and five adjustment plate devices. The five brush rollers are arranged on a left supporting plate and a right supporting plate through even distribution and arrangement frames of planet structures. The adjustment plate devices are arranged between the adjacent brush rollers. A brush drum motor drives a brush drum transmission device to form the brush drum drive device through a brush drum synchronous belt. The brush roller motor drives a brush roller transmission device through a synchronous belt. A main transmission belt wheel of the brush roller synchronous rotation device is driven by the brush roller transmission device. A brush roller double-sided synchronous belt changes the direction through tensioning belt wheels and drives five brush roller transmission belt wheels to synchronously rotate. An outlet drive roller of the sanding arrangement device drives sanding cloth to be subjected to sanding arrangement through the outlet brush roller by means of a cloth guide roller and an adjustment pressing plate. The sanding system has the advantages of being capable of saving energy, convenient to install and detach and good in sanding effect.

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

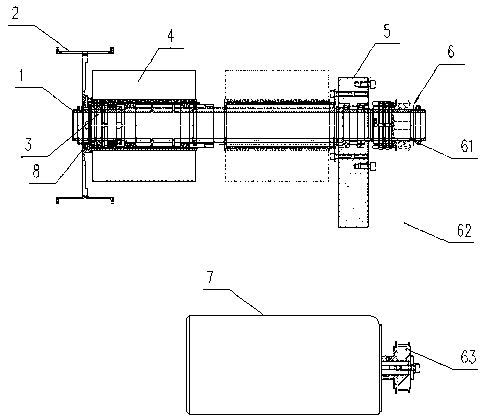

Enameled wire unwinding device

ActiveCN103545052AAchieve clampingAchieve releaseCable/conductor manufactureMechanical engineeringMobility devices

Owner:WUXI XIZHOU MAGNET WIRES

Sheath yarn winding device

The invention relates to a sheath yarn winding device which comprises a stiff stand, a hollow spindle, an aircraft, a bearing, a bearing sleeve, a yarn roll sleeve and a damper. The damper comprises a damping coil and a friction plate, the hollow spindle is rotatably supported on the stiff stand, the bearing sleeve is connected to the hollow spindle through the bearing, the aircraft without relative rotation is connected to the bearing sleeve, the damping coil is hollowly sleeved on the hollow spindle and does not rotate along with the hollow spindle, the friction plate is arranged between the damping coil and the bearing sleeve and connected with the bearing sleeve, and the yarn roll sleeve is hollowly sleeved on the outer sides of the bearing sleeve and the damper. The sheath yarn winding device has the advantages that yarn releasing tension is controlled by the hysteresis damper, various impact usually happening in operation of the device is avoided, abrasion is low, the device stably, safely and reliably runs and is simple to operate, pay-off tension is easily controlled, additionally, the structure is compact, and running cost in production is low.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

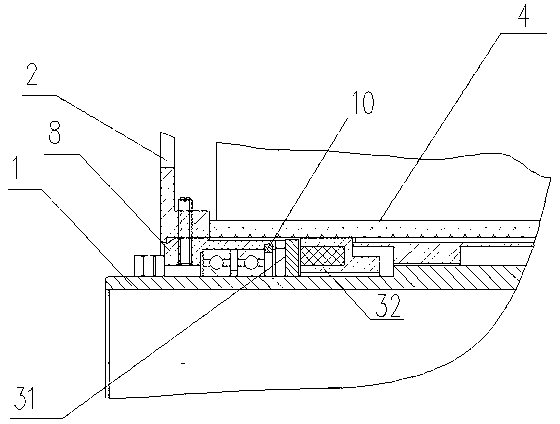

Sheath metal belt unwinding device applied to production of optical cable

The invention relates to a sheath metal belt unwinding device applied to production of an optical cable. The sheath metal belt unwinding device comprises an air cushion cover, an air cushion, a spring, a baffle plate, an air cushion cover flange, a magnetic powder brake, a transmission shaft bearing pedestal, a lifting plate, an outer sleeve bearing pedestal, an outer sleeve connection flange, anouter sleeve, a plurality of expansion sleeve inclined blocks, a clamping spring and an inner sleeve, wherein one end of a transmission shaft is connected with the baffle plate in a rotatable manner;the air cushion cover is arranged at the outer end of the baffle plate; one side of the magnetic powder brake, which is opposite to the baffle plate, is connected with the air cushion cover flange, and the other side of the magnetic powder brake is provided with the lifting plate; opposite sides of the magnetic powder brake and the lifting plate are connected with each other through the transmission shaft bearing pedestal; the transmission shaft is supported on the bearing pedestal through a corresponding bearing; the outer sleeve bearing pedestal is connected to the other side face of the lifting plate; the outer sleeve connection flange is sleeved on the transmission in a hollow manner; the outer sleeve connection flange is connected with the outer sleeve; the inner sleeve is connected to the other end of the transmission shaft; and a plurality of holes in the circumferential direction of the outer sleeve are correspondingly inserted with the expansion sleeve inclined blocks. The sheath metal belt unwinding device has the advantages of small impact, low abrasion, simple operation, safety, reliability and compact structure.

Owner:西安北方光通信有限责任公司

Direct heat setting method and device for two-for-one twisting

The invention discloses a direct heat setting method and device for two-for-one twisting, belonging to the technical fields of textiles. A heat setting box is additionally arranged above a two-for-one twisting spindle of a two-for-one twisting machine, twisted yarns are directly subjected to heat setting and then subjected to winding setting. Twisted monofilaments are subjected to heat setting by means of the direct heat setting process for two-for-one twisting at constant temperature and constant speed, so that the setting effect is improved. A technological process of subsequent vacuum heat setting for two-for-one twisting in the prior art is omitted, so that labor and electricity are saved.

Owner:绍兴华裕纺机有限公司

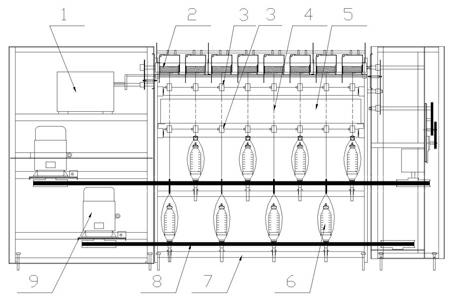

Pneumatic shot blast machine

PendingCN107584430AEasy to polishHighly innovativeAbrasive machine appurtenancesAbrasive blasting machinesEngineeringMechanical engineering

The invention discloses a pneumatic shot blast machine which comprises a shot-blast room, a shot-blast device and a conveying device, wherein the conveying device penetrates through the shot-blast room; the shot-blast device comprises an upper shot blast vessel, two groups of lateral shot blast vessels and a lower shot blast vessel, the upper shot blast vessel is connected to the upper end of theshot blast room, and the lateral shot blast vessels and the lower shot blast vessel are connected to the lateral end of the shot blast room; the upper shot blast vessel comprises an upper shot blast support, a first rotary disk, a first locating plate and a first shot blast pipe; each lateral shot blast vessel comprises a lateral shot blast support, a balance weight mechanism, a second rotary disk, a locating mechanism and a second shot blast pipe; the balance weight mechanism comprises a protection cover, a balance weight block arranged in a lower portion of the protection cover and a drivingwheel arranged in an upper portion of the protection cover; the lower shot blast vessel comprises a lower shot blast support, a third rotary disk, a third locating plate and a third shot blast pipe;a shot blast room rear notch is formed in a shot blast room lateral wall at the rear end of a shot blast room lateral notch. The pneumatic shot blast machine can perform better shot blast cleaning onirregular-shaped engine cylinder objects and has high creativity.

Owner:QINGDAO ANTAI HEAVY IND MACHINERY

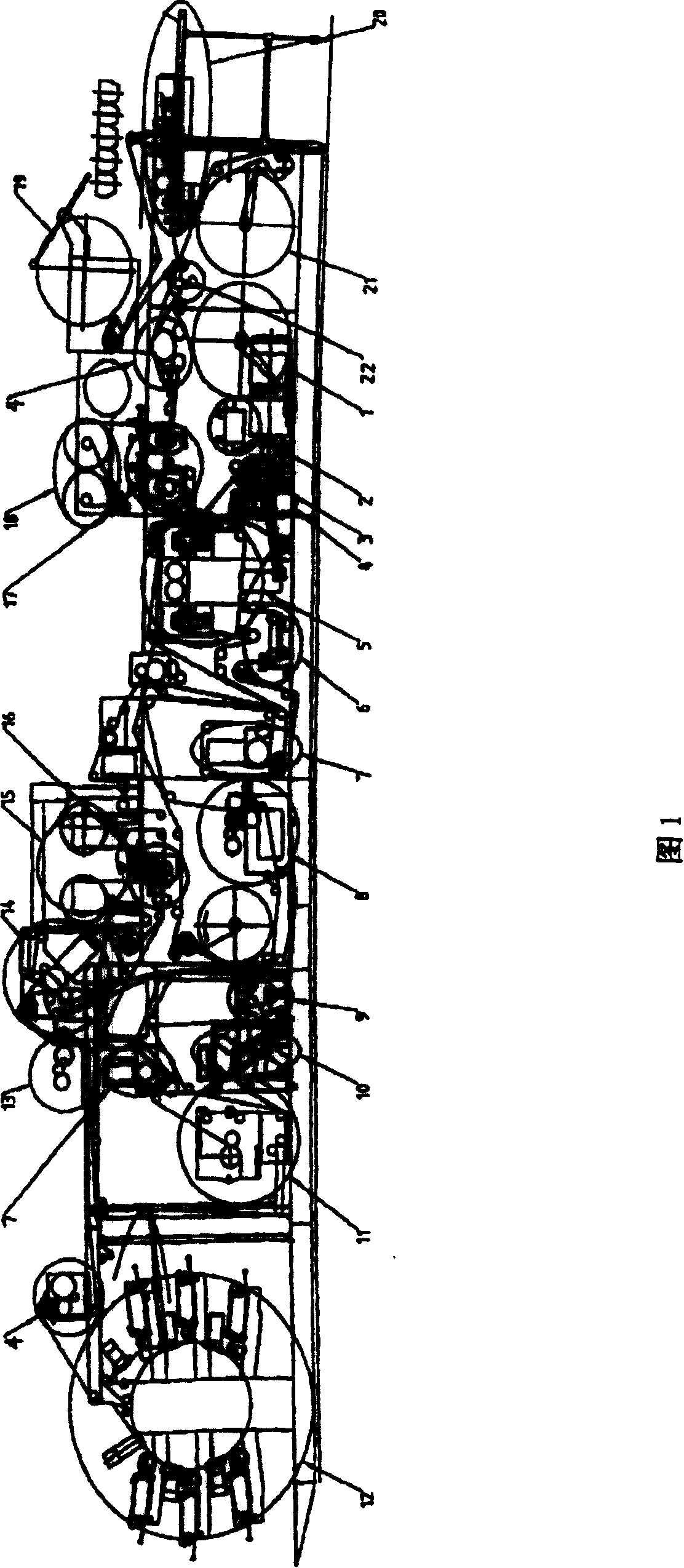

Adhensive rotary printer

InactiveCN100382963CViscous stabilitySticky and flexibleRotary pressesScreen printingSmall footprint

A rotary press for printing on non-drying adhesive matter is composed of paper feeder, paper receiver, speed reducer, AC servo tension control and tract unit, platen unit, skew corrector, servo motor cooling and driving unit, flexible plate printing unit, paper chip and static electricity remover, corona unit, silk screen printing unit, satellite relief printing unit, gilded film sticking-UV baking-cooling driver, golden foil feeder, reel, gilded film cutting unit, etc.

Owner:SHANGHAI XINMIN TAIYO KIKAI

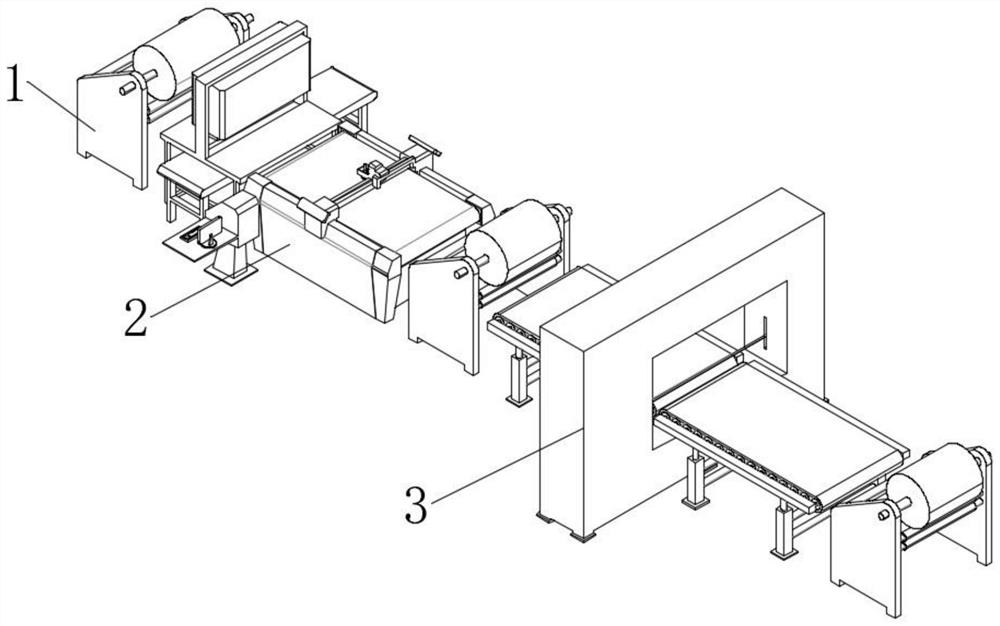

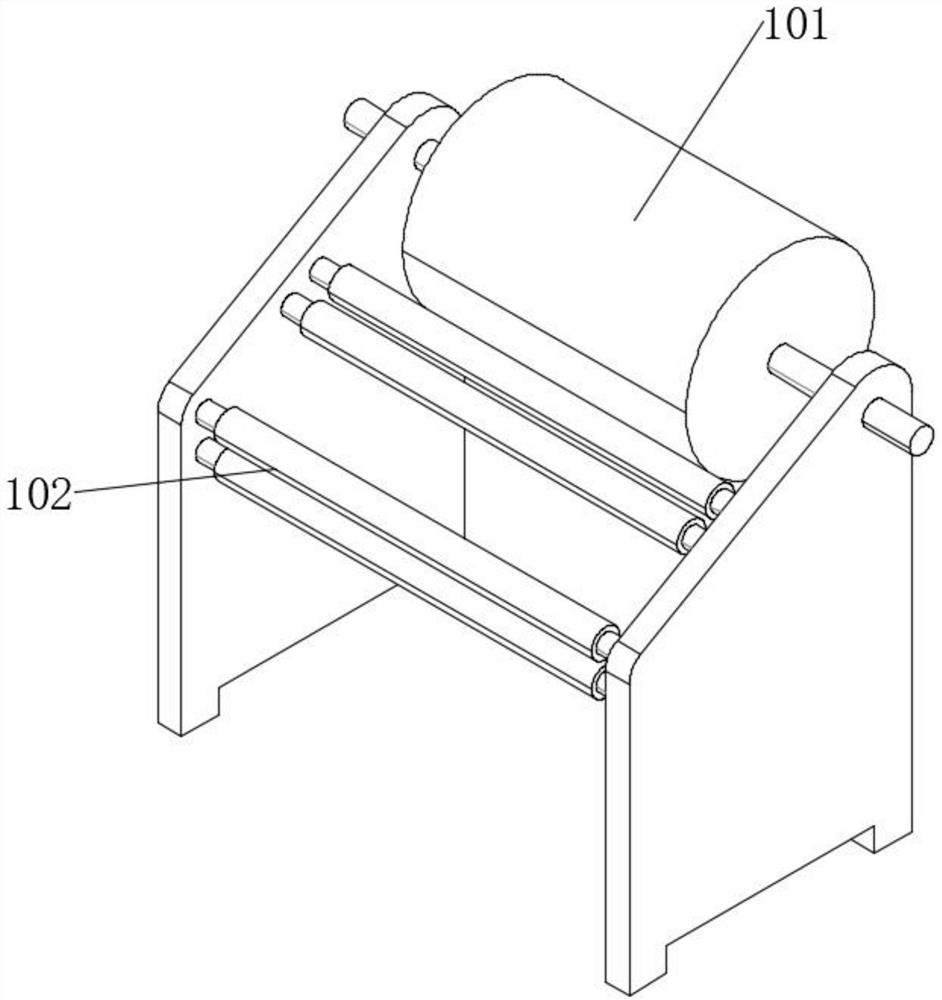

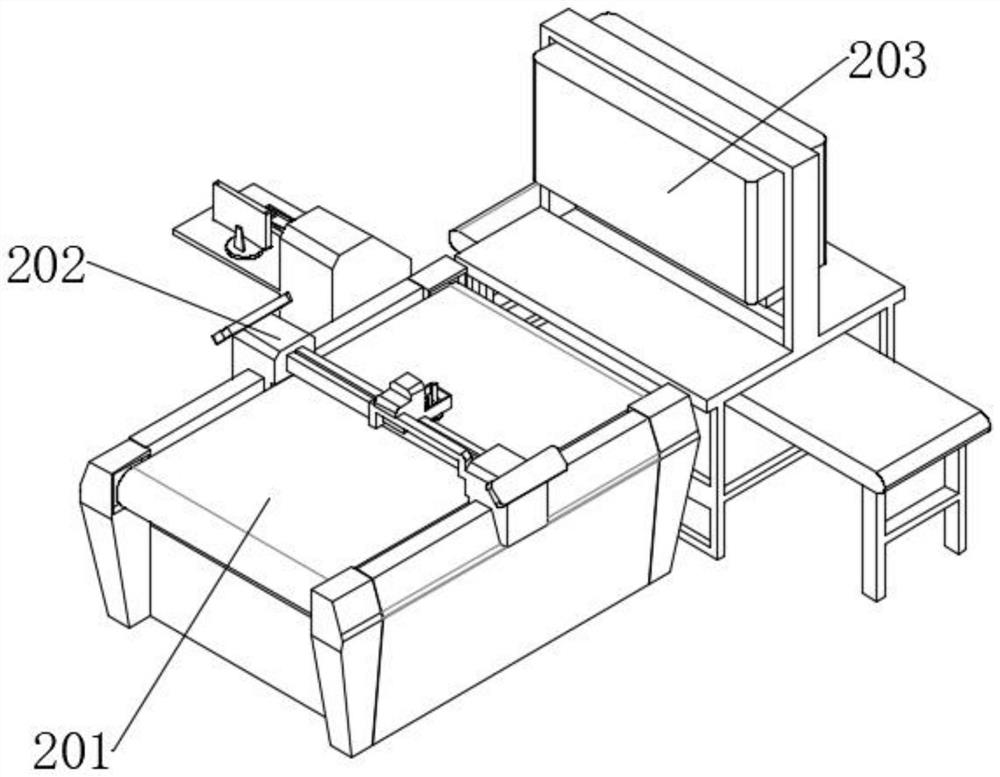

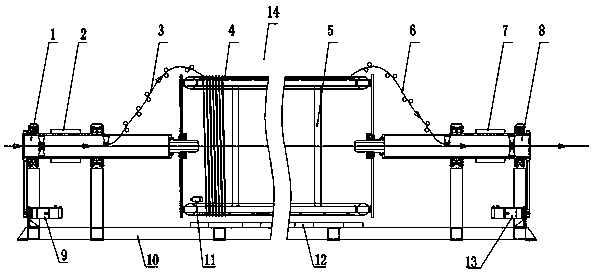

Method for controlling cotton felt tailoring size precision

The invention discloses a method for controlling cotton felt tailoring size precision, and belongs to the field of cotton felt tailoring methods. The method for controlling cotton felt tailoring sizeprecision can achieve production technology automation. A reeling and unreeling device can achieve automatic unreeling and unreeling of reeled cloth, a horizontal tailoring device can achieve horizontal-direction tailoring of the cloth, the tailoring thickness is adjustable, and a vertical tailoring device can tailor the cloth into the needed shape. In the production process, an integrated vacuumdust removal device body is adopted, it is ensured that waste fiber and dust generated in the tailoring process are automatically collected, and green and environment-friendly production is ensured. In the vacuum dust removal device body, the principle of heat expansion and cold shrinkage is adopted for achieving the following operation: in the normal work process, gathering fiber capturing hooksare in a bending state, so that felt fiber scraps are conveniently captured, in the process that the fiber capturing hooks are cleaned through hot water, the fiber capturing hooks are in a vertical state, and accordingly the felt fiber scraps captured by the fiber capturing hooks are conveniently cleaned.

Owner:HAIAN DISCORY INSTR CO LTD

Spring curtain lifting and collecting mechanism

The invention discloses a spring curtain lifting and collecting mechanism which comprises a bottom frame, a servo motor, a first coupler, a collecting box and a fixing block, the servo motor is installed on the outer wall of one side of the bottom frame, a rotating shaft is installed at the output end of the servo motor, and the first coupler is installed at one end of the rotating shaft; fixing blocks are mounted on the two sides of the top of the bottom frame; and two sets of collecting boxes arranged side by side are installed on the back face of the bottom frame, a curtain collecting roller is installed on the outer wall of one side of one set of collecting boxes in a penetrating mode, two sets of steel rope collectors arranged side by side are installed on the outer surface of the curtain collecting roller, and steel rope guide mechanisms are installed on the inner walls of one sides of the two sets of collecting boxes. According to the invention, a group of motors are adopted for control, the difficulty in control can be reduced, the opening force of the curtain sheets can be controlled to a certain extent through the springs, the curtain dust removal operation can be carried out in the opening process of the curtain, and a part for dust removal is clamped and connected with the combined frame body, so that the detachable performance is realized.

Owner:JIANGSU SHUNHE INTERNET OF THINGS TECH CO LTD

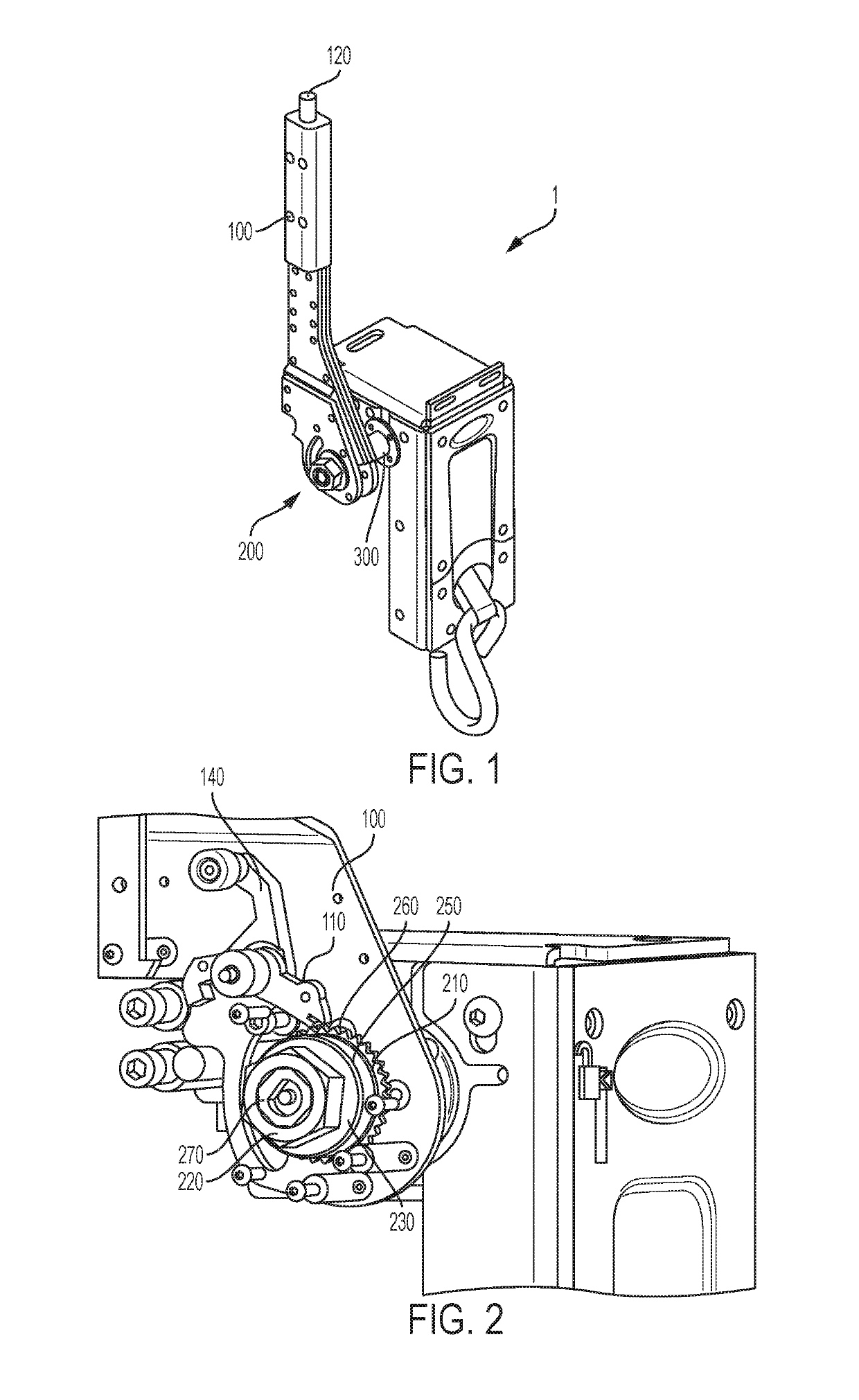

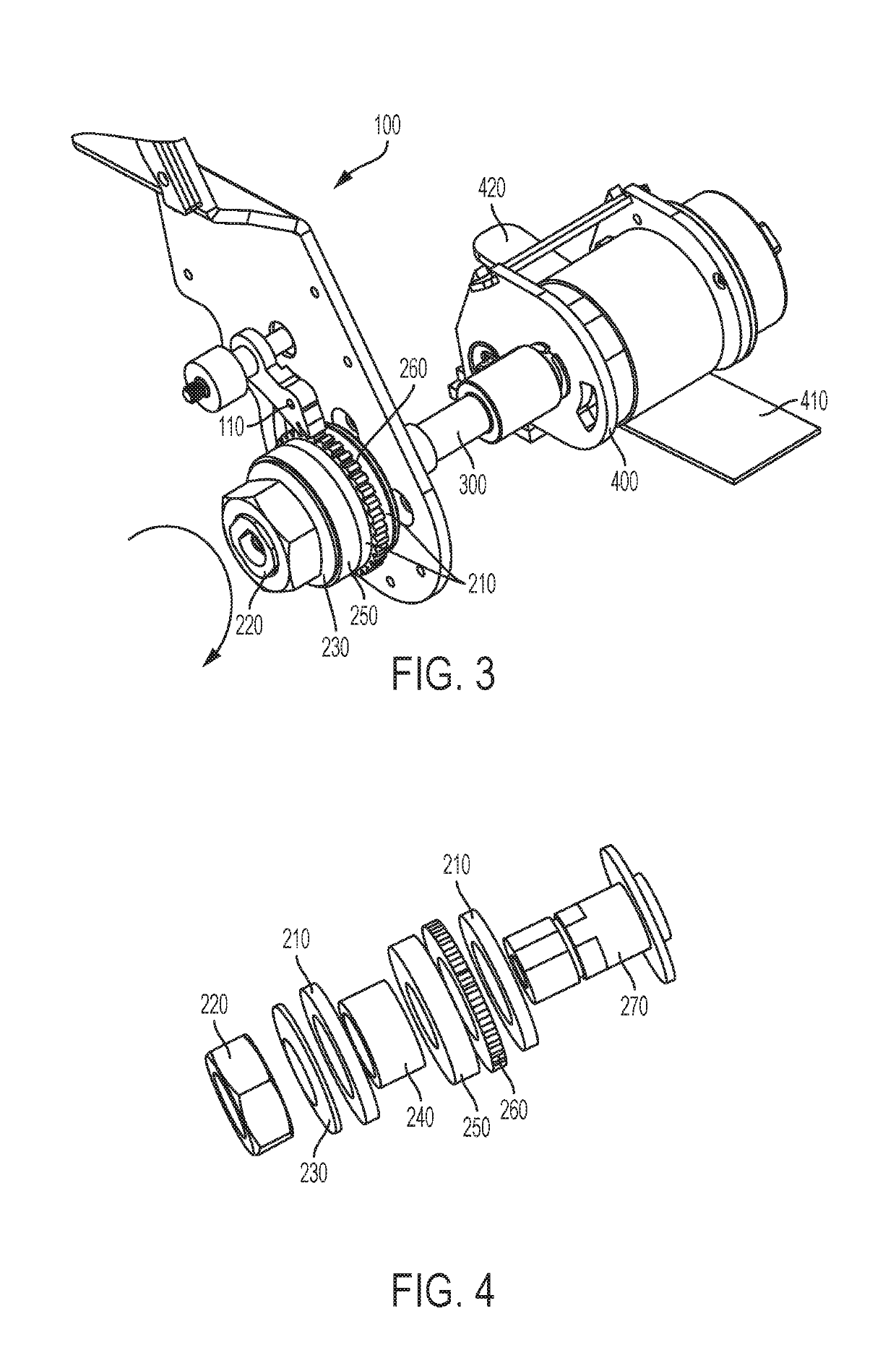

Mobility restraint device tensioner

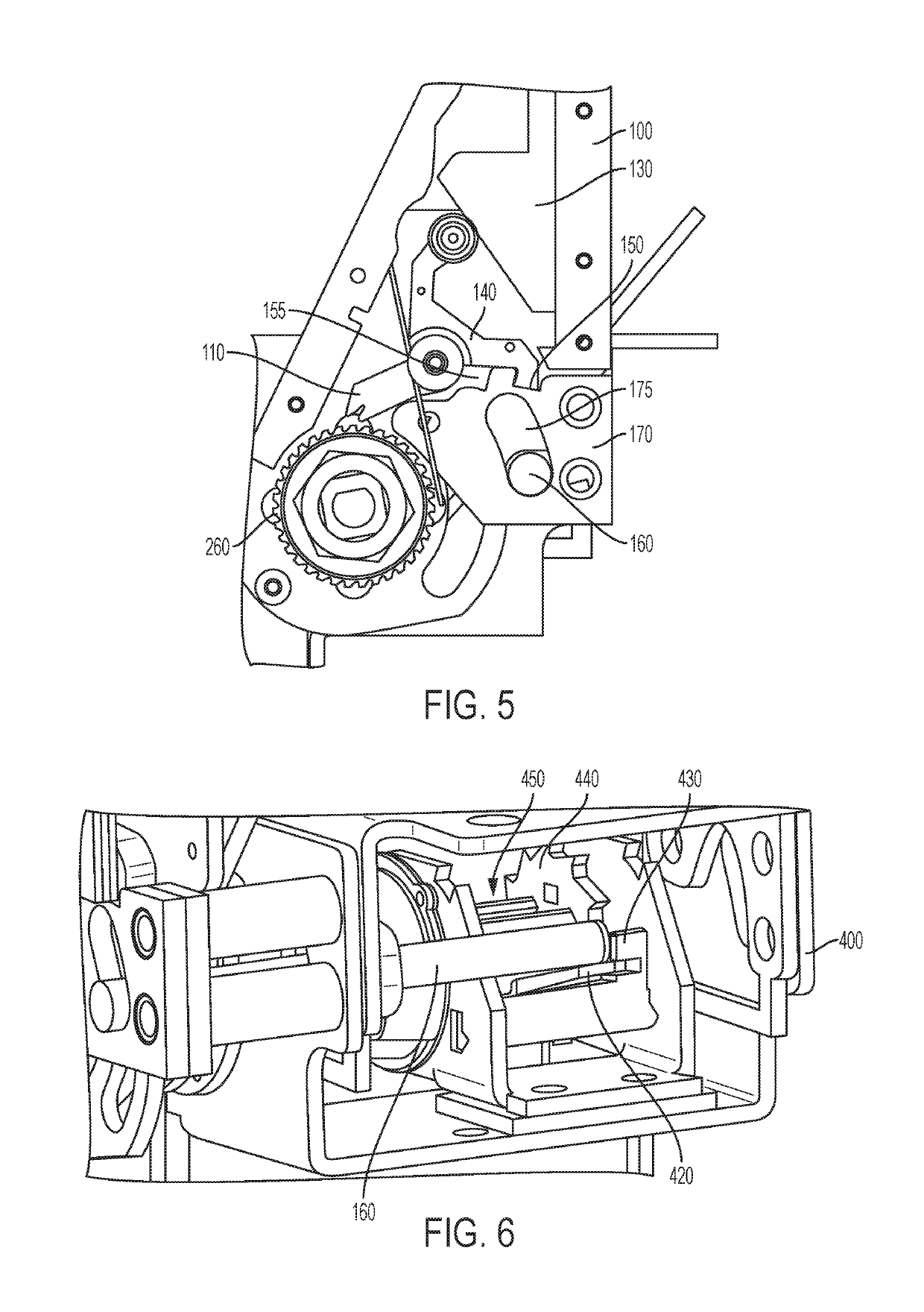

ActiveUS10342719B2Small footprintReduce distractionsSlip couplingSupplementary fittingsWheelchairDrive shaft

A tensioning device is provided for tensioning a retractor in a wheelchair securement system. The tensioning device may include a clutch assembly for communicating rotational movement of a handle to a drive shaft operably connected to the spool of the retractor. The clutch assembly may include a pawl operably connected to the handle, which pawl communicates rotational movement of the handle to a drive sprocket. The clutch assembly may also include a friction member which communicates rotation of the drive sprocket to the drive shaft up to a predetermined amount of rotational force. If the rotational force exceeds the predetermined amount, the friction member will slip and cease to transfer rotational movement from the drive sprocket to the drive shaft. The clutch assembly may also include a compression member for compressing the friction member and drive sprocket whereby the predetermined amount of force may be adjusted.

Owner:VALEDA

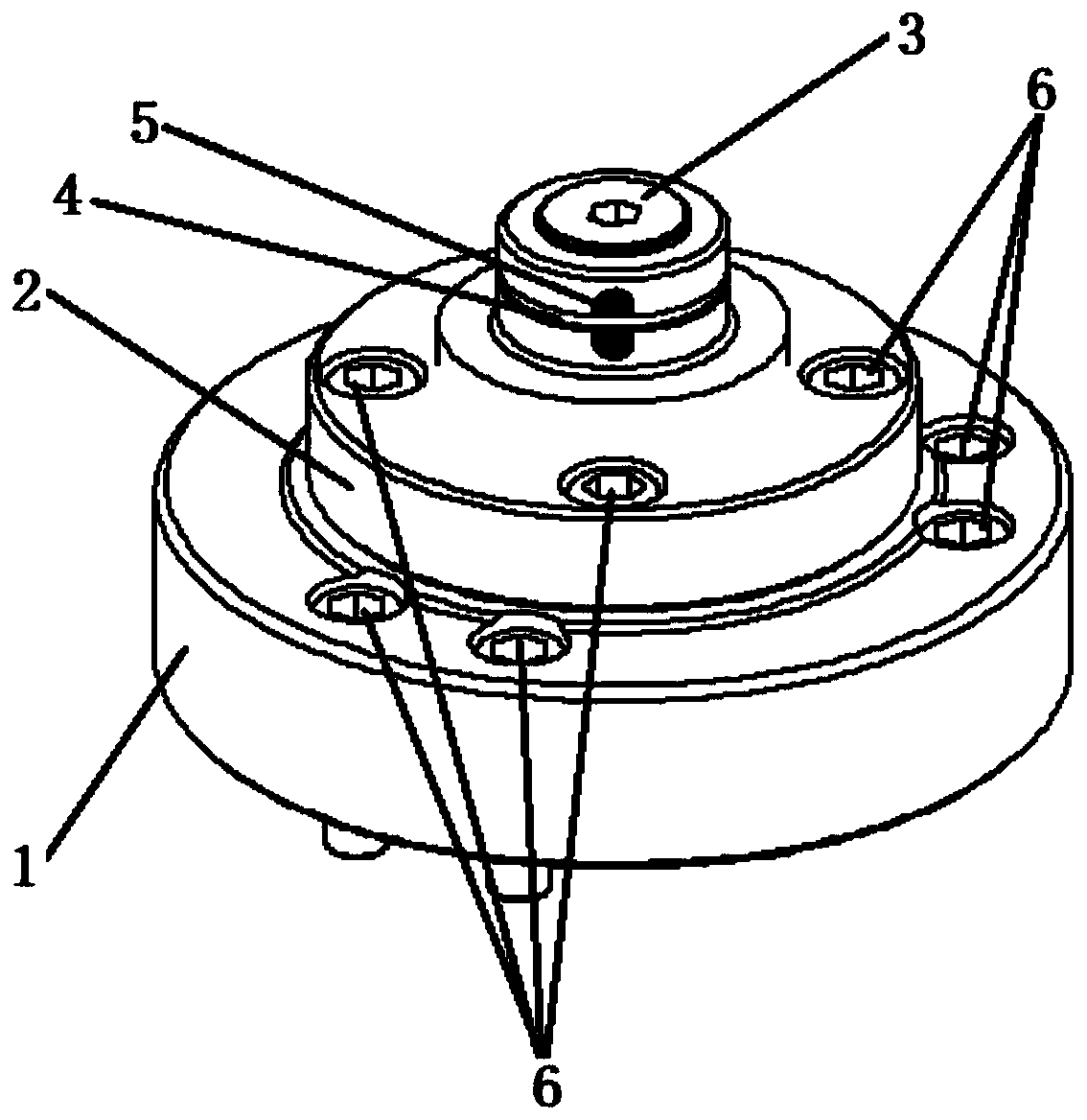

Rough turning fixture for disc type gear

PendingCN109834310AReduce manufacturing costGuarantee quality and efficiencyChucksRubber ringEngineering

The invention discloses a rough turning fixture for a disc type gear. The rough turning fixture comprises a flange disc, a mandrel, a pulling rod, a rubber ring and a plurality of sliding blocks; oneend of the flange disc is connected with a machine tool, and the other end of the flange disc is connected with the mandrel; the other end of the mandrel is a part installing and clamping end, and a pulling rod installing hole is formed in the part installing and clamping end, and the diameter of the pulling rod installing hole is gradually increased in the direction away from the flange disc; sliding block installing holes with the number same as the number of the sliding blocks are evenly formed in the side wall of the pulling rod installing hole; the sliding blocks are arranged in the sliding block installing holes and can move up and down in the sliding block installing holes; the rubber ring is arranged in a pulling rod installing hole groove which is formed in the outer side of the pulling rode installing hole in a sleeving mode, and the rubber ring is connected with sliding block grooves formed in the top ends of the sliding blocks; one end of the pulling rod is a circular truncated cone end, and the other end of the pulling rod is connected with the machine tool; the circular truncated cone end of the pulling rod is located in the pulling rod installing hole; and the bottomends of the sliding blocks are attached to the outer surface of the pulling rod circular truncated cone end. The rough turning fixture for the disc type gear is wide in clamping range and low in cost, significantly improves the machining quality and efficiency of rough turning molding, and provides guarantee for subsequent gear machining.

Owner:BAOJI FAST GEAR

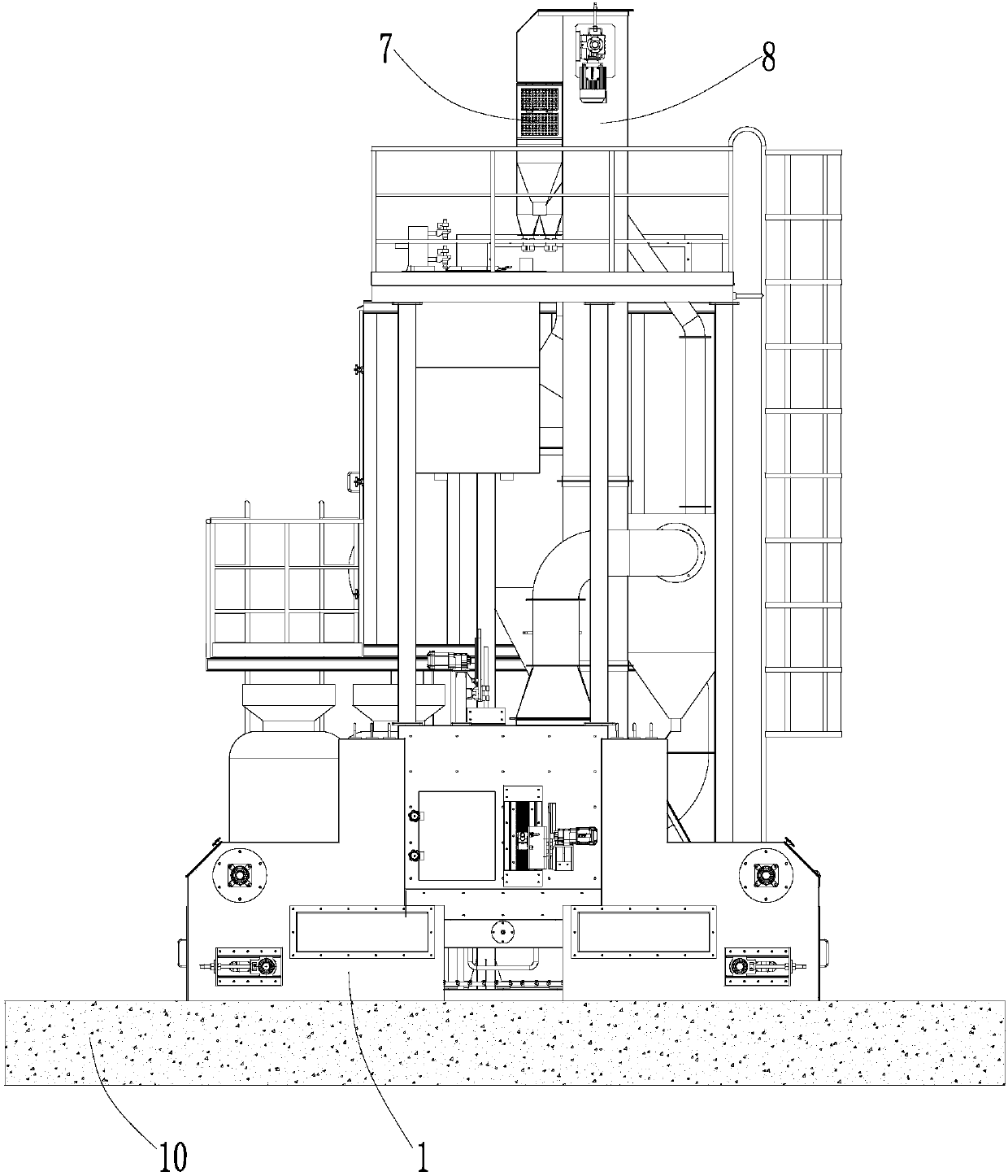

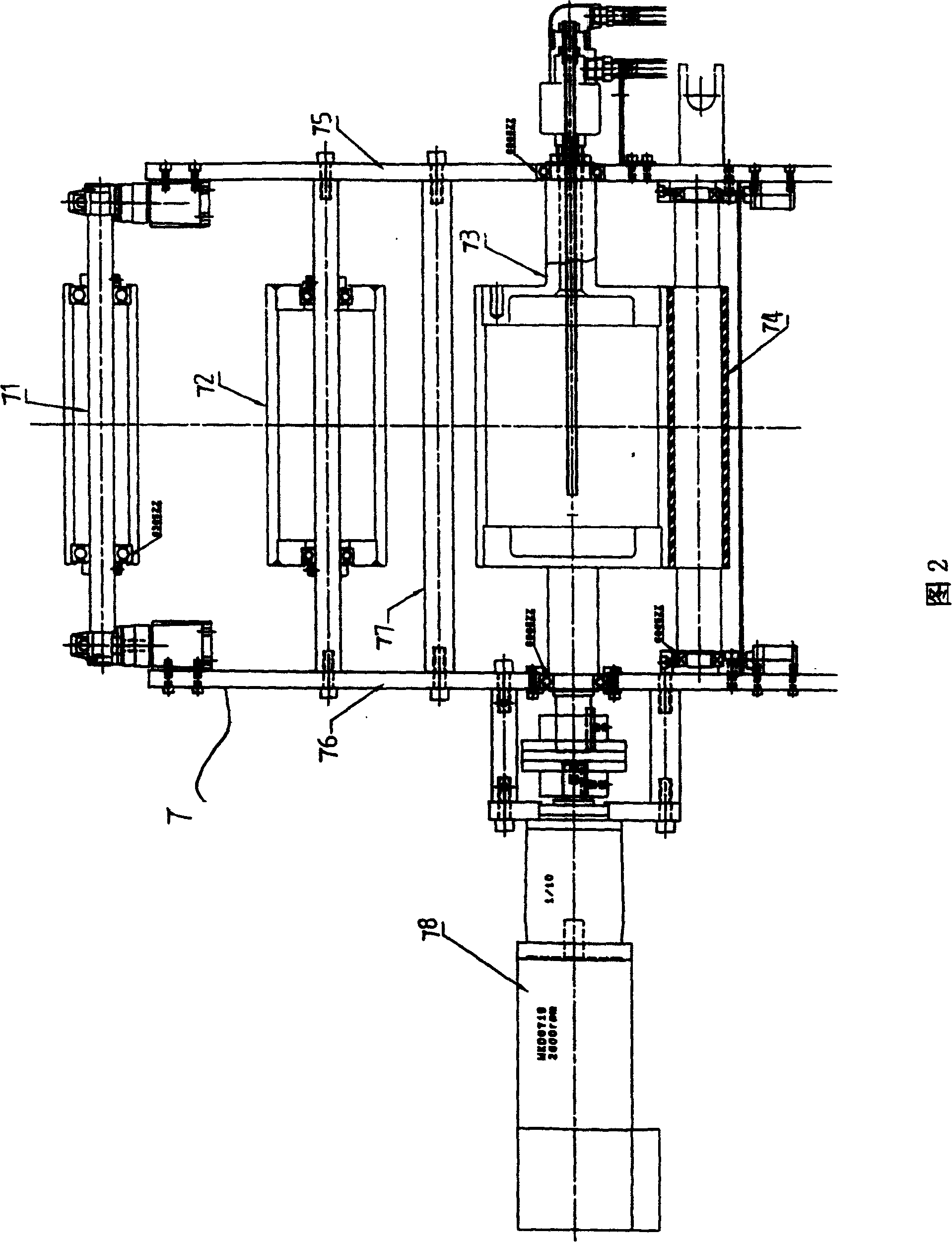

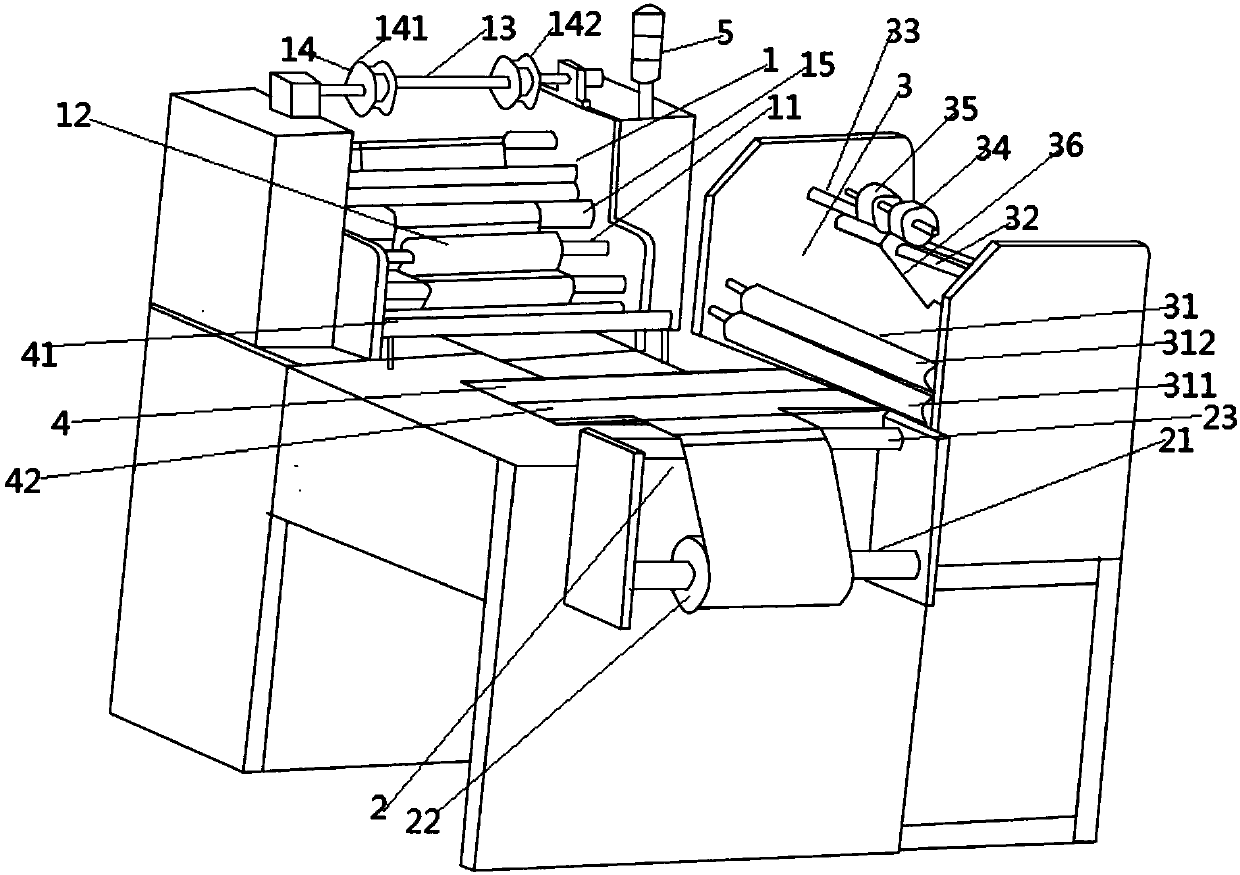

Material compositing device and process

ActiveCN105946332AControllable tensionNice appearanceLamination ancillary operationsLaminationEngineeringCam

The invention belongs to the mechanical field. A material compositing device sequentially comprises a traction mechanism, a first gluing mechanism, a folding mechanism, a local cut-off and punching device, a cut-off transverse state converting mechanism, a guide roller, a flapping mechanism, a shaping mechanism, a second gluing mechanism and a transfer wheel along a material conveying direction, wherein the flapping mechanism comprises a cam which is used for flapping material when coming in fit with the cut-off transverse state converting mechanism. The material compositing device has the beneficial effects that a flexible and ventilated non-woven fabric and an elastic material are composited online, and the elastic material in a composite is locally processed to be fit for a human body, thereby meeting the requirements of attractive appearance and use comfort. In a production process of a compositing process, the tension of the material is easily controlled, the comfort level is guaranteed, and furthermore, multiple types of products can be produced from the same raw material, so that the cost is beneficially lowered.

Owner:ANQING HENG CHANG MACHINERY

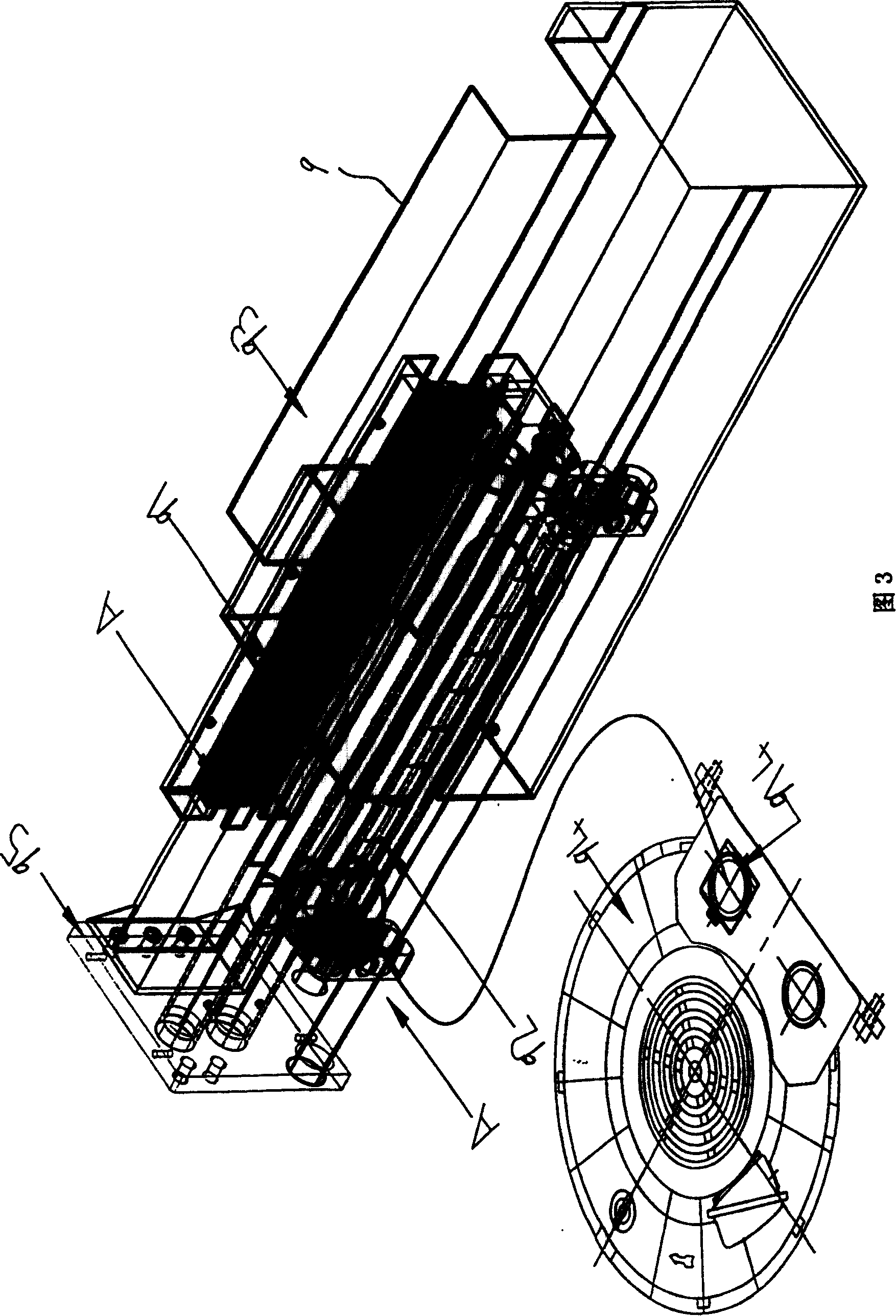

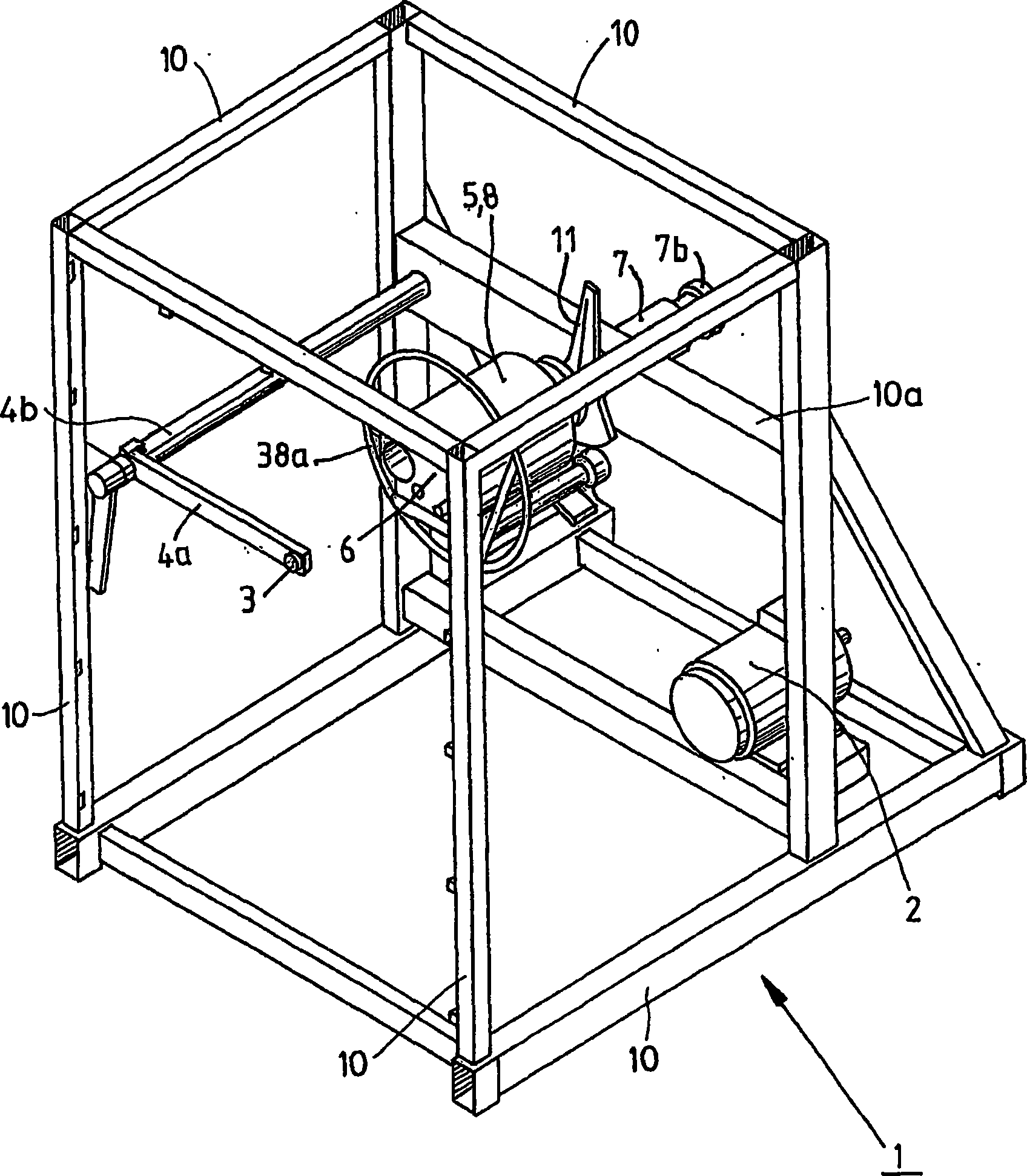

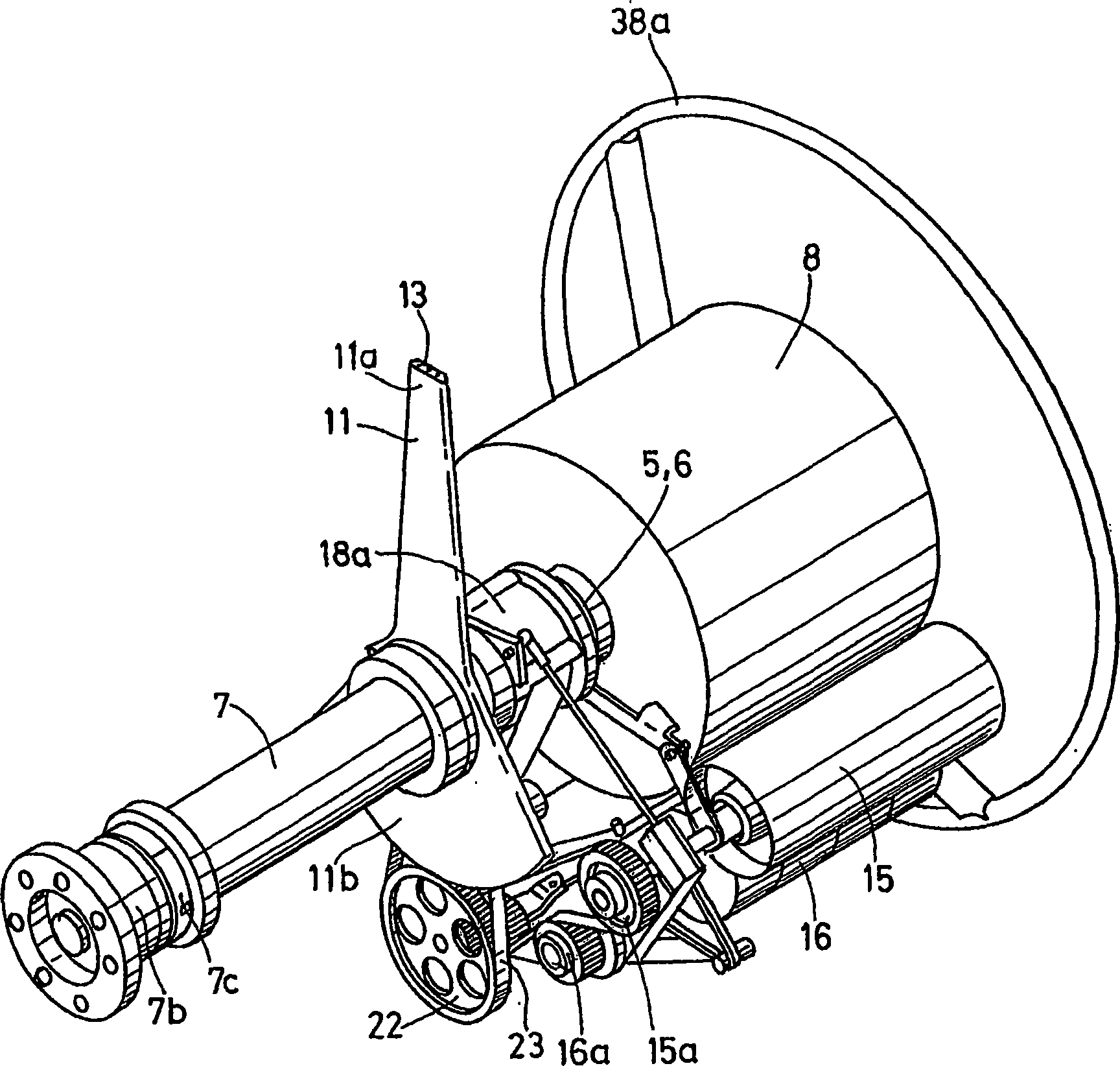

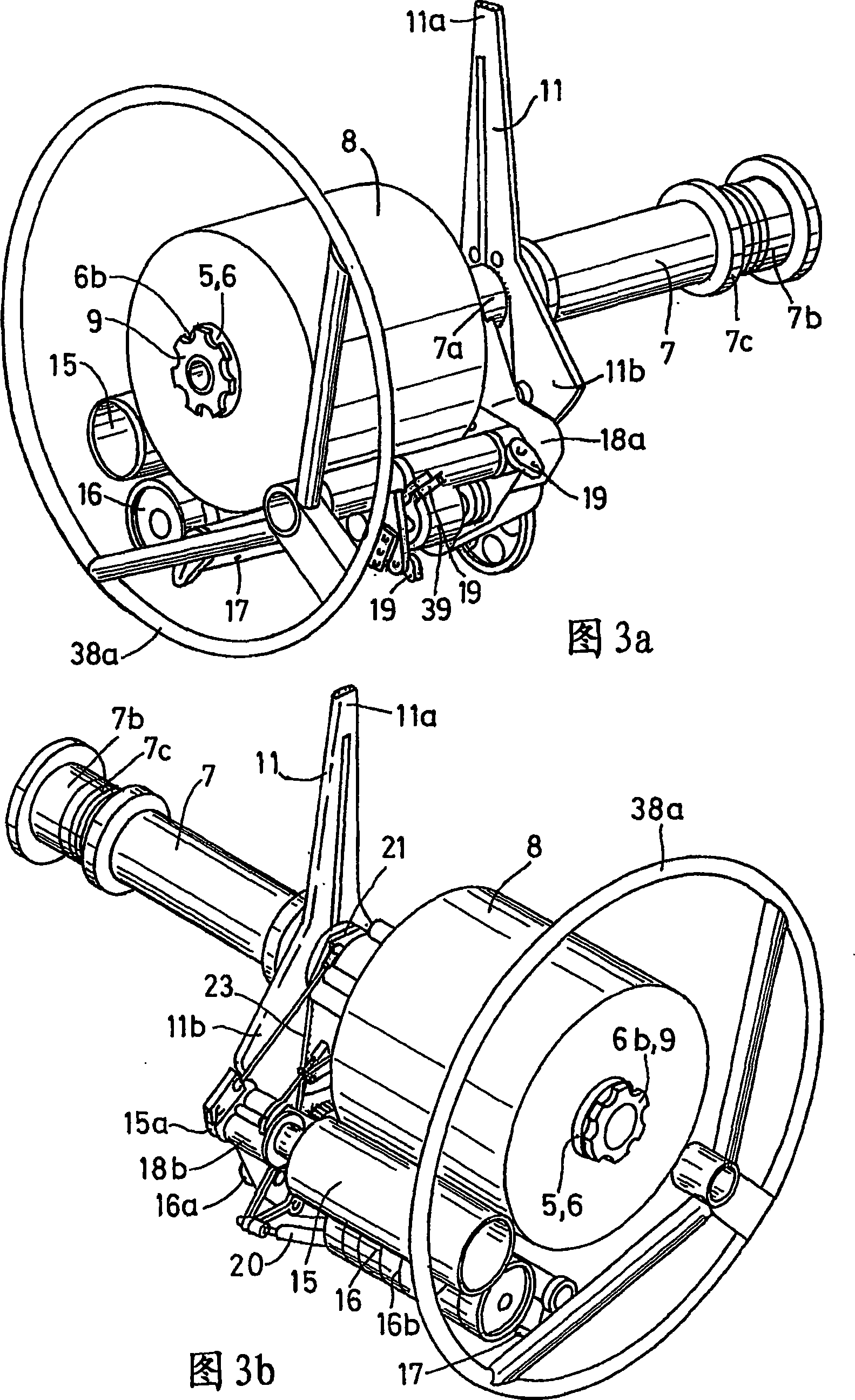

Device for winding an elongate, threadlike element on a winding element

InactiveCN1867707ACompact structureOptimize structureContinuous wound-up machinesEngineeringConductor Coil

The invention relates to a device for winding an element consisting of at least one elongated filiform strand on a winding element, said device comprising a frame having at least the following elements: for said elongate filiform element The inlet, and the winding element driven in rotation around the winding shaft, the device also includes at least a driving device for rotationally driving the winding element. According to the invention, the winding device is characterized in that twisting means are mounted on said frame, said twisting means being directed towards said The filamentary element imparts one or more turns per unit length (twisting in the case of a single strand of elongate filamentary element, or twisting in the case of multiple strands of elongate filamentary element).

Owner:TEN CATE THIOLON

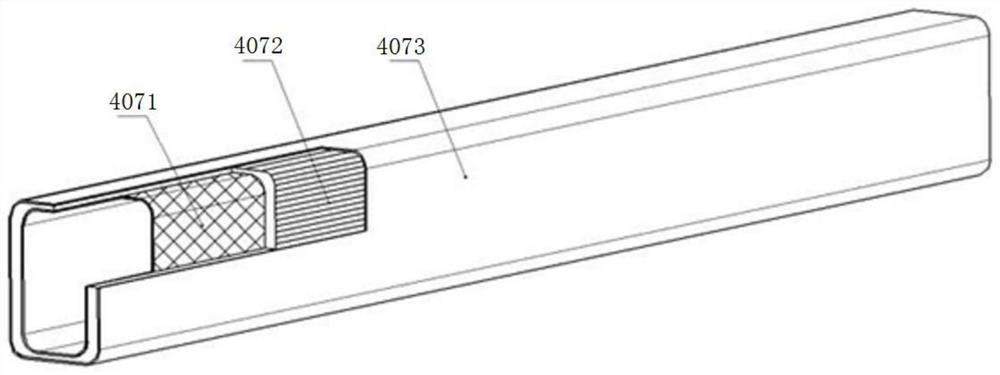

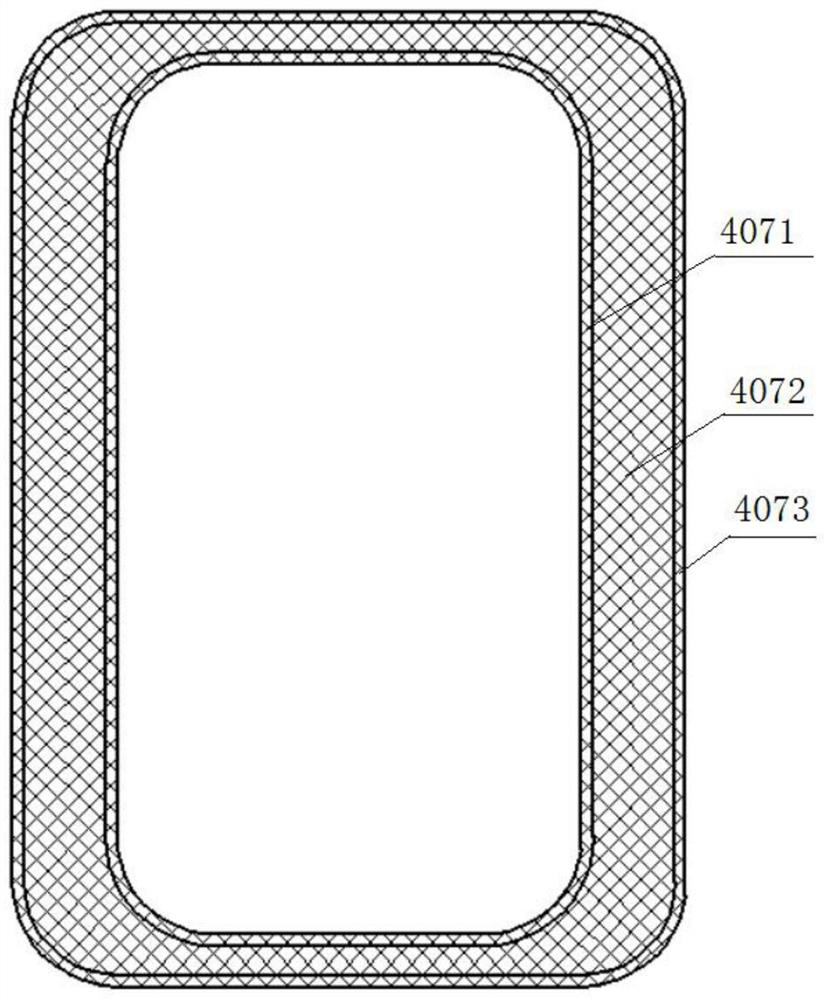

Composite material space truss structure and preparation method based on curing forming mold

InactiveCN111976228AControllable tensionAvoid complicated splicing and assemblyLayered productsFiberWinding machine

The invention relates to a composite material space truss structure and a preparation method based on a curing forming mold, relates to the technical field of space stations, and solves the technicalproblems that in the prior art, a truss structure of a space station is formed in a multi-round-pipe mode through equal-tension winding, the structural form is single, the length of the structure is limited by the specification of a winding machine, short-pipe and short-rod splicing is usually achieved through a metal adapter, the damage risk of composite material bonding tapping is increased, andthe effective load is reduced. The composite material space truss structure is technically characterized by comprising a square pipe body with the wall thickness being of a three-layer structure, 12Kcarbon fibers are adopted in an inner layer and an outer layer, and 50K large-tow carbon fibers are adopted in a middle layer. The truss structure has the beneficial effects of avoiding complex splicing and assembling of the short pipes and the short rods, reducing the risk and the weight of the connecting ends, further improving the effective load and improving the truss foundation for a large space structure.

Owner:长春长光宇航复合材料有限公司

Color tape slitting device with leader tape automatic sticking function

PendingCN107696102AReduce relative frictionReduce labor costsMetal working apparatusEngineeringElectrical and Electronics engineering

The invention discloses a color tape slitting device with a leader tape automatic sticking function. The color tape slitting device comprises a small-roll color tape roll assembly, a primary-roll color tape feed assembly, a leader tape feed assembly and a head-tail tape slitting assembly. The small-roll color tape roll assembly is used for slitting a primary-roll color tape and rolling a slit small-roll color tape, the small-roll color tape roll assembly is provided with a film cutter combining part and receiving shafts, and arrayed film cutters are arranged on the film cutter combining part.The primary-roll color tape feed assembly is provided with a tension adjusting rod, and the primary-roll color tape is arranged in the tension adjusting rod in a penetrating mode. The leader tape feedassembly is used for sticking a leader tape to the tail end of the small-roll color tape, and tape pressing wheels are arranged on the leader tape feed assembly. When the two or more sets of tape pressing wheels are arranged, the two sets in the tape pressing wheels are perpendicularly and symmetrically arranged, and the two sets of tape pressing wheels are the first tape pressing wheels and thesecond tape pressing wheels. The head-tail tape slitting assembly is provided with a pressing plate, and the pressing plate is fixedly connected with the head-tail tape slitting assembly. In this way,the production cost is saved, and the work efficiency of the device is more improved.

Owner:YIHE PRECISION IND SUZHOU

Preparation method of black colored ribbon Glencheck double-faced woolen cloth and equipment for producing wrap yarn of black colored ribbon Glencheck double-faced woolen cloth

ActiveCN112323218AControl tensionControllable tensionContinuous wound-up machinesWoven fabricsYarnFiber

The invention discloses a preparation method of black colored ribbon Glencheck double-faced woolen cloth. The preparation method comprises the following steps: preparing lantern yarn and the wrap yarn; using the wrap yarn as inserted yarn and interweaving the wrap yarn with black yarn and white yarn to manufacture the black colored ribbon Glencheck double-faced woolen cloth, wherein the wrap yarnis formed by wrapping lantern yarn around space-dyed nylon filaments. The invention further discloses equipment for producing the wrap yarn in the black colored ribbon Glencheck double-faced woolen cloth, so that the tension during filament feeding can be controlled, and thus the tension of the filaments can be the same as that of staple fibers, and the wrapping effect of the filaments is better.

Owner:江阴市长泾花园毛纺织有限公司

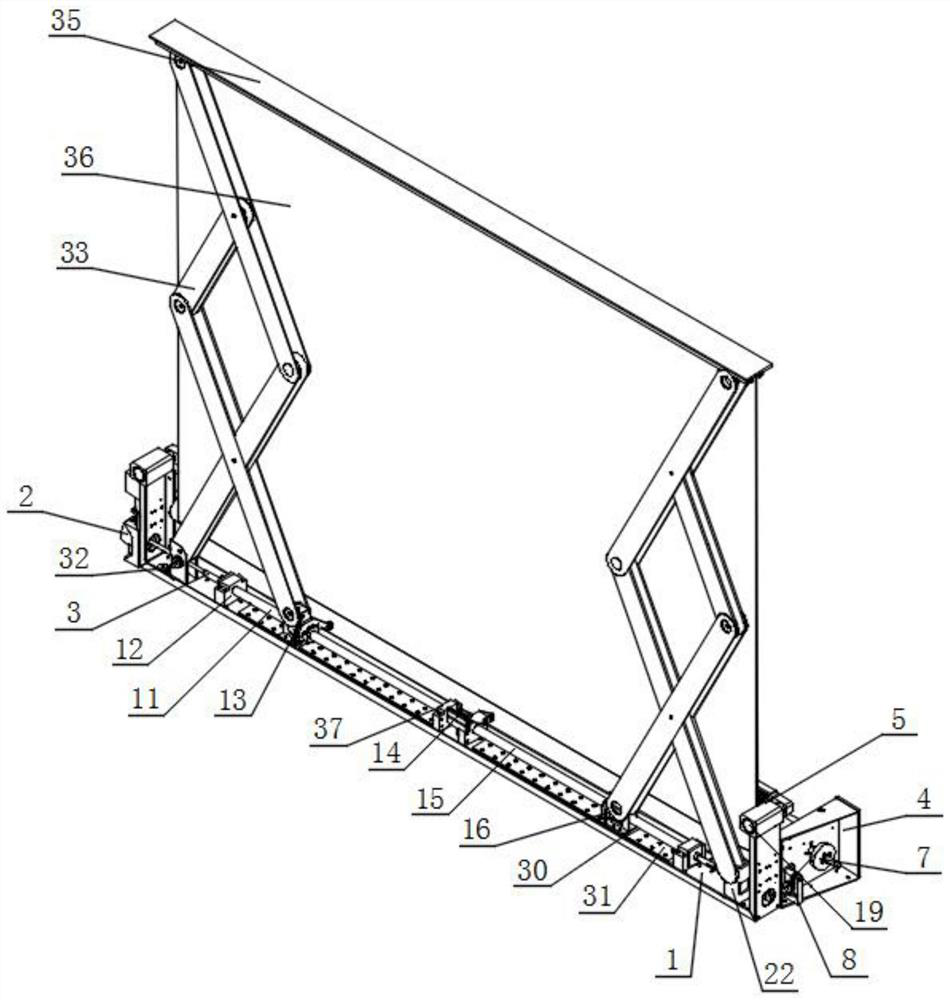

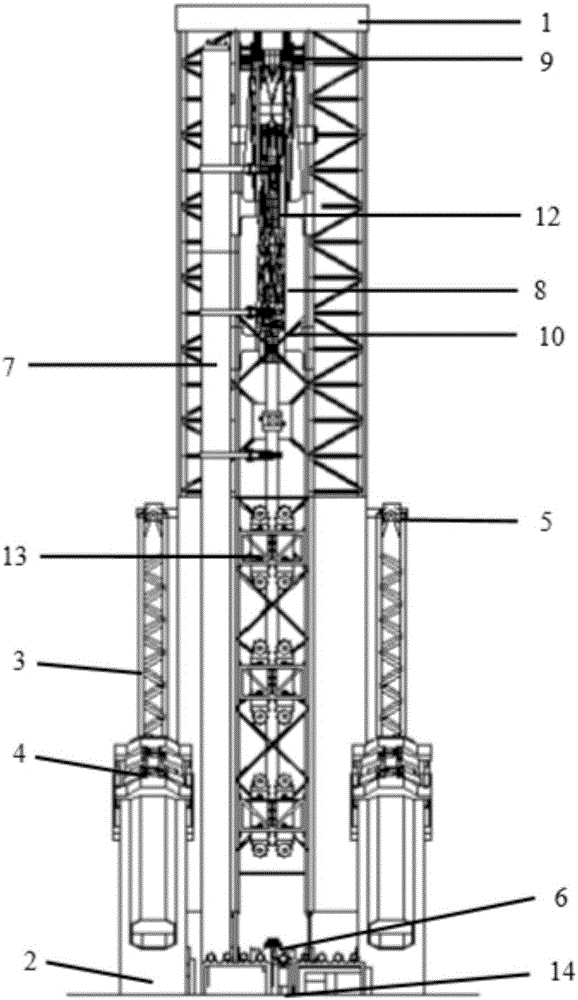

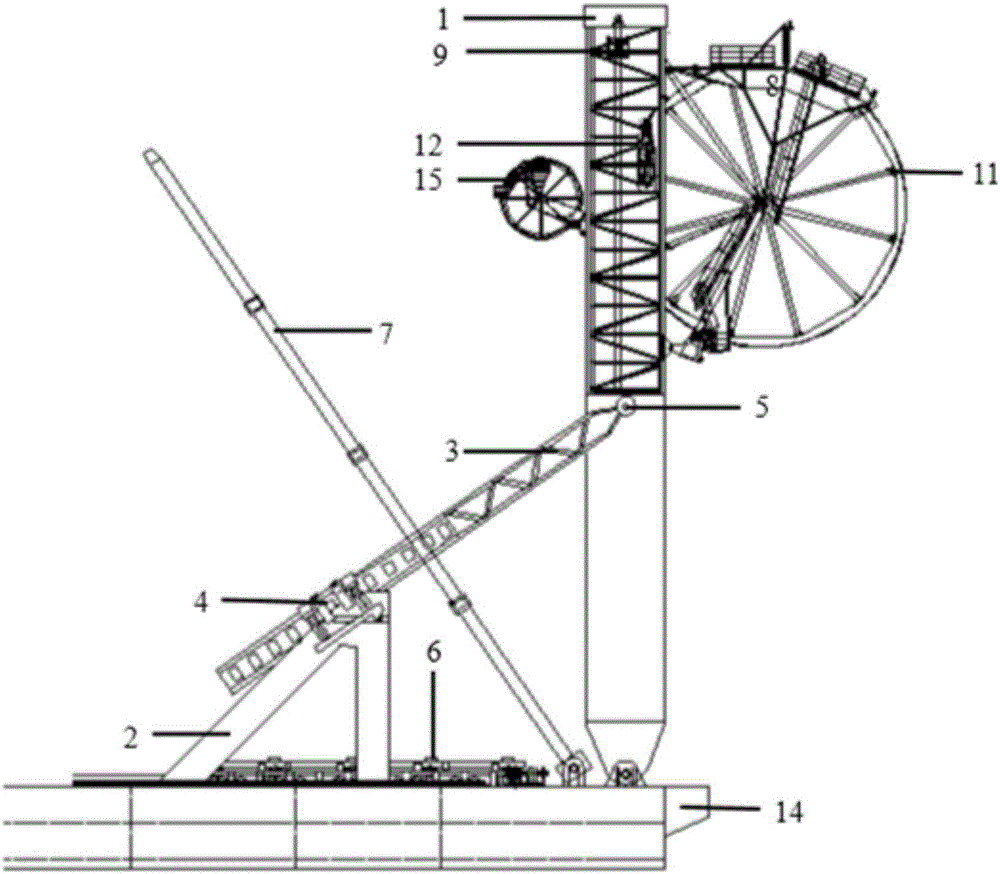

Novel four-joint J-shape-winding drum integrated laying system

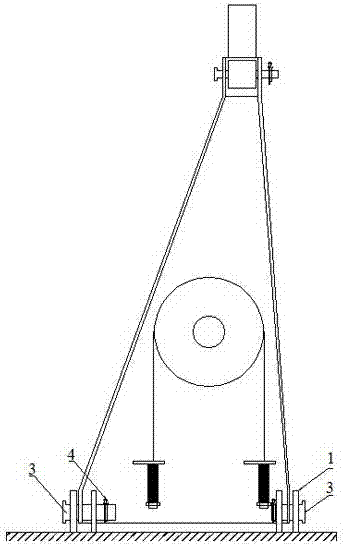

ActiveCN105757341AReduced stress situationsImprove laying qualityPipe laying and repairLoading armTower

The invention provides a novel four-joint J-shape-winding drum integrated laying system. The laying system mainly comprises a laying tower, a winding drum, a laying tower angle adjusting system, a straightening system, a pipe laying and conveying system and key equipment for pipe laying, wherein the laying tower angle adjusting system comprises A frames, angle adjusters, hydraulic cylinders and angle adjuster connecting shafts; the straightening system comprises a correcting wheel, a straightener and a straightening roller; the pipe laying and conveying system comprises a horizontal conveying system, a loading arm and an elevator; the key equipment for pipe laying comprises a tensioner and a moving platform. The laying system can complete pipe laying work of pipes in various sizes, materials and diameters at various water depths; not only can the total use amount of equipment be reduced, but also laying manners can be switched timely according to actual laying requirements, and under the condition that stress to the pipe is reduced, the quality and the efficiency of pipe laying are improved, the economy is improved, and the system has quite high comprehensive operation capacity.

Owner:河南天宏重工科技有限公司

Composite device and process of a material

ActiveCN105946332BControllable tensionNice appearanceLamination ancillary operationsLaminationEngineeringCam

The invention belongs to the mechanical field. A material compositing device sequentially comprises a traction mechanism, a first gluing mechanism, a folding mechanism, a local cut-off and punching device, a cut-off transverse state converting mechanism, a guide roller, a flapping mechanism, a shaping mechanism, a second gluing mechanism and a transfer wheel along a material conveying direction, wherein the flapping mechanism comprises a cam which is used for flapping material when coming in fit with the cut-off transverse state converting mechanism. The material compositing device has the beneficial effects that a flexible and ventilated non-woven fabric and an elastic material are composited online, and the elastic material in a composite is locally processed to be fit for a human body, thereby meeting the requirements of attractive appearance and use comfort. In a production process of a compositing process, the tension of the material is easily controlled, the comfort level is guaranteed, and furthermore, multiple types of products can be produced from the same raw material, so that the cost is beneficially lowered.

Owner:ANQING HENG CHANG MACHINERY

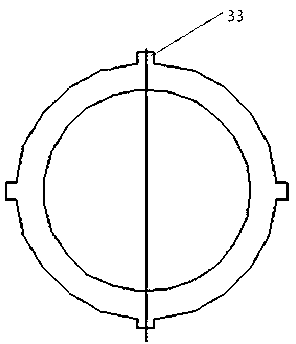

Large-capacity falling-barrel-type constant tension dynamic line storing equipment

PendingCN110577107ANo damageEliminate the phenomenon of being buttonedFilament handlingEngineeringLine structure

The invention discloses large-capacity falling-barrel-type constant tension dynamic line storing equipment. A line storing equipment consists of a line-feeding falling barrel, a falling-barrel flexible mechanical arm, a line-storing barrel body, a line discharging barrel, a discharging-barrel flexible mechanical arm and an equipment base, the feeding and discharging barrels rotate synchronously with the corresponding flexible mechanical arms, the rotating speed of the feeding and discharging barrels can be adjusted according to the tension requirement, and a line storing barrel is fixed between the feeding and discharging barrels through a bearing and relatively fixed to the base through a fixed magnet in the middle of the equipment base. The large-capacity falling-barrel-type constant tension dynamic line storing equipment has the beneficial effects that by arranging the flexible feeding and discharging barrel arms, line is naturally bent, the line cannot be damaged, and the line storing and straightening functions are achieved; barrel feeding and discharging modes are adopted, tying and untying of the line in the line storing process appear in pairs, the phenomenon of irregular line tying is eliminated, the stability of the line structure is ensured accordingly, regular constant tension line arranging of the stored line on the line storing barrel is achieved, and the first-infirst-out line storing and releasing principle is effectively achieved accordingly, so that the tension of the line is capable of being controlled in the line storing process.

Owner:徐立清

Weighing and pressurizing device arranged on on-line friction belt conveyor

PendingCN112298927ANormal toneControllable tensionConveyorsControl devices for conveyorsGear wheelLoad cell

The invention discloses a weighing and pressurizing device arranged on an on-line friction belt conveyor. According to a method, two sets of weighing devices and a set of pressurizing device are included, and the pressurizing device is fixed between the two sets of weighing devices; each weighing device comprises a conveying belt, carrier rollers and the like, wherein the carrier rollers are arranged below the conveying belt, a bearing plate is arranged below the carrier rollers, and weighing sensors are arranged below the bearing plate; and the pressurizing device is composed of an upper cross beam and two end structures, the upper cross beam is arranged above the conveying belts, the two end structures are the same and are symmetrically arranged,each end structure is composed of a supporting frame, an upper gear and the like, each supporting frame is provided with horizontal holes and inclined holes, the upper cross beam penetrates through the horizontal holes, the upper gears penetrate through the upper cross beam, one end of a long round pipe penetrates through the inclined holes, the other end of the long round pipe is in contact with the side edges of the conveying belts, a sleeve penetrates through the long round pipe, lower gears are meshed with the upper gears, a spring sleeves the long round pipe, one end of the spring makes contact with the sleeve, and the other endof the spring makes contact with with a protruding baffle of the long round pipe. The tension of the conveying belts can be controlled, the cost is low, and maintenance is convenient.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Part machining machine tool

InactiveCN112846801ARealize processingImprove work efficiencyOther manufacturing equipments/toolsTool bitMachine parts

The invention relates to a machining device, in particular to a part machining machine tool which comprises a moving mechanism, a machined part fixing mechanism, a grinding mechanism, a machining moving mechanism and a cutter adjusting mechanism. The machined part fixing mechanism is fixedly installed on the moving mechanism, the grinding mechanism is in threaded connection with the moving mechanism, the machining moving mechanism is in threaded connection with the moving mechanism, and the cutter adjusting mechanism is in threaded connection with the machining moving mechanism. According to the device, double tool bits can be used for machining the two ends of a machined material at the same time, symmetry and accuracy are guaranteed, the machining speed is increased, meanwhile, switching of a single tool and double tools can be achieved, part machining through the single tool bit is achieved, the device further has the grinding function, grinding paper can be fully utilized, and the waste phenomenon is avoided.

Owner:哈尔滨市双城区佳翀建材经销部

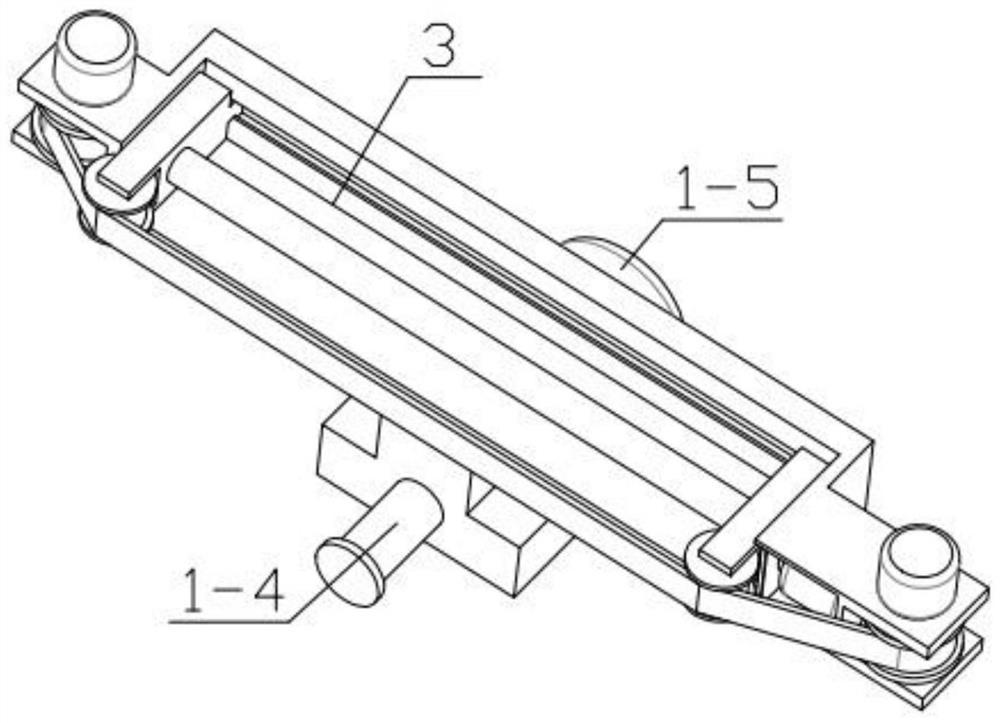

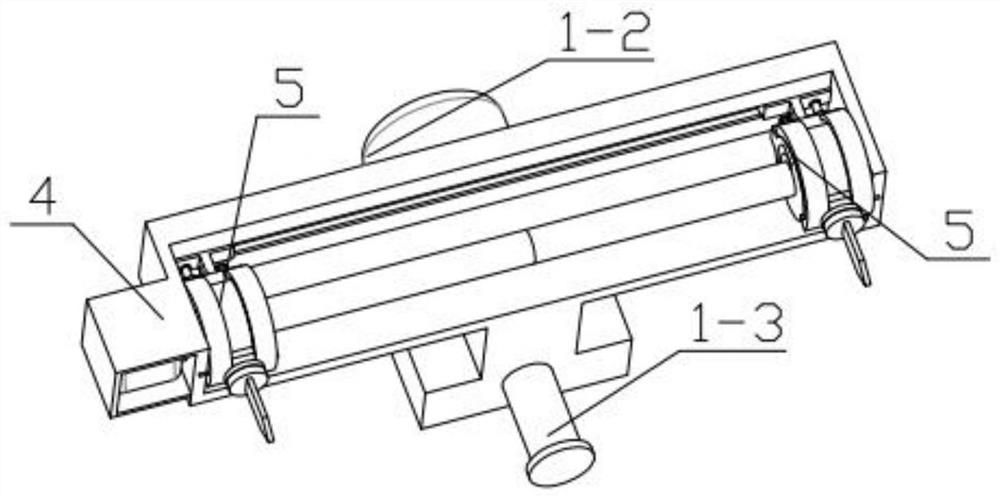

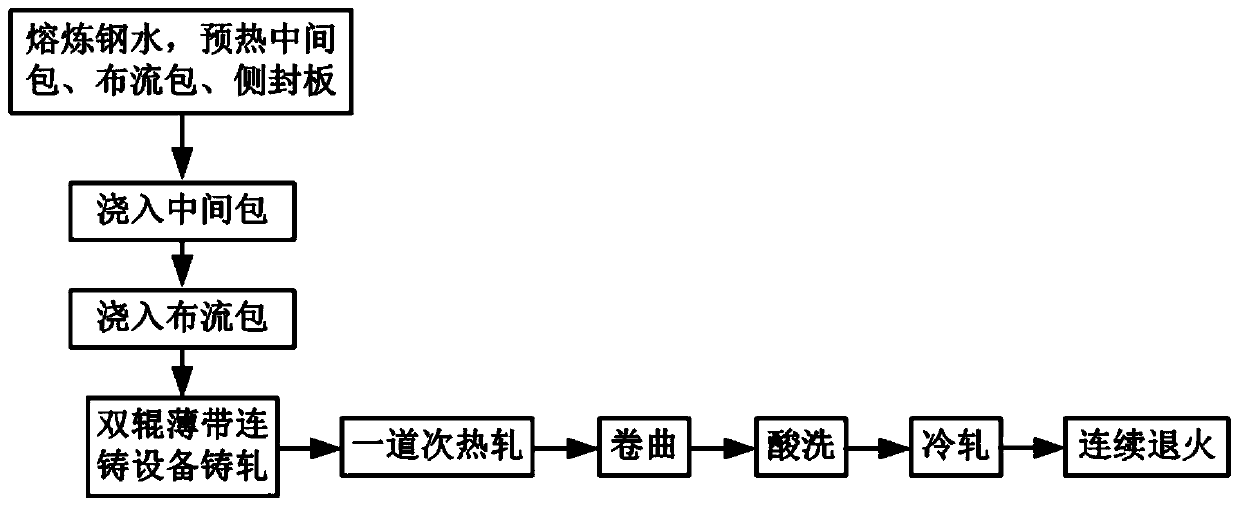

A kind of preparation method of IF steel strip

ActiveCN108796191BEvenly distributedShort manufacturing processMetal rolling arrangementsAlloyContinuous annealing

Owner:NORTHEASTERN UNIV LIAONING

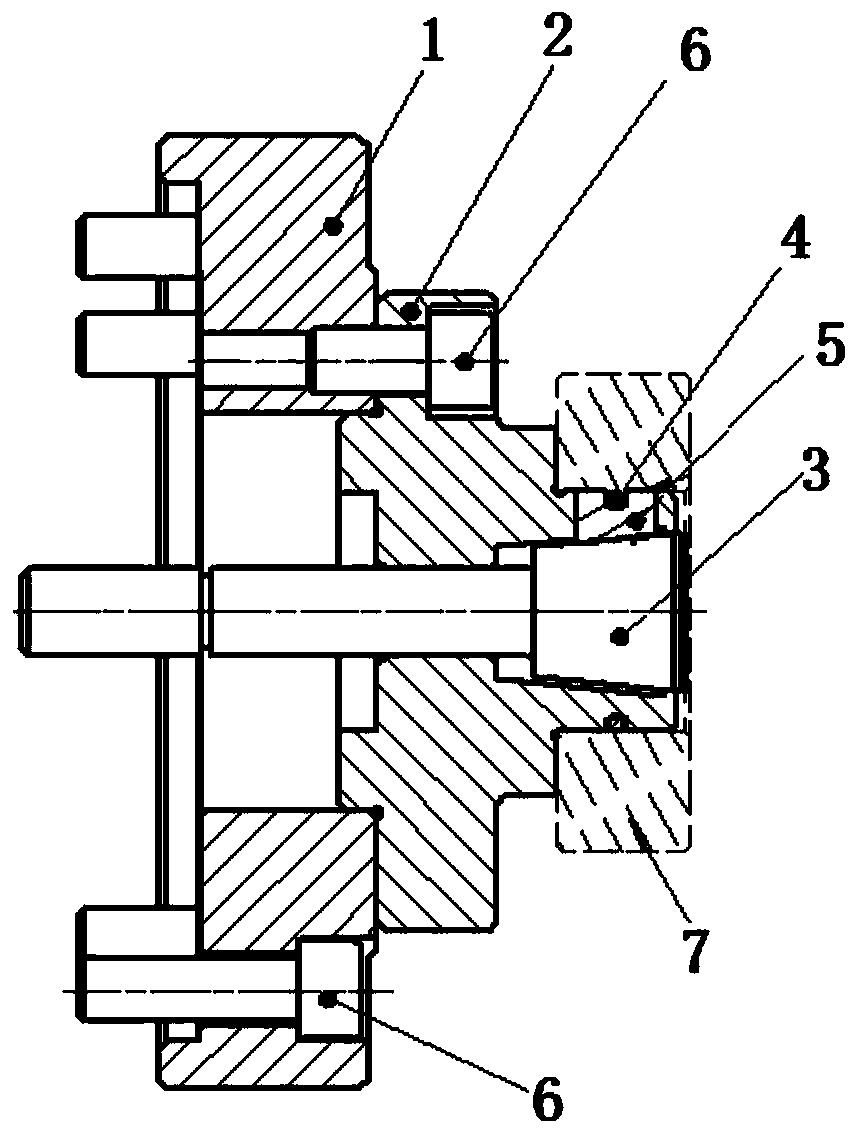

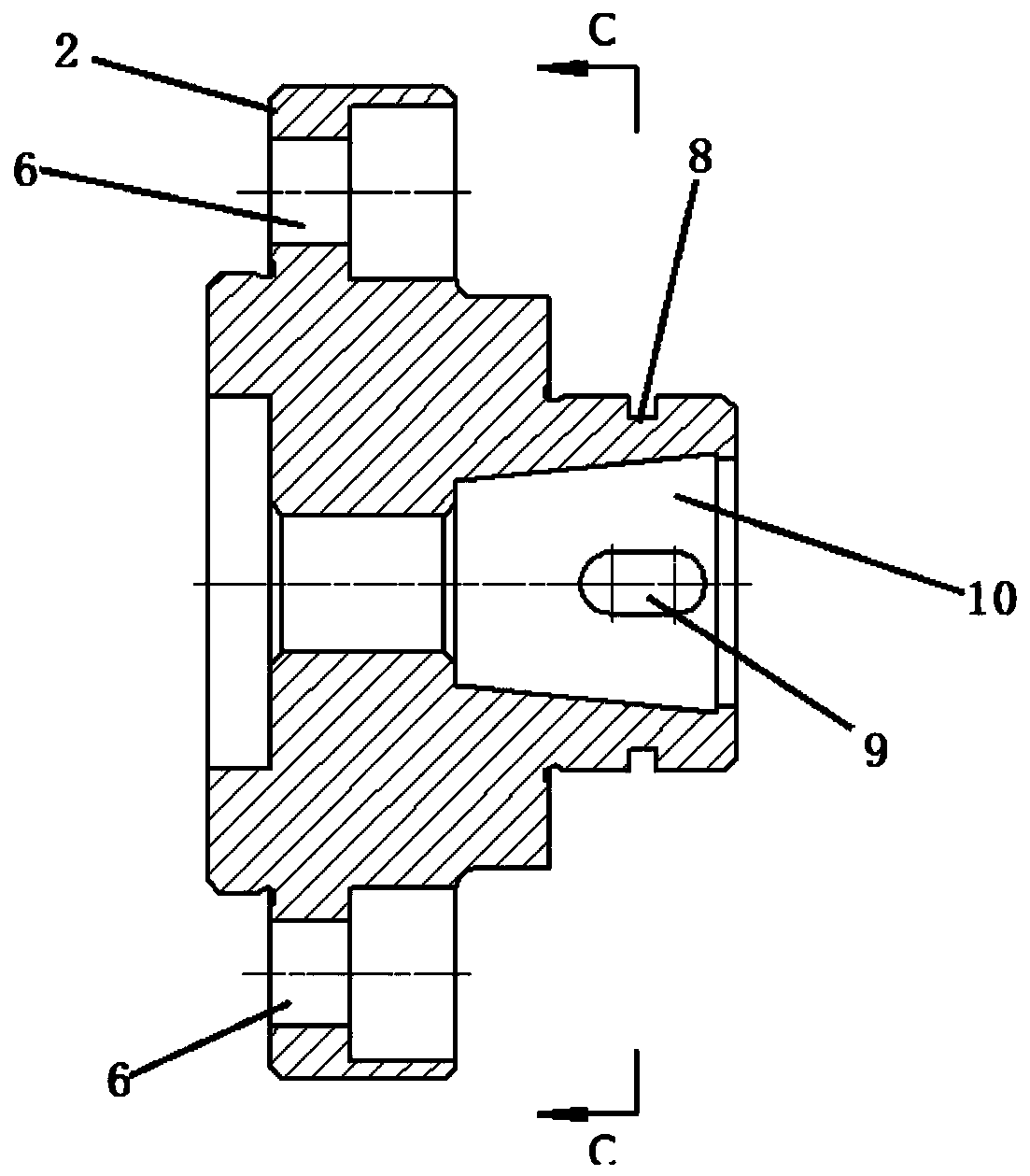

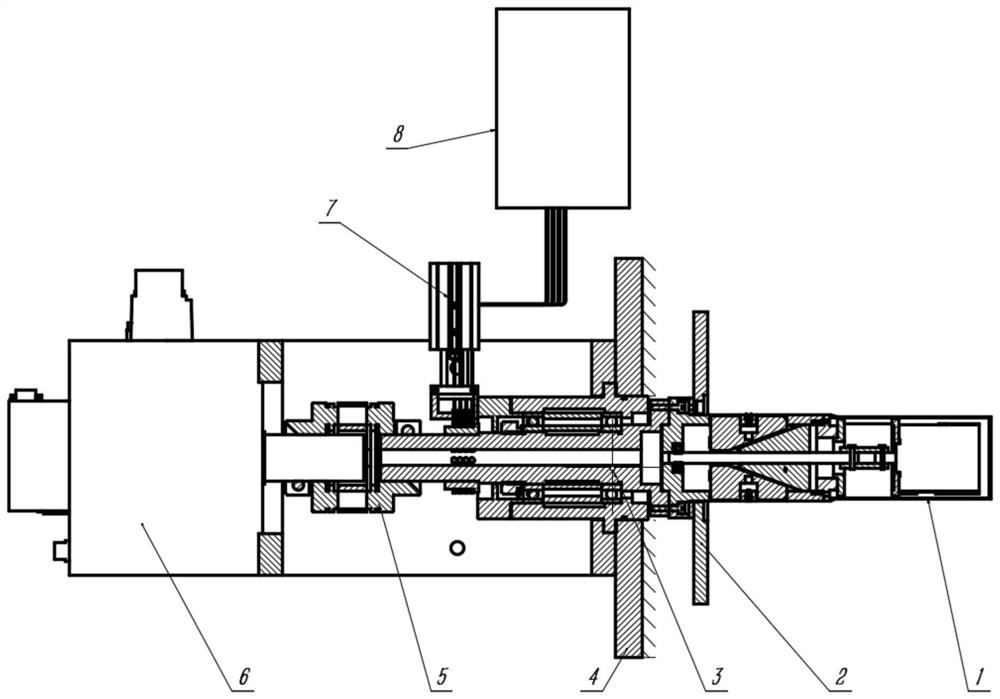

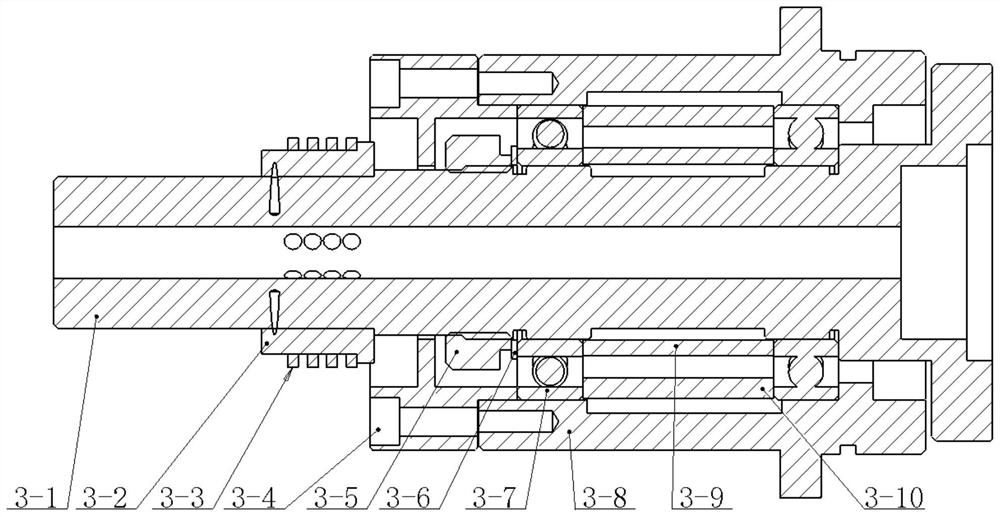

Mechanism for tensioning workpiece through electric screw tensioning shaft, regulation and control method and application

The invention belongs to the technical field of tensioning of workpieces through electric screw tensioning shafts in high-speed rotating machines, and discloses a mechanism for tensioning the workpieces through the electric screw tensioning shafts, a regulation and control method and application. And the cone nut pushes the tensioning claws in the inclined plane guide groove to stretch out and retract along the peripheral surface to realize tensioning or loosening in the front-back movement process. According to the mechanism for tensioning the workpiece through the electric screw tensioning shaft on the high-speed rotating mechanism, due to the fact that a screw nut kinematic pair has the self-locking capacity and is large in pushing force, rapid tensioning of the workpiece is guaranteed, and tensioning is reliable. The mechanism for tensioning the workpiece through the electric screw tensioning shaft adopts a motor to drive a screw nut kinematic pair to adjust the tensioning force, and the tensioning force can be known and controllable. The defects existing in the using process of the expansion shaft, the using process of a manual mechanical expansion shaft and the using process of an electric drive expansion shaft are overcome.

Owner:WUHAN GUANYOU TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com