Large-capacity falling-barrel-type constant tension dynamic line storing equipment

A large-capacity, constant-tension technology, applied in the field of wire storage equipment and cable storage equipment, can solve the problems of inconsistent cable tension between discs, large land occupation length, affecting cable quality, etc., to ensure stability and tension. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

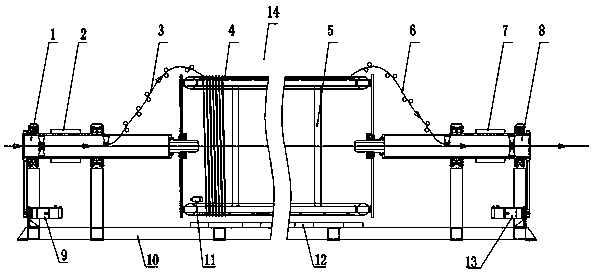

[0016] 1. If figure 1 As shown, the present invention provides a large-capacity bucket-type constant tension dynamic wire storage device, which includes a wire storage device body (14) consisting of a wire-feeding bucket (1), a flexible mechanical arm for the bucket (3), and a wire-dropping bucket (8). , a barrel-exiting flexible robotic arm (6), and an equipment base (10), one end of the equipment base (10) is fixedly connected to an incoming line drop barrel (1), and one side of the equipment base (10) is located The lower part of the incoming line drop barrel (1) is fixedly connected with a drop barrel rotation drive (9), which drives the components (1) and (3) to rotate synchronously, and the middle part of the equipment base (10) is fixedly connected with a fixed magnet (12 ), used to locate the line storage barrel (4) directly above the fixed magnet (12), the line storage barrel (4) is fixed on the central shaft of the access barrel through bearings, and the line storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com