Sheath metal belt unwinding device applied to production of optical cable

A technology for optical cables and metal strips, applied in the field of sheath metal strip unwinding devices, which can solve the problems of frequent movement of moving parts, unstable tension control, troublesome tension control, etc., and achieve compact structure, low operating cost, and easy tension control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in detail:

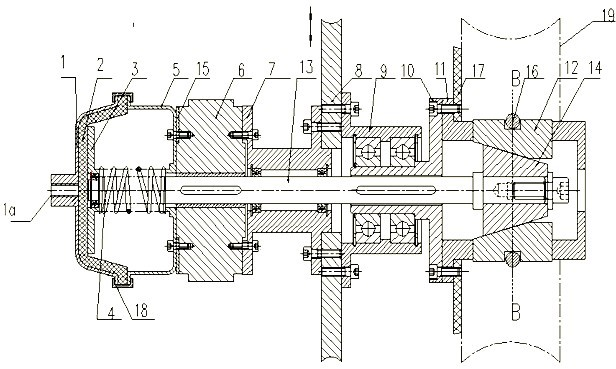

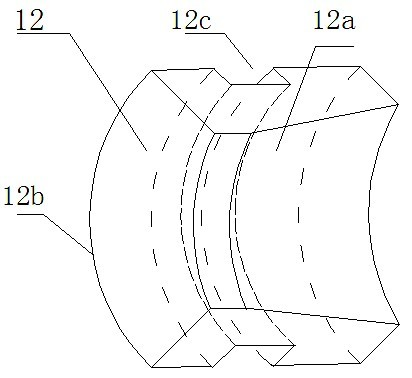

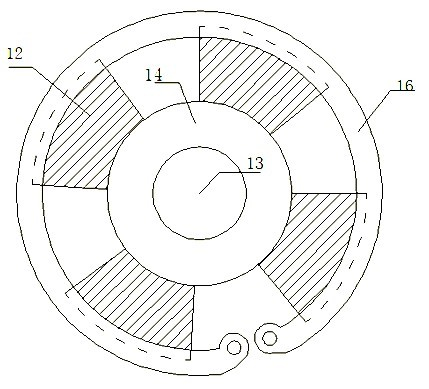

[0019] control figure 1 The sheath metal tape unwinding device in the optical cable production of this embodiment is mainly composed of an air cushion cover 1, an air cushion 2, a baffle plate 3, a spring 4, an air cushion cover flange 5, a magnetic powder brake 6, a transmission shaft bearing seat 7, and a lifting plate 8. Outer shell bearing seat 9, outer shell connecting flange 10, outer shell 11, expansion sleeve inclined block 12, transmission shaft 13, inner sleeve 14, magnetic powder brake gasket 15, retaining spring 16, material blocking plate 17 and air cushion cover connector 18 constitute. The air cushion 2 is close to the inner surface of the air cushion cover 1, the circumferential edges of the air cushion cover 1 and the air cushion 2 are sealed and connected, the baffle 3 is close to the air cushion, and the center of the baffle 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com