Device for winding an elongate, threadlike element on a winding element

A winding element, filamentary technology, applied in the direction of continuous winding spinning machine, textile and paper making, spinning machine, etc., can solve time-consuming and other problems, and achieve the effect of economical structure, easy operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following description, the same components are denoted by the same reference numerals.

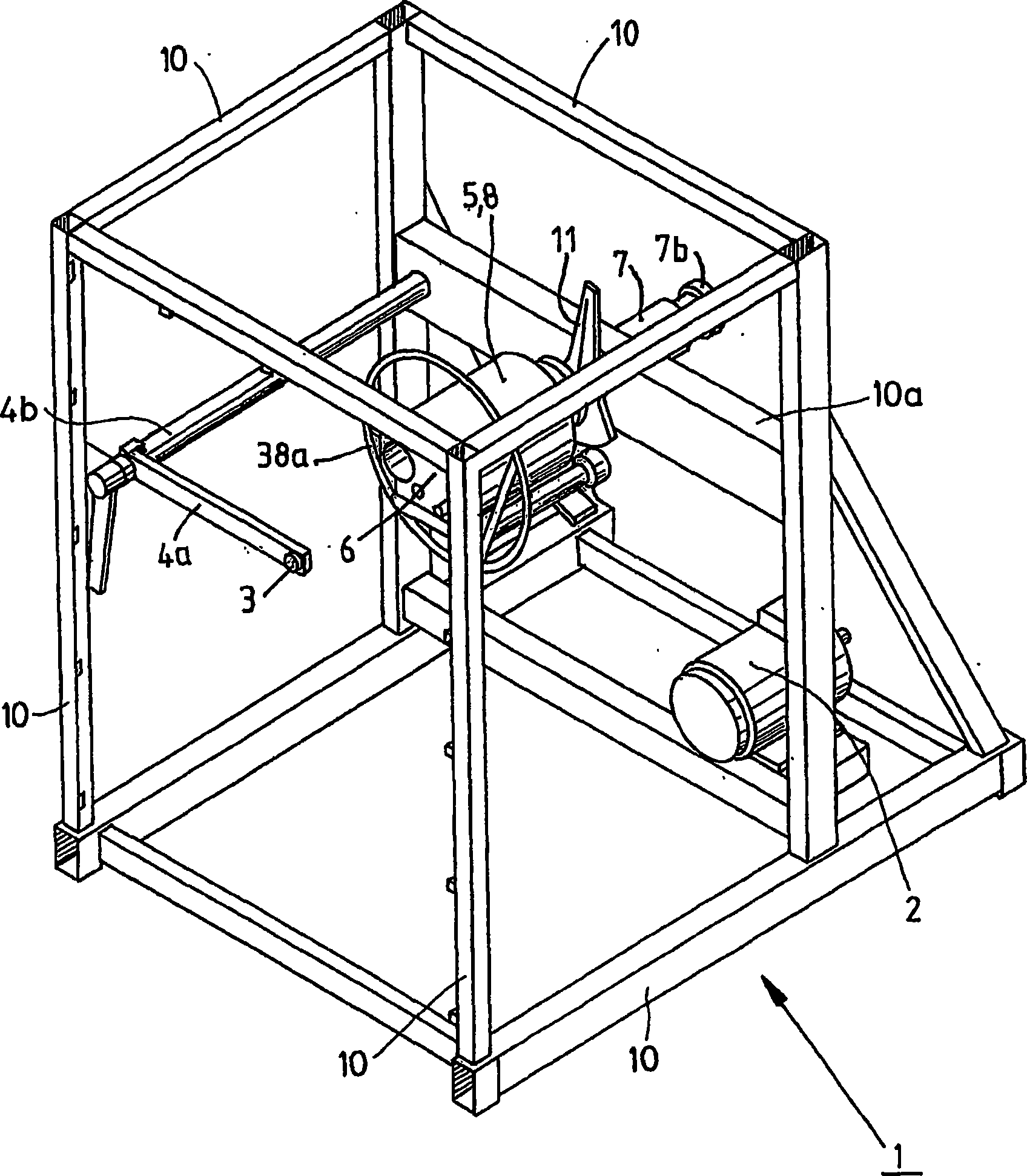

[0038] figure 1A general view showing an embodiment of a winding device according to the present invention. The device 1 consists of a frame 10 made up of several vertical and horizontal members. All the specific parts of the winding device according to the invention are arranged around the shaft 7, which is mounted in a bearing in the support beam 10a of the frame 10 in such a way that the first end 7a of the shaft 7 (not shown) extends into the inside of the frame 10, while the other end of the shaft 7, i.e. the second end 7b, extends to the outside of the frame, as figure 1 shown. The second end 7 b of the shaft 7 is configured as a pulley over which an endless carrier, for example a V-belt, runs over the drive shaft of the drive device 2 . The drive shaft 2 can be, for example, an electric motor, which is connected to a fixed structure outside the frame 10 and transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com