Enameled wire unwinding device

A pay-off device and enamelled technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problem that the tension sheave cannot provide constant tension, and achieve diameter increase, stable tension, and easy pay-off tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

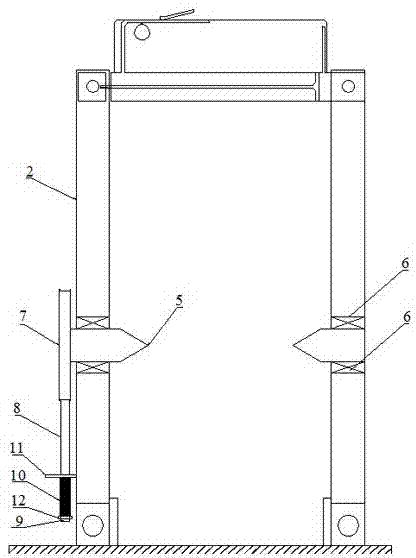

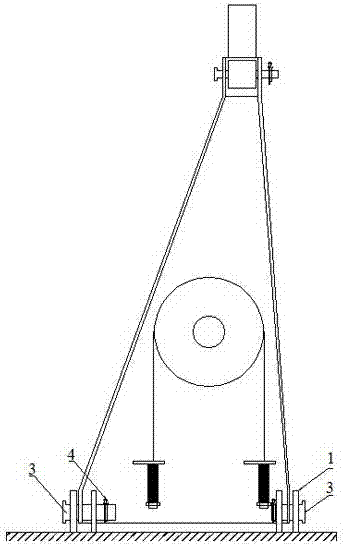

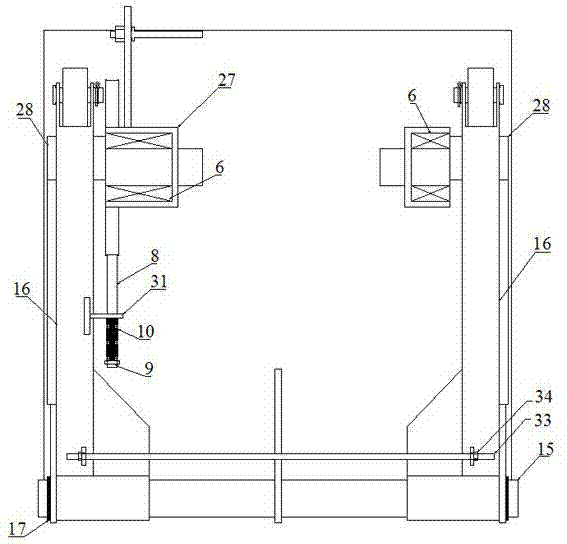

[0011] Such as image 3 , Figure 4 As shown, the present invention includes a tension sheave 7 and a damping band 8. The end of the damping band 8 placed on the tension sheave 7 is connected to the screw one 9. The diameter of the tension sheave 7 is 35cm~40cm, and the bracket two 13 is welded on One end of the base plate 14, the shaft 15 passes through the junction of the bracket two 13 and the support arm 16 and is positioned by the snap spring one 17, the ear plate one 18 is welded on the support arm 16, and one end of the cable-stayed support 19 cooperates with the pin 3 and the cotter pin 4 It is connected and fixed on the ear plate one 18, and the support column 20 is provided with a pin hole 21, and one end of the support column 20 is connected and fixed to the end of the support arm 16 through the pin hole 21, the pin 3 and the cotter pin 4. The support column 20, the cable-stayed support 22 The other end is connected and fixed to the ear plate 2 23 through the coope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com