Patents

Literature

80results about How to "Large feed force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

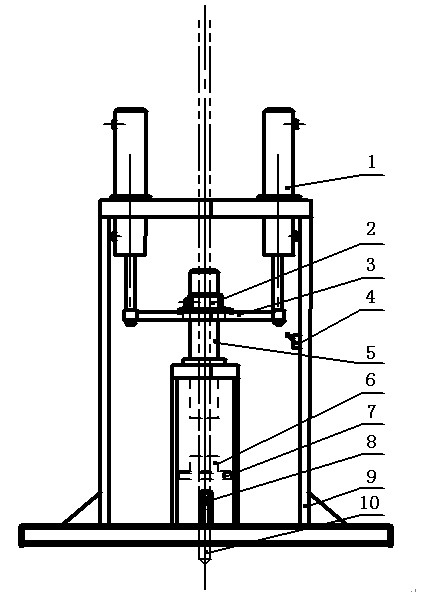

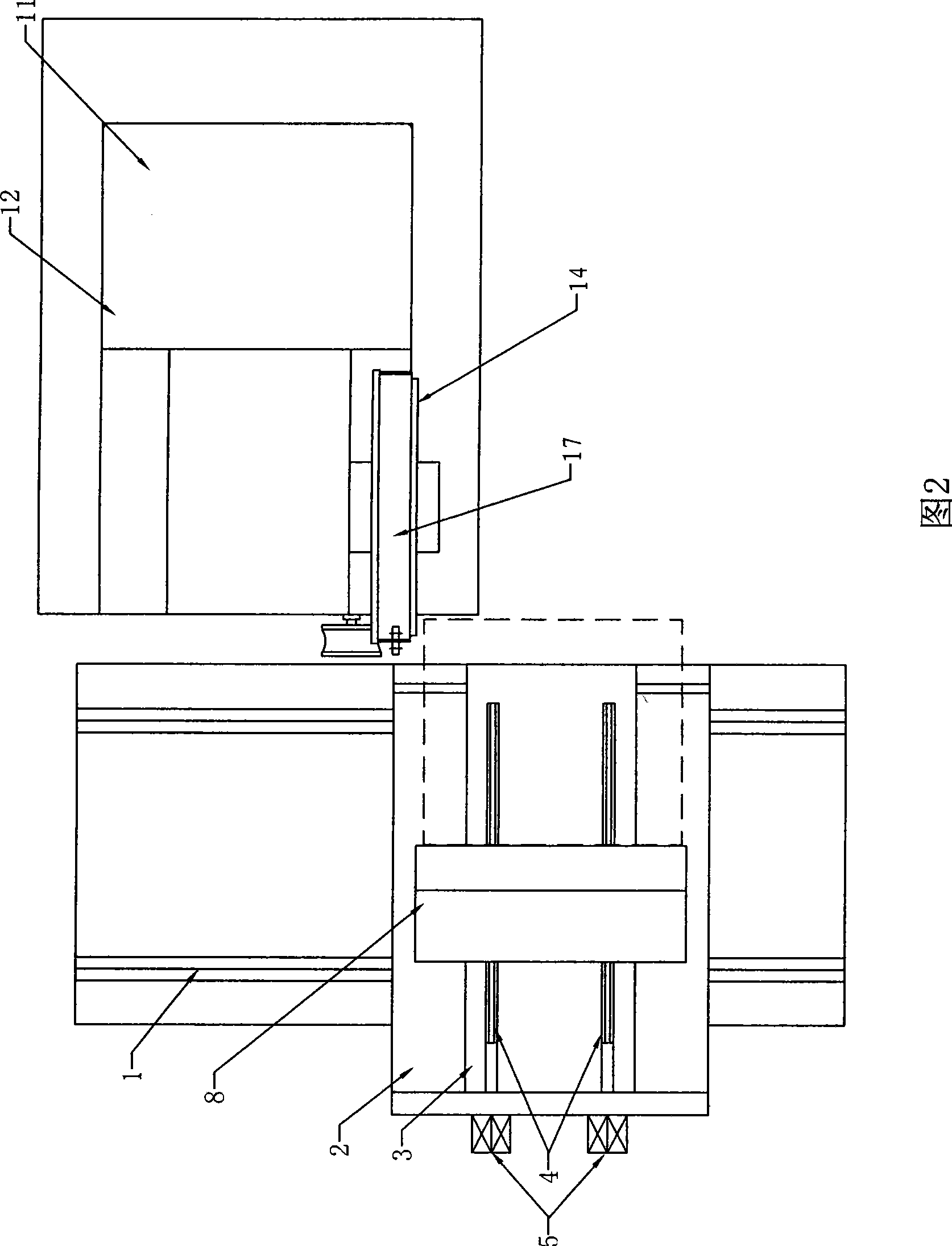

Full-hydraulic continuous-penetration static sounding machine with double oil cylinder groups

InactiveCN102116018ALarge feed forceAchieve clampingServomotorsIn situ soil foundationContinuous/uninterruptedHydraulic pump

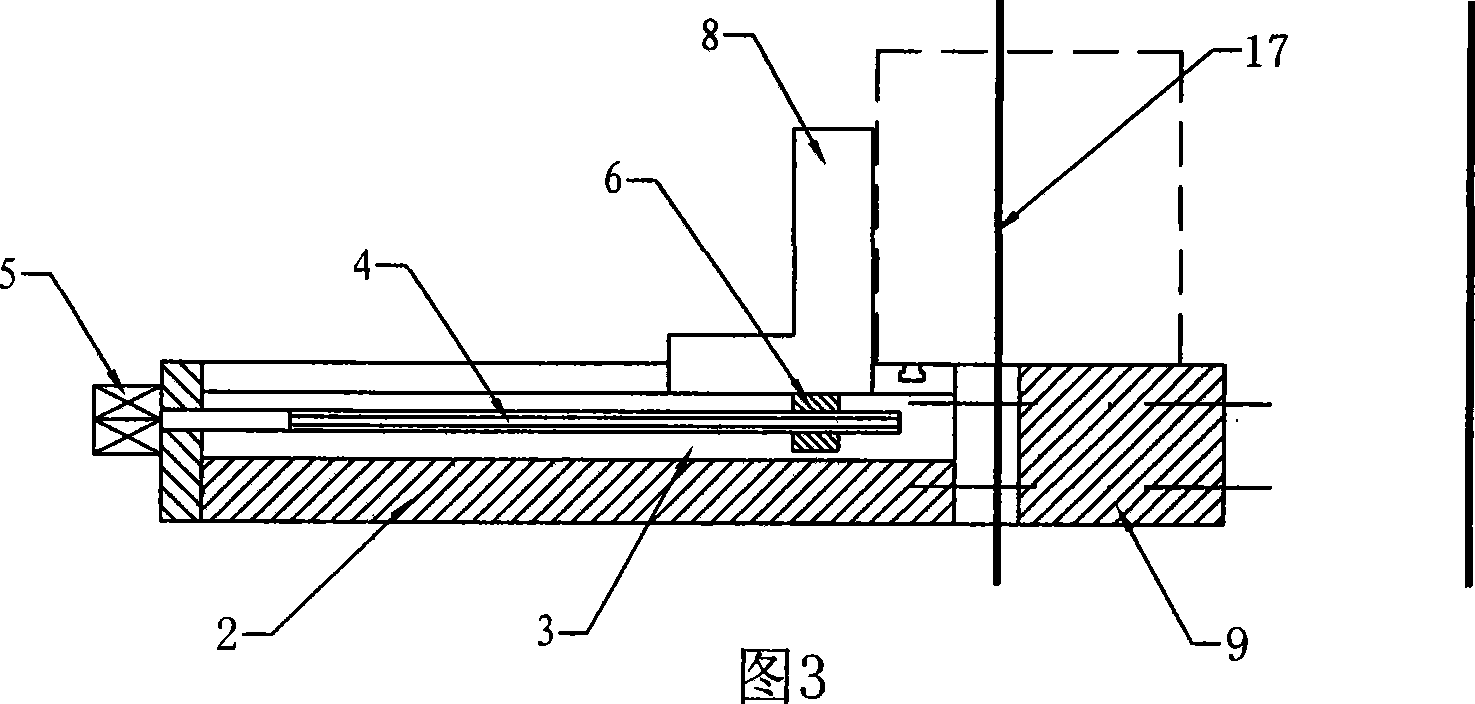

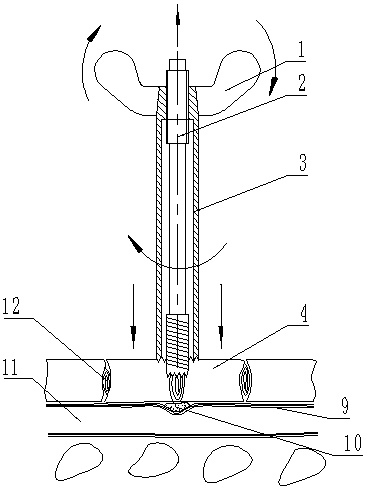

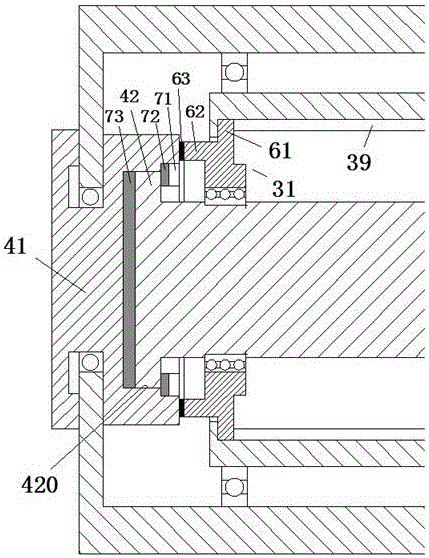

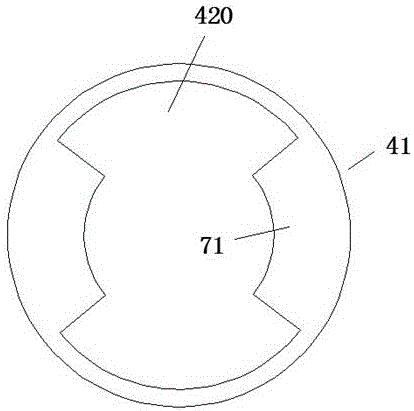

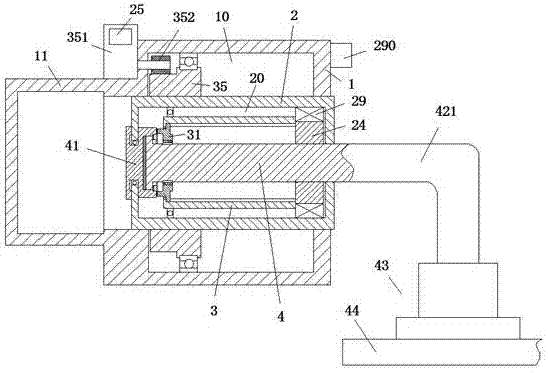

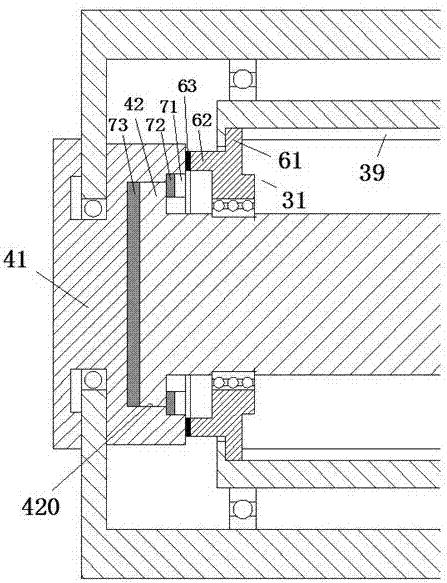

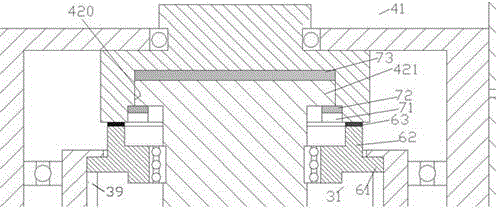

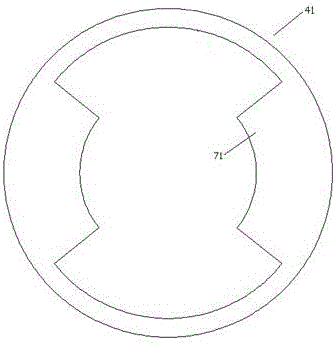

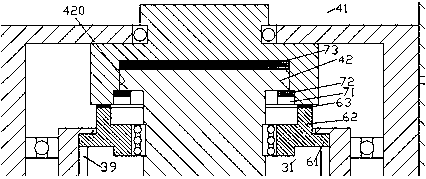

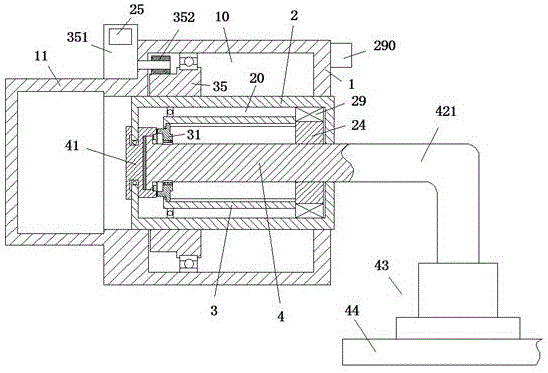

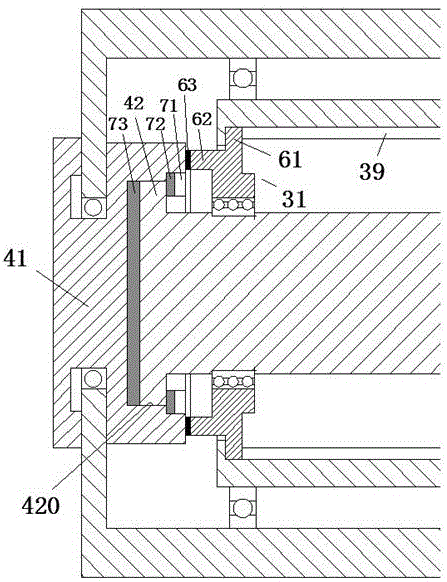

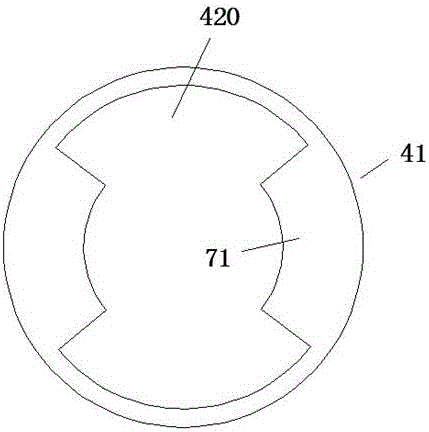

The invention relates to a full-hydraulic continuous-penetration static sounding machine with double oil cylinder groups. Two groups of oil cylinders are adopted and mounted on a frame in a cross shape in a manner of being divided into an upper layer and a lower layer; each group of oil cylinder is fixedly connected together through a cross beam; hydraulic chucks are mounted on the cross beams; stroke limiting switches are mounted below the oil cylinders; a probe rod passes through center inner holes of the two hydraulic chucks; and a hydraulic control system is further provided with valve groups, reversing valves, a hydraulic pump, an electro-hydraulic proportional speed regulating valve KT, a relief valve, a pressure gauge and an oil box. The static sounding machine adopts double oil cylinder group feeding and automatic reversing control; the double hydraulic chucks automatically clamps or loosens the probe rod and automatically achieves continuous uninterrupted feeding through the cooperation of the movement of the oil cylinders; and steady uniform speed feeding is achieved by utilizing the electro-hydraulic proportional speed regulating valve. The static sounding machine has the advantages of simple structure, reliable operation, high efficiency, economy and durability, is convenient for operation, is suitable for the technical field of geotechnical engineering, such as geotechnical engineering, high-speed railway construction, expressway construction and port engineering, and has a wide application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

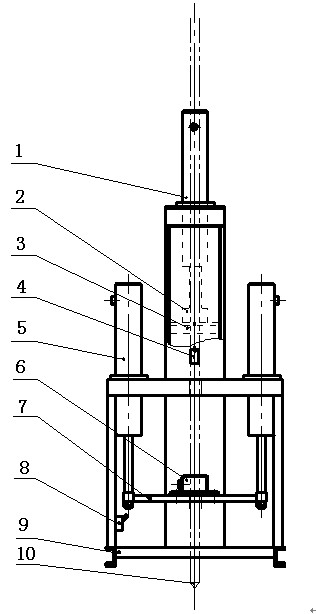

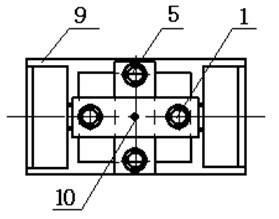

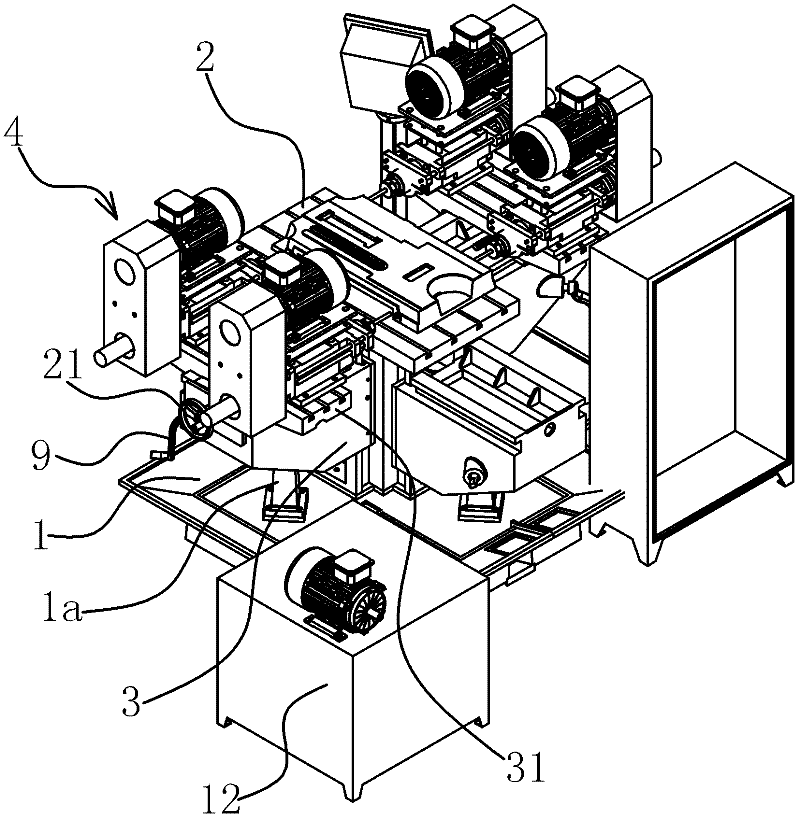

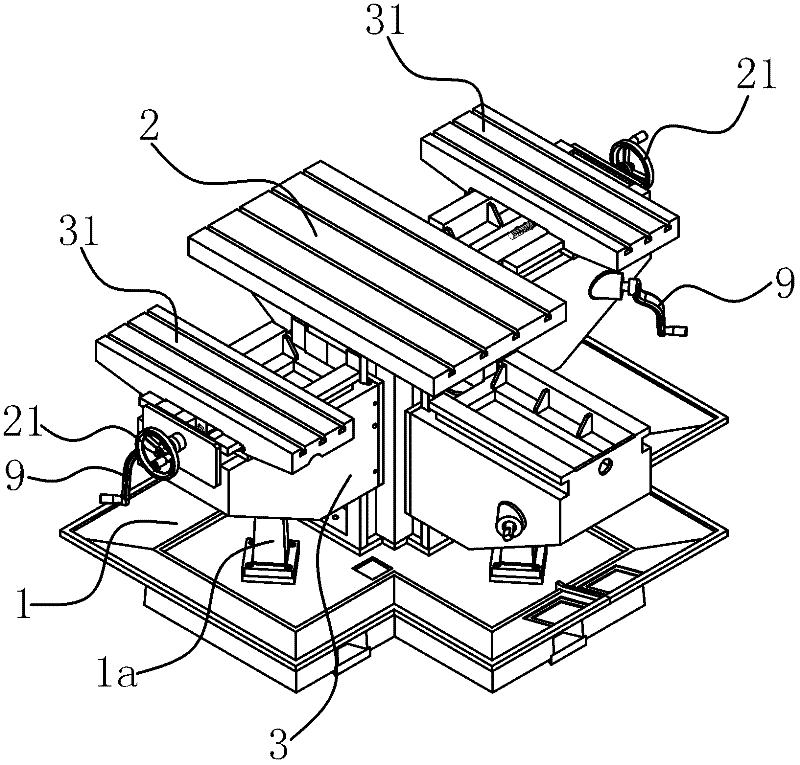

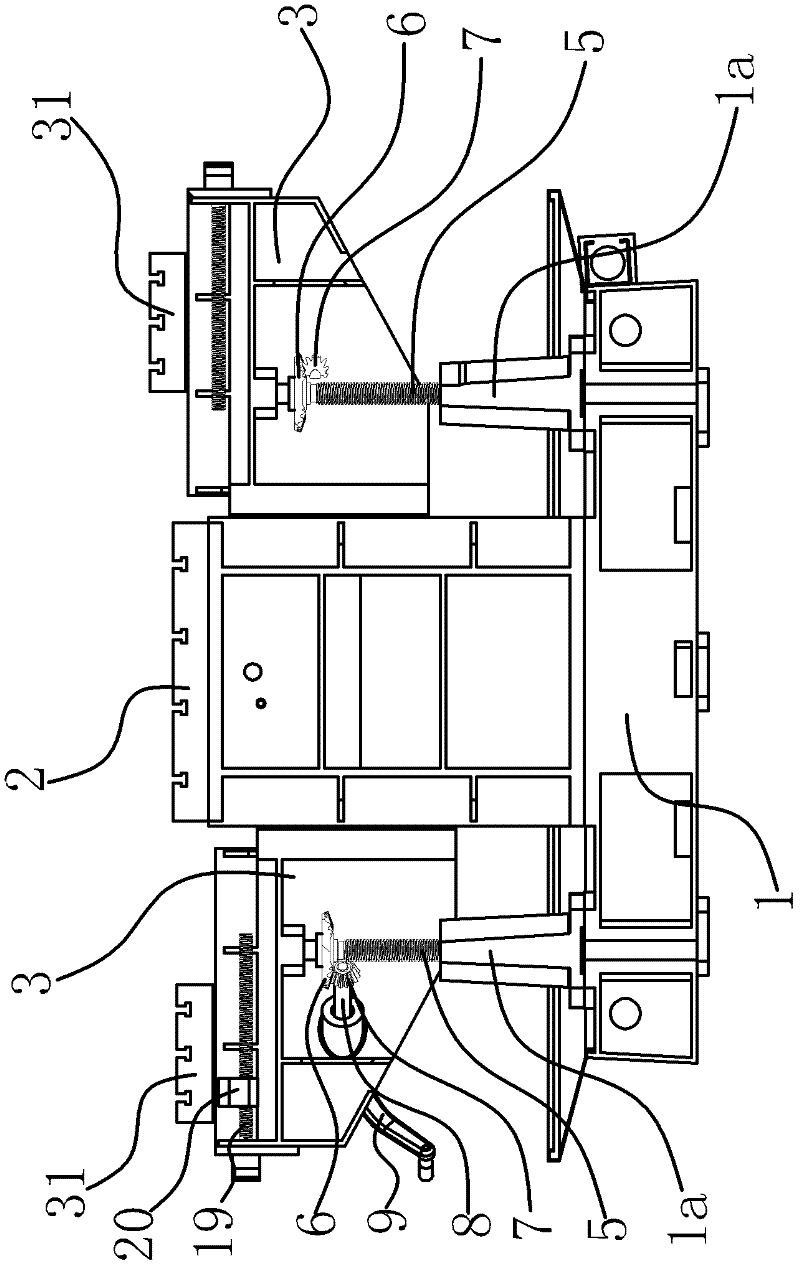

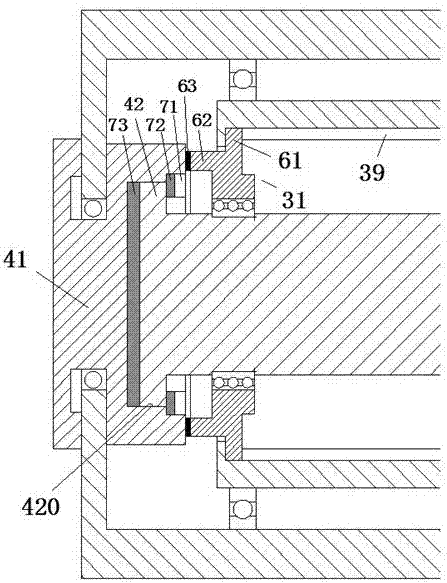

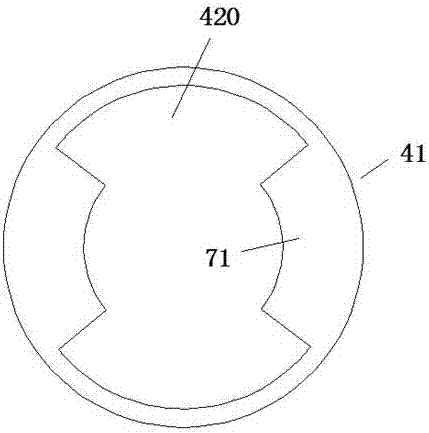

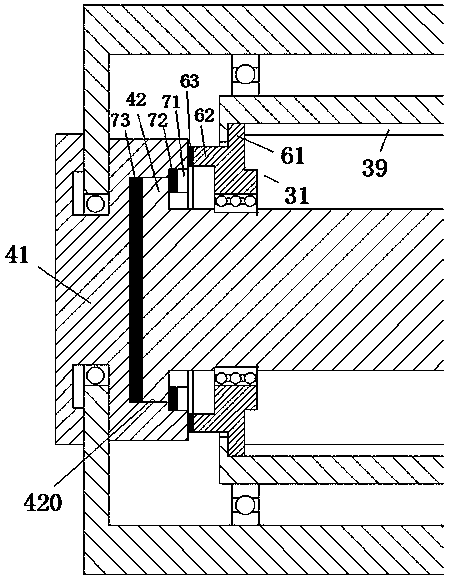

Horizontal combined machine tool with lifting spindle

ActiveCN102528455AImprove versatilityEasy to operateFeeding apparatusOther manufacturing equipments/toolsScrew threadMachine tool

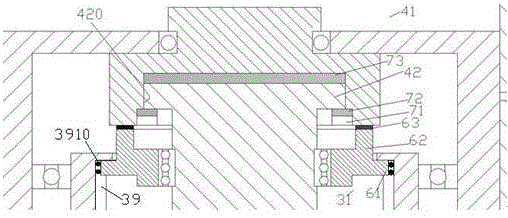

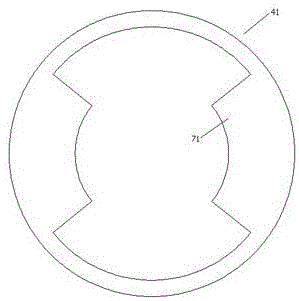

The invention provides a horizontal combined machine tool with a lifting spindle, which belongs to the technical field of machinery and solves the problem that a spindle of an existing horizontal drilling and tapping machine tool is incapable of lifting. The horizontal combined machine tool with the lifting spindle comprises a tool body, a working platen and a spindle lifting table, a spindle platen is arranged on the spindle lifting table, a spindle box is arranged on the spindle platen, a connecting support is arranged on the tool body, a screw rod is arranged between the spindle lifting table and the connecting support, one end of the screw rod is fixedly connected with the spindle lifting table, the other end of the screw rod is connected onto the connecting support in a threaded manner, an adjusting mechanism capable of driving the screw rod to rotate is arranged on the spindle lifting table, a feeding mechanism is arranged on the spindle box, and a driving mechanism is arranged between the spindle lifting table and the spindle platen. The vertical distance and the horizontal distance from the spindle platen of the horizontal combined machine tool with the lifting spindle to the working platen can be adjusted, holes aligned to different positions of a plurality of sides of a workpiece can be machined, and the horizontal combined machine tool with the lifting spindle is high in universality.

Owner:ZHEJIANG XILING

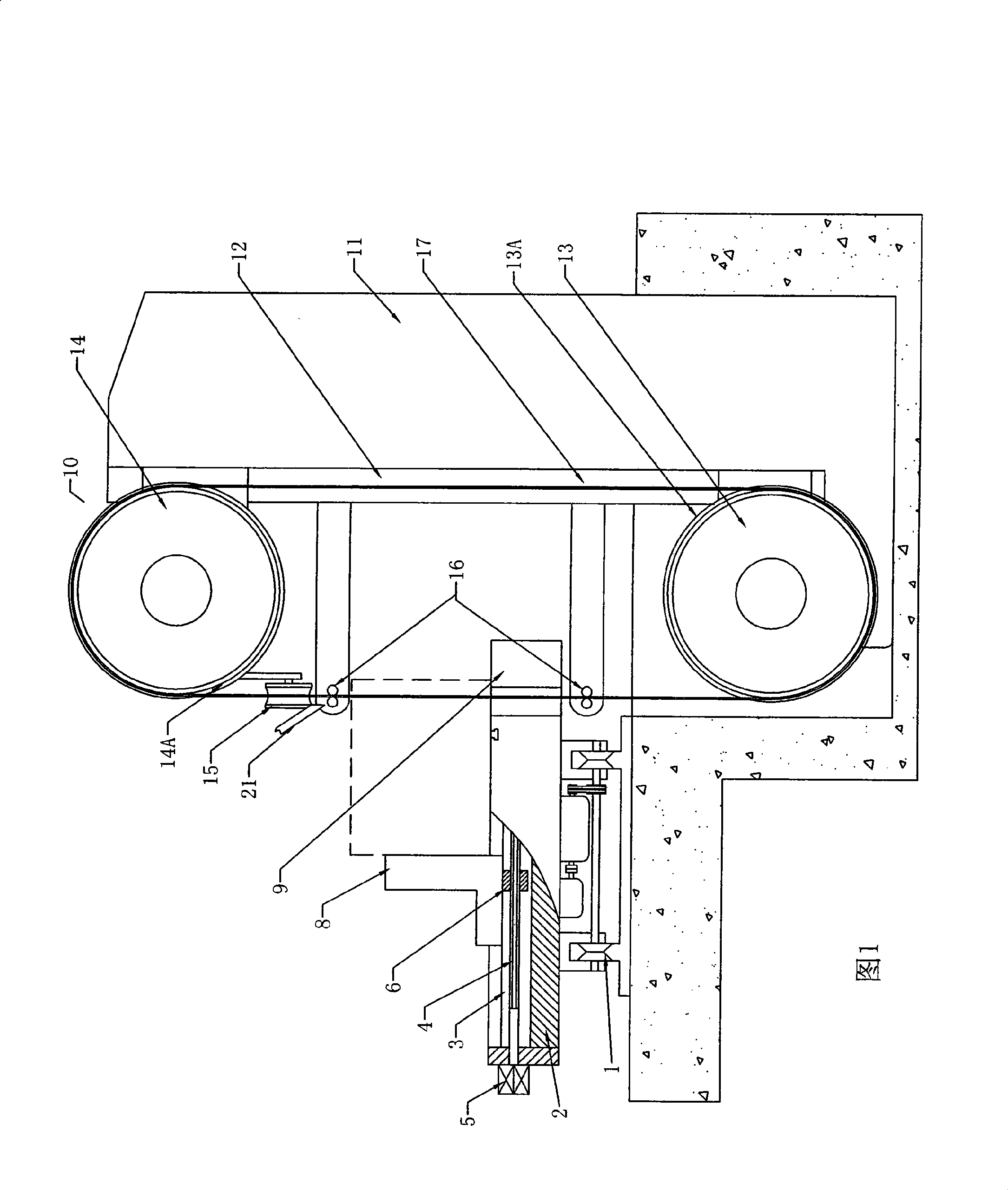

Stone sawing machine

InactiveCN101428450AEliminate chatterLarge feed forceStone-like material working toolsAutomatic controlFixed frame

A stone sawing machine comprises a fixed frame, a movable frame, a driving wheel, a driven wheel, a ring-shaped saw blade, a orbit, a workbench and a mobile push pressure plate, wherein, lugs are formed on one side of the driving wheel and one side of the driven wheel; holding devices which clamp a downward moving saw blade are arranged on the upper surface and the lower surface of the workbench and a stone respectively; an auxiliary table board is arranged outside the working end of the workbench; the mobile push pressure plate is pushed by a transverse pushing device which comprises a lead screw, a driving device and a slide block; a cooling device is arranged on the machined surface of the stone; the saw blade comprises a saw body, rectangular teeth and blades; the rectangular teeth are formed on one side of the saw body; and two blades are welded on the two sides of the saw body. The stone sawing machine has the advantages that the difficult problem for cutting ultra-wide hard stone flakes is solved; the difficult problem for cutting ultrathin stone flakes is solved; the difficult problem of non-uniform thickness cutting is solved; the difficult problem for curved surface cutting is solved; the manufacturing cost is reduced; and manpower can be reduced, and the work efficiency can be improved by adopting the controlling of an automatic control system.

Owner:陈少波

Garden irrigating device

InactiveCN106305356AEasy to useImprove bindingWatering devicesCultivating equipmentsElectric machineryEngineering

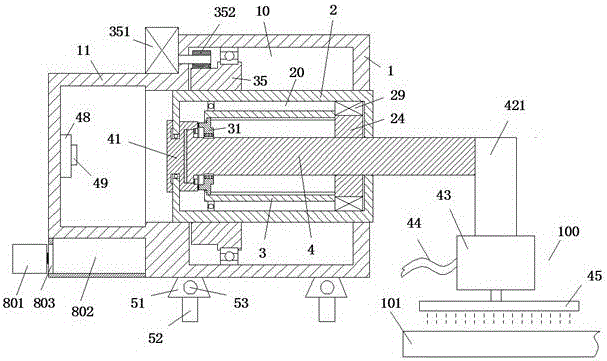

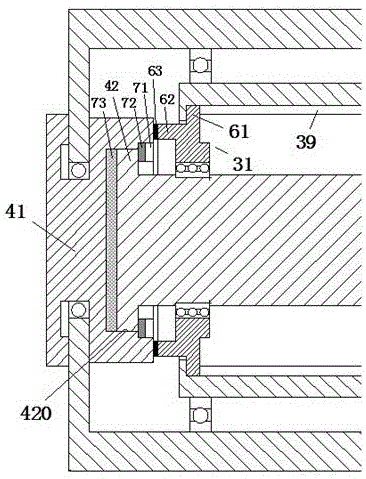

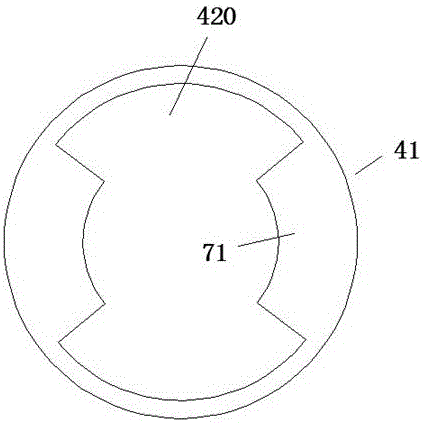

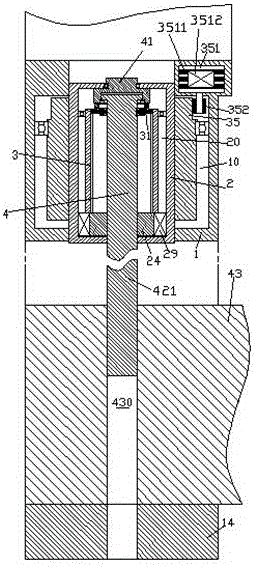

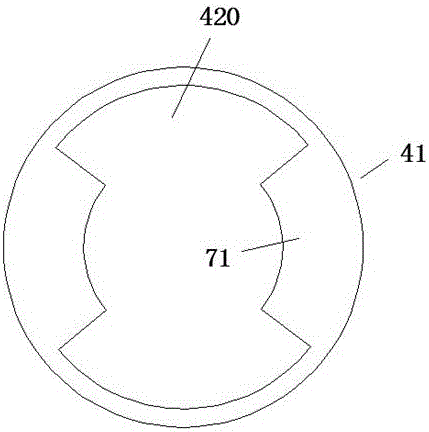

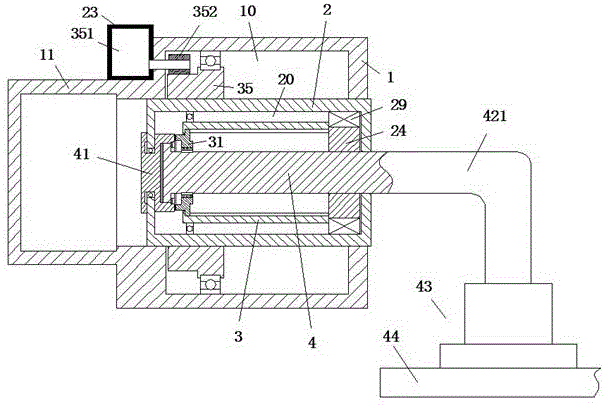

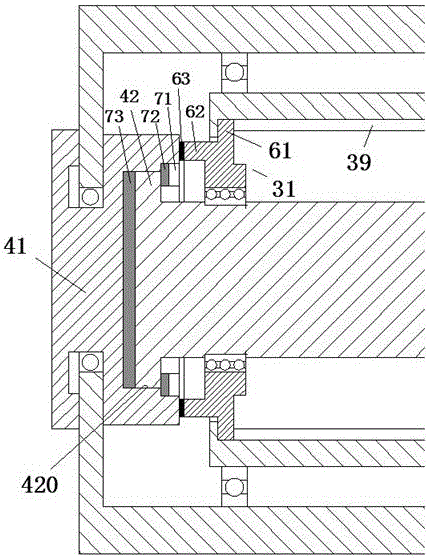

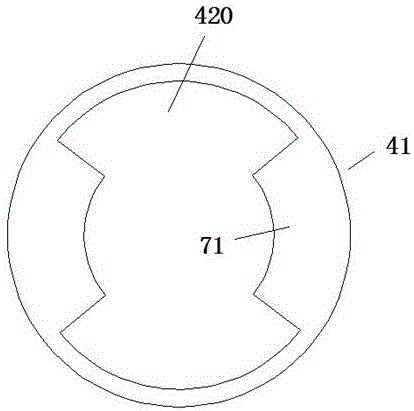

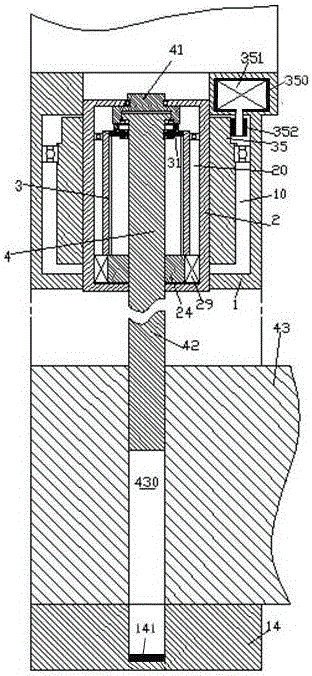

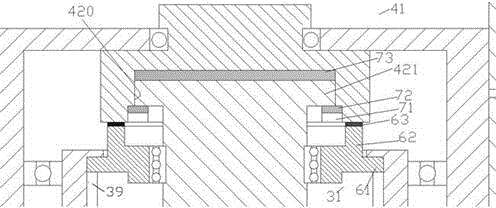

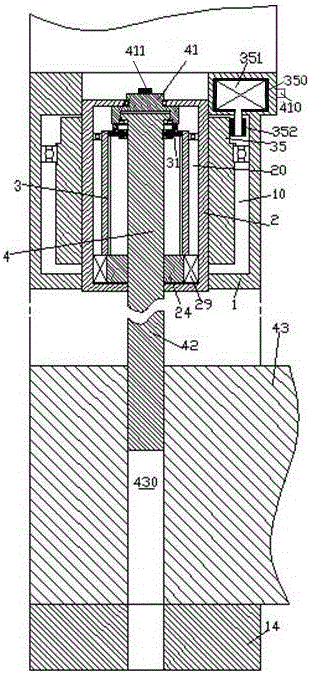

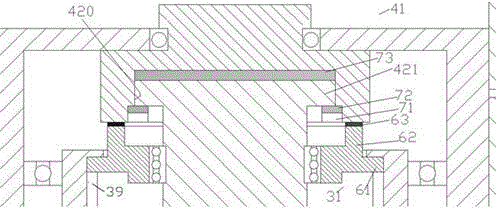

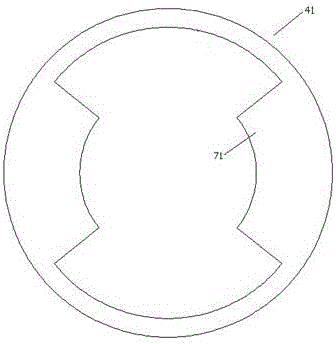

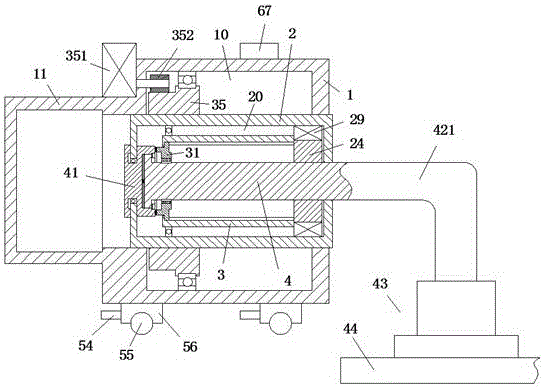

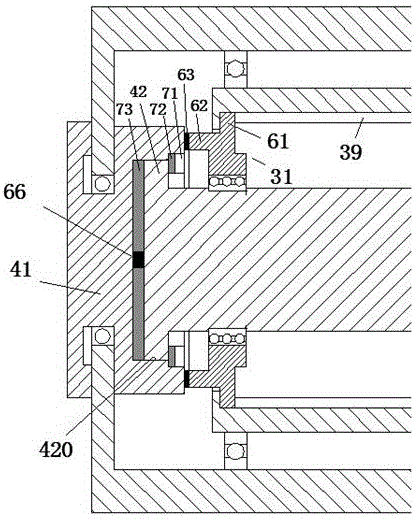

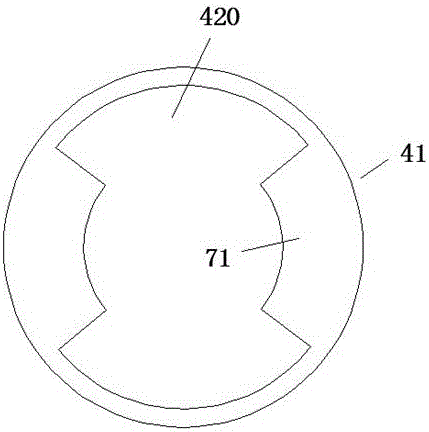

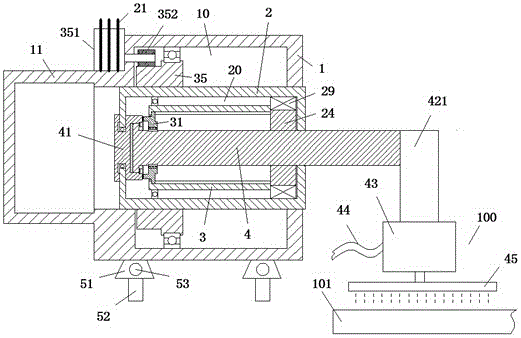

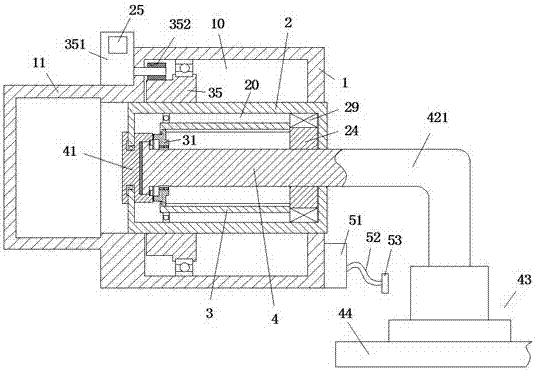

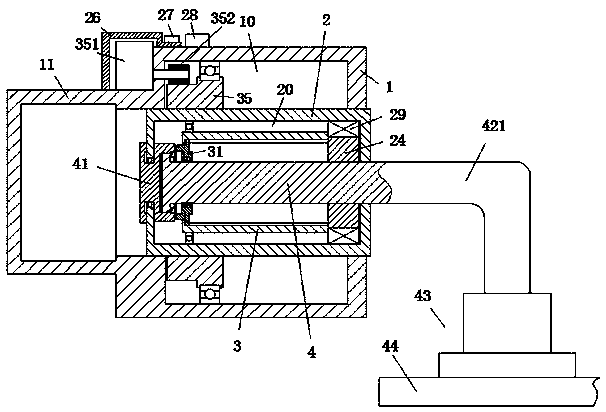

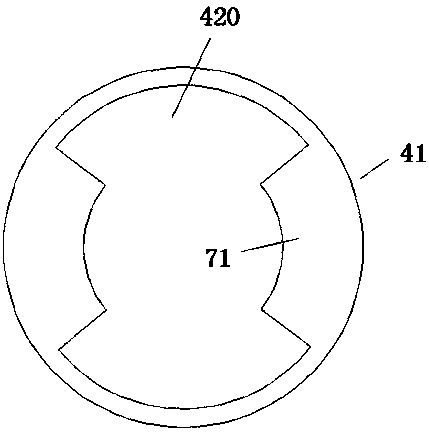

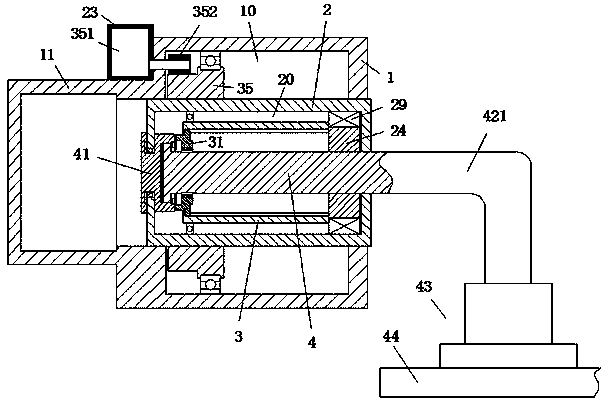

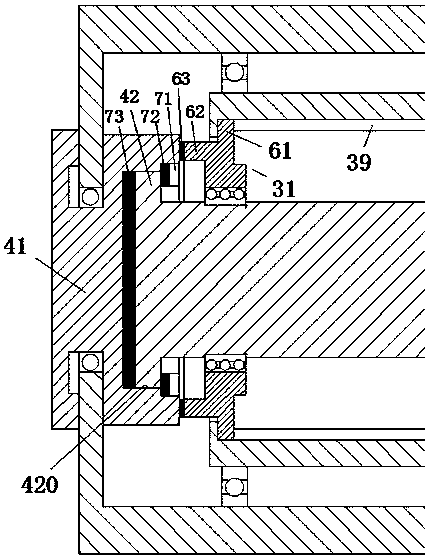

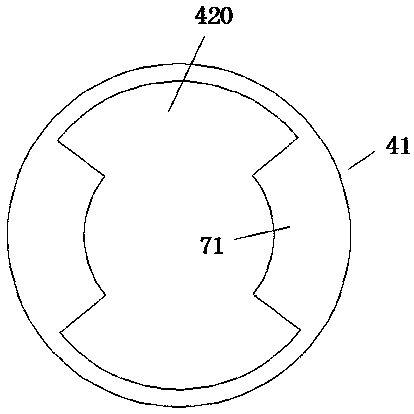

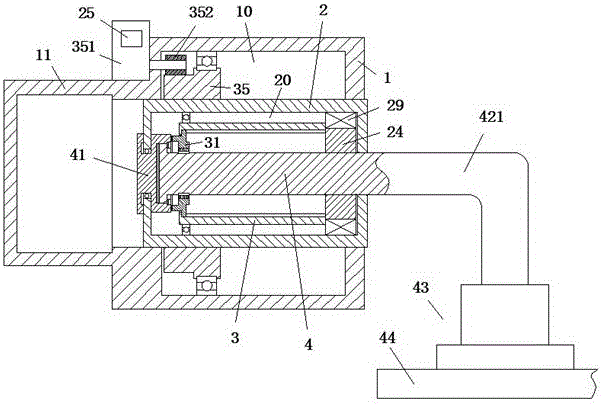

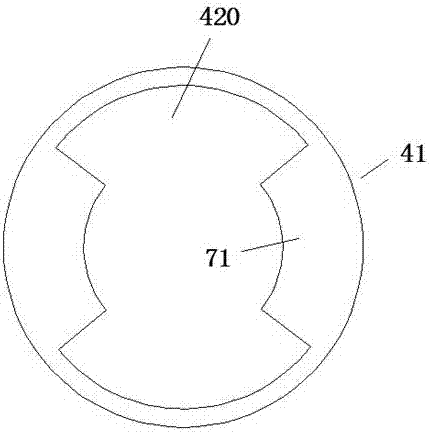

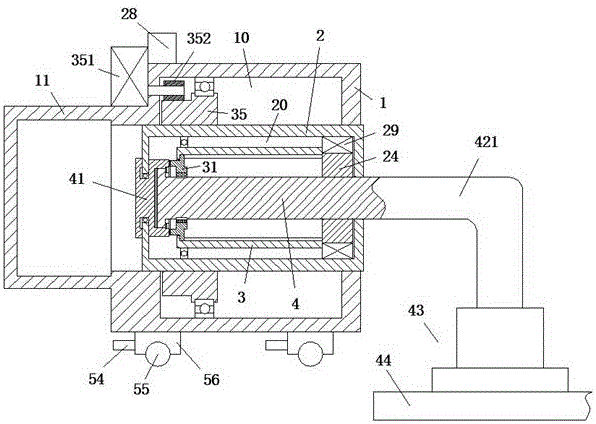

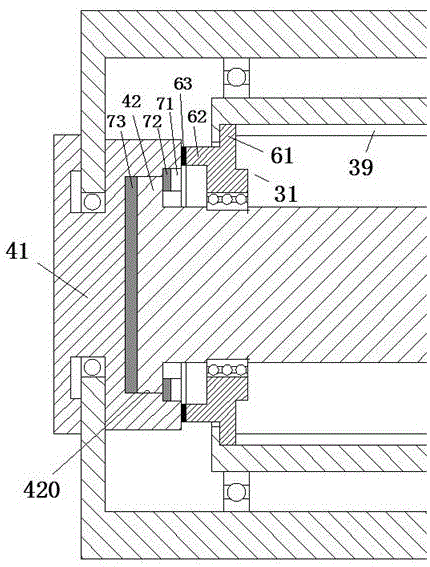

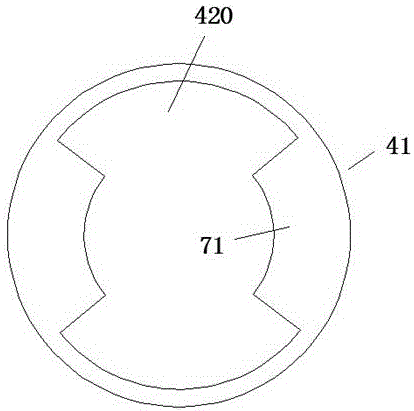

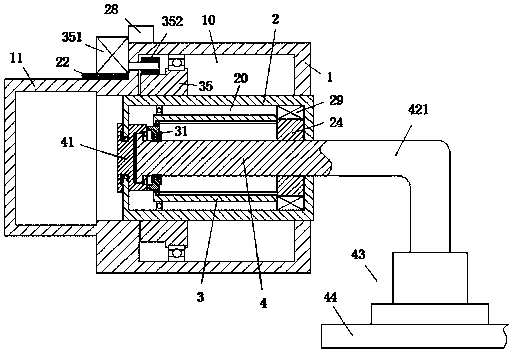

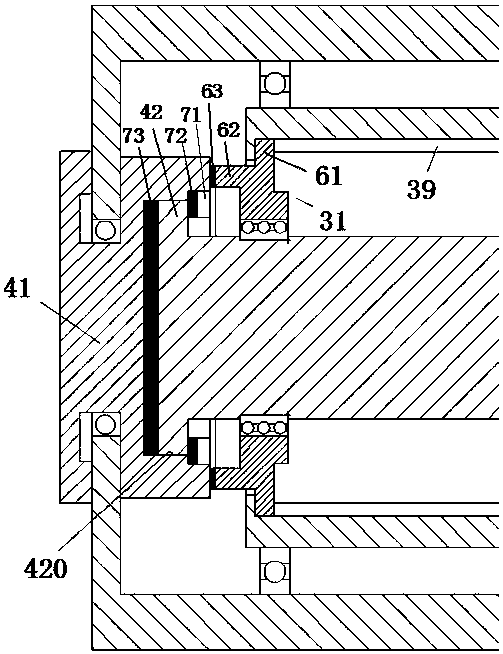

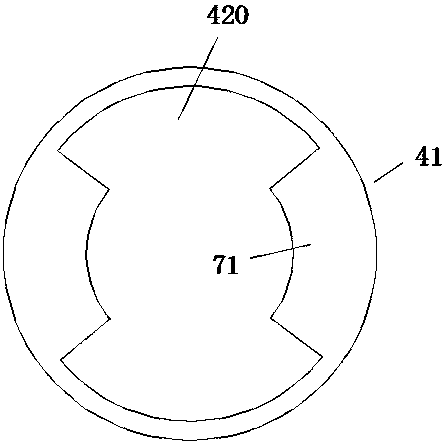

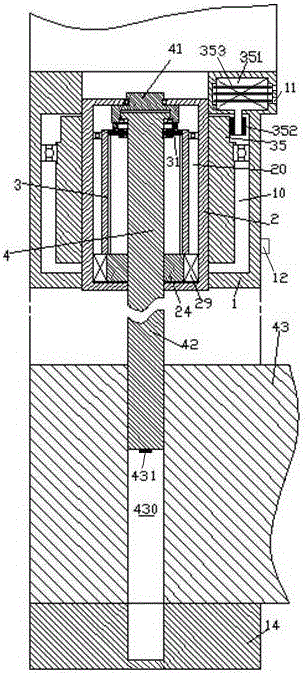

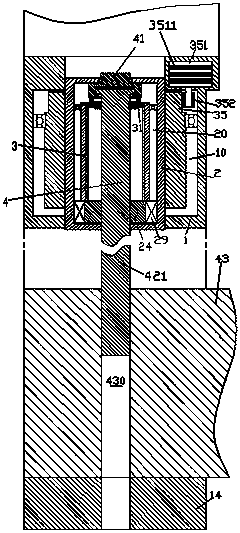

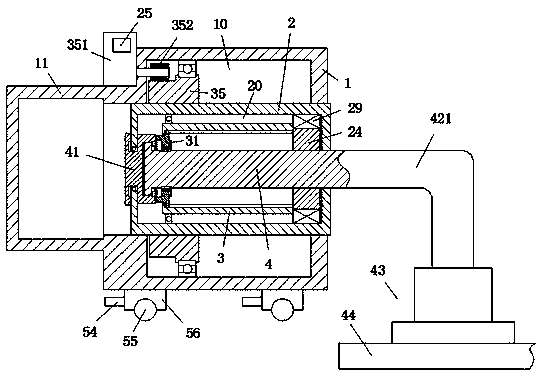

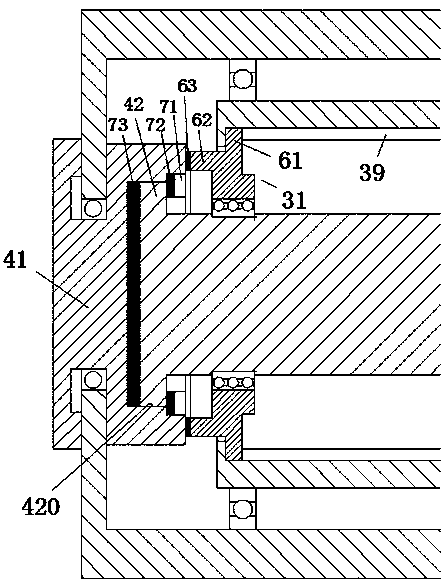

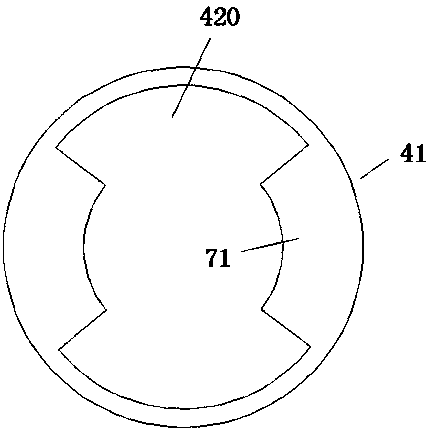

The invention provides a garden irrigating device. The garden irrigating device comprises an enclosure (1), an external driving motor (351) mounted on the enclosure (1), a thread driving sleeve (35) which is peripherally rotatably and axially fixedly mounted in a cavity (10) of the enclosure (1) through a bearing, a driving sleeve (2) which is matched with an internal thread of the thread driving sleeve (35), an internal driving motor (29) which is axially fixedly mounted in a cavity (20) of the driving sleeve (2), an internal thread driving block (24) which is peripherally driven by the internal driving motor (29) to rotate and is axially fixed, and a movable thread rod (4) which is in thread matching with the internal thread driving block (24), wherein rolling wheel seats (51) are mounted at the bottom of the enclosure (1) and rolling wheels (52) on the rolling wheel seats (51) can be used for driving the enclosure (1) to move.

Owner:毛建锋

Workbench latch device with high locking efficiency

ActiveCN106041544AReduce equipment costsReduce maintenance difficultyLarge fixed membersMaintainance and safety accessoriesDrive motorEngineering

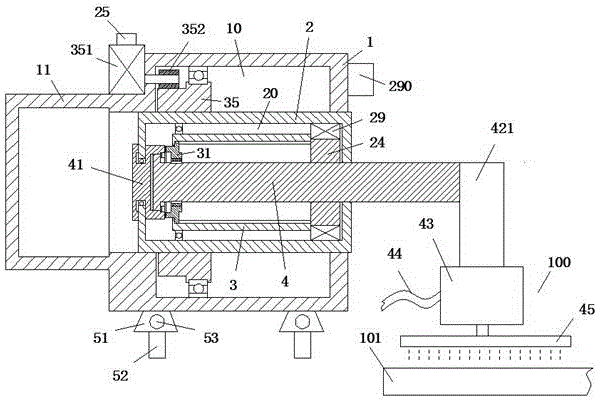

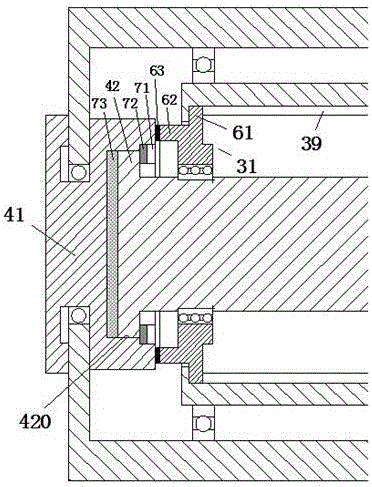

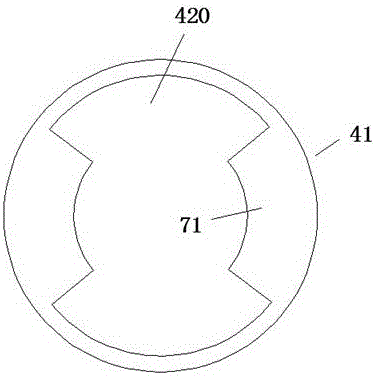

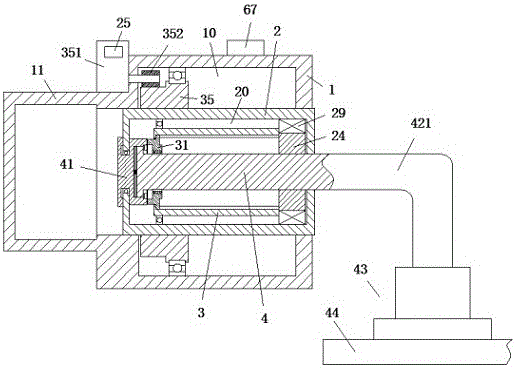

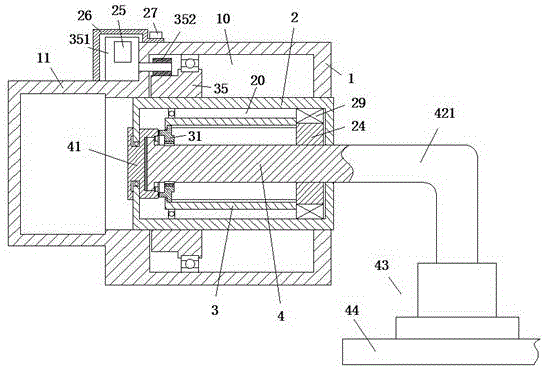

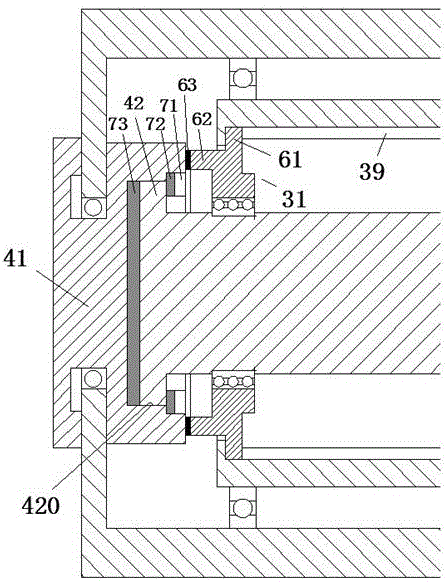

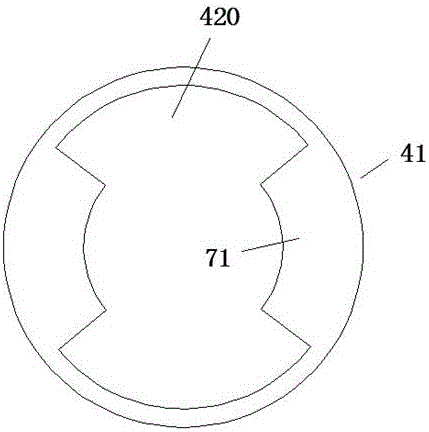

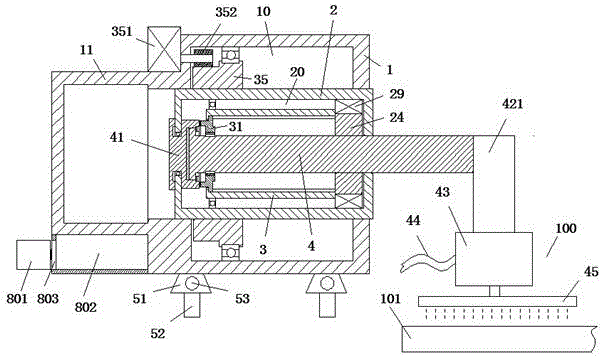

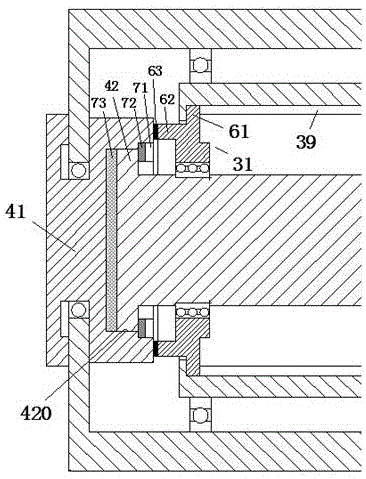

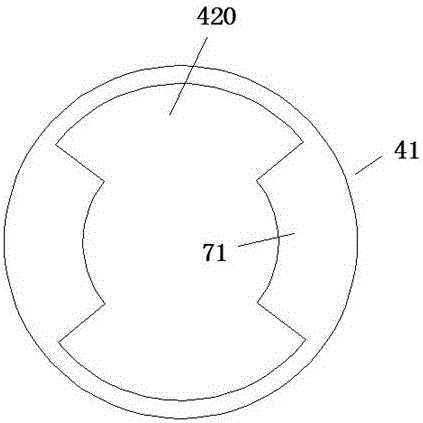

A workbench latch device with high locking efficiency comprises a shell (1) fixedly connected with a frame, a thread sleeve drive motor (351) mounted on the shell (1), a threaded toothed ring (35) axially fixed in a cavity (10) of the shell (1) through a bearing, a threaded sleeve (2) fitting an internal thread of the threaded toothed ring (35), an internal screw member drive motor (29) axially fixed in an inner cavity (20) of the threaded sleeve (2), an internal threaded block (24) axially fixed and rotatable under peripheral driving of the internal screw member drive motor (29), and an internal screw member (4) in threaded fit with the internal threaded block (24).

Owner:BEIJING GW TECH +1

Anterior cervical vertebra decompression trepan with automatic depth control function

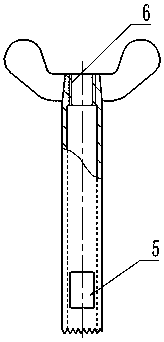

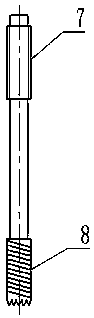

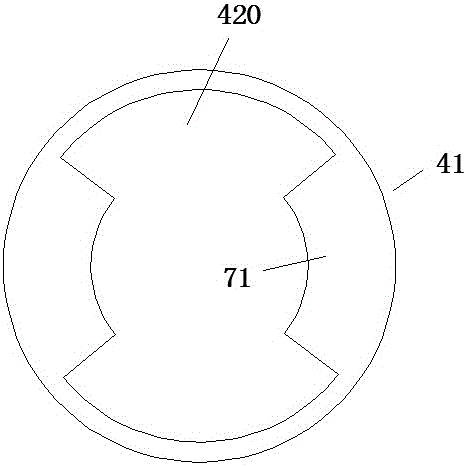

PendingCN109044478ASafe and convenient cutting operationLarge feed forceSurgical sawsMedicineFree state

The invention discloses an anterior cervical vertebra decompression trepan with an automatic depth control function. The trepan includes an internal guide rod and an outer trepan body sleeving the internal guide rod; the outer trepan body is a hollow cavity, teeth are arranged at the lower end of the outer trepan body, a rotary handle is arranged at the upper end, and an inner thread is arranged at the upper portion of the cavity; a self-tapping thread is arranged at the lower portion of the internal guide rod, and a fine thread matched with the inner thread is arranged at the upper portion ofthe internal guide rod; the large diameter of the self-tapping thread of the internal guide rod is smaller than or equal to the inner diameter of the outer trepan body; an observation window is formed in the lower portion of the outer trepan body. Through threaded cooperation between a trepan body and a mechanical device, downward transmission of a cutting force is achieved, and only the rotary handle needs to be rotated, then cutting of a cervical vertebra can be cut off; after the trepan body penetrates through a bone substance, a fixing rod and an annular bone column in the trepan body canstay in a free state, the rotation intensity can be quickly reduced, the cutting depth of the trepan cannot be increased even if the trepan continues to rotate, a downward action force cannot be generated again, and it is ensured that medulla spinalis in a spinal canal cannot be damaged by the trepan.

Owner:SHANDONG UNIV OF TRADITIONAL CHINESE MEDICINE

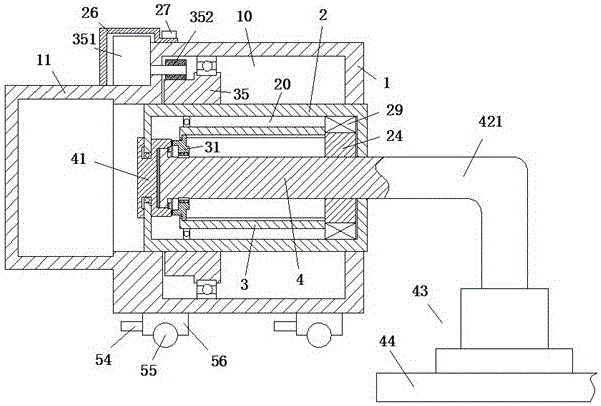

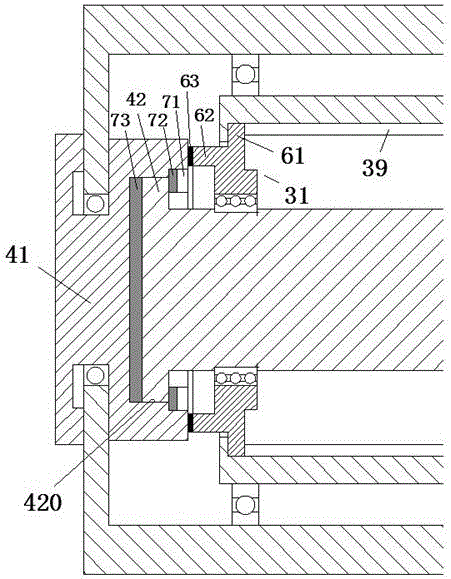

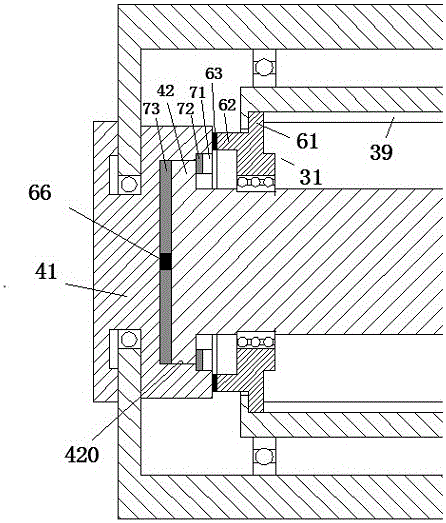

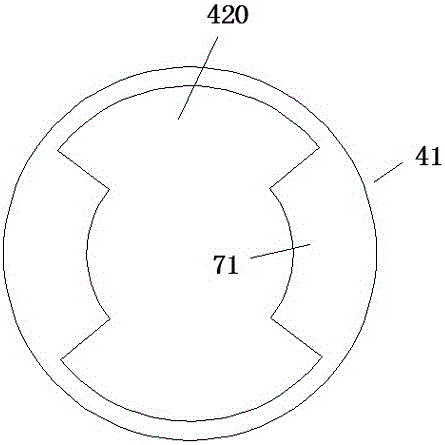

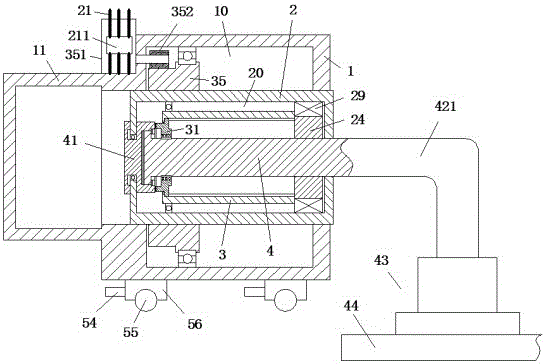

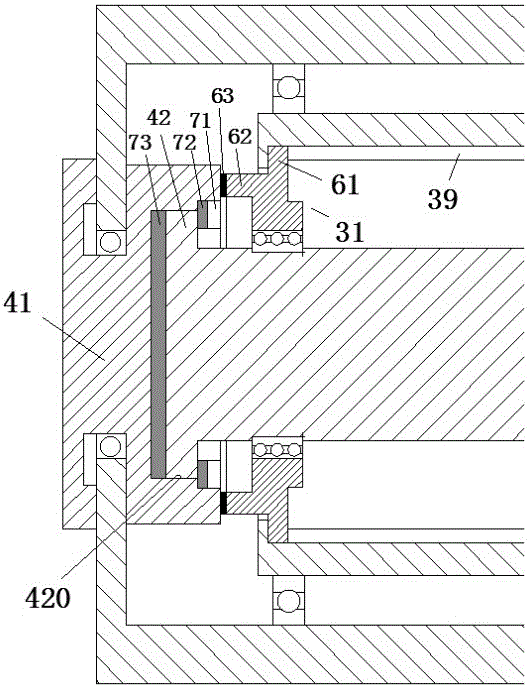

Safety machining device used for plate surface

ActiveCN106181620ASolve the problem of excessive lengthImprove bindingGrinding drivesPlane surface grinding machinesGear driveEngineering

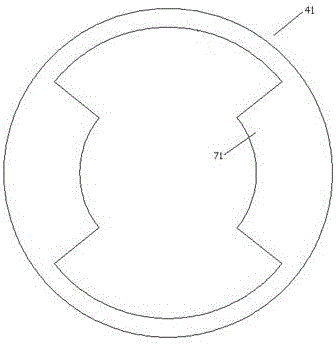

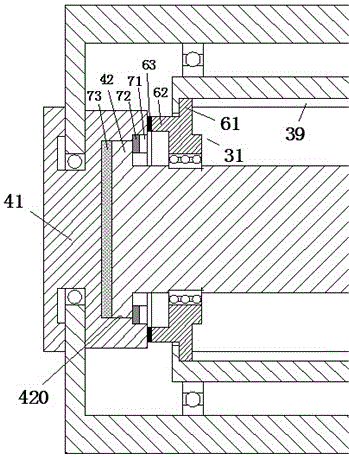

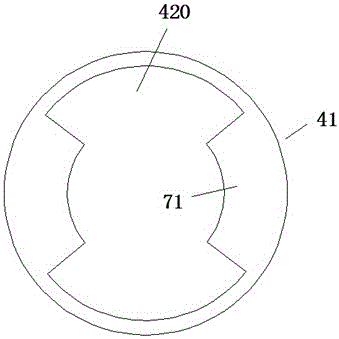

The invention discloses a safety machining device used for a plate surface. The safety machining device comprises a shell (1), a gear drive motor (351) installed on the shell (1), a threaded gear sleeve (35) which can rotate in the circumferential direction and is axially and fixedly installed in a cavity (10) in the shell (1) through a bearing, a threaded sleeve (2) matched with an inner thread of the threaded gear sleeve (35), a hollow shaft motor (29) axially and fixedly installed in an inner cavity (20) of the threaded sleeve (2), an inner threaded block (24) which can be circumferentially driven by the hollow shaft motor (29) to rotate and is axially fixed, and an inner screw part (4) in threaded fit with the inner threaded block (24). The gear drive motor (351) is engaged with the threaded gear sleeve (35) through a gear (352) which is in power connection.

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

Noise reduction machining device for panel surface treatment

ActiveCN106271921ASolve the problem of excessive lengthImprove bindingGrinding drivesPlane surface grinding machinesGear driveEngineering

The invention relates to a noise reduction machining device for panel surface treatment. The noise reduction machining device comprises a shell (1), a gear driving motor (351) installed on the shell (1), a thread gear sleeve (35) which can rotate in the circumferential direction through a bearing and is fixedly installed in a cavity (10) of the shell (1) in the axial direction, a threaded sleeve (2) matched with an internal thread of the thread gear sleeve (35), a hollow shaft motor (29) fixedly installed in an inner cavity (20) of the threaded sleeve (2) in the axial direction, an internal thread block (24) which can rotate under circumferential driving of the hollow shaft motor (29) and an internal screw rod (4) in threaded fit with the internal thread block (24); and the gear driving motor (351) is meshed with the thread gear sleeve (35) through a gear (352) in power connection.

Owner:江苏中康金属材料有限公司

Improved garden irrigation device

InactiveCN106234166AReduce equipment costsReduce maintenance difficultyClimate change adaptationWatering devicesEngineeringWater irrigation

The invention relates to an improved garden irrigation device. The improved garden irrigation device comprises a chassis (1), an outer driving motor (351) arranged on the chassis (1), a screw thread driving sleeve (35) which can rotate in the circumferential direction by virtue of a bearing and is axially fixedly arranged in the cavity (10) of the chassis (1), a driving sleeve (2) matched with an internal screw thread of the screw thread driving sleeve (35), an inner driving motor (29) axially fixedly arranged in the cavity (20) of the driving sleeve (2), an internal screw thread driving block (24) which is driven by the inner driving motor (29) in the circumferential direction, can rotate and is axially fixed and a movable threaded rod (4) matched with the internal screw thread driving block (24) by virtue of a screw thread, wherein a roller base (51) is arranged at the bottom of the chassis (1), and a movable roller (52) arranged on the roller base (51) is used for driving the chassis (1) to move.

Owner:张帆

Adjustable plate machining equipment

InactiveCN106078379ASolve the problem of excessive lengthImprove bindingGrinding drivesInterengaging clutchesGear driveEngineering

Adjustable plate machining equipment comprises a shell (1), a gear driving motor (351), a thread gear sleeve (35), a thread sleeve (2), a hollow shaft motor (29), an inner thread block (24) and an inner screw component (4), wherein the gear driving motor (351) is mounted on the shell (1), the thread gear sleeve (35) can circumferentially rotate via a bearing and is mounted in a cavity (10) of the shell (1) in an axially-fixed manner, the thread sleeve (2) is matched with inner threads of the thread gear sleeve (35), the hollow shaft motor (29) is mounted in an inner cavity (20) of the thread sleeve (2) in an axially-fixed manner, the inner thread block (24) can be circumferentially driven by the hollow shaft motor (29) to rotate and is axially fixed, the inner screw component (4) is in thread fit with the inner thread block (24), and the gear driving motor (351) is engaged with the thread gear sleeve (35) through a gear (352) in power connection with the gear driving motor (351).

Owner:嘉兴市万宝集成家居有限公司

Durable machining device for surface treatment of plate

InactiveCN106112714ASolve the problem of excessive lengthImprove bindingGrinding drivesGearingGear driveEngineering

The invention discloses a durable machining device for surface treatment of a plate. The durable machining device comprises a shell (1), a gear driving motor (351) installed on the shell (1), a threaded tooth sleeve (35) which can rotate circumferentially through a bearing and is axially and fixedly installed in a cavity (10) of the shell (1), a threaded sleeve (2) matched with an inner thread of the threaded tooth sleeve (35), a hollow shaft motor (29) axially and fixedly installed in an inner cavity (20) of the threaded sleeve (2), an inner threaded block (24) which can be circumferentially driven by the hollow shaft motor (29) to rotate and is axially fixed, and an inner screw part (4) in threaded fit with the inner threaded block (24). The gear driving motor (351) is engaged with the threaded tooth sleeve (35) through a gear (352) in power linkage.

Owner:张文灶

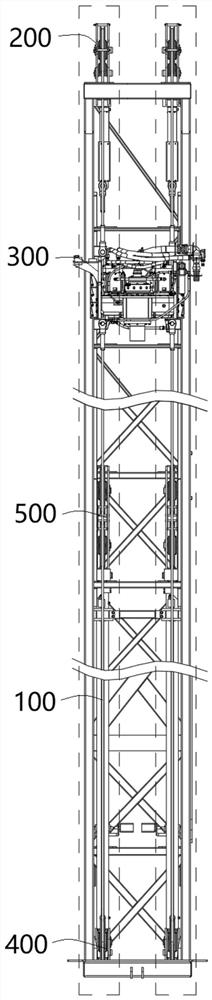

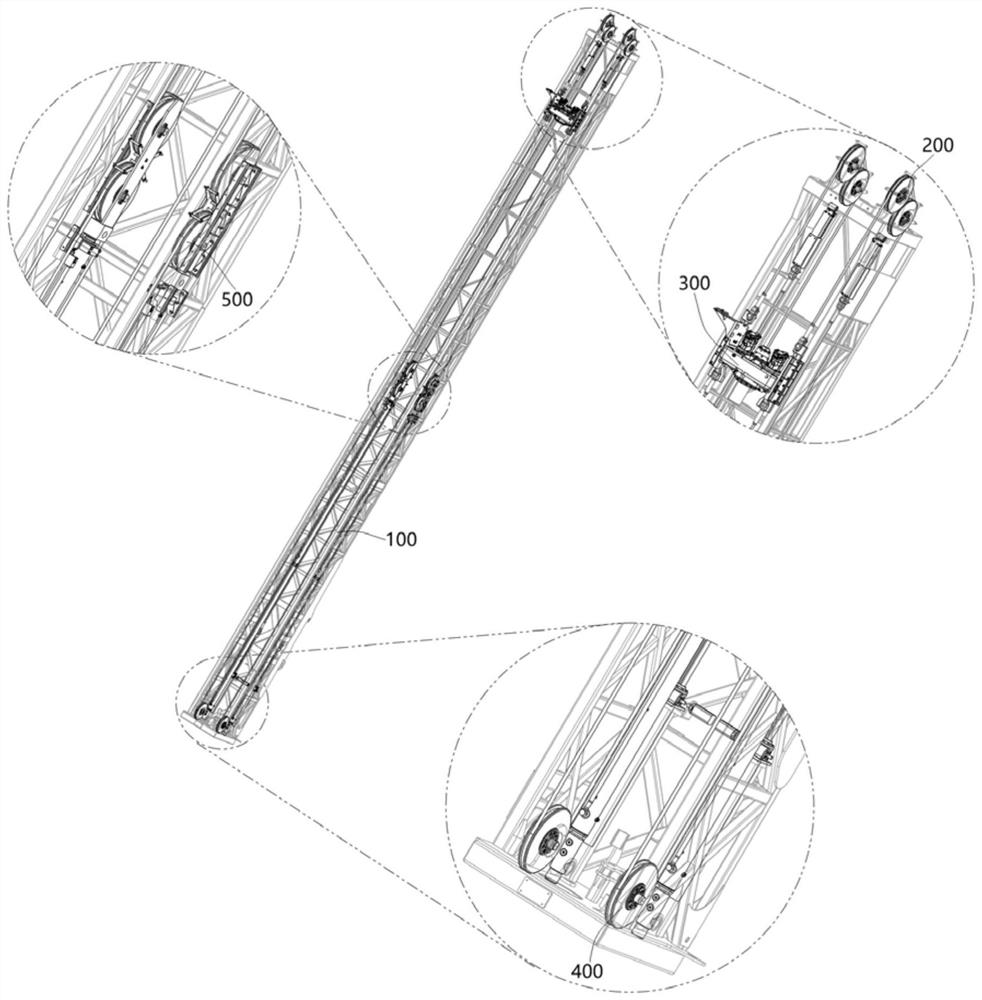

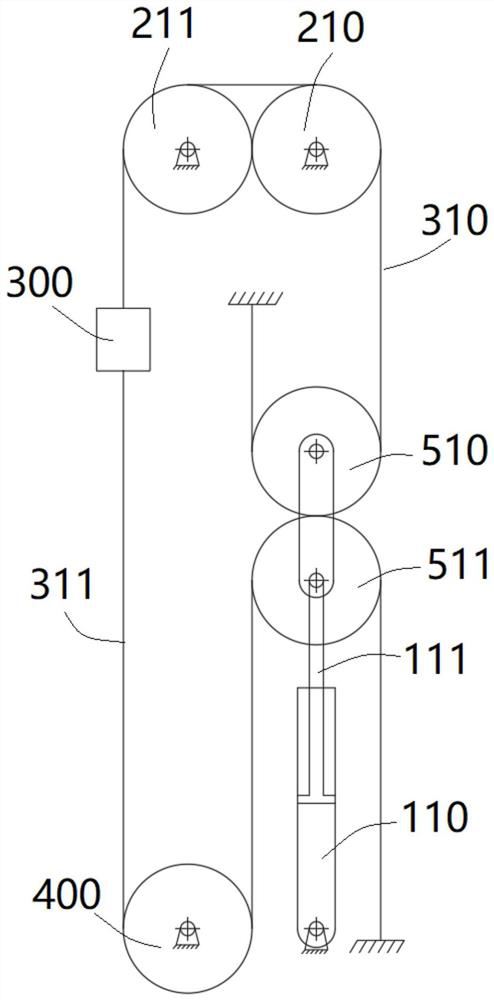

Double-oil-cylinder feeding system of blast hole drilling machine

PendingCN112814585AIncrease pressureEasy to liftDrilling rodsDrilling casingsHydraulic pumpBlock and tackle

The invention discloses a double-oil-cylinder feeding system of a blast hole drilling machine, and belongs to the technical field of mining machinery. The double-oil-cylinder feeding system comprises two feeding oil cylinders, a power head and a movable pulley block, wherein the two feeding oil cylinders are arranged on a tower device in parallel and are supplied with oil by the same hydraulic pump; the power head is pulled by a steel wire rope; the steel wire rope bypasses the movable pulley block and is fixed on the tower device; and the feeding oil cylinders are used for driving the movable pulley block to move, so that the power head can move up and down. The double-oil-cylinder feeding system of the blast hole drilling machine overcomes the inconvenience caused by insufficient power of the existing feeding system of the blast hole drilling machine. Two sets of independent oil cylinder feeding systems are arranged on the two sides of the tower device, the two sets of hydraulic oil cylinders act simultaneously and are in a parallel state, the pressure and the flow are the same, the feeding oil cylinders have the same load, synchronous operation can be realized, the two sides of the power head are stressed simultaneously and are stressed in a balanced mode, and the force of the feeding oil cylinders is converted into the downward pressure and the upward lifting of the power head during working.

Owner:ATLAS COPCO NANJING CONSTR & MINING EQUIP

Workbench bolt lock structure for machining equipment

InactiveCN106078246AAxial locking is achievedAvoid collisionLarge fixed membersDrive motorEngineering

A workbench bolt lock structure for machining equipment comprises a shell (1) fixedly connected with a rack, a threaded sleeve driving motor (351) mounted on the shell (1), a threaded gear ring sleeve (35), a threaded sleeve (2), an internal screw part driving motor (29), an internal threaded block (24) and an internal screw part (4). The threaded gear ring sleeve (35) is axially and fixedly mounted in a chamber (10) of the shell (1) through a bearing. The threaded sleeve (2) is matched with an internal thread of the threaded gear ring sleeve (35). The internal screw part driving motor (29) is axially and fixedly mounted in an inner cavity (20) of the threaded sleeve (2). The internal threaded block (24) can be circumferentially driven by the internal screw part driving motor (29) to rotate and is axially fixed. The internal screw part (4) is in threaded fit with the internal threaded block (24).

Owner:陈广生

Processing device for plate surface

InactiveCN106239287ASolve the problem of excessive lengthImprove bindingGrinding drivesPlane surface grinding machinesGear driveEngineering

The invention discloses a processing device for a plate surface. The processing device comprises a shell (1), a gear drive motor (351) installed on the shell (1), a threaded tooth sleeve (35) which can circumferentially rotate through a bearing and is axially fixedly installed in a cavity (10) of the shell (1), a threaded sleeve (2) which is in inside threaded matching with the threaded tooth sleeve (35), a hollow shaft motor (29) fixedly installed in an inner cavity (20) of the threaded sleeve (2) axially, an inside threaded block (24) which can circumferentially rotate driven by the hollow shaft motor (29) and is axially fixed and an inside screw rod (4) which is in threaded matching with the inside threaded block (24), wherein the gear drive motor (351) is meshed with the threaded tooth sleeve (35) through a gear (352) which is linked by power.

Owner:王建定

Worktable latching device for machining

InactiveCN106239181ASolve the problem of excessive lengthLarge feed forceLarge fixed membersEngineeringDrive motor

A worktable latching device for machining comprises a housing (1) fixedly connected to a frame, a threaded sleeve driving motor (351) mounted on the housing (1), a threaded toothed ring sleeve (35) axially and fixedly mounted in a cavity (10) of the housing (1) by means of a bearing, a threaded sleeve (2) matched with internal threads of the threaded toothed ring sleeve (35), an internal screw piece driving motor (29) axially and fixedly mounted in an inner cavity (20) of the threaded sleeve (2), an internal thread block (24) which can be circumferentially driven by the internal screw piece driving motor (29) to rotate and is fixed axially, and an internal screw piece (4) which is in thread fit with the internal thread block (24).

Owner:陈广生

Machining device for processing surfaces of boards

ActiveCN106271931ASolve the problem of excessive lengthImprove bindingGrinding carriagesGrinding drivesGear driveEngineering

A machining device for processing surfaces of boards comprises a shell (1), a gear drive motor (351), a threaded toothed sleeve (35), a threaded sleeve (2), a hollow shaft motor (29), an inner threaded block (24) and an inner screw part (4), wherein the gear drive motor (351) is mounted on the shell (1), the threaded toothed sleeve (35) can peripherally rotate through a bearing and is axially fixedly mounted in the cavity (10) of the shell (1), the threaded sleeve (2) is matched with the threaded toothed sleeve (35), the hollow shaft motor (29) is axially fixedly mounted in the cavity (20) of the threaded sleeve (2), the inner threaded block (24) can be driven by the hollow shaft motor (29) to rotate and is axially fixed, the inner screw part (4) is matched with the inner threaded block (24) in a threaded manner, and the gear drive motor (351) meshes with the threaded toothed sleeve (35) through a power-connection gear (352).

Owner:BENGBU JINGUANG WHEEL

Water spraying device for garden lawn

InactiveCN106305364AEasy to useImprove bindingWatering devicesCultivating equipmentsEngineeringWater spray

The invention provides a water spraying device for a garden lawn. The water spraying device comprises an enclosure (1), an external driving motor (351) mounted on the enclosure (1), a thread driving sleeve (35) which is peripherally rotatably and axially fixedly mounted in a cavity (10) of the enclosure (1) through a bearing, a driving sleeve (2) which is matched with an internal thread of the thread driving sleeve (35), an internal driving motor (29) which is axially fixedly mounted in a cavity (20) of the driving sleeve (2), an internal thread driving block (24) which is peripherally driven by the internal driving motor (29) to rotate and is axially fixed, and a movable thread rod (4) which is in thread matching with the internal thread driving block (24), wherein rolling wheel seats (51) are mounted at the bottom of the enclosure (1) and rolling wheels (52) on the rolling wheel seats (51) can be used for driving the enclosure (1) to move.

Owner:余炳强

Machining device for panel surface treatment

ActiveCN106271919AReduce equipment costsReduce maintenance difficultyGrinding drivesPlane surface grinding machinesSurface finishingEngineering

The invention relates to a machining device for panel surface treatment. The machining device comprises a shell (1), a gear driving motor (351) installed on the shell (1), a thread gear sleeve (35) which can rotate in the circumferential direction through a bearing and is fixedly installed in a cavity (10) of the shell (1) in the axial direction, a threaded sleeve (2) matched with an internal thread of the thread gear sleeve (35), a hollow shaft motor (29) fixedly installed in an inner cavity (20) of the threaded sleeve (2) in the axial direction, an internal thread block (24) which can rotate under circumferential driving of the hollow shaft motor (29) and an internal screw rod (4) in threaded fit with the internal thread block (24); and the gear driving motor (351) is meshed with the thread gear sleeve (35) through a gear (352) in power connection.

Owner:江苏德重新材料技术有限公司

A kind of stable plate surface processing equipment

ActiveCN106181617BSolve the problem of excessive lengthImprove bindingGrinding drivesInterengaging clutchesGear driveEngineering

The invention discloses board steadiness surface working equipment. The board steadiness surface working equipment comprises a shell (1), a gear drive motor (351), a threaded gear sleeve (35), a threaded sleeve (2), a hollow shaft motor (29), an internal threaded block (24) and an internal screw rod (4), wherein the gear drive motor (351) is installed on the shell (1); the threaded gear sleeve (35) can rotate in the circumferential direction through a bearing and is fixedly installed in a cavity (10) of the shell (1) in the axial direction; the threaded sleeve (2) is matched with an internal thread of the threaded gear sleeve (35); the hollow shaft motor (29) is fixedly installed in an inner cavity (20) of the threaded sleeve (2) in the axial direction; the internal threaded block (24) is driven by the hollow shaft motor (29) in the circumferential direction to rotate and is fixed in the axial direction; the internal screw rod (4) is in screw-thread fit with the internal threaded block (24); and the gear drive motor (351) is engaged with the threaded gear sleeve (35) through a power connection gear (352).

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

A plate surface processing device with a safety shield

ActiveCN106271930BSolve the problem of excessive lengthImprove bindingGrinding carriagesGrinding drivesGear driveEngineering

A plate surface machining device provided with a safety protective cover comprises a shell (1), a gear drive motor (351) installed on the shell (1), a threaded tooth sleeve (35) which can rotate circumferentially through a bearing and is axially and fixedly installed in a cavity (10) of the shell (1), a threaded sleeve (2) which is matched with inner threads of the threaded tooth sleeve (35), a hollow shaft motor (29) which is axially and fixedly installed in an inner cavity (20) of the threaded sleeve (2), an internally threaded block (24) which is driven by the hollow shaft motor (29) to rotate circumferentially and is axially fixed and an inner screw piece (4) which is in screw-thread fit with the internally threaded block (24). The gear drive motor (351) is meshed with the threaded tooth sleeve (35) through a gear (352) which is in power connection with the gear drive motor (351).

Owner:JIASHAN HUIJIALE DECORATION MATERIALS CO LTD

A processing device used on the surface of a plate and capable of reducing noise

ActiveCN106271921BSolve the problem of excessive lengthImprove bindingGrinding drivesPlane surface grinding machinesGear driveEngineering

The invention relates to a noise reduction machining device for panel surface treatment. The noise reduction machining device comprises a shell (1), a gear driving motor (351) installed on the shell (1), a thread gear sleeve (35) which can rotate in the circumferential direction through a bearing and is fixedly installed in a cavity (10) of the shell (1) in the axial direction, a threaded sleeve (2) matched with an internal thread of the thread gear sleeve (35), a hollow shaft motor (29) fixedly installed in an inner cavity (20) of the threaded sleeve (2) in the axial direction, an internal thread block (24) which can rotate under circumferential driving of the hollow shaft motor (29) and an internal screw rod (4) in threaded fit with the internal thread block (24); and the gear driving motor (351) is meshed with the thread gear sleeve (35) through a gear (352) in power connection.

Owner:江苏中康金属材料有限公司

Garden lawn water spraying device convenient to use

InactiveCN106258847AReduce equipment costsReduce maintenance difficultyWatering devicesSpray nozzlesDrive motorEngineering

Provided is a garden lawn water spraying device convenient to use. The garden lawn water spraying device comprises a machine shell (1), an outer drive motor (351) installed on the machine shell (1), a threaded drive cover (35) which is installed in a cavity (10) of the machine shell (1) rotatably in the circumferential direction and fixedly in the axial direction through a bearing, a drive sleeve (2) which is matched with an internal thread of the threaded drive cover (35), an inner drive motor (29) which is axially and fixedly installed in a chamber (20) of the drive sleeve (2), an internal thread drive block (24) which can be driven by the inner dive motor (29) in the circumferential direction to rotate and is axially fixed and a mobile threaded rod (4) matched with the thread of the internal drive block (24); rolling wheel bases (51) are installed at the bottom of the machine shell (1), and mobile rolling wheels (52) are arranged on the rolling wheel bases (51) to be used for driving the machine shell (1) to move.

Owner:毛建锋

Adjustable processing device for sheet surfaces

InactiveCN106271929ASolve the problem of excessive lengthImprove bindingGrinding carriagesGrinding drivesGear driveEngineering

The invention discloses an adjustable processing device for sheet surfaces. The adjustable processing device comprises a casing body (1), a gear driven motor (351) mounted on the casing body (1), a thread gear sleeve (35) circumferentially, rotationally, axially and fixedly mounted in a cavity (10) of the casing body (1) through a bearing, a screw sleeve (2) matched with the internal thread of the thread gear sleeve (35), a hollow shaft motor (29) axially and fixedly mounted in an inner cavity (20) of the screw sleeve (2), an inner screw block (24) axially fixed and capable of being rotated under circumferential driving of the hollow shaft motor (29), and an inner screw part (4) in thread fit with the inner screw block (24), wherein the gear driven motor (351) is meshed with the thread gear sleeve (35) through a gear (352) which is in power connection.

Owner:王建定

A sheet metal processing equipment

ActiveCN106181621BSolve the problem of excessive lengthImprove bindingGrinding drivesPlane surface grinding machinesGear driveScrew thread

The invention discloses panel processing equipment. The panel processing equipment comprises a shell (1), a gear driving motor (351) which is installed on the shell (1), a threaded gear sleeve (35) which can rotate in the circumferential direction through a bearing and is fixedly installed in a cavity (10) of the shell (1) in the axial direction, a threaded sleeve (2) which is matched with an internal thread of the threaded gear sleeve (35), a hollow shaft motor (29) which is fixedly installed in an inner cavity (20) of the threaded sleeve (2) in the axial direction, an internal thread block (24) which can rotate through circumferential driving of the hollow shaft motor (29) and is fixed in the axial direction, and an internal threaded rod (4) which is in screw-thread fit with the internal thread block (24). The gear driving motor (351) is engaged with the threaded gear sleeve (35) through a power connection gear (352).

Owner:江苏顺优金属科技有限公司

Machining device for plate surface treatment

InactiveCN106181619ASolve the problem of excessive lengthImprove bindingGrinding drivesInterengaging clutchesGear driveEngineering

The invention discloses a machining device for plate surface treatment. The machining device comprises a shell (1), a gear drive motor (351) installed on the shell (1), a threaded gear sleeve (35) which can rotate in the circumferential direction and is axially and fixedly installed in a cavity (10) in the shell (1) through a bearing, a threaded sleeve (2) matched with an inner thread of the threaded gear sleeve (35), a hollow shaft motor (29) axially and fixedly installed in an inner cavity (20) of the threaded sleeve (2), an inner threaded block (24) which can be circumferentially driven by the hollow shaft motor (29) to rotate and is axially fixed, and an inner screw part (4) in threaded fit with the inner threaded block (24). The gear drive motor (351) is engaged with the threaded gear sleeve (35) through a gear (352) which is in power connection.

Owner:王建定

A shock-absorbing processing device for the surface of a plate

ActiveCN106112715BSolve the problem of excessive lengthImprove bindingNon-rotating vibration suppressionGrinding drivesGear driveEngineering

The invention discloses a machining device used for the surface of a plate and being capable of achieving shock absorption. The machining device comprises a shell (1), a gear driving motor (351) installed on the shell (1), a threaded tooth sleeve (35) which can rotate circumferentially through a bearing and is axially and fixedly installed in a cavity (10) of the shell (1), a threaded sleeve (2) matched with an inner thread of the threaded tooth sleeve (35), a hollow shaft motor (29) axially and fixedly installed in an inner cavity (20) of the threaded sleeve (2), an inner threaded block (24) which can be circumferentially driven by the hollow shaft motor (29) to rotate and is axially fixed, and an inner screw part (4) in threaded fit with the inner threaded block (24). The gear driving motor (351) is engaged with the threaded tooth sleeve (35) through a gear (352) in power linkage.

Owner:JIASHAN HUASEN WOOD

Novel workbench latch device for machining equipment

InactiveCN106239180ASolve the problem of excessive lengthLarge feed forceLarge fixed membersDrive motorEngineering

The invention discloses a novel workbench latch device for machining equipment. The novel workbench latch device comprises a shell body (1) fixedly connected with a rack, a threaded sleeve driving motor (351) installed on the shell body (1), a threaded gear ring sleeve (35) installed in a cavity (10) of the shell body (1) coaxially and fixedly through a bearing, a threaded sleeve (2) matched with an inner thread of the threaded gear ring sleeve (35), an inner screw piece driving motor (29) coaxially and fixedly installed in an inner cavity (20) of the threaded sleeve (2), an inner threaded block (24) which can be driven by the inner screw piece driving motor (29) to rotate in the circumferential direction and is fixed in the axial direction and an inner screw piece (4) matched with a thread of the inner threaded block (24).

Owner:陈广生

A workbench latch device

ActiveCN106181441BSolve the problem of excessive lengthLarge feed forceLarge fixed membersElectric machineryEngineering

A workbench latching device, comprising a housing (1) fixedly connected to a frame, a threaded sleeve drive motor (351) installed on the housing (1), axially fixedly installed on the The threaded ring sleeve (35) in the chamber (10) of the housing (1), the threaded sleeve (2) matched by the internal thread of the threaded ring sleeve (35), are axially fixedly installed on the The internal screw drive motor (29) in the inner cavity (20) of the threaded sleeve (2), and the internal screw drive motor (29) circumferentially drives the rotatable and axially fixed internal thread block ( 24) and the internal screw member (4) threaded by the internal thread block (24).

Owner:徐州力达缝纫设备制造有限公司

A movable plate processing device

ActiveCN106181528BSolve the problem of excessive lengthImprove bindingFeeding apparatusGear driveEngineering

A movable plate machining device comprises a shell (1), a gear driving motor (351) mounted on the shell (1), a threaded gear sleeve (35), a threaded sleeve (2), a hollow shaft motor (29), an internal threaded block (24) and an inner screw part (4). The threaded gear sleeve (35) can circumferentially rotate through a bearing and is fixedly mounted in a chamber (10) of the shell (1) in the axial direction. The threaded sleeve (2) is matched with an internal thread of the threaded gear sleeve (35). The hollow shaft motor (29) is axially and fixedly mounted in an inner cavity (20) of the threaded sleeve (2). The internal threaded block (24) is circumferentially driven by the hollow shaft motor (29) to rotate and axially fixed. The inner screw part (4) is in threaded fit with the internal threaded block (24). The gear driving motor (351) is engaged with the threaded gear sleeve (35) through a gear (352) in power connection.

Owner:ZHONGSHAN TAIXING FURNITURE CO LTD

Panel processing equipment

ActiveCN106181621ASolve the problem of excessive lengthImprove bindingGrinding drivesPlane surface grinding machinesGear driveEngineering

The invention discloses panel processing equipment. The panel processing equipment comprises a shell (1), a gear driving motor (351) which is installed on the shell (1), a threaded gear sleeve (35) which can rotate in the circumferential direction through a bearing and is fixedly installed in a cavity (10) of the shell (1) in the axial direction, a threaded sleeve (2) which is matched with an internal thread of the threaded gear sleeve (35), a hollow shaft motor (29) which is fixedly installed in an inner cavity (20) of the threaded sleeve (2) in the axial direction, an internal thread block (24) which can rotate through circumferential driving of the hollow shaft motor (29) and is fixed in the axial direction, and an internal threaded rod (4) which is in screw-thread fit with the internal thread block (24). The gear driving motor (351) is engaged with the threaded gear sleeve (35) through a power connection gear (352).

Owner:江苏顺优金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com