Machining device for panel surface treatment

A surface treatment and processing device technology, which is applied in the direction of grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve the problems of long screw rod length, etc., achieve the effect of firm combination, reduce maintenance difficulty, and save equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

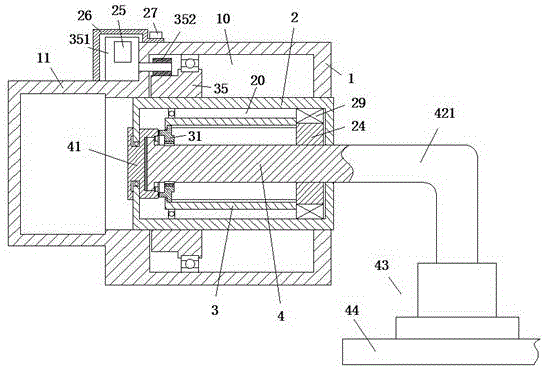

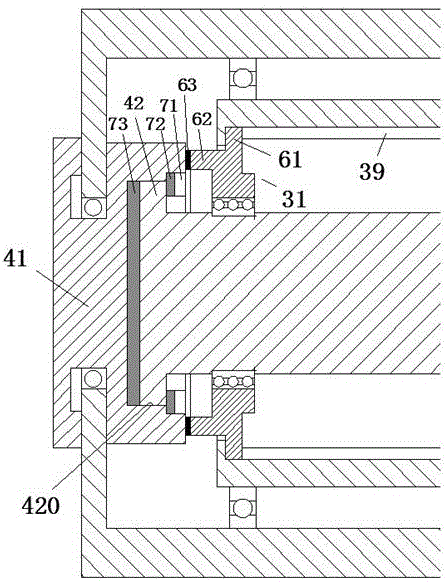

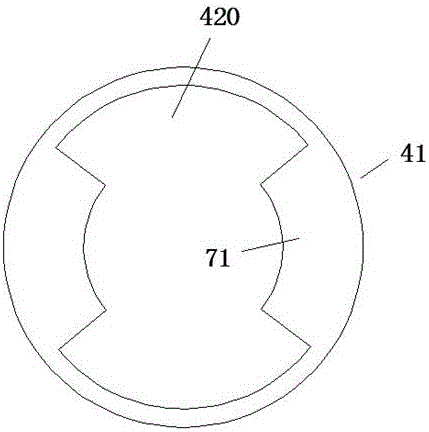

[0009] Combine below Figure 1-3 The present invention will be described in detail.

[0010] The processing device for plate surface treatment according to the embodiment of the present invention includes a housing 1, a gear drive motor 351 installed on the housing 1, and is mounted on the housing rotatably in the circumferential direction and axially fixedly through a bearing. The threaded sleeve 35 in the cavity 10 of the body 1, the threaded sleeve 2 that cooperates with the internal thread of the threaded sleeve 35, and the hollow shaft axially fixedly installed in the inner cavity 20 of the threaded sleeve 2 The motor 29, the rotatable and axially fixed internal thread block 24 driven circumferentially by the hollow shaft motor 29 and the internal screw member 4 threadedly engaged with the internal thread block 24, wherein the gear drive motor 351 is driven by power The gear 352 connected with the threaded sleeve 35 meshes, the threaded sleeve 2 can slide left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com