Double-oil-cylinder feeding system of blast hole drilling machine

A feed system, double oil cylinder technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problem of drilling pressure can not reach the drilling diameter, drilling depth, poor drilling capacity mining area work requirements, installation inconvenience, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

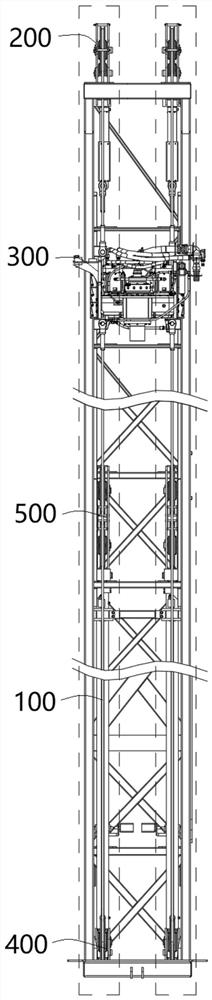

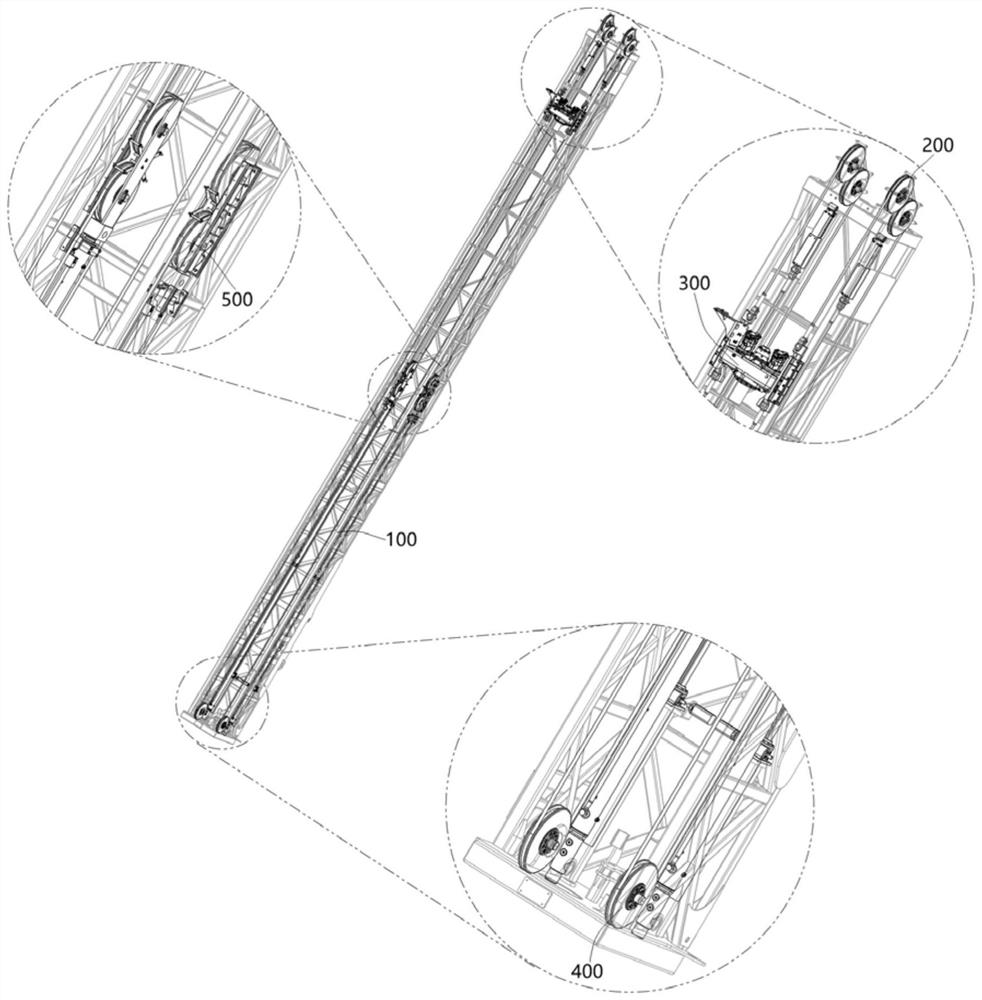

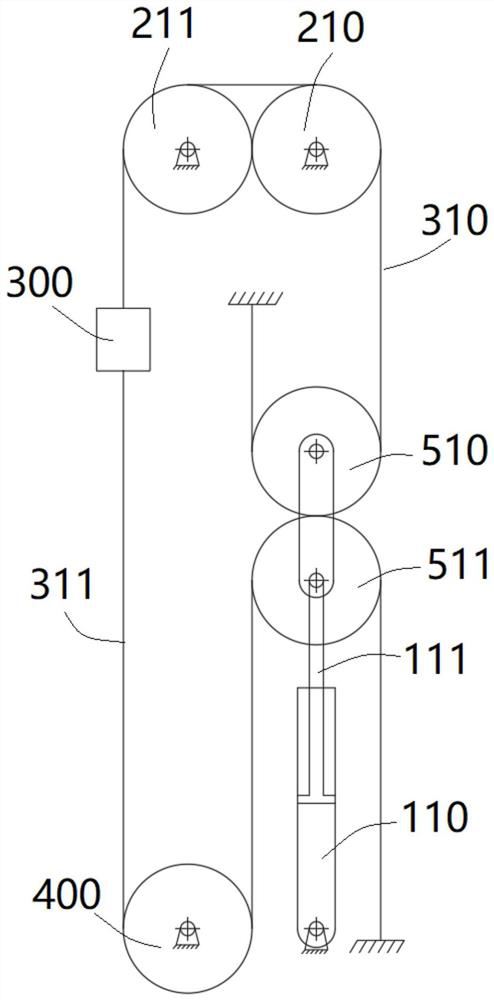

[0050] combine figure 1 , a dual-cylinder feed system for a blasthole drilling rig in this embodiment, including two feed cylinders 100 arranged side by side on the tower device and supplied with oil by the same hydraulic pump, a power head 300, a movable pulley block 500, and a power head 300 is pulled by a wire rope, and the wire rope is passed around the driven pulley block 500 and fixed on the tower device. The feed cylinder 100 is used to drive the movable pulley block 500 to move, thereby realizing the up and down movement of the power head 300 .

[0051] Specifically in this embodiment, two feed cylinders 100 arranged side by side and fed by the same hydraulic pump jointly drive the same power head 300 to move up and down. The power head 300 includes a hydraulic motor and a reducer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com