Apparatus and technology for compounding material

A composite device and process technology, which is applied in the field of machinery, can solve the problems of irregularity and easy wrinkling of elastic composite materials, and achieve the effects of comfortable use, beautiful appearance, and improved product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

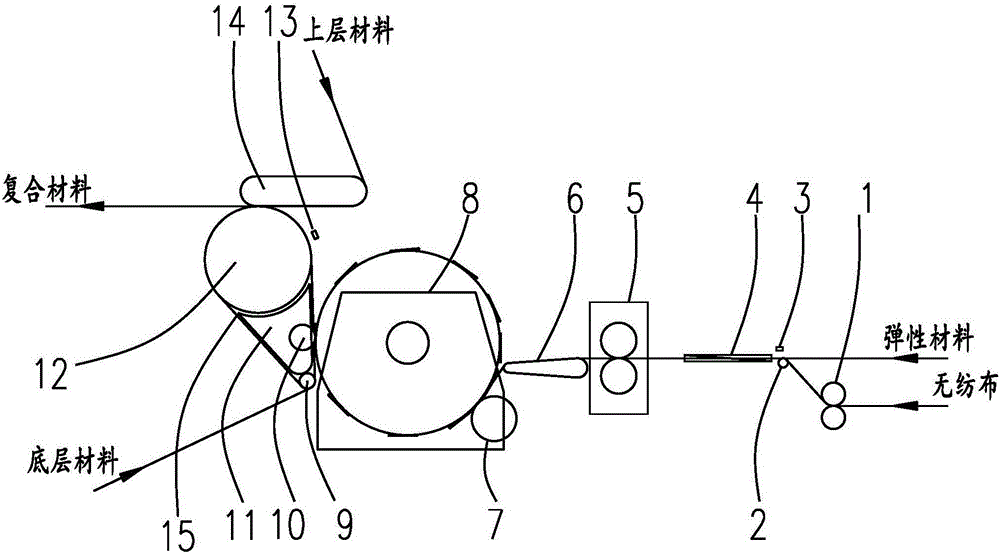

[0025] like figure 1 As shown in the figure, a composite device for materials includes a traction mechanism 1, a guide roller 2, a first gluing mechanism 3, a folding mechanism 4, a partial cutting and punching unit 5, a second negative pressure conveying mechanism 6, The cutting and turning mechanism 8, the guide roller 9, the beating mechanism 10, the first negative pressure conveying mechanism, the second gluing mechanism 13 and the transfer wheel 12; the upper part of the transfer wheel 12 is provided with a third negative pressure conveying mechanism 14; The first negative pressure conveying mechanism includes a perforated belt 15 wound on the transfer wheel 12 and the guide roller 9, and a negative pressure body 11 is also provided between the transfer wheel 12 and the guide roller 9. The wheel 12 and the negative pressure body 11 are provided with a negative pressure cavity that communicates with the through hole on the belt 15. The beating mechanism 10 is located betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com