A kind of preparation method of IF steel strip

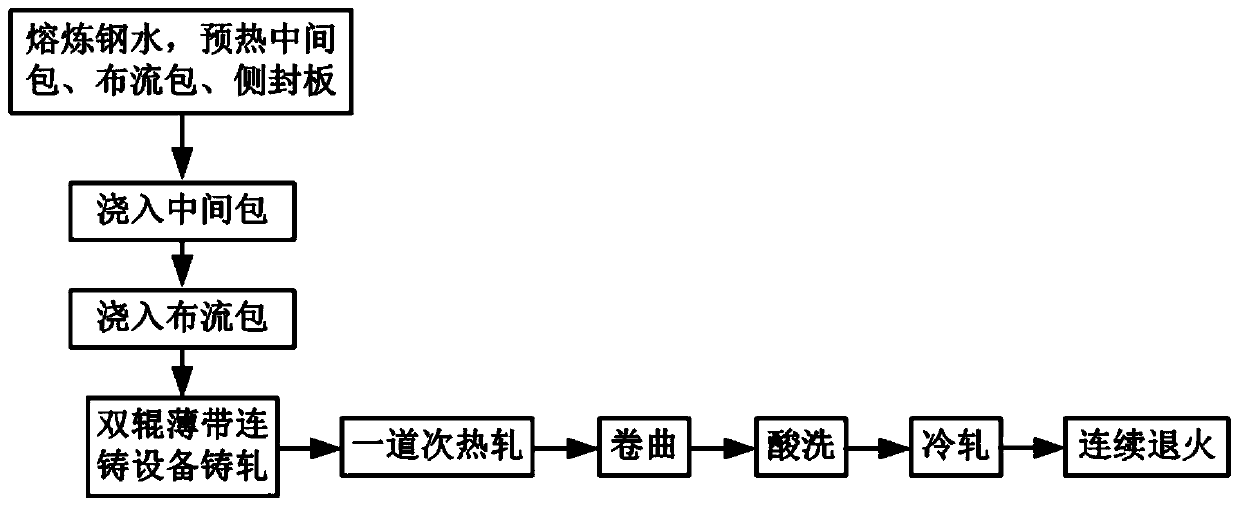

A technology for continuous casting of steel strips and twin-roll strips, applied in metal rolling and other directions, can solve the problems of high energy consumption, high cost, and long production process of cold-rolled IF steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the present embodiment, the preparation method of IF steel thin strip comprises the steps:

[0028] (1) Converter smelting first, then RH vacuum smelting molten steel, the composition of molten steel by mass percentage is: C 0.008%, Mn 0.15%, Si 0.02%, B 0.02%, V 0.04%, P 0.005%, N 0.005%, O 0.002%, S 0.002%, and the balance is Fe. Preheat the temperature of the tundish to 1350°C, preheat the temperature of the ladle to 1300°C, preheat the temperature of the side sealing plate to 1250°C, control the temperature of the molten steel on the inner surface of the ladle to 1700°C, pour the molten steel in the ladle into the middle In the ladle, it is poured from the tundish into the distribution ladle, and then poured from the distribution ladle into the twin-roll thin strip continuous casting equipment. When the molten steel enters the molten pool, the superheat is controlled at 40°C, and the thickness obtained by casting and rolling is 3.0mm cast belt;

[0029] (2) Aft...

Embodiment 2

[0033] In the present embodiment, the preparation method of IF steel thin strip comprises the steps:

[0034] (1) Converter smelting first, then RH vacuum smelting molten steel, the composition of molten steel by mass percentage is: C 0.0005%, Mn0.8%, Si 0.1%, B 0.01%, V 0.09%, P 0.08%, N 0.003%, O 0.001%, S 0.001%, and the balance is Fe. Preheat the temperature of the tundish to 1300°C, preheat the temperature of the ladle to 1350°C, preheat the temperature of the side sealing plate to 1270°C, control the temperature of the molten steel on the inner surface of the ladle to 1720°C, pour the molten steel in the ladle into the middle In the ladle, it is poured from the tundish into the distribution ladle, and then poured from the distribution ladle into the twin-roll thin strip continuous casting equipment. When the molten steel enters the molten pool, the superheat is controlled to be 30°C, and the thickness obtained by casting and rolling is 3.5mm cast belt;

[0035] (2) Aft...

Embodiment 3

[0039] In the present embodiment, the preparation method of IF steel thin strip comprises the steps:

[0040] (1) Converter smelting first, then RH vacuum smelting molten steel, the composition of molten steel by mass percentage is: C 0.005%, Mn0.3%, Si 0.08%, B 0.013%, V 0.07%, P 0.01%, N 0.001%, O 0.0012%, S 0.0012%, and the balance is Fe. Preheat the temperature of the tundish to 1320°C, preheat the temperature of the cloth ladle to 1320°C, preheat the temperature of the side sealing plate to 1350°C, control the temperature of the molten steel on the inner surface of the ladle to 1710°C, pour the molten steel in the ladle into the middle In the ladle, it is poured from the tundish into the distribution ladle, and then poured from the distribution ladle into the twin-roll thin strip continuous casting equipment. When the molten steel enters the molten pool, the superheat is controlled to be 10°C, and the thickness obtained by casting and rolling is 1.8mm cast belt;

[0041...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com