Part machining machine tool

A technology of parts processing and machine tools, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of difficult control of precision, lack of precision, low processing effect, etc., to achieve full utilization, avoid waste, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

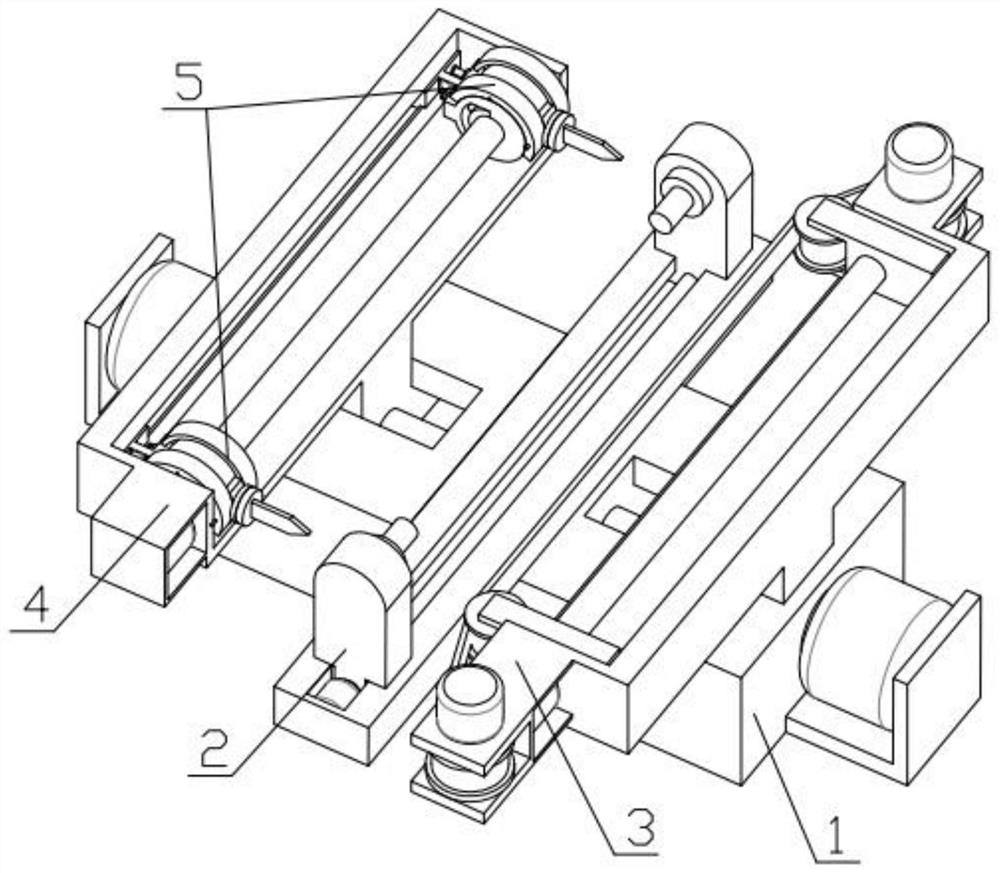

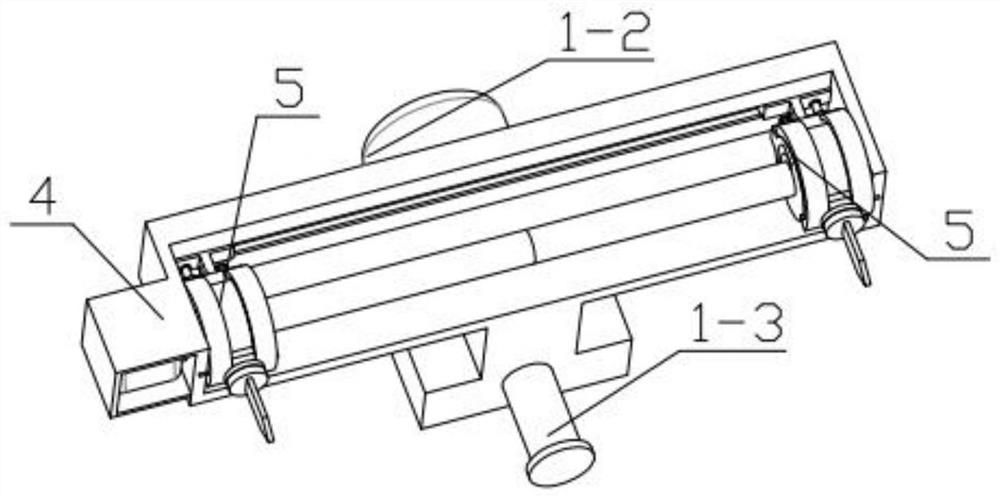

[0034] Combine below Figure 1-15 Illustrating this embodiment, a machine tool for machining parts includes a moving mechanism 1 , a workpiece fixing mechanism 2 , a grinding mechanism 3 , a machining moving mechanism 4 and a knife adjusting mechanism 5 , and the workpiece fixing mechanism 2 is fixedly installed on the moving mechanism 1 Above, the grinding mechanism 3 is threadedly connected with the moving mechanism 1 , the machining moving mechanism 4 is threadedly connected with the moving mechanism 1 , and the adjusting knife mechanism 5 is threadedly connected with the machining moving mechanism 4 .

specific Embodiment approach 2

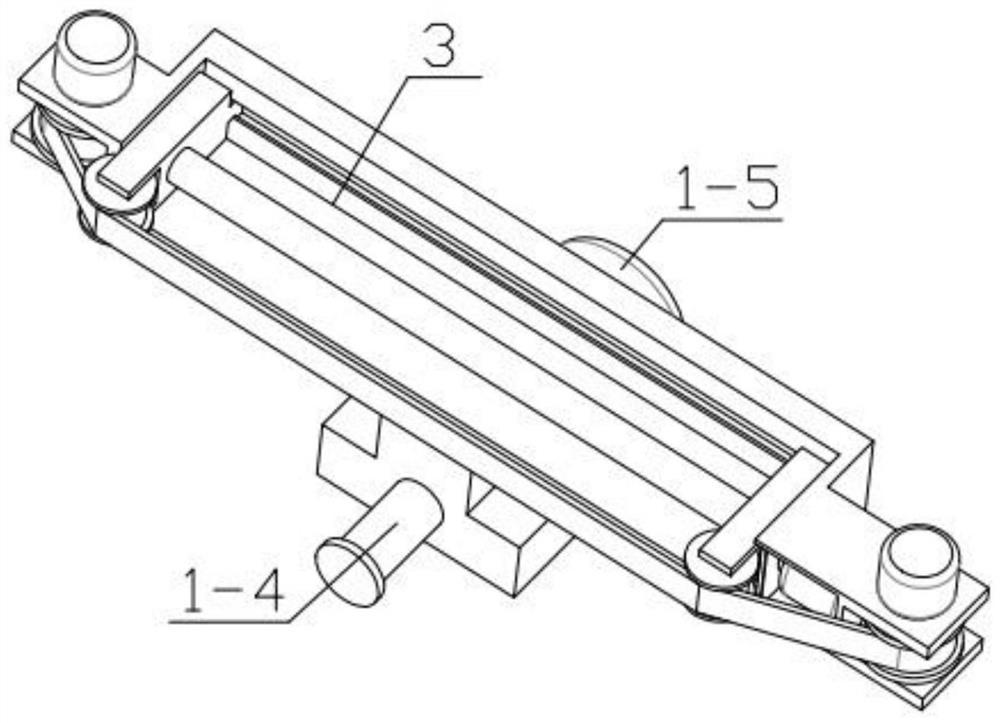

[0036] Combine below Figure 1-15 This embodiment will be described. This embodiment will further describe the first embodiment. The workpiece fixing mechanism 2 includes a mounting horizontal plate 2-1, a motor three 2-2, a two-way threaded rod one 2-3, and a sliding seat 2-4. , fixture 2-5, internal motor 2-6, installation horizontal plate 2-1 is fixedly installed on the main base 1-1, motor three 2-2 is fixedly installed in the groove of the installation horizontal plate 2-1, motor three The output end of 2-2 is fixedly installed with a two-way threaded rod-2-3, the other end of the two-way threaded rod-2-3 is rotatably installed in the groove set on the installation horizontal plate 2-1, and the two-way threaded rod-2-3 is installed. Threaded connection with the sliding seat 2-4, the sliding seat 2-4 is slidably installed in the groove set on the installation horizontal plate 2-1, and the internal motor 2-6 is fixedly installed in the groove set on one of the sliding seats...

specific Embodiment approach 3

[0038] Combine below Figure 1-15 This embodiment will be described. This embodiment will further describe the second embodiment. The workpiece fixing mechanism 2 includes a mounting horizontal plate 2-1, a motor three 2-2, a two-way threaded rod one 2-3, and a sliding seat 2- 4. The fixture 2-5, the internal motor 2-6, the installation horizontal plate 2-1 are fixedly installed on the main base 1-1, the motor 3 2-2 is fixedly installed in the groove of the installation horizontal plate 2-1, the motor The output end of the three 2-2 is fixedly installed with a bidirectional threaded rod 1 2-3. 3. It is threadedly connected with the sliding seat 2-4, the sliding seat 2-4 is slidably installed in the groove provided on the installation horizontal plate 2-1, and the sliding seat 2-4 is fixedly installed with a clamp 2-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com