Device for machining superfine oil spraying inclined holes in oil spraying plate part of oil sprayer through lasers

A laser processing and fuel injector technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency and processing quality, no specific structure of the worktable device, no given and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

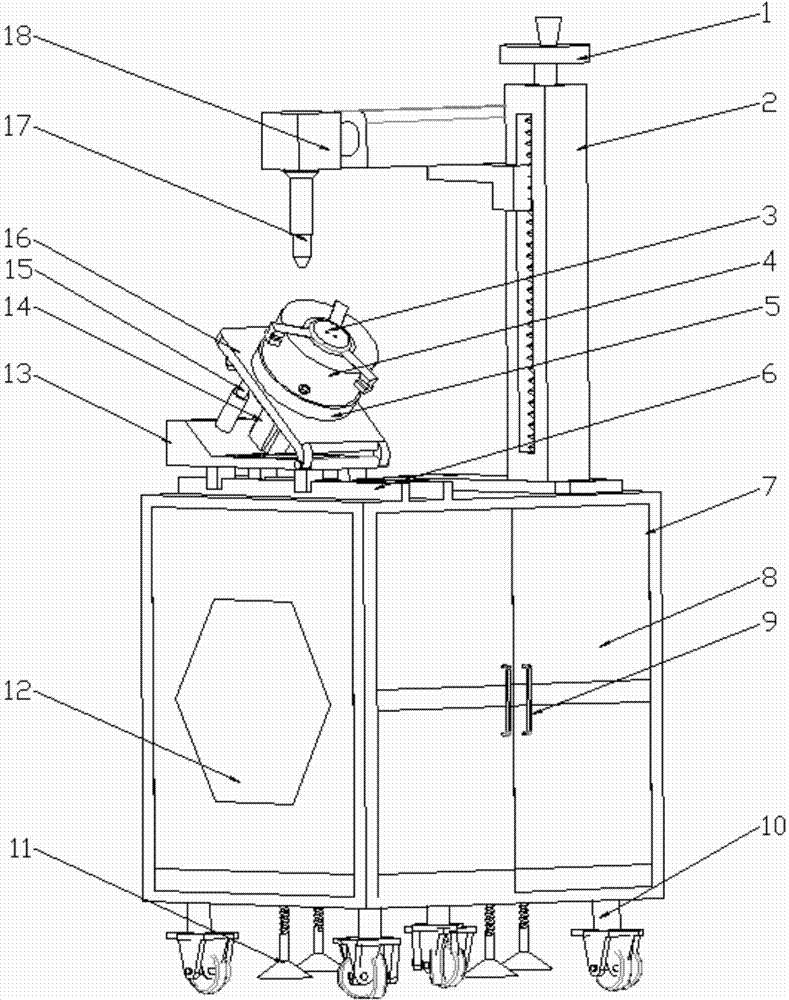

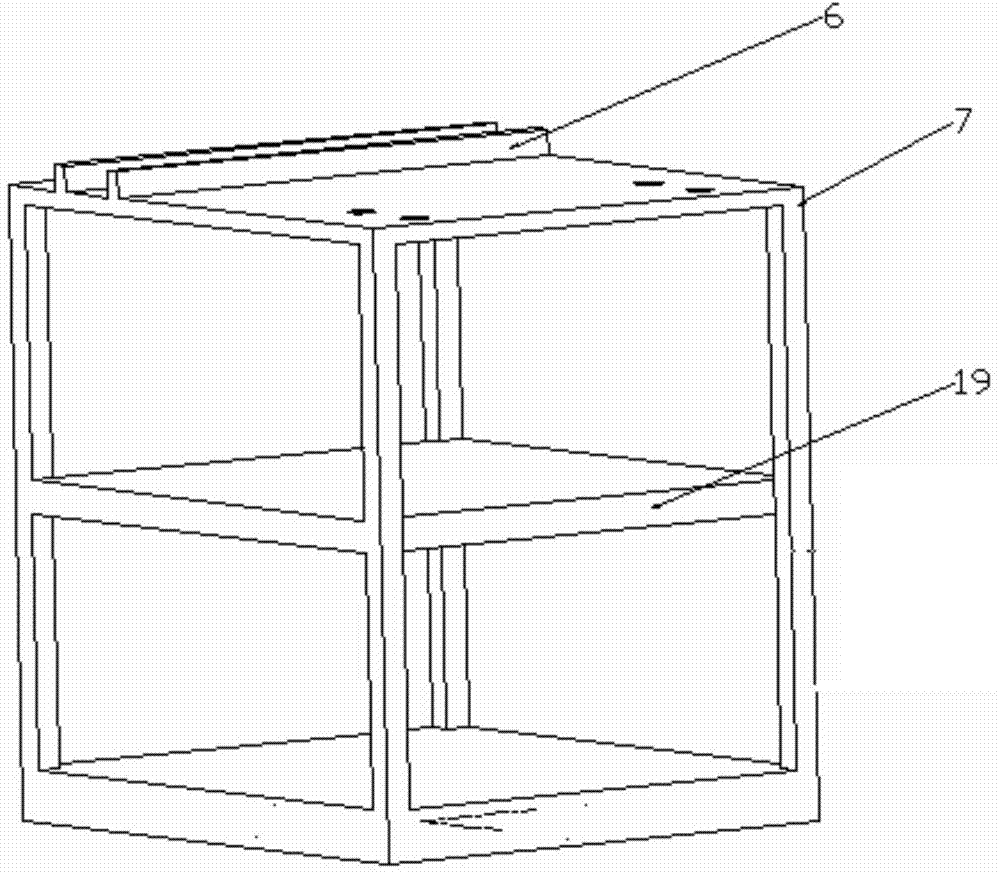

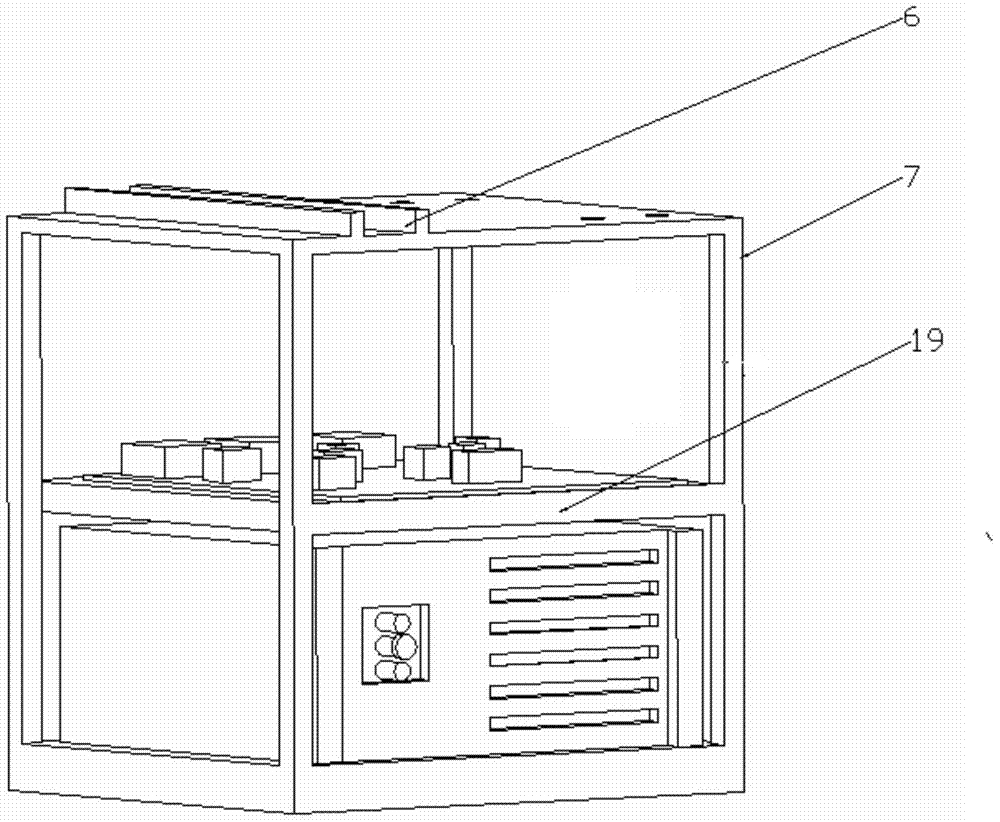

[0034] Such as figure 1 As shown, the present invention provides a device for laser processing the fine fuel injection oblique holes on the fuel injection plate parts of the fuel injector, including three major parts: the fuselage, the laser processing unit and the workbench; the fuselage is equipped with There is a laser processing unit for micro-hole processing and a workbench for carrying the workpiece to be processed and sliding back and forth in the horizontal plane along the fuselage. The laser processing unit moves up and down in the vertical direction driven by the driving device; Driven by the driving device, the workpiece table can be arbitrarily tilted within the range of 0-90 degrees relative to the horizontal plane and can be rotated 360 degrees at any inclined position within the range of 0-90 degrees; and the laser proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com