Pneumatic shot blast machine

A cleaning machine and shot blasting technology, applied in the field of machinery, can solve the problems of long conveying distance of conveyor belt, difficult to control, single, etc., and achieve the effect of high innovation, shortening conveying distance and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

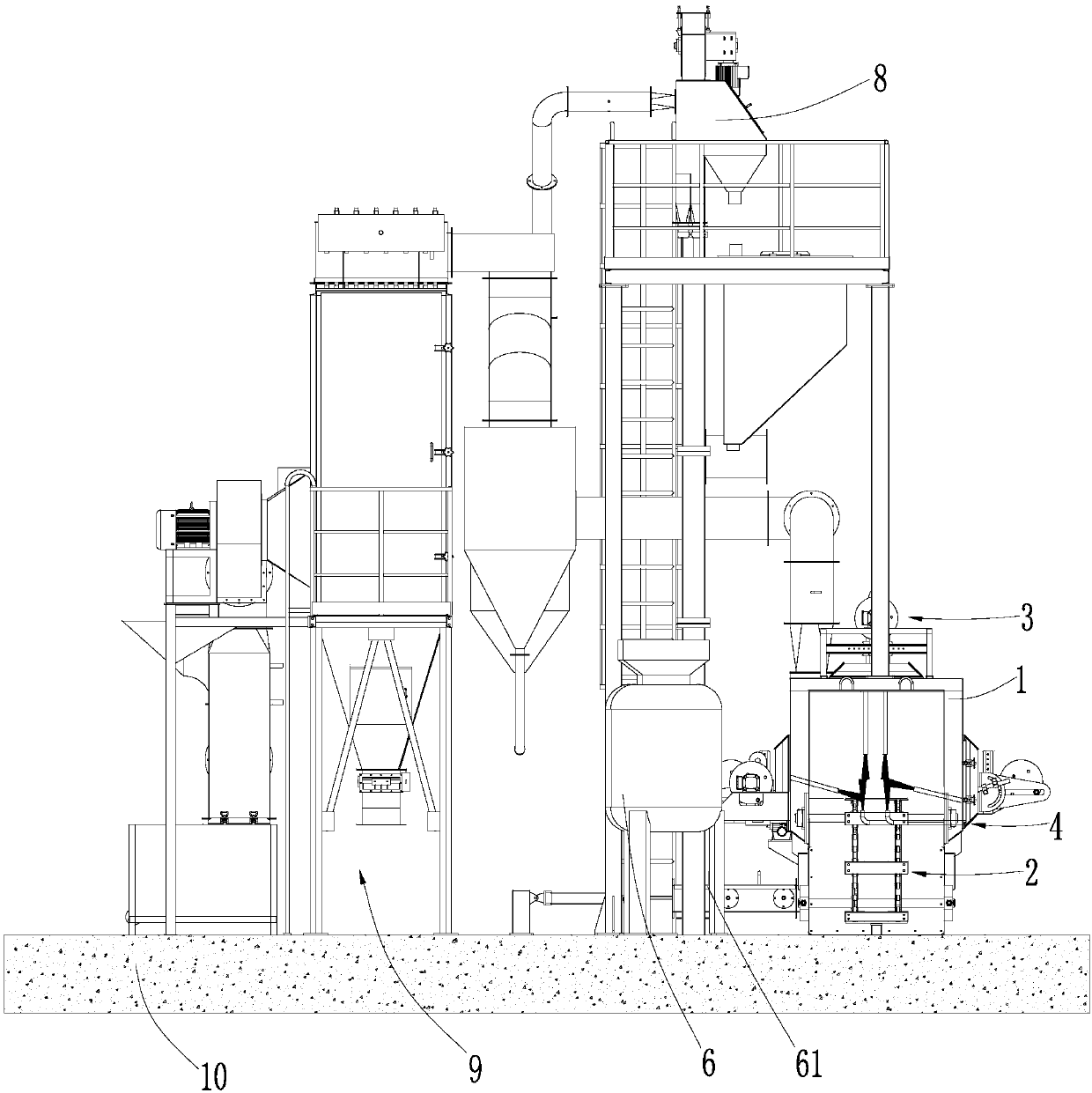

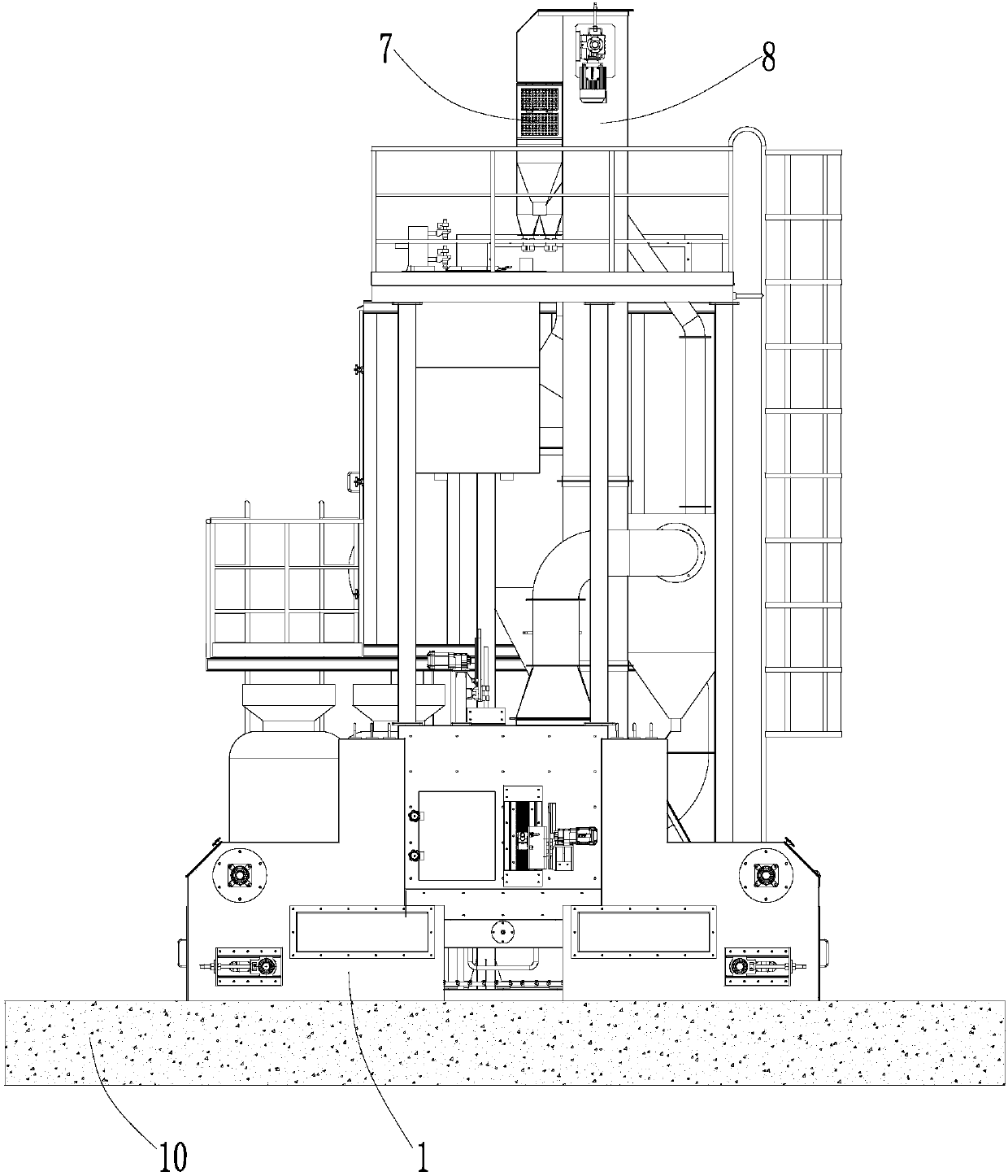

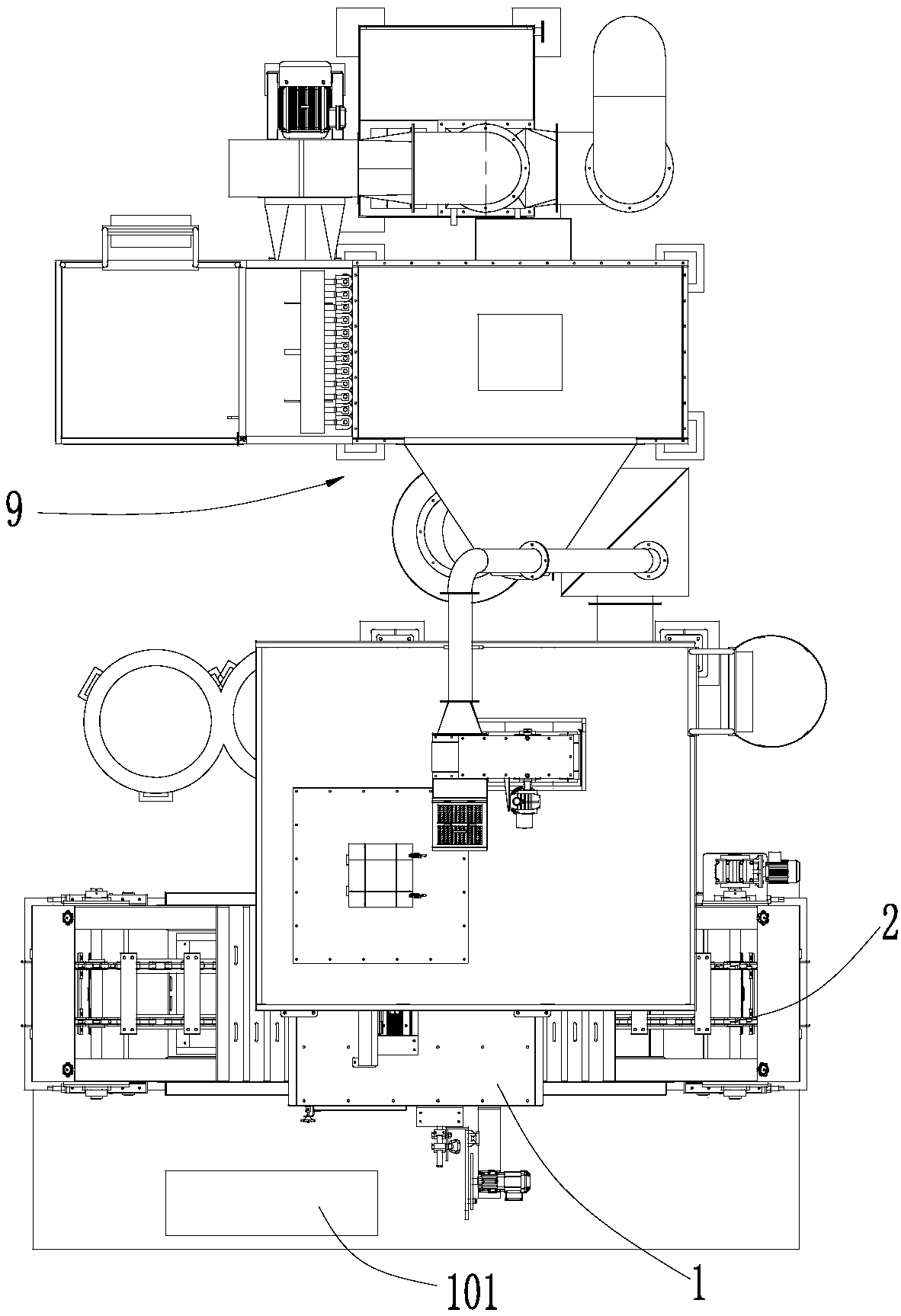

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

[0032] combine Figure 1 to Figure 9 , a shot blasting machine, comprising a shot blasting chamber 1, a shot blasting device and a conveying device 2, the conveying device 2 passes through the shot blasting chamber 1, and the shot blasting device includes an upper blasting device 3, a side blasting device 4 and a lower blasting device The shot blaster 5 and the side shot blaster 4 are divided into two groups: the left shot blaster and the right shot blaster, the upper shot blaster 3 is connected to the upper end of the shot blasting chamber 1, the side shot blaster 4 and the lower shot blaster 5 are all connected to the side end of shot blasting chamber 1.

[0033] Transmission device 2 comprises transmission support frame 21, transmission chain 22, reduction motor 23, belt seat bearing mechanism 24, slideway mechanism 25 and pallet mechanism 26, and transmission support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com