Sheath yarn winding device

A yarn tying device and sheath technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of self-adjustment of tension, yarn accumulation and pitch, production troubles, etc., to achieve compact structure, stable equipment operation, The effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

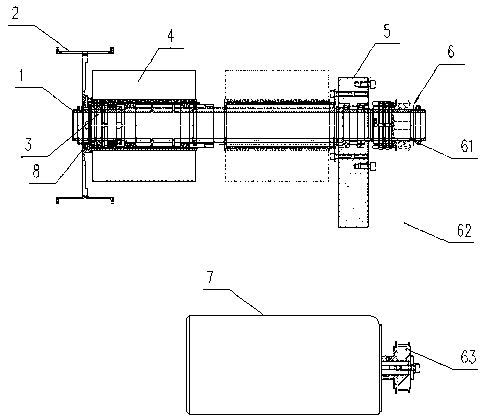

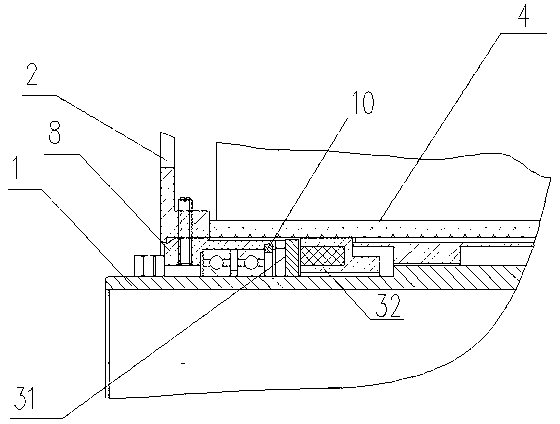

[0018] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

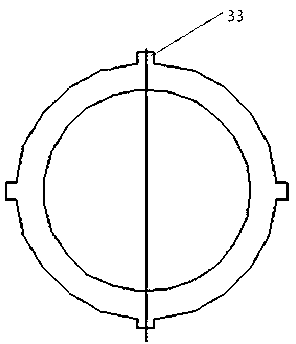

[0019] control Figure 1-2 , The sheath binding device provided by the present invention mainly consists of a rigid base 5, a hollow main shaft 1, an aircraft 2, a bearing 9, a bearing sleeve 8, a yarn ball cover 4 and a damper 3. The damper 3 includes a damping coil 32 and a friction plate 31; the hollow main shaft 1 is rotatably supported on the rigid base 5, and the bearing sleeve 8 is connected to the hollow main shaft 1 through a bearing. The inner ring of the bearing 9 is tightly fitted on the hollow main shaft 1 , and the outer ring of the bearing 9 is tightly fitted in the bearing sleeve 8 . One end of the bearing 9 abuts against the corresponding step surface of the bearing sleeve 8 , and the other end is limited by the circlip 10 to achieve axial positioning. The aircraft 2 is sleeved on one end of the bearing sleeve 8, and the two are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com