Preparation method of black colored ribbon Glencheck double-faced woolen cloth and equipment for producing wrap yarn of black colored ribbon Glencheck double-faced woolen cloth

A technology of double-sided woolen and wrapping yarn, which is applied in the direction of continuous winding spinning machine, yarn, spinning machine, etc., can solve the problems of difficult control of filament tension and difficult control of filament wrapping effect, and achieve wrapping effect. Easy, good wrapping, consistent tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

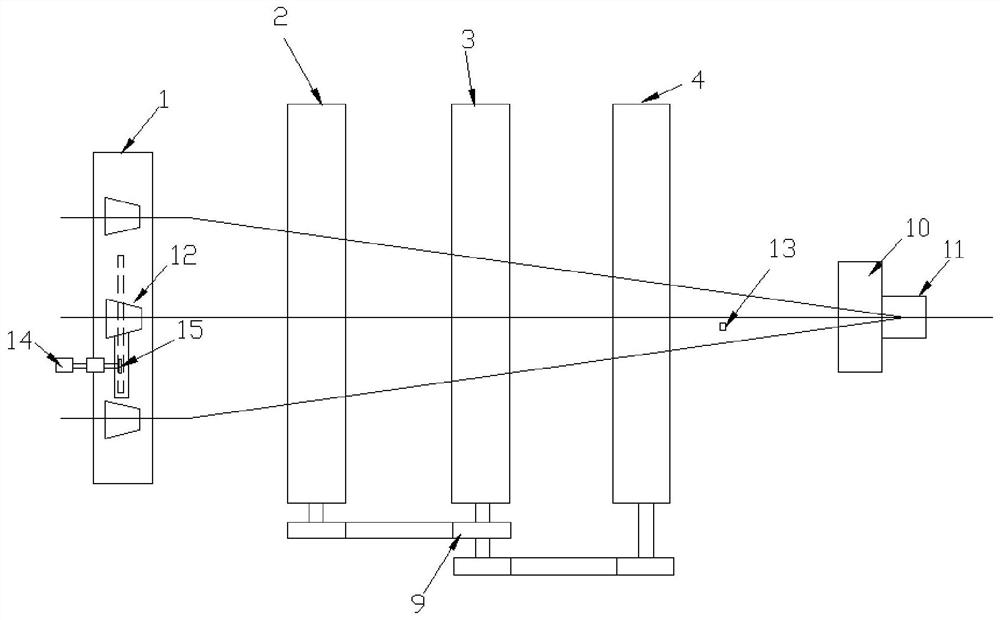

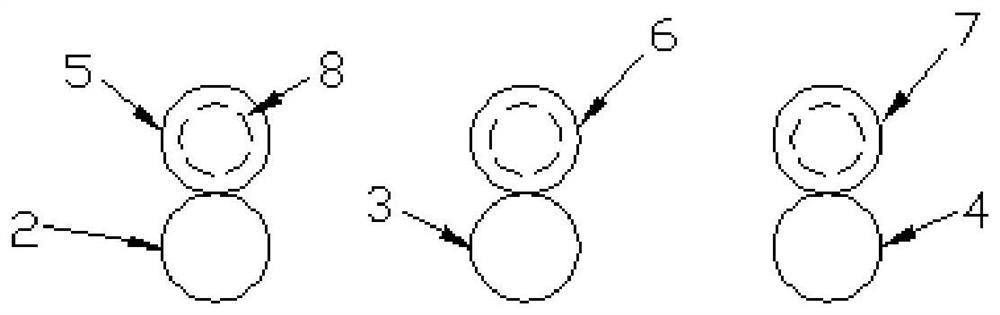

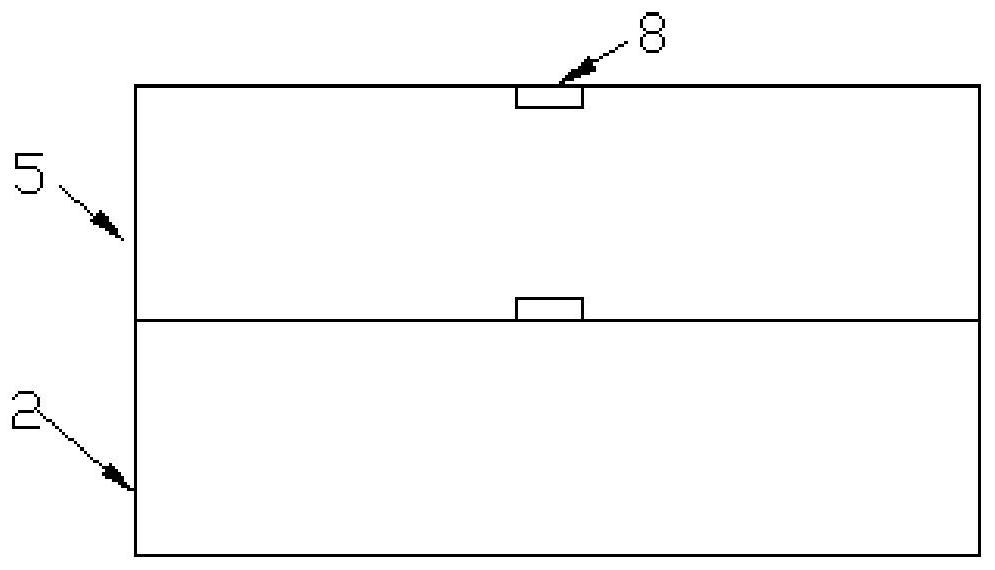

[0018] Such as Figure 1 to Figure 3 shown (for ease of illustration, figure 1 The back rubber roller, middle rubber roller and front rubber roller are not shown), the present invention is a kind of preparation method of double-faced gringe with black color ribbon, comprising the following steps: preparing lantern yarn, preparing wrapped yarn; wrapped yarn as inlay The yarn is interwoven with black yarn and white yarn to make a double-faced woolen fabric with black ribbon; among them, the wrapping yarn is to wrap the segment-dyed nylon filament on the lantern yarn. The lantern yarn is made of polyester yarn with 2 metric counts, and the nylon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com