Spring curtain lifting and collecting mechanism

A collection mechanism and curtain technology, applied in the direction of instruments, projection devices, optics, etc., can solve the problems of inconvenient removal and replacement, trouble, etc., and achieve the effect of improving the display effect, reducing the difficulty and reducing the overall structure noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

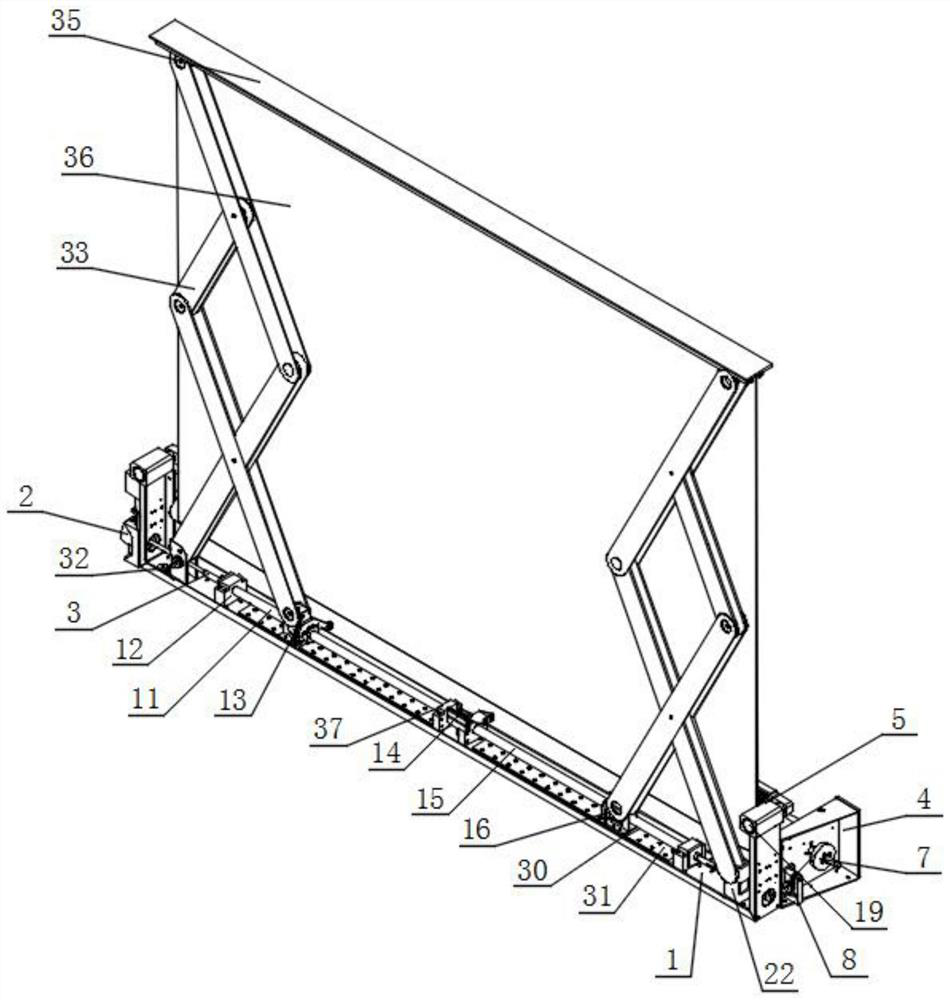

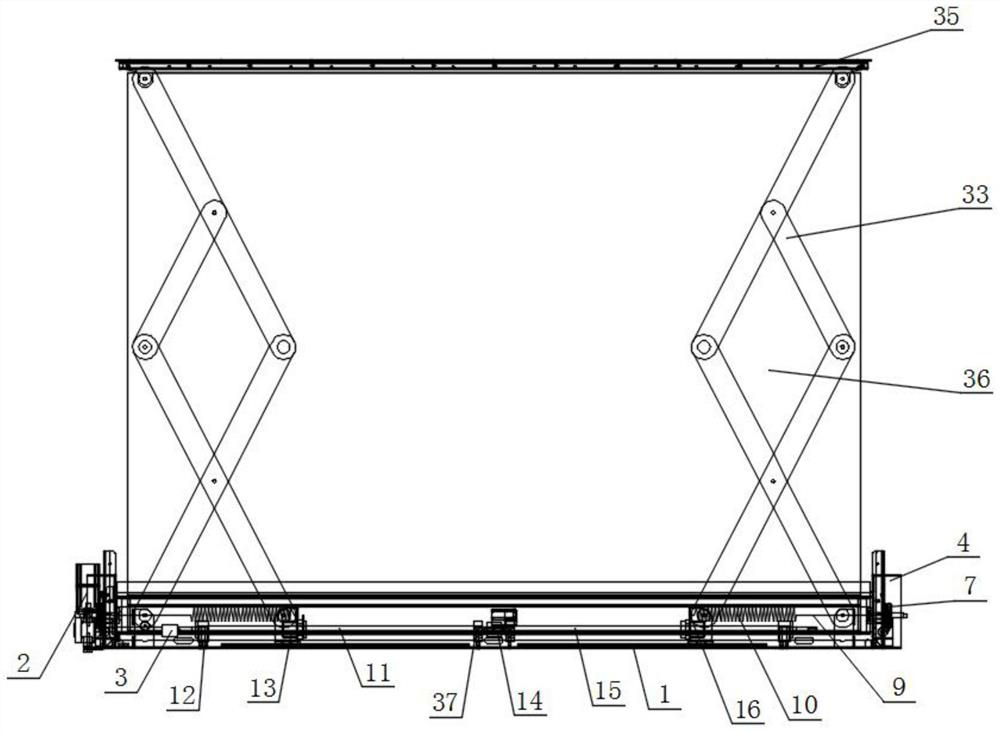

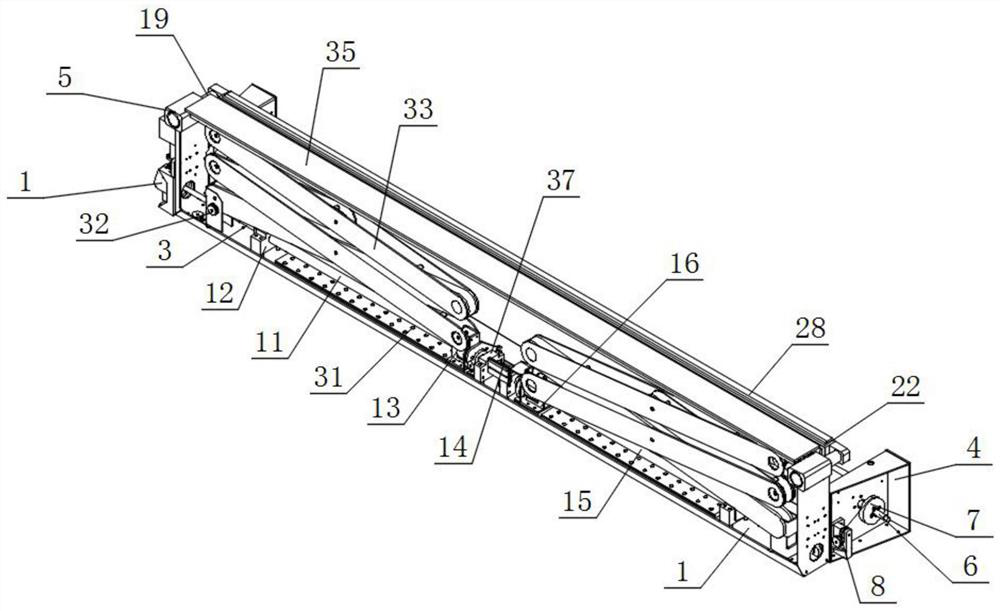

[0042] Such as figure 2 and Figure 4 Shown, a kind of spring realizes curtain lifting and collecting mechanism, comprises bottom frame 1, servo motor 2, shaft coupling 3, collection box 4 and fixed block 5, and the side outer wall of bottom frame 1 is equipped with servo motor 2, and servo motor The output end of 2 is equipped with a rotating shaft, and one end of the rotating shaft is installed with a coupling-3, and one end of the coupling-3 extends into the interior of the bottom frame 1;

[0043] Specifically, the bottom frame 1 provides a relatively stable installation space for the components above it, and facilitates the mutual cooperation between the components. After the servo motor 2 is started, the shaft installed at the output end can rotate clockwise or counterclockwise accordingly. It is used to drive the coupling-3 installed at one end of the rotating shaft to follow the rotation, the coupling-3 is used to connect the rotating shaft and the screw rod-11, and ...

Embodiment 2

[0050] Such as figure 1 , image 3 As shown, the end of the coupling-3 away from the servo motor 2 is equipped with a screw-11, the outer surface of the screw-11 is equipped with a support seat-12, and the bottom of the support seat-12 is connected to the bottom wall of the bottom frame 1 Fitting, screw nut 13 is installed on the outer surface of screw rod 11, and the outer wall of the side of screw nut 13 close to servo motor 2 is connected with one end of one group of springs 10, and one end of screw rod 11 is installed There is a coupling two 14, and the end of the coupling two 14 away from the screw one 11 is equipped with a screw two 15, and the outer surface of the screw two 15 is equipped with a screw nut two 16, and the screw nut two 16 is far away from the servo motor 2 One side of the outer wall is connected with one end of another group of springs 10.

[0051] Specifically, screw rod one 11 is combined into a whole through coupling two 14 and screw rod two 15, and...

Embodiment 3

[0053] Such as Figure 5 , Figure 6 and Figure 8 As shown, the fronts of two groups of fixed blocks 5 are all provided with thread grooves 17, the inwalls of thread grooves 17 are provided with threaded sleeves 18, and the inwalls of threaded sleeves 18 are equipped with electric telescopic rods 19, and the back sides of electric telescopic rods 19 extend Out of the inside of the threaded groove 17, a connecting block 20 is installed on the backs of two groups of electric telescopic rods 19, and a groove 21 is arranged on the front of the connecting block 20, and the inner wall of the groove 21 is fitted with the outer wall of the electric telescopic rod 19, one of them One side outer wall of the group connection block 20 is equipped with a combination frame body 22, the top of the combination frame body 22 is provided with a notch 23, the front of the combination frame body 22 is provided with a through groove 24, and the inwall of the notch 23 is provided with a sponge st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com