Patents

Literature

378results about How to "Easy to cross" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical device

Owner:SALVIAC

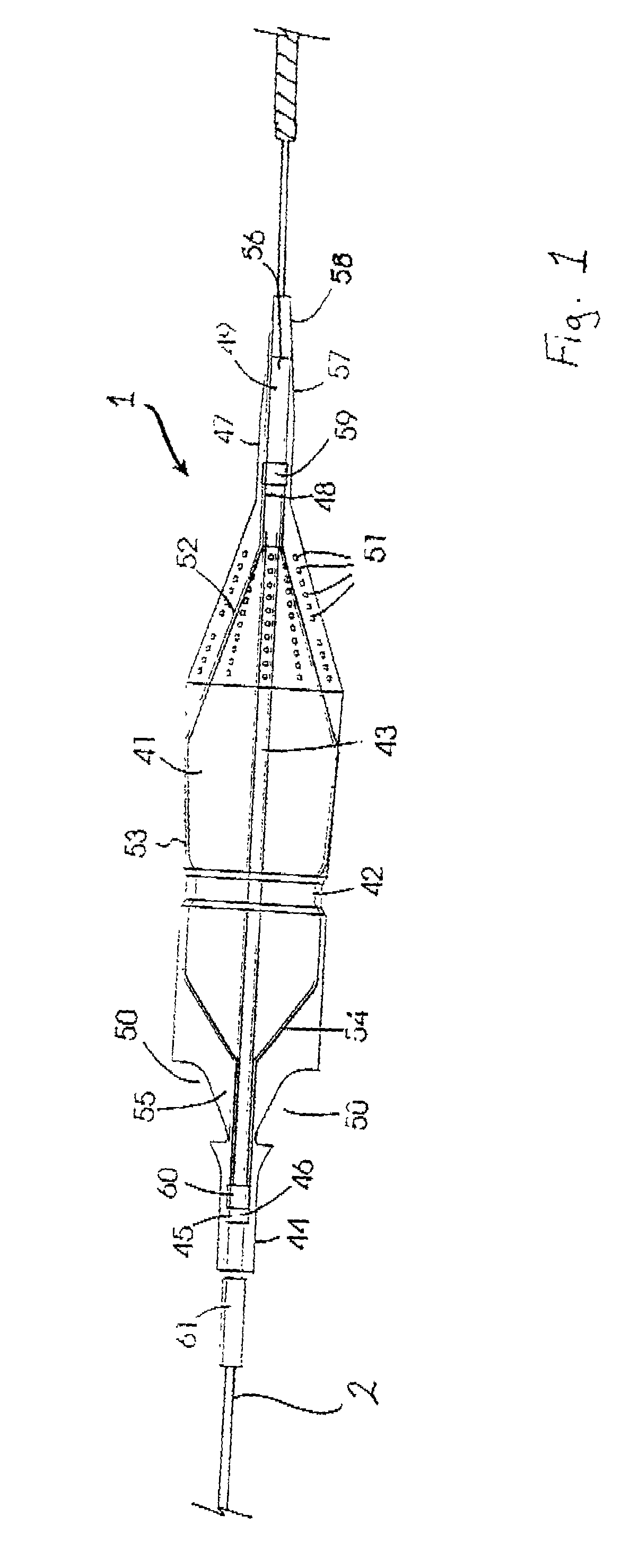

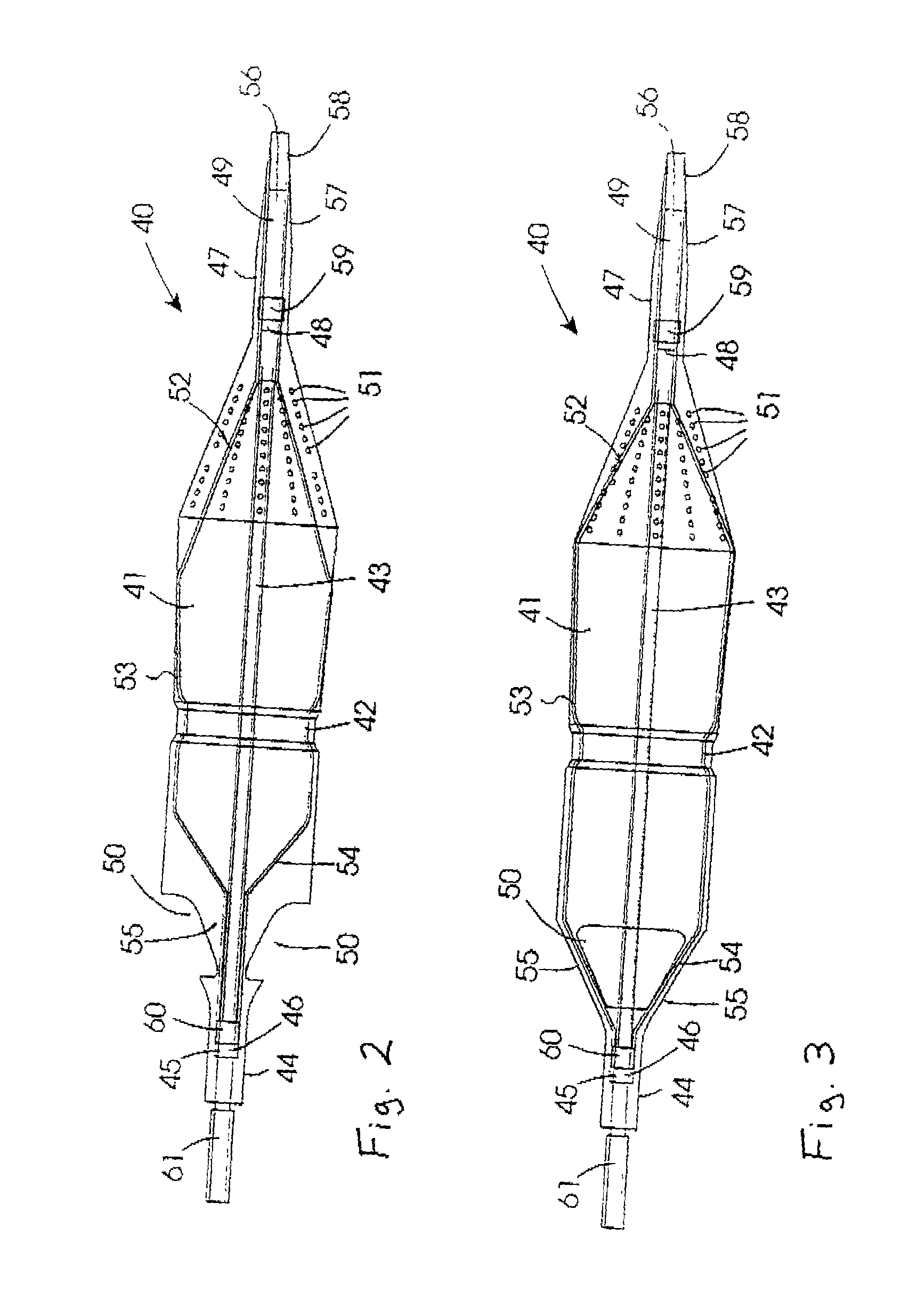

Heart valve delivery system with valve catheter

ActiveCN101291637AEasy to crossReduce or eliminate damageStentsBalloon catheterDelivery systemCatheter device

A heart valve delivery system is provided wherein a prosthetic valve is carried on a valve catheter inside a delivery sleeve. A step balloon protrudes from the delivery sleeve and provides a tapered surface for facilitating advancement through a body vessel. The step balloon also aids in crossing the leaflets of a native valve. After the prosthetic valve is positioned within the native valve, the delivery sleeve is retracted to expose the prosthetic valve. In one embodiment, the delivery sleeve is retracted by the use of a lead screw, which effectuates relative movement between the valve catheter and delivery sleeve. The prosthetic valve is preferably self-expandable. If necessary, the step balloon may be expanded to securely seat the prosthetic valve at the site of the native valve. The prosthetic valve is preferably coupled to the valve catheter by a plurality of flexible extension arms which allow the prosthetic valve to be collapsed after initial deployment such that the prosthetic valve may be repositioned if necessary.

Owner:EDWARDS LIFESCIENCES CORP

Medical device

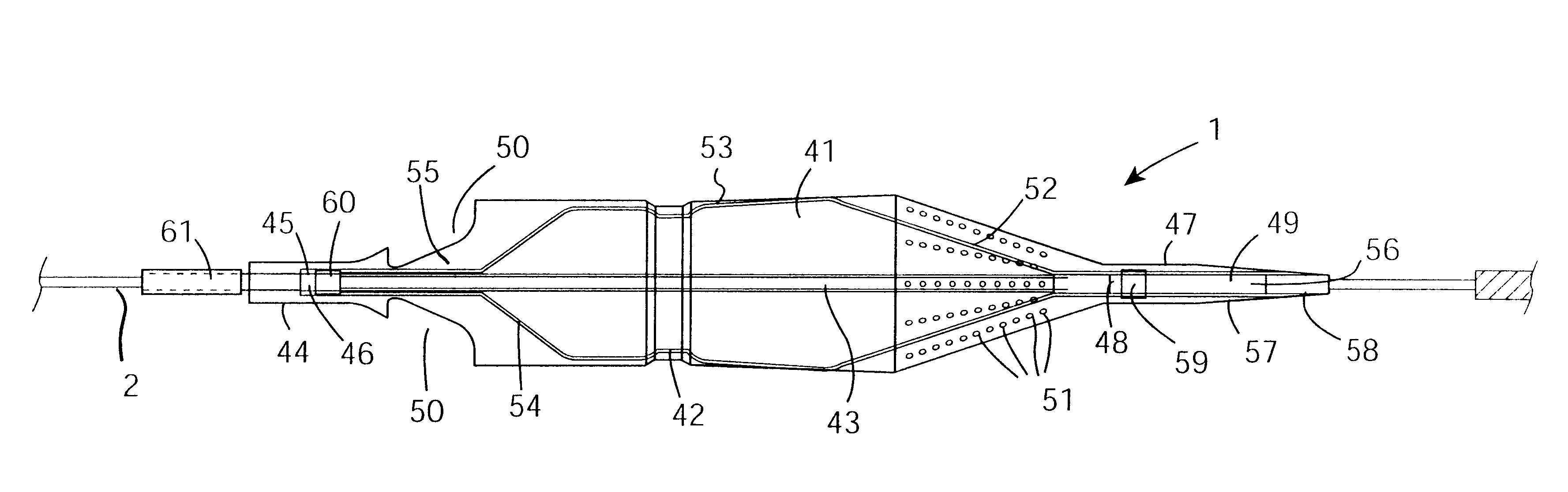

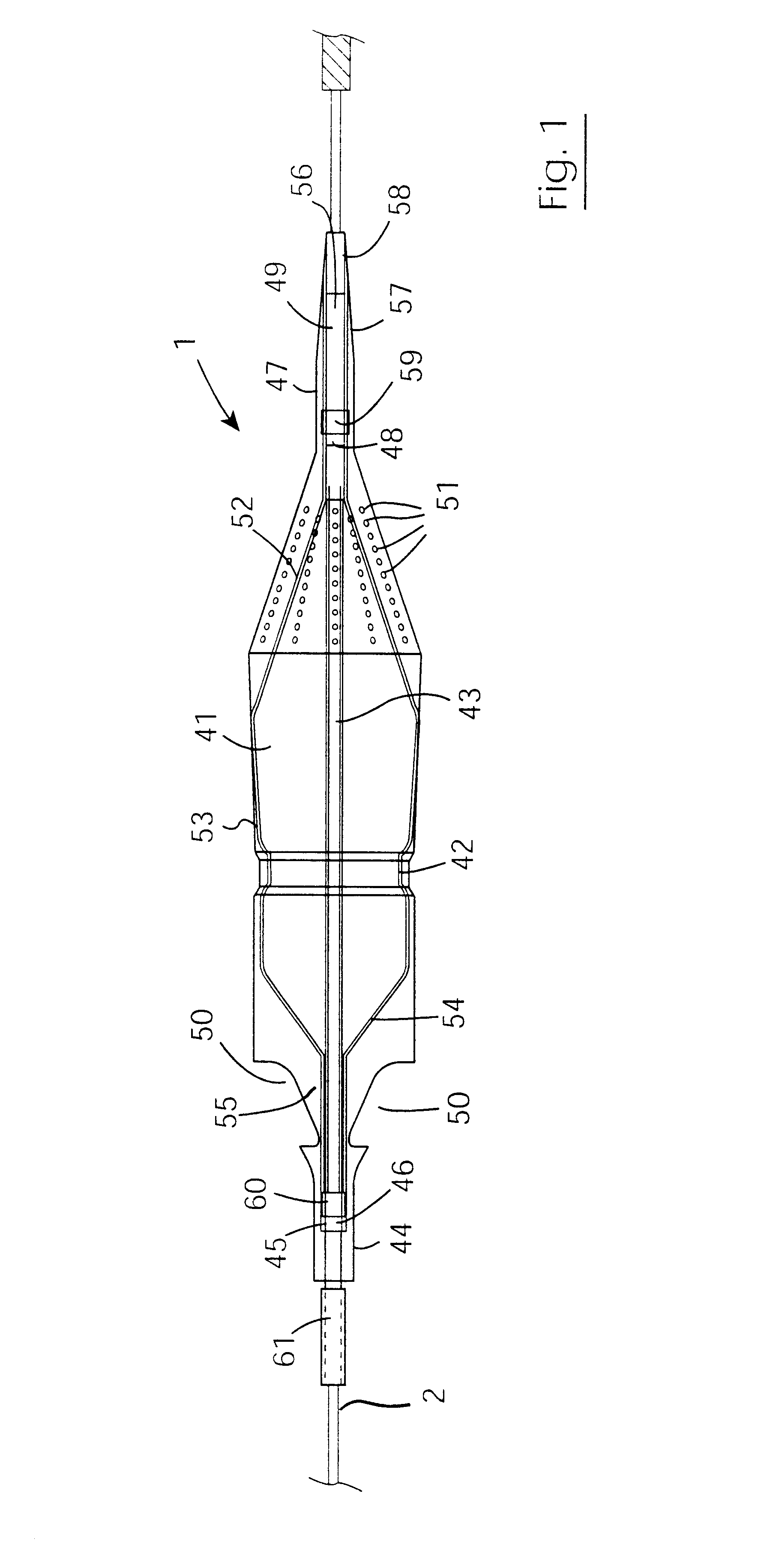

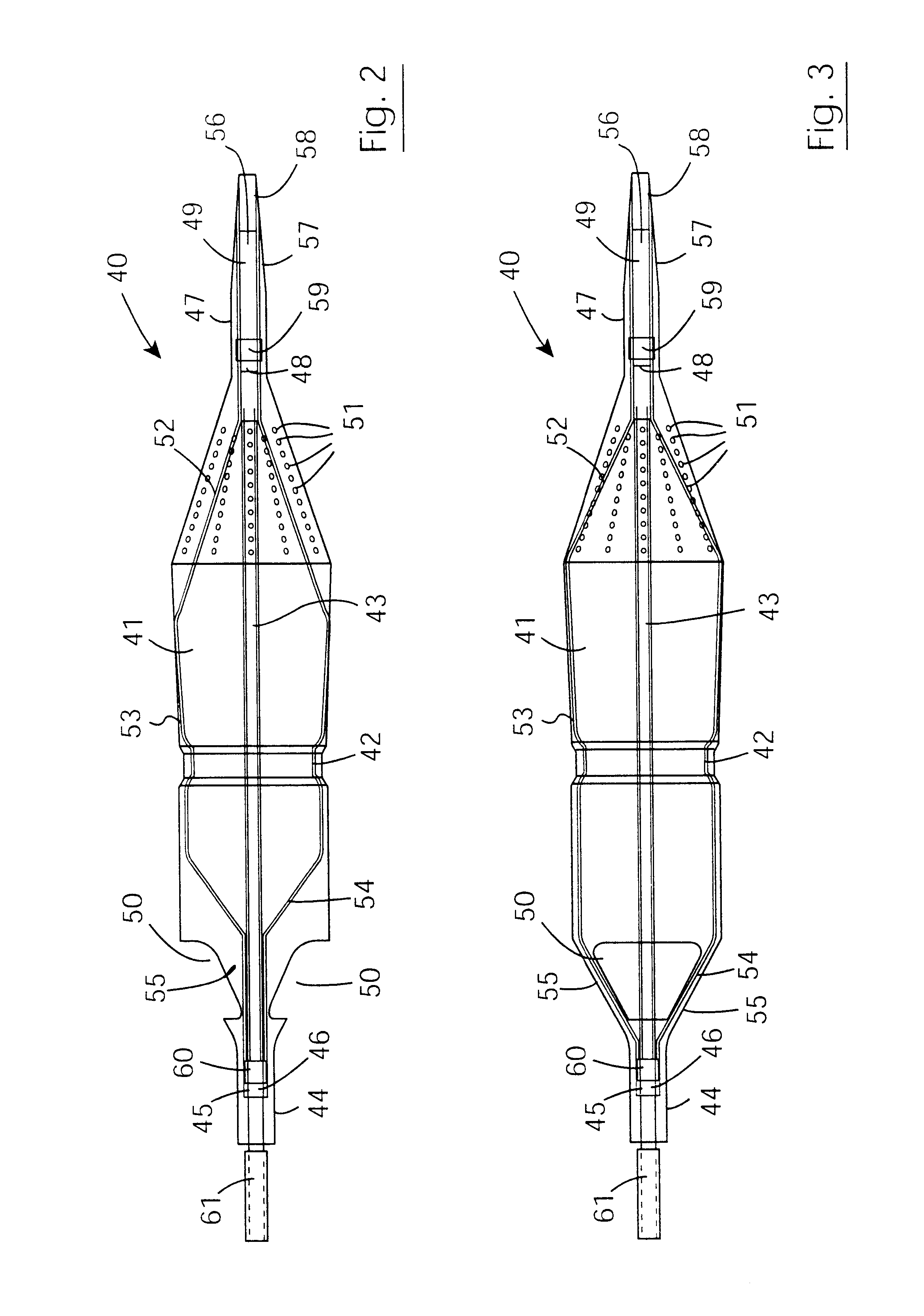

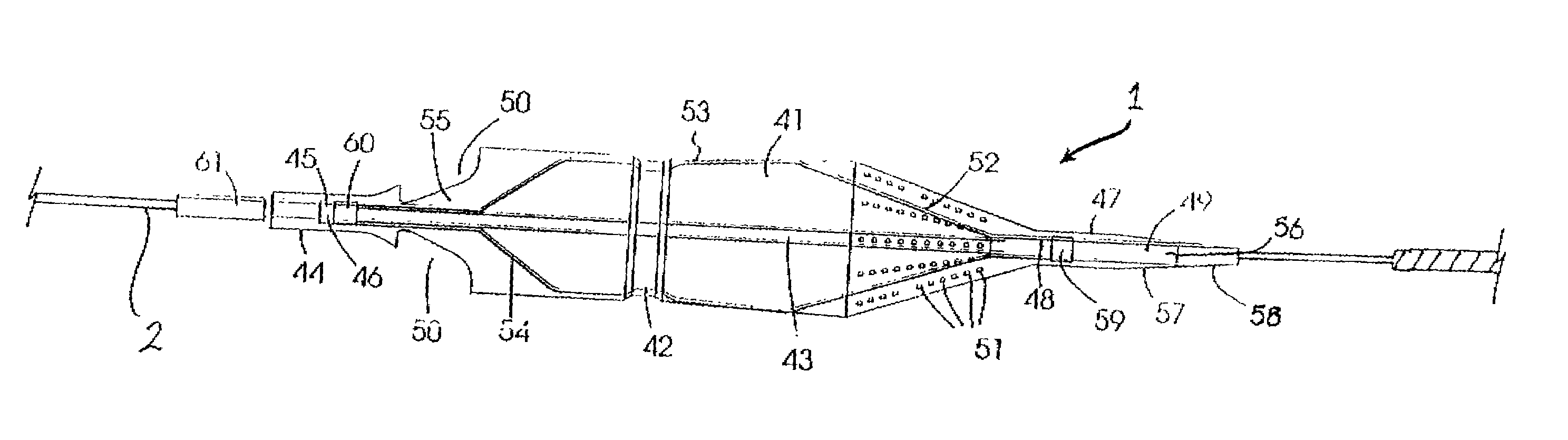

A collapsible filter element (40) for a transcatheter embolic protection device (1). The filter element (40) comprises a collapsible filter body (41) which is movable between a collapsed stored position for movement through a vascular system and an expanded position for extension across a blood vessel such that blood passing through the blood vessel is delivered through the filter element (40). A proximal inlet portion of the filter body (41) has two inlet openings (50) sized to allow blood and embolic material enter the filter body (41), and a distal outlet portion of the filter body (41) has a plurality of small outlet openings (51) to allow through-passage of blood, but to retain embolic material within the filter body (41). The filter body (41) is of an oriented polymeric material.

Owner:SALVIAC

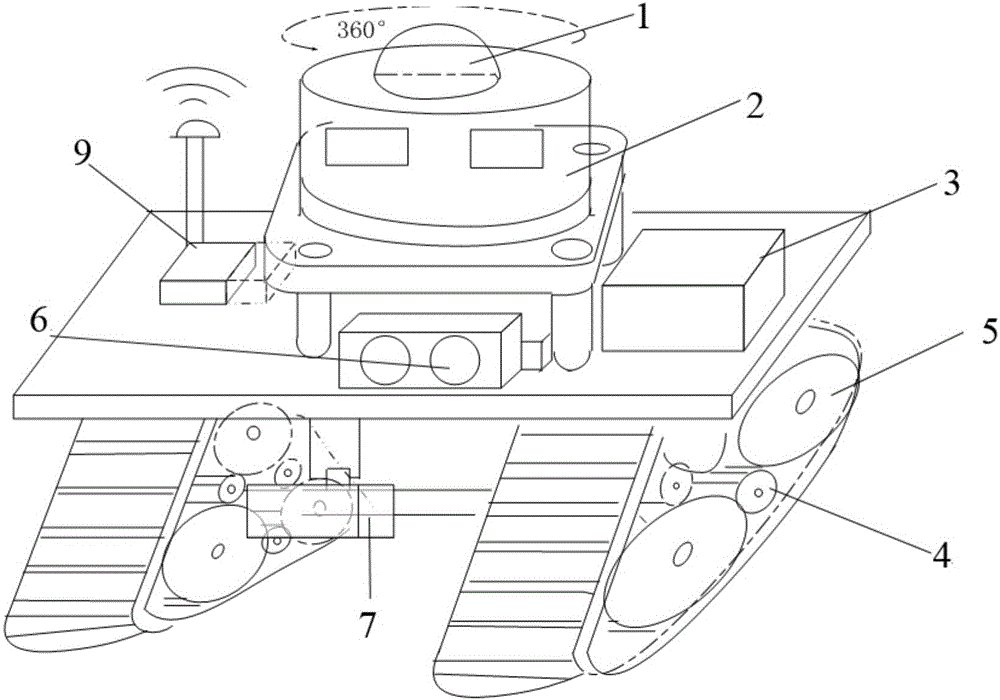

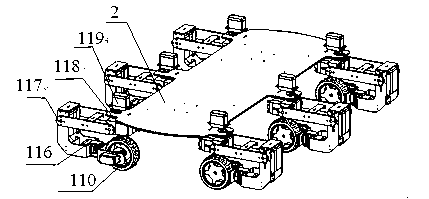

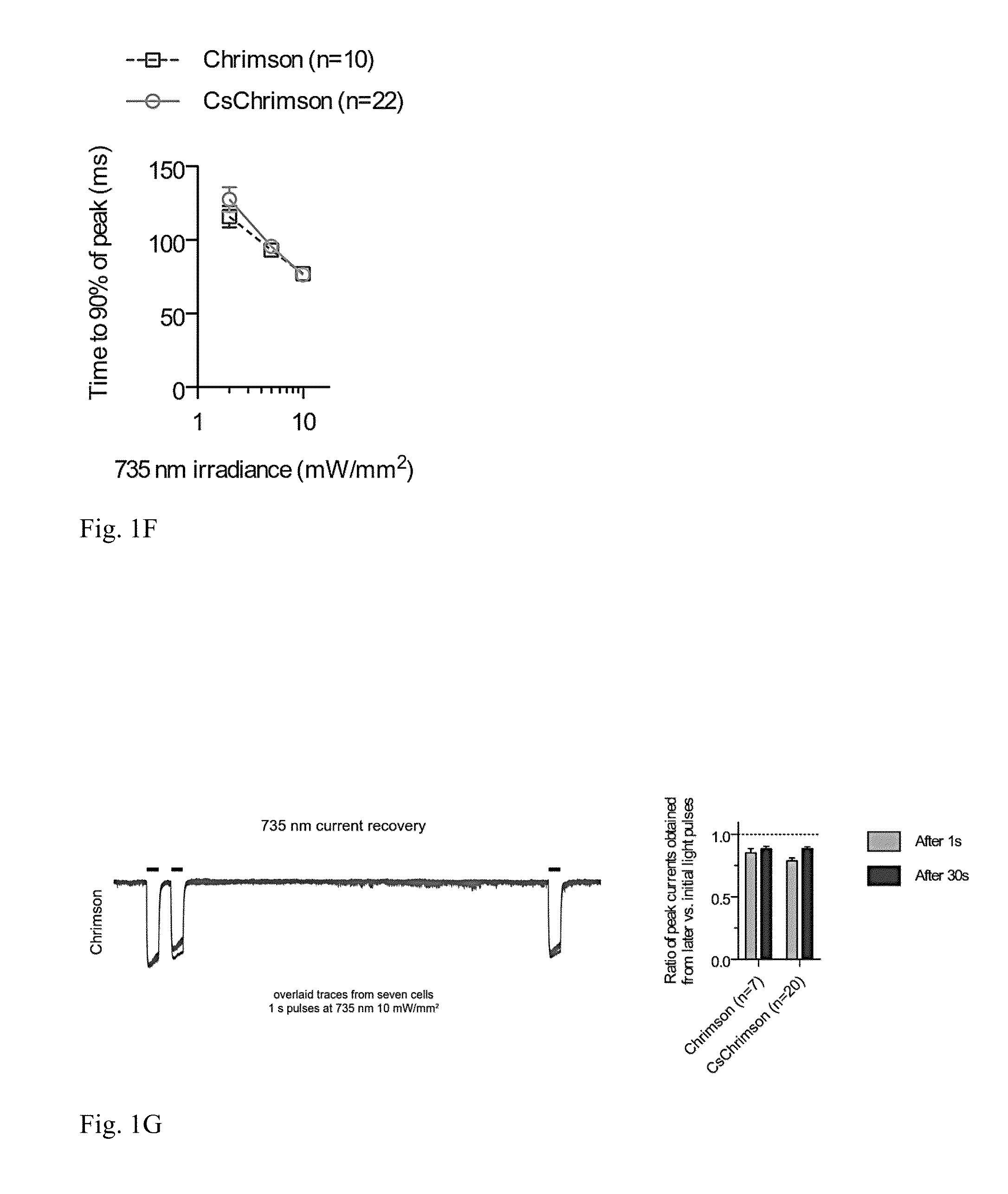

Complex-environment multi-sensor intelligent detection robot

InactiveCN106003064AGuaranteed traversal capabilityEasy to crossProgramme-controlled manipulatorEndless track vehiclesInfraredRemote control

The invention relates to a complex environment multi-sensor intelligent detection robot, which includes a triangular crawler intelligent autonomous mobile car, a 360-degree three-dimensional rotating three-dimensional laser scanner, a wireless communication module, an image acquisition device, an infrared detector and an environment detection sensor module, 360-degree three-dimensional The rotating three-dimensional laser scanner, wireless communication module, image acquisition equipment, infrared detector and environmental detection sensor module are all arranged on the triangular crawler intelligent autonomous mobile car, and the 360-degree three-dimensional rotating three-dimensional laser scanner is connected to the intelligent controller. The environmental information collected by the image acquisition equipment, infrared detector and environmental detection sensor module is transmitted to the remote control center through the wireless communication module, and is used to complete life search, detection and exploration tasks in complex environments or places that are inaccessible to humans. Compared with the prior art, the present invention has the advantages of precise positioning and high reliability.

Owner:SHANGHAI UNIV OF ENG SCI

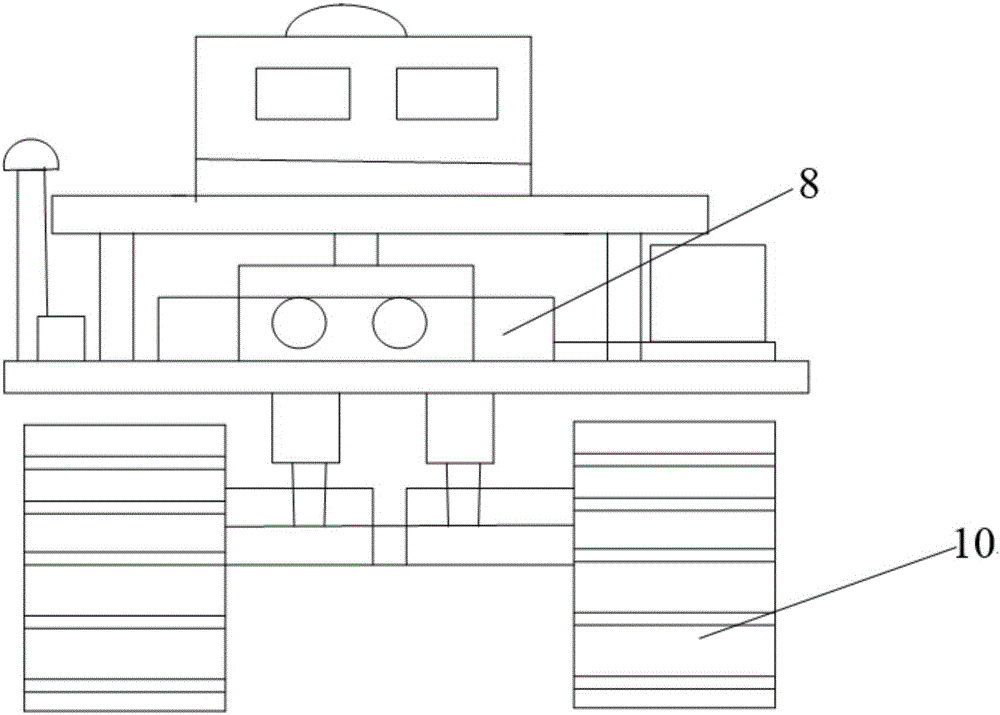

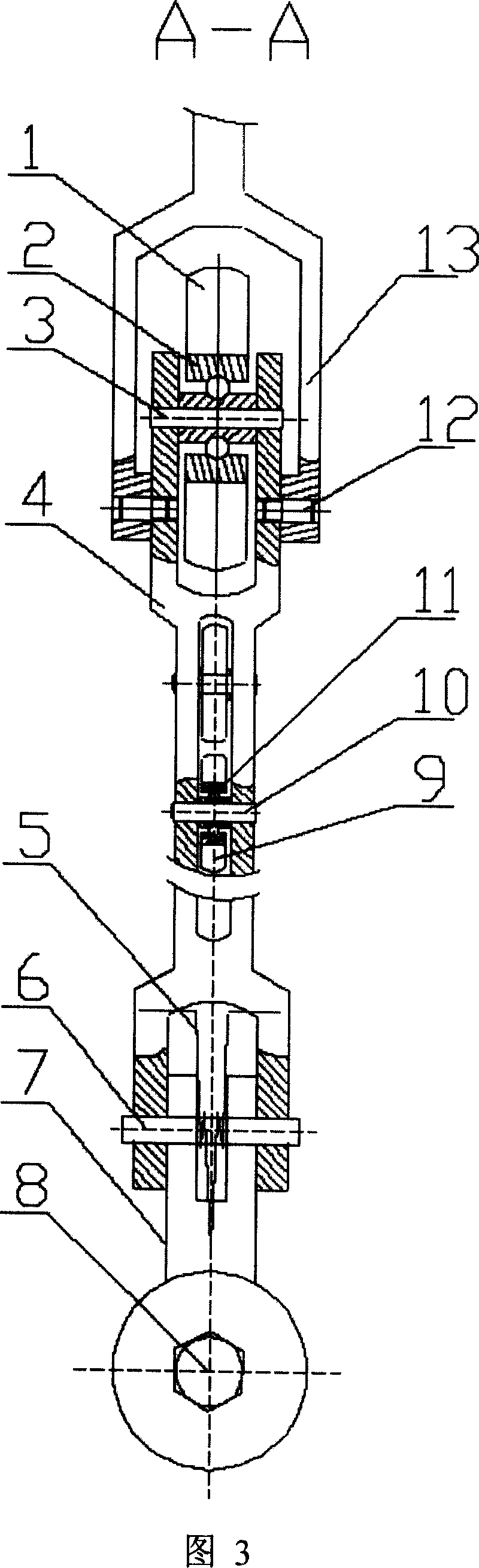

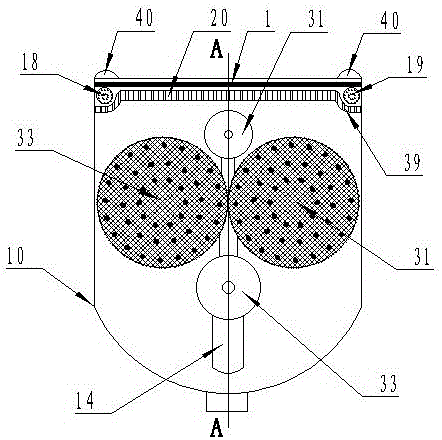

Diameter changeable pipeline cleaning robot having parallel four-bar mechanism

ActiveCN1962091AImprove passabilityImprove reliabilityHollow article cleaningManipulatorSpring forceEngineering

The invention relates to a diameter-variable tube washing robot with parallel four-rod device, wherein it is formed by several same tube washing devices, that connected by flexible springs; each unit is formed by support, flexible panel and washing head; the support is formed by several parallel four-rod devices around the central axle; via torsion spring, the parallel four-rod device will open, and the rolling wheel on the swing rod will contact the inner wall of tube, to support the whole tube washing device; when meeting obstacle, the four-rod device will overcome torsion spring to contract; the washing head is mounted on the connecting rod of four-rod device, to contact the inner wall of tube via spring; the flexible panel on the back swing rod can block the inner fluid, to generate pushing force, and move the support forwards. The invention can avoid additive powder and clean any tubes.

Owner:溧阳常大技术转移中心有限公司

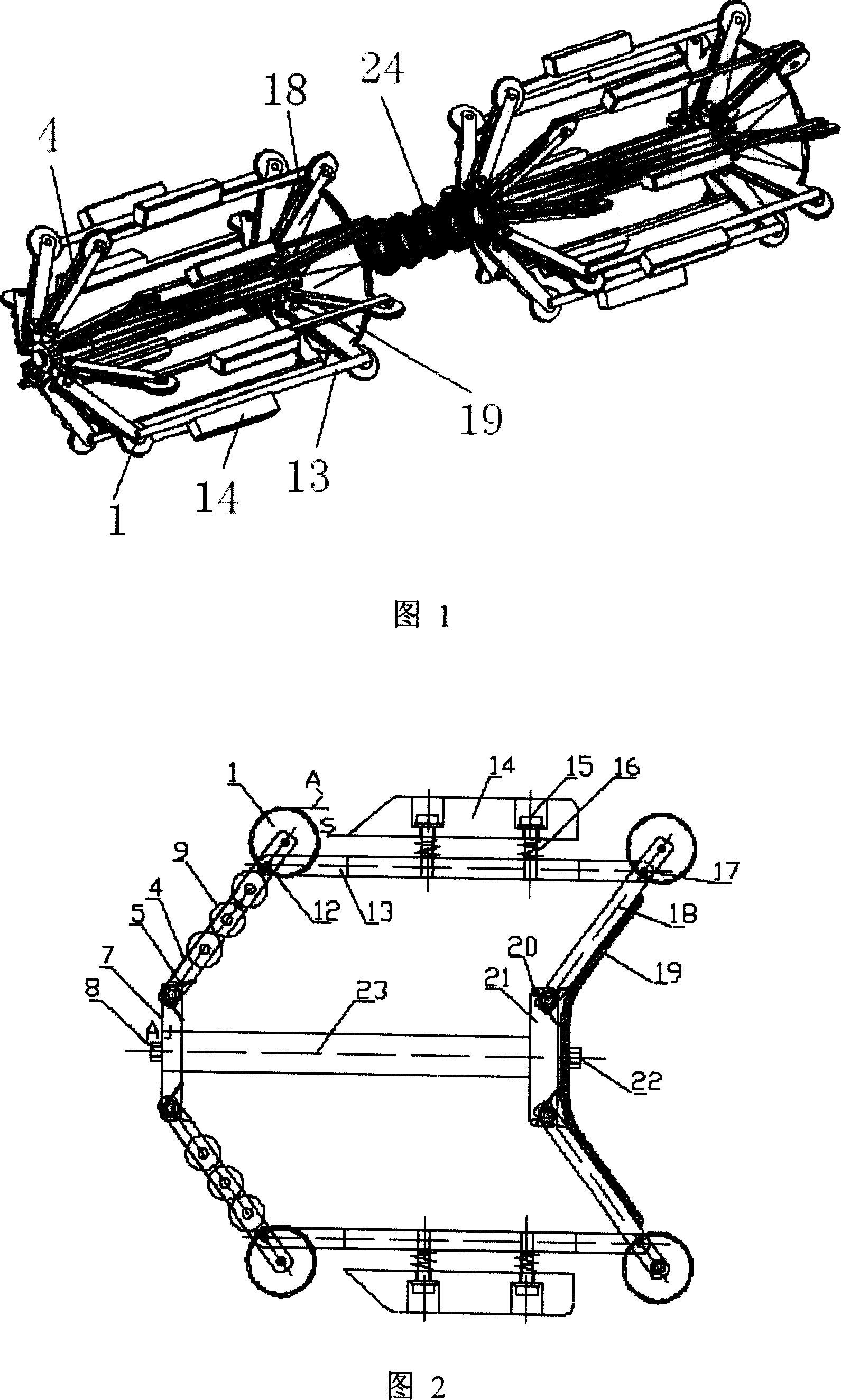

Multi-joint creeping high-altitude cleaning robot

InactiveCN101999871AEasy to crossAchieve leapfroggingCarpet cleanersFloor cleanersEngineeringSource system

The invention relates to a multi-joint creeping high-altitude cleaning robot comprising a robot body (1), a creeping part (2) and a cleaning part (3), wherein the robot body (1) comprises an adsorption system and an air source system, and the adsorption system and the air source system are both arranged on a base plate of the robot body (1); the creeping part (2) comprises six feet, the six feet are respectively provided with three joints and uniformly distributed at both sides of the robot body (1), and each feet is articulated with the base plate of the robot body (1); the cleaning part (3) comprises a middle cleaning system and a rear cleaning system, wherein the middle cleaning system is arranged below the base plate of the robot body (1), and the rear cleaning system is fixed on the tail part of the robot body (1). The invention realizes the functions of spanning barriers or cracks and being absorbed on a curved surface, has good cleaning effect and high efficiency and can be adapted to a more complex high-altitude operating environment, thereby greatly reducing the unsafe hidden dangers under manual operation.

Owner:GUANGZHOU UNIVERSITY

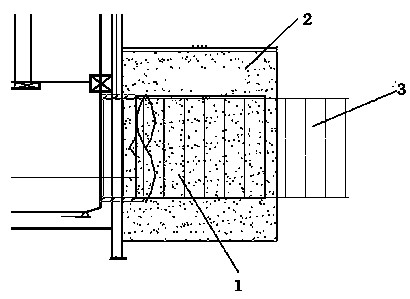

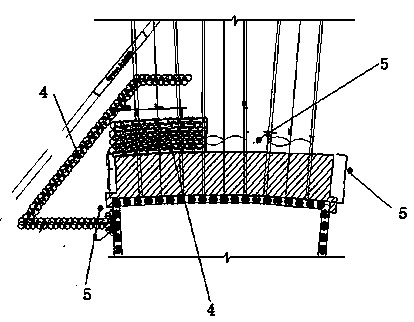

Constructing method for shield entering into hole while passing through pipeline

The invention relates to a constructing method for a shield entering into a hole while passing through a pipeline. The constructing method comprises the following steps: (1) reinforcing an end shaft three-axe agitating pile entering into the hole and a rotary spraying pile, increasing a reinforcing area to 9 meters and keeping a reinforcing depth as 3 meters under a tunnel; (2) arranging a row of isolating piles between a sewage pipe and a station end shaft, isolating a lateral soil pressure of a soil body under the sewage pipe, and preventing pipeline settlement caused by a released soil pressure stress, wherein the isolating piles are three-axe agitating piles; (3) arranging four dewatering wells in a scope of entering the hole, dewatering and reducing a water level to 1 meter under a hole door; (4) except mounting a waterproof device around the hole door, mounting a double-layer spring steel plate, and filling sponge in the middle; (5) finishing an operation of chiseling the hole door within the shortest time; (6) adjusting all parameters, causing the shield to safely and quickly enter into the hole while passing through the pipeline; and (7) cleaning soil and turning a shielding machine. The constructing method provided by the invention has the advantages that the shielding machine successfully enters into the hole while passing through the pipeline, a successful construction case of a high-risk construction process of entering the hole of the shield under a complex condition is achieved, and abundant construction experiences for silt construction and close-range pipeline passing of the shield are provided.

Owner:SHANGHAI MECHANIZED CONSTR GRP

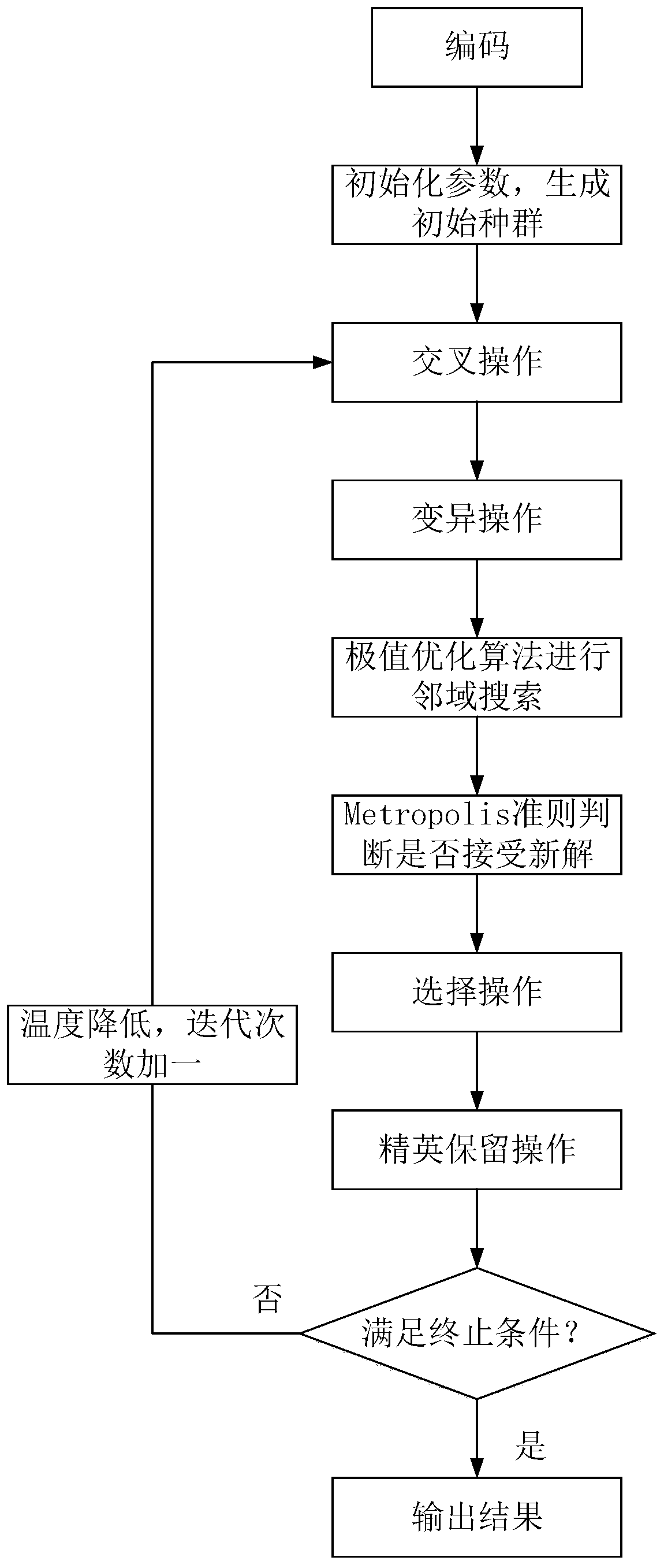

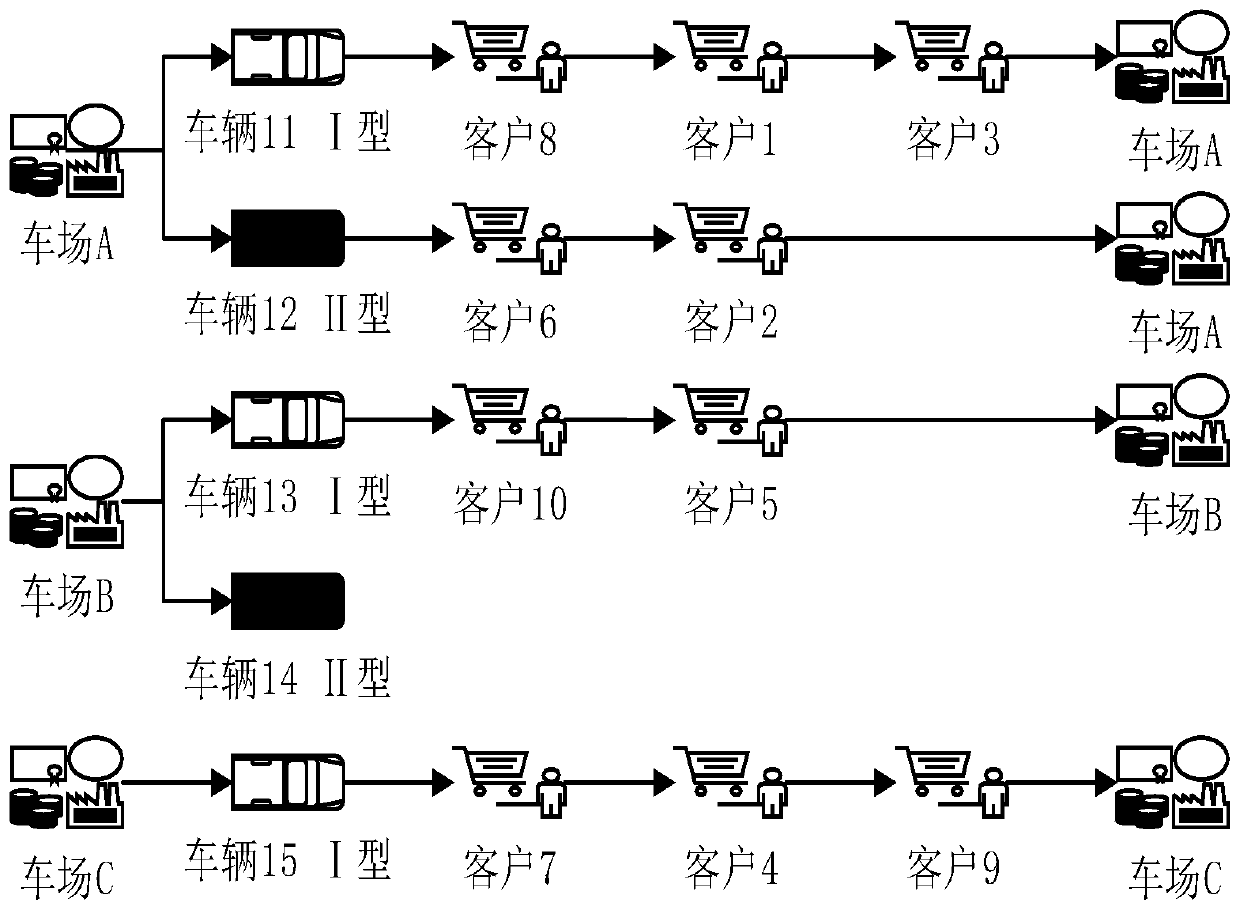

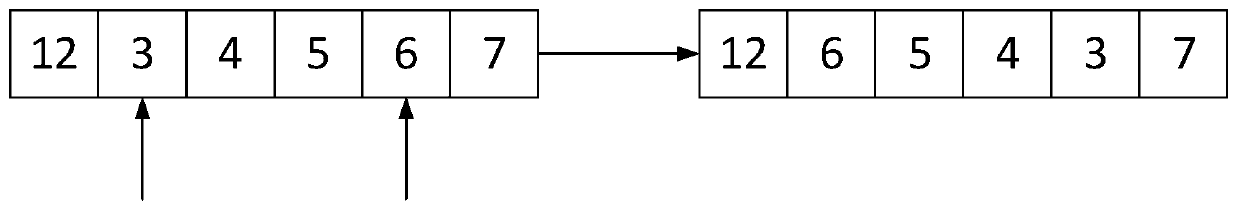

A multi-parking-lot and multi-vehicle-type vehicle path scheduling control method

ActiveCN109919376AGive full play to the local search abilityEasy to crossForecastingLogisticsNeighborhood searchDelivery vehicle

The multi-parking-lot and multi-vehicle-type vehicle path scheduling control method comprises the steps of 1, establishing an objective function by taking the lowest total cost of all delivery vehicles as an objective; Step 2, performing a coding step; 3, performing population initialization; 4, evaluating all the individuals by adopting the objective function as a fitness function; Step 5, performing selection and crossover operation; step 6, performing mutation operation; 7, performing neighborhood search on each individual in the population by using an improved extreme value optimization algorithm; Step 8, calculating fitness of all individuals in the population; Step 9, performing selecting; Step 10, performing elite retention; Step 11, completing iteration in sequence; Step 12, judging whether a termination condition is met or not, the termination condition being that the number of iterations g reaches the maximum number of iterations MaxGen or the number of iterations Nu of whichthe Gb fitness value remains unchanged reaches the specified number of iterations Kbest, if yes, continuing to execute the step 13, and if not, returning to execute the step 5; Step 13, outputting the individual Gb and the fitness value fGb thereof; And 14, interpreting the optimal individual Gb and the fitness value fGb thereof. The invention aims to improve the search efficiency and convergencespeed of the algorithm.

Owner:ZHEJIANG UNIV OF TECH

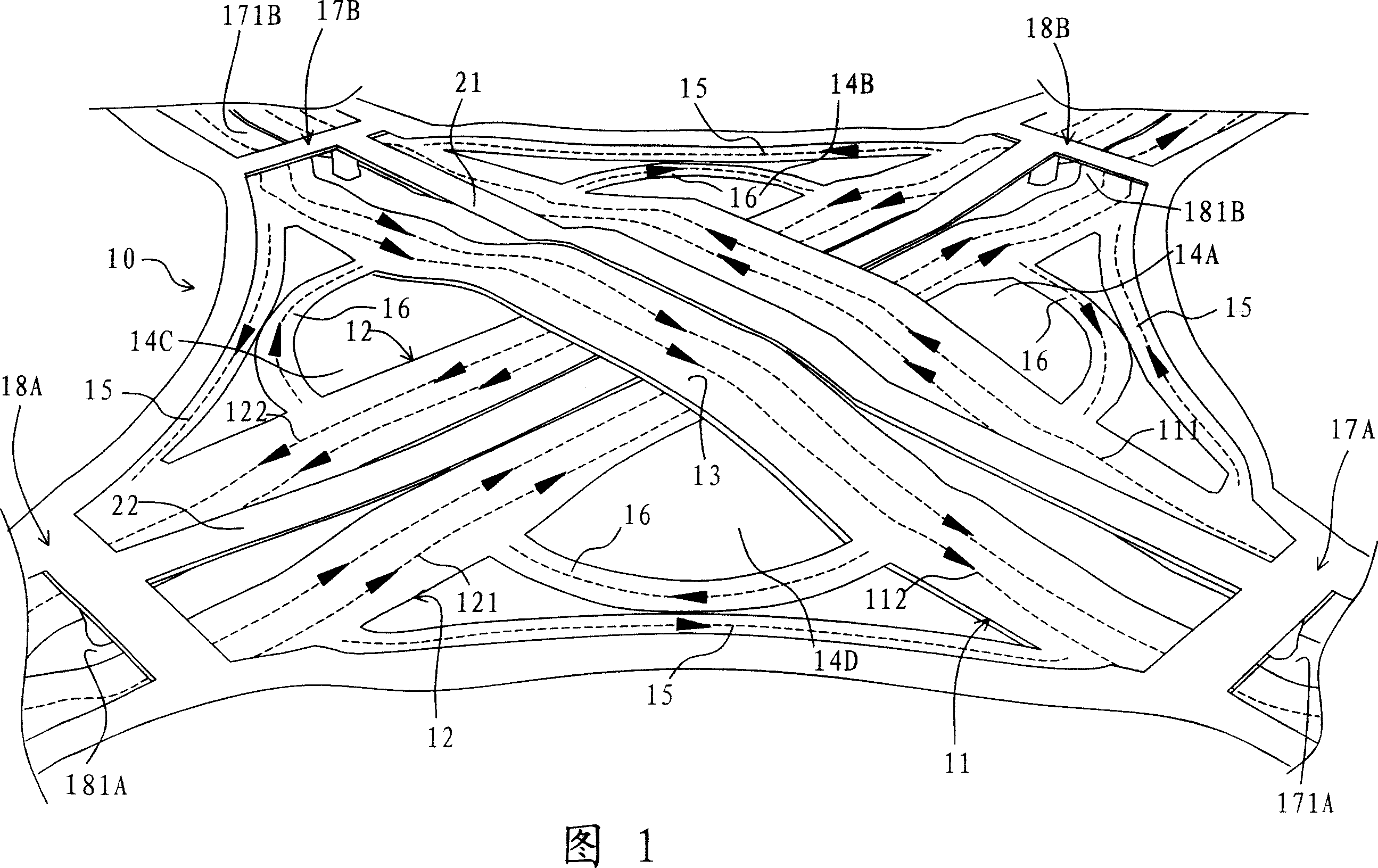

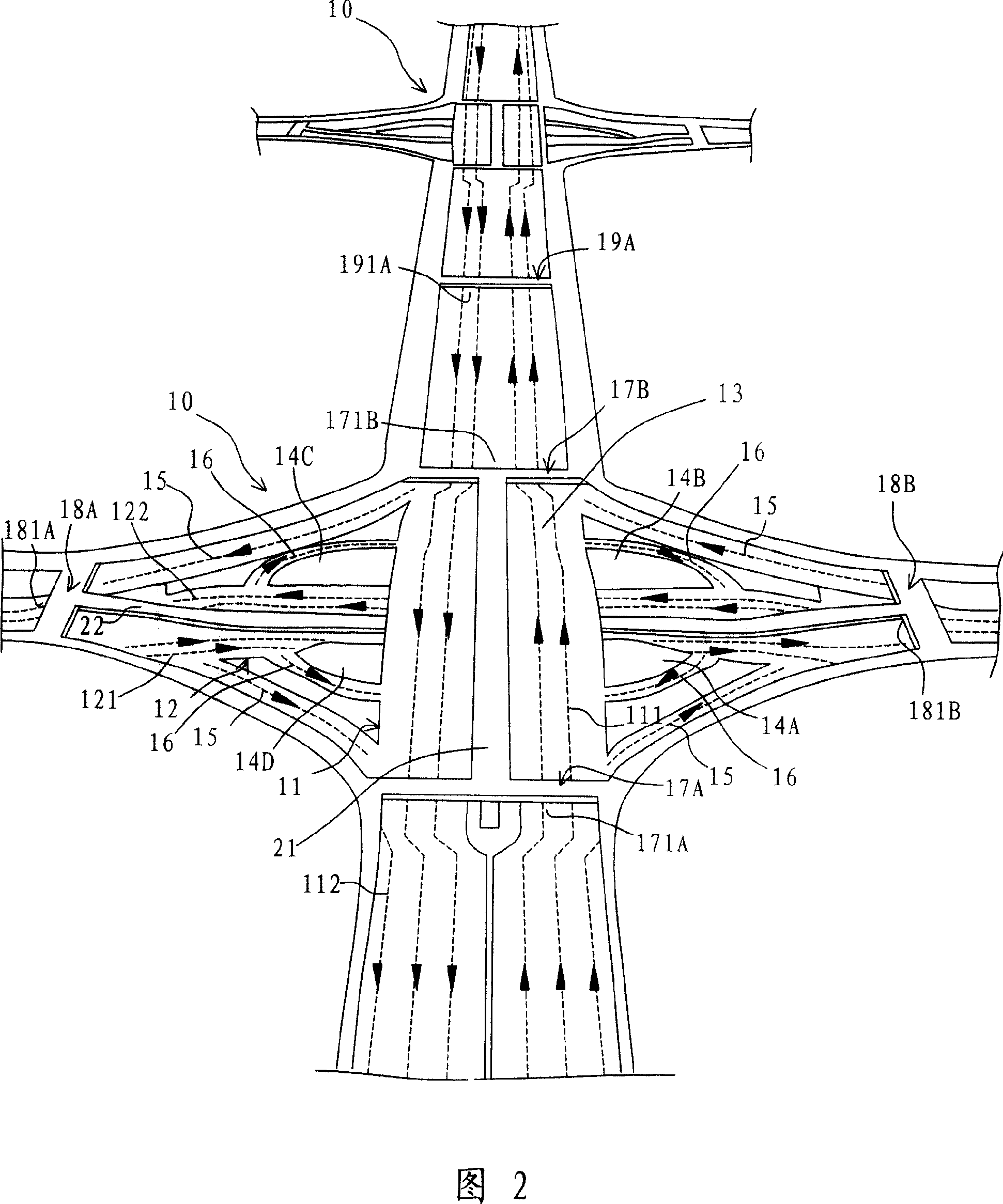

Non-traffic light non-barrier urban multi-level fast traffic road structure

A city solid quick traffic road without traffic light and obstacle is characterized in that a, the cross between longitudinal and transverse roads are solid designed, b, one of longitudinal and transverse roads extends over the horizontal road before the cross to span the vertical road to be transitioned to following horizontal road, c, the part of longitudinal or transverse road outside the cross is disposed with a right steering road connected to the vertical road, d, the longitudinal and transverse roads near the outer side of cross are respectively arranged with a walk bridge along the horizontal road, e, tow sides and under the walk bridge of longitudinal and transverse roads are arranged with concave vehicle roads, f, two side walk bridges at the cross of longitudinal and transverse roads are arranged with a walk channel between, while the walk channel is communicated with two end walk bridges. The invention can eliminate traffic light at cross, to travel people and vehicle independently, to improve traffic efficiency and safety.

Owner:彭振华

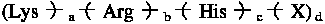

Hyperbranched polyamino acid, preparation method and application thereof

InactiveCN101575412AImprove responseEfficient transductionOther foreign material introduction processesChemical compositionArginine

The invention relates to hyperbranched polyamino acid. The chemical composition is as follows: in the formula of (Lys-)a-(-Arg-)b-(-His-)c-(-X)d, Lys, Arg and His are respectively lysine, arginine and histidine, X is one of or a plurality of any amino acids except for the amino acids above, wherein a is not less than 0.2 and not more than 0.95, b is not less than 0 and not more than 0.8, c is not less than 0 and not more than 0.8, d is not less than 0 and not more than 0.3, and the sum of a, b, c and d is 1. The preparation method is as follows: uniformly mixing lysine or lysine salt with other amino acids or the amino acid salts contained in the hyperbranched polyamino acid to react for 2-64h at the temperature of 130-180 DEG C and then obtain yellow solid, and finally purifying the coarse product with a precipitation method to obtain the hyperbranched polyamino acid. The hyperbranched polyamino acid obtained in the invention can be used as nonviral gene carrier for the transduction of huamn or animal cell gene, and the hyperbranched polyamino acid nonviral gene carrier provided by the invention is reasonable in design, simple in preparation method, high in transfection efficiency, low cytotoxicity and favorable transduction efficiency in the presence of blood serum.

Owner:WUHAN UNIV

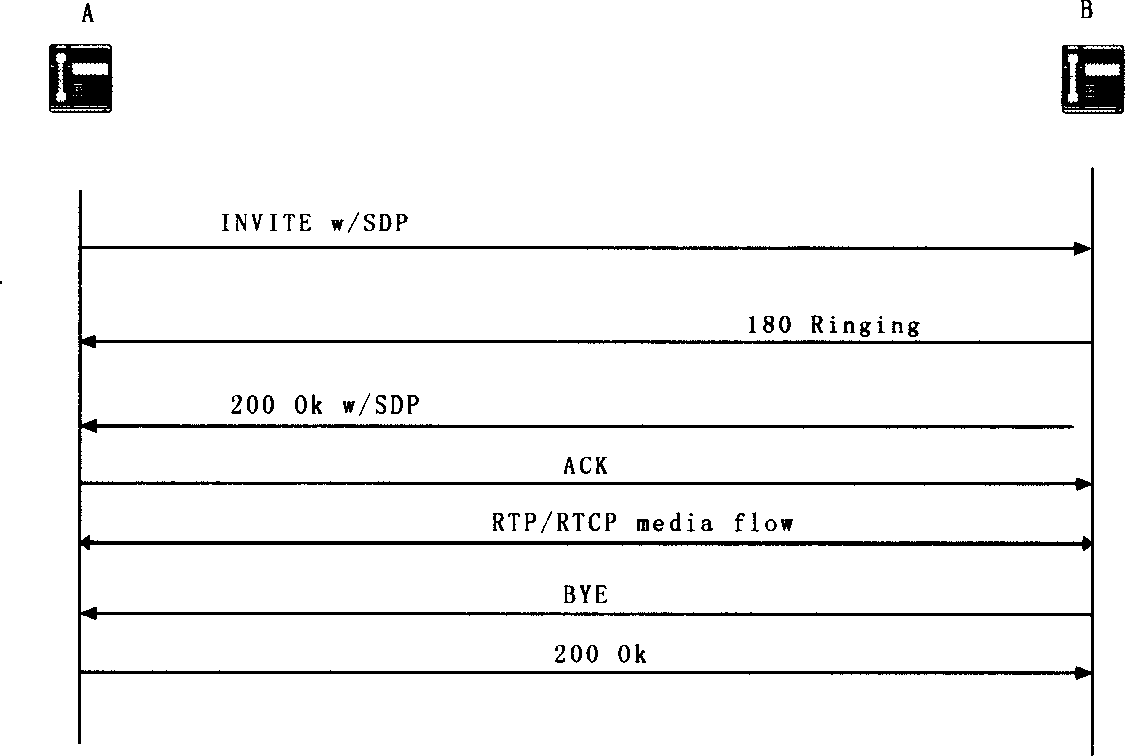

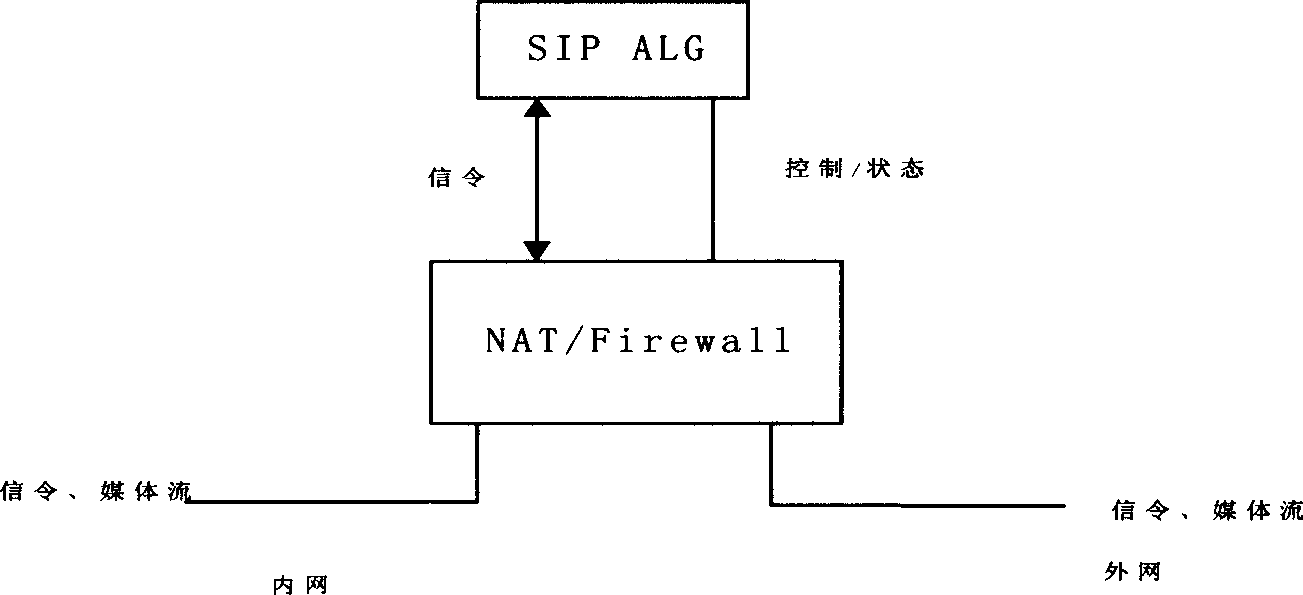

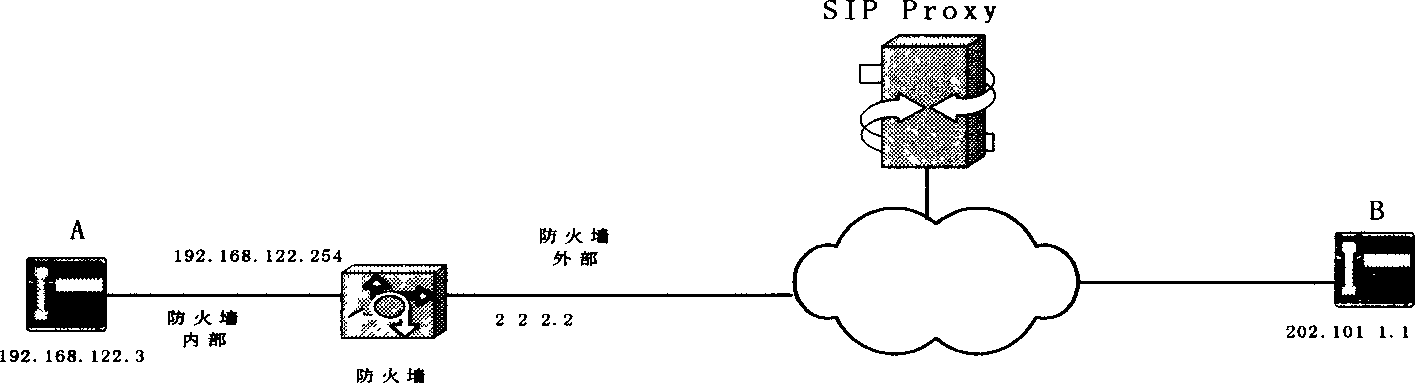

SIP crossing supported firewall implementing method

InactiveCN1604589AExtension limitClear hierarchyData switching networksConnection tableProtocol for Carrying Authentication for Network Access

It is a firewall implementation method that supports the session startup protocol crossover in the field of network security technique. The content is: the firewall analyses the IP division that enters the system. After the IP division enters the system through network interface, the firewall analyses the IP heading information, judges whether the data load is SIP signal information or voice division; the SIP ALG processes the SIP message, SIP ALG analyses SIP message heading to make sure this message belongs to which calling connection. The SIP ALG uses one calling connection state table to track all the calling connection state and modify the content of SIP message heading and / or SDP message according to the information of state table; the firewall processes the down-transferred SIP message from SIP ALG, or performs the instruction issued by SIP ALG, and returns the result to the SIP ALG; according to the result of instruction performing by firewall, the SIP ALG sets or modifies the calling connection table, and sends the SIP message to the firewall, or performs the clearing of calling connection table.

Owner:无锡三通科技有限公司

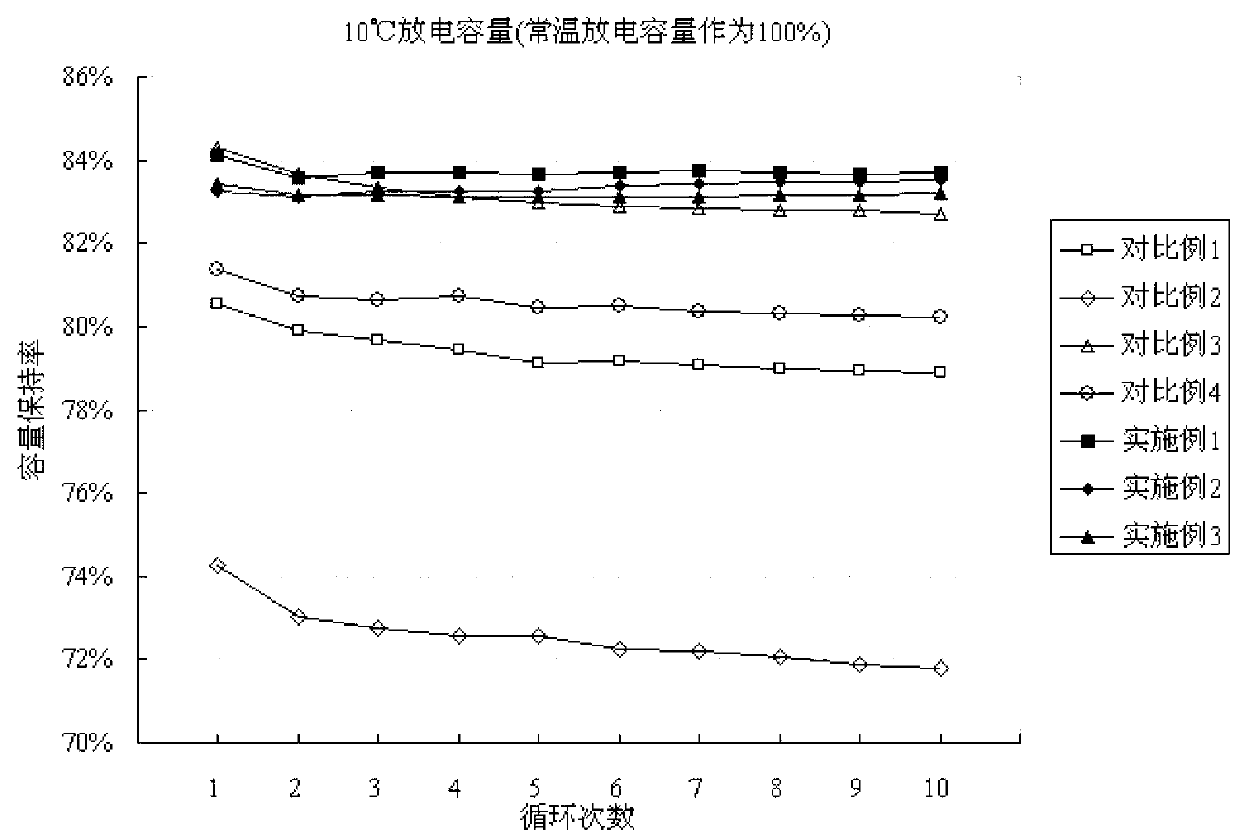

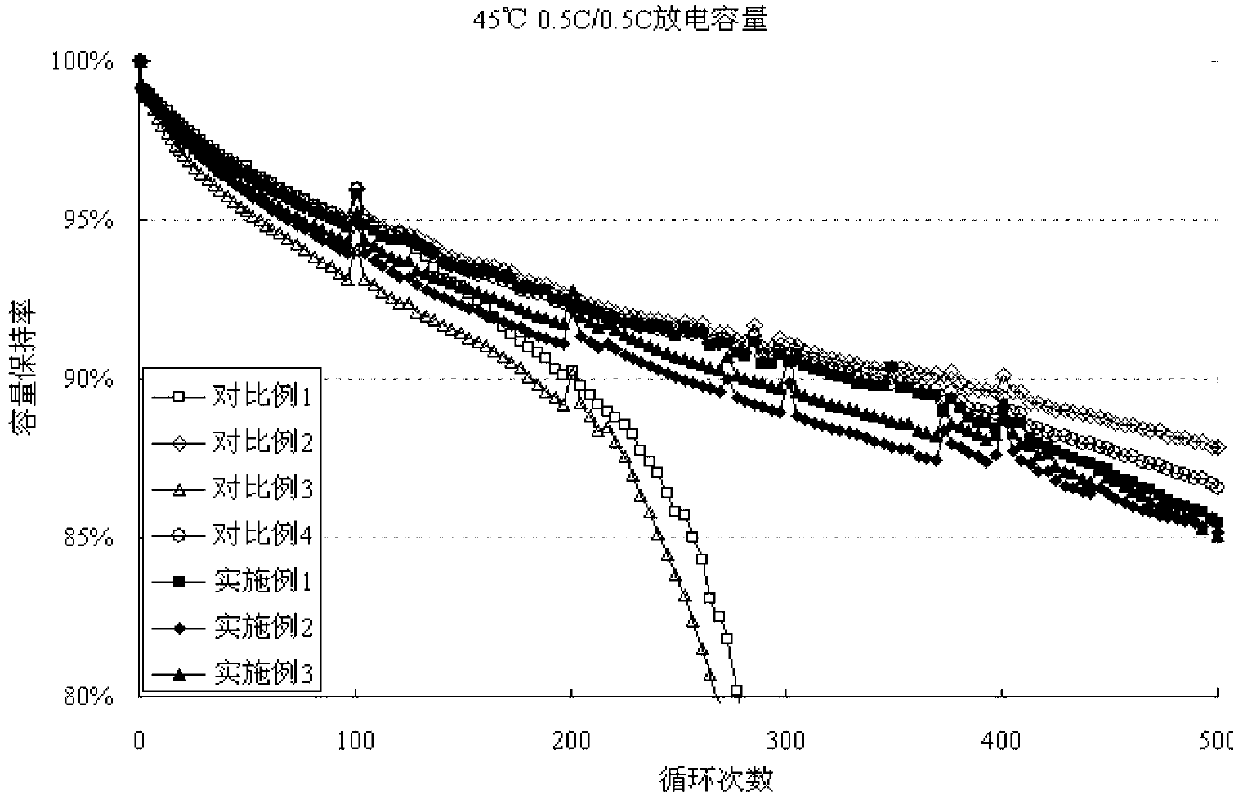

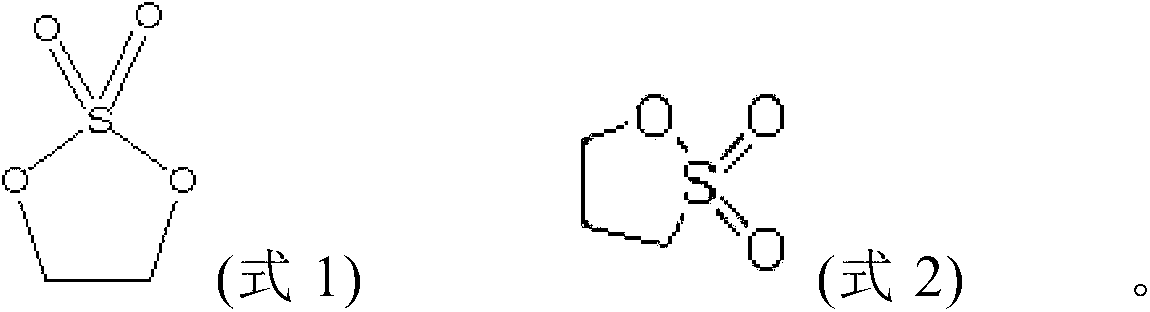

Lithium ion battery and electrolyte thereof

ActiveCN103107355AExcellent low temperature charge and discharge performanceGuaranteed high temperature storage and cycle performanceSecondary cellsCharge and dischargeLithium electrode

The invention provides a lithium ion battery and electrolyte thereof. The electrolyte of the lithium ion battery comprises a non-aqueous solvent, lithium salt dissolved in the non-aqueous solvent, cyclic sulfate or sulphonate without a branched chain, and cyclic sulfate with a branched chain. The lithium ion battery comprises a positive plate, a negative plate, a diaphragm arranged between the positive plate and the negative plate, and the electrolyte. The lithium ion battery and the electrolyte thereof have excellent low-temperature charge and discharge performance, and the quite high-temperature storage, circulation and other performances can be guaranteed.

Owner:NINGDE AMPEREX TECH

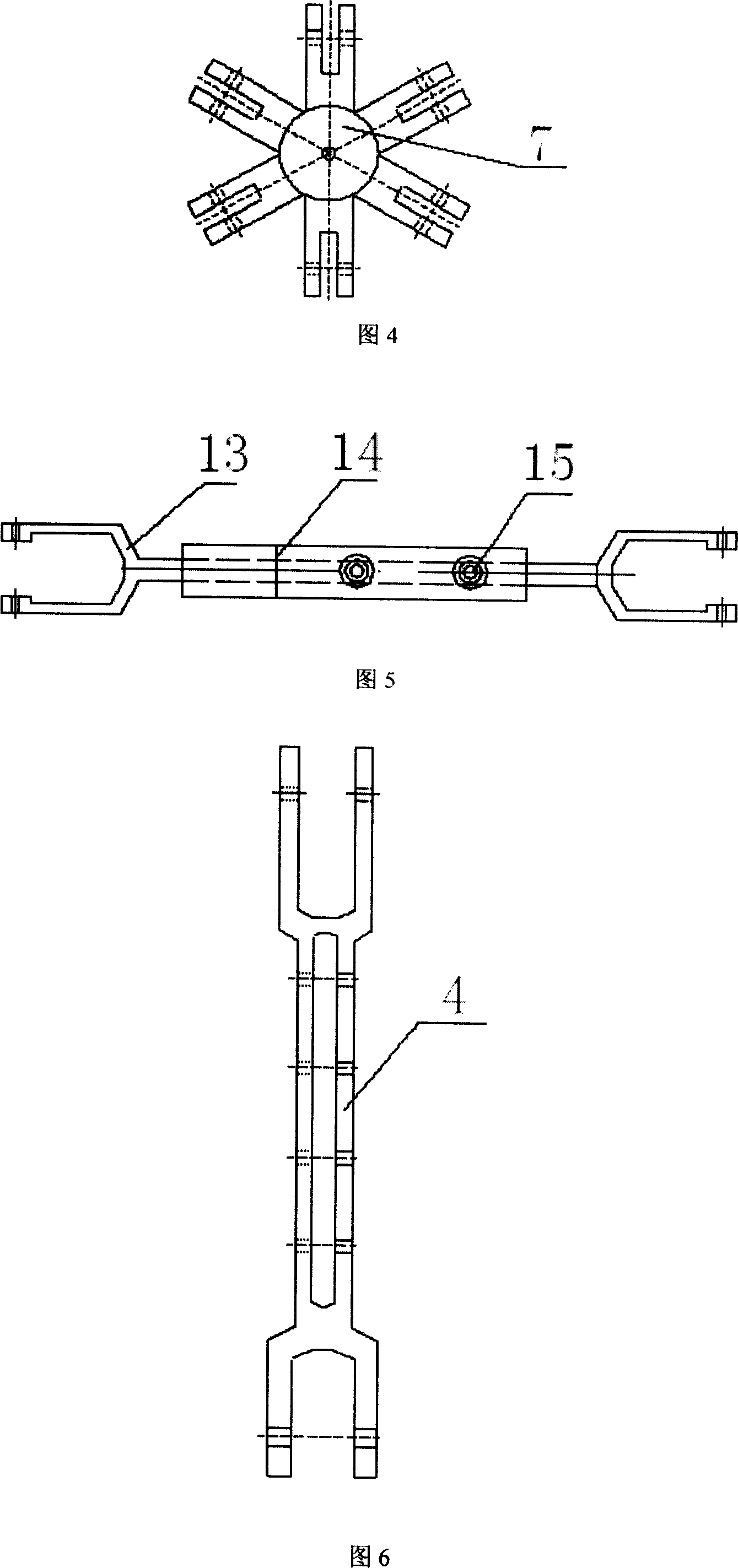

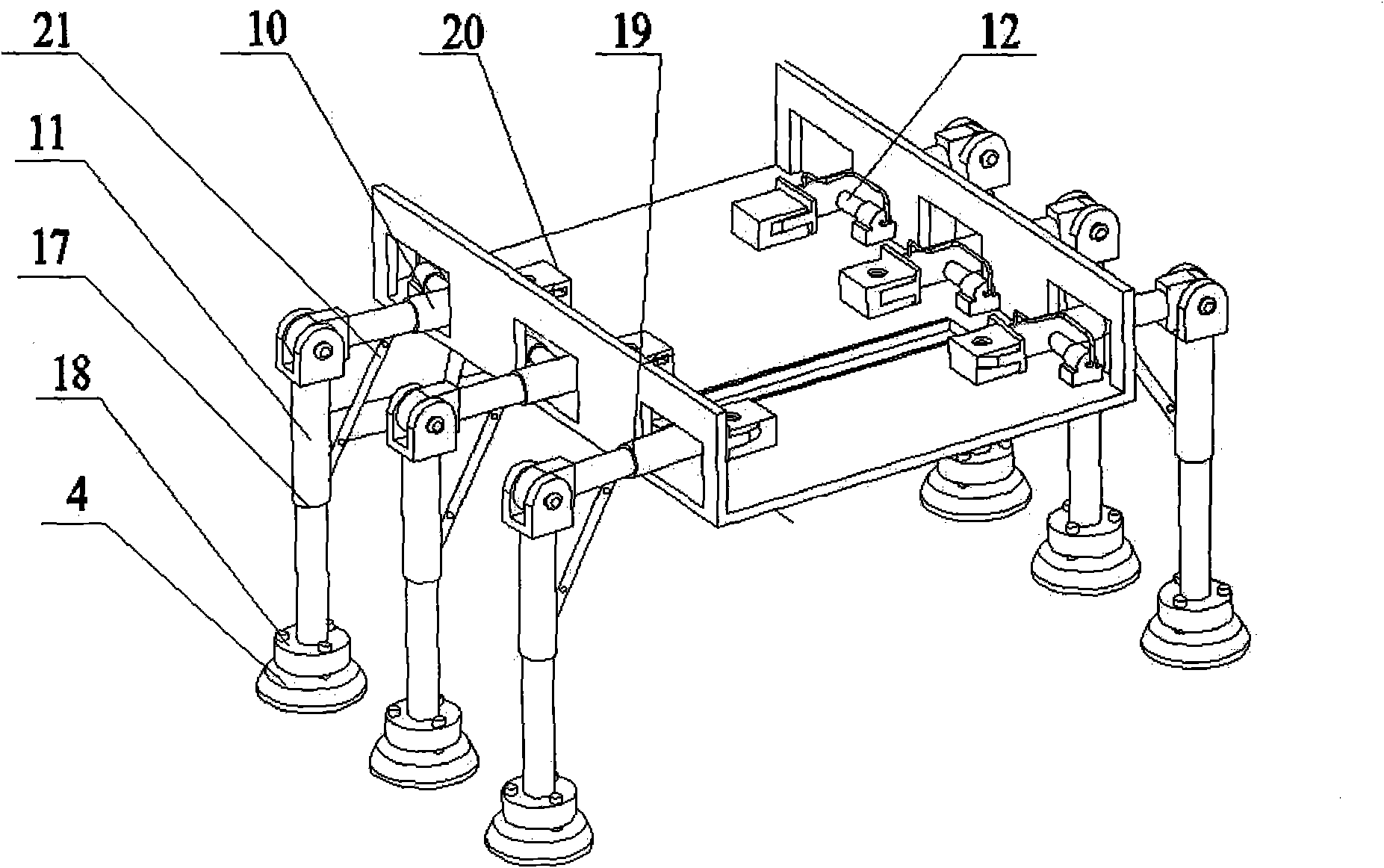

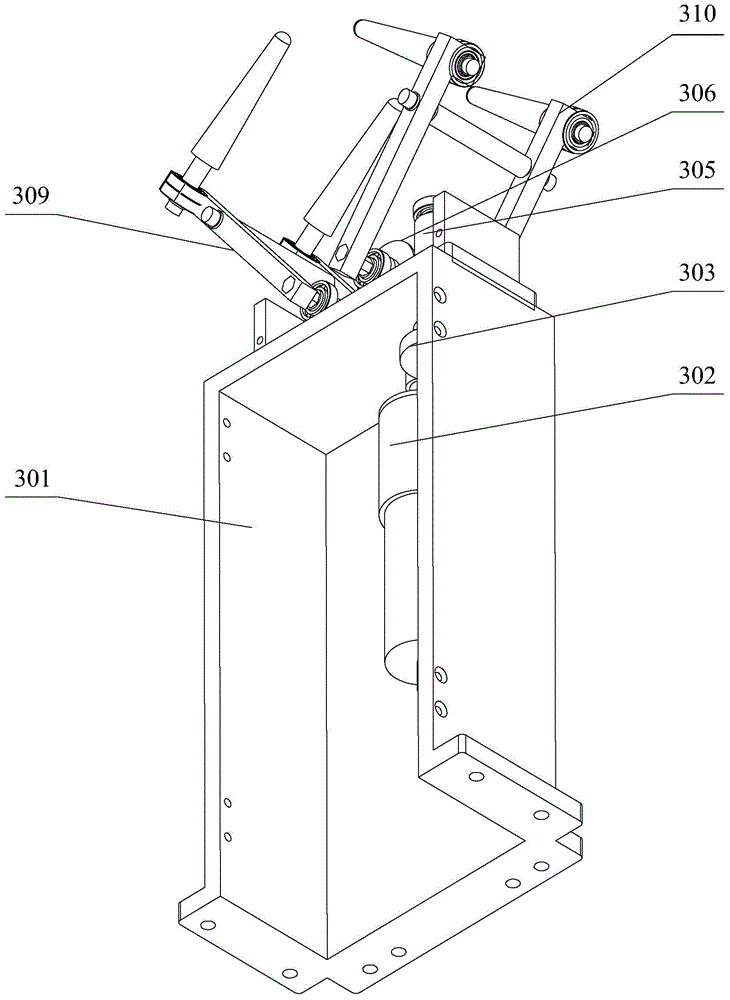

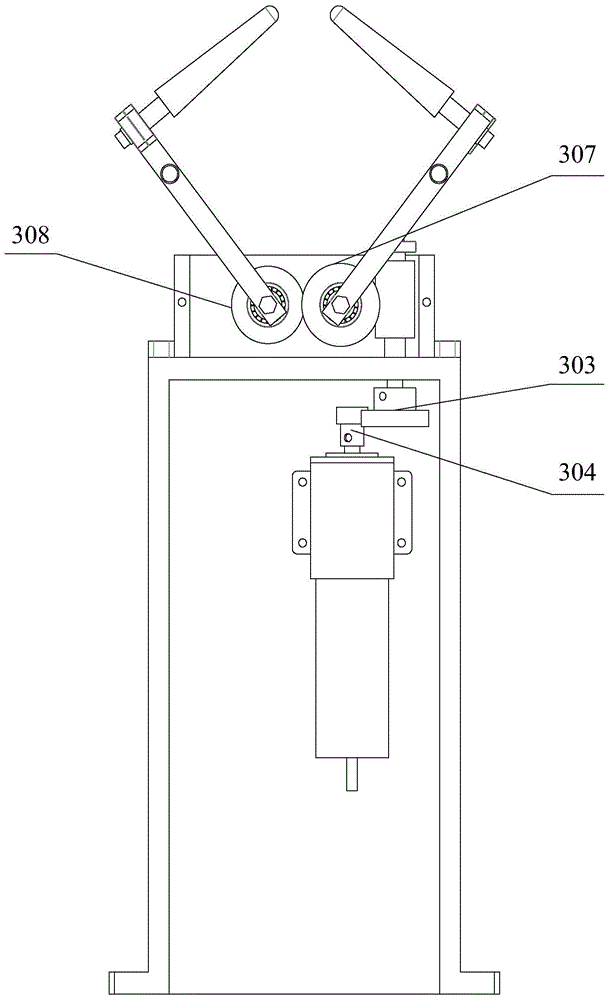

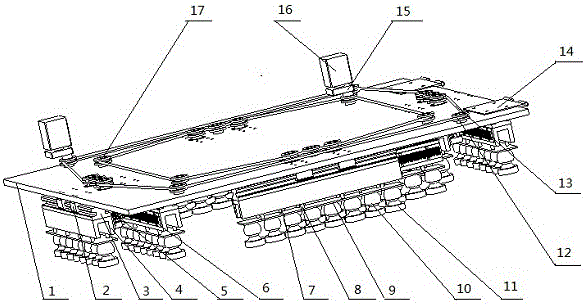

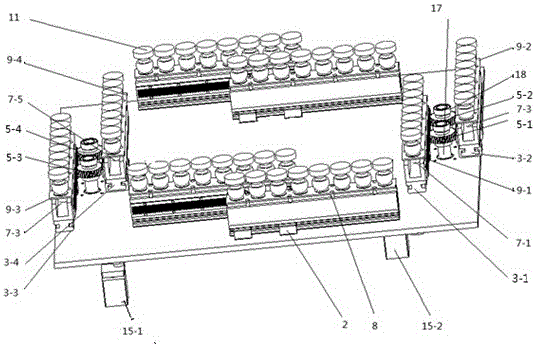

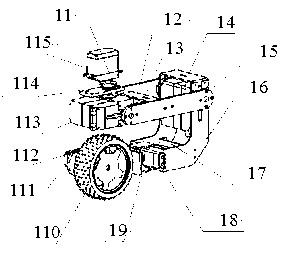

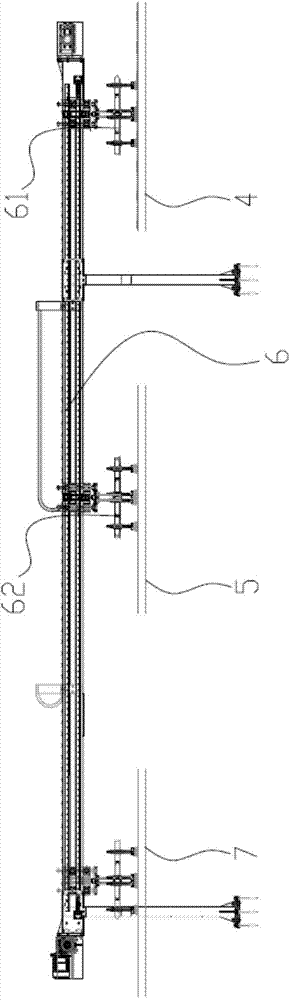

Clamping mechanism and inspection robot walking mechanism

ActiveCN103606851AWon't fallRealize the pressing effectApparatus for overhead lines/cablesDrive wheelEngineering

The invention discloses a clamping mechanism. The clamping mechanism comprises a supporting box, a supporting frame, a first rotating shaft, a second rotating shaft, a clamping drive device, a first clamping claw and a second clamping claw, wherein the supporting frame is arranged on the supporting box; the first rotating shaft and the second rotating shaft are arranged on the supporting frame in a rotating mode and are in transmission connection through a transmission mechanism; the clamping drive device is used for driving the first rotating shaft or the second rotating shaft to rotate; the first clamping claw is fixed to the first rotating shaft; the second clamping claw is fixed to the second rotating shaft. According to the clamping mechanism, the clamping drive device is used for driving the first rotating shaft or the second rotating shaft to rotate and then driving the first clamping claw and the second clamping claw to do opposite movements or separating movements, and therefore the purpose of holding lines or loosening lines can be achieved. When a drive wheel and a clamping wheel cross obstacles, the lines can be clamped through the clamping mechanism, and it can be ensured that an inspection robot will not fall off from the lines. The invention further discloses an inspection robot walking mechanism provided with the clamping mechanism.

Owner:STATE GRID CORP OF CHINA +2

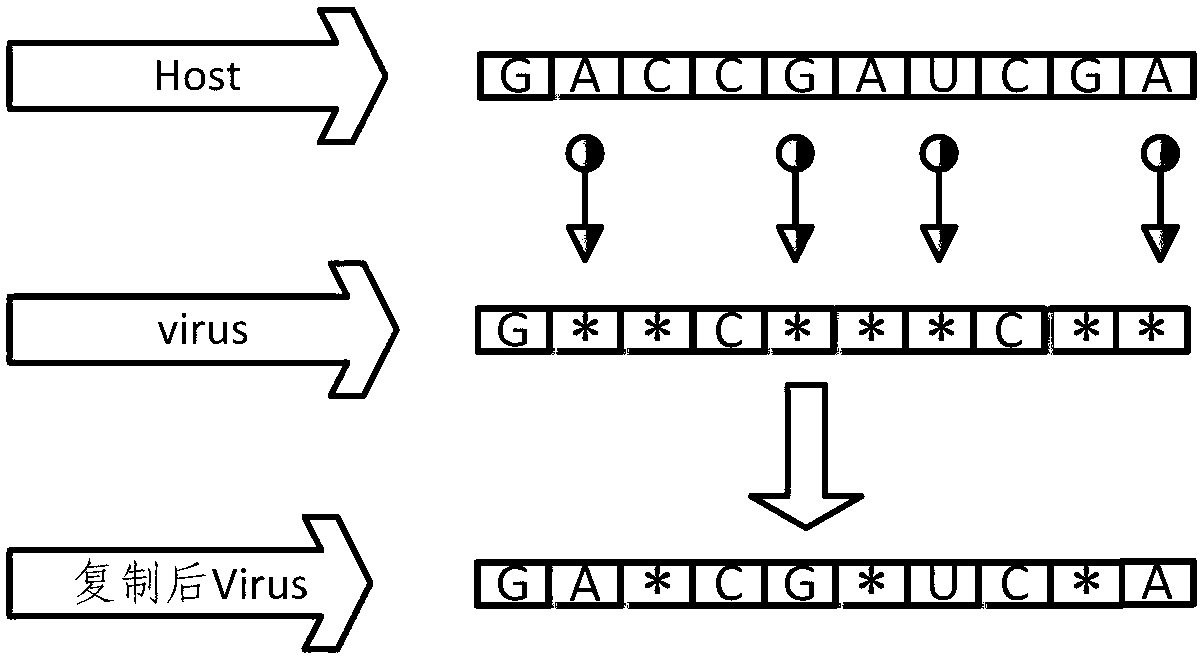

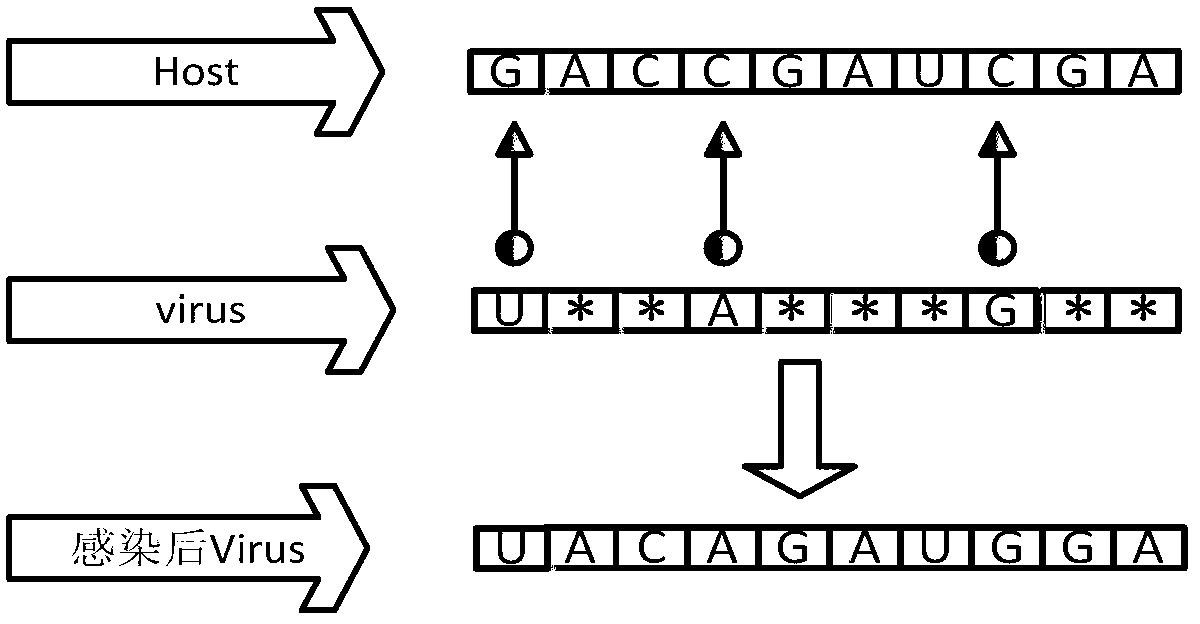

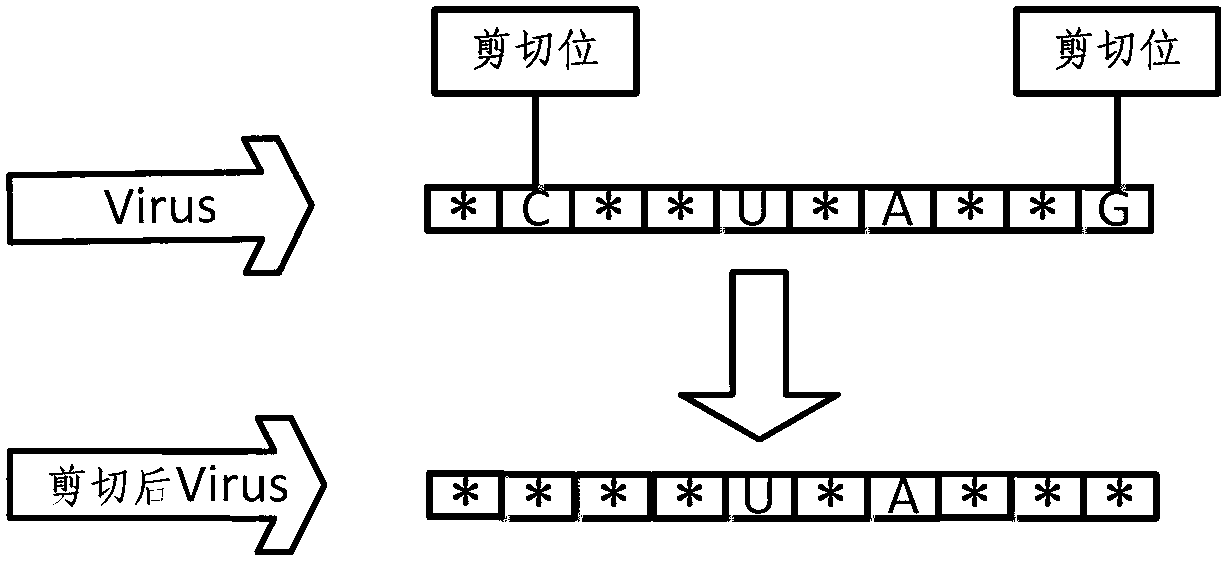

VERNA-genetic algorithm (GA) gasoline concoction optimized dispatching method

ActiveCN103065204AImplement local searchImplement random searchGenetic modelsForecastingGasolineGenetic algorithm

The invention discloses a VERNA-genetic algorithm (GA) gasoline concoction optimized dispatching method. The VERNA-GA gasoline concoction optimized dispatching method comprises that first of all, a gasoline concoction dispatching model aiming at profit and constraint satisfaction is constructed according to information of blending component oil, product oil and market supply and demand under conditions of a concoction model with high prediction accuracy and production dispatching constraint, then a VERNA-GA method is adopted, wherein a calculation structure of the VERNA-GA method comprises operations of selection, cross and mutation of a main group and operations of infection, copy and deletion of a virus group, parameter set and searching and optimization of formula are carried out according to an algorithm parameter value range provided in the VERNA-GA gasoline concoction optimized dispatching method, and gasoline concoction optimized dispatching production is carried out according to the formula. The VERNA-GA gasoline concoction optimized dispatching method provides concoction optimized dispatching schemes for gasoline of one day and a plurality of days, is in no need of formula experience, when the formula is randomly searched in the production constraint range, the formula which is reliable in quality and high in profit can be rapidly found out, and operation and expansion of optimized dispatching scale are easy.

Owner:ZHEJIANG UNIV

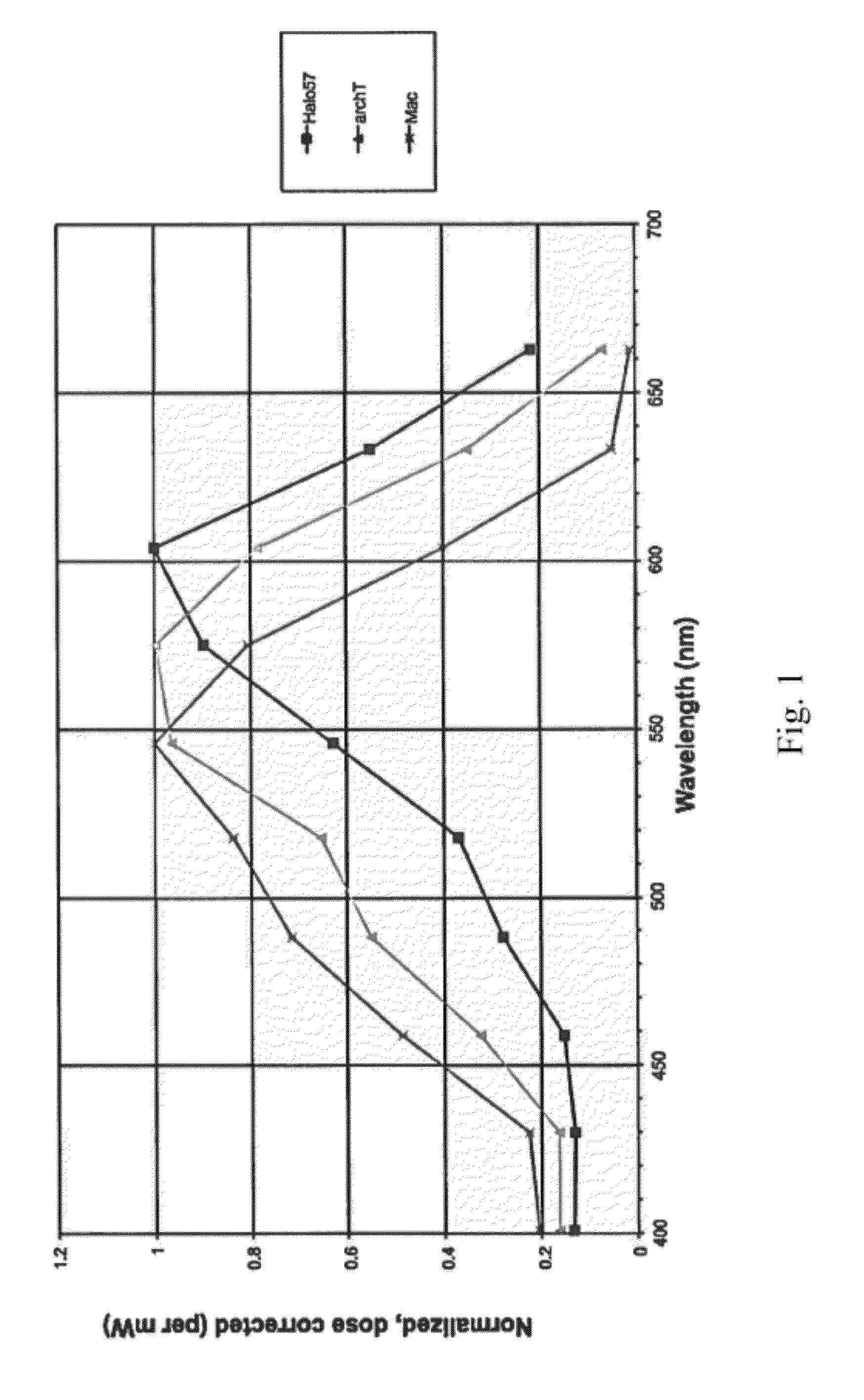

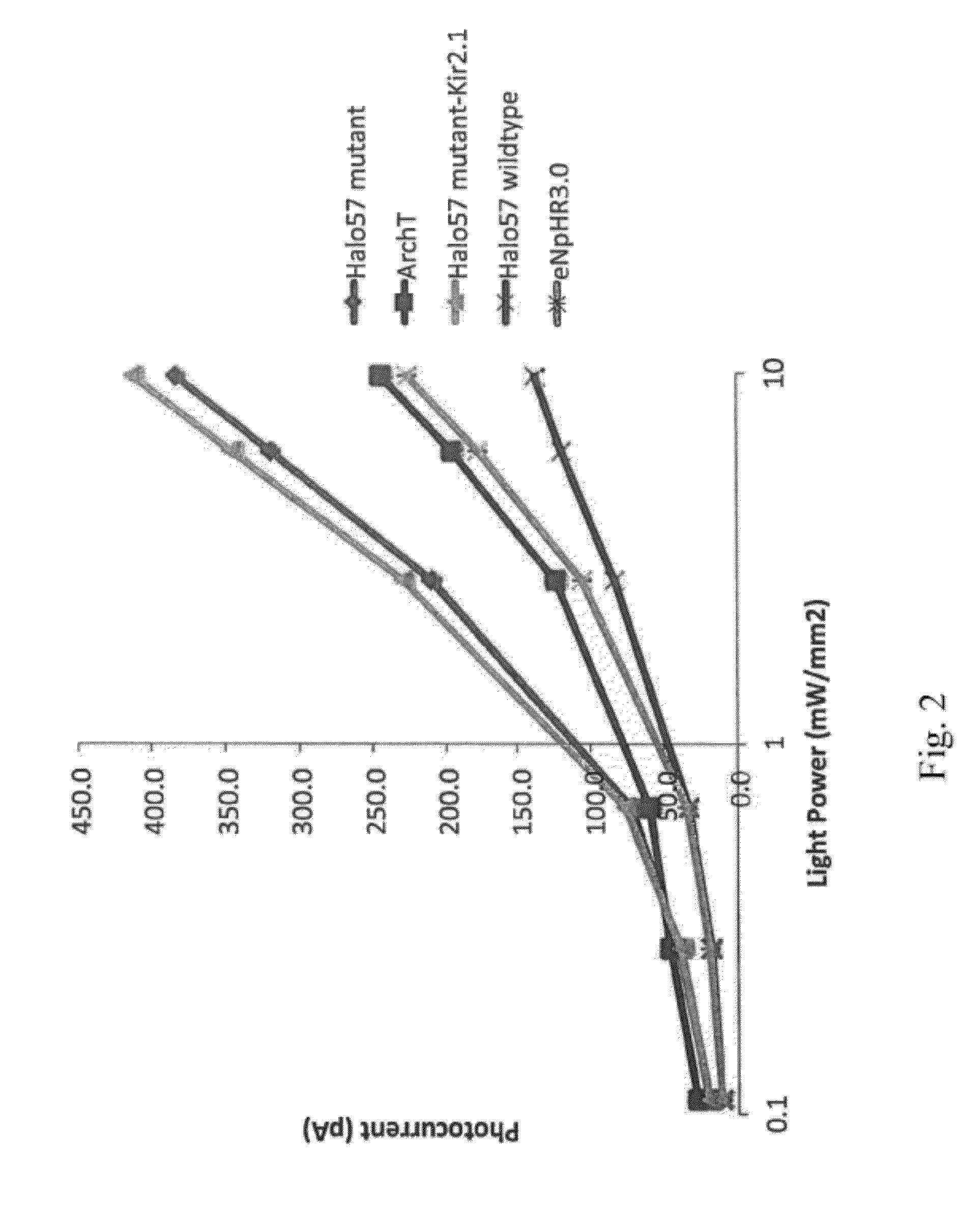

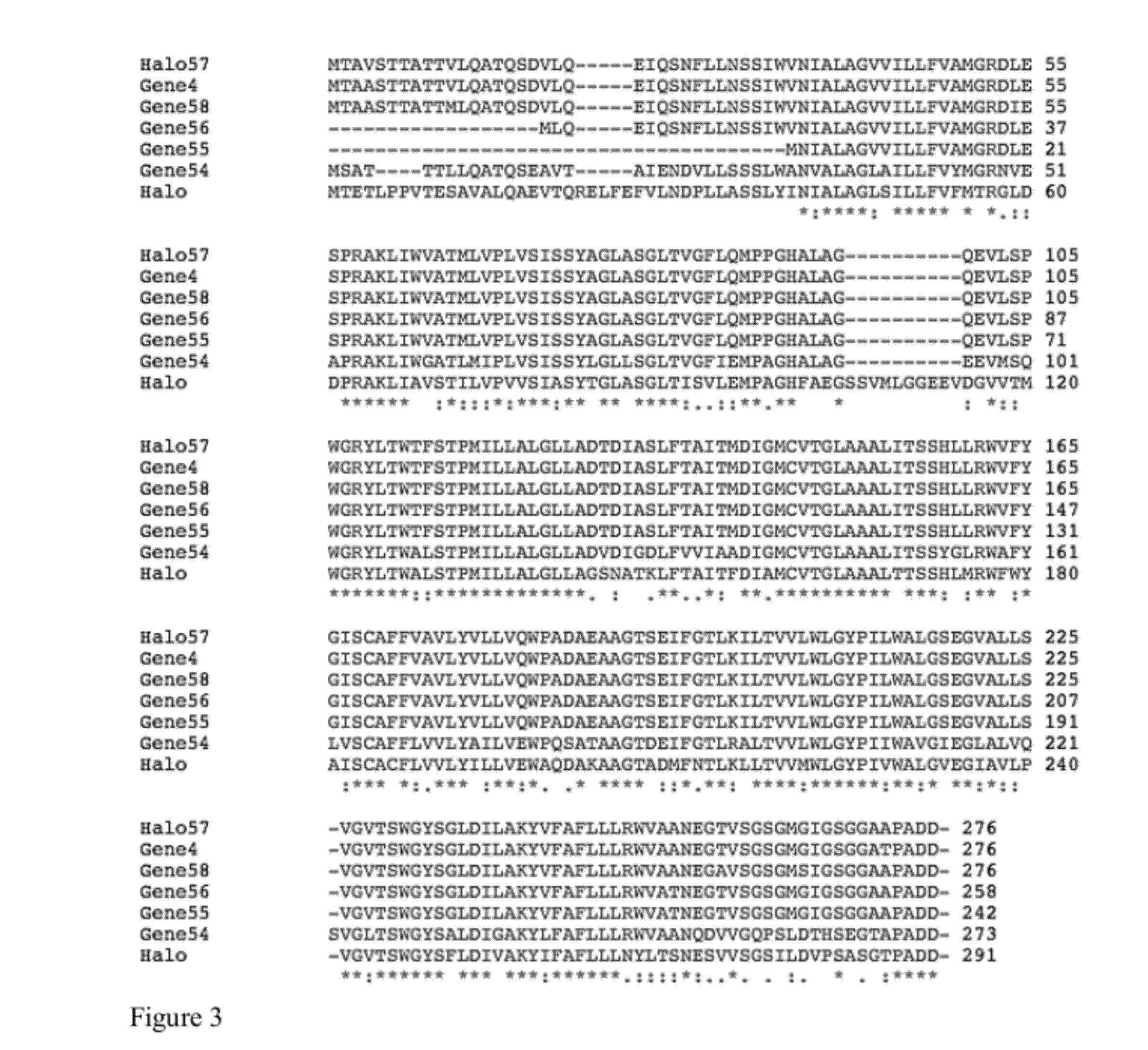

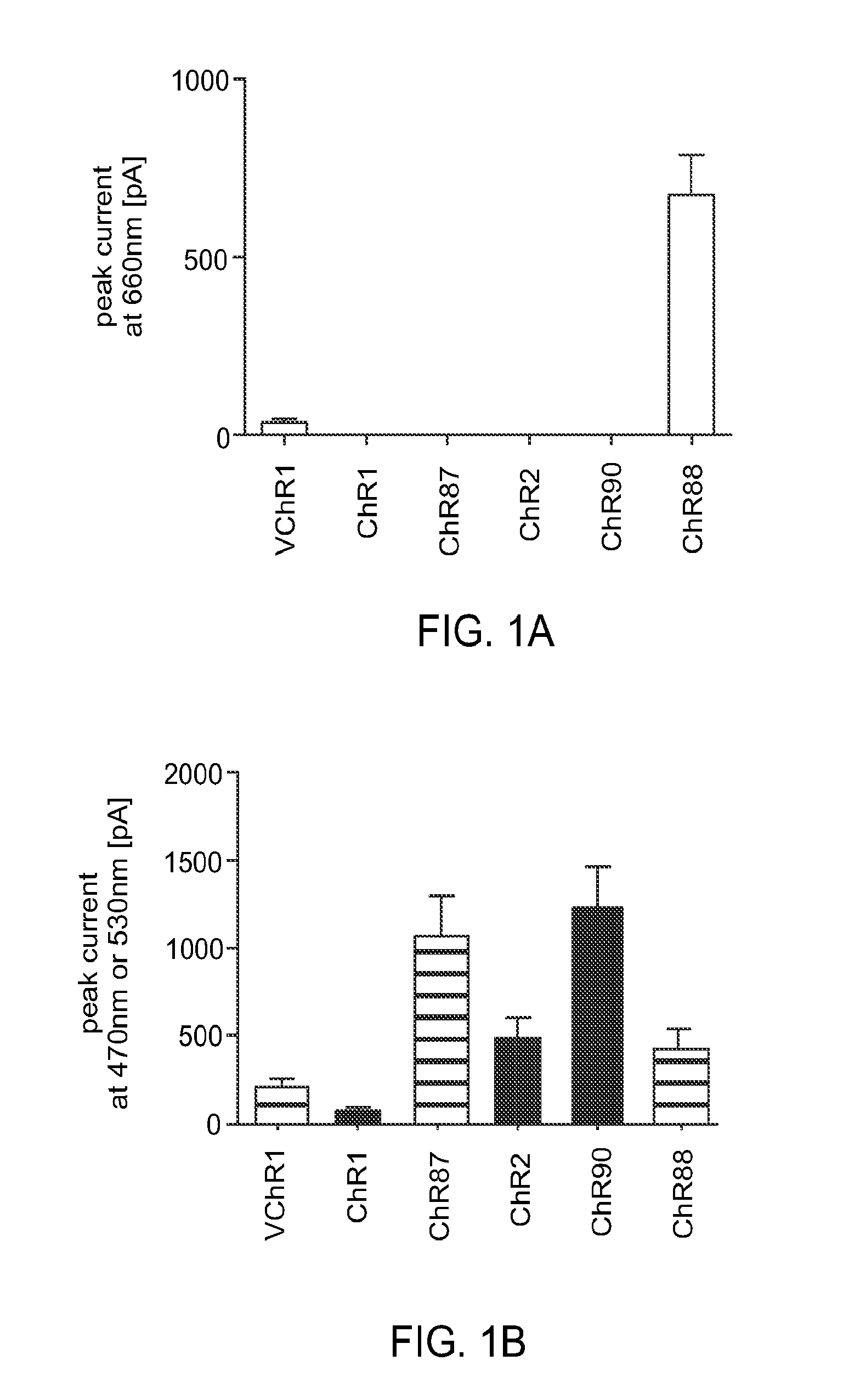

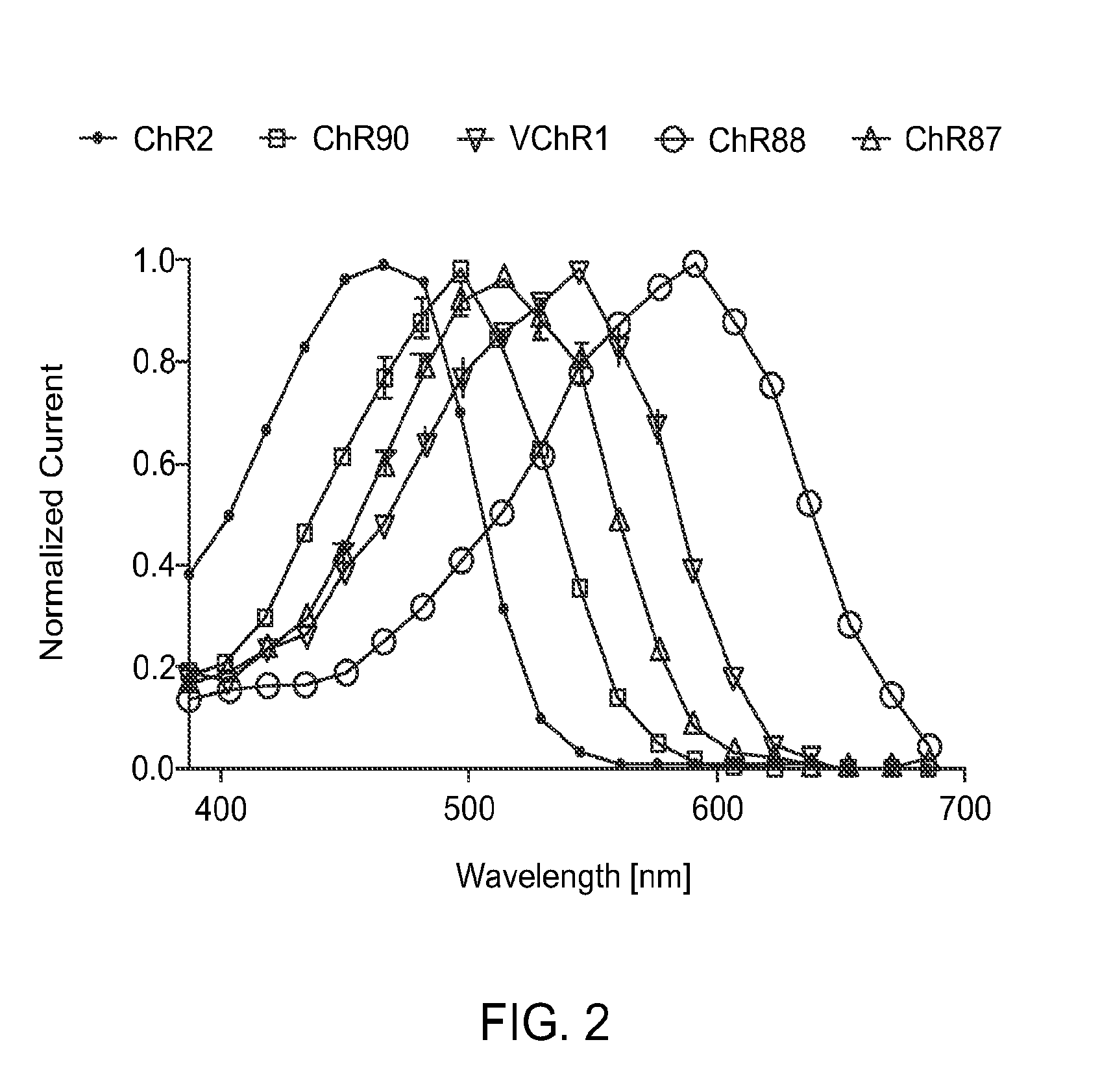

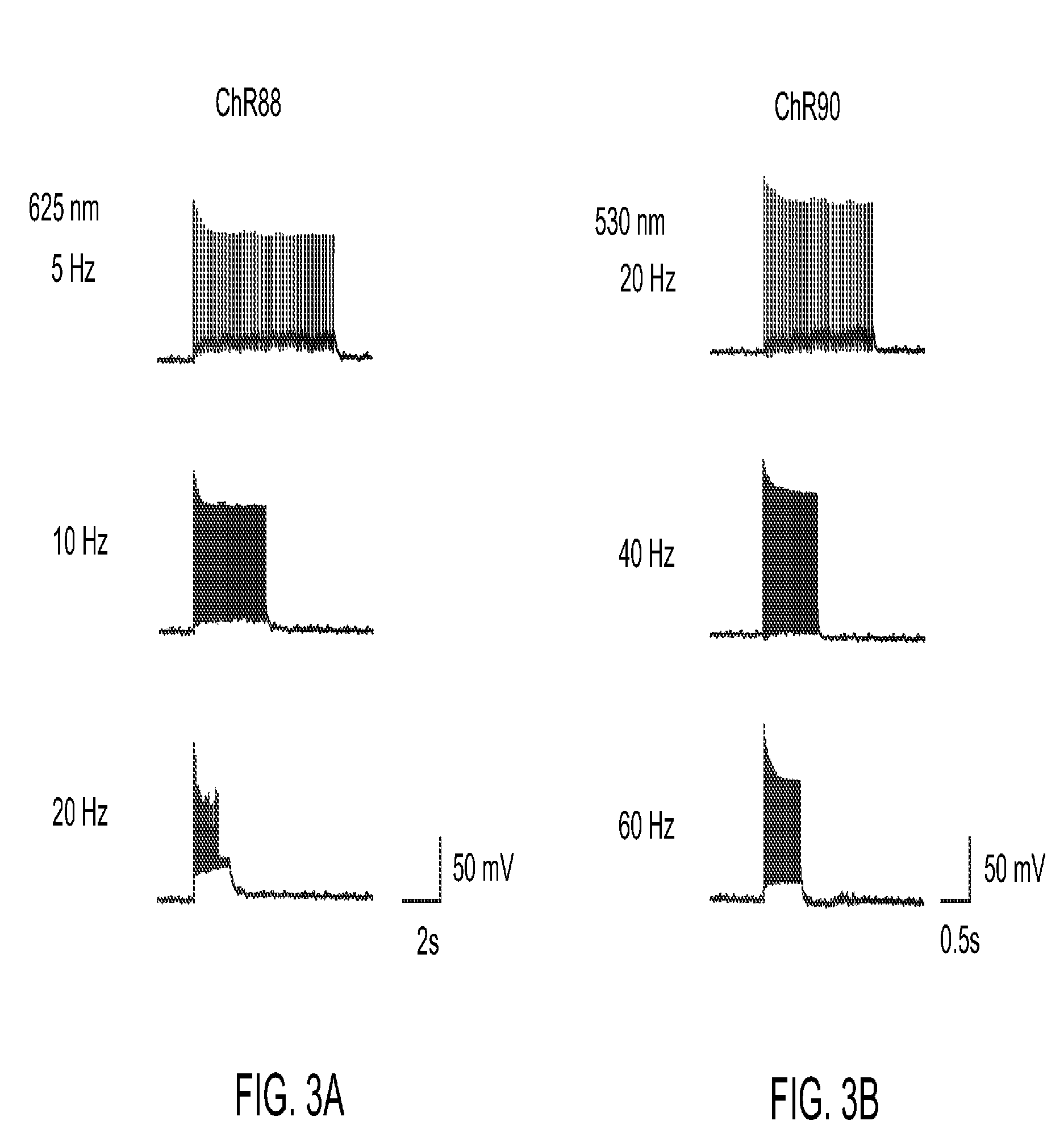

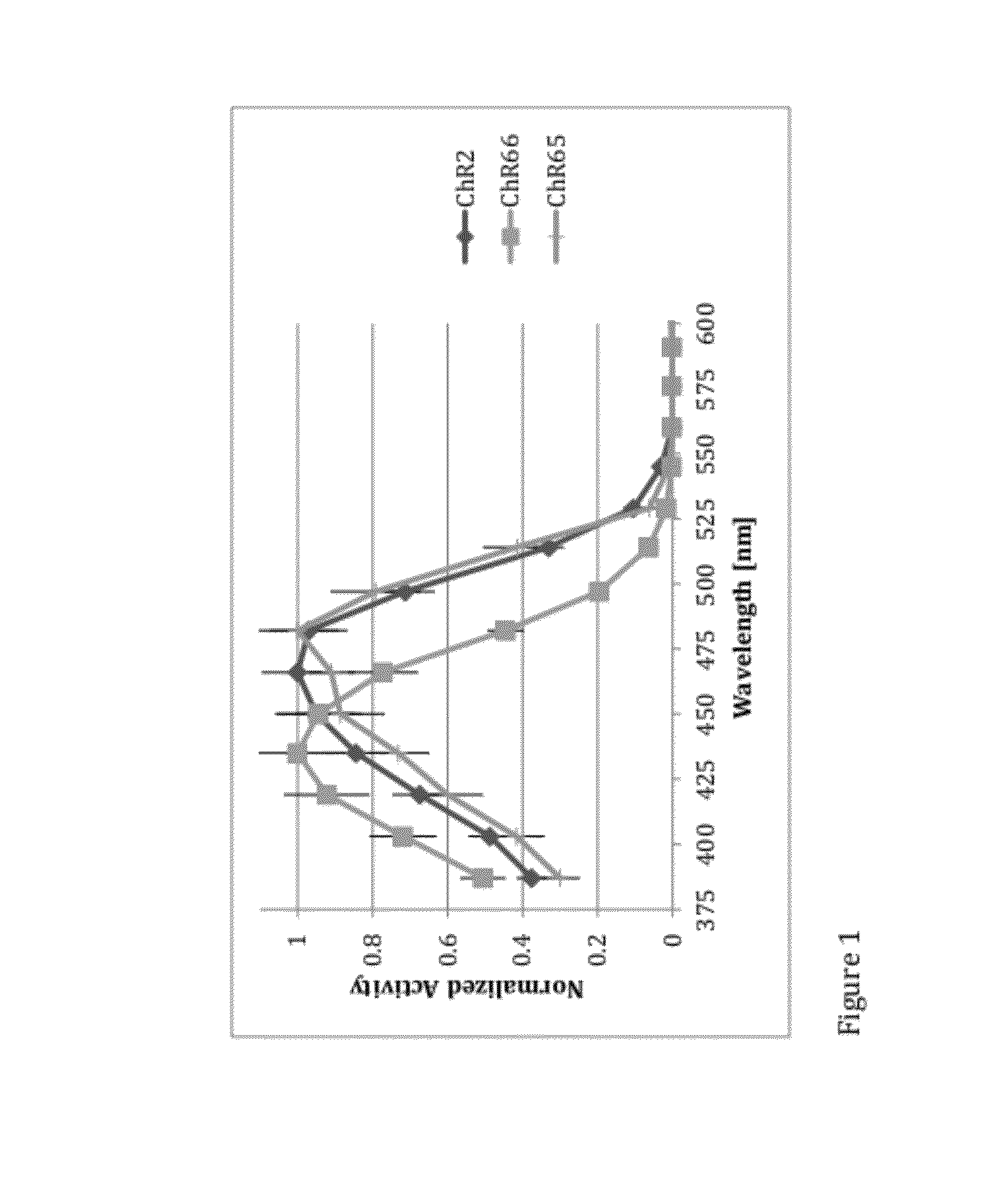

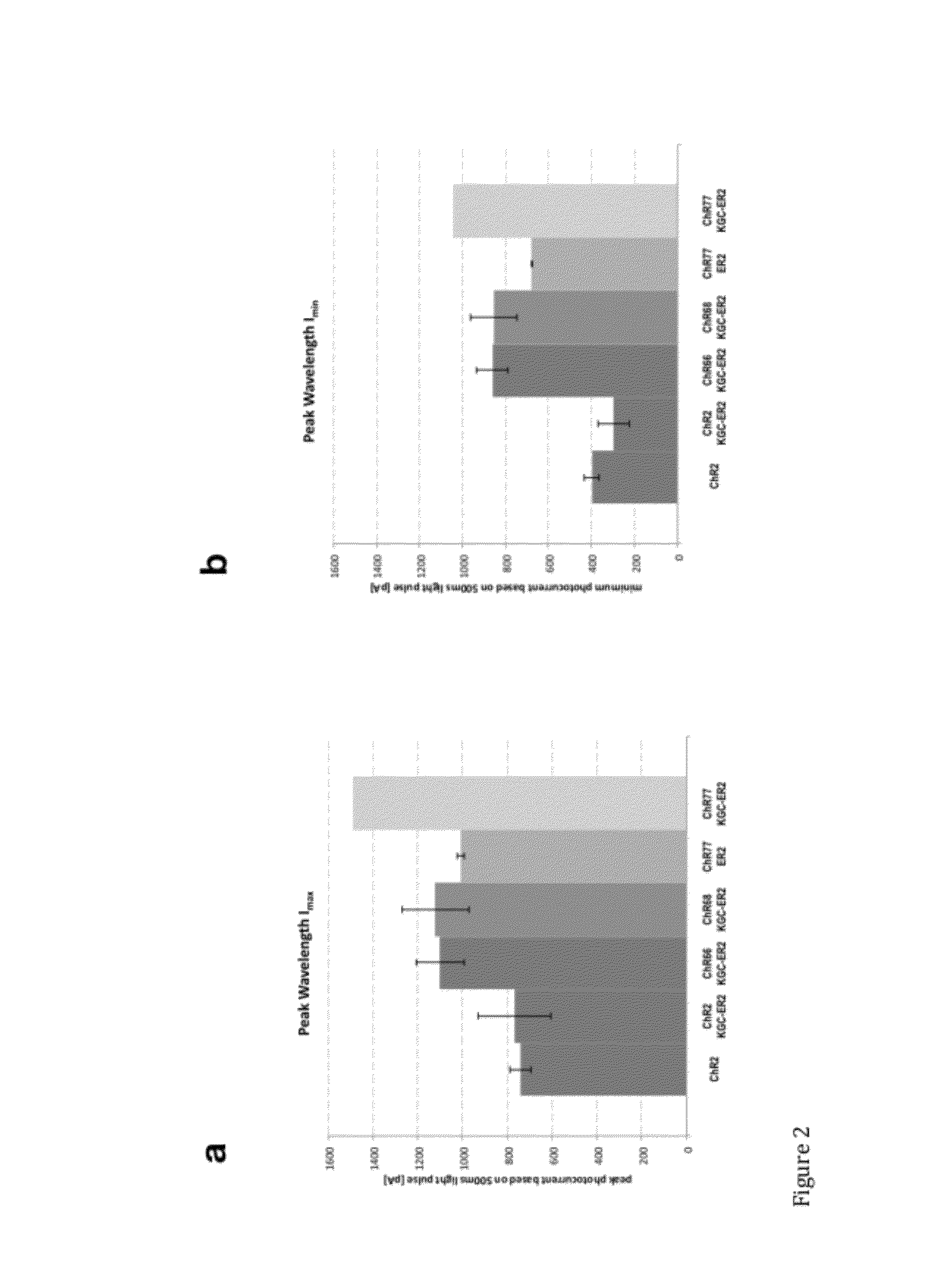

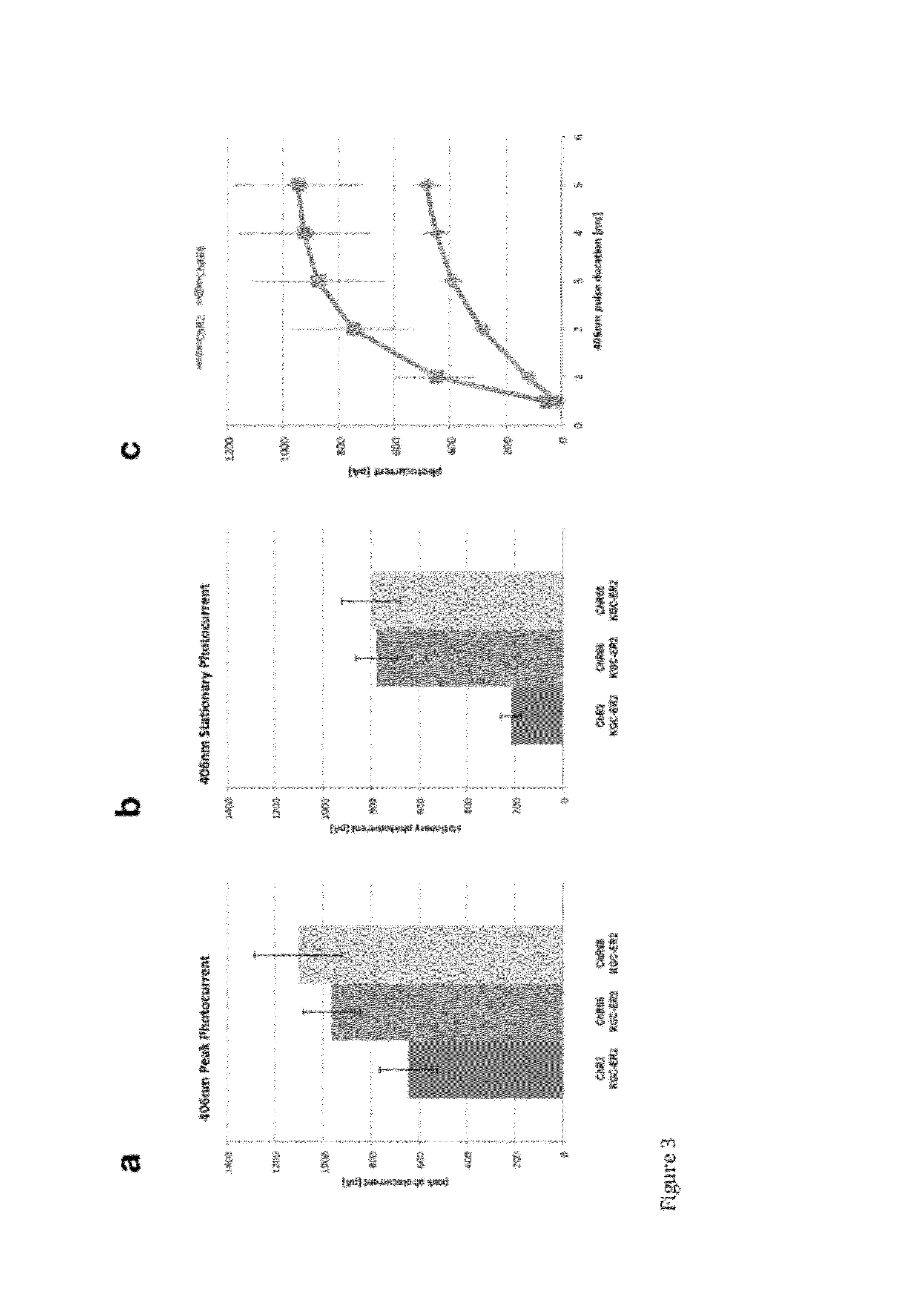

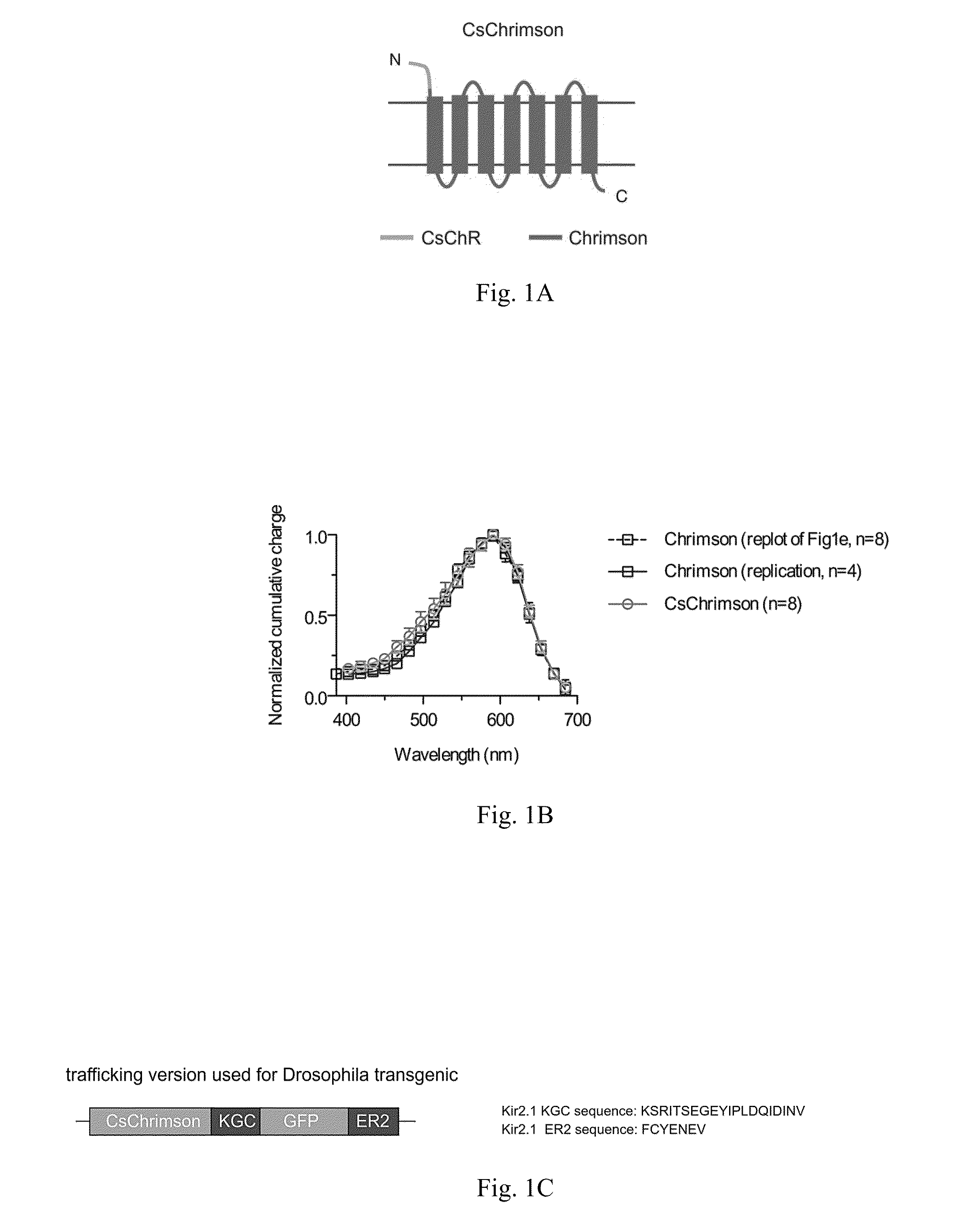

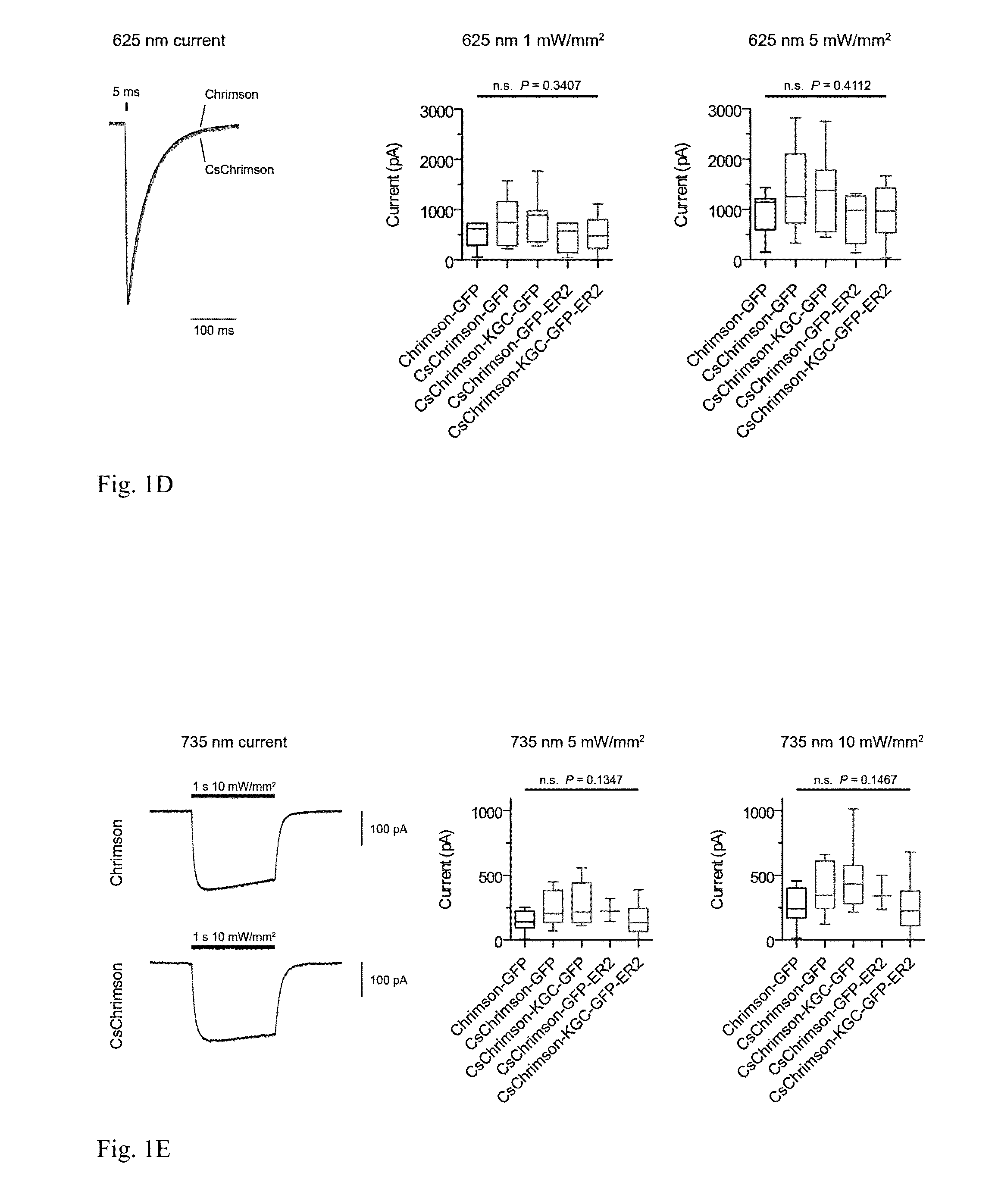

Channelrhodopsins for optical control of cells

ActiveUS20140324134A1Improve ionic conductivityDecrease in ion conductivityPeptide/protein ingredientsMicrobiological testing/measurementCell activityLight activated

Owner:THE GOVERNORS OF THE THE UNIV OF ALBERTA +1

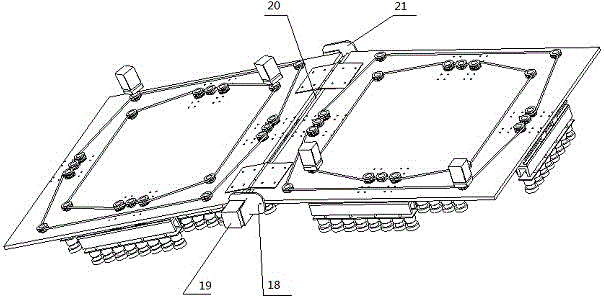

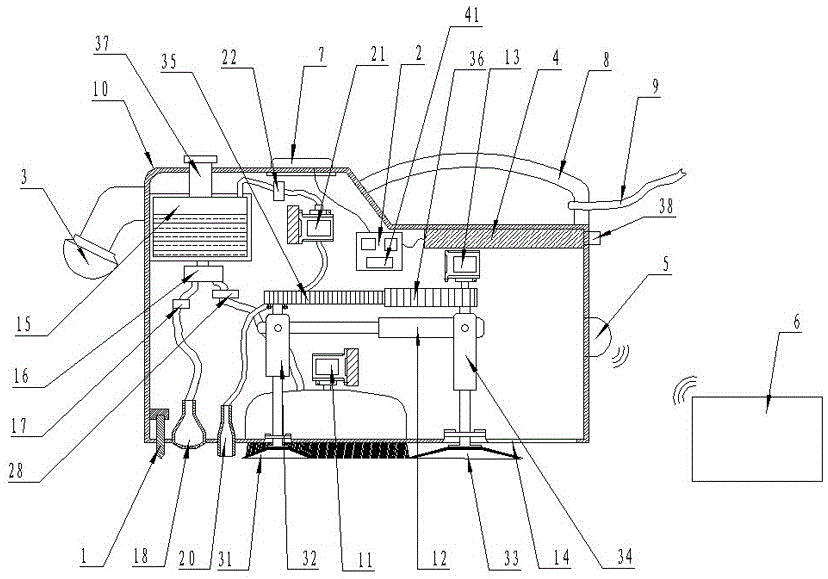

Hinge type wall climbing robot capable of working on metal wall

The invention discloses a hinge type wall climbing robot capable of working on a metal wall. The wall climbing robot comprises wall climbing robot units, hinges and a folding mechanism, wherein the wall climbing robot units are rotatably connected through the hinges, and the folding mechanism is mounted at the joint of the two wall climbing robot units. Due to the fact that linear guide rail mechanisms are mounted on each wall climbing robot unit in four directions, each wall climbing robot unit can walk in two freedom degrees; each linear guide rail is provided with a cylinder, and the cylinders stretch and retract to drive supporting plates to move up and down, so that each wall climbing robot unit has the obstacle crossing capacity; and two rows of electromagnets are adopted for attraction when each wall climbing robot unit walks, eight rows of electromagnets can be used for attraction when the robot works, and therefore the robot is reliable in attraction, safe in work and compact in attraction structure.

Owner:SHANGHAI UNIV

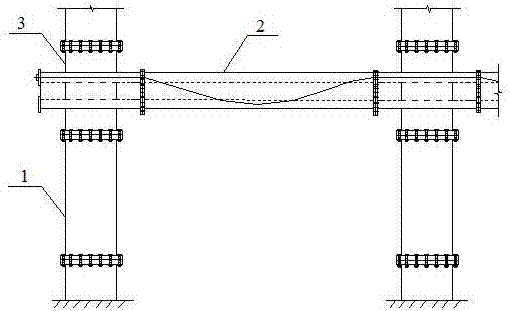

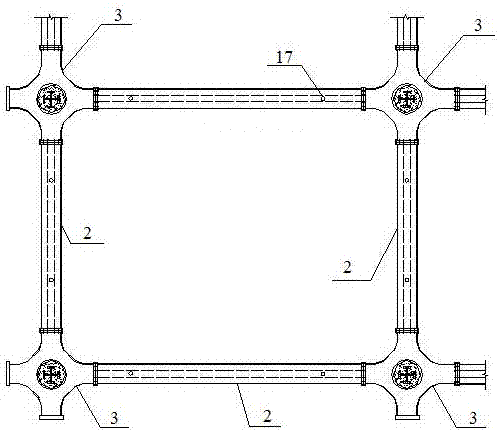

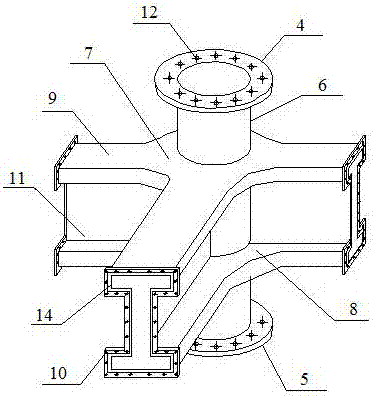

Steel pipe concrete frame with prestressing tendons and construction method thereof

ActiveCN106869315APower transmission is clearAccurate connectionLoad-supporting elementsCurve shapePre stress

The invention relates to a steel pipe concrete frame with prestressing tendons and a construction method thereof. The steel pipe concrete frame with the prestressing tendons is formed by connecting composite columns with composite beams through joints. The composite beams are horizontally arranged among the composite columns. The joints are outer sleeving integral type joints internally filled with self-compacting concrete. The composite columns are sectional-type steel pipe concrete composite columns with built-in profile steel. The composite beams are internal-prestress I-shaped steel pipe concrete composite beams. The prestressing tendons arranged in the composite beams bypass joint outer pipes from upper strengthening annular plates with cavities. The prestressing tendons are positioned through single-hole positioning plates and hole-formed double-hole main positioning plates, form symmetrical curve shapes and achieve tensioning and anchoring at joint end beams. The self-compacting fine stone concrete of the composite beams and self-compacting fine stone concrete of the joint end beams are through and form a whole with the joint outer pipes after curing. The problem that beam-column connecting joints of a novel steel pipe concrete frame with prestressing tendons are complex and liable to damage is solved.

Owner:广西万纵建设工程有限公司

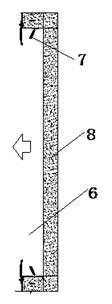

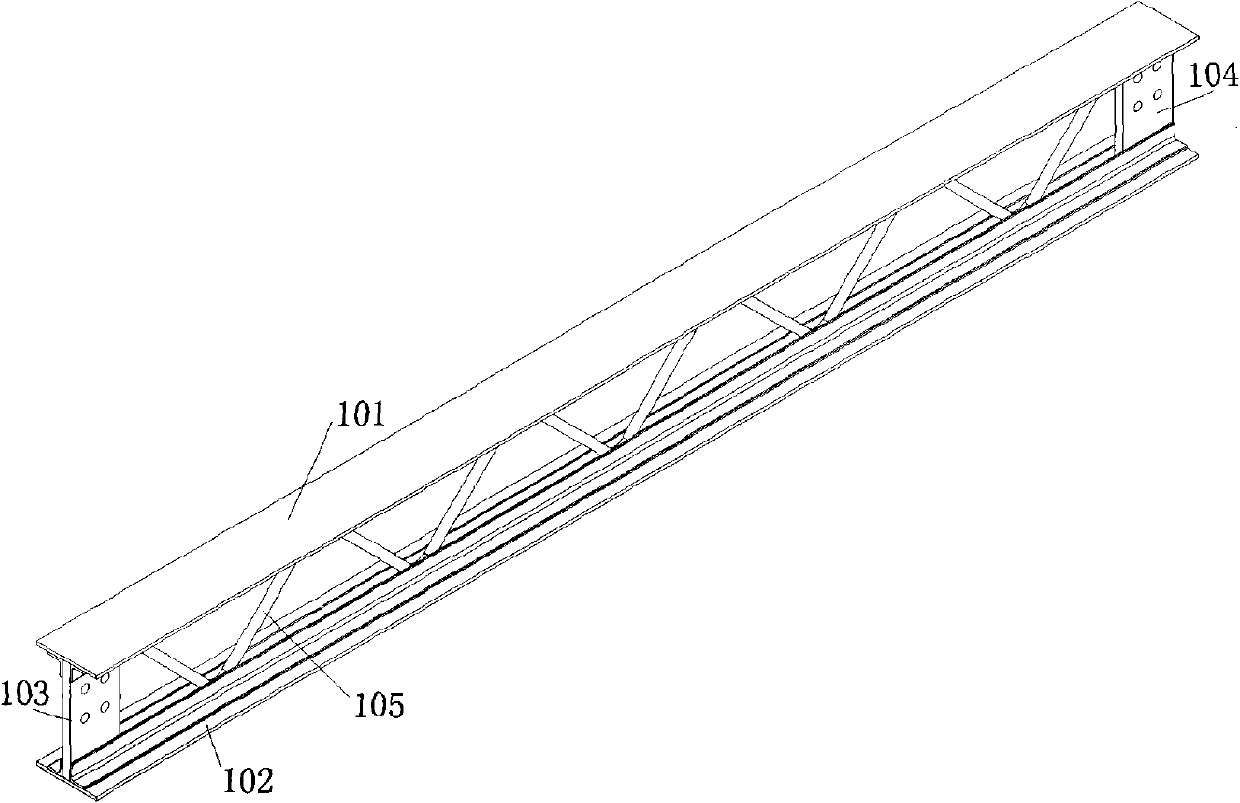

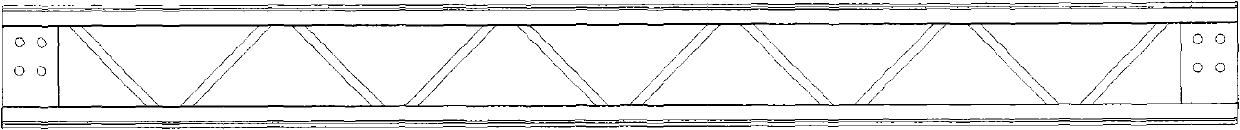

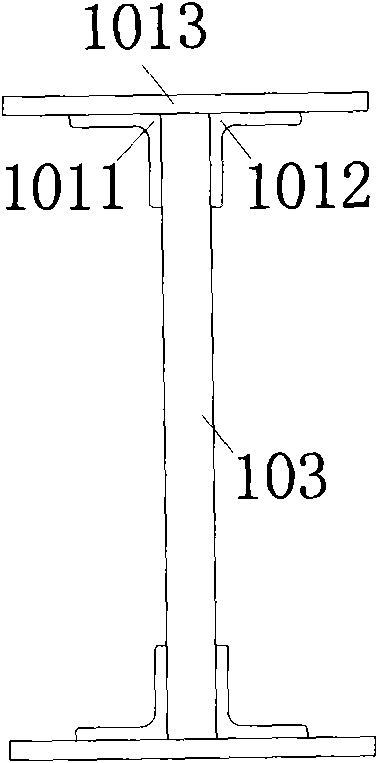

Hollow steel girder and steel framework system

The invention discloses a hollow steel girder, which comprises a top flange, a bottom flange, at least one row of web members and two end part gusset plates, wherein the end part gusset plates are arranged at two ends of the top flange and the bottom flange, and are respectively connected with the top flange and the bottom flange; and the web members have a truss structure, and are arranged between the top and bottom flanges and the end part gusset plates. Spaces facilitating the passing of pipelines are formed between the top and bottom flanges and the web members with the truss structure, advantages of the truss structure and a solid girder are comprehensively applied, the height of the steel girder is reduced to the utmost, and the effective using floor height of a building is enlarged as possible; and components of the hollow steel girder have good structural performance, and the hollow steel girder can meet requirement of civil and residential buildings on floor height, and has wide applicable range and good application prospect.

Owner:CE CENT FOR ENG RES TEST & APPRAISAL

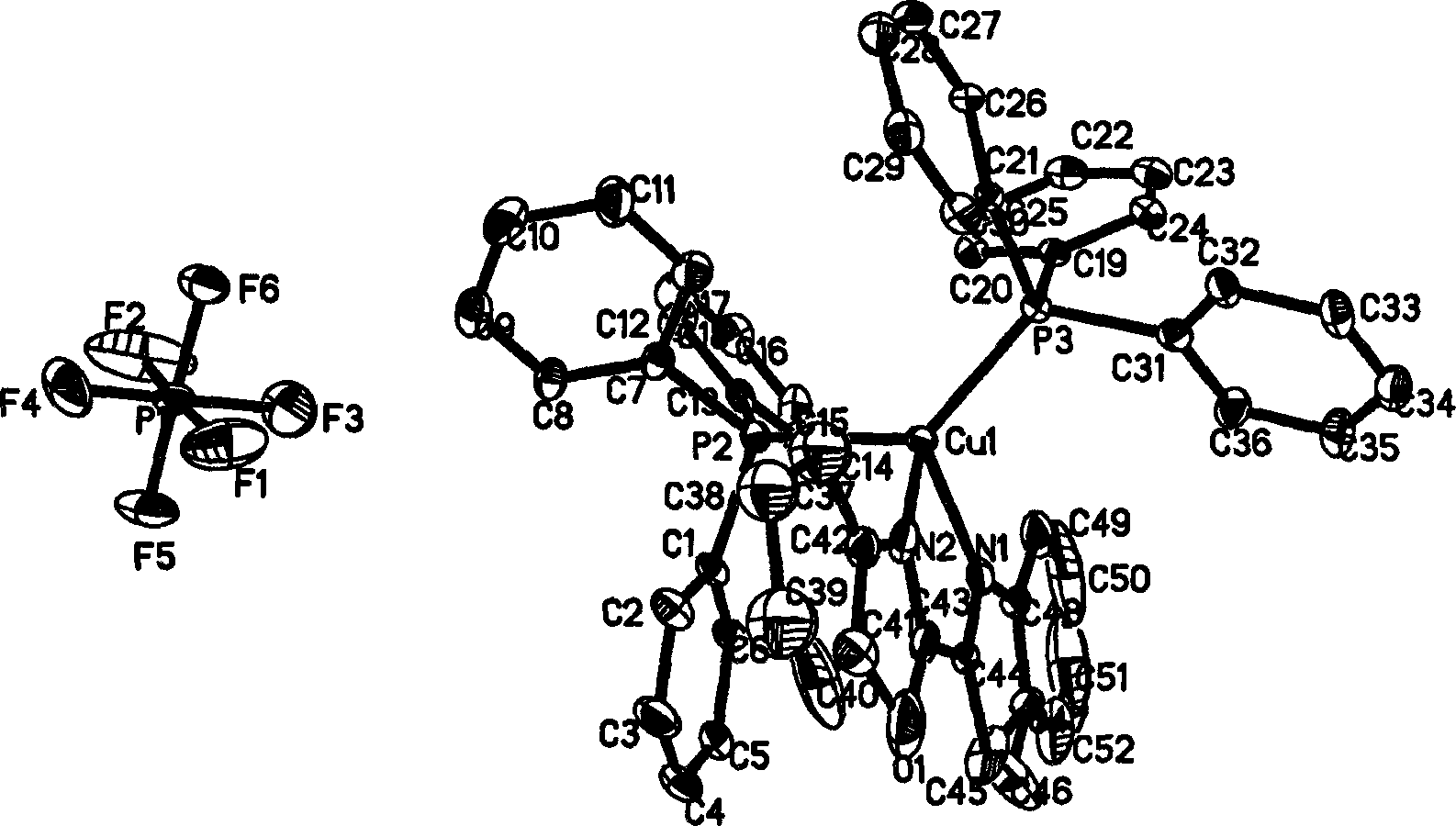

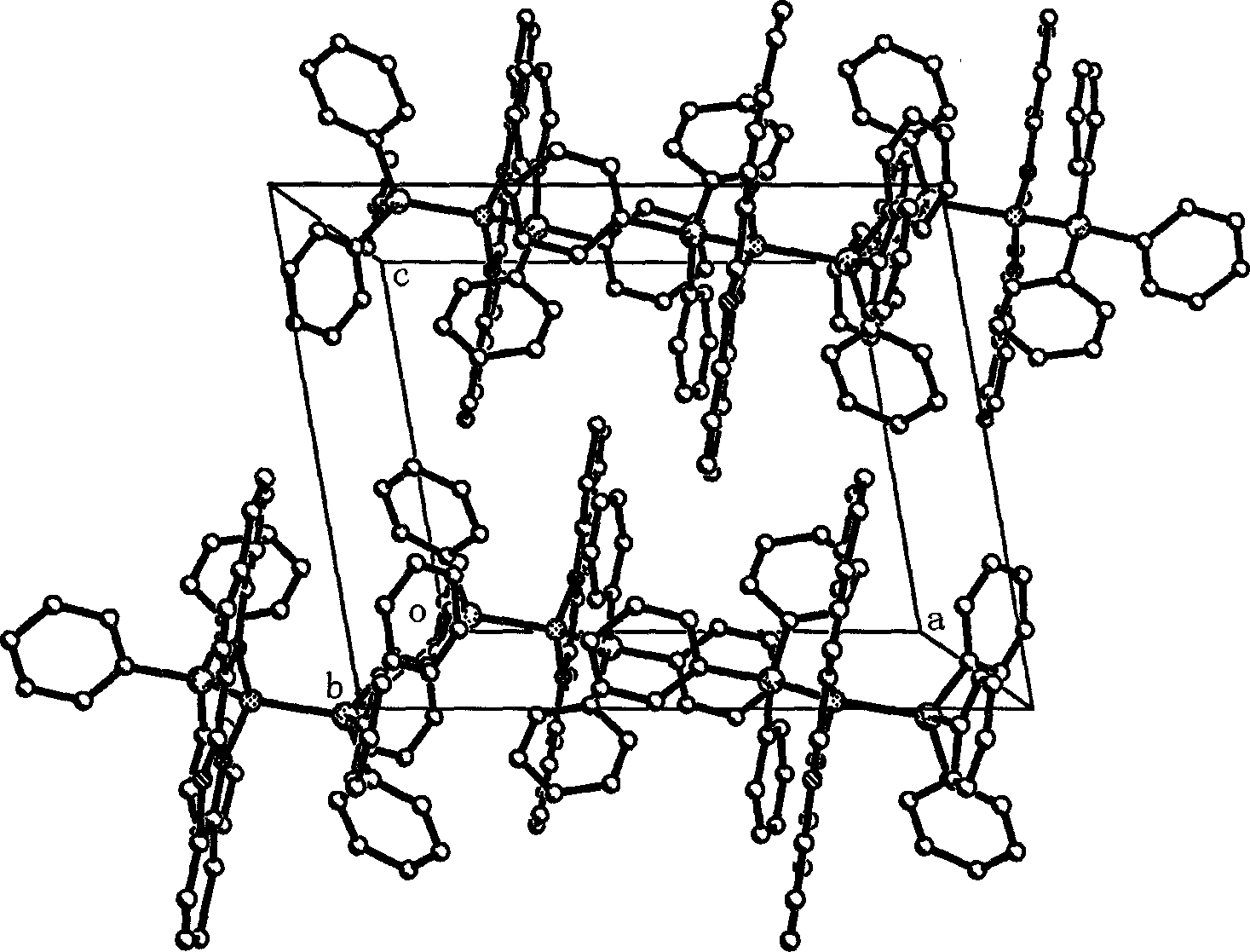

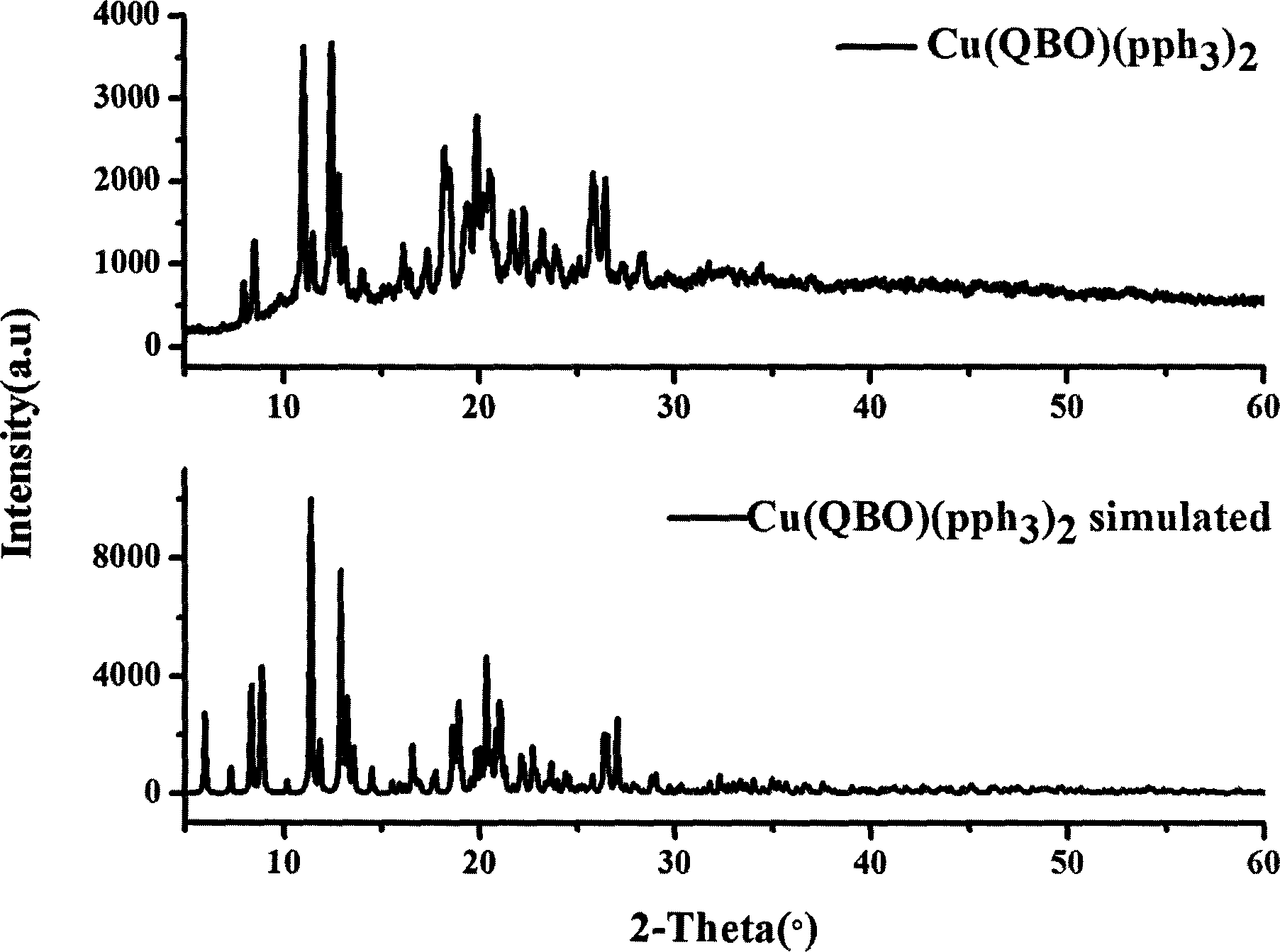

Benzoxazolylquinoline ligand-based cuprous complex luminescent material

InactiveCN103833777AGood phosphorescent emission performanceSuppression of nonradiative transitionsGroup 5/15 element organic compoundsCopper organic compoundsBenzoxazoleQuinoline

The invention discloses a cuprous complex luminescent material capable of emitting orange-yellow phosphorescent light and a preparation method thereof. The phosphorescent complex of the luminescent material is obtained by carrying out complexing on a monovalent copper salt with a ligand; the molecular structure of the phosphorescent complex is [Cu(QBO)(PPh3)2]PF6, and in the formula, PPh3 and QBO are electrically neutral ligands triphenylphosphine and 2-(2-benzoxazole) quinoline. The complex has the advantages of easy micromolecular purification and high luminous efficiency, and also high thermal stability. The material is obtained by directly mixing and reacting Cu(CH3CN)4PF6 with a dichloromethane solution of the ligands, and has the advantages of simple and convenient process, simple equipment, easily available raw materials, low cost and the like. The material can be taken as a photoluminescent orange-yellow-light material and also can be used as a luminescent layer phosphorescent material in an electroluminescent device composed of a plurality of layers of organic materials.

Owner:CHINA JILIANG UNIV

Multi-moving-mode bionic moving robot

ActiveCN102849140ASmooth motionThe way of movement is to move quickly and stablyVehiclesVideo monitoringControl system

The invention discloses a multi-moving-mode bionic moving robot, which is characterized by consisting of a machine body platform, six machine legs in the same structures, a video monitoring system based on 3G (3rd generation) network and a double-rocker-rod remote operation and control system based on remote operation, wherein the machine legs comprise four joint parts and one wheel part, each joint part is driven by a large-torque steering engine with the rotating angle being 180 degrees, one steering engine is in charge of driving one joint, the wheel parts are driven by large-toque steering engines with the rotating angle being 360 degrees, and the whole circle rotation can be realized. The two ends of the steering machine rotating center shaft are respectively fixed by bearings, the six machine legs are symmetrically arranged at two sides of the robot machine body platform for forming a bionic mechanism, a connecting rod arranged at the lower end of the machine legs adopts a right-angle reverse L-shaped deign, one end of the connecting rod is connected with the machine body, the other end of the connecting rod is in contact with the ground, the video monitoring system mainly comprises a sending end and a receiving end, and the remote operation and control system carries out operation and control by aiming at the six machine legs, and mainly comprises a sending end and a receiving end.

Owner:彼合彼方机器人(天津)有限公司

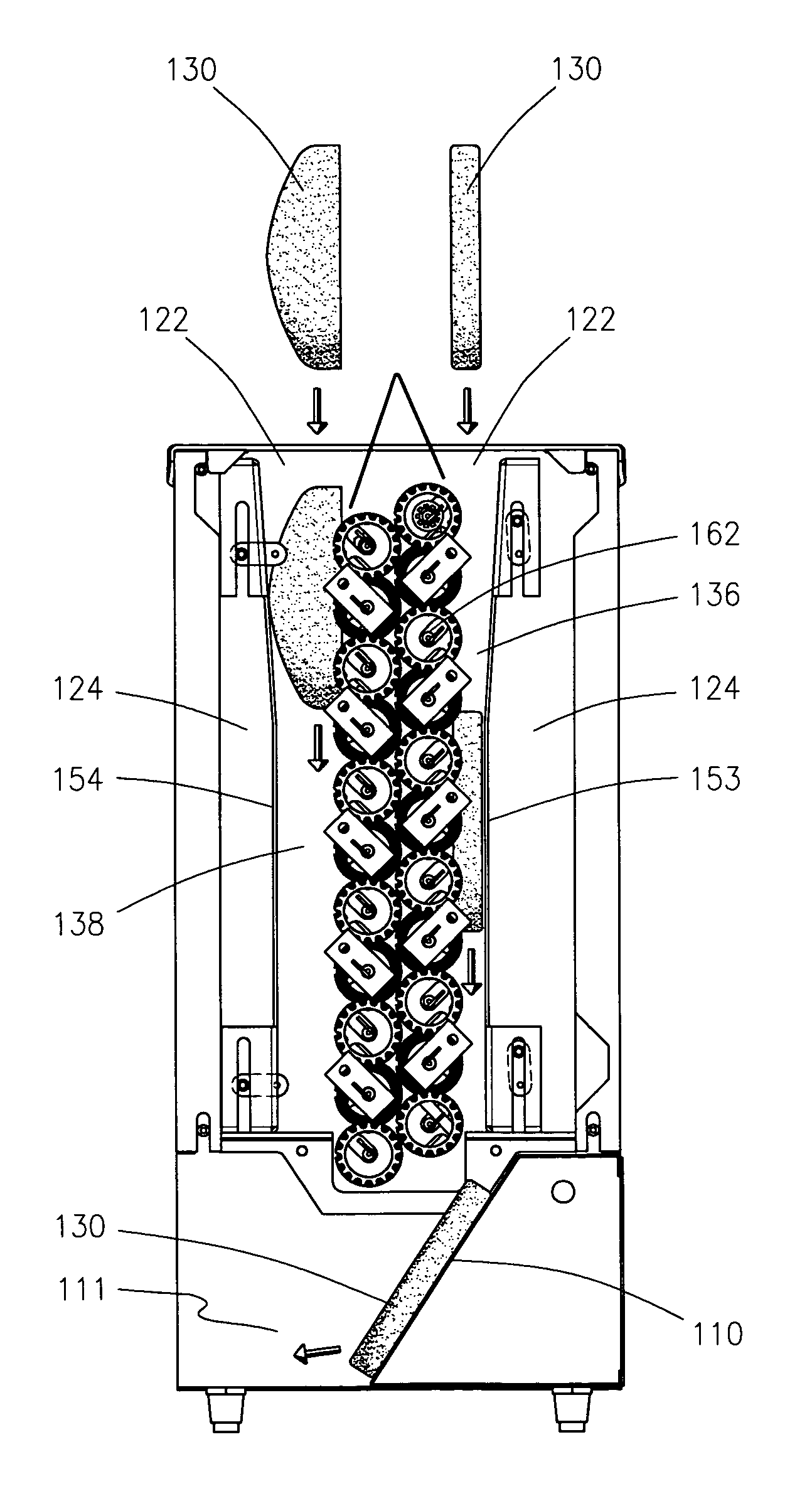

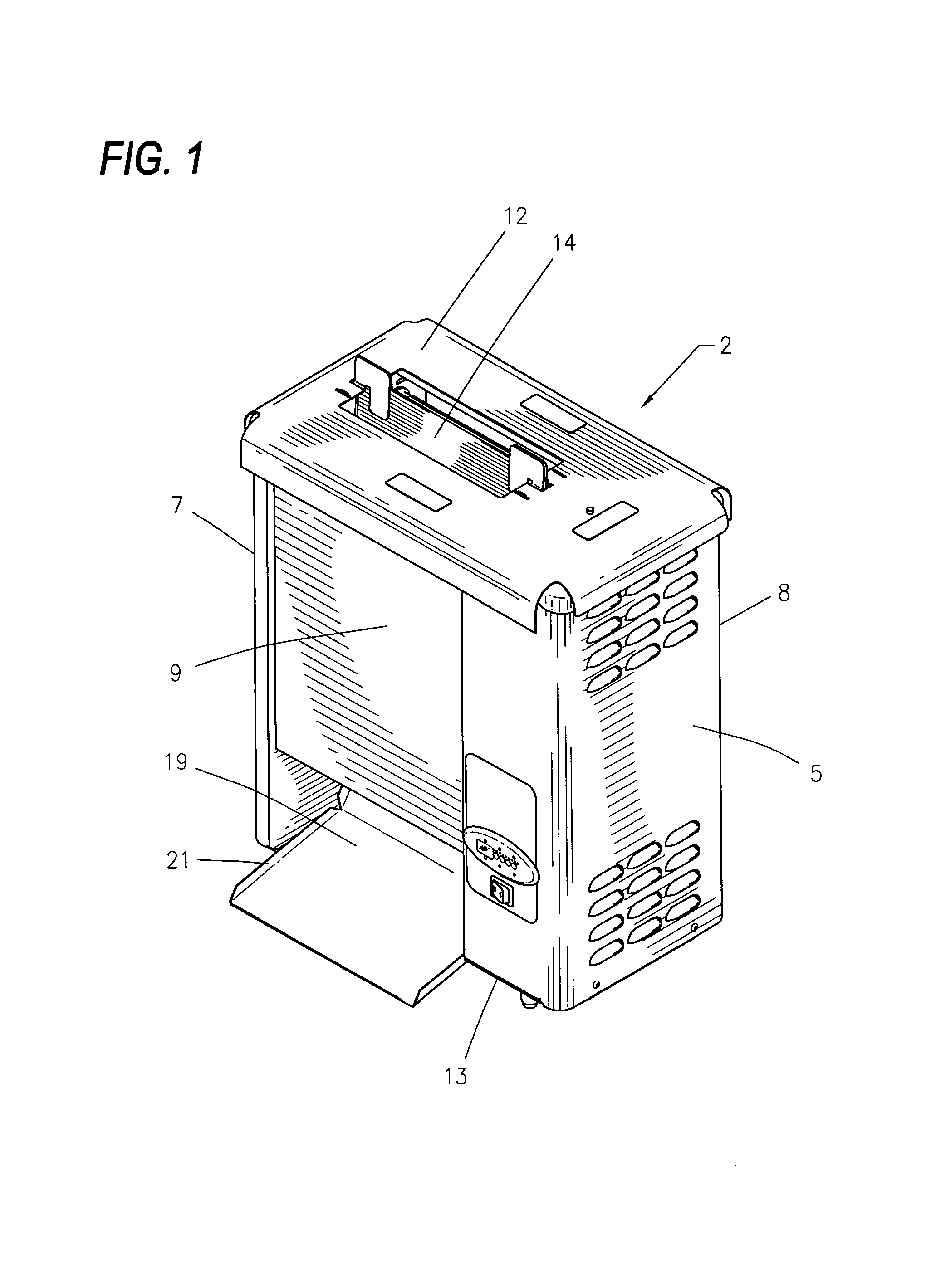

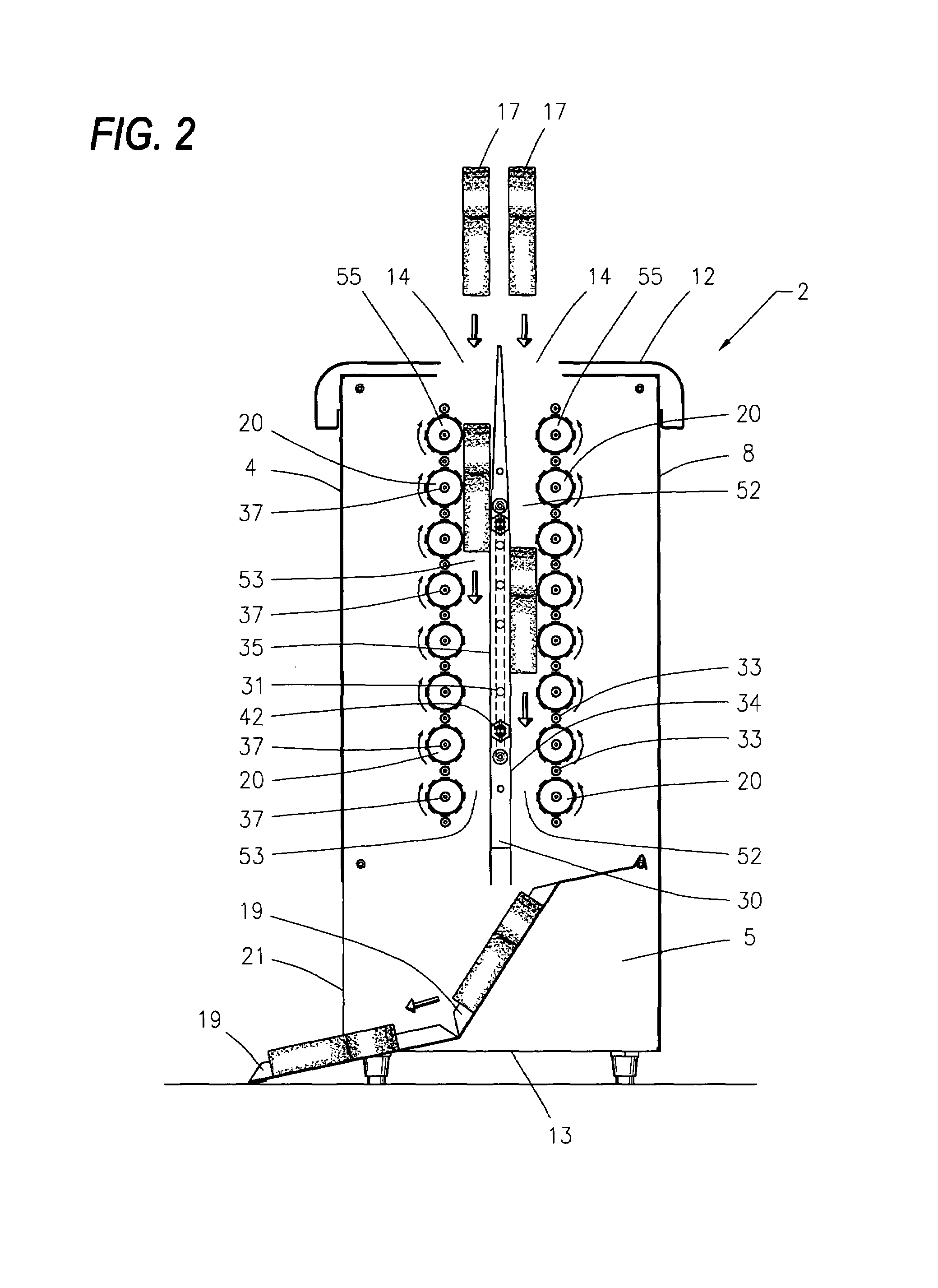

Apparatus and method for a chain motivated toaster with vertically aligned rollers

InactiveUS7285755B1Easy to crossOhmic-resistance heating detailsFurnace typesSprocketInternal heating

A vertically oriented roller oven have an oven housing forming an oven cavity, one or more food product inlet openings, an internal heating portion distinguishably separated by first and second series of centrally disposed vertically aligned and axially displaced rollers and an exit opening each in communication with the oven cavity. First and second backing plates are respectfully positioned opposite each of said first and second series of centrally disposed vertically aligned and axially displaced rollers to frictionally engage and capture a food product and causing the food product to descendingly traverse the internal portion of the oven cavity between the plurality of vertically aligned and axially displaced rollers and correspondingly positioned first and second backing plates. A conveying means is disclosed which includes a continuously linked chain motivated by an electric motor connected to a sprocket mountably affixed to a roller seating bracket and an engagement gear located on an end of at least one vertically aligned and axially displaced roller within said first or second roller series.

Owner:AMERICAN PERMANENT WARE CORP

Light-activated ion channel molecules and uses thereof

InactiveUS20120214188A1Easy to crossFermentationVector-based foreign material introductionCell activityLight activated

Owner:MASSACHUSETTS INST OF TECH +1

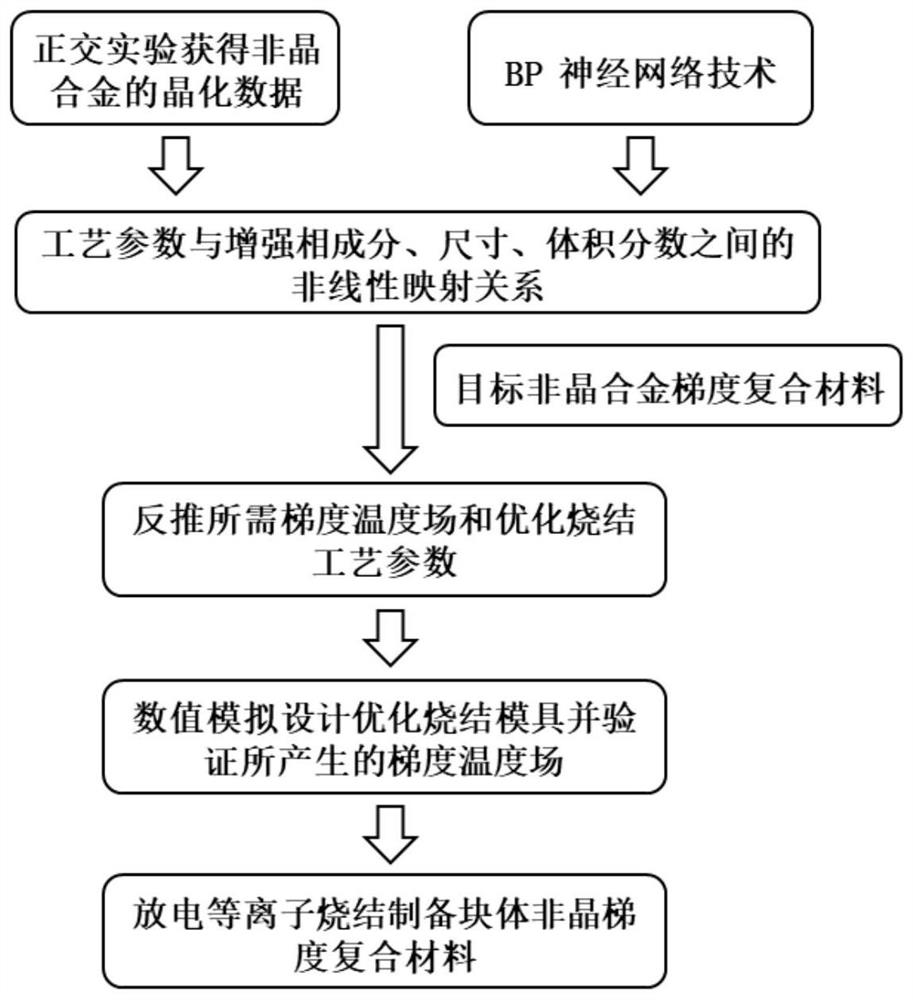

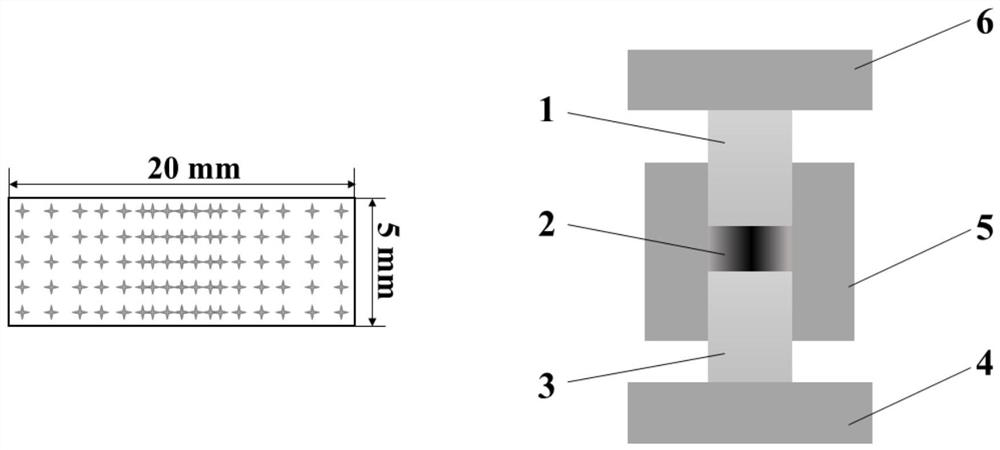

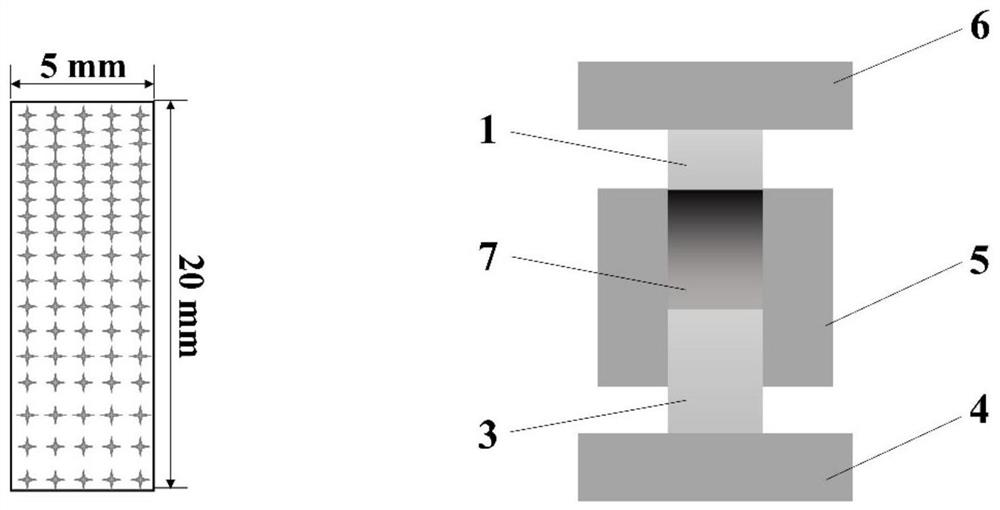

Preparation method of amorphous alloy gradient composite material

ActiveCN112935251AEasy to manufactureSimple processImage analysisChemical processes analysis/designNerve networkIsothermal crystallization

The invention belongs to the field of amorphous alloy composite material preparation, and particularly relates to a preparation method of an amorphous alloy gradient composite material. According to the preparation method of the amorphous alloy gradient composite material, an isothermal crystallization rule of an amorphous alloy matrix is obtained through an experiment, and a nonlinear mapping relation between sintering process parameters and reinforcement phase characteristic parameters is established through a neural network; a required temperature field is reversely deduced by combining reinforcement phase distribution characteristics of a target amorphous alloy gradient composite material, and then a sintering mold is designed by taking amorphous alloy powder or a block as a raw material and adopting a spark plasma sintering technology and combining numerical simulation, and spark plasma sintering treatment is carried out on the amorphous alloy powder under the required sintering process parameters and temperature field to obtain the amorphous alloy gradient composite material with continuous gradient distribution of the reinforced phase. According to the preparation method of the amorphous alloy gradient composite material, flexible design and preparation forming of the large-size bulk amorphous alloy gradient composite material can be achieved, the process is simple and efficient, a reinforced phase is obtained in an in-situ endogenous mode, and the interface bonding state is good.

Owner:HUAZHONG UNIV OF SCI & TECH

Cylindrical cuspend magnetic field thruster

InactiveCN104595139ALight in massChanging the magnetic field configurationMachines/enginesUsing plasmaEngineeringDistributor

The invention relates to a cylindrical cuspend magnetic field thruster, and relates to a cuspend magnetic field thruster, which aims at solving the problem of overlong thruster ceramic passage caused by the smaller radial size of the existing ionizing area. An air guide device is arranged on a working medium spraying hole, a conducting bolt is arranged in the other working medium spraying hole in a penetrating way, two ceramic gaskets sleeve the conductive bolt and are fixed by a nut, an annular anode is fixedly arranged in the middle part of the inside wall of a cylindrical ceramic channel body, an air distributor is arranged in the cylindrical ceramic channel body, a second aluminum alloy end cover, a magnet, a plurality of second magnetic pieces, a first magnetic piece, a coil, a magnetic piece base, a first aluminum alloy bracket and a bracket plate sequentially sleeve the outside wall of the cylindrical ceramic channel body from right to left, the magnet bracket sleeves the magnet, the coil bracket sleeves the coil, the outer aluminum alloy sleeve sleeves the first magnetic piece, the second magnetic pieces and the magnet bracket, and the aluminum alloy bracket sleeves the outer wall of the cylindrical ceramic channel body. The cylindrical cuspend magnetic field thruster is applied to the field of aerospace.

Owner:HARBIN INST OF TECH

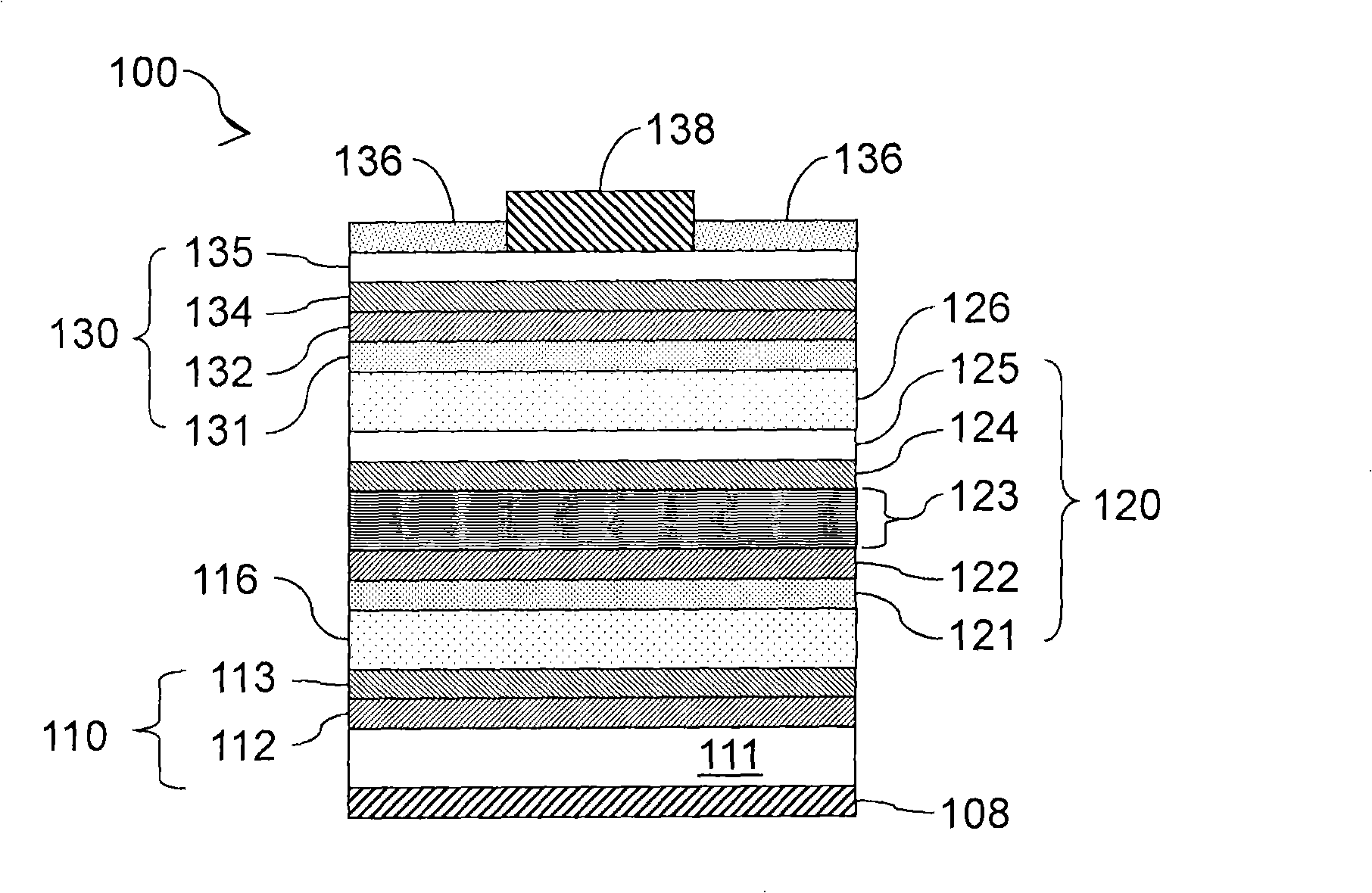

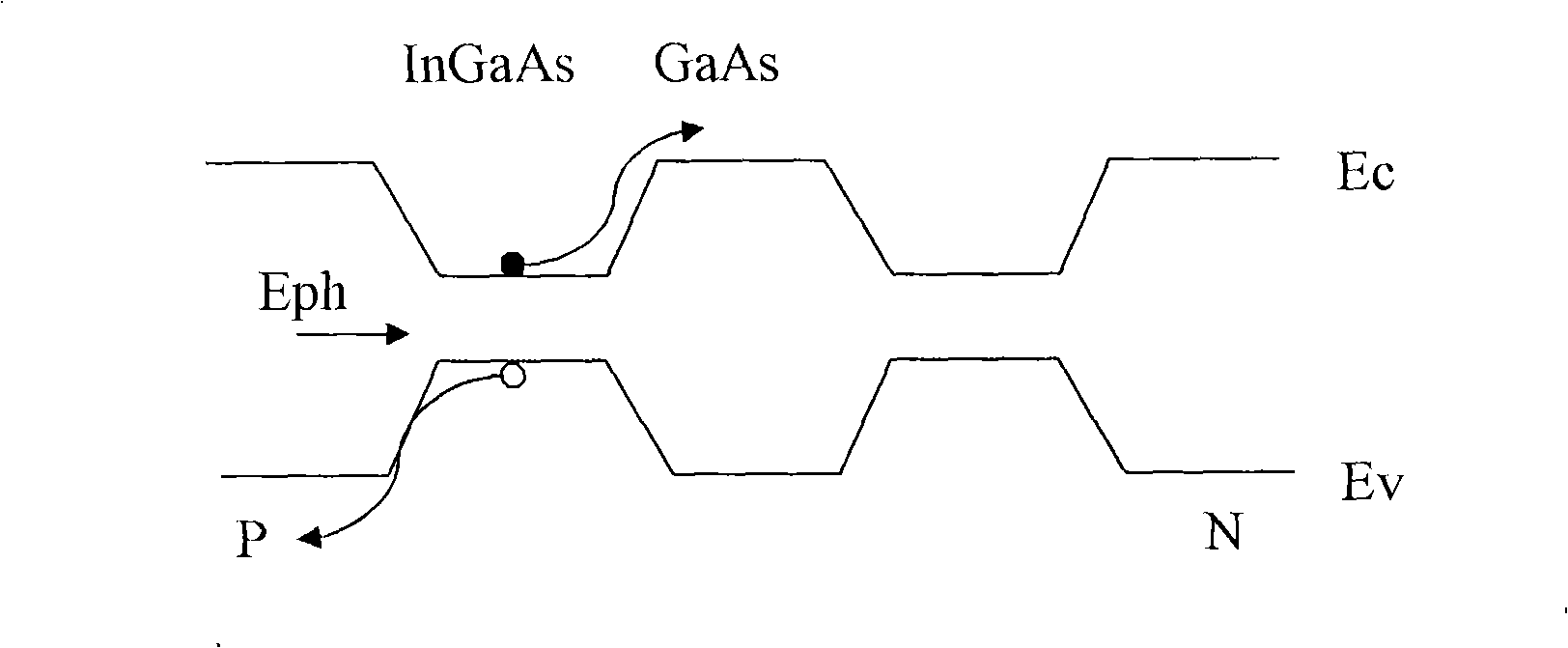

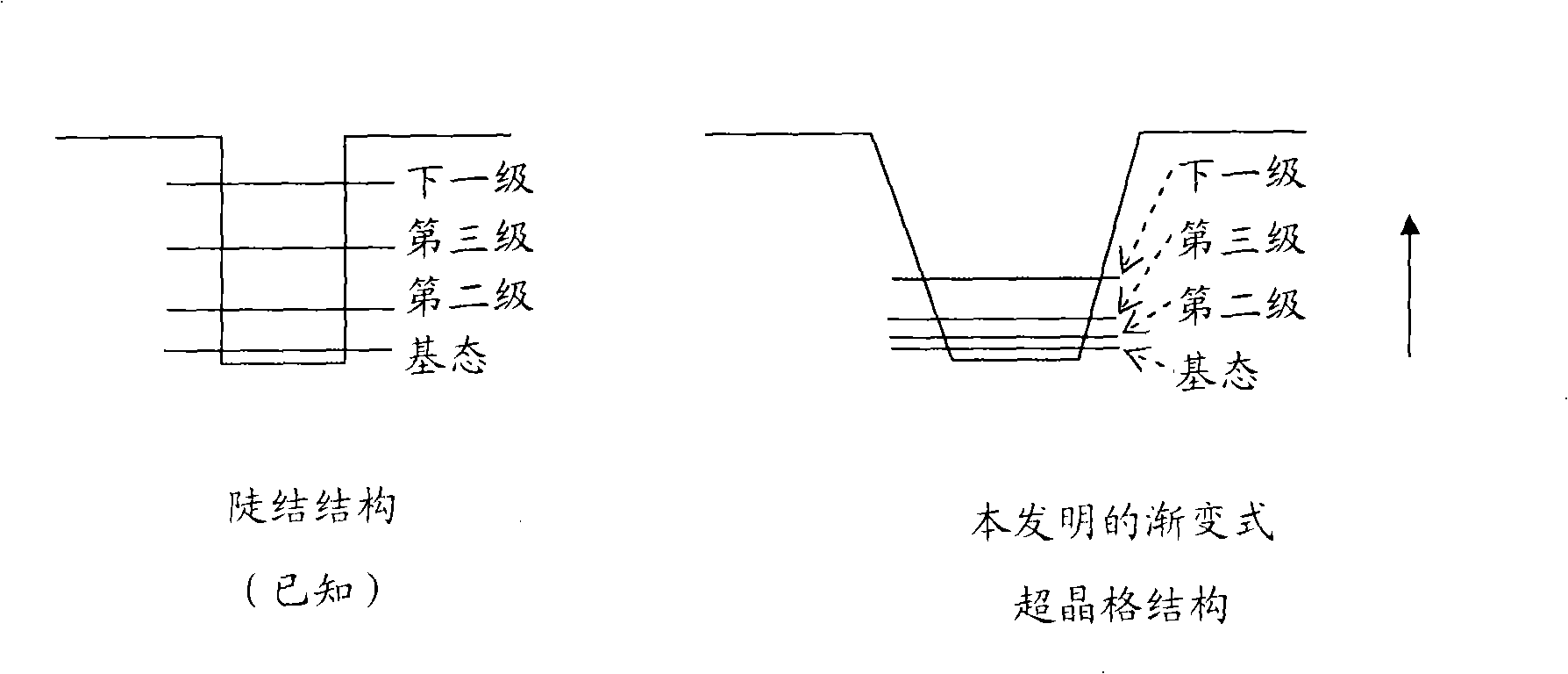

Solar cell with morphing type superlattice structure

InactiveCN101304051AImprove efficiencyReduced series resistancePhotovoltaic energy generationSemiconductor devicesFrequency spectrumSolar cell

The invention discloses a solar cell which consists of a plurality of stack 'pn' knot structures and a plurality of tunnel-through junction layers, wherein the tunnel-through junction layers are positioned between the stack 'pn' knot structures; moreover, one of the stack 'pin' knot structures comprises at least one p-typed semiconductor layer, one n-typed semiconductor layer, and one gradient superlattice structure positioned between the p-typed and the n-typed semiconductor layers. An energy gap of the gradient superlattice structure is between the energy gap of indium gallium phosphide (InGap) and the energy gap of gallium arsenide (GaAs). Therefore, a wavelength response range can be improved up to 1.0ev to add the wavelength response frequency spectrum; besides, owing to the gradient superlattice structure, a voltage barrier come up against by a current carrier in the area is relatively small and is easy to be stepped over, thus adding efficiency.

Owner:IND TECH RES INST

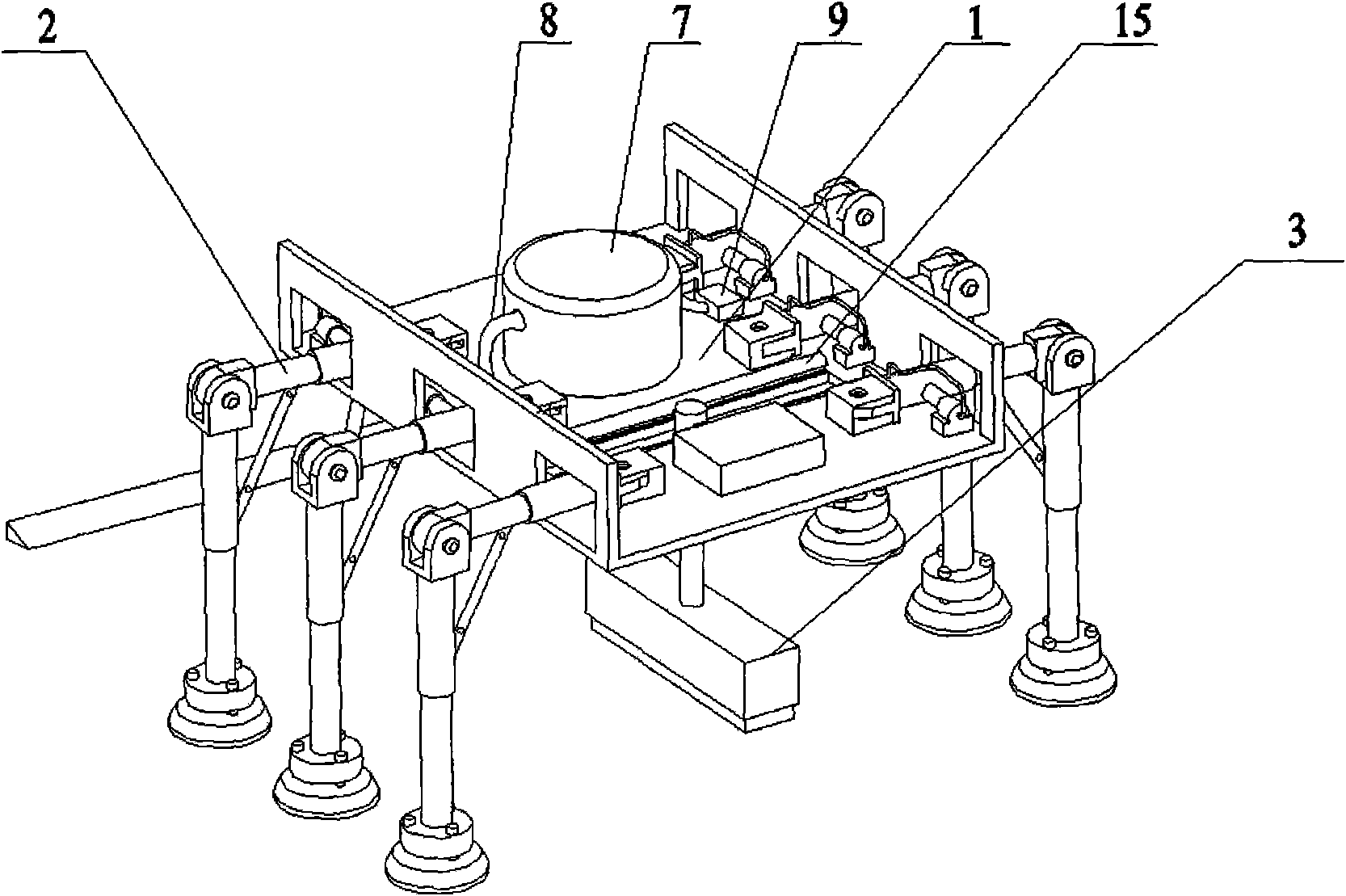

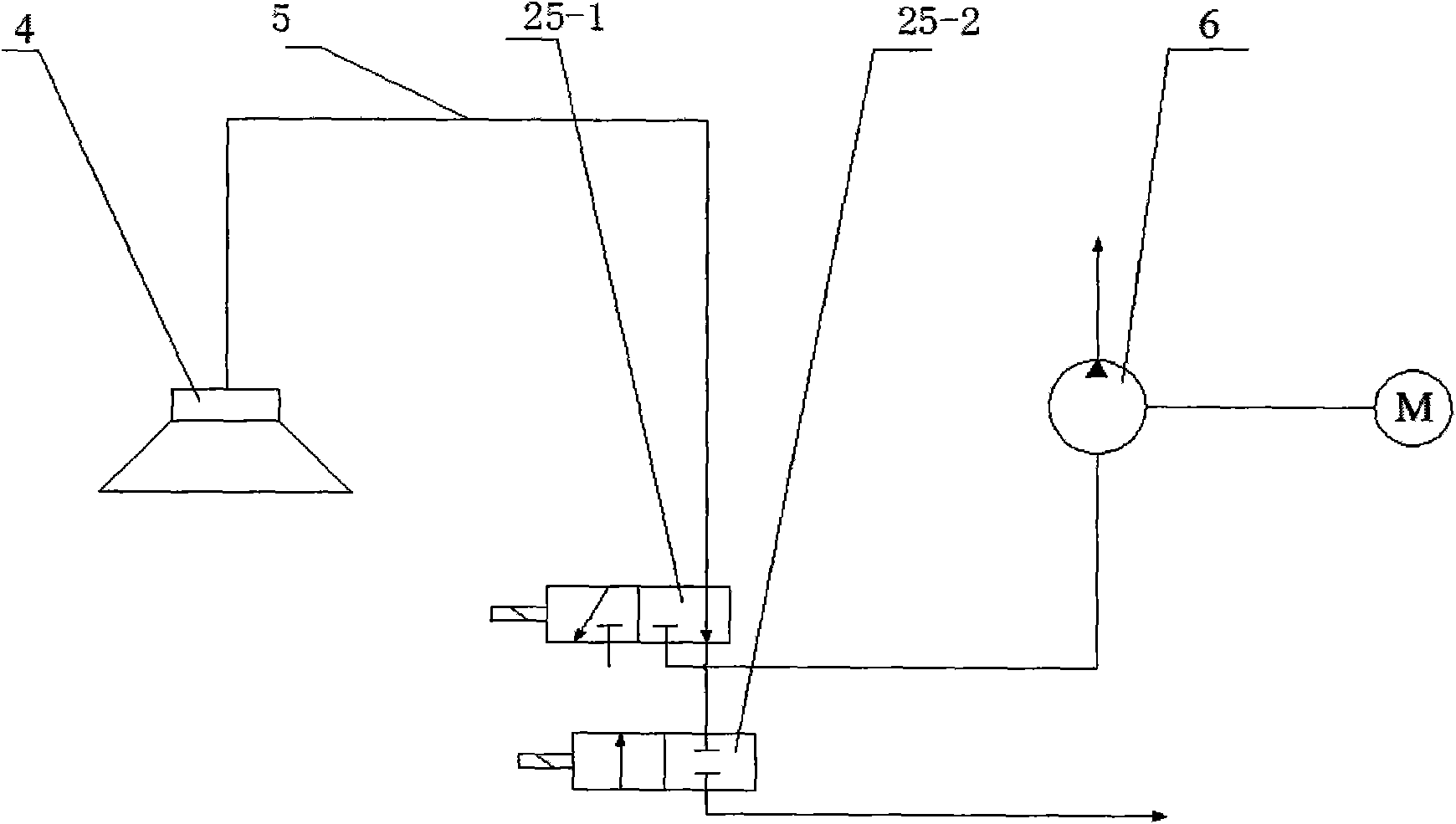

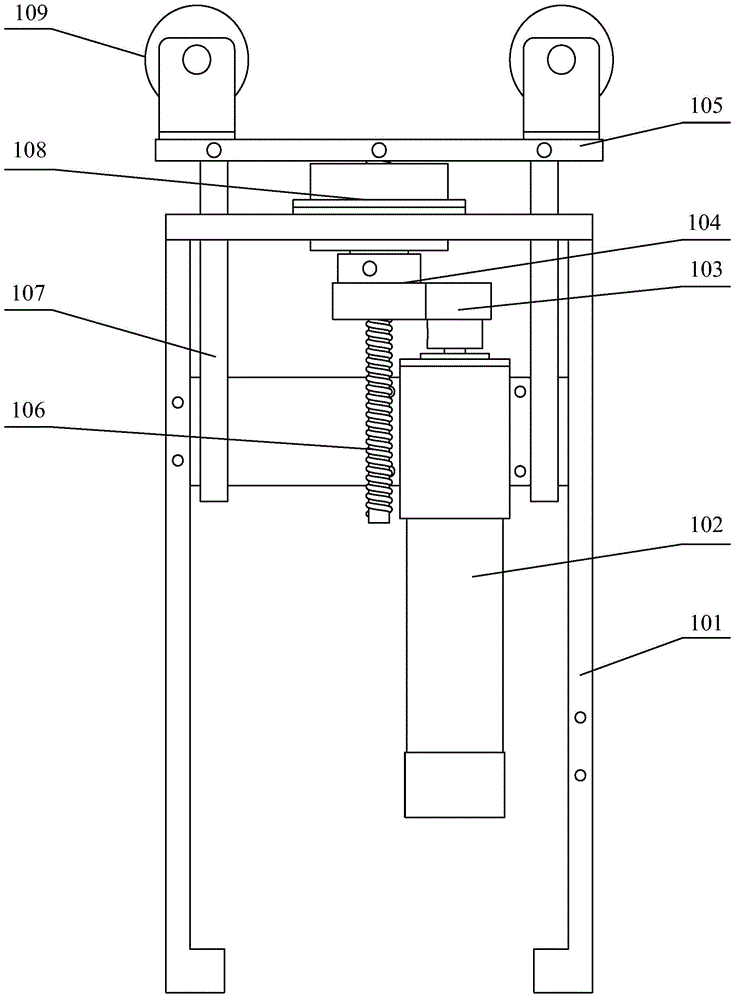

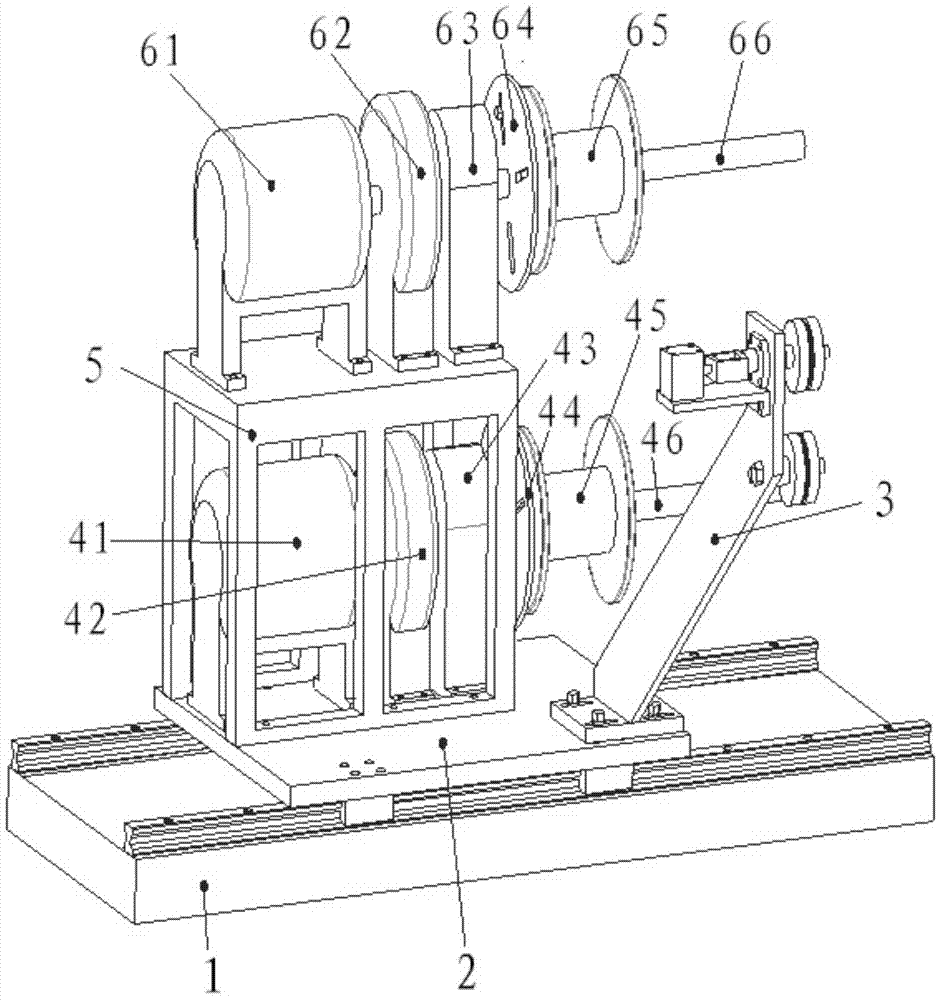

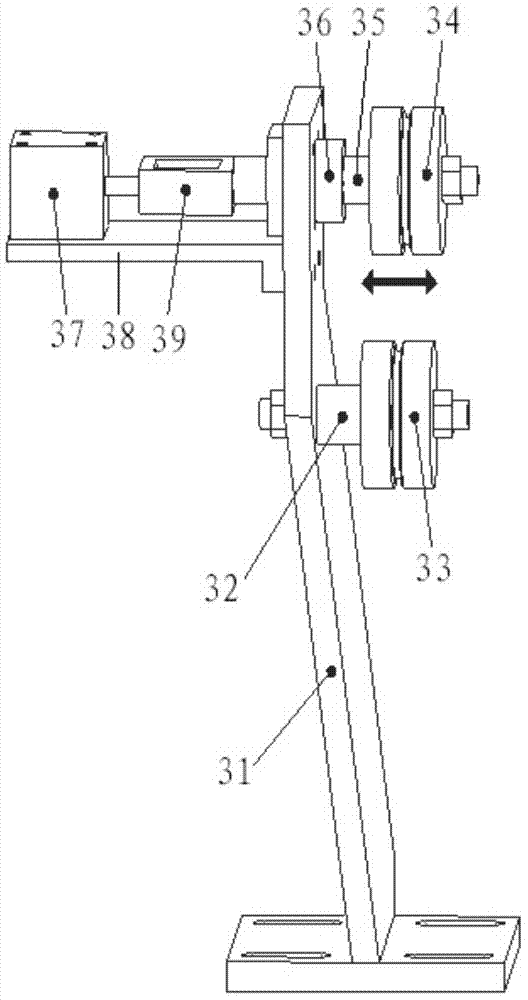

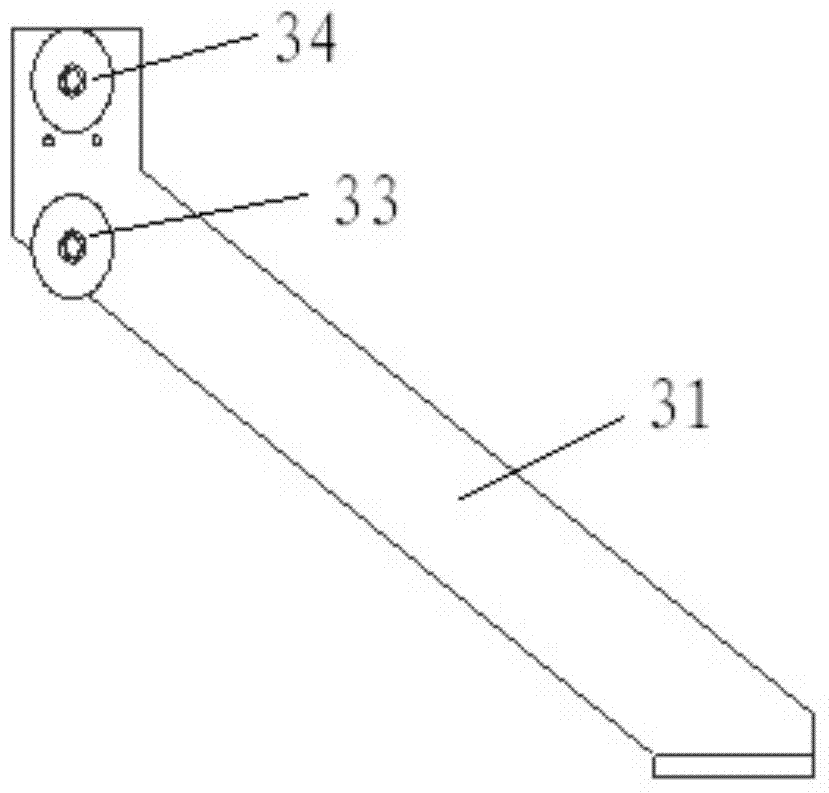

Coil winding paying-off device

ActiveCN104779049AEasy to crossControllable tensionFilament handlingCoils manufactureEngineeringMechanical engineering

A coil winding paying-off device comprises a workbench, an upper tension paying-off mechanism, a lower tension paying-off mechanism, a rack and a wire crossing and reversing mechanism. The upper tension paying-off mechanism is installed on the rack which is installed on the workbench, the lower tension paying-off mechanism is installed on the workbench and located below the upper tension paying-off mechanism, the wire crossing and reversing mechanism is installed on the workbench, and the workbench is installed on a horizontal moving sliding table. According to the coil winding paying-off device, the upper tension paying-off mechanism and the lower tension paying-off mechanism provide independent tension output for two sets of paying-off coils respectively, the wire crossing and reversing mechanism conducts left and right crossing and reversing on wires of each layer in the coil winding process, and the horizontal moving sliding table adjusts the double tension paying-off mechanisms and the wire crossing and reversing mechanism to move left and right in the coil winding process; by means of the coil winding paying-off device, the tension of all the wires in the coil winding process is more controllable, crossing of the wires among the layers is more convenient, and the operation is easier.

Owner:ALLTECH MEDICAL SYST

Pre-processing production system for deep-processing of automotive glass

ActiveCN104511819ARealize in-line productionReduce operating costsEdge grinding machinesWindowsProcess qualityAir bearing

The invention relates to a pre-processing production system for deep-processing of automobile glass; the pre-processing production system comprises a sheet-taking table, a cutting machine, a sheet-breaking and air-bearing table, an edge grinding machine, a suction arm, a transition conveyor, a sheet washing machine, a power blower, a cleaning, testing, overturning and discharging conveyor, a corner conveyor, a pre-targeting machine, a silk printer, a silk-printing, testing, overturning and discharging conveyor, a drying machine, an air-cooler and a discharging machine; and the edge grinding machine comprises a wheel-grinding shaft, a rocker arm, a hand wheel, locking screws, an upright column, a table top and a grinding wheel for grinding edges. The pre-processing production system for deep-processing of the automobile glass has the following beneficial effects: manual equipment and automatic equipment and combined, so that the pipelining working of the pre-processing for deep-processing of the automobile glass is realized; the production system is simple and stable in processing quality of glass; the internal glass and the external glass of coaches and minibuses are processed on the production system, so that the production staff is reduced, the labor intensity is reduced, the production field is saved, the production efficiency is improved and the operating cost of enterprises is reduced effectively.

Owner:XINYI AUTOMOBILE GLASS (SHENZHEN) CO LTD

Channelrhodopsin variants and uses thereof

ActiveUS20160039902A1Improve ionic conductivityDecrease in ion conductivityElectrotherapyPeptide/protein ingredientsCell activityLight activated

CsChrimson light-activated ion channel polypeptides, their encoding polynucleotides, and variants thereof are provided. Methods of introducing and using CsChrimson light activated ion channels and variants thereof for to alter cell activity and function are also provided.

Owner:MASSACHUSETTS INST OF TECH +1

Self-absorption-drying, circulating, long-acting and full-intelligent glass cleaning robot

InactiveCN106618358AQuick clearSolve cleaning problemsAutomatic obstacle detectionTravelling automatic controlEngineeringSelf-absorption

The invention relates to a self-absorption-drying, circulating, long-acting and full-intelligent glass cleaning robot. A cleaning contact assembly comprises a first cleaning contact, a second cleaning contact and a servo motor, and the first cleaning contact and the second cleaning contact are in a bilateral symmetry structure and are located at the bottom of a shell and connected with the servo motor separately; a slideway for allowing a second telescopic rotating suction cup mechanism to slide front and back is arranged at the bottom of the shell, a first telescopic rotating suction cup mechanism is connected with a piston end of an electric telescopic cylinder, the second telescopic rotating suction cup mechanism is connected with the outer end of a cylinder body of the electric telescopic cylinder, a rotating motor is connected with a gear set, and the gear set is connected with the first telescopic rotating suction cup mechanism and the second telescopic rotating suction cup mechanism separately; a remote PC end is in wireless connection with a control chip, and actions of the robot are remotely controlled. The robot is high in intelligent degree and easy and convenient to operate, manual intervention is not needed in the glass cleaning process, the robot can easily cross a window frame even if the robot encounters the window frame, the working efficiency is high, and the working labor intensity is greatly reduced.

Owner:杨卫东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com