Benzoxazolylquinoline ligand-based cuprous complex luminescent material

A luminescent material, benzoxazole technology, applied in the field of cuprous complex luminescent materials and luminescent materials, can solve the problems of being expensive, affecting the popularization and application of OEL and market performance, and achieving low production cost, good phosphorescence emission performance, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Cuprous complex luminescent material [Cu(QBO)(PPh3) 2 ]PF 6 Preparation of:

[0033] A. Weigh 0.2mmol of Cu(CH 3 EN) 4 PF 6 , placed in an Erlenmeyer flask, added 10mL of dichloromethane, and stirred to obtain a colorless and clear solution 1;

[0034] B. Weigh 0.2mmol of QBO with a copper salt stoichiometric ratio of 1:1, put it in a 10mL beaker, add 5mL of dichloromethane, and stir to make it a yellow clear solution 2;

[0035] C. Weigh 0.4mmol of PPh3 with copper salt stoichiometric ratio 1:2, place in a 10mL beaker, add 5mL of dichloromethane and stir to obtain clear solution solution 3;

[0036] D. Pour solutions 2 and 3 into solution 1 in turn, stir for 1 h, evaporate the resulting solution to dryness at 40° C., and dry to obtain the product orange-yellow microcrystalline powder.

Embodiment 2

[0038] Cuprous complex luminescent material [Cu(QBO)(PPh3) 2 ]PF 6 Single crystal acquisition and characterization:

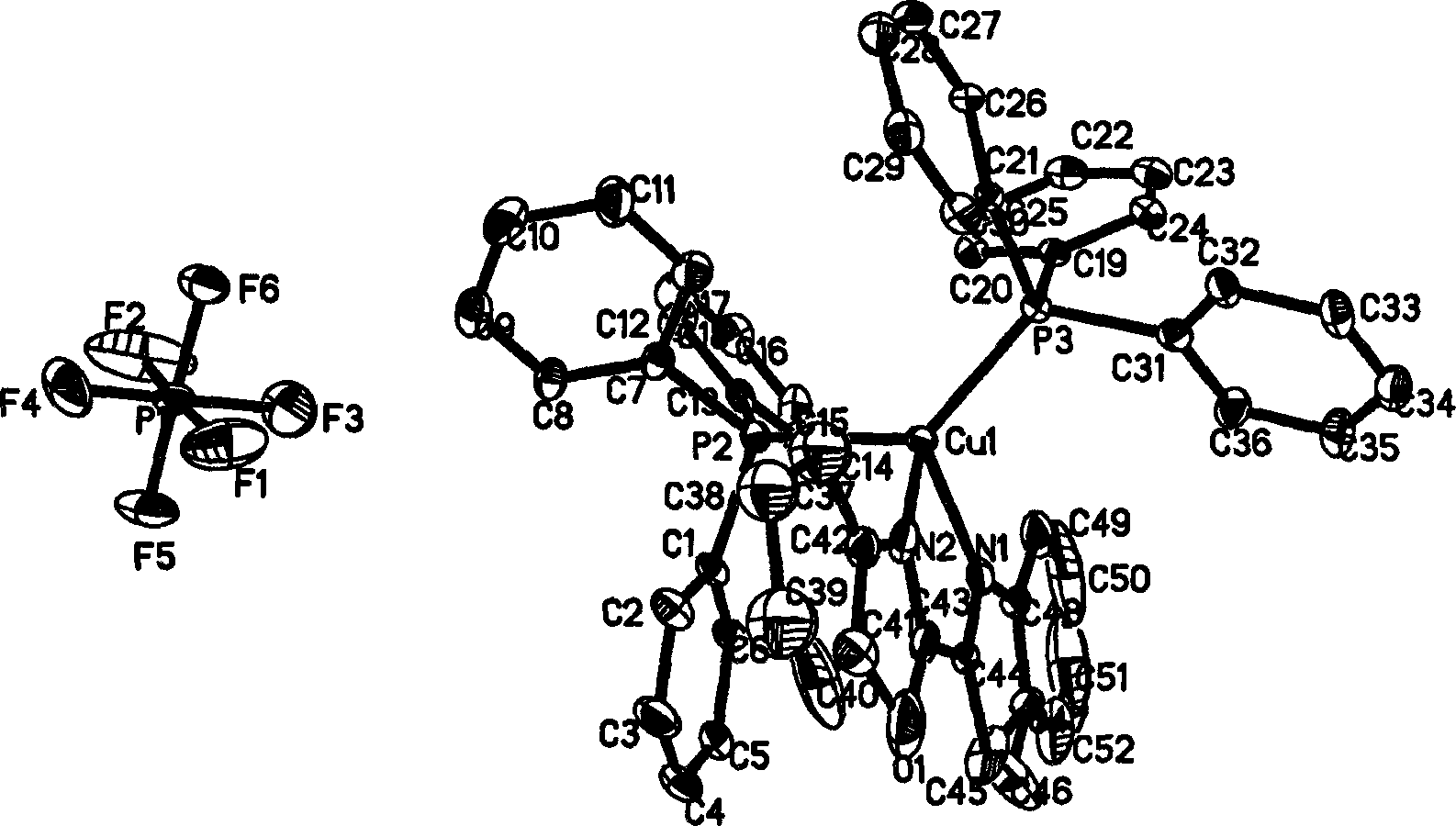

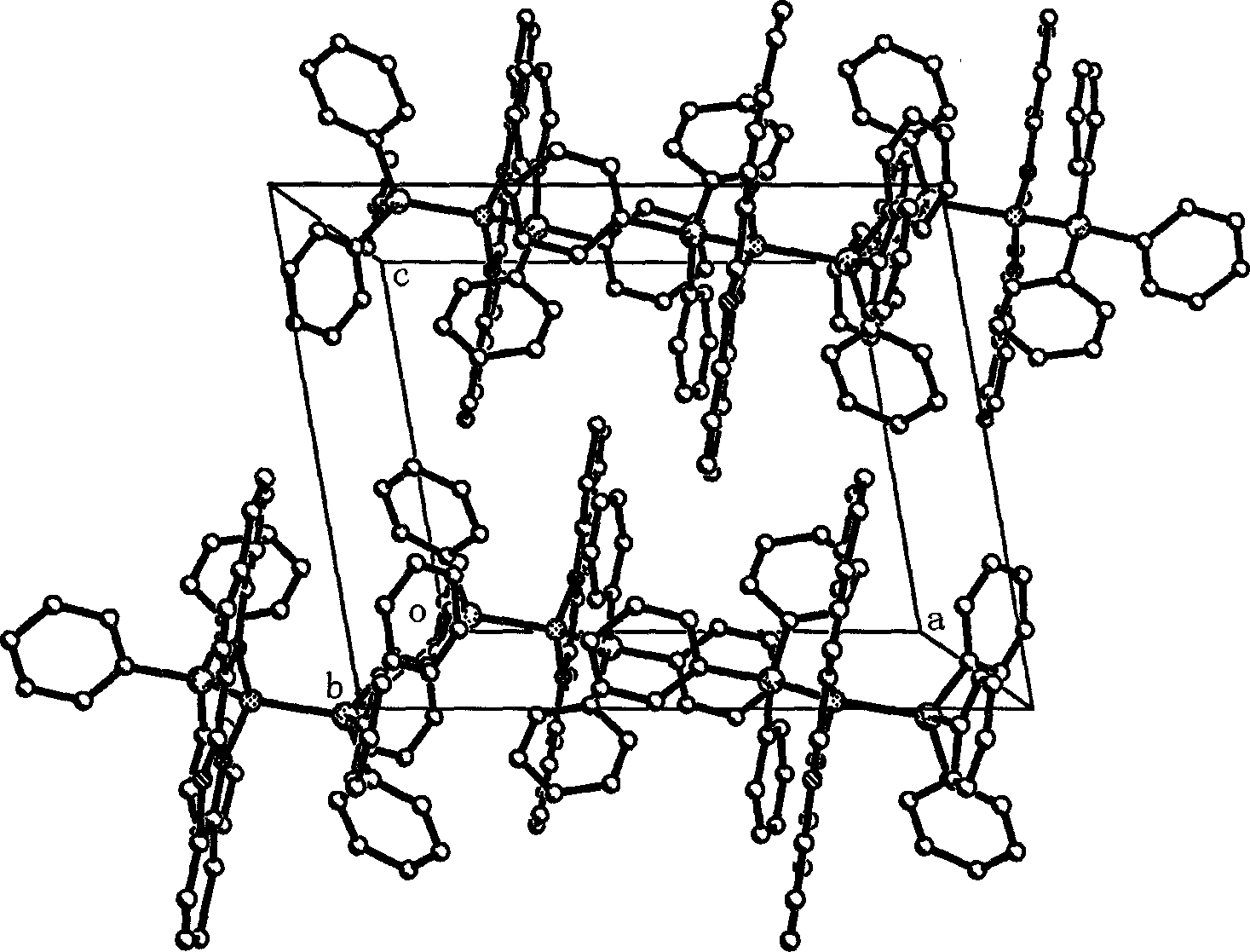

[0039] The single crystal was obtained by interfacial diffusion method, and 0.1 mmol of [Cu(QBO)(PPh3) was weighed 2 ]PF 6 Powder, dissolved in 2mL of dichloromethane, placed in a 5mL test tube, and then covered with isopropanol on the solution to promote crystallization of the product, sealed, and left to stand for several days to obtain yellow transparent block crystals, choose a size of 0.42 The single crystal of ×0.38×0.32mm was used for X-ray single crystal diffraction, and the analysis obtained [Cu(QBO)(PPh3) 2 ]PF 6 molecular structure. The molecular structure of the compound is shown in the attached figure 1 .

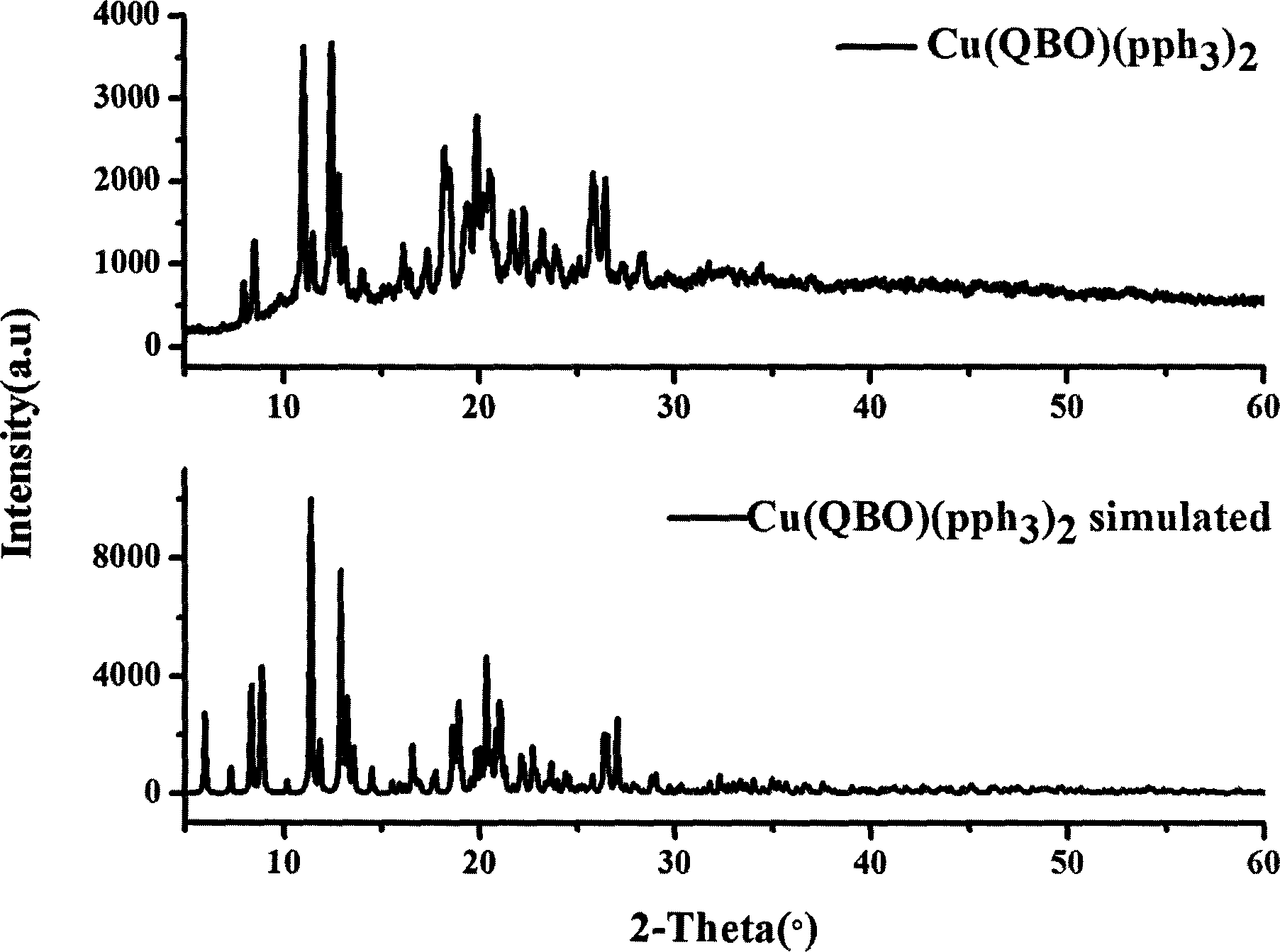

[0040] For the complex luminescent material [Cu(QBO)(PPh3) 2 ]PF 6 A series of performance tests were carried out on the pure phase crystalline powder samples. TG and DSC tests show that the material has good thermal stability, see att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com