Diameter changeable pipeline cleaning robot having parallel four-bar mechanism

A parallel four-bar mechanism, pipeline cleaning technology, applied in the directions of manipulators, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of troublesome energy supply, pipeline robots have not been widely used, blocked pipelines, etc., to achieve high reliability, The effect of enhancing practical ability and high pipeline passing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

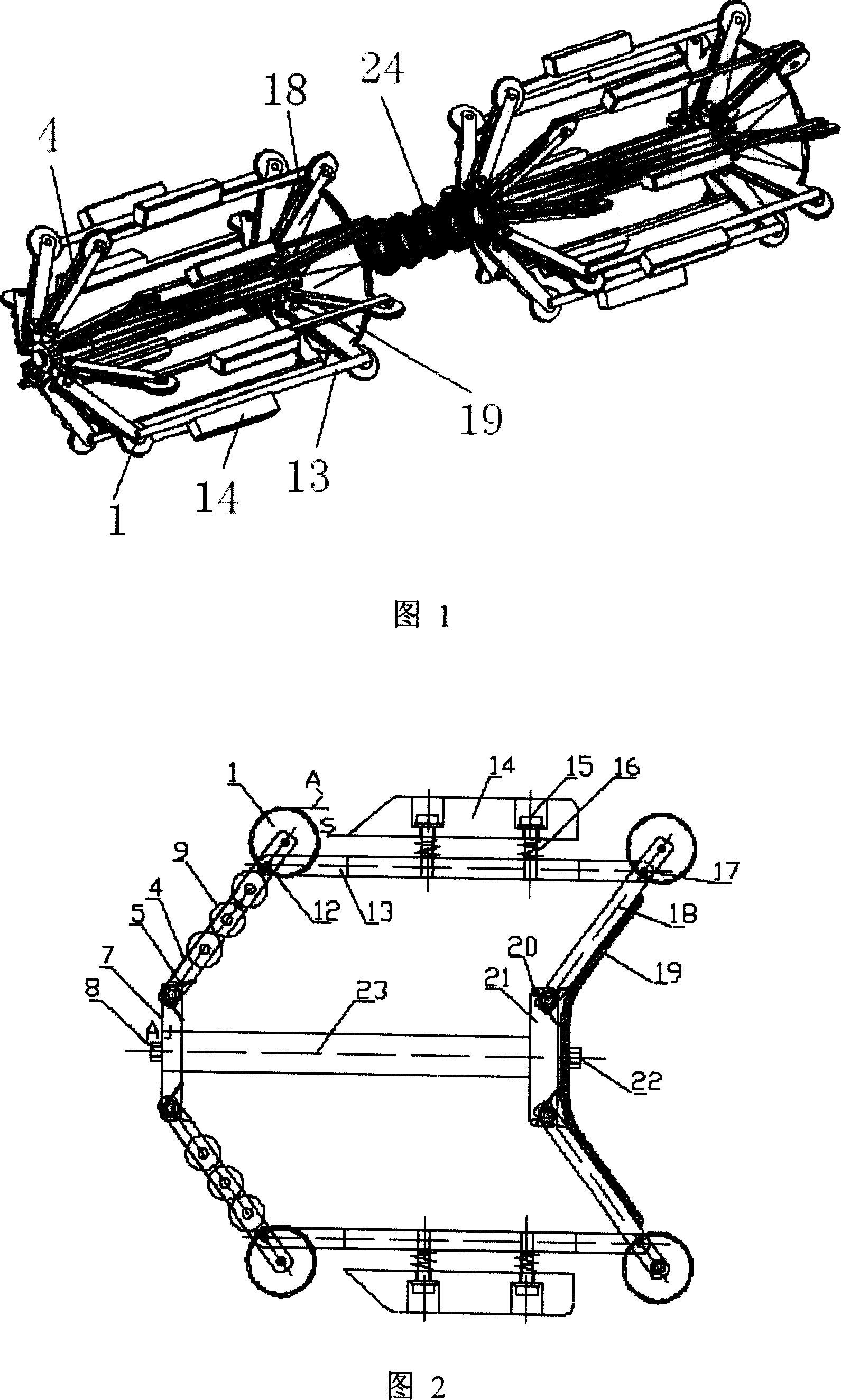

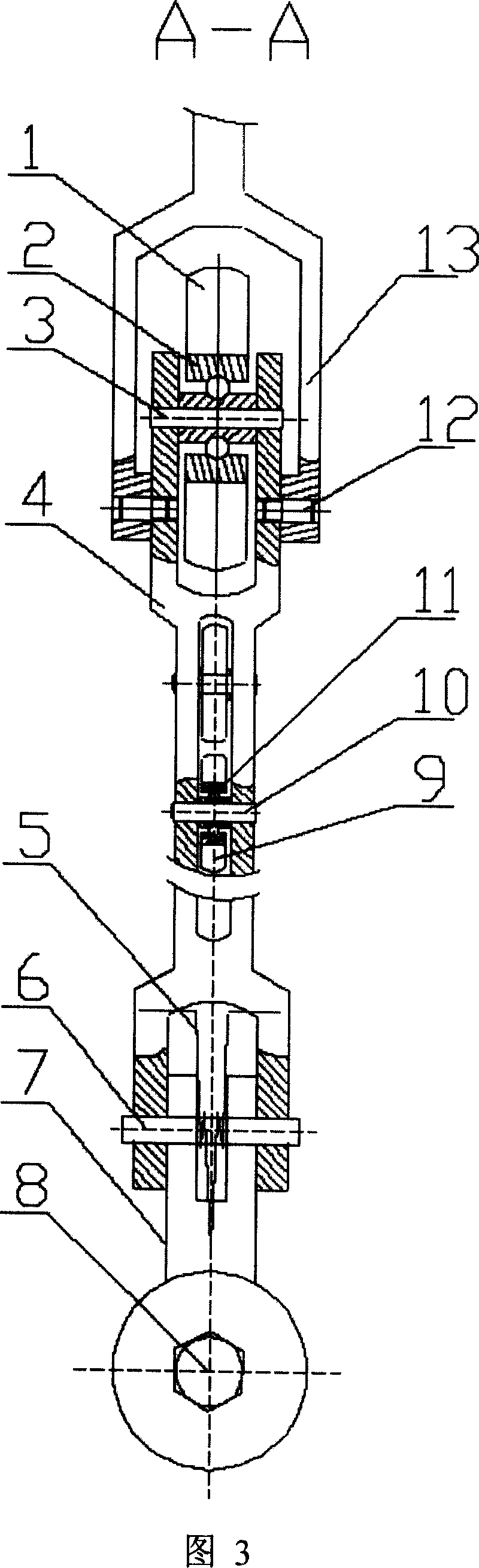

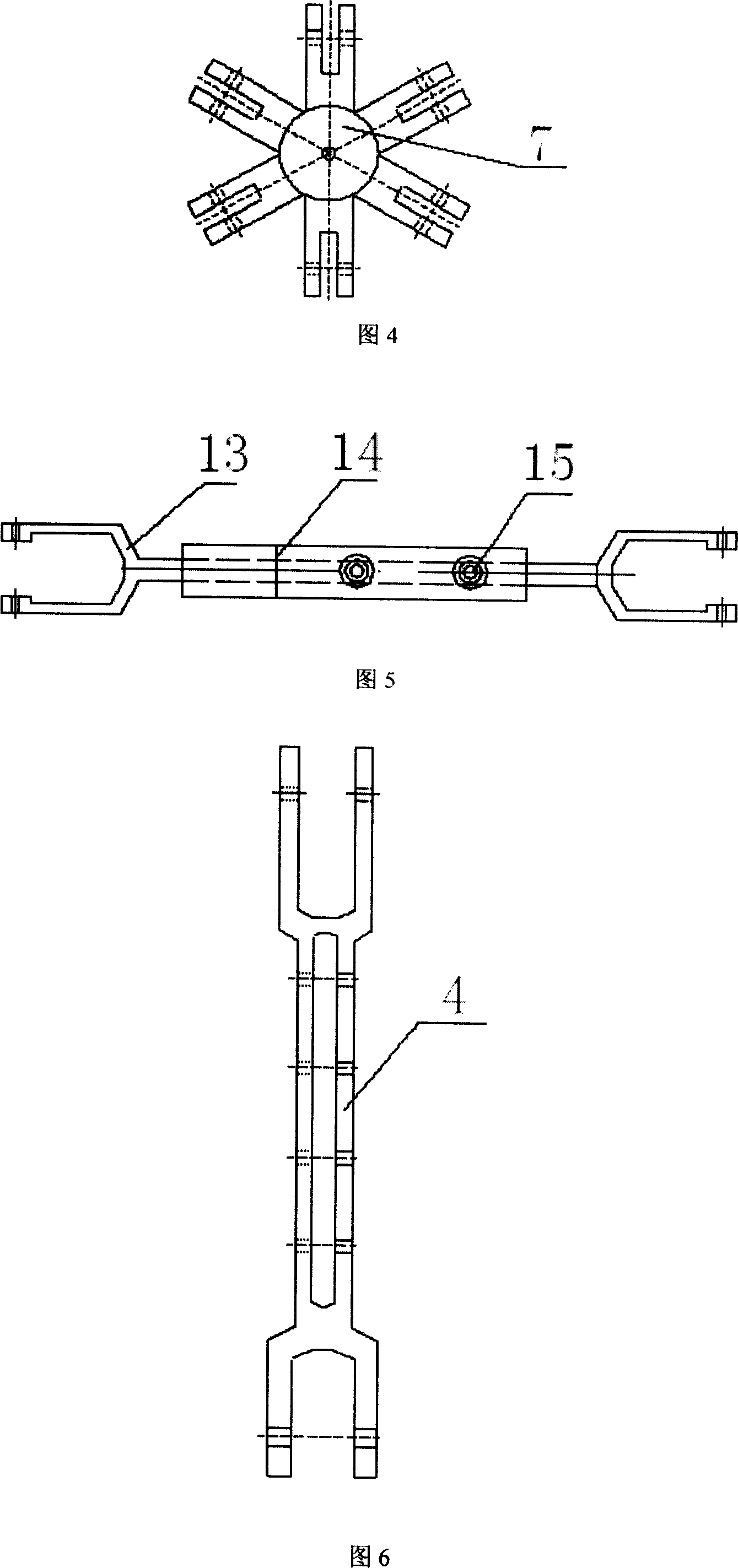

[0016] A variable-diameter pipeline cleaning robot with a parallel four-bar mechanism, which is composed of multiple sections or a single section, each section has the same structure, and is connected by a central spring (24) between the sections; for a single-section pipeline cleaning mechanism, the A plurality of parallel four-bar support mechanisms equally divided around the central axis (23), cleaning parts and flexible panels (19); the single parallel four-bar support mechanism is supported by the center, the front rocker part, and the rear rocker part , connecting rod parts; for the central support, it consists of a central shaft (23), a front leg (7), a screw (8), a rear leg (21), a screw (22), and a limit pin (20); for the front The rocker part consists of a rolling wheel (1), a bearing (2), an axle (3), a front rocker (4), a torsion spring (5), an axle (6), a rolling wheel (9), an axle (10), The bearing (11) is composed of; for the rear rocker part, it is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com