Profiling claw type floating stubble, grass cleaning mechanism

A claw-type, stubble-clearing technology, used in sowing, collecting machines, agricultural machinery and implements, etc., can solve problems such as large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific content of the present invention is further described below in conjunction with the embodiment shown in the accompanying drawings:

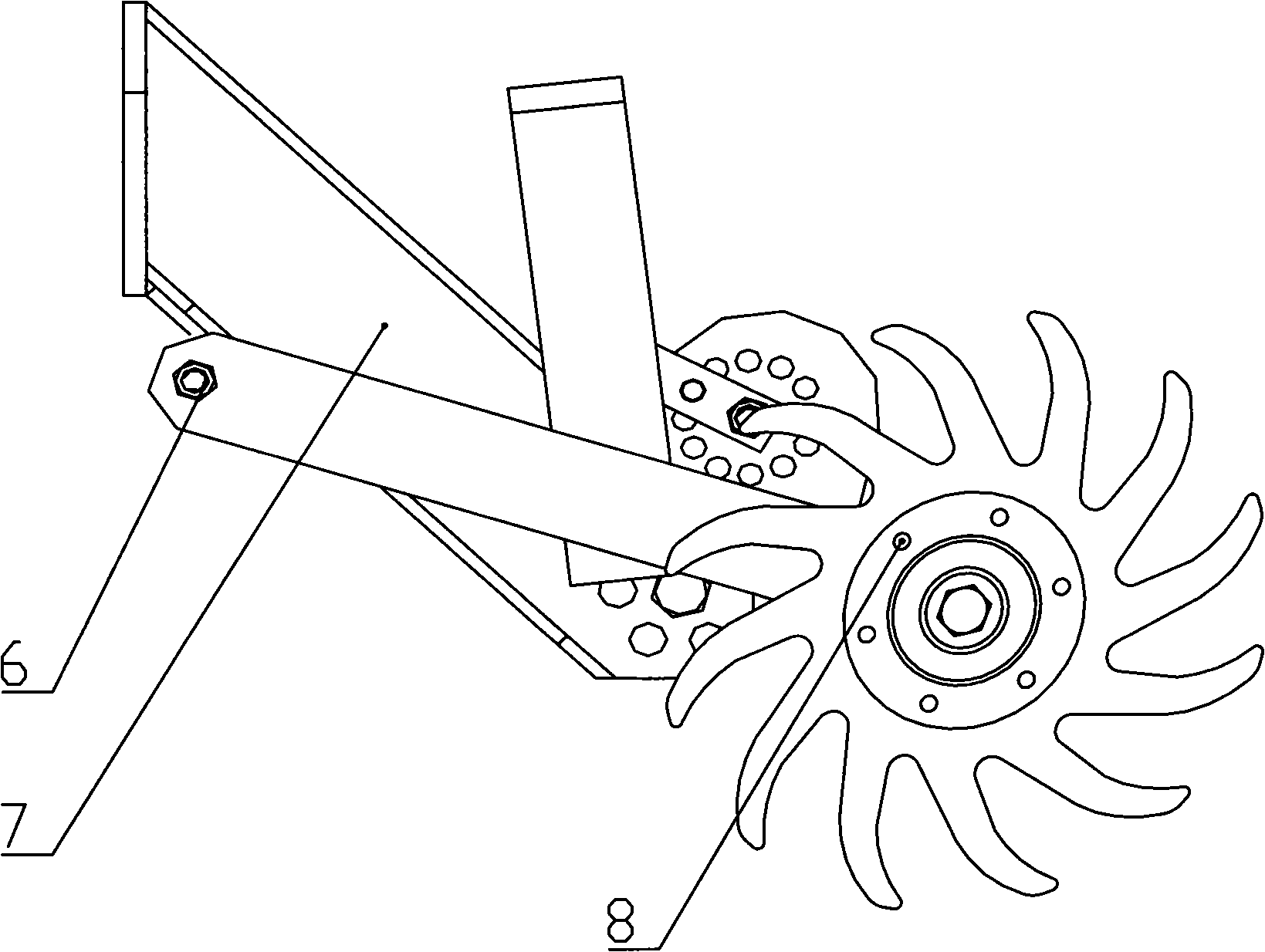

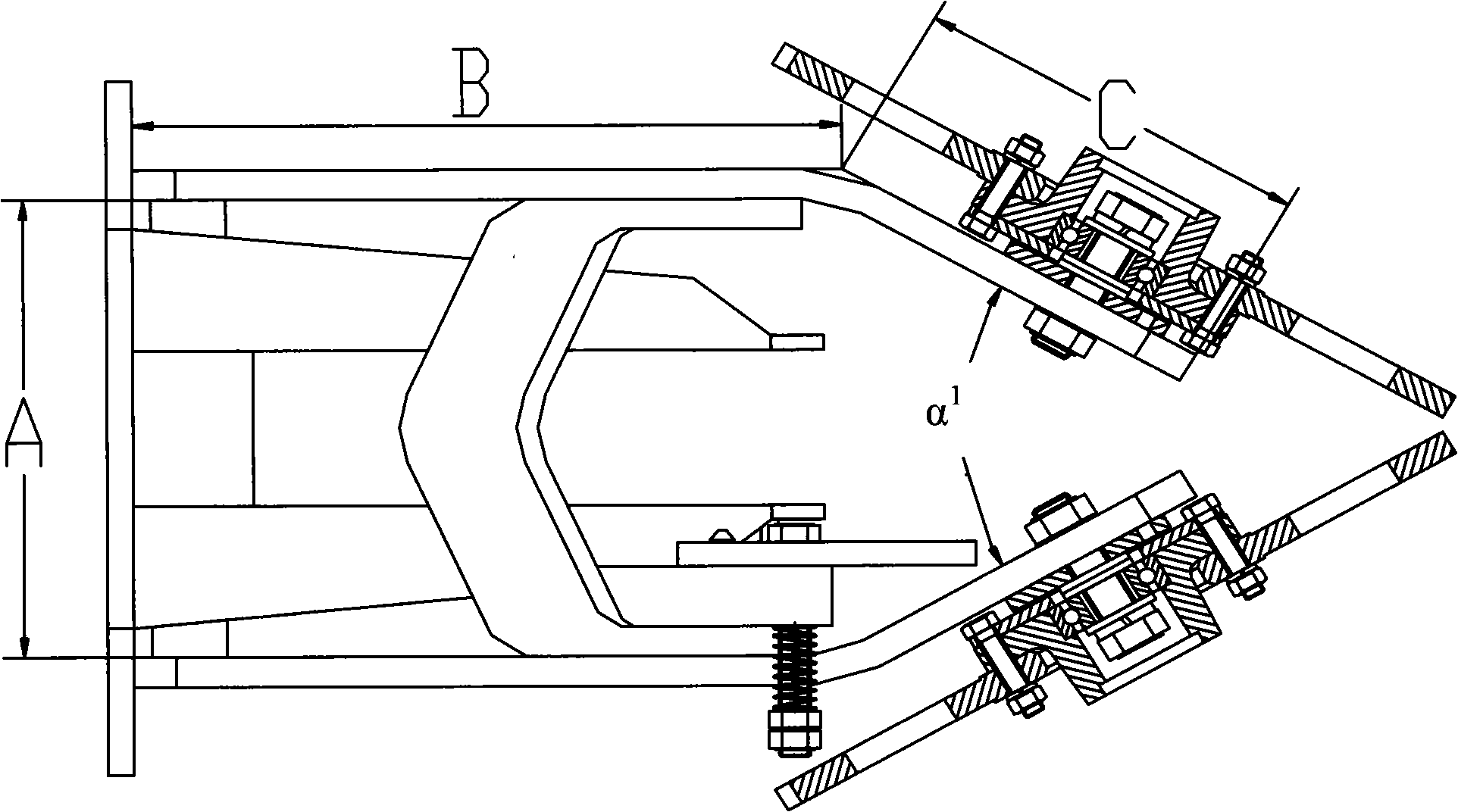

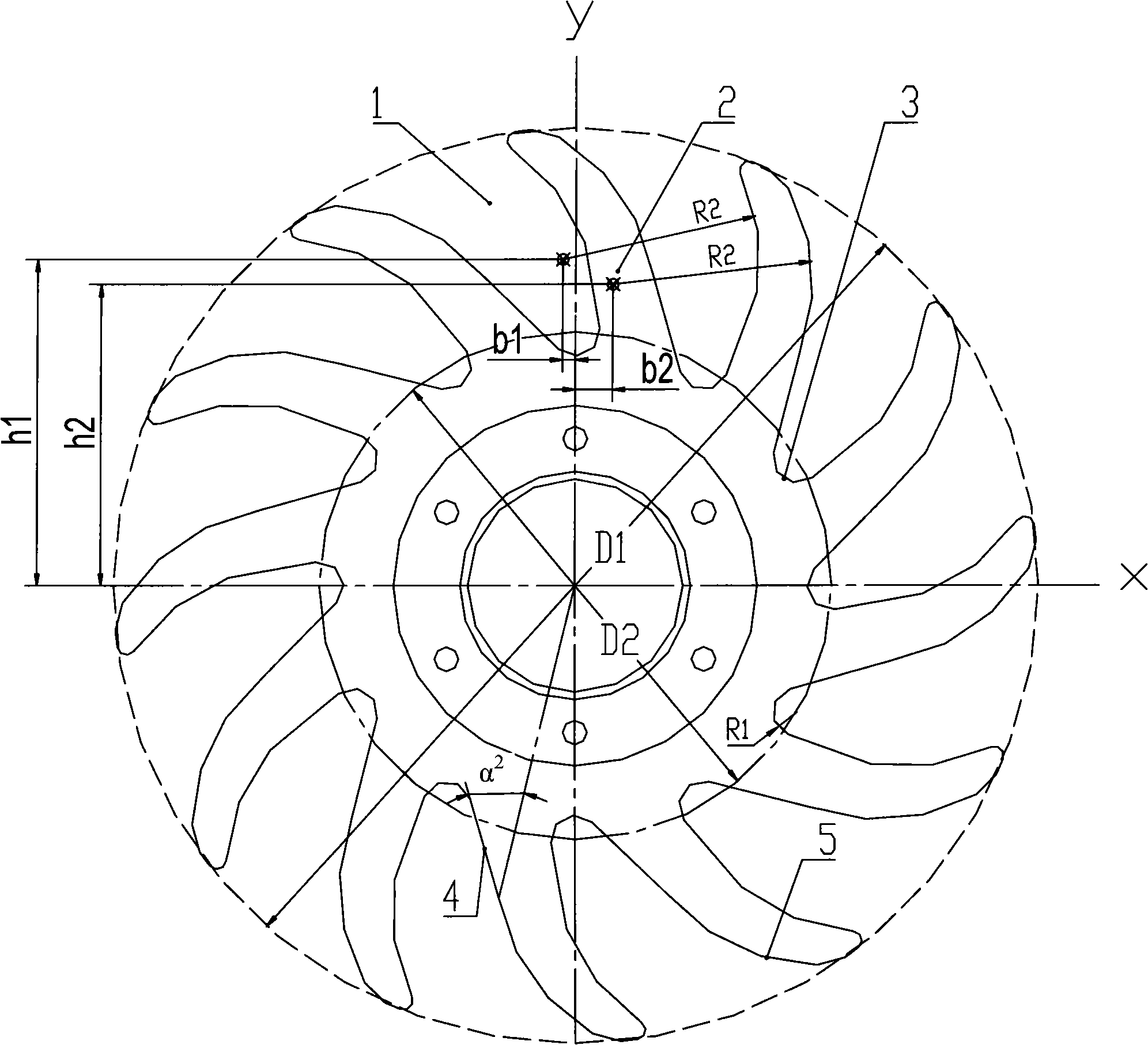

[0026] Floating clearer assembly (see figure 2 ) is mainly composed of the lower limit support arm frame 7 (refer to Figure 5) and the grass wheel assembly 8 (refer to image 3 ) consists of two parts. Mould Wheel Assembly (Refer to image 3 ) including bearing seat and bearing 11, bearing cap 21, adjusting cam 12, convergence support arm mounting frame 13 and weeding wheel 1 and other main working parts. Wherein the grass wheel and the cam are the key parts implementing the present invention.

[0027] At first the bearing seat 11 with the bearing is inserted in the center hole of the mowing wheel 1, and the bolt 20 is correspondingly passed through the bearing cover 21 and the shaft seat 11 circumferential hole to be connected to the mowing wheel 1 together. Use the bolt 10 to penetrate into the inner hole of the bearing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com