Automobile brake disc and manufacturing method thereof

A technology for automobile brakes and brake discs, applied in the direction of brake discs, etc., can solve the problems of casting dimensional accuracy, poor surface finish, difficult control of internal shrinkage pores, difficult parts disassembly and maintenance, etc., to reduce processing costs , increase the payload of the car, and the effect of easy control of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

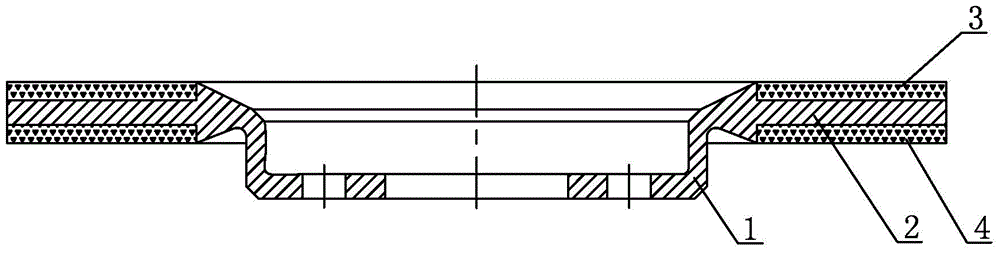

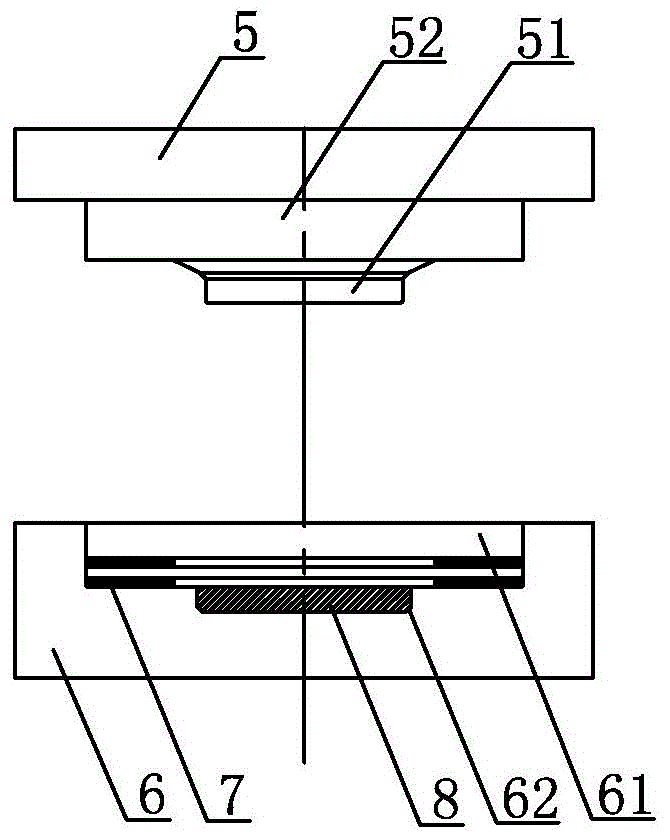

[0038] Embodiment 1: as figure 1 The automobile brake disc shown is a solid brake disc of Φ288mm (outer diameter)×44.3mm (thickness). The brake disc body is an aluminum alloy brake disc body. The two aluminum alloy brake disc body 1 A layer of wear-resistant layers 3 and 4 are respectively compounded on the two working surfaces. The wear-resistant layers 3 and 4 are wear-resistant layers of ceramic reinforced material. The wear-resistant layer of ceramic reinforced material is metallurgically combined with the aluminum alloy brake disc body 1 through extrusion casting process. , the preparation method of the solid brake disc comprises the following steps:

[0039] 1) Preparation of raw materials for the production of ceramic reinforcing materials: by volume fraction, weigh 13% of short aluminum silicate fibers, 7% of silicon carbide particles, 20% of low-temperature binders and 60% of high-temperature binders to be dried agent, the low-temperature adhesive is a 5% carboxymeth...

Embodiment 2

[0045] Embodiment 2: It is a solid brake disc, its structure is the same as that of Embodiment 1, and the specific structure diagram is shown in figure 1 , the preparation method of the solid brake disc comprises the following steps:

[0046] 1) Preparation of raw materials for the production of ceramic reinforcement materials: by volume fraction, weigh 10% of alumina short fibers, 10% of fly ash particles, 5% of silicon carbide particles and 25% of low-temperature binder to be dried And 50% high-temperature adhesive, the low-temperature adhesive is a carboxymethyl cellulose aqueous solution with a concentration of 3%, and the high-temperature adhesive is a silica sol solution with a concentration of 12%;

[0047] 2) Production of ceramic prefabricated parts: Mix the prepared alumina short fibers, fly ash particles, silicon carbide particles, low-temperature binder and high-temperature binder evenly, then quantitatively pour into the prefabricated part mold, and vacuumize to ...

Embodiment 3

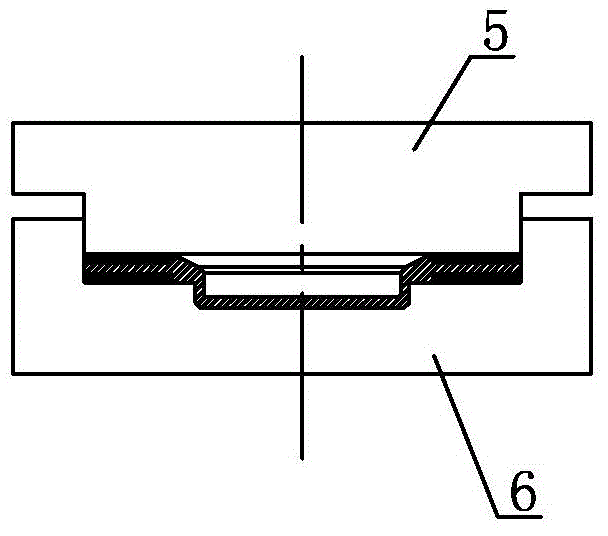

[0052] Embodiment 3: as Figure 4The automobile brake disc shown is a ventilated brake disc of Φ288mm (outer diameter)×44.3mm (thickness), including the brake disc body 1, which is an aluminum alloy brake disc body, and the brake The disc body 1 includes a brake outer disc 21 and a brake inner disc 22. The brake outer disc 21 and the brake inner disc 22 are connected by connecting ribs 23. The working surfaces of the brake outer disc 21 and the brake inner disc 22 are compounded with a wear-resistant layer 3 respectively. And 4, the preparation method of this ventilation brake disc comprises the following steps:

[0053] 1) Preparation of raw materials for the production of ceramic reinforcing materials: by volume fraction, weigh 5% of alumina short fibers, 10% of aluminum silicate short fibers, 10% of fly ash particles and 25% of low-temperature viscous Mixture and 50% high-temperature binder, the low-temperature binder is a carboxymethyl cellulose aqueous solution with a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com