Constructing method for shield entering into hole while passing through pipeline

A construction method and hole-entry technology, which are applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of improper tunnel construction, easy to produce adverse consequences, damage to surface structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

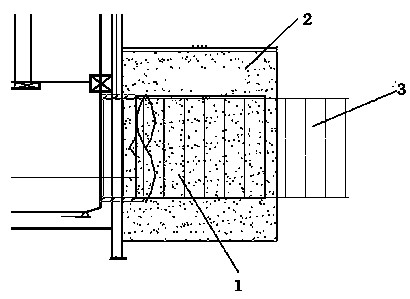

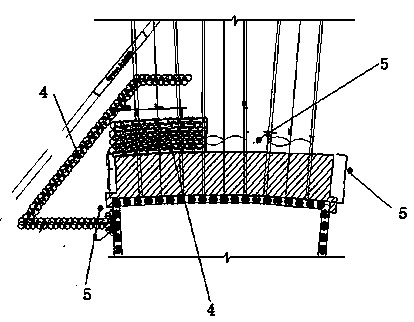

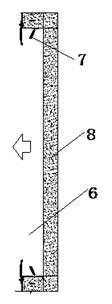

[0006] It consists of the following steps: (1) Reinforcement with three-axis mixing piles + jet grouting piles at the end of the tunnel, the reinforcement area is increased to 9 meters, and the reinforcement depth is 3 meters below the tunnel; (2) Between the sewage pipe and the station end well Set up a row of isolation piles between the sewage pipes to isolate the lateral soil pressure of the soil below the sewage pipe and prevent the pipeline from settling due to the release of soil pressure stress. The type of isolation piles is: three-axis mixing pile, Set up 4 dewatering wells for pre-precipitation, and lower the water level to 1 meter below the entrance. (4) In addition to installing waterproof devices around the entrance, it is also necessary to install double-layer spring steel plates filled with sponge in the middle. (5) In the shortest The work of chiseling the hole door is completed within the specified time, (6) adjust various parameters, and the shield machine can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com