Lithium ion battery and electrolyte thereof

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries and their electrolytes, can solve the problems of non-negligible resistance, unobvious battery performance, and low battery discharge capacity, achieve superior low-temperature charge and discharge performance, and ensure high-temperature storage And the effect of circulation and other performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation of electrolyte

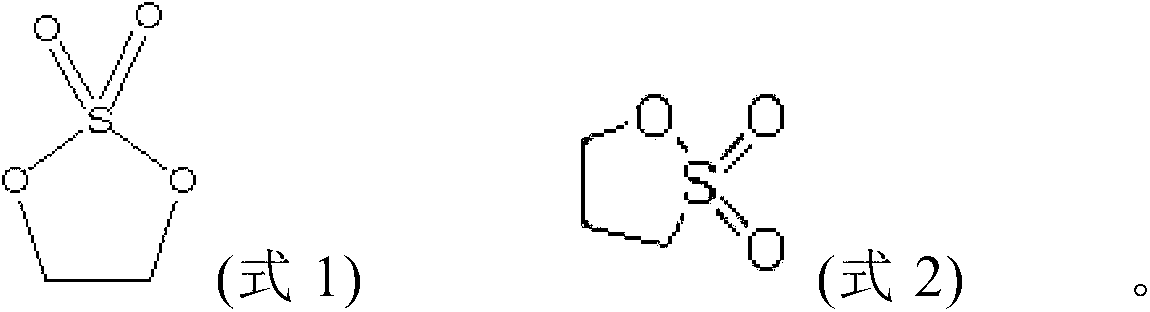

[0058] Electrolyte was prepared in the same way as Comparative Example 1, except that the electrolyte was ethylene carbonate (EC), dimethyl carbonate (DMC), diethyl carbonate (DEC), 1,3-propanesulfonic acid Esters, 4-methylethylene sulfate were mixed in a weight ratio of 28.8:28.8:38.4:3:1 and dissolved in 1MLiPF 6 .

[0059] Preparation of B cell

[0060] Same as Comparative Example 1.

Embodiment 2

[0062] A preparation of electrolyte

[0063] Electrolyte was prepared in the same way as Comparative Example 1, except that the electrolyte was ethylene carbonate (EC), dimethyl carbonate (DMC), diethyl carbonate (DEC), 1,3-propanesulfonic acid Esters, 4-methylethylene sulfate were mixed in a weight ratio of 28.5:28.5:38:3:2, and 1M LiPF6 was dissolved.

[0064] Preparation of B cell

[0065] Same as Comparative Example 1.

Embodiment 3

[0067] A preparation of electrolyte

[0068] Prepare electrolytic solution according to the same method as comparative example 1, the difference is that this electrolytic solution is ethylene carbonate (EC), dimethyl carbonate (DMC), diethyl carbonate (DEC), 4-methyl ethylene sulfate , Ethylene sulfate is mixed in a weight ratio of 28.8:28.8:38.4:1:3, and dissolved in 1MLiPF 6 .

[0069] Preparation of B cell

[0070] Same as Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com