Hinge type wall climbing robot capable of working on metal wall

A wall-climbing robot and hinge technology, applied in the field of robotics, can solve the problems of poor obstacle-crossing ability, small load capacity, and unsuitability for large-scale surface work on ships, and achieve large load capacity, high work efficiency, and superior obstacle-crossing ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

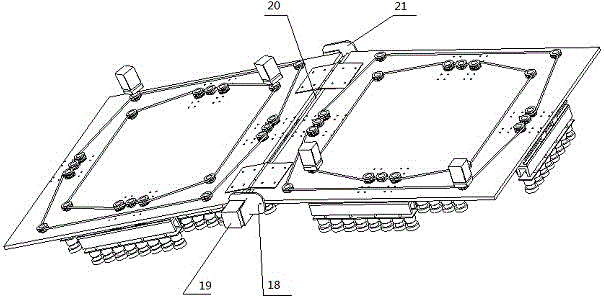

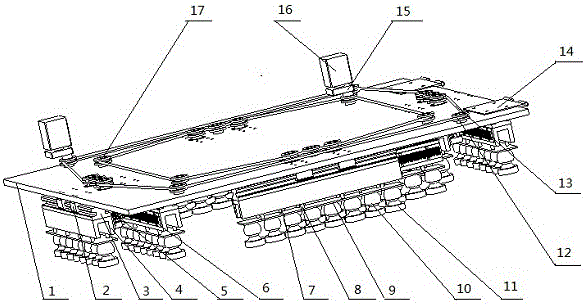

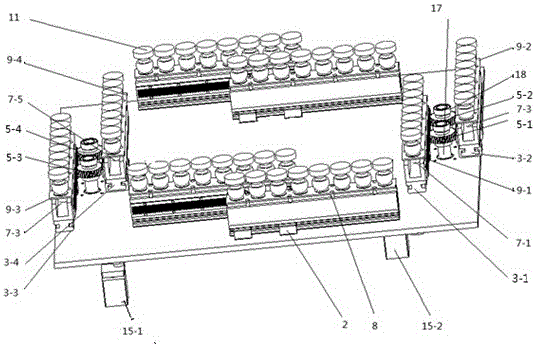

[0025] Such as Figure 1 to Figure 7 Shown, a kind of hinge type metal wall surface work wall-climbing robot, comprises wall-climbing robot unit, hinge 14 and folding mechanism, is connected by hinge 14 rotation between described wall-climbing robot unit, and described folding mechanism is installed on two The connection between two wall-climbing robot units.

[0026] The wall-climbing robot unit includes a frame 1, a fixed slider 2, a linear guide rail 3, a support frame 4, a rack 5, a gear 6, a linear motor 7, a support column 8, a support plate 9, a ball joint 10, an electromagnet 11, Pulley 12, belt 13, speed reducer 15, driving motor 16, rotating shaft 17, are equipped with 16 fixed sliders 2 on the four frames of described frame 1, every two fixed sliders 2 are a group, and a straight line The guide rails 3 cooperate so that the linear guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com