Steel pipe concrete frame with prestressing tendons and construction method thereof

A technology of concrete filled steel tubes and prestressed tendons, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of complex beam-column connection nodes, difficult positioning of prestressed tendons, and easy damage. To achieve the effect of reducing the deformation of the beam, the span is large, and it is not easy to damage and corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing, the present invention will be further described:

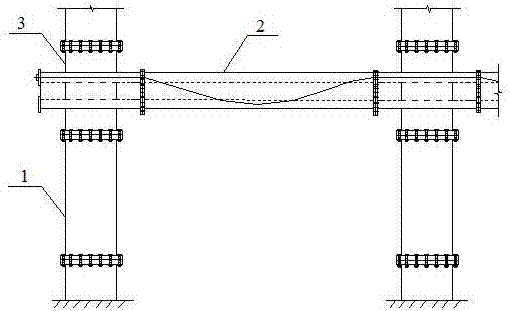

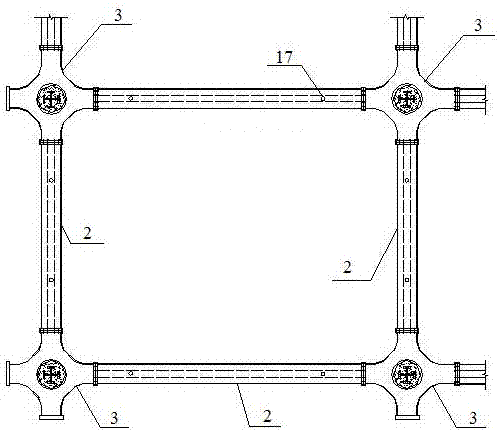

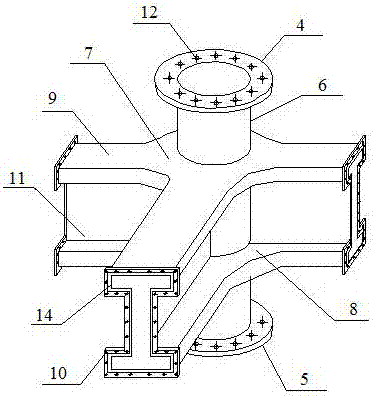

[0044] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 13 As shown, this CFST frame with prestressed tendons is composed of composite columns 1 and composite beams 2 connected by joints 3, composite beams 2 are horizontally arranged between composite columns 1, and joints 3 are the jackets of internally filled self-compacting concrete 13 Integral joint; jacket Integral joint includes a joint outer tube with an upper connecting ring 4 and a lower connecting ring 5. Both the upper connecting ring 4 and the lower connecting ring 5 are provided with bolt holes 12, and the upper part of the joint outer tube 6 has an upper reinforcement The cavity ring plate 7 has a lower reinforced cavity ring plate 8 on the lower part, and the upper reinforced cavity ring plate 7 extends horizontally outward to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com