Patents

Literature

150results about How to "Give full play to mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent FRP (Fiber Reinforce Plastic)-concrete composite structure and manufacturing method thereof

The invention discloses an intelligent FRP (Fiber Reinforce Plastic)-concrete composite structure and a manufacturing method of the intelligent FRP-concrete composite structure. The intelligent composite structure comprises an intelligent FRP layer, a reinforced concrete core and an anchoring device, wherein the intelligent FRP layer is formed by carbon fibers or carbon fiber mixed with other fibers and impregnated by resin, and in the composite structure, the intelligent FRP layer both serves as structural material and plays a sensing function. The intelligent FRP layer is wrapped on the stressed side of the reinforced concrete core, certain prestress is applied on the intelligent FRP layer to better play the high strength property of the FRP, and the intelligent FRP layer is connected with the reinforced concrete core through resin adhesion and mechanical connection of anchorage device. The intelligent FRP-concrete composite structure not only has high carrying capacity, self sensing function, excellent corrosion resistance and high durability, but also has strong designability of performance and structure.

Owner:SOUTHEAST UNIV

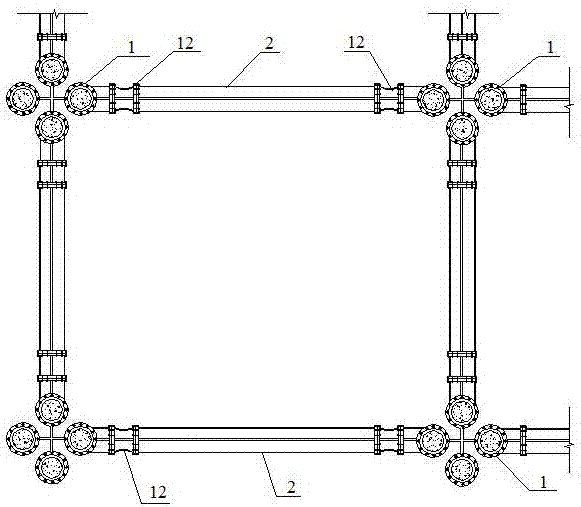

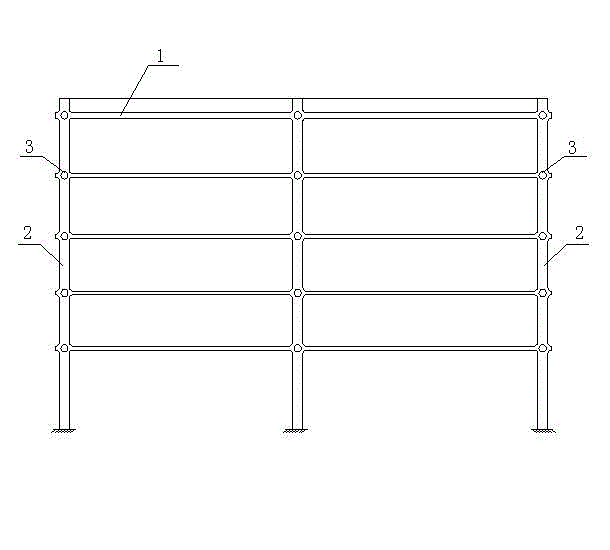

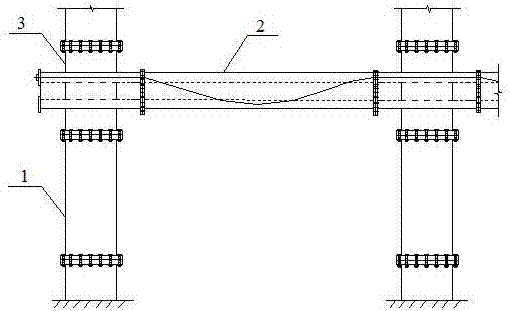

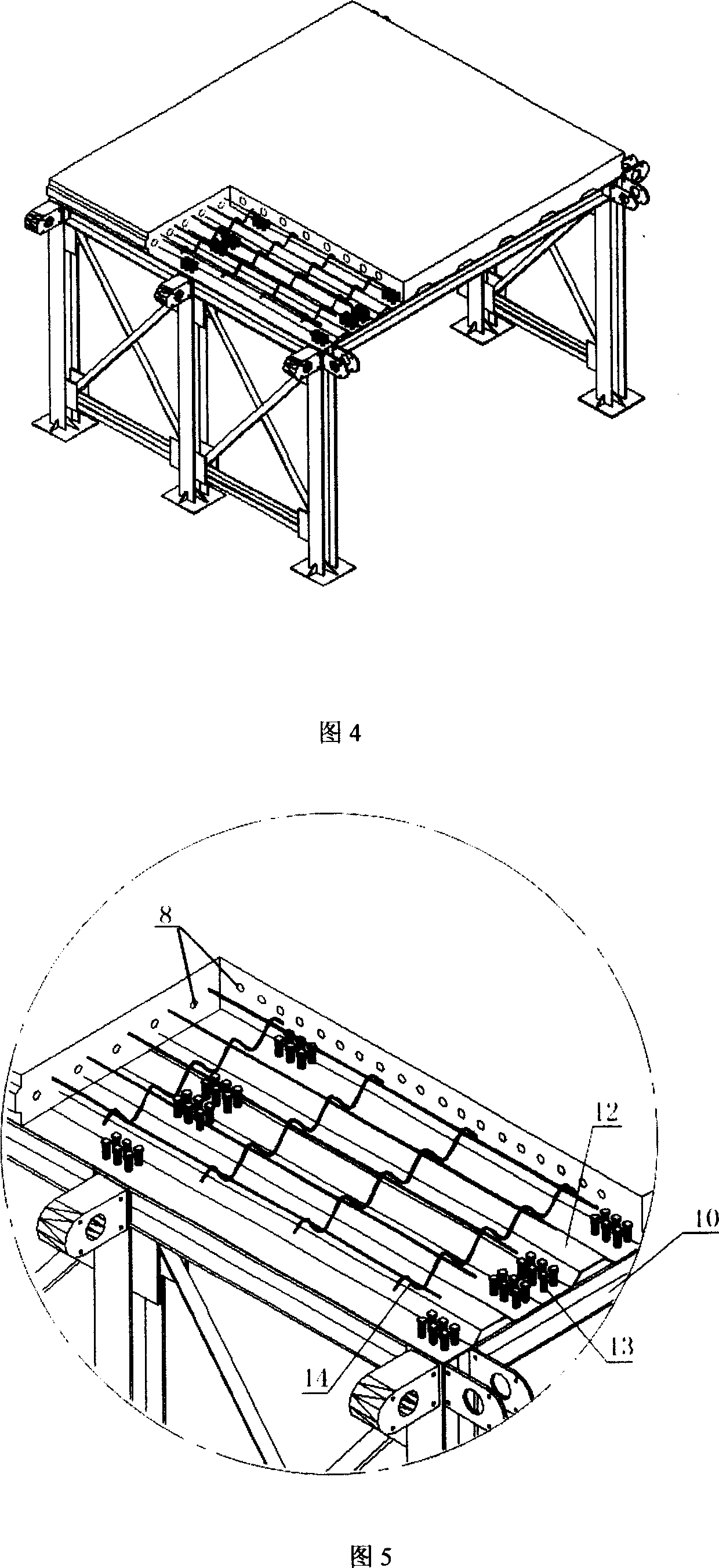

Composite frame system with beam column flanges being made of steel pipe concrete and construction method

ActiveCN106869316ASimplify the construction processLabor savingStrutsPillarsComposite beamsBeam column

The invention relates to a composite frame system with beam column flanges being made of steel pipe concrete and a construction method. The composite frame system with the beam column flanges being made of the steel pipe concrete is formed by connecting composite columns with composite beams through joints. The composite beams are horizontally arranged among the composite columns. The joints are steel pipe concrete integral type joints. The composite columns are cross-shaped or I-shaped composite columns with the flanges being made of the circular steel pipe concrete. The composite beams are I-shaped honeycombed beams with the flanges being made of the steel pipe concrete. The joints and the composite columns are fixedly connected at respective connecting plates through high-strength bolts. The joints and the composite beams are connected through buffer sections which are I-shaped honeycombed beams with the flanges being made of the steel pipe concrete. The cross sections of the buffer sections are variable cross sections gradually diminished from the two ends to the centers, and the cross sections of the buffer sections are smallest at the midpoints. The problems that according to an existing steel-concrete composite structure, construction is complex, connection and stability between the composite structure are poor, and the joints are liable to damage under the earthquake effect are solved.

Owner:青岛义和钢构集团控股有限公司

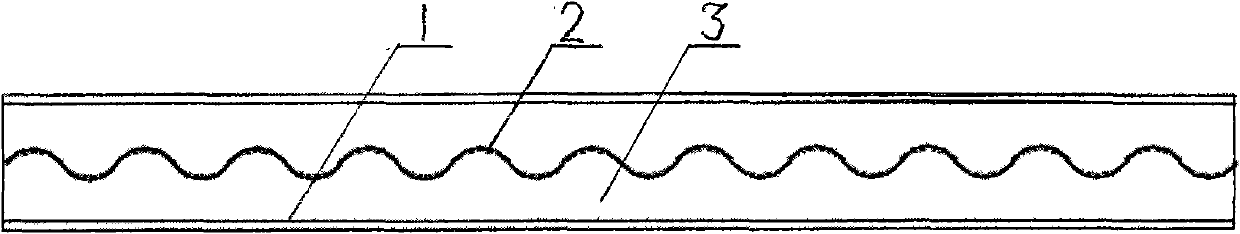

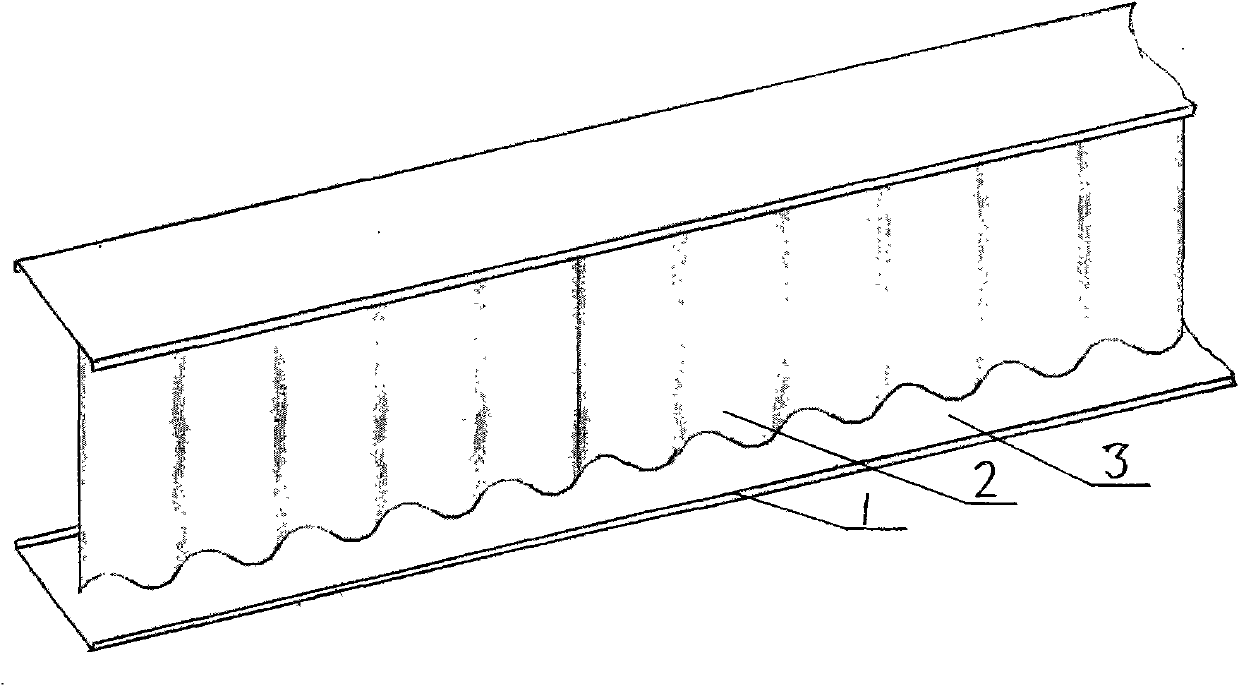

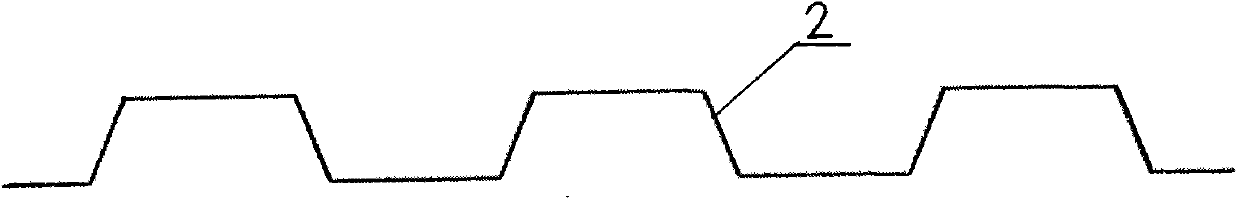

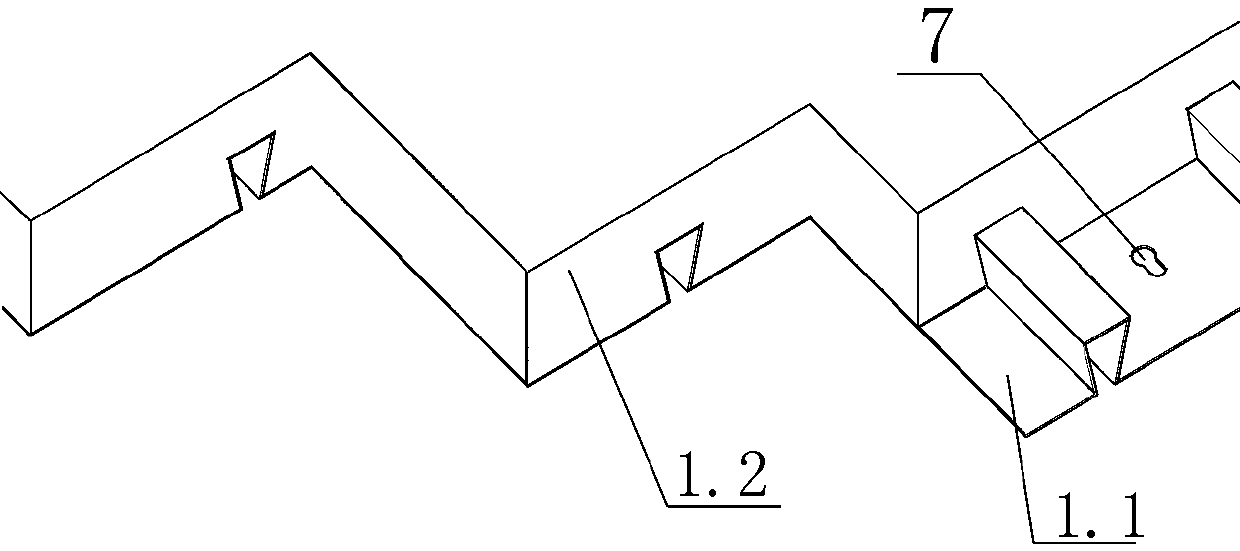

H-shaped steel structural part and production method thereof

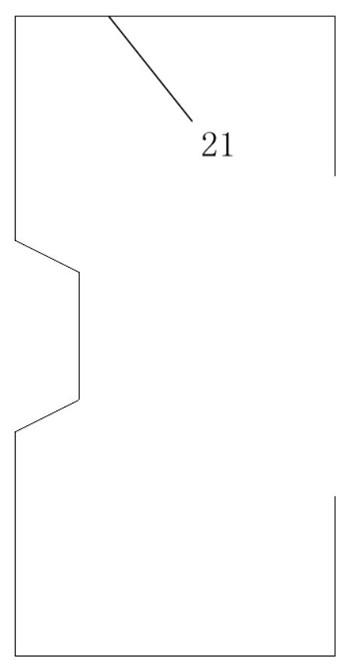

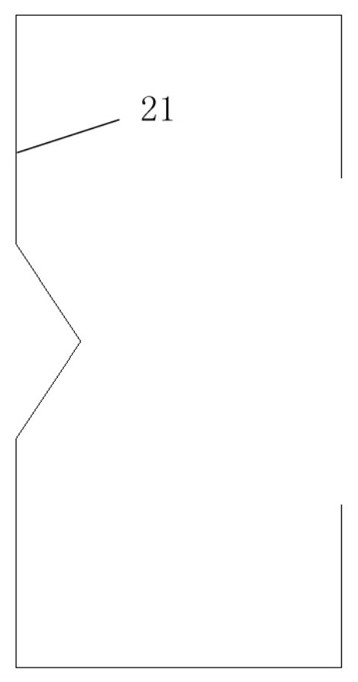

InactiveCN102704567AIncrease stiffnessReduce distortionBuilding constructionsFully developedWave shape

The invention provides an H-shaped steel structural part and a production method thereof. According to the H-shaped steel structural part, two opposite flange plates are provided, a web plate of which the cross section is wave-shaped is fixedly welded between the middles of the two flange plates longitudinally, and inwards folded edges are formed on two rims of each flange plate. By the H-shaped steel structural part, stiffening force is formed after rims of the flange plates are folded, so that the limit of a width-to-thickness ratio is greatly broken through, and mechanical properties of steel is fully developed; the web plate of which the cross section is wave-shaped has extremely high shear buckling resisting capacity, so that the web plate can be thinned, and a stiffening plate is not required; and advantages of the flange plates and the web plate are integrated, so that the rigidity of the structural part is enhanced, deformation of the structural part under the action of external force is reduced, the load-bearing property of the structural part is effectively improved, the dead loads of main load-bearing members such as beams and columns are reduced, and the using effect is improved. The steel structural part can be in a uniform cross-section shape or a variable cross-section shape and can be widely applied to steel load-bearing members.

Owner:山东万事达建筑钢品股份有限公司

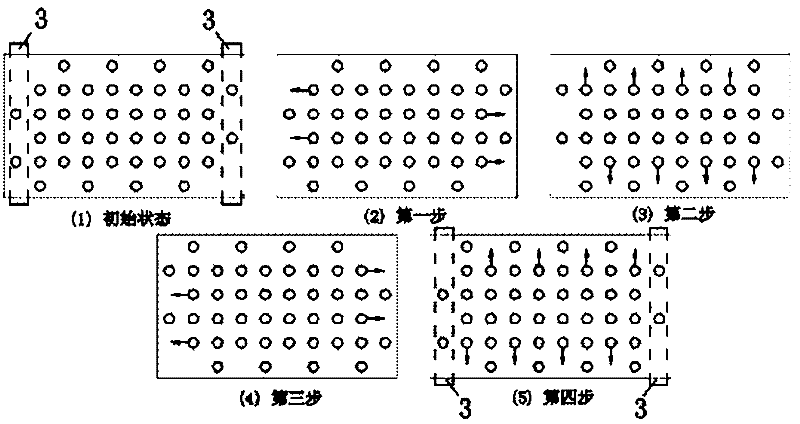

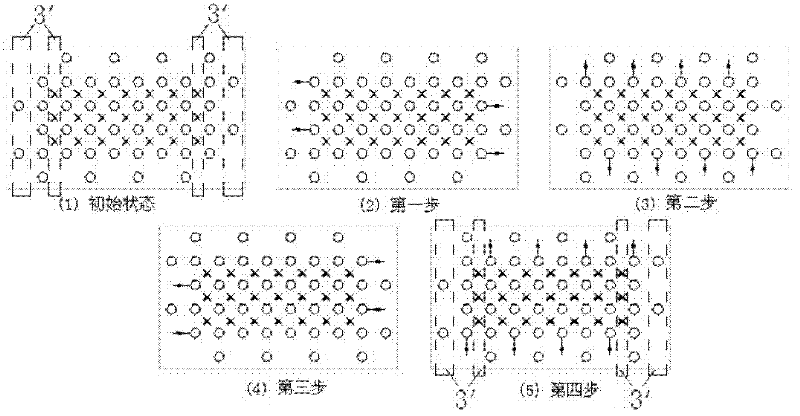

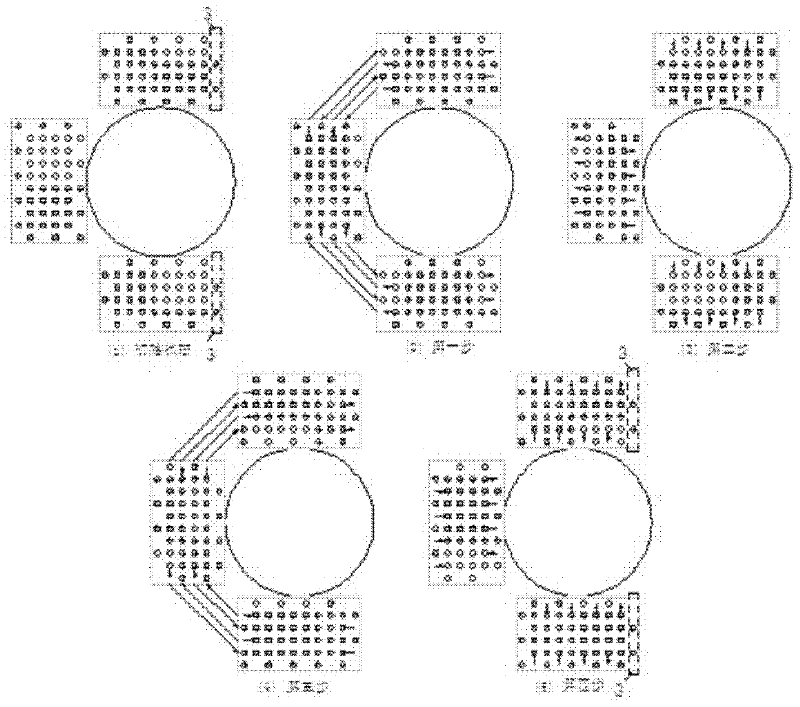

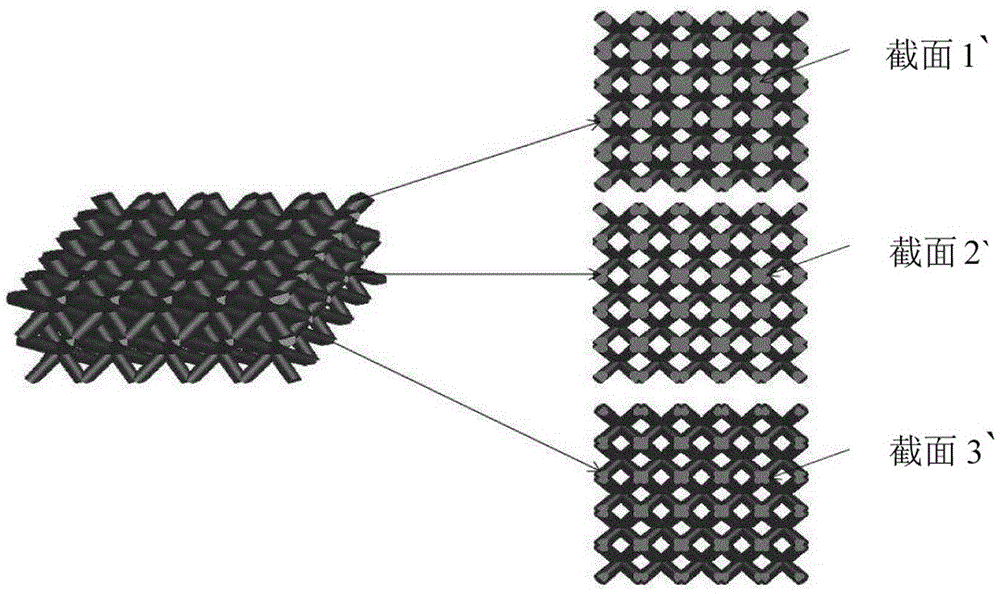

Preparation method of performing body with extendable cross section dimension

The invention relates to a preparation method of a performing body with extendable cross section dimension. According to the method, a three-dimensional multidirectional structure is adopted, and the performing body with the extendable cross section dimension is prepared through fiber beam throwing-out and planting, so the problem that the dimension of the vertical center line is limited by the equipment volume in the existing three-dimensional weaving performing body preparation method is solved. The preparation method has the advantages that on the premise of not increasing the weaving equipment volume, the dimension of the direction vertical to the weaving axis is approximately and exponentially widened, the application of a three-dimensional weaving structure to a large-dimension component becomes possible, yarns in the prepared integrally connected performing body are complete and continuous, the mechanical property of the yarns is favorably and fully exerted, and the yarns can be applied to structural compound materials with higher mechanical property requirements. The reparation method can be used for preparing the performing body with the extendable cross section dimension, and the application of the three-dimensional weaving performing body onto the larger-area structure component is widened.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

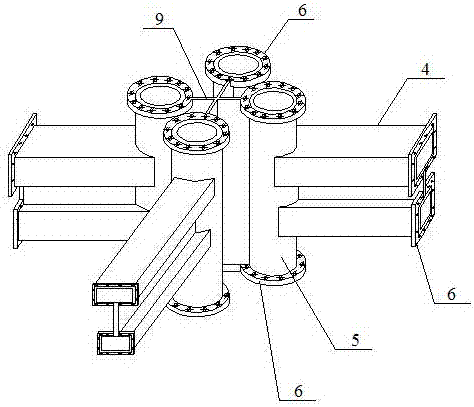

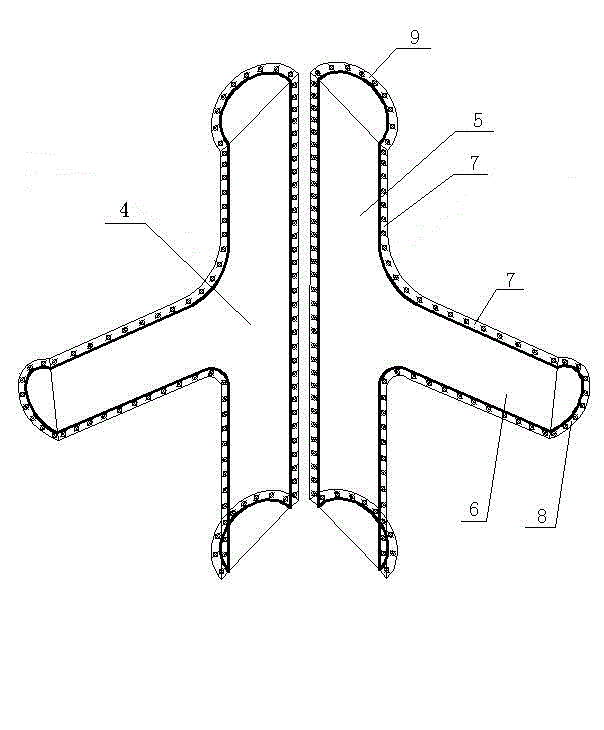

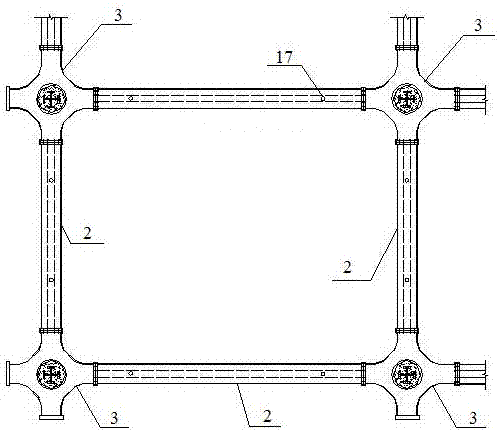

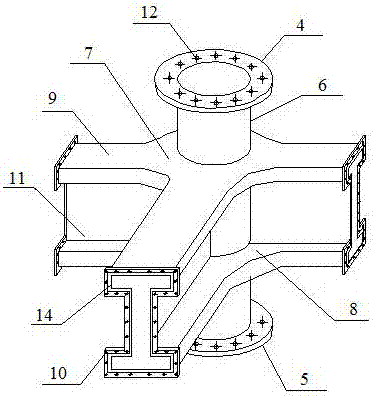

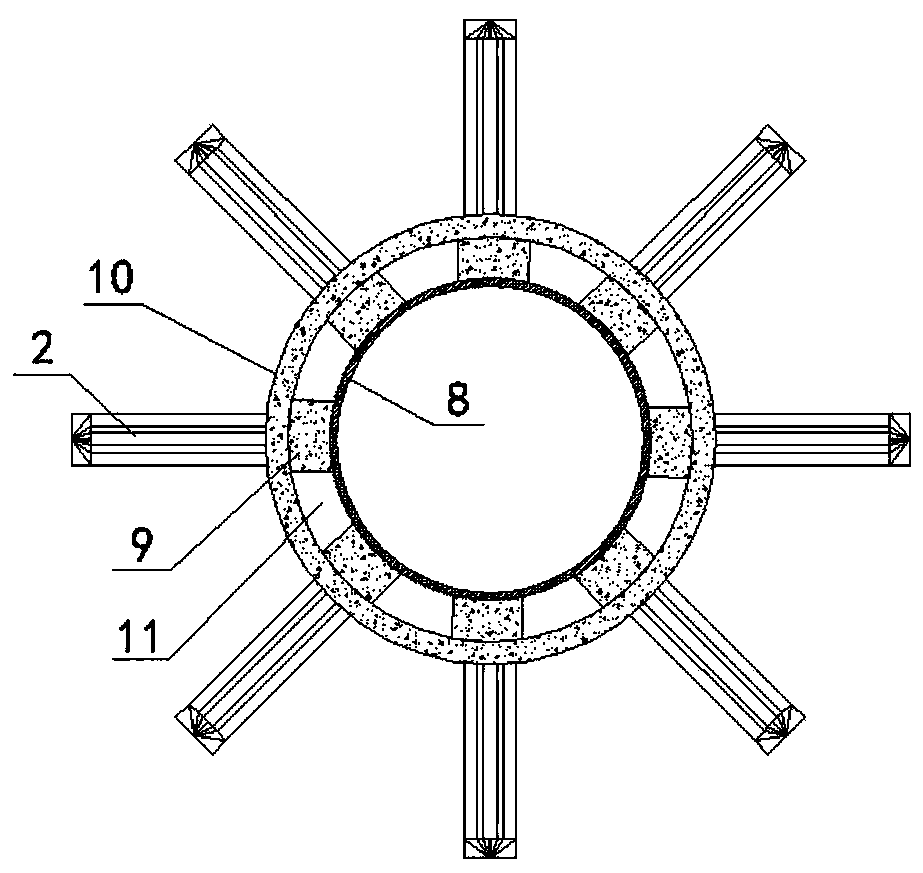

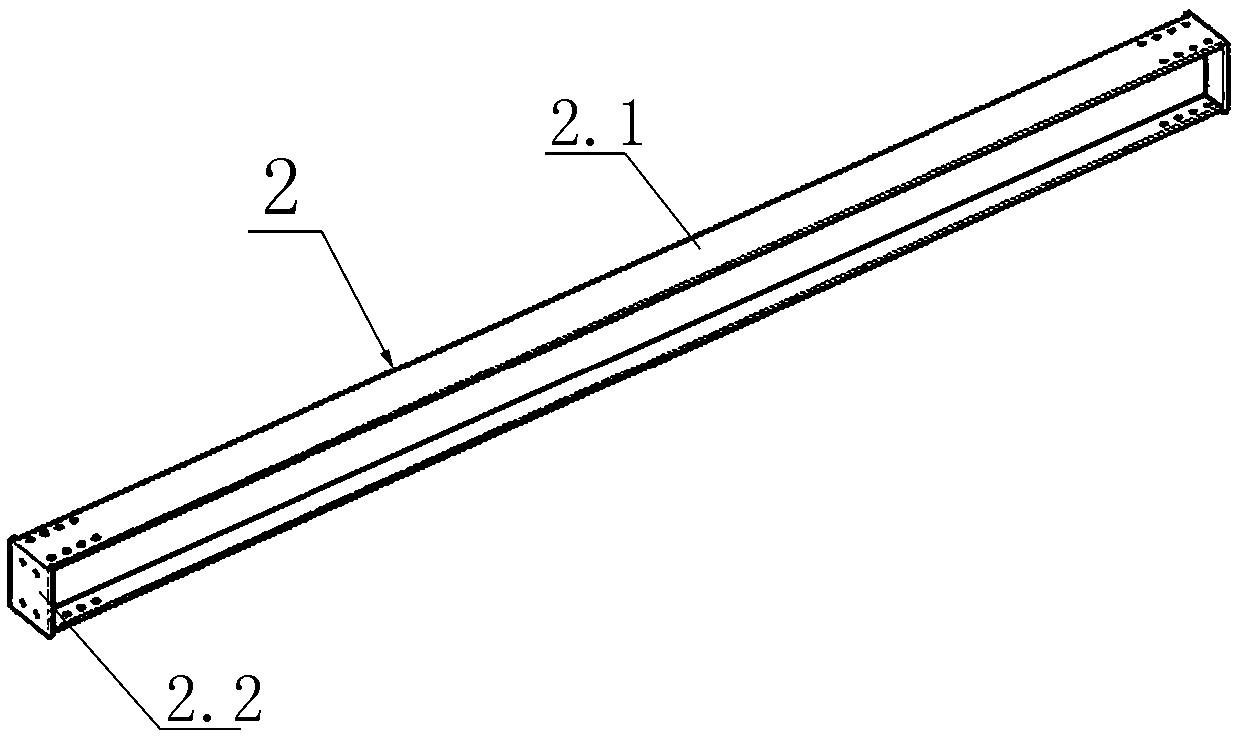

Fiber reinforce plastic (FRP) combination structure frame where integral type node is adopted and construction method thereof

InactiveCN102747781AImprove bearing capacityIncrease stiffnessBuilding material handlingFiberButt joint

The invention relates to a fiber reinforce plastic (FRP) combination structure frame where an integral type node is adopted and a construction method thereof. The FRP combination structure frame where the integral type node is adopted is formed by enabling an FRP pipe concrete combination beam and FRP pipe concrete combination columns to be connected. The FRP pipe concrete combination beam is horizontally arranged between the FRP pipe concrete combination columns, and the FRP integral type node is fixedly connected at the junction of the FRP pipe concrete combination beam and the FRP pipe concrete combination columns. The FRP integral type node is formed by enabling two node single bodies to be in butt joint and then be fixedly connected through bolts, each node single body is integrally formed after a vertical half pipe and a horizontal half pipe are joined, two longitudinal end faces of the vertical half pipe respectively extend outwards to form connecting lugs, and the upper end face and the lower end face of the vertical half pipe respectively extend outwards to form horizontal column connecting pieces. Two horizontal end faces of the horizontal half pipe respectively extend outwards to form connecting lugs, and the left end face and the right end face of the horizontal half pipe respectively extend outwards to form beam column connecting pieces. Steel ribs can be added in FRP pipes of the frame beam and the columns, or prestressed ribs are arranged in the beam, and bearing capability and rigidity of a component can be improved.

Owner:NORTHEAST GASOLINEEUM UNIV

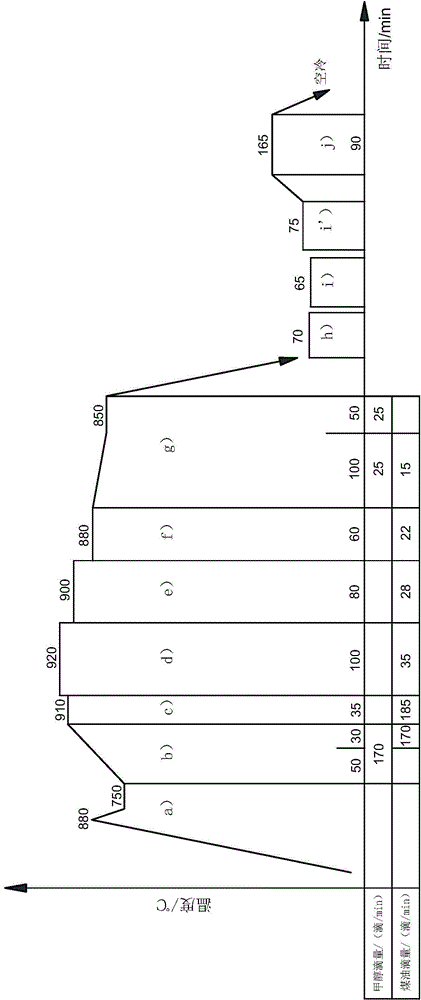

Carburizing and quenching process of automobile gear

InactiveCN104357796AGuaranteed reliabilityGuaranteed service lifeSolid state diffusion coatingFurnace typesWear resistanceUltimate tensile strength

The invention provides a carburizing and quenching process of an automobile gear. By adopting a pit-type gas carburizing furnace to perform carburizing treatment on the automobile gear, the carburizing and quenching process comprises the following steps: a) performing primary preheating, namely, gradually raising the temperature in the furnace to 880 + / -5 DEG C and then putting the automobile gear in the furnace, gradually reducing the temperature in the furnace to 750 + / -5 DEG C, preserving the heat for 30 minutes. The carburizing and quenching process of the automobile gear disclosed by the invention adopts a manner of repeatedly preheating and diffusing, so that the depth of an effective carburizing layer of the automobile gear is 1.1-1.2mm after carburizing to obtain a finished product, and the surface hardness is 58-62HRC, and therefore, the wear resistance, the strength and the fatigue limit of the components are improved, and the mechanical performances of the gear material are sufficiently brought into play. Moreover, distortions such as diameters changes, uneven changes in an addendum circle and an inner hole, plane warpage as well as dimension changes between gears are not produced, so that the reliability and the service life of the automobile gear are guaranteed.

Owner:余姚市鸿胜汽车配件有限公司

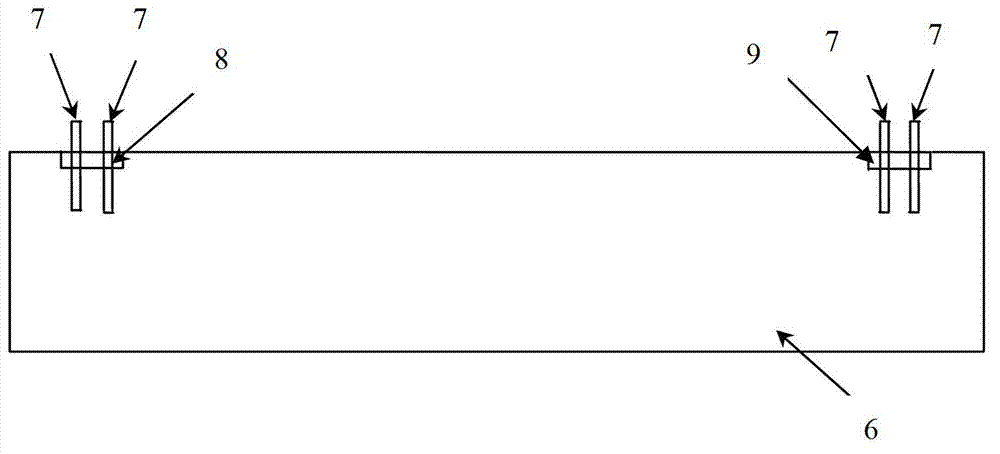

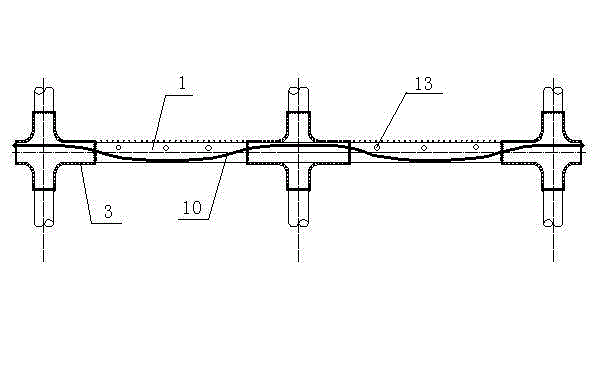

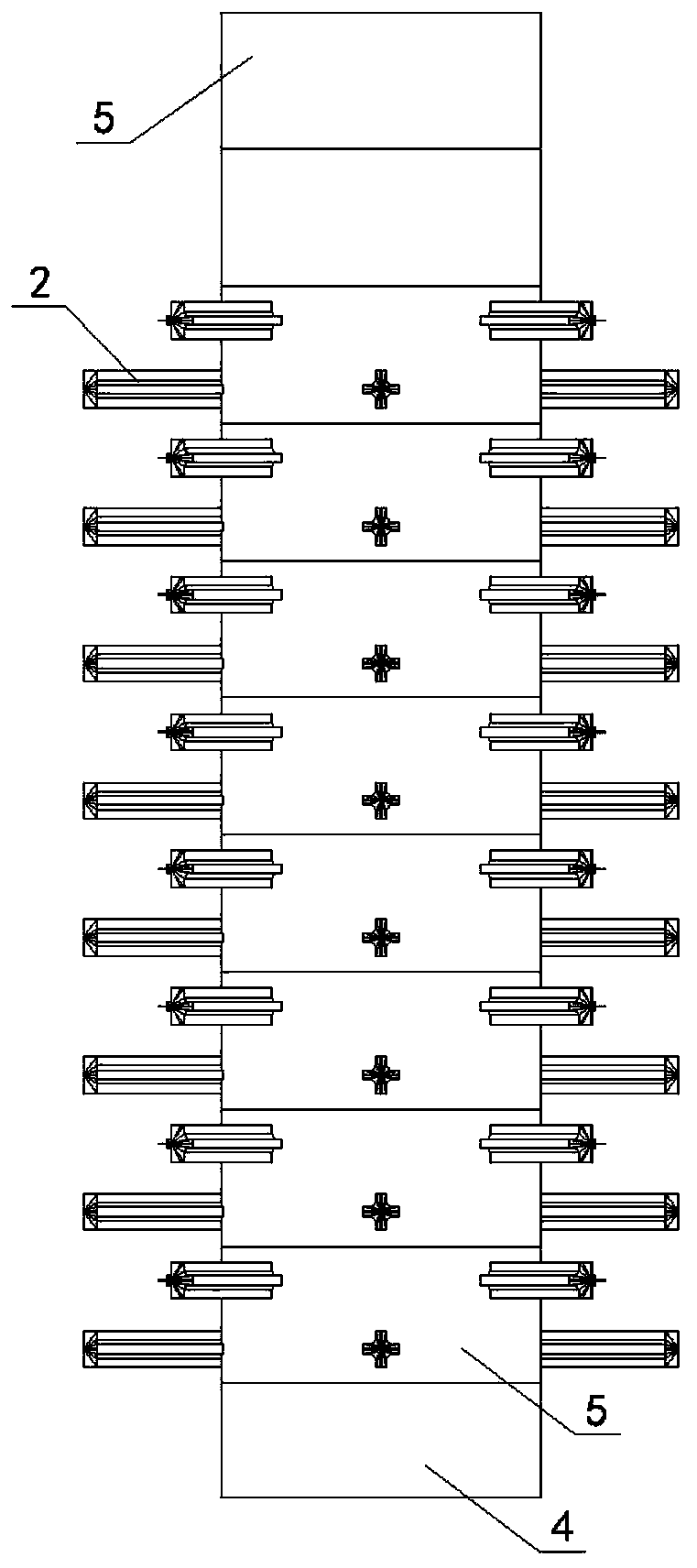

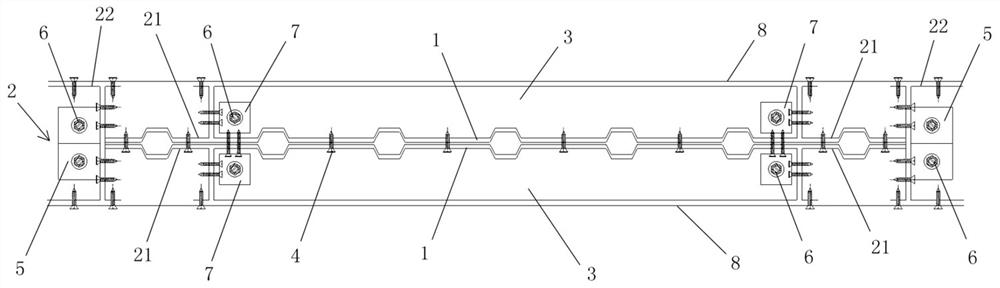

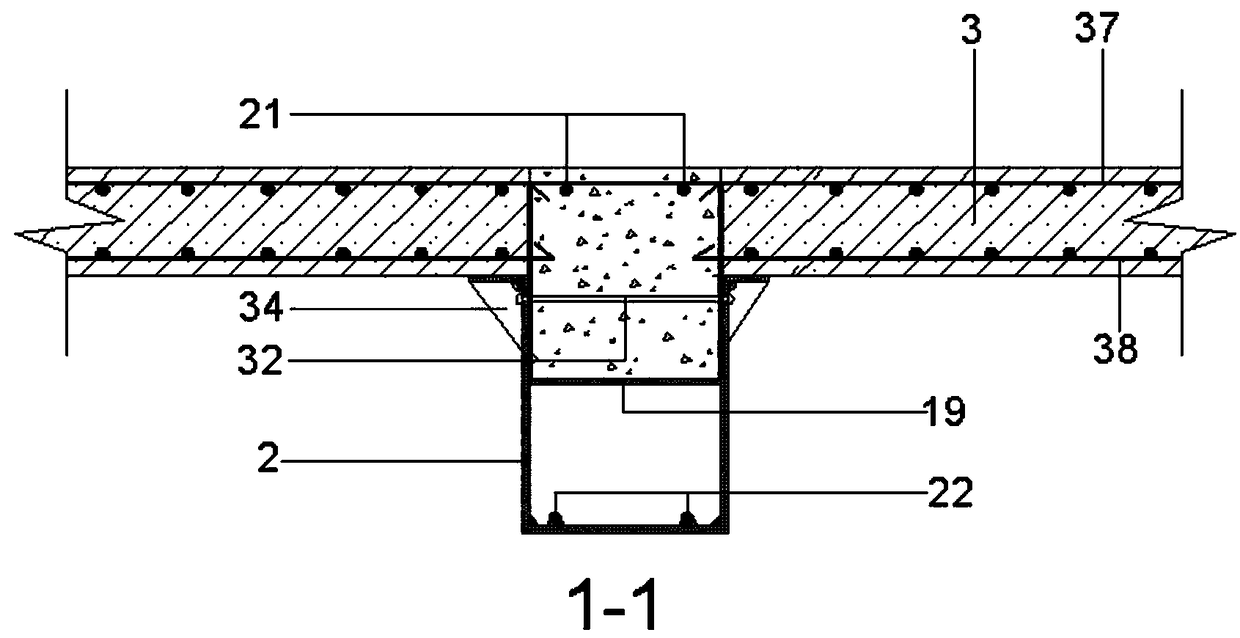

Steel pipe concrete frame with prestressing tendons and construction method thereof

ActiveCN106869315APower transmission is clearAccurate connectionLoad-supporting elementsCurve shapePre stress

The invention relates to a steel pipe concrete frame with prestressing tendons and a construction method thereof. The steel pipe concrete frame with the prestressing tendons is formed by connecting composite columns with composite beams through joints. The composite beams are horizontally arranged among the composite columns. The joints are outer sleeving integral type joints internally filled with self-compacting concrete. The composite columns are sectional-type steel pipe concrete composite columns with built-in profile steel. The composite beams are internal-prestress I-shaped steel pipe concrete composite beams. The prestressing tendons arranged in the composite beams bypass joint outer pipes from upper strengthening annular plates with cavities. The prestressing tendons are positioned through single-hole positioning plates and hole-formed double-hole main positioning plates, form symmetrical curve shapes and achieve tensioning and anchoring at joint end beams. The self-compacting fine stone concrete of the composite beams and self-compacting fine stone concrete of the joint end beams are through and form a whole with the joint outer pipes after curing. The problem that beam-column connecting joints of a novel steel pipe concrete frame with prestressing tendons are complex and liable to damage is solved.

Owner:广西万纵建设工程有限公司

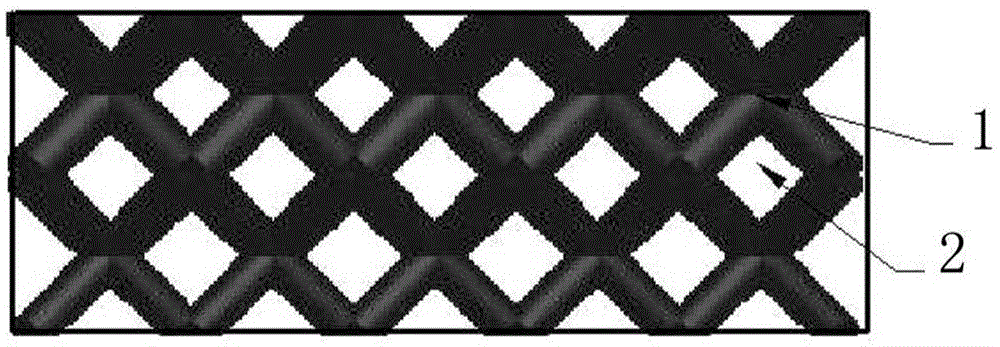

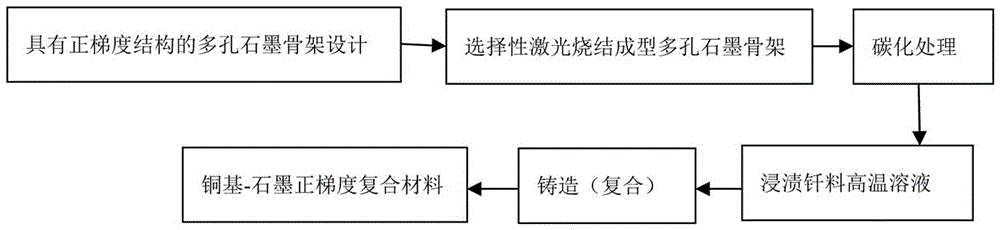

Copper base-graphite positive gradient composite and preparation method thereof

ActiveCN105648259AImprove wear resistanceInhibit expansionGearingCylindersSelective laser sinteringNetwork structure

The invention discloses a copper base-graphite positive gradient composite and a preparation method thereof. The copper base-graphite positive gradient composite is prepared by compounding copper alloy and a three-dimensional porous graphite skeleton with the positive gradient structure feature. During preparation, a three-dimensional porous graphite skeleton green body with the positive gradient structure feature is prepared by utilizing a selected laser sintering forming technology firstly, then carbonization treatment is carried out on the three-dimensional porous graphite skeleton green body to obtain the three-dimensional porous graphite skeleton, liquid solder is coated on the three-dimensional porous graphite skeleton through a dipping manner, and finally, copper alloy liquid metal is poured in the three-dimensional porous graphite skeleton by adopting a casting manner to obtain the needed copper base-graphite positive gradient self-lubricating composite. The preparation method ensures the graphite content to be in positive gradient change from the outside to the inside, graphite to be uniformly distributed on the arbitrary frictional wear surface and the copper alloy to form a continuous network structure in a composite system, and thus excellent electric and thermal conductivities and excellent mechanical property of a copper matrix are fully exerted.

Owner:CHINA THREE GORGES UNIV

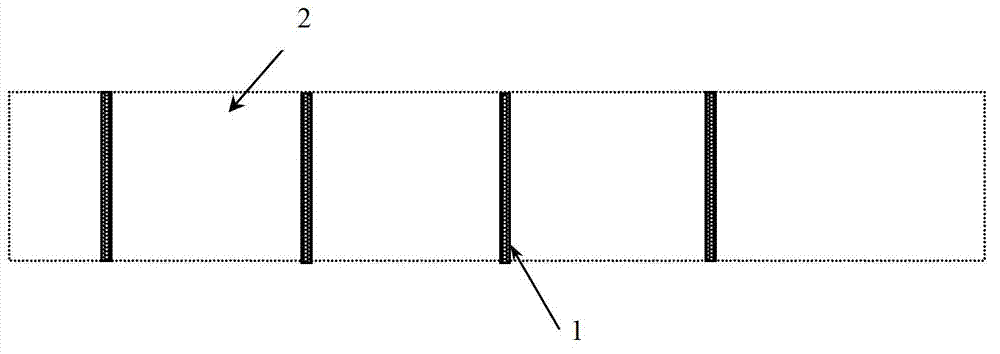

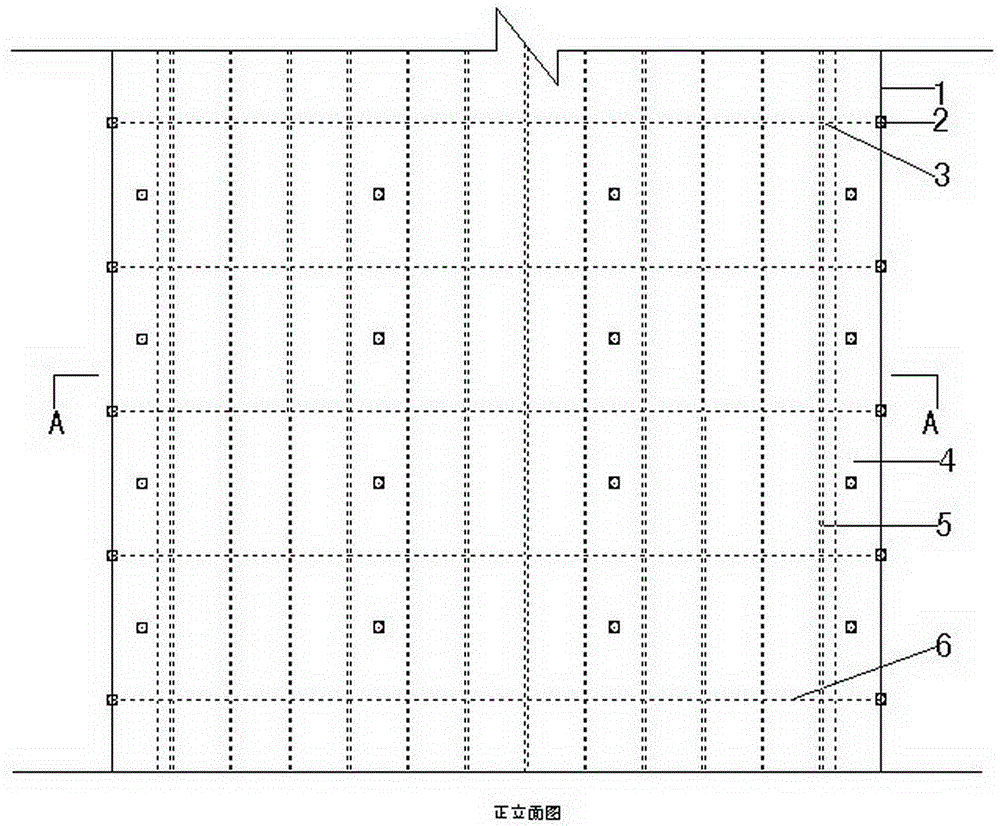

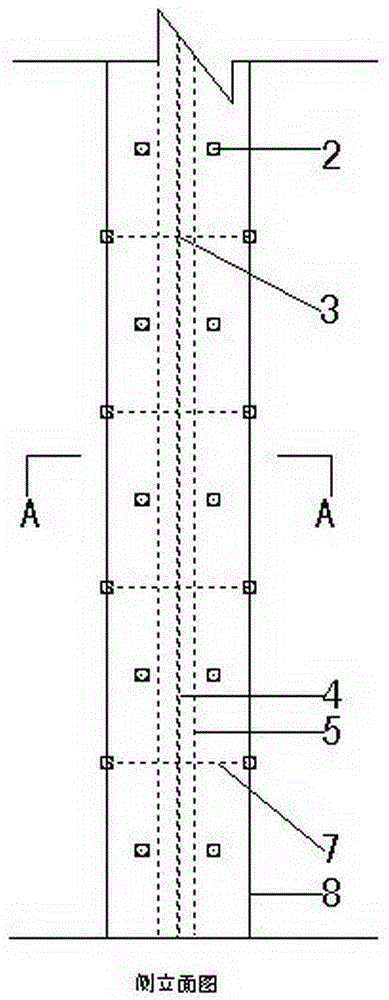

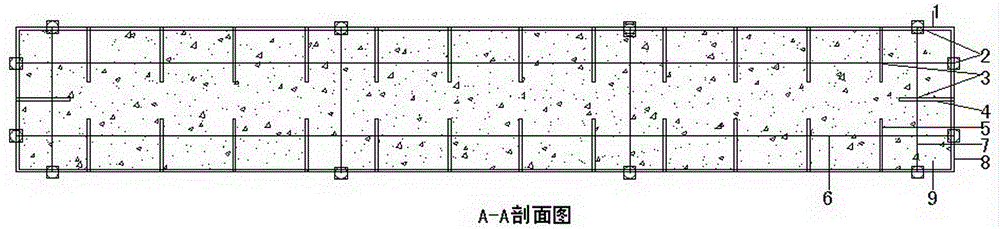

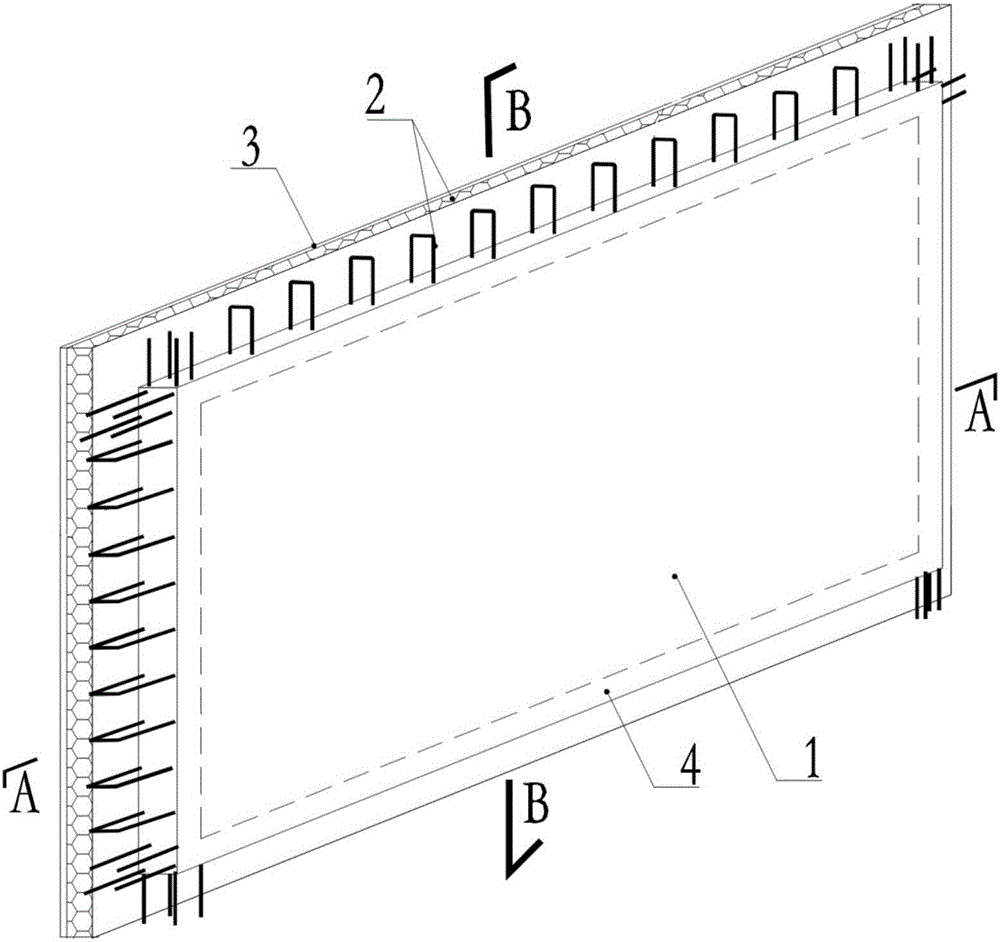

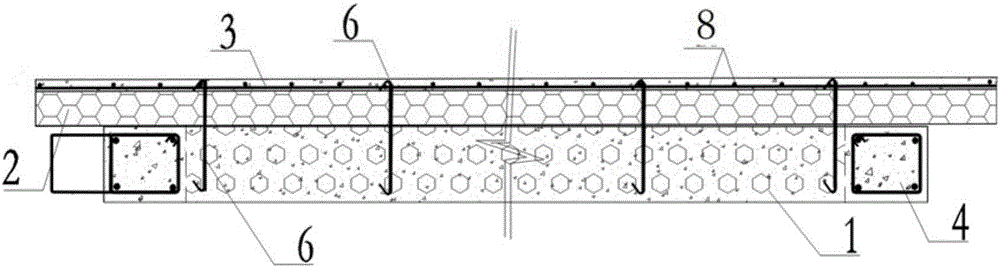

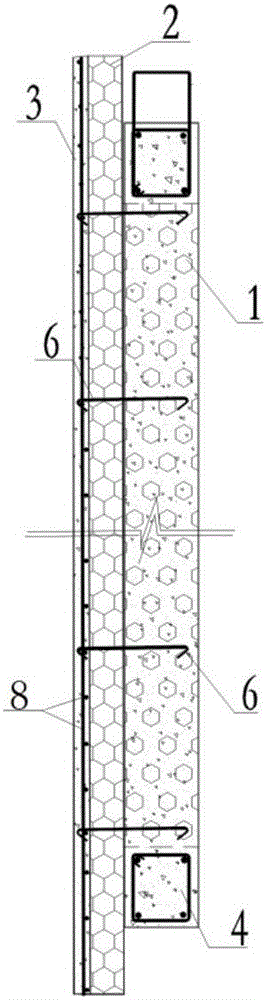

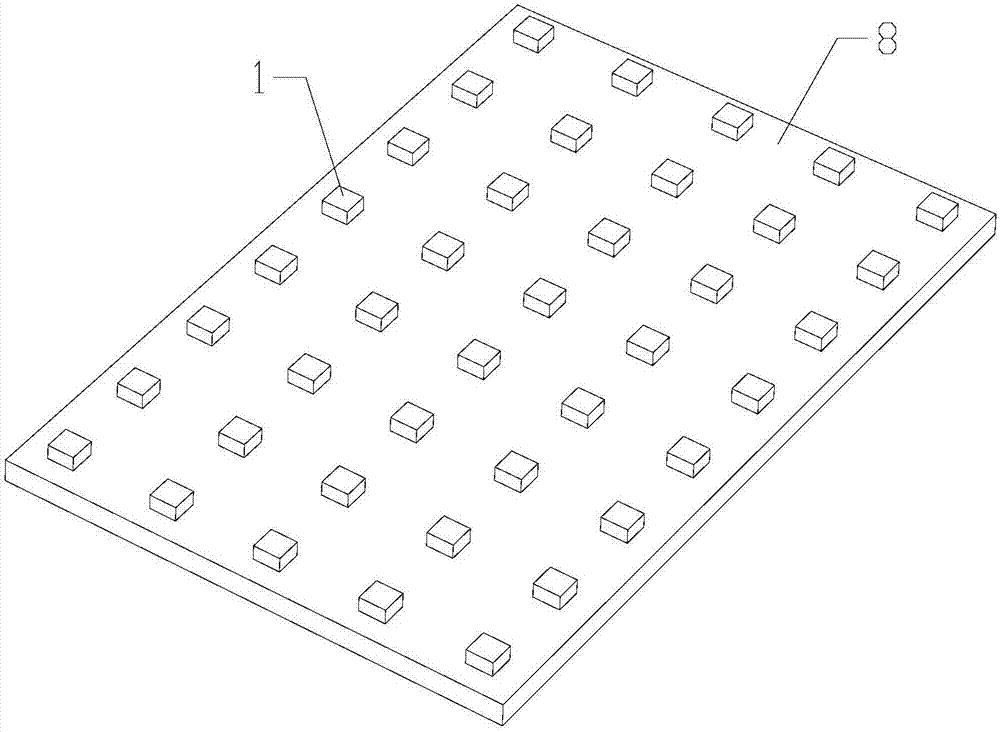

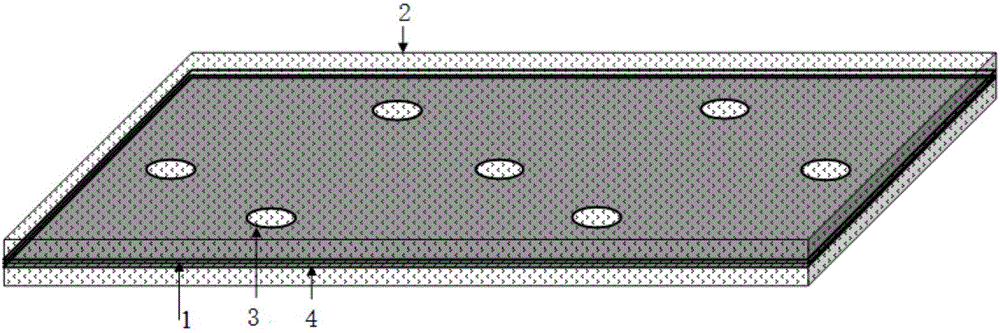

Punched rib and pull rod constraint double-layer steel plate concrete shear wall

The invention discloses a punched rib and pull rod constraint double-layer steel plate concrete shear wall. The punched rib and pull rod constraint double-layer steel plate concrete shear wall comprises two opposite wall body steel plates, connection steel plates at the two ends of a wall body, filling concrete defined by the steel plates on the four sides, punched stiffening ribs and pulling rods penetrating through the punched stiffening ribs. The punched stiffening ribs are arranged on the inner side faces of the steel plates and connected through the pulling rods penetrating through holes. The pulling rods comprise the pulling rods in the wall length direction and the pulling rods in the wall thickness direction. The pulling rods in the wall length direction penetrate through the stiffening ribs arranged in the wall length direction and the connection steel plates at the two ends. The pulling rods at the two ends of the wall body in the wall thickness direction penetrate through the stiffening ribs in the wall thickness direction and the two opposite wall body steel plates. The pulling rods at other portions in the wall thickness direction are arranged between every two adjacent stiffening ribs arranged in the wall length direction every other 2-5 stiffening ribs, and are staggered with the pulling rods in the wall thickness direction along the wall height part at proper intervals. The bearing capacity and ductility of the shear wall can be improved.

Owner:HENAN POLYTECHNIC UNIV

Environmental-friendly and multifunctional recycled concrete sound barrier panel

InactiveCN101881008AHigh porosityImprove sound absorptionNoise reduction constructionSound barrierResource saving

The invention discloses an environmental-friendly and multifunctional recycled concrete sound barrier panel, which comprises a sound insulation panel and a sound absorption module molded on the sound insulation panel by overall casting. The environmental-friendly and multifunctional recycled concrete sound barrier panel, the sound insulation panel and the sound absorption module of the invention are formed integrally, the bonding strength is high between two panels, at the same time, a connecting reinforcement bar is used for reinforcement, the overall strength is high, and the panel is solid and reliable, thereby effectively solving the fundamental problems of insufficient sound absorption performance and inadequate sound absorption panel strength for the traditional sound insulation panel. Moreover, the reclamation technology of construction wastes is fully used to apply recycled aggregates in a sound barrier panel. The replacement rate of construction wastes to natural aggregates can be more than 50 percent. Therefore, the invention has the advantages of resource saving and excellent performance.

Owner:上海德滨环保科技有限公司

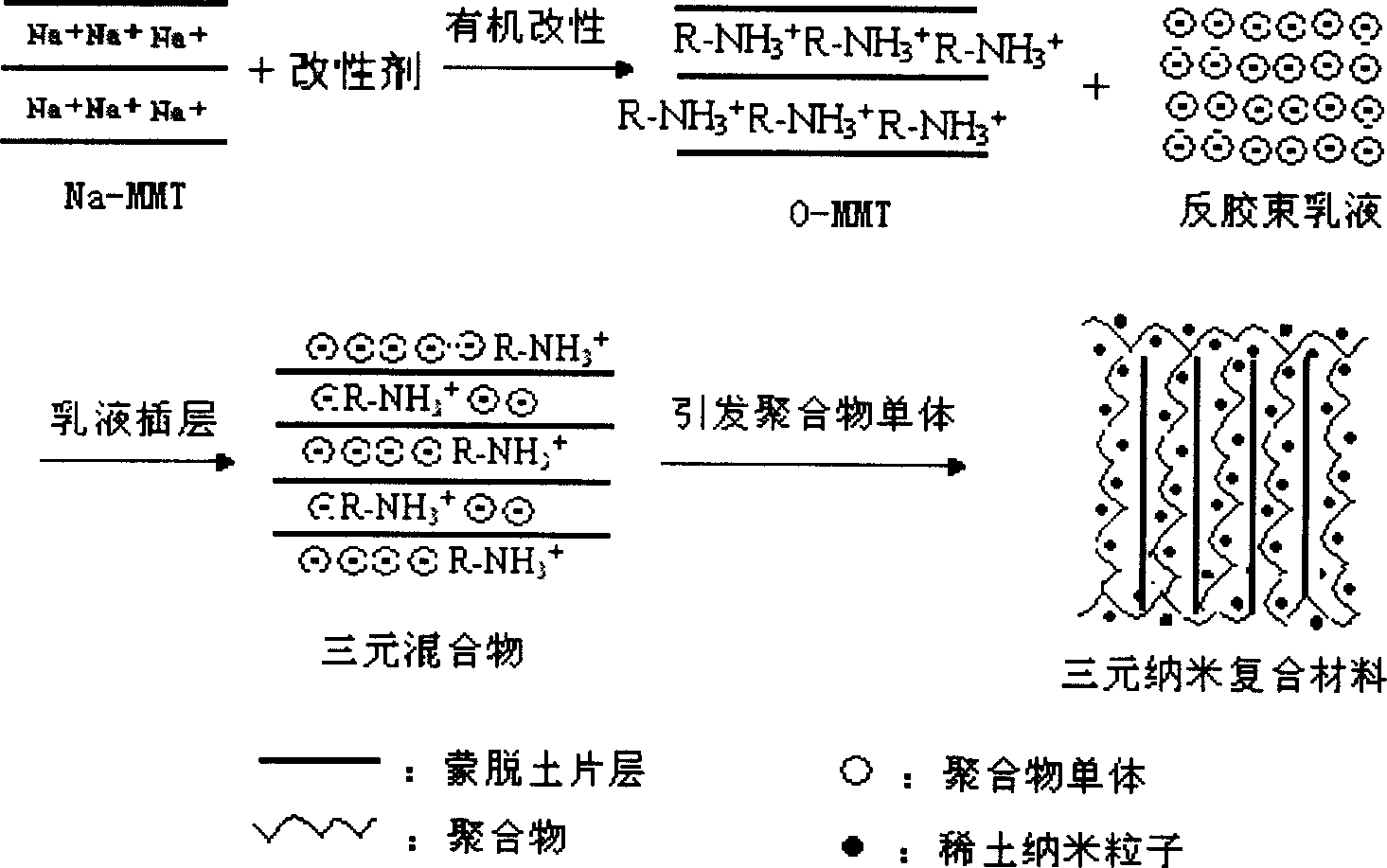

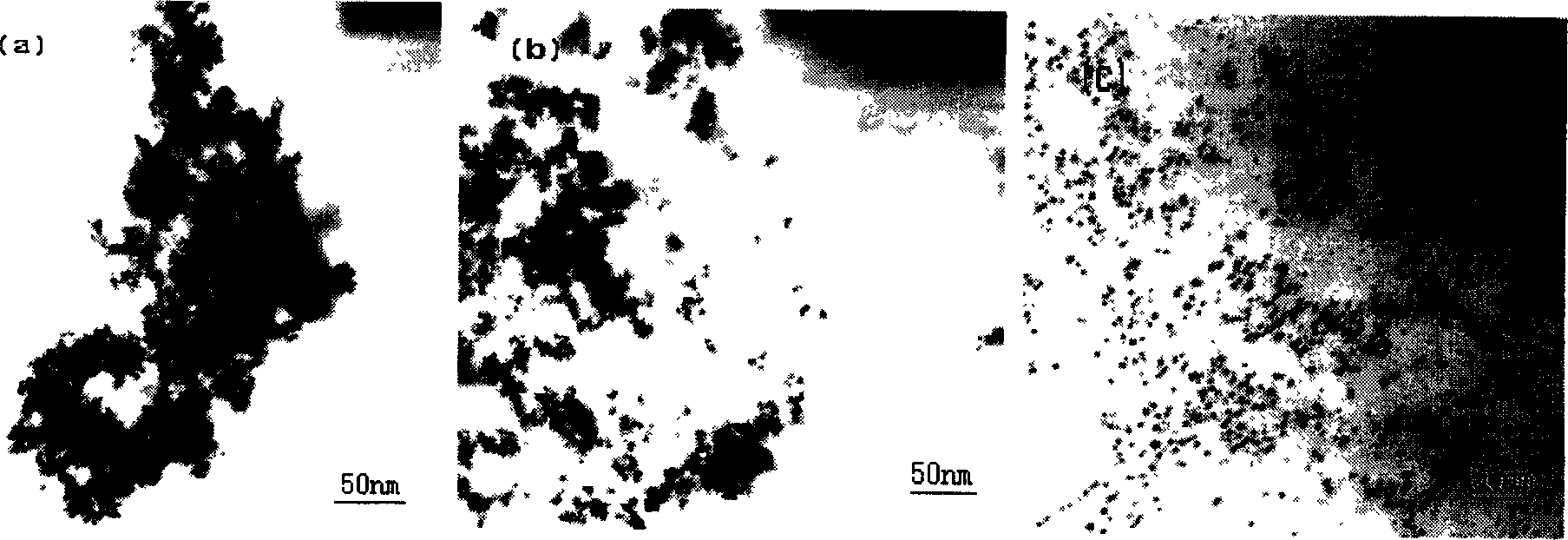

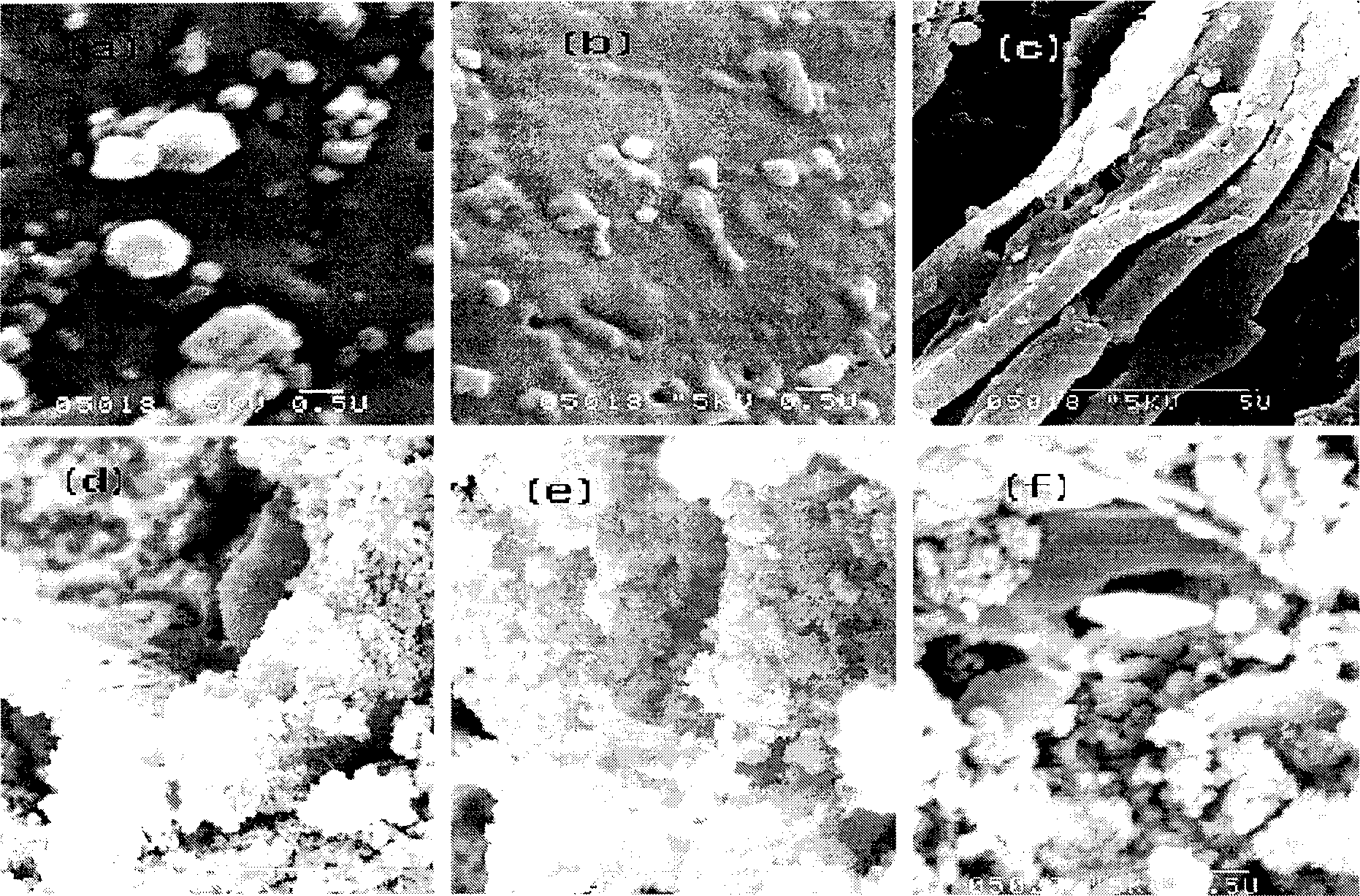

Montmorillonite/rare-earth particle/polymer ternary nano composite material and its preparing method

The invention discloses a method to manufacture montmorillonite / rare earth particle / polymer ternary nm compounding material. The layer inserting of rare earth particle and the making of the monomer polymerizing with compounding material of the invention are taken synchronistically. The organic modification of the abio-nm particle and the dispersing process in the ahead-driving body are canceled, thus, the manufacturing time is shortened. It is easy to operate and has high production efficiency.

Owner:NORTHWEST NORMAL UNIVERSITY

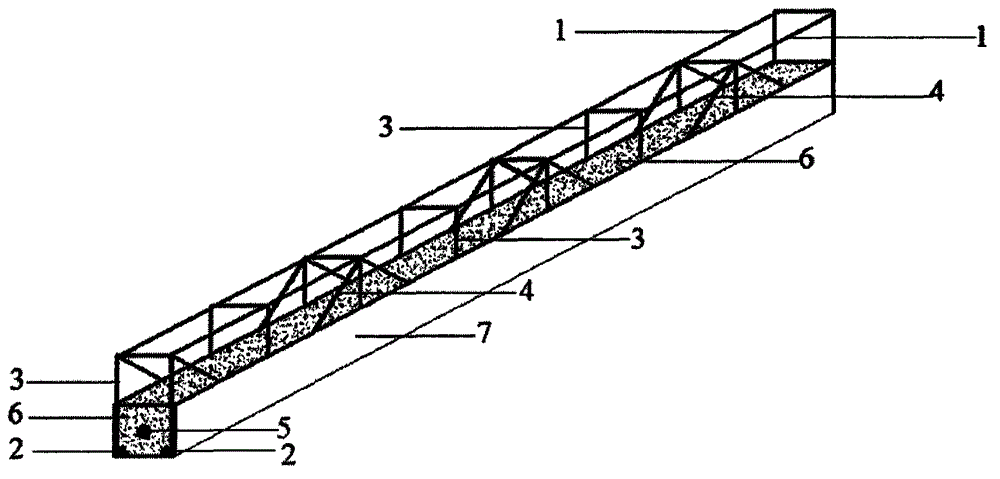

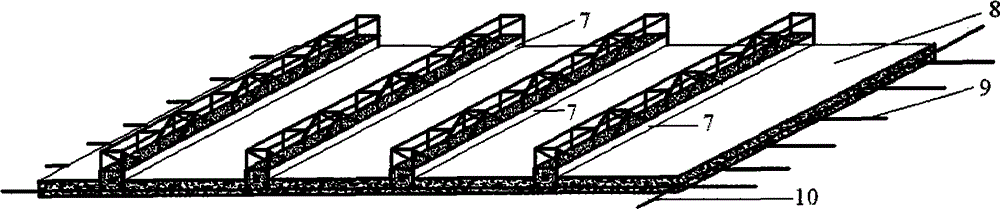

Self-supporting pre-stress combination beam lightweight aggregate concrete composite slab

The invention relates to a self-supporting pre-stress combination beam composite lightweight aggregate concrete formwork system, comprising manufacturing of a pre-tensioned pre-stressing steel bar truss-concrete combined beam and manufacturing of prefabricated composite slabs. The manufacturing of a pre-tensioned pre-stressing steel bar comprises steps: 1,binding and welding a beam steel bar truss, a framework height being height of a floor slab subtracting thickness of an upper protection layer and a lower protection layer, a beam top and a bottom steel bar being not provided with a protection layer; 2, laying and tensioning a pre-stressed bar, the position of the pre-stressed bar being the center of the section of beam concrete; 3, pouring concrete in a prefabricated form; 4, after the concrete reaches design strength, relaxing the pre-stressed bar, to form a pre-stressing steel bar-concrete combined beam; 5, laying prefabricated composite slab steel bars, installing a pre-stressed beam on the composite slab steel bars according to design, and connecting the pre-stressed beam with plate steel bars; 6, pouring a lightweight aggregate concrete composite slab, to form the self-supporting pre-stress combination beam composite lightweight aggregate concrete formwork.

Owner:QIQIHAR UNIVERSITY

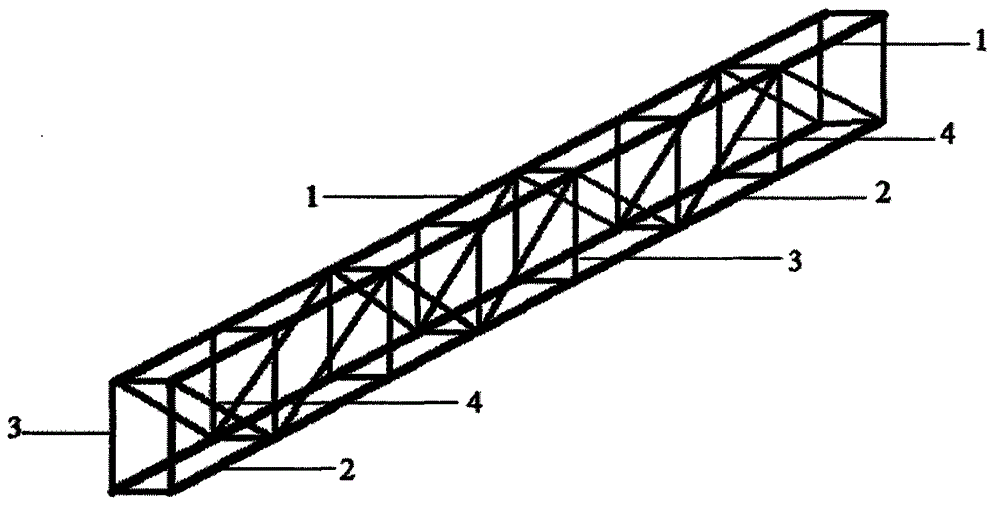

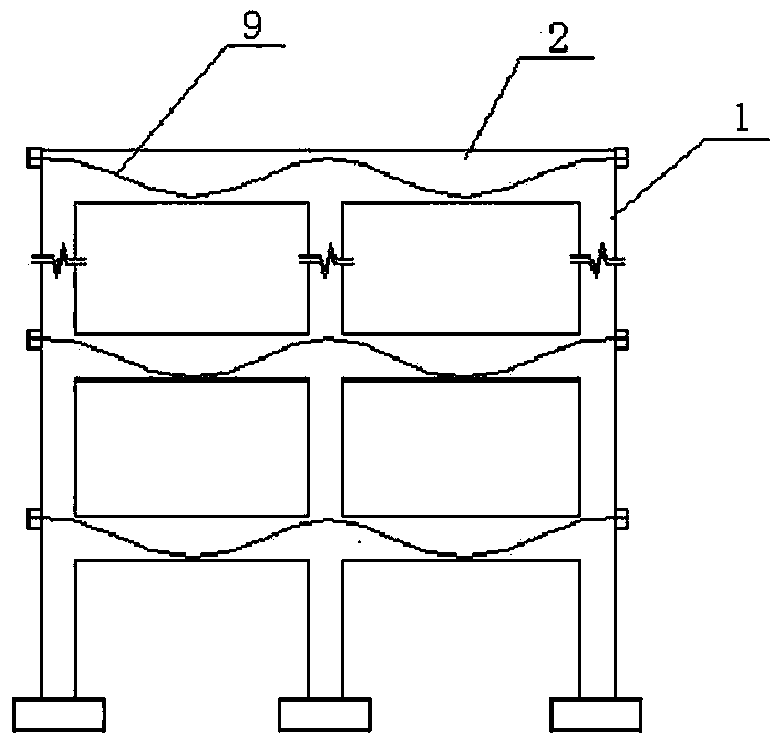

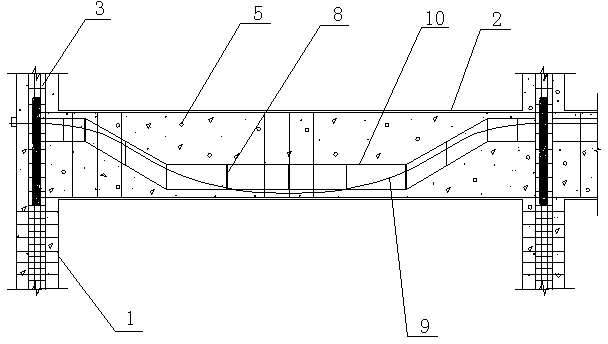

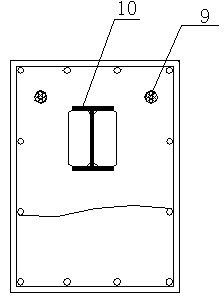

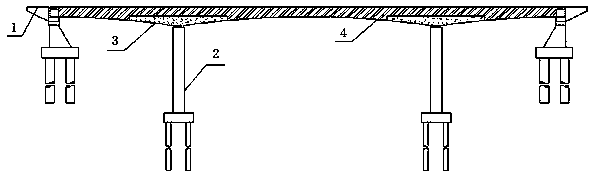

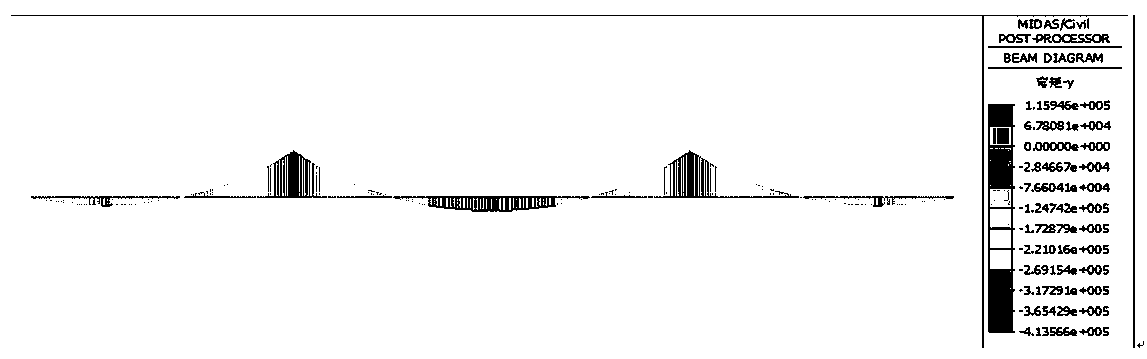

Frame type combined structure man-vehicle passage

ActiveCN1936184AGive full play to mechanical propertiesSave engineering materialsRoadwaysBridge structural detailsMarine engineeringEconomic benefits

The invention relates to a street and crossing that could realize people and vehicles passing separately. It has installable composite structure that adopts frame structure to combine steel material and concrete having strong tensile property to make full of the mechanical property of the materials. The entire capability of the street would be improved through optimizing the entire structure size. The invention has the advantages of decreasing project material, realizing industrial producing, lowering constructing cost, having good comprehensive economic benefits, etc.

Owner:钟宝驹

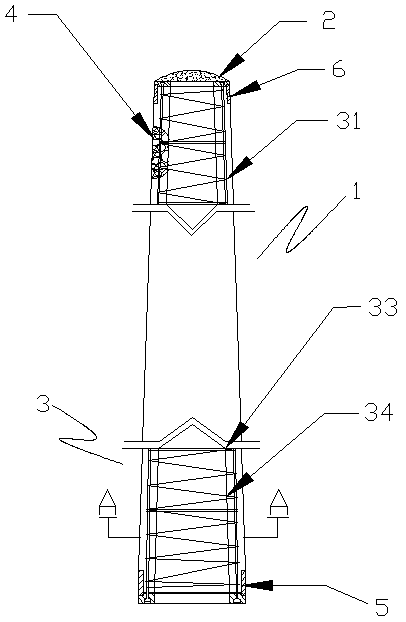

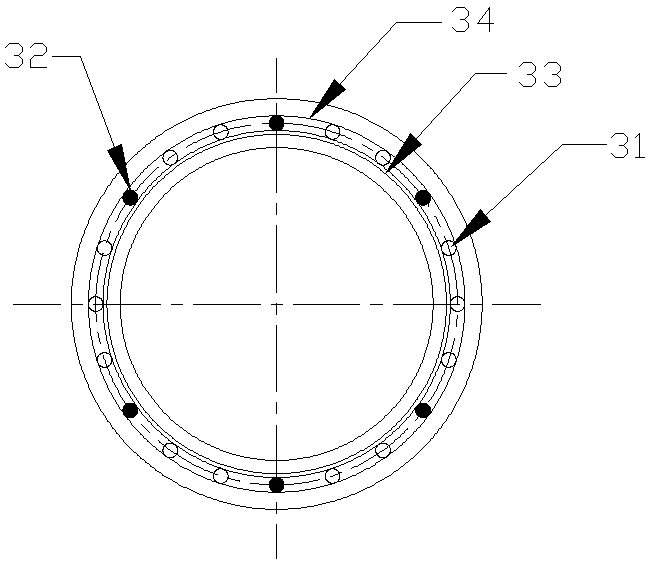

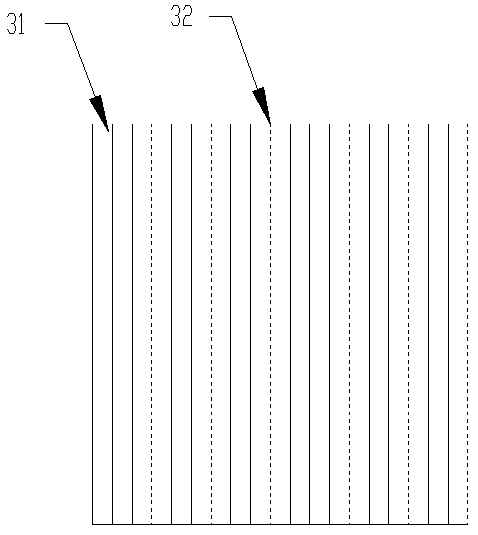

Two-wall hollow fabricated root-type open caisson foundation

PendingCN110093942AEffective force transmissionAvoid stress concentrationCaissonsEconomic benefitsDouble wall

The invention discloses a two-wall hollow fabricated root-type open caisson foundation. The two-wall hollow fabricated root-type open caisson foundation is composed of a shaft, root keys and a back cover, the shaft is of an annular tubular structure with two hollow walls, and is composed of a shaft inner wall, a rib wall and an outer wall in the radial direction, and a formed cavity between the well walls communicates vertically so that mud sucking equipment can be lowered and moved in the cavity between the well walls; bottom feet of the shaft are blade feet, and root keys are arranged on thepositions, penetrating through the shaft inner wall, the rib wall and the outer wall and protruding and extending from the outer wall, of the shaft; the shaft is formed by connection of a bottom segment and a plurality of standard segments in the vertical direction, the bottom segment is in a blade shape, and the blade feet are formed; and for the shaft which is completely jointed and sunk in place, the root keys are arranged in the shaft, and then the bottom of the shaft is poured to form the back cover. According to the two-wall hollow fabricated root-type open caisson foundation, main components are connected by prefabricated components correspondingly, the structure is simple, fast and accurate sinking of an open caisson can be realized, the construction difficulty is effectively lowered, the operational safety factor is improved, industrial mass production is facilitated, and economic benefits are obvious.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

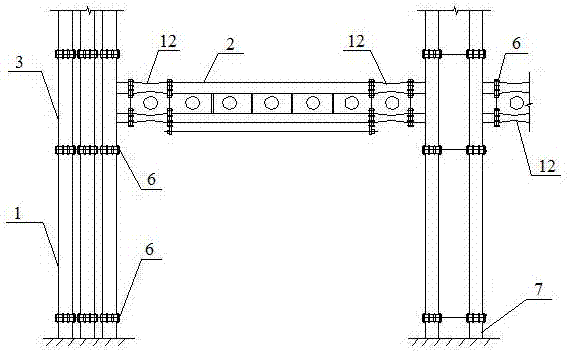

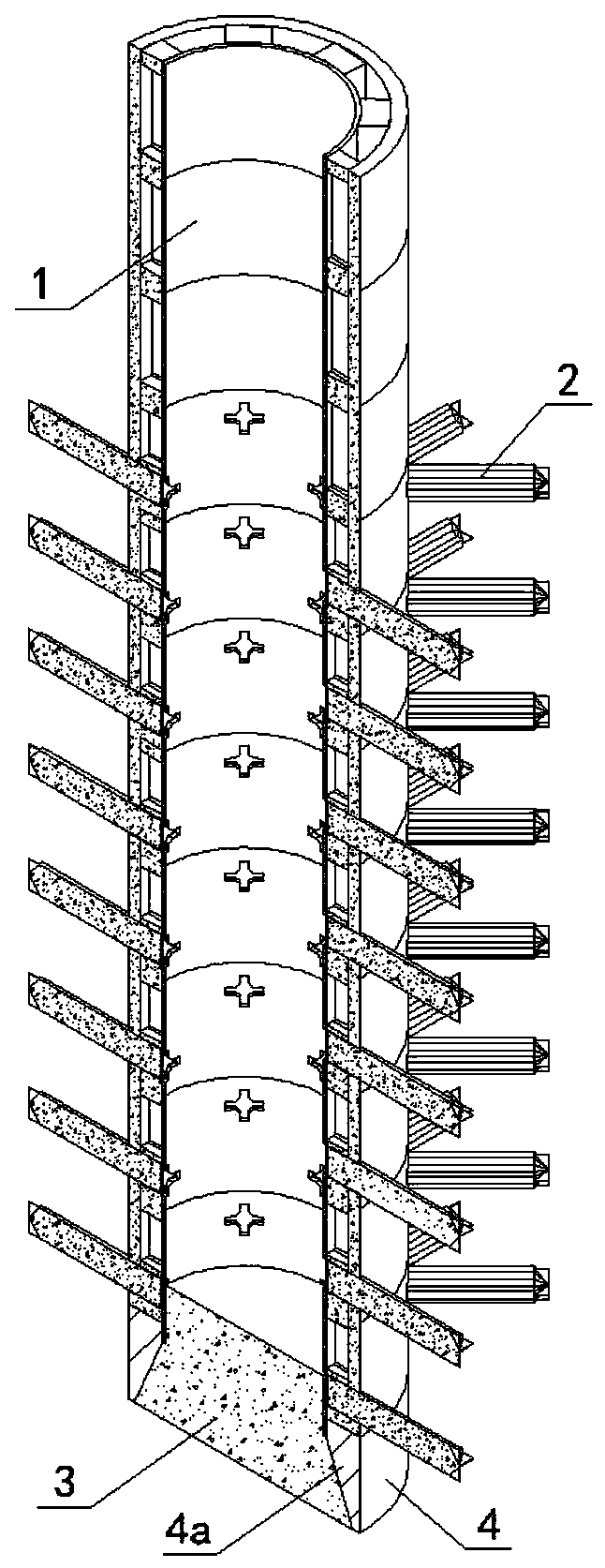

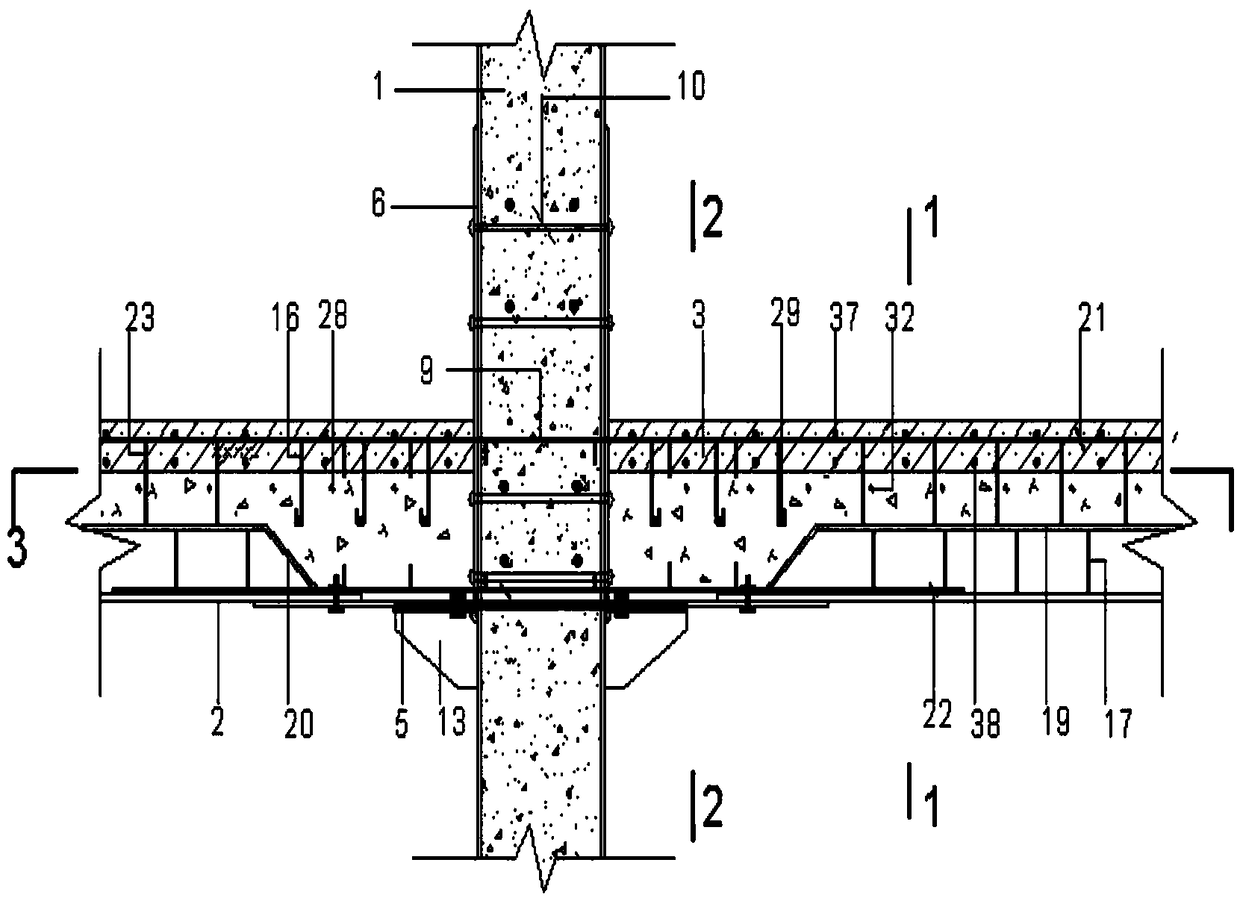

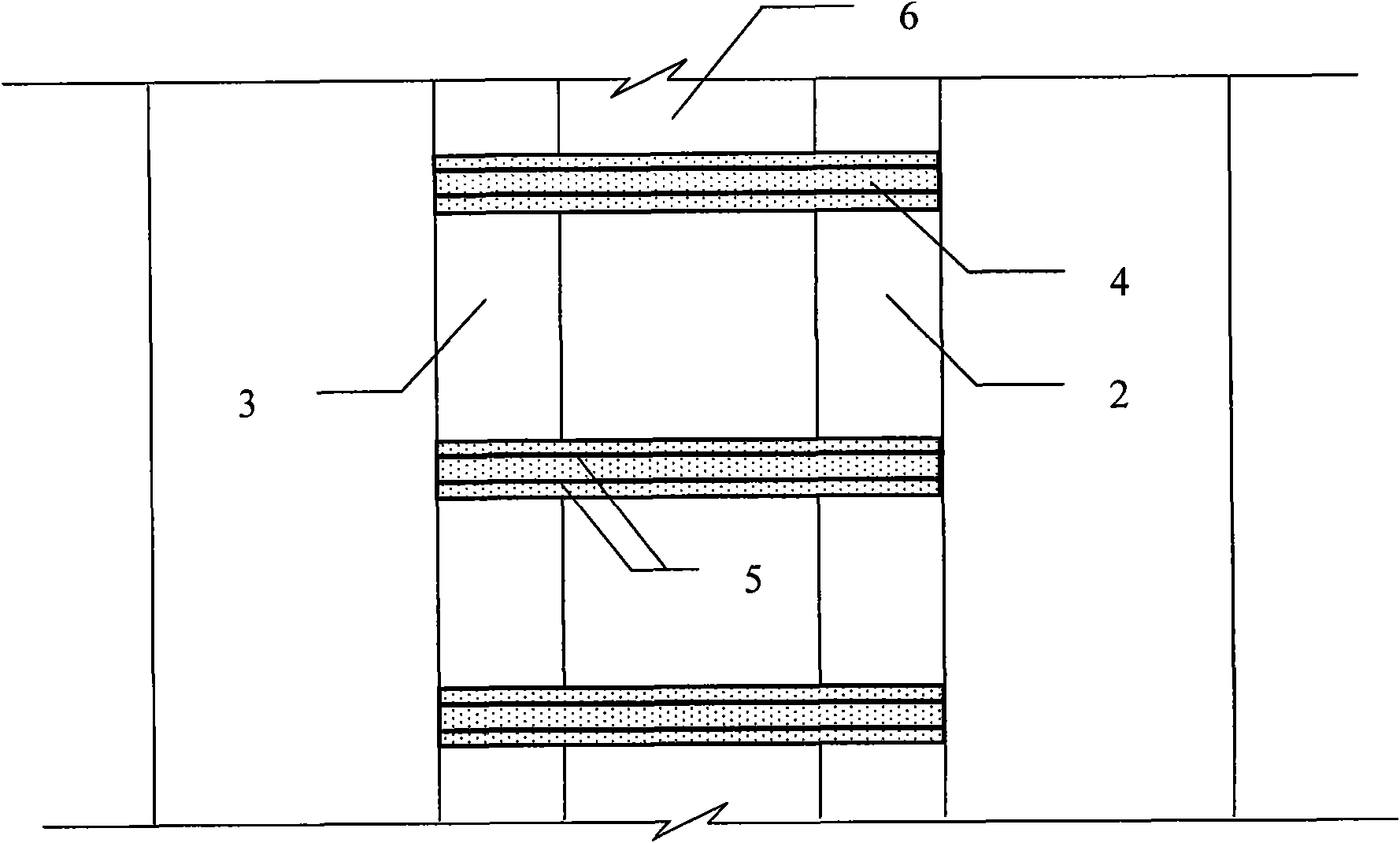

Combination column and combination beam frame with internally-arranged high-strength concrete core columns and construction method thereof

InactiveCN103967128AReduce section sizeReduce workloadBuilding constructionsPre stressControl theory

The invention relates to a combination column and combination beam frame with internally-arranged high-strength concrete core columns and a construction method of the combination column and combination beam frame. The special strong combination column and combination beam frame with the internally-arranged core columns is provided with internally-arranged asymmetric steel rib or plastic rib prestressed concrete combination beams and reinforcing bar concrete combination columns with the internally-arranged core columns, the combination beams are horizontally arranged between the combination columns, and the combination beams are connected with the combination columns at intersections through joints. The core columns are formed by pouring longitudinal ribs, stirrups and concrete together, the longitudinal ribs are distributed around the core columns and are wrapped by the stirrups, and the core columns are placed in the reinforcing bar concrete columns. Transverse stiffening ribs are arranged on steel ribs or plastic ribs in the combination beams, the steel ribs or the plastic ribs at the midspan positions are arranged on the lower portions of the combination beams, the steel ribs or the plastic ribs on supports are arranged on the upper portions of the combination beams, and prestressed ribs are arranged in the combined beams in the length direction. The prestressed ribs on the beam and column joints penetrate through two sides of the core columns, and are tensioned and anchored at the ends of the combination columns. The section size of the columns can be obviously reduced, too wide columns are prevented from existing in a system, and the prestressed ribs in the combination beams can generate evenly-distributed counterforce to eliminate part of external loads.

Owner:NORTHEAST GASOLINEEUM UNIV

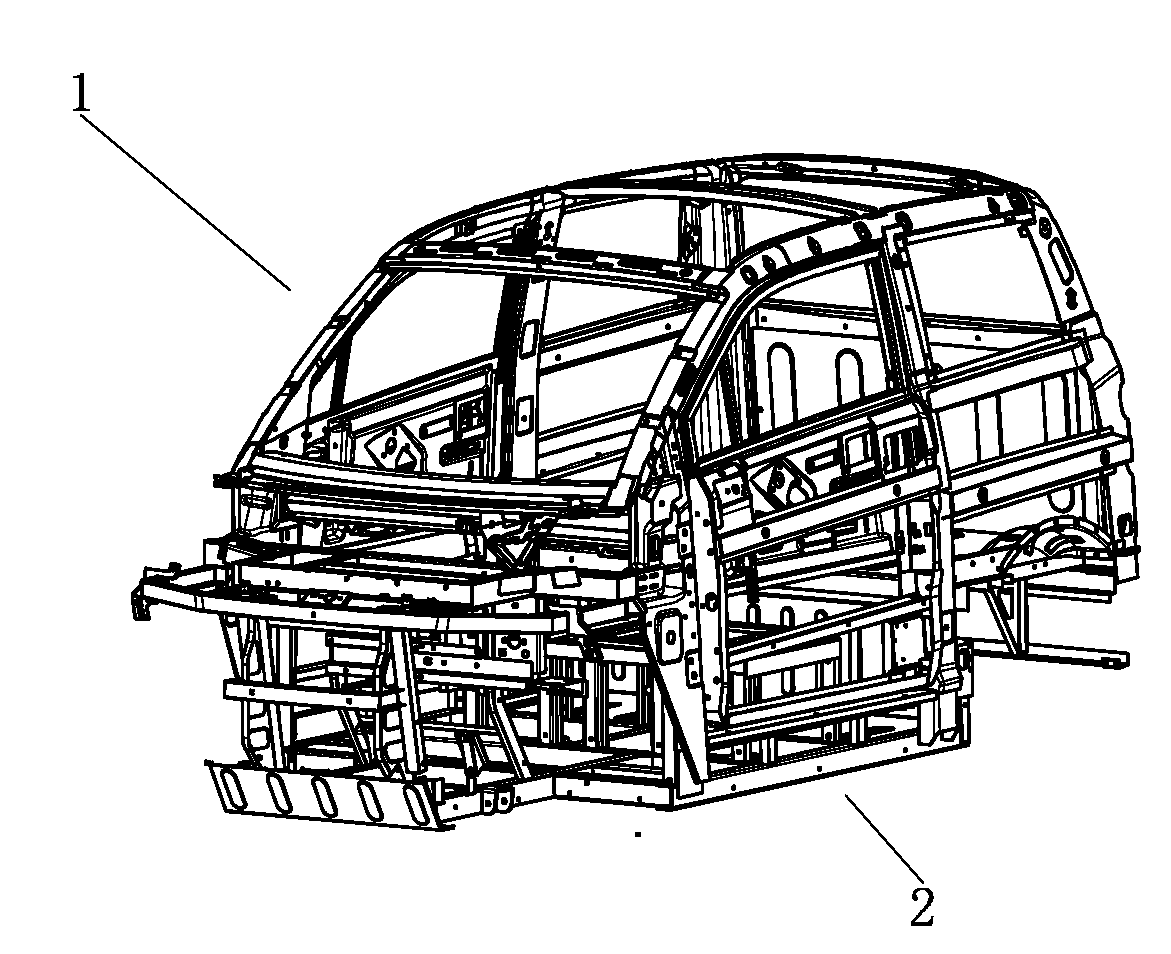

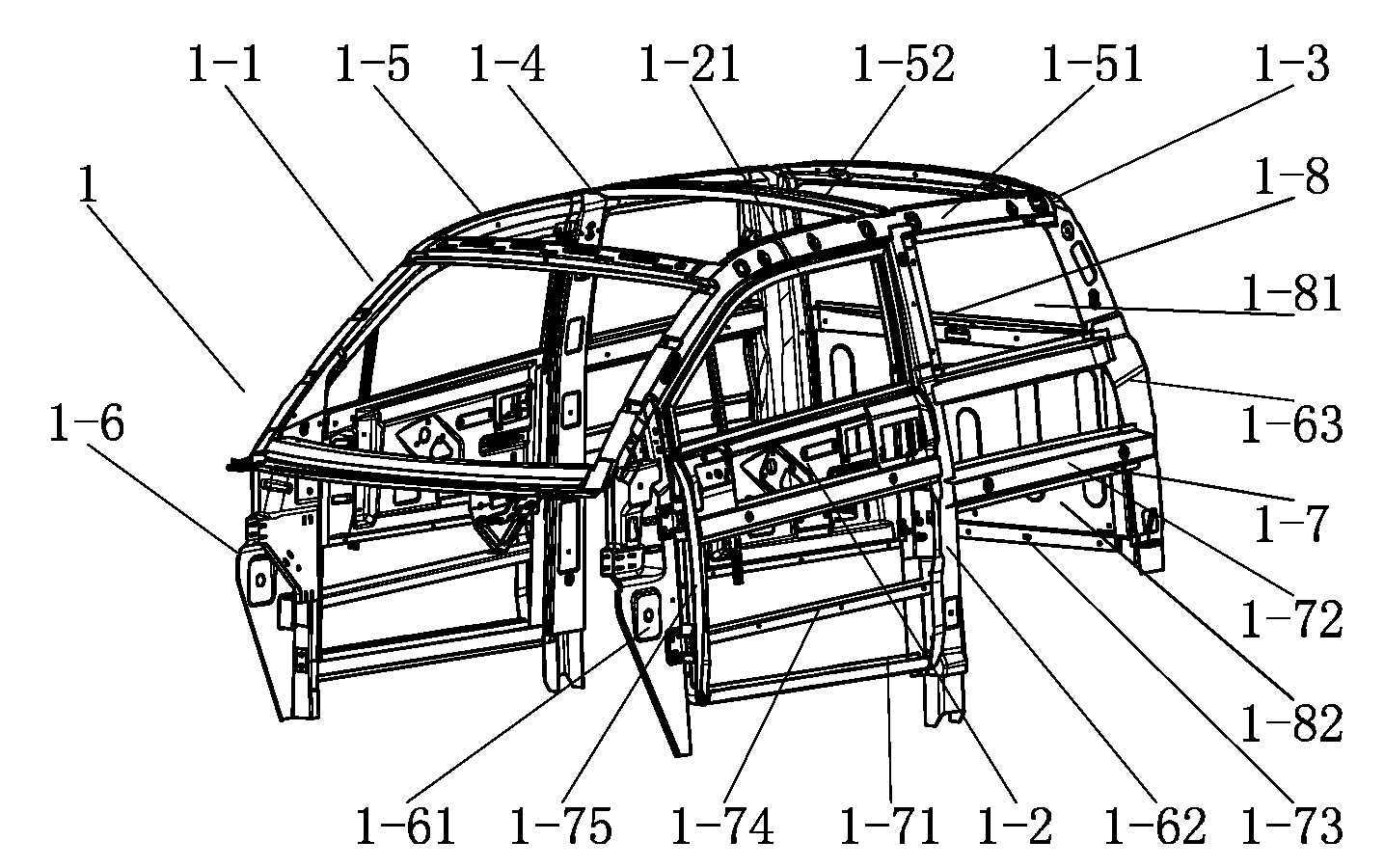

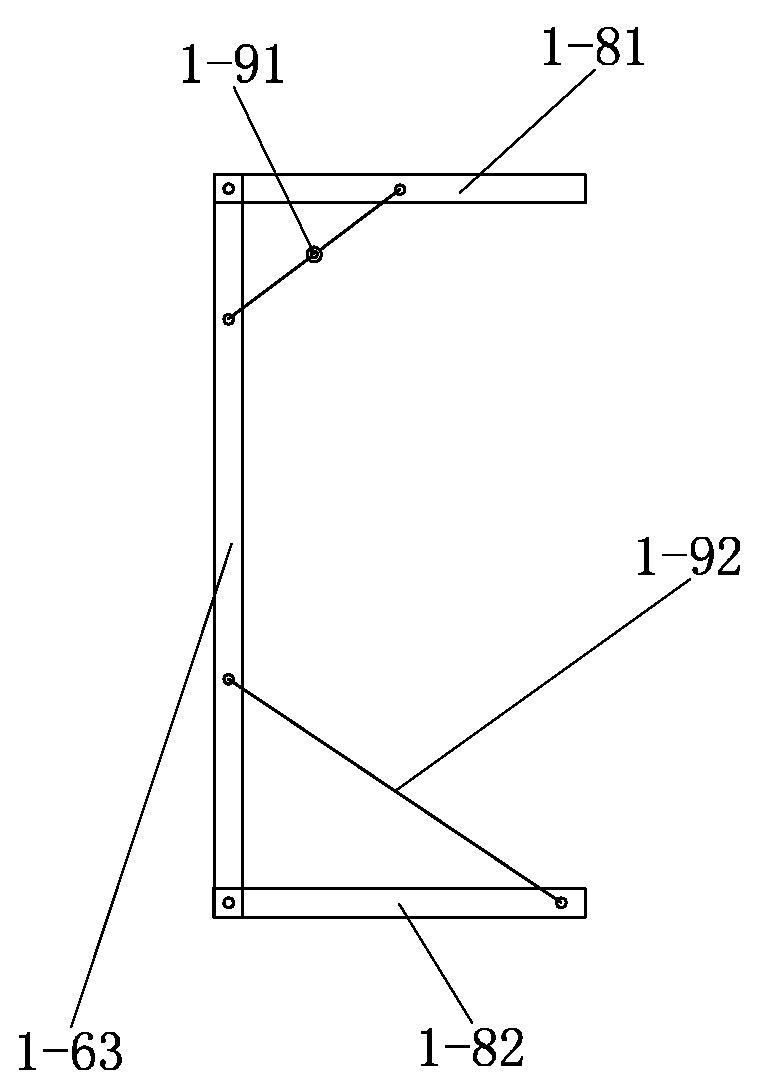

Lightweight electric vehicle

InactiveCN103318263AGuaranteed StrengthGuaranteed stiffnessMonocoque constructionsVehicle frameElectrical battery

The invention discloses a lightweight electric vehicle which comprises a vehicle body structure of the electric vehicle and a frame structure connected with the lower portion of the vehicle body structure. The vehicle body structure comprises a vehicle body and a vehicle door, wherein the vehicle body and the vehicle door are composed of a skeleton and thermoplastic boards, wherein the thermoplastic boards cover the inner surfaces and the outer surfaces of the skeletons. The skeleton is composed of a plurality of stamping rod parts which are welded to form a cage-shaped vehicle body skeleton in an integral mode. The surface of the cage-shaped vehicle body skeleton is provided with threaded fixing holes for fixing the thermoplastic boards which are fixedly connected with the cage-shaped vehicle body skeleton through screws and form a whole closed vehicle body. A body of the vehicle frame structure is composed of a crossbeam frame. A battery bin is arranged in the middle of the crossbeam frame. According to the lightweight electric vehicle, strength, rigidity and safety of the vehicle body and the vehicle door can be ensured, the weight of the vehicle body and the weight of the vehicle door can also be obviously relieved, strength and rigidity of a chassis can be effectively improved, when four wheels are stressed unevenly, the vehicle body will not deform, and batteries can be arranged in the most safe position.

Owner:北京宏瑞汽车科技股份有限公司

Assembly type light heat insulation wall for building outer wall

InactiveCN106368352AAvoid cold bridgeLow thermal conductivityWallsClimate change adaptationInsulation layerStructure function

The invention discloses an assembly type light heat insulation wall for a building outer wall. The assembly type light heat insulation wall comprises a wall layer, a heat insulation layer and a protective layer which are arranged from inside to outside. The wall layer is composed of a light wall and an edge component arranged on at least one edge of the light wall. A fixed connecting piece is arranged between the wall layer, the heat insulation layer and the protective layer. One end of the fixed connecting piece is embedded in the light wall of the wall layer, the other end of the fixed connecting piece penetrates the heat insulation layer and then is connected into the protective layer. According to the assembly type light heat insulation wall for the building outer wall, a cold bridge of a wall connecting component is avoided, a better energy saving goal is achieved, the problem of contradiction between efficient heat insulation and durability is solved, and a building function and a structure function are organically integrated.

Owner:刘祥锦

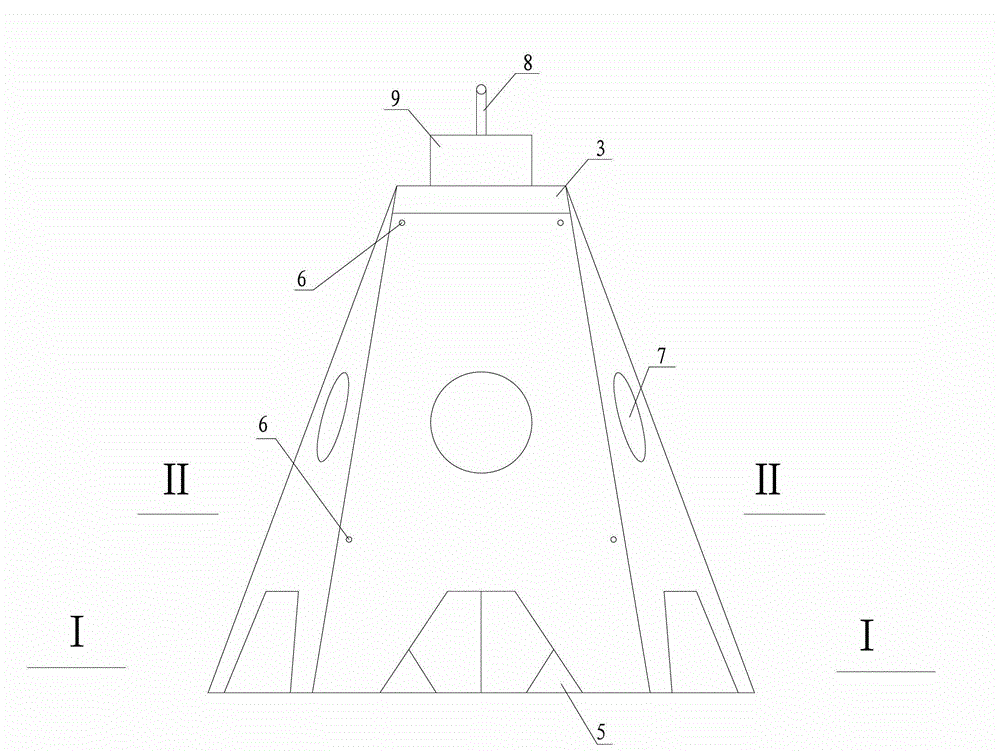

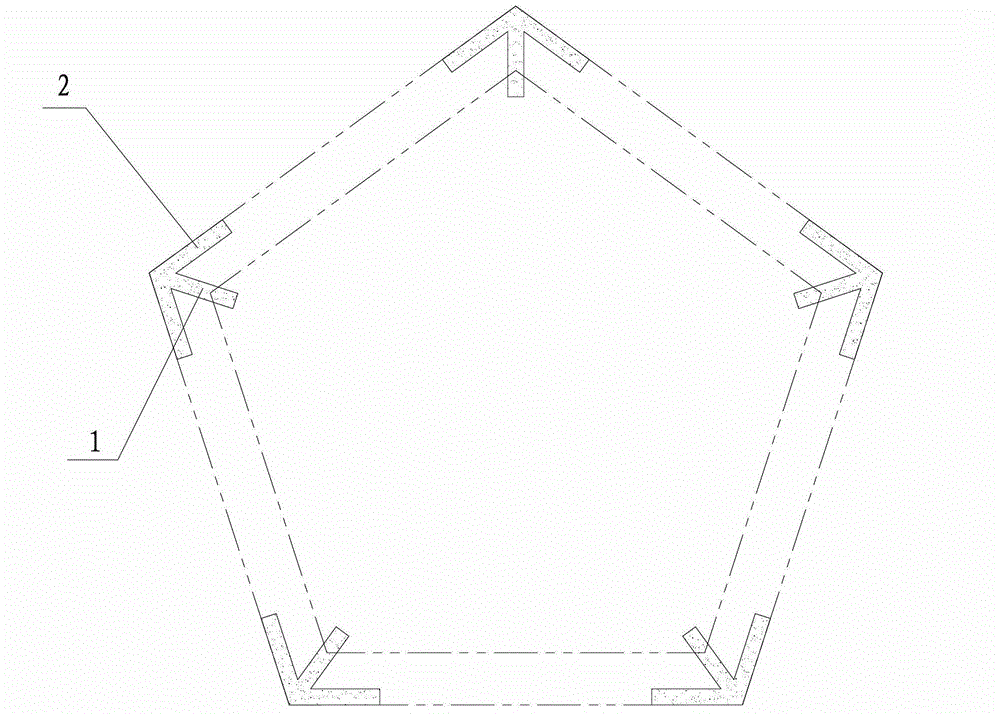

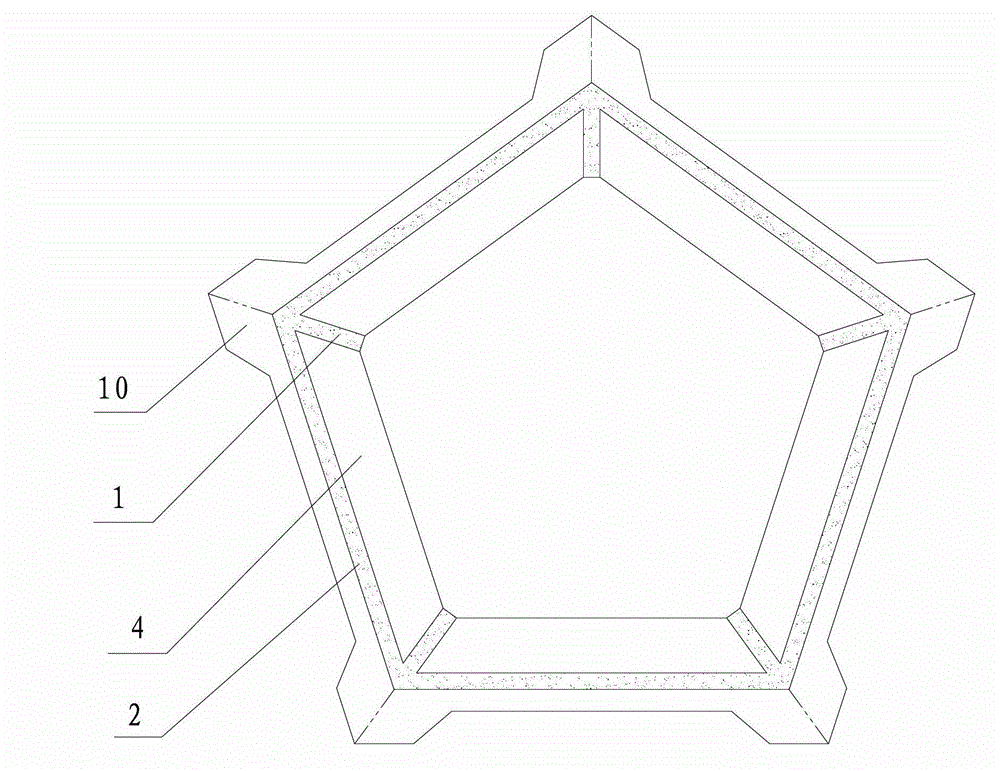

Artificial fish reef type vertical anchor

ActiveCN102874381AGive full play to mechanical propertiesReduce consumptionAnchorsEngineeringArtificial reef

The invention relates to an artificial fish reef type vertical anchor which comprises trapezoidal plates, ribbed plates, a top plate, a connecting device and horizontal plates, wherein the trapezoidal plates are isosceles trapezoidal plates with notches in the middles of the lower edges, pairwise side edges of five groups of trapezoidal plates with same specifications are mutually connected to form a three-dimensional structure with a regular pentagonal cross section, the top plate is connected above the trapezoidal plates, a connecting device is arranged above the top plate, the ribbed plates are arranged on the inner sides of connecting places of pairwise adjacent trapezoidal plates, the distances between the ribbed plates and the trapezoidal plates at two sides of the ribbed plates are equal, the horizontal plates are arranged on the inner sides of the trapezoidal plates and positioned between every two ribbed plates, the horizontal plates are positioned on positions slightly above the notches of the trapezoidal plates, the horizontal plates are parallel with the top plate, exhaust holes are formed in the trapezoidal plates, in the wall surfaces of the horizontal plates below horizontal positions and the wall surfaces, which are close to the upper edges, of the trapezoidal plates, and holes are formed in the trapezoidal plates, and the wall surfaces of the horizontal plates above the horizontal positions. The artificial fish reef type vertical anchor has the advantages of low cost, strong corrosion resistance, improvement of natural environment, and the like.

Owner:誉海海洋工程装备(江苏)有限公司

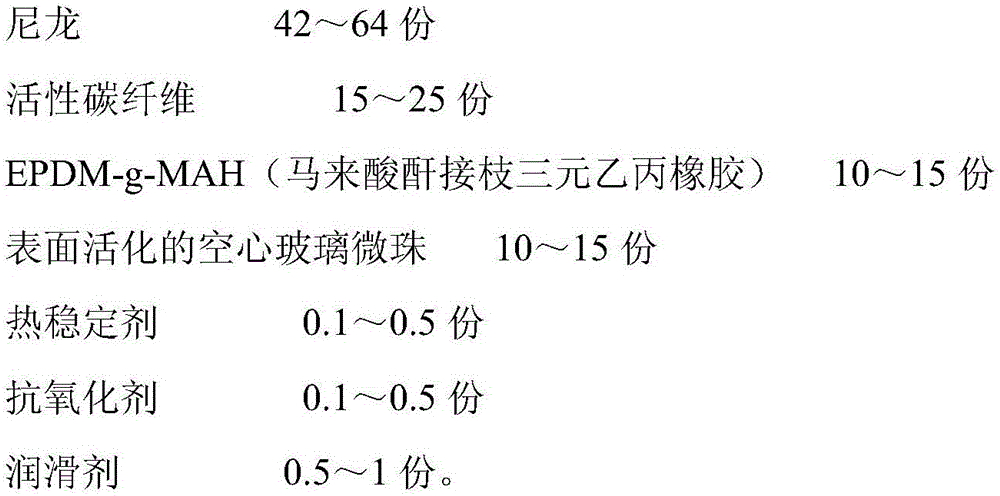

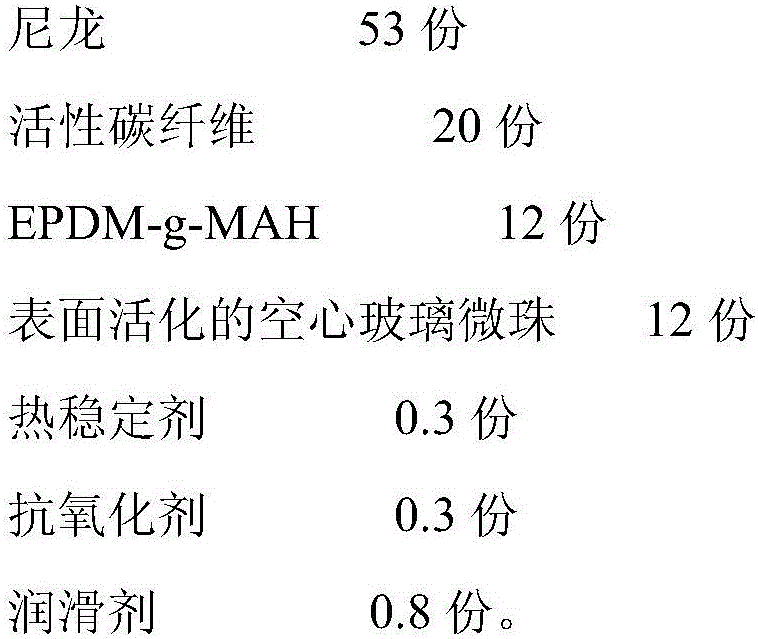

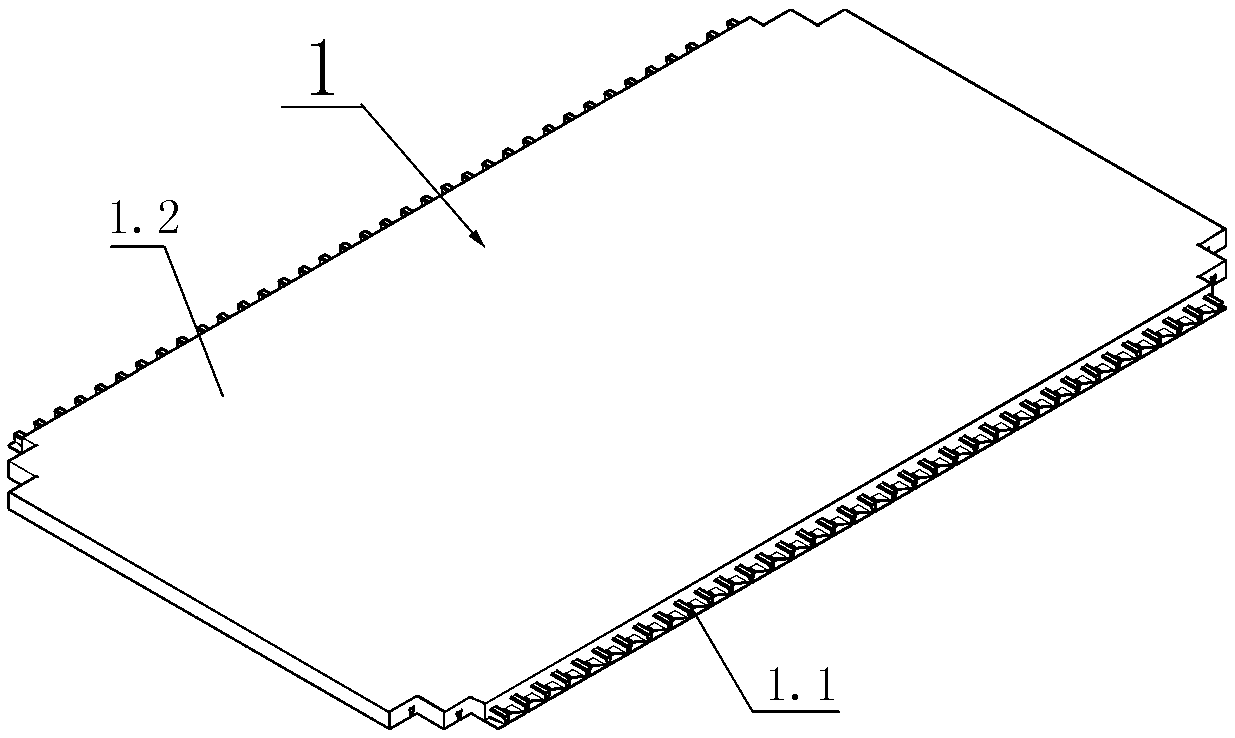

Carbon fiber reinforced nylon composite draw-bar box castor

The invention discloses a carbon fiber reinforced nylon composite draw-bar box castor .The castor is prepared from nylon, active carbon fibers, EPDM-g-MAH, surface-activated hollow glass micro-beads, a heat stabilizer, an antioxidant and a lubricating agent; the heat stabilizer, the antioxidant, the lubricating agent and the dried nylon, EPDM-g-MAH and surface-activated hollow glass micro-beads are mixed in a high-speed mixer, and a mixture is obtained; the mixture and the active carbon fibers are subjected to injection molding, and the draw-bar box castor is obtained .The carbon fiber reinforced nylon composite draw-bar box castor has the advantages of being high in performance, moderate in cost, easy to form and machine and the like and has a wide industrial application prospect.

Owner:XIANGXING FUJIAN BAG ANDLUGGAGE GRP CO LTD

Assembly type steel reinforced concrete framework spatial module structure and system and construction method

PendingCN107605038AImprove prefabrication rateImprove hoisting efficiencyBuilding material handlingReinforced concreteFloor slab

The invention provides an assembly type steel reinforced concrete framework spatial module structure and system and a construction method. The spatial module structure comprises a bell-shaped five-face spatial modular structure composed of four prefabricated walls, section steel columns, section steel beams, section steel longitudinal beams and a steel concrete composite floor slab; the prefabricated wall comprises a rectangular wall panel main body and section steel rods which are detachably connected to two sides of the wall panel main body; the section steel columns are detachably connectedwith two adjacent prefabricated walls; the section steel beams are detachably connected to tops of the transverse prefabricated walls; the section steel longitudinal beams are detachably connected totops of longitudinal prefabricated walls; shear resistant connecting members are connected with intervals to tops of the section steel longitudinal beams in the long axis direction; the steel concrete composite floor slab is detachably connected to the section steel beams and the section steel longitudinal beams. The invention solves the technical problems that the prior assembled building structural system has the problems of low assembly rate, poor anti-seismic performance, large workload of hoisting on site and complex site construction.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

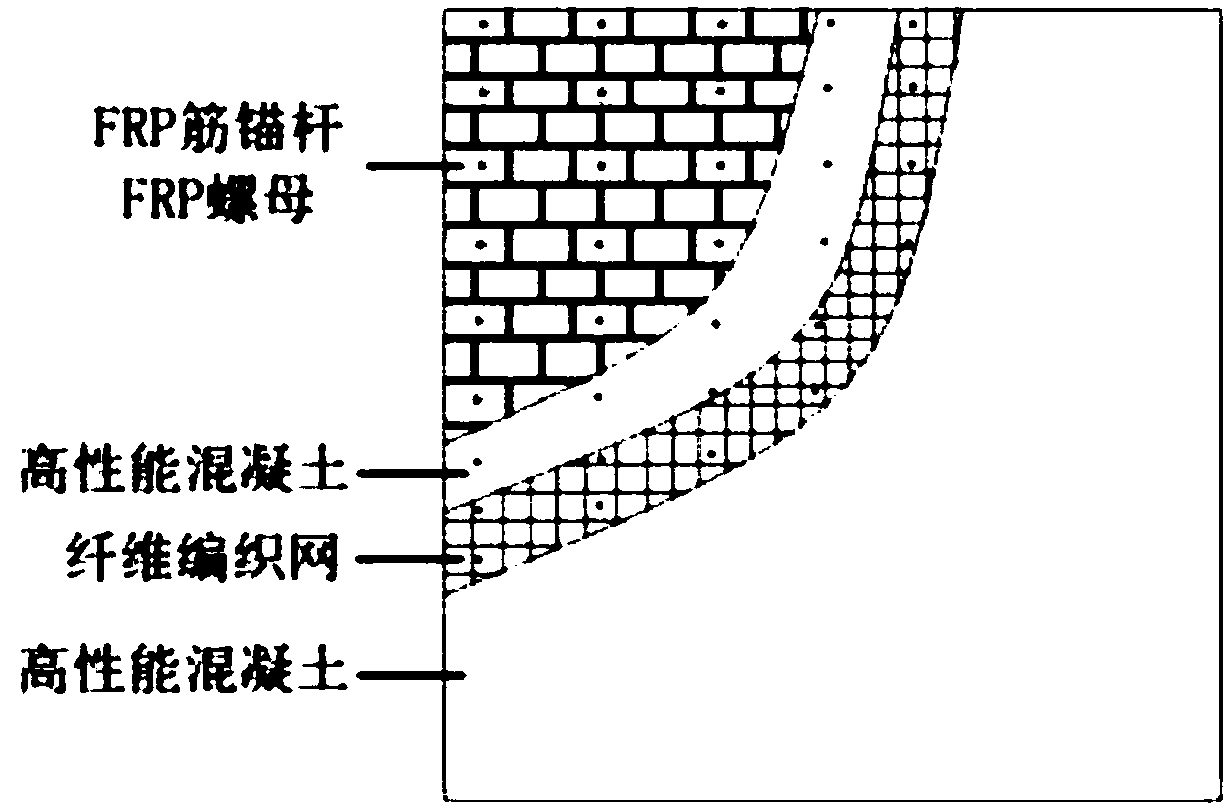

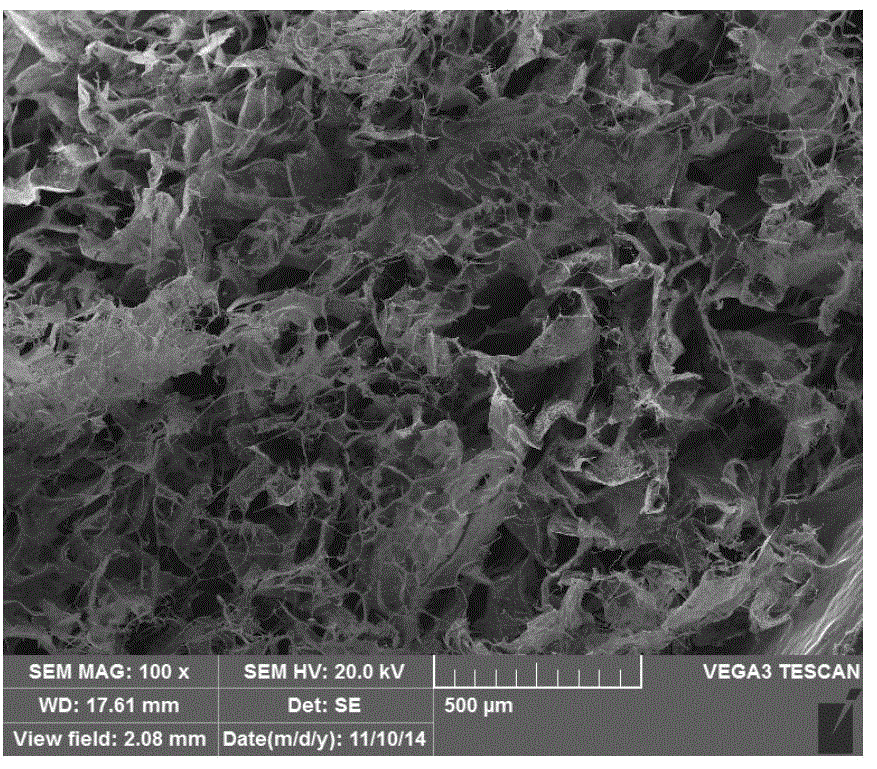

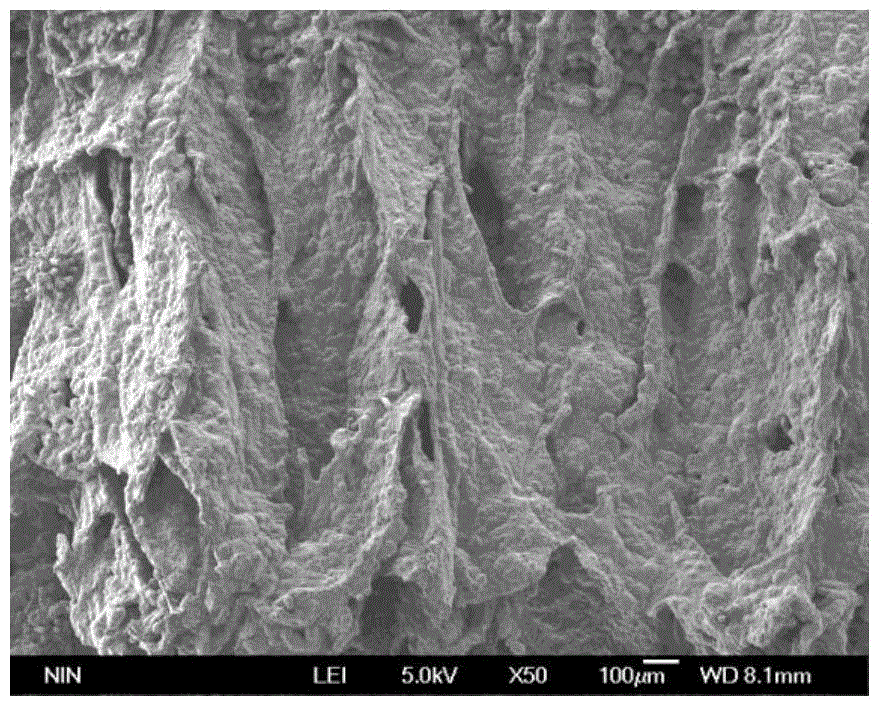

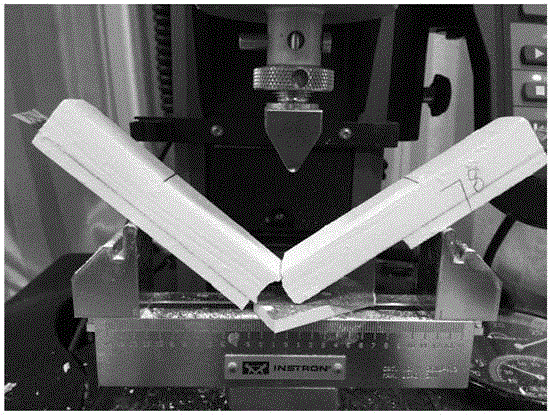

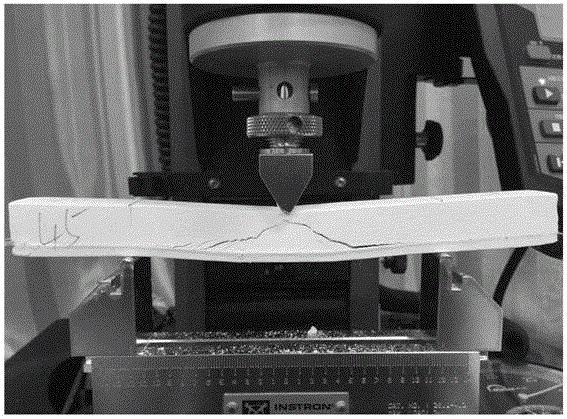

Reinforcement method of TRC for improving anti-seismic performance of multi-piece brick masonry wall

InactiveCN108532981AImprove seismic performanceImprove shear resistanceClimate change adaptationBuilding repairsFiberBrick masonry

The invention discloses a reinforcement method of TRC for improving an anti-seismic performance of multi-piece brick masonry wall, and belongs to the technical field of repair, reinforcement and construction of masonry walls. The reinforcement method comprises the steps that a plurality of penetrating circular holes are drilled in the wall to be reinforced, and fiber reinforced plastic (FRP) rib anchor rods are used for penetrating through the circular holes; the surface of the wall to be reinforced is coated with high-performance concrete, a fiber woven net is impregnated with epoxy resin, and the surface of the fiber woven net is coated with the high-performance concrete again; If one layer of fiber woven net can not meet the requirement of wall anti-seismic performance improvement, twoor more layers of fiber woven nets can be laid; and wet water curing is carried out until the high-performance concrete age is reached. According to the reinforcement method of TRC for improving the anti-seismic performance of the multi-piece brick masonry wall, in-plane shear resistance and out-of-plane bending resistance of the multi-piece brick masonry wall are improved, the risk of serious damage or even collapse of a masonry structure in earthquake is reduced, the inadaptability of a masonry material caused by the use of the epoxy resin in FRP reinforcement is avoided, deficiency of low reinforcement efficiency of engineered cementitious composite (ECC) reinforcement is effectively improved, and the integrity of multi-piece brick masonry wall is improved.

Owner:CHINA UNIV OF MINING & TECH

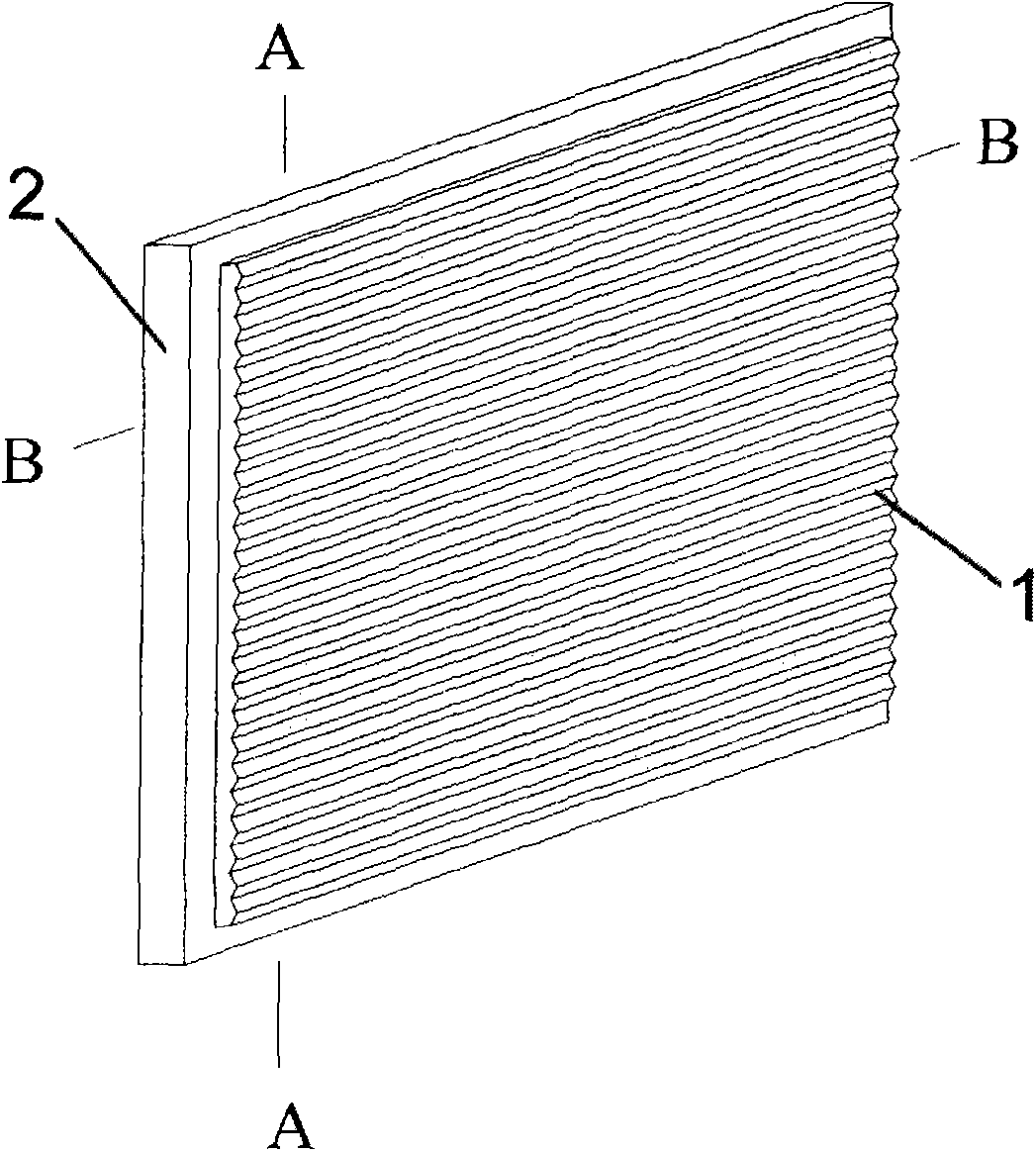

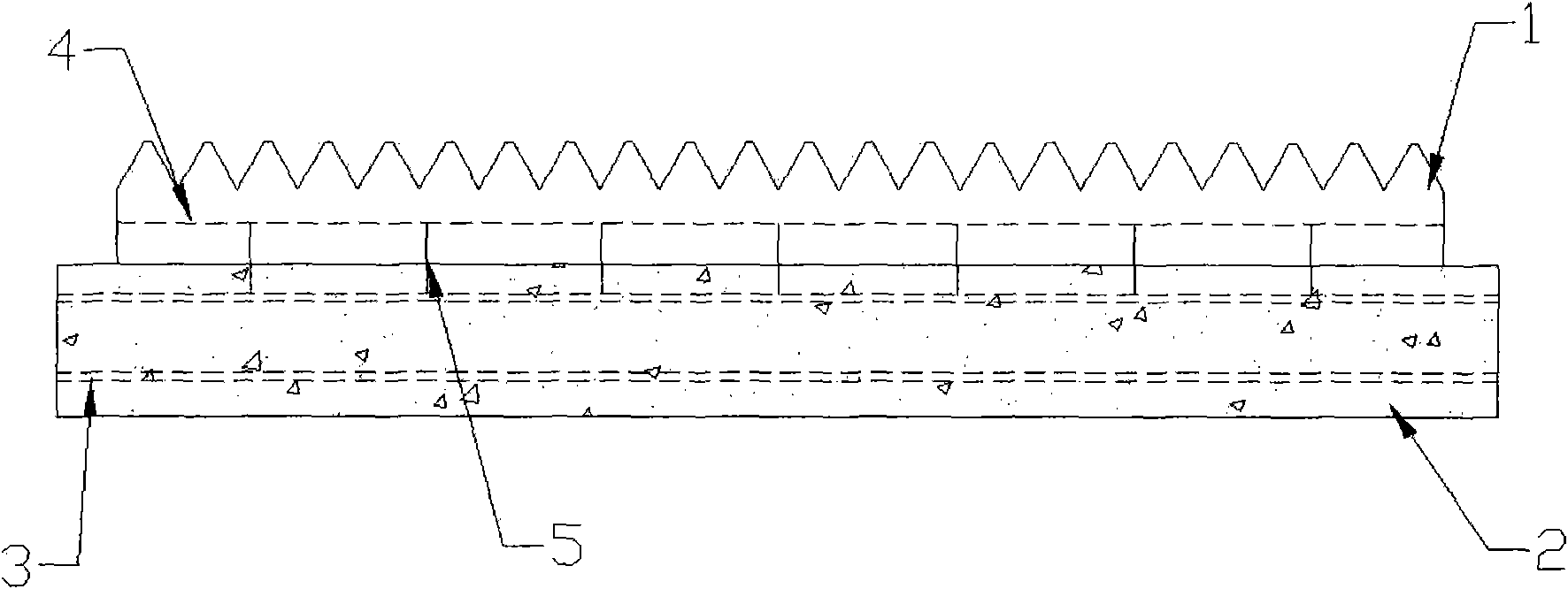

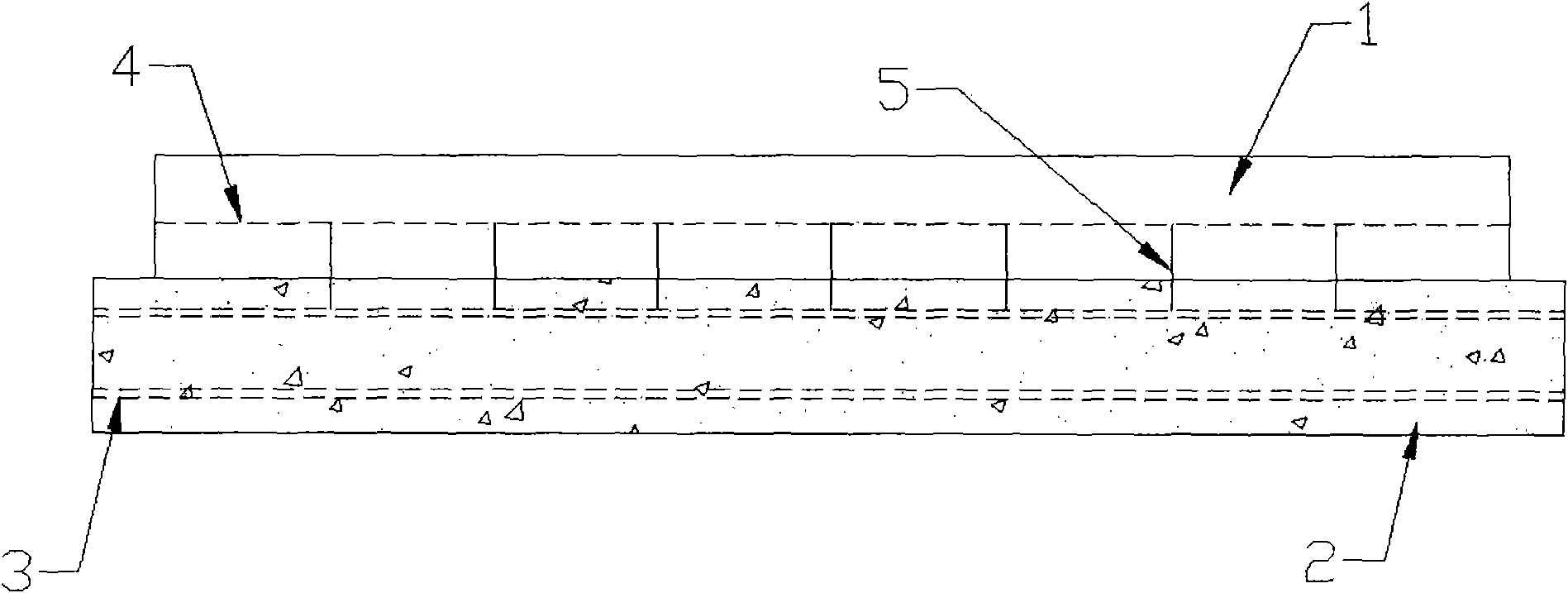

Cold-bend steel embedded double corrugated steel plate shear wall

ActiveCN111809774AIncreased shear strengthIncrease lateral stiffnessStrutsWallsEngineeringUltimate tensile strength

The invention discloses a cold-bend steel embedded double corrugated steel plate shear wall. The cold-bend steel embedded double corrugated steel plate shear wall comprises two corrugated steel plates, an upper steel beam, a lower steel beam, and two cold-bend thin-walled steel end posts. Both of the upper steel beam and the lower steel beam are formed by two L-shaped angle steels in a back-to-back mode. The upper ends of the two corrugated steel plates are arranged between the two L-shaped angle steels of the upper steel beam in an embedded mode. The lower ends of the two corrugated steel plates are arranged between the two L-shaped angle steels of the lower steel beam in an embedded mode. The two corrugated steel plates are located on the central axis of the shear wall. The corrugated steel plates are connected with the L-shaped angle steels through connecting pieces penetrating through the two corrugated steel plates and the L-shaped angle steels. The two corrugated steel plates connected with each other through the connecting pieces in a penetrated mode. The cold-bend thin-walled steel end posts are respectively connected with the two sides of the two corrugated steel plates. The cold-bend steel embedded double corrugated steel plate shear wall is high in buckling bearing capacity, relatively small in deformation outside a plane, low in noise when the steel plates are buckling. The shear wall can also be installed in the modular mode, and is convenient in construction and installation with good integrity, continuity, shear strength, and lateral stiffness.

Owner:HUNAN UNIV

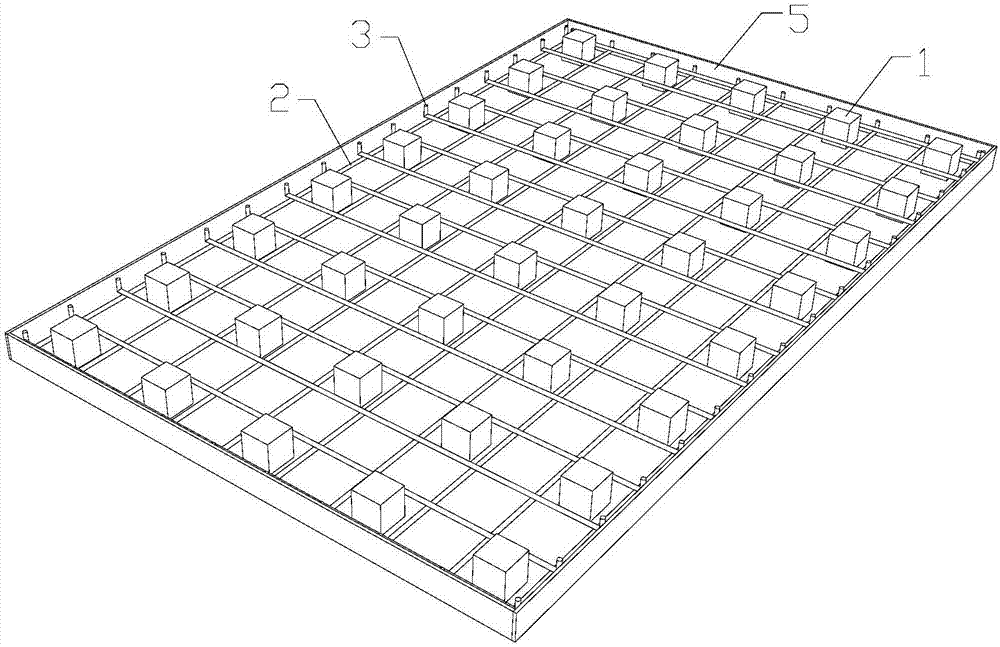

Recycled concrete precast floor slab structure and manufacturing method

The invention relates to the field of precast fabricated type concrete structure buildings, in particular to a recycled concrete precast floor slab structure and a manufacturing method. The recycled concrete precast floor slab structure comprises two types of precast floor slabs, namely, a recycled concrete precast superimposed floor slab and a recycled concrete wholly-precast floor slab; and a precast layer part of the recycled concrete precast superimposed floor slab, and a tensile zone and a compressive zone part bearing less pressure of the recycled concrete wholly-precast floor slab are made of recycled concrete. When a concrete floor slab is stressed, mainly the upper part is subjected to pressure and the lower part is subjected to tensile force, the pressure on the lower part is mainly borne by steel bars, so that the lower part is made of recycled concrete having lower strength, the pressure on the upper part is borne by non-recycled concrete having higher strength, the advantages of mechanical properties of respective materials are fully exerted, and the practical stress requirements are met.

Owner:SHENYANG JIANZHU UNIVERSITY

Value limiting stress concrete electric pole

InactiveCN107762239AScientific and reasonable designReinforcement is reasonableTowersRebarReinforced concrete

The invention belongs to the field of power conveying equipment, and particularly relates to a value limiting stress concrete electric pole. The value limiting stress concrete electric pole comprisesa reinforced concrete pole body, the cross section of the reinforced concrete pole body is an annular surface, the pole body is in a conical shape, the taper is 1 to 75, and the top end of the pole body is provided with a concrete top cover. The pole body comprises a steel bar skeleton and a concrete protective layer. The steel bar skeleton is wrapped with the concrete protective layer. The steelbar skeleton comprises main ribs, auxiliary ribs, an erection bar and a helical bar. According to the value limiting stress concrete electric pole, the main bars and the auxiliary bars adopt PC steelplates, by applying different stress, the comprehensive performance of the electric pole is improved, steel materials are saved, and the production efficiency is improved.

Owner:广东永基电力器材厂有限公司

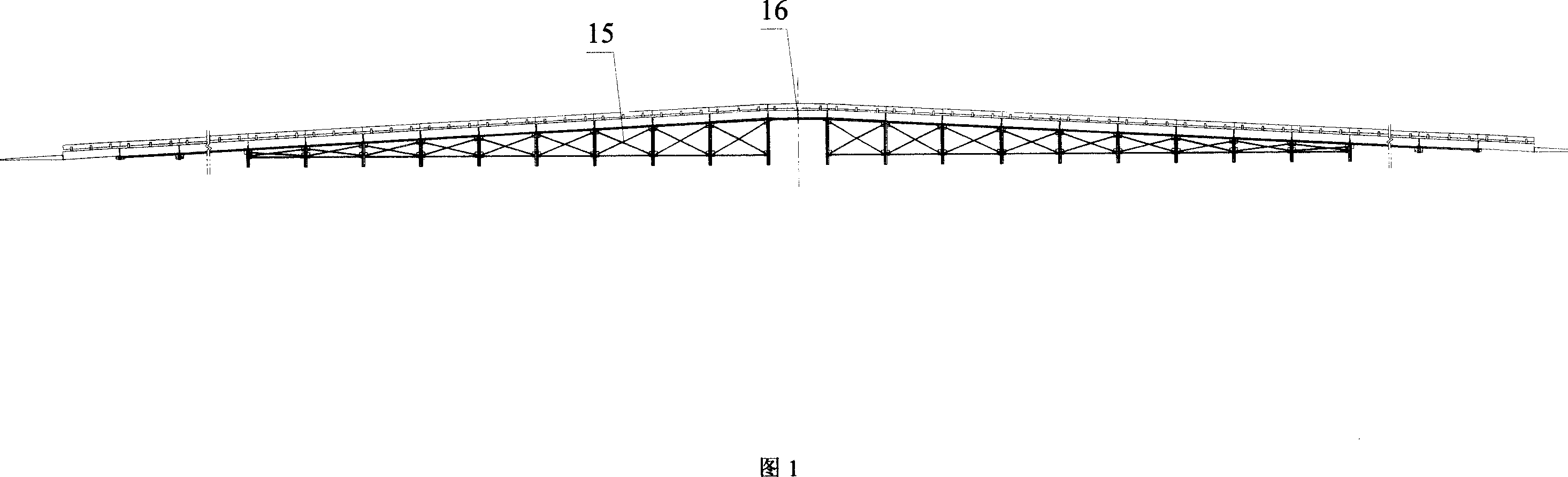

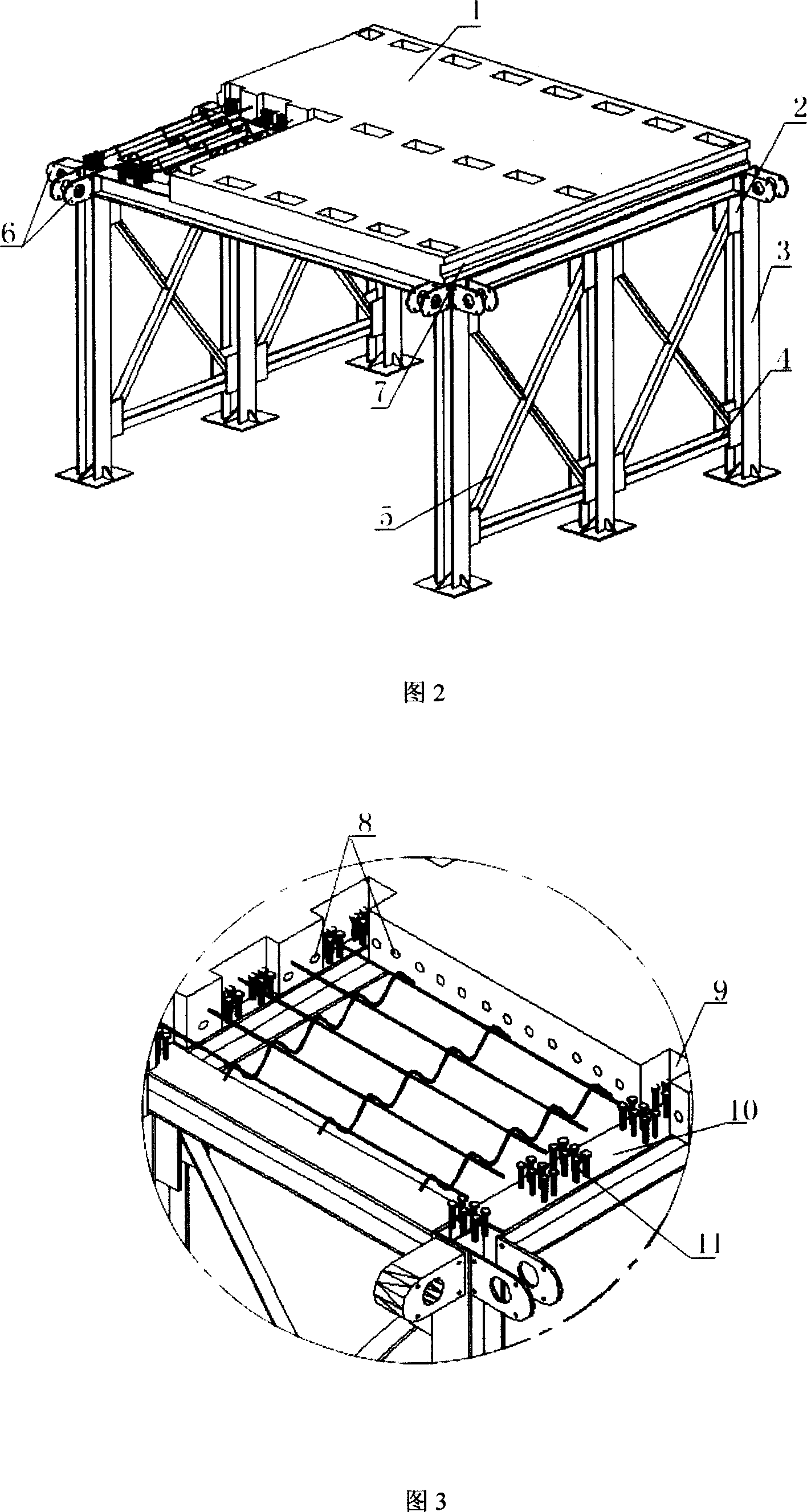

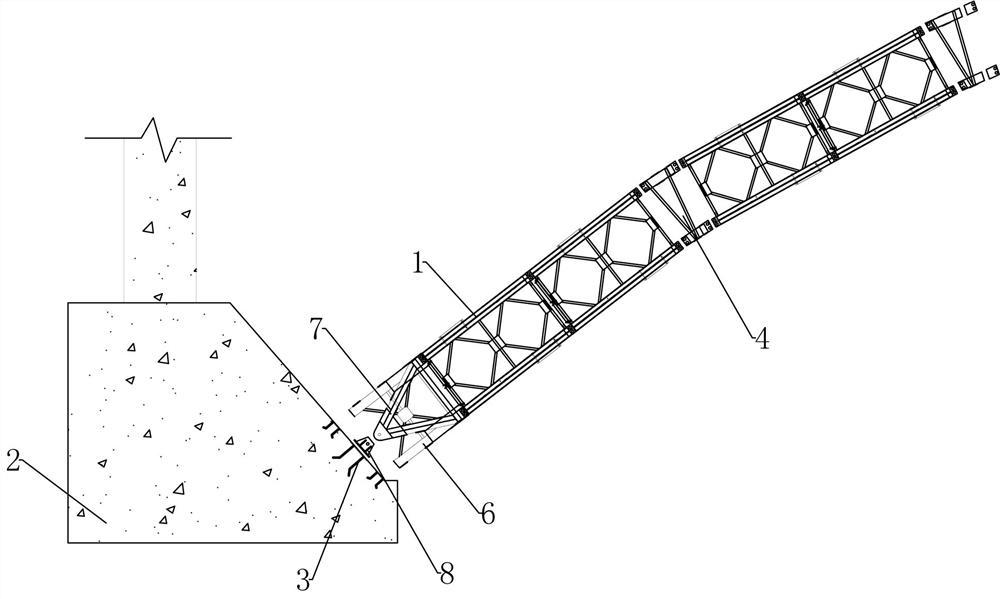

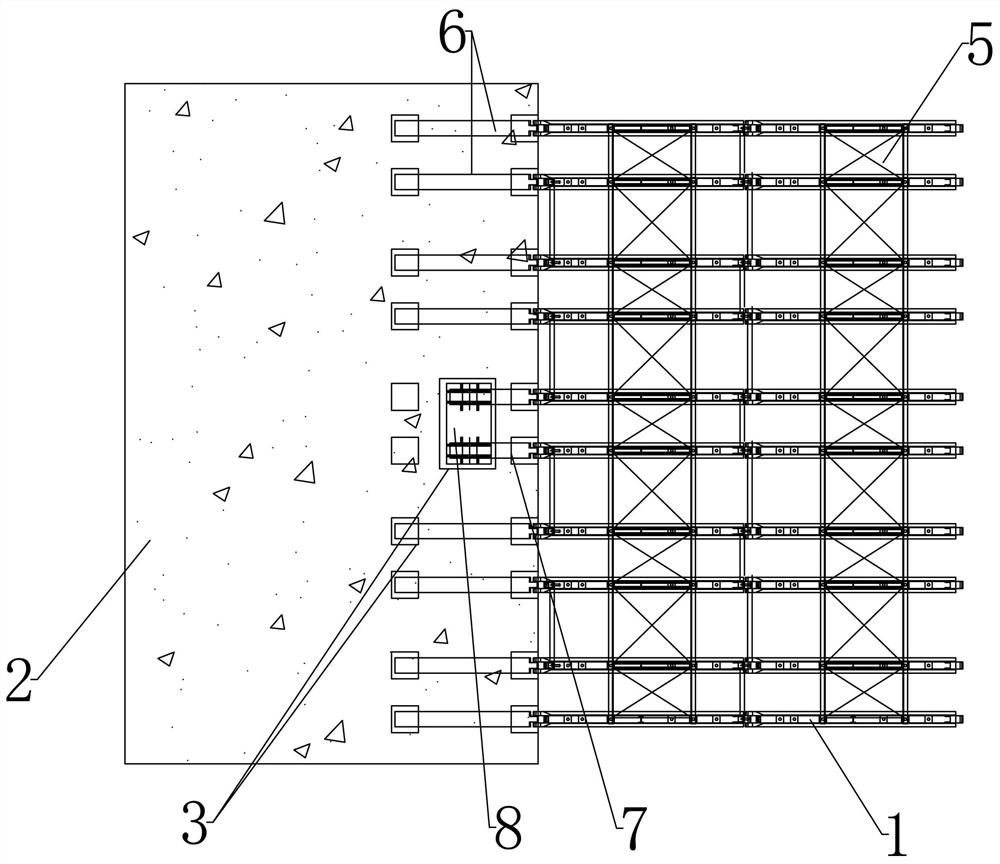

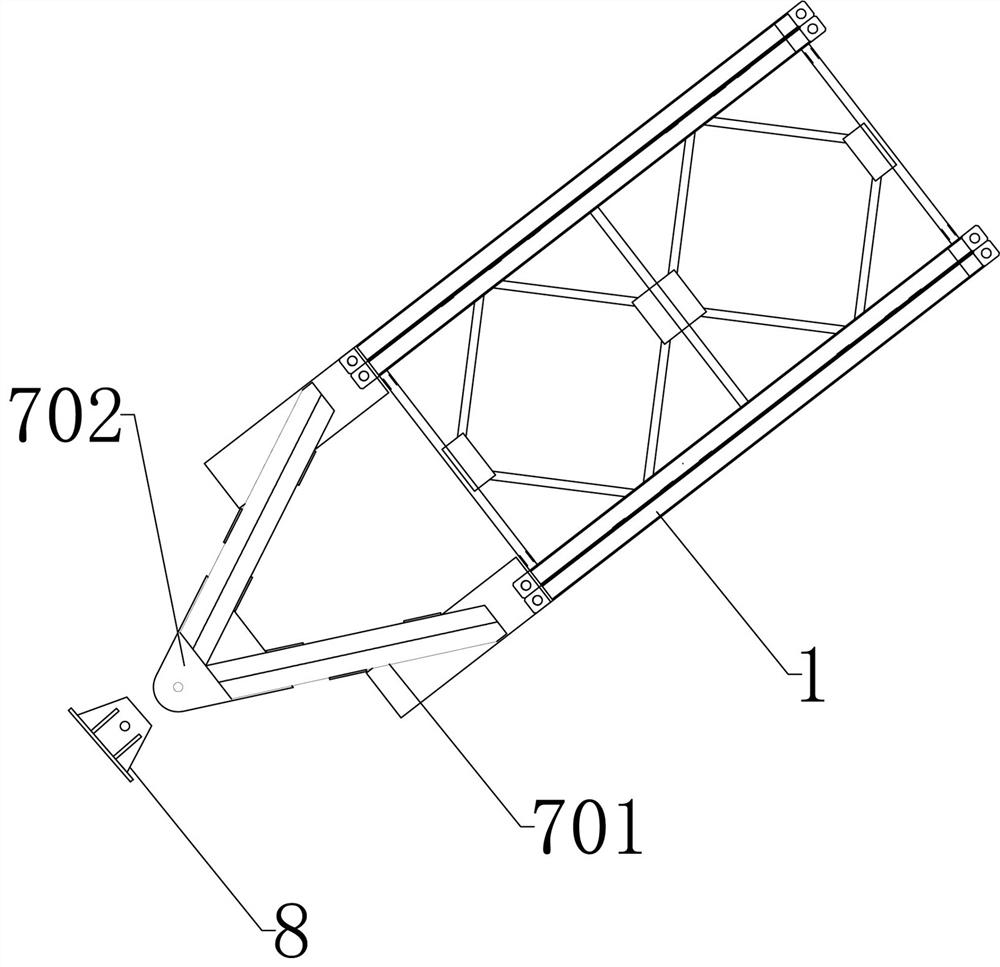

Reinforced bailey piece steel arch connecting structure and assembling and connecting method thereof

ActiveCN111893860AGive full play to mechanical propertiesSpeed up the assembly into an archTruss-type bridgeBridge erection/assemblyConstruction engineeringArch supports

The invention provides a reinforced bailey piece steel arch connecting structure and an assembling and connecting method thereof. The reinforced bailey piece steel arch comprises a plurality of assembling sections, each assembling section is formed by connecting a plurality of reinforced bailey pieces, embedded parts are arranged in arch seat concrete, the assembling sections at the ends are connected with the embedded parts through connecting arch foot sections, and the assembling sections are connected through connecting sections. According to the structure, the reinforced bailey steel archis convenient to mount, the mounting position precision is easy to control, and the structure is suitable for splicing and connecting reinforced bailey arch support frames with higher requirements onbearing capacity.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG +1

High-assembling-rate steel tube concrete frame structure system and connecting method

The invention discloses a high-assembling-rate steel tube concrete frame structure system and a connecting method, and belongs to the field of fabricated building structures. The high-assembling-ratesteel tube concrete frame structure system comprises a concrete column, a combined beam, a concrete plate, a column-column flange connecting joint, a beam-column connecting joint, a field post-cast concrete and a mounting method thereof. Concrete upper and lower columns are connected together through a column top flange and a column bottom flange by bolts, the column bottom flange is connected with a U-shaped steel plate by bolts, the inside of the U-shaped steel plate is connected with the combined bema by bolts, the concrete plate is mounted at the outwards turned flange of the combined beamand the outwards turned flange of the U-shaped steel plate, and is fixed by anchoring pulling anchor bolts, and finally, the field post-cast concrete is poured finally. The invention mainly solves the problem that an existing concrete frame structure is high in assembling operation amount and low in mounting efficiency.

Owner:CHINA MCC17 GRP

Method for treating corbel with longitudinal crack in riverine highway

InactiveCN101634129AAvoid Longitudinal CracksCut reflex spreadPaving detailsHorizontal forcePull force

The invention relates to a method for treating a corbel with a longitudinal crack in a riverine highway, overcoming the defect that the prior art comprising the prior radical treating effects of excavation, back filling, grid laying, grouting, impermeable wall setting and the like can not fundamentally inhibit the destruction function of transverse pulling force to beds. The invention adopts the corbel as a reinforced concrete member, the corbel is longitudinally laid perpendicular to the highway below the face of the highway, and the development and the extension of the longitudinal crack can be effectively prevented by utilizing the favorable tensile property of steel bars. Namely, the corbel has the function of strengthening the tensile capability of embankment foundation soil bodies or fillers, the placement direction of the steel bars inside the corbel is vertical to the direction of the crack, the steel bars can completely bear transverse horizontal force borne by the beds because of favorable tensile property, the longitudinal cracking of the beds is prevented, and the reflection and the diffusion of the longitudinal crack of the beds towards the face of the highway are thoroughly cut off. For the service life of the highway, the steel bars are wrapt by a concrete material, and the durability of the steel bars can be effectively ensured.

Owner:YANGZHOU UNIV

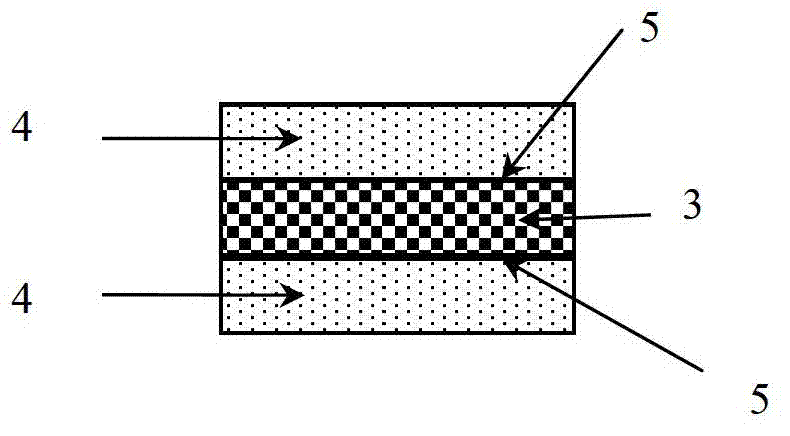

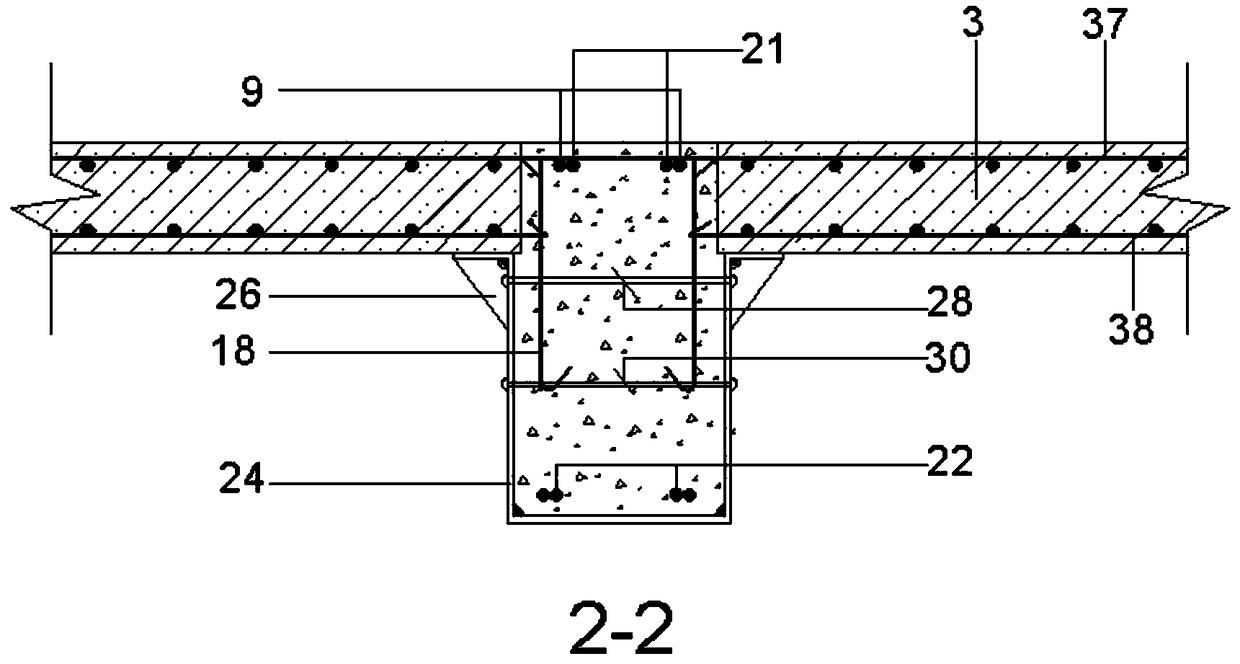

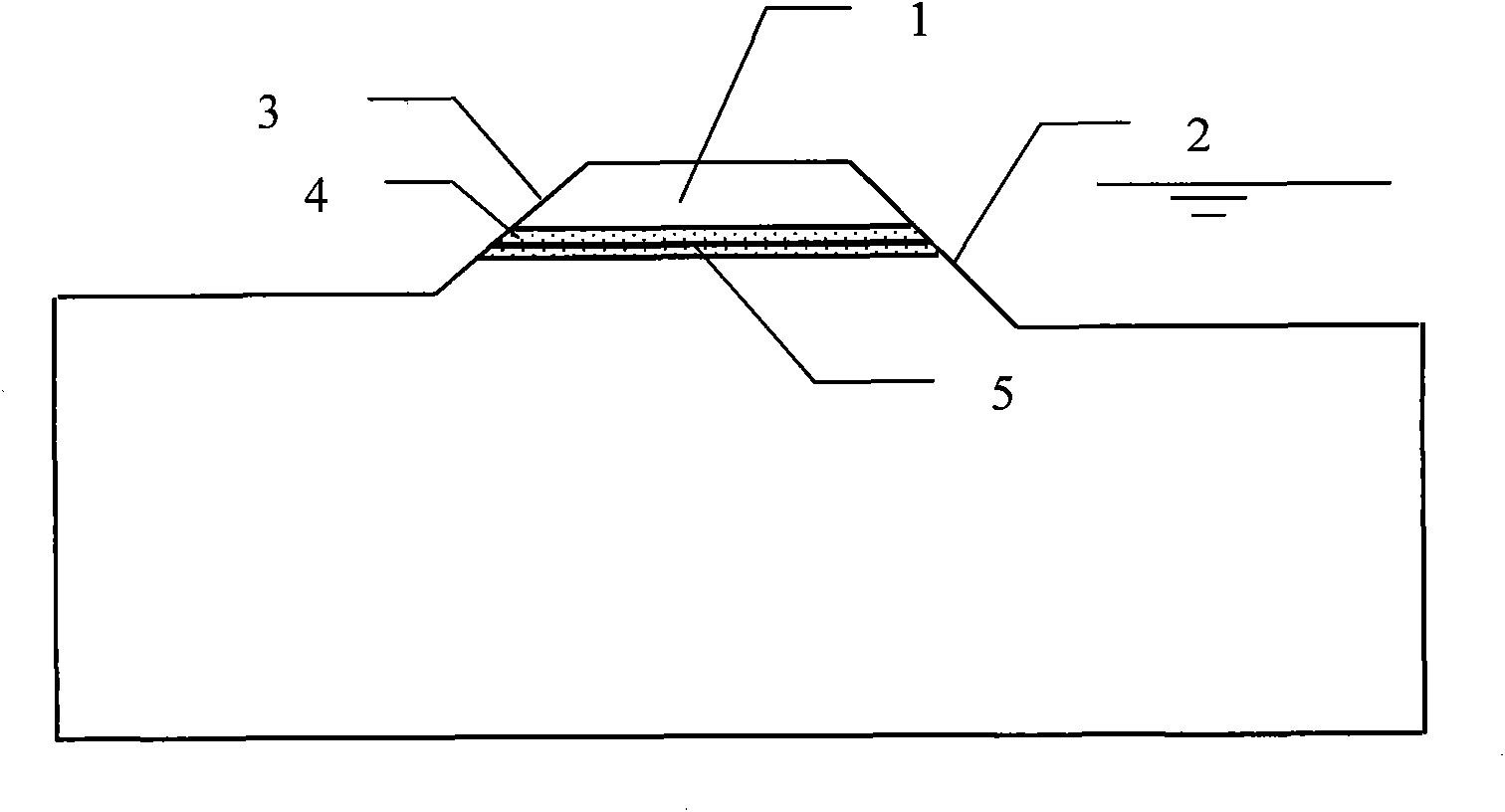

Partially laminated beam bridge

InactiveCN110258300AEliminate load effectsImprove deformation resistanceBridge structural detailsBridge materialsPre stressWhole body

The invention discloses a partially laminated beam bridge which is mainly formed by a bridge abutment (1), a pier (2) and a beam body. A pressure zone of the beam body located above the pier (2) is of a concrete structure (3); the other part of the beam body is of a steel structure (4); a rabbet is arranged above the concrete structure (3); an embedded part and a shear connector are welded around the combination part of the concrete structure (3) and the steel structure (4); and in the later period, after the steel structure (4) is placed in place, the steel structure (4) and the embedded part are welded together, and micro-expansion concrete is poured to form a whole body. According to the partially laminated beam bridge provided by the invention, the excellent characteristics of tensile strength and concrete compressive strength of steel can be fully played, so that the material utilization rate is maximized; compared with a prestressed concrete continuous beam bridge, the partially laminated beam bridge is light in weight, so that a spanning capability of the bridge can be remarkably improved; and compared with a full-steel bridge, the partially laminated beam bridge is large in rigidity, less in steel consumption and low in cost.

Owner:广西鸿鹄结构工程技术信息咨询有限公司

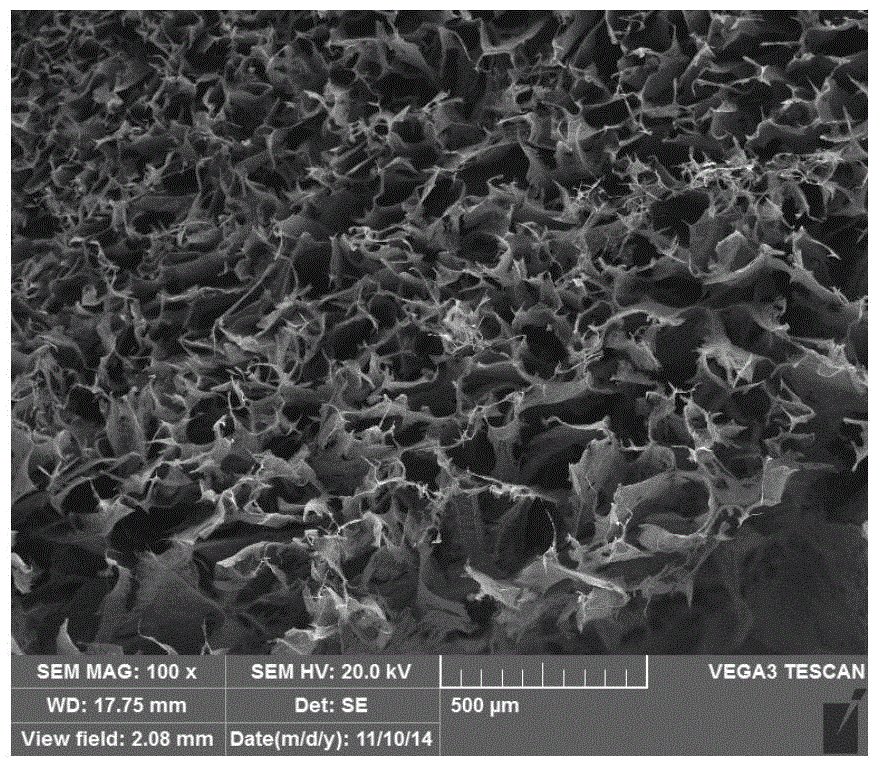

Preparation method of micro-nanofiber/ceramic matrix composite

InactiveCN104803685AGood dispersionThe volume fraction can be adjusted in a wide rangeDispersityMicro nano

The invention discloses a preparation method of micro-nanofiber / ceramic matrix composite. The preparation method comprises the following steps: micro-nanofiber is prepared into an aerogel preform and the preform adopts special microstructures of two-dimensional and three-dimensional micro-nanofiber frameworks, high specific surface area, micro-nano level holes, low density, good dispersity of micro-nanofiber, and the like; on the basis, a pyrolytic carbon interface layer is deposited on the preform by using chemical vapour infiltration (CVI); in the end, a ceramic matrix is deposited to be densified to finish the preparation of the micro-nanofiber / ceramic matrix composite. The micro-nanofiber introduced in the method is good in dispersity and wide in the adjustable range of volume fraction, can fully exert the functions of crack deflection, extraction and bridging of micro-nanofiber and can effectively improve the mechanical property of the composite.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Amorphous alloy-gypsum composite board, preparation method and application thereof.

ActiveCN106476357AStrong corrosion resistanceTo achieve common workWater-setting substance layered productMetal layered productsCrack resistanceAlloy

The invention relates to an amorphous alloy-gypsum composite board, a preparation method and an application thereof. The amorphous alloy-gypsum composite board comprises an amorphous alloy strip layer and gypsum layers, wherein the amorphous alloy strip layer is clamped between the gypsum layers, and the whole composite board is integrally cast and formed. The preparation method comprises the following steps: firstly putting amorphous alloy into a mould, exerting certain pre-tensile stress on the amorphous alloy, adding water into gypsum powder and then pouring the mixture into the mould, releasing the pre-tensile stress after the board is formed and detaching the mold, so as to obtain the amorphous alloy-gypsum composite board. The amorphous alloy strip positioning accuracy is achieved, the integrity of the amorphous alloy strip and the gypsum is good, the binding force is strong, and the bending and cracking resistance of the gypsum is improved, the composite board has electromagnetic shielding performance, and meanwhile, the mechanical property and the electromagnetic shielding performance are high in designability.

Owner:江苏磐云泰科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com