Two-wall hollow fabricated root-type open caisson foundation

A prefabricated, hollow technology, applied in infrastructure engineering, caissons, buildings, etc., can solve the problems of high labor and material consumption, heavy on-site workload, and long operation cycle, so as to reduce material consumption, project cost, and progress. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

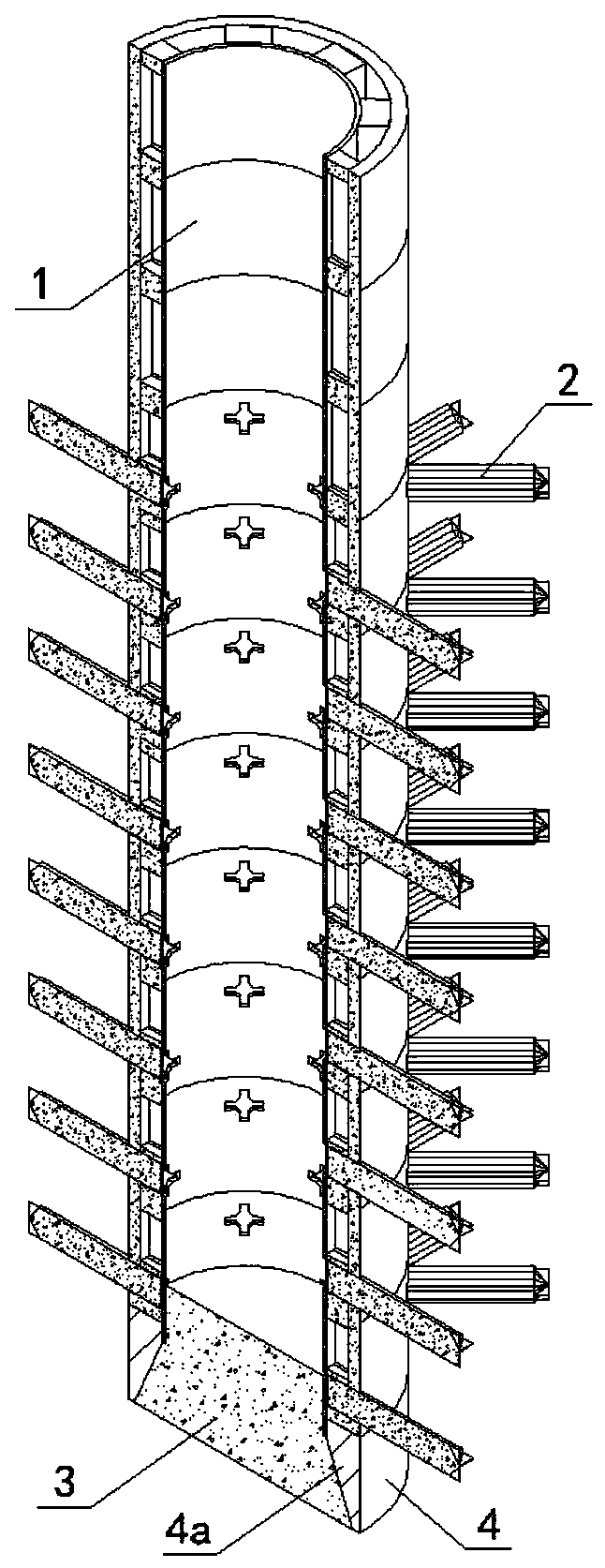

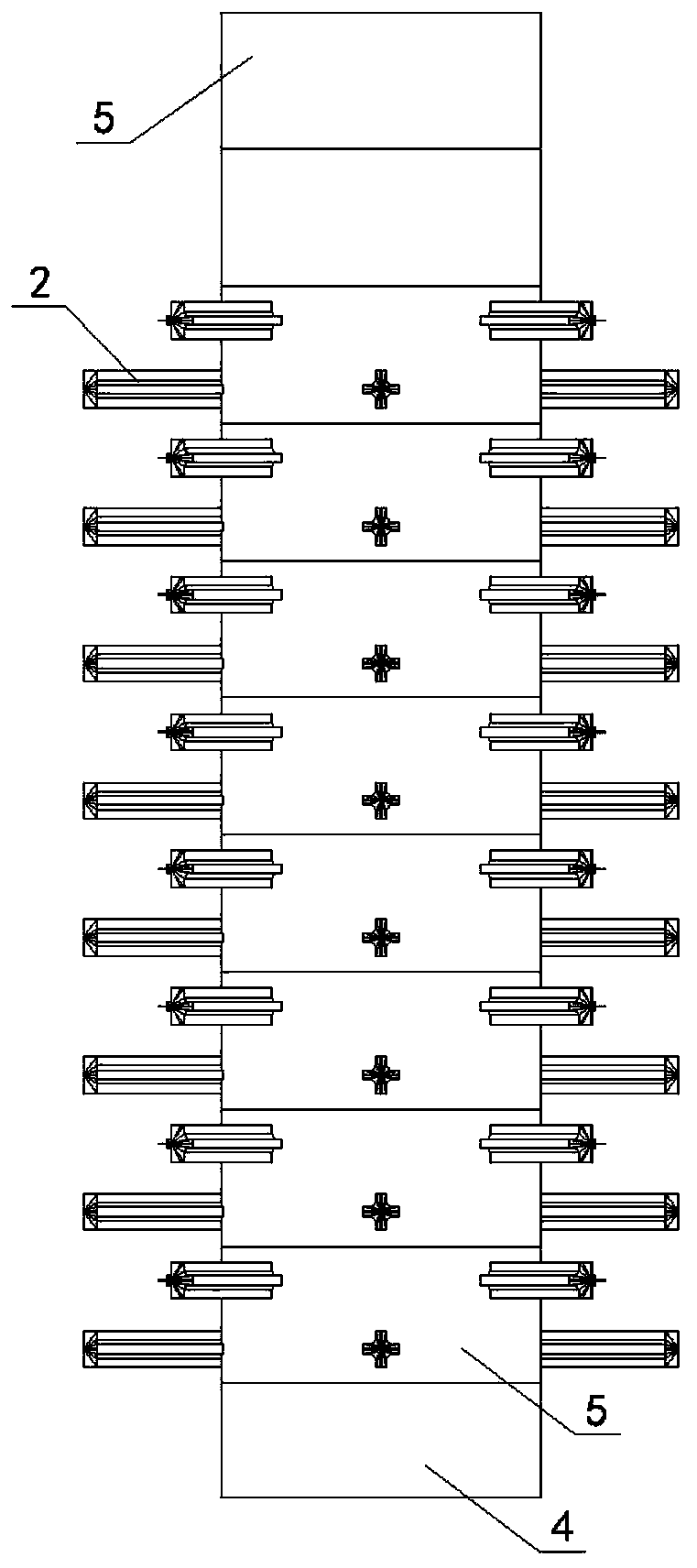

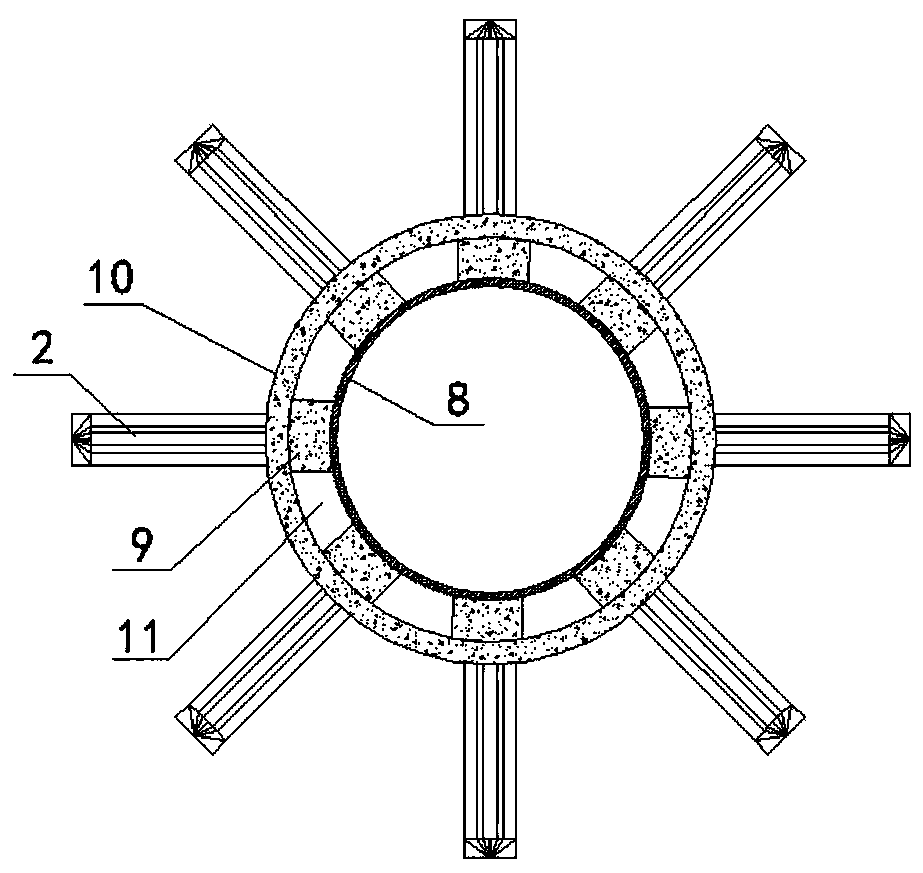

[0030] see figure 1 , figure 2 , image 3 with Figure 4 , the double-wall hollow assembled root caisson foundation in this embodiment is composed of a shaft 1, a root key 2 and a back cover 3; The rib wall 9 and the outer wall 10 are composed, and the well wall cavity 11 formed by the shaft inner wall 8, the rib wall 9 and the outer wall 10 runs through vertically. The cavity size of the well wall cavity 11 meets the requirement that the dredge The need for lowering and moving in the cavity 11; the foot of the well shaft 1 is a blade foot; on the well shaft 1, a root key 2 is arranged radially through the inner wall 8, the rib wall 9 and the outer wall 10 of the well shaft and protruding from the outer wall 10 ; The shaft 1 is vertically connected by the bottom segment 4 and several standard segments 5, the bottom segment 4 is in the shape of a blade, forming a blade foot 4a; The root key 2 is set in the shaft, and then the bottom of the shaft 1 is poured to form the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com