Connection joint for steel tube and angle steel in steel tube tower of transmission line

A steel pipe and connection type technology for transmission lines, applied in towers, building types, buildings, etc., can solve the problem of high construction cost of steel pipe towers, achieve the effects of high node stiffness, ensure effective force transmission, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

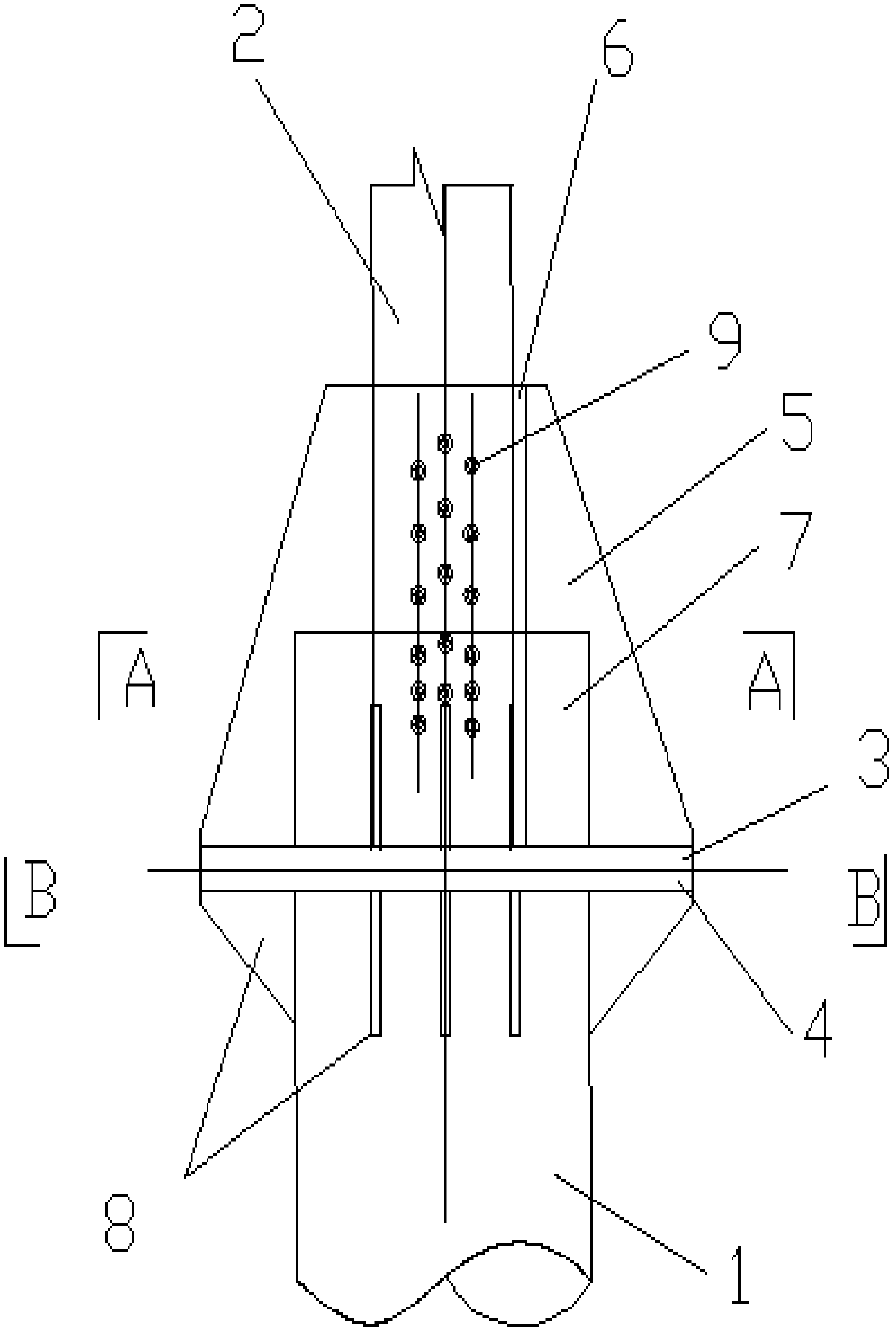

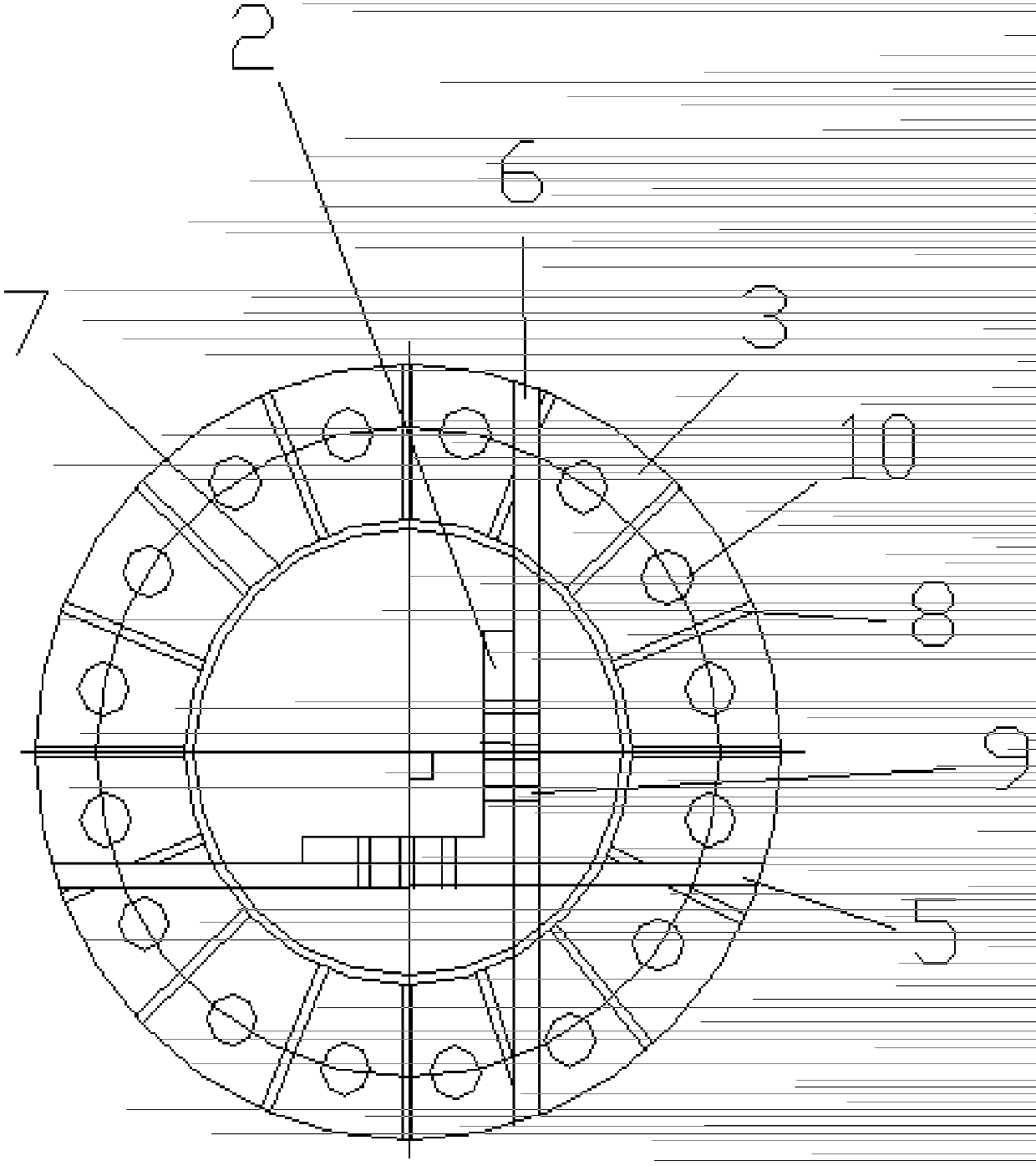

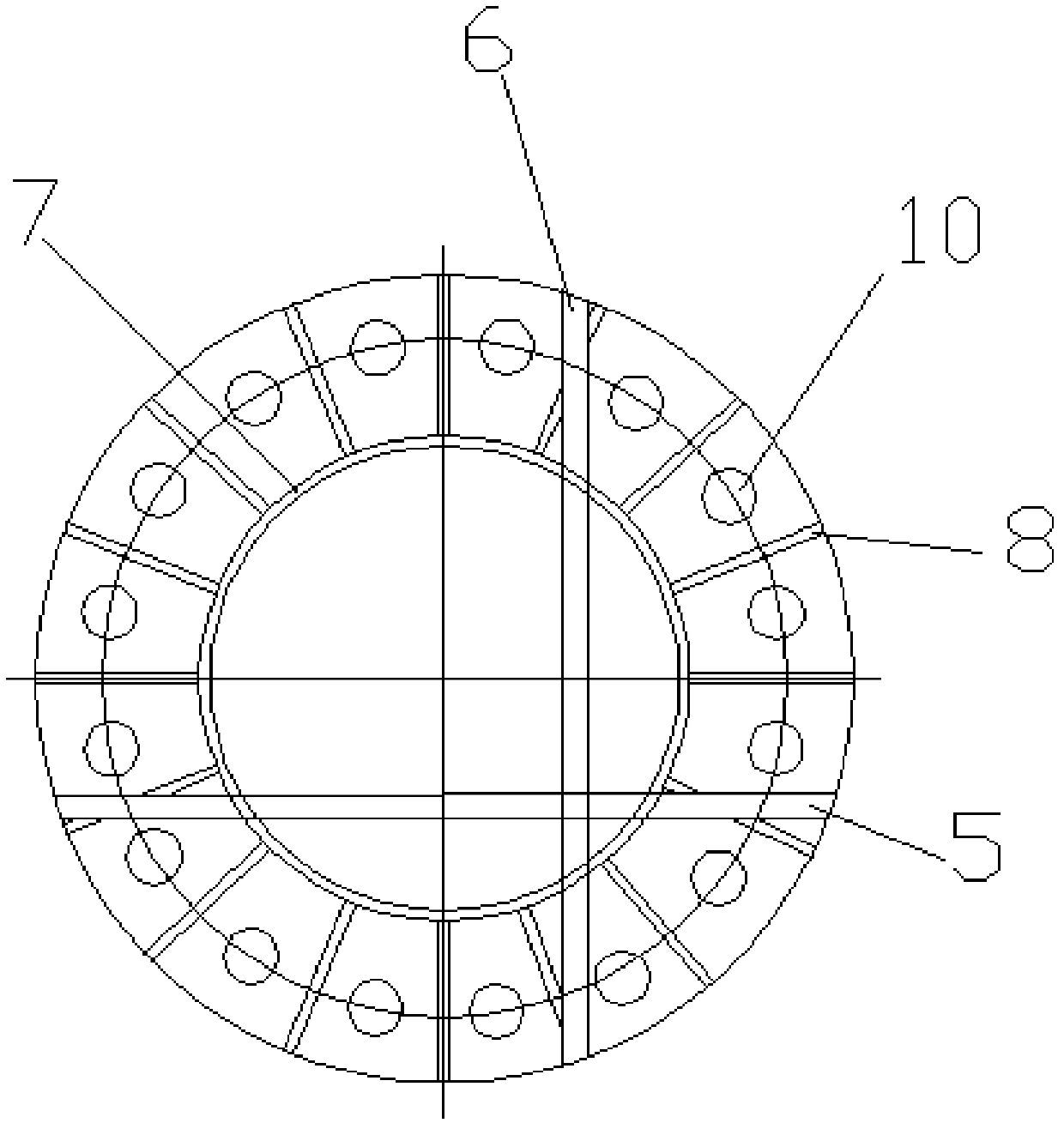

[0024] Such as Figure 1-4 As shown, the invention of this example is a connecting joint of steel pipe variable angle steel in the steel pipe tower of transmission line, including steel pipe 1, angle steel 2 and flange, and the flange is divided into upper flange 3 and lower flange with equal diameters Plate 4, one end of the upper flange 3 and one end of the lower flange 4 are connected by bolt II 10; the other end of the lower flange 4 is welded with the steel pipe 1 to form a lower flange joint, and the axial centerline of the lower flange 4 Returning to the axial center line of the steel pipe 1, a stiffening plate 8 is provided at the node connecting the lower flange 4 and the steel pipe 1, which is connected by welding. The surface of the stiffening plate 8 is perpendicular to the surface of the flange, and the stiffening plate The distribution form of 8 is as attached Figure 3-4 As shown, the stiffening plate 8 is uniformly and symmetrically distributed with the midpoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com