Partially laminated beam bridge

A pier and girder technology applied in the field of partially superimposed girder bridges to achieve the effects of low cost, high material utilization and short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

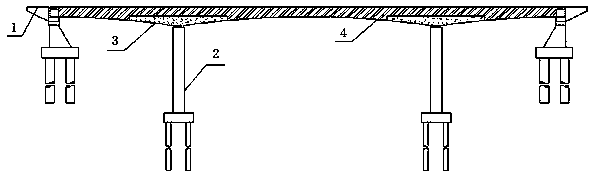

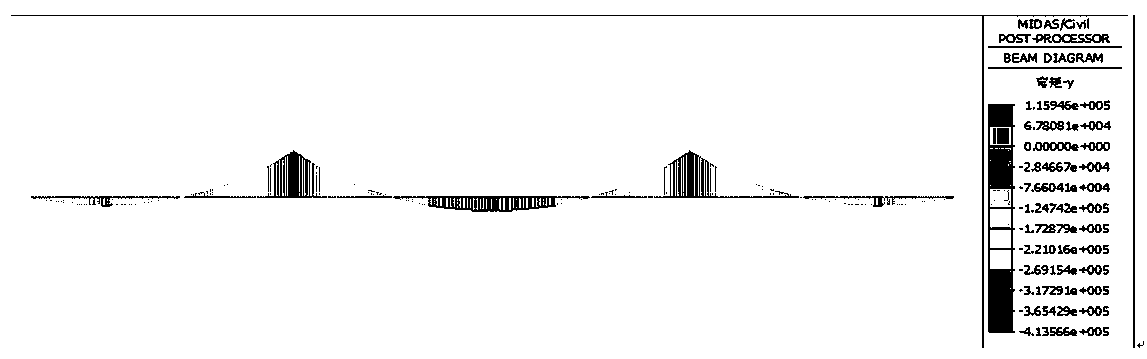

[0082] The span arrangement (90m+3×165m+90m) of the partially superimposed girder bridge in this embodiment is the same as that of the North Branch Bridge of the Second Nanjing Yangtze River Bridge. Specifically: if figure 1As shown, a partially laminated girder bridge is mainly composed of abutment 1, pier 2, concrete structure 3 and steel structure 4; the concrete structure 3 is arranged in the compression area of the girder above the pier 2, and the rest are steel structures 4. To reduce the weight of the structure. A falcon is set above the concrete structure 3, and the embedded parts and shear connectors are welded around the junction of the concrete structure 3 and the steel structure 4. After the steel structure 4 is placed in place later, the steel structure 4 and the embedded parts welded together and poured with micro-expanding concrete to form the whole. The concrete structure arranged above the pier does not increase the load effect of the structure, but also g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com