Patents

Literature

45results about How to "Improve section stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

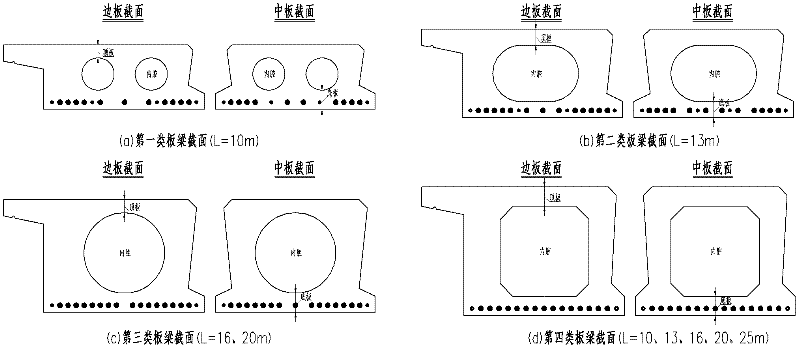

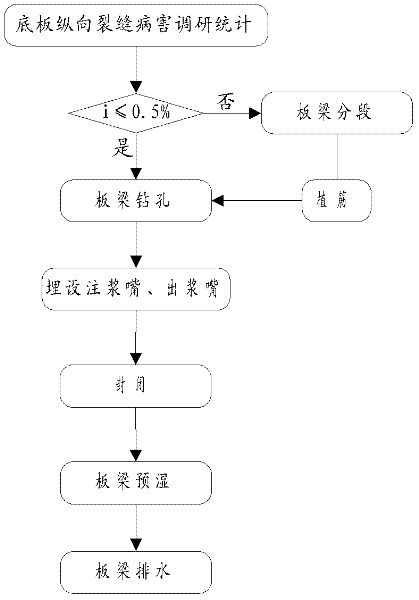

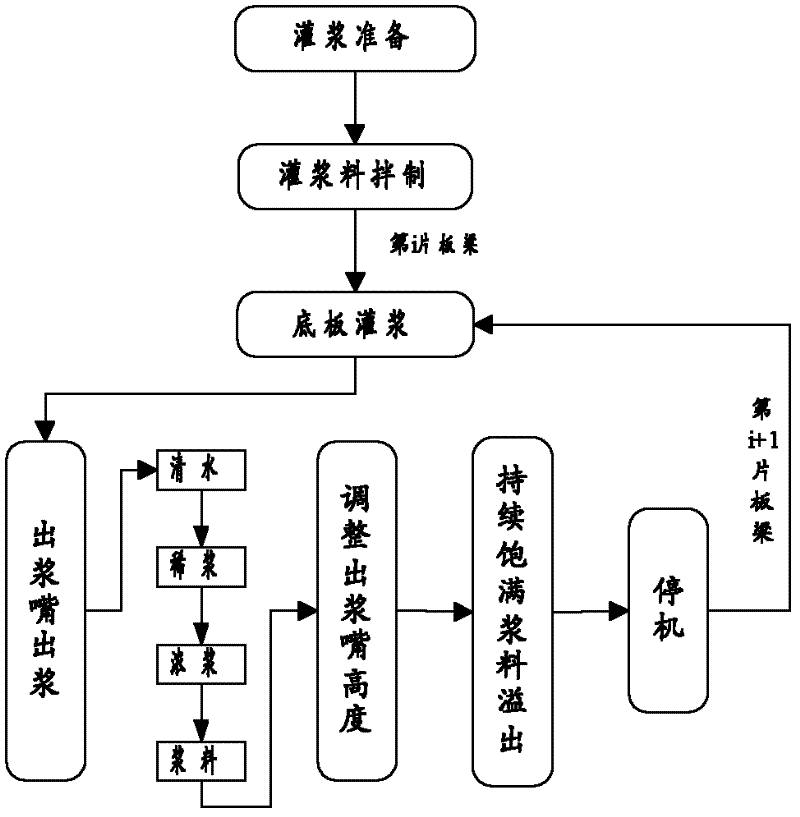

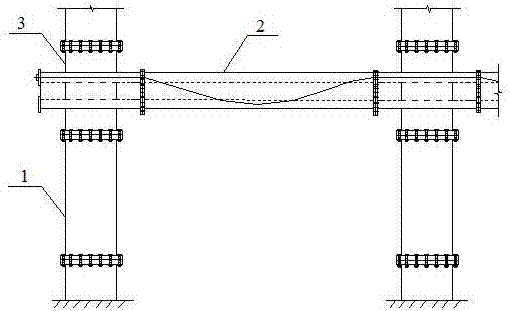

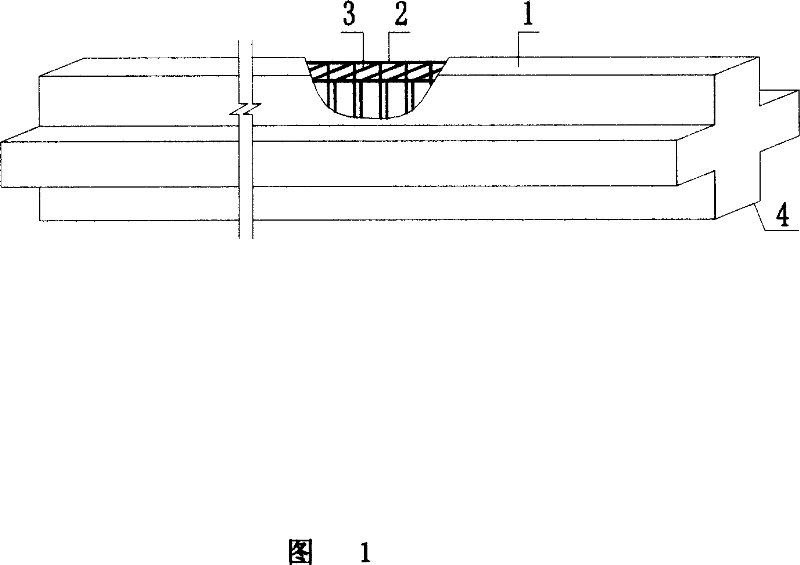

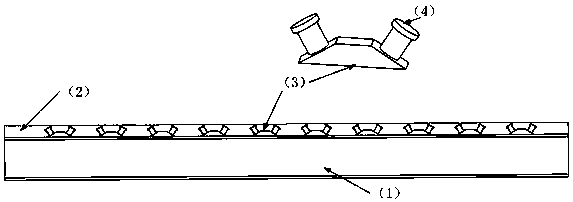

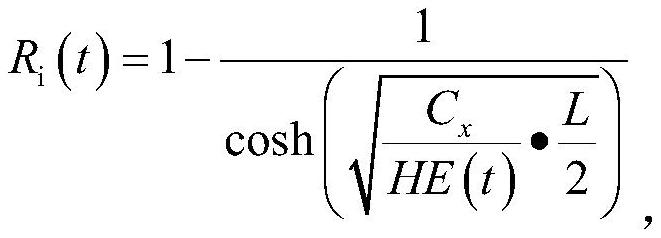

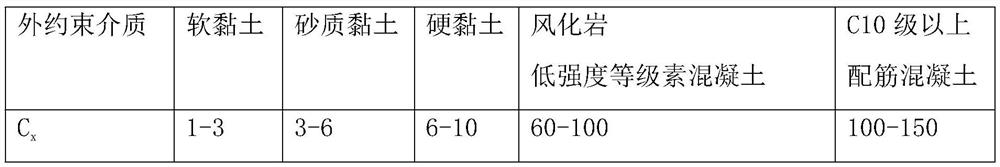

Vertical crack grouting and reinforcing method of prestressed concrete hollow slab bridge bottom plate

ActiveCN102392420AReduce transverse tensile stressImprove the forceBridge erection/assemblyBridge strengtheningPre stressPrestressed concrete

The invention provides a vertical crack grouting and reinforcing method of a prestressed concrete hollow slab bridge bottom plate. According to the method, pressure grouting equipment is mainly adopted to pour a cement-based grouting material into a prestressed concrete hollow plate cavity with a certain thickness, wide, deep and long vertical cracks on the bottom plate can be actively sealed fundamentally through effective adhesion of the grouting material and bottom plate concrete, thereby preventing leakage water inside plates and steams, as well as steam and harmful media and the like in air from entering the cracks to result in rust corrosion and breakage of prestressed steel stranded wires, and further improving the durability and safety of a bridge structure.

Owner:刘其伟

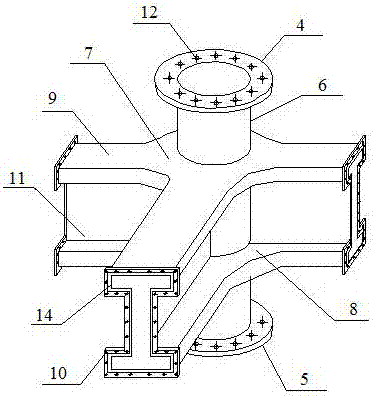

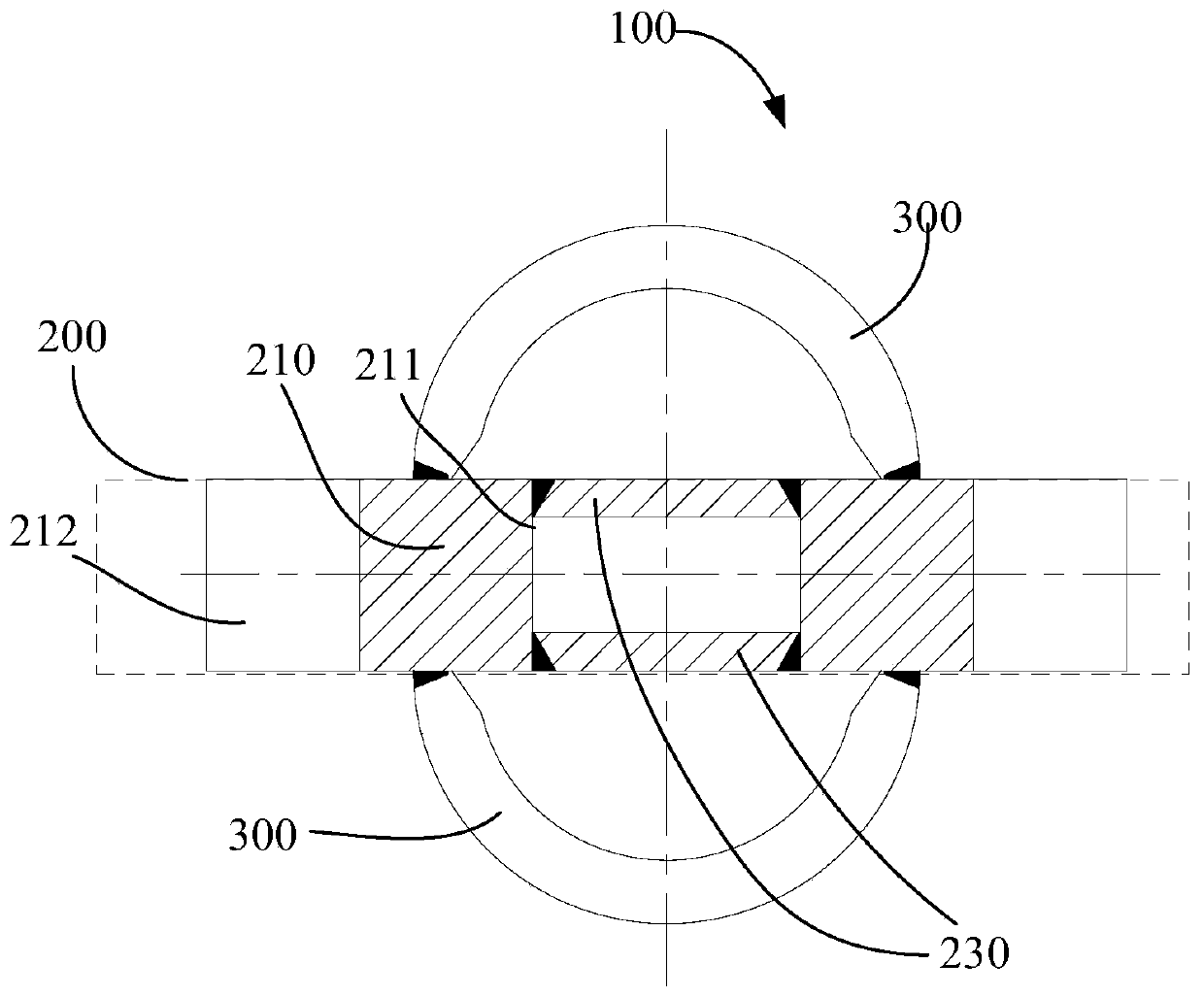

Steel pipe concrete frame with prestressing tendons and construction method thereof

ActiveCN106869315APower transmission is clearAccurate connectionLoad-supporting elementsCurve shapePre stress

The invention relates to a steel pipe concrete frame with prestressing tendons and a construction method thereof. The steel pipe concrete frame with the prestressing tendons is formed by connecting composite columns with composite beams through joints. The composite beams are horizontally arranged among the composite columns. The joints are outer sleeving integral type joints internally filled with self-compacting concrete. The composite columns are sectional-type steel pipe concrete composite columns with built-in profile steel. The composite beams are internal-prestress I-shaped steel pipe concrete composite beams. The prestressing tendons arranged in the composite beams bypass joint outer pipes from upper strengthening annular plates with cavities. The prestressing tendons are positioned through single-hole positioning plates and hole-formed double-hole main positioning plates, form symmetrical curve shapes and achieve tensioning and anchoring at joint end beams. The self-compacting fine stone concrete of the composite beams and self-compacting fine stone concrete of the joint end beams are through and form a whole with the joint outer pipes after curing. The problem that beam-column connecting joints of a novel steel pipe concrete frame with prestressing tendons are complex and liable to damage is solved.

Owner:广西万纵建设工程有限公司

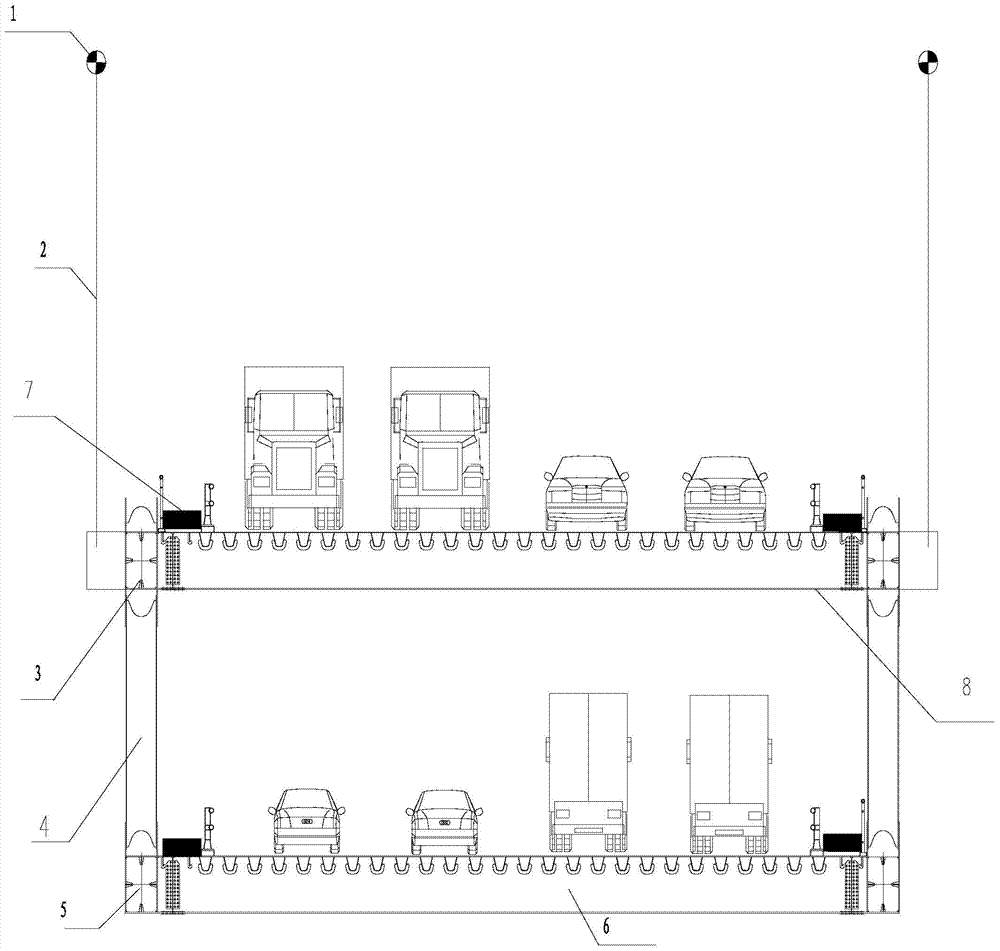

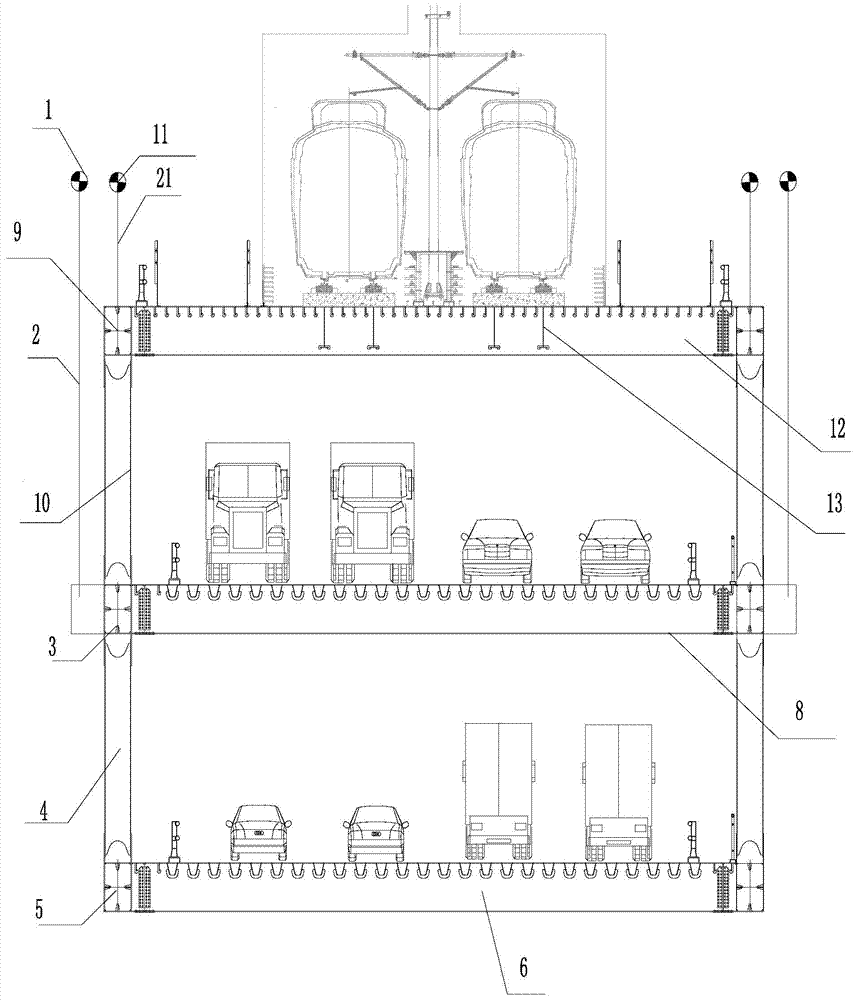

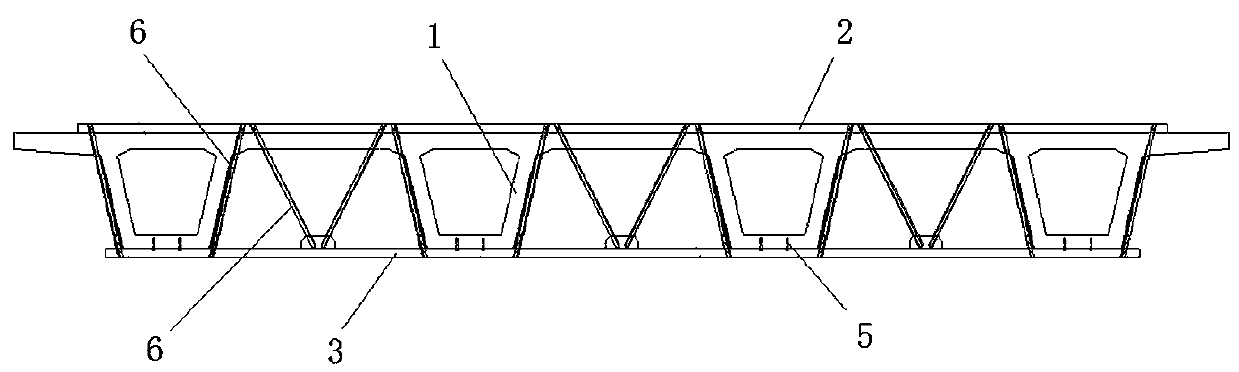

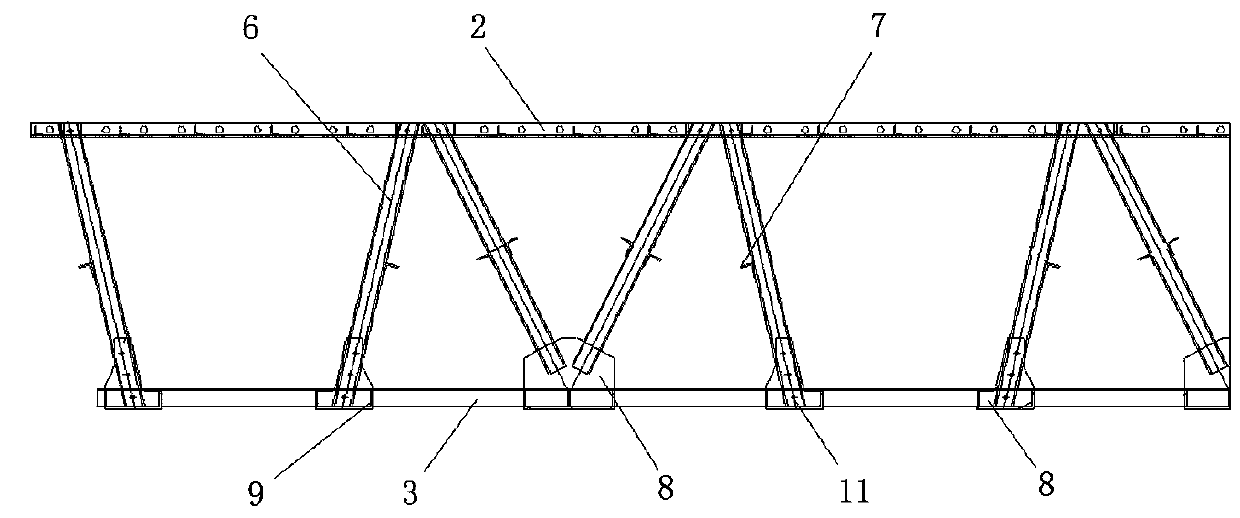

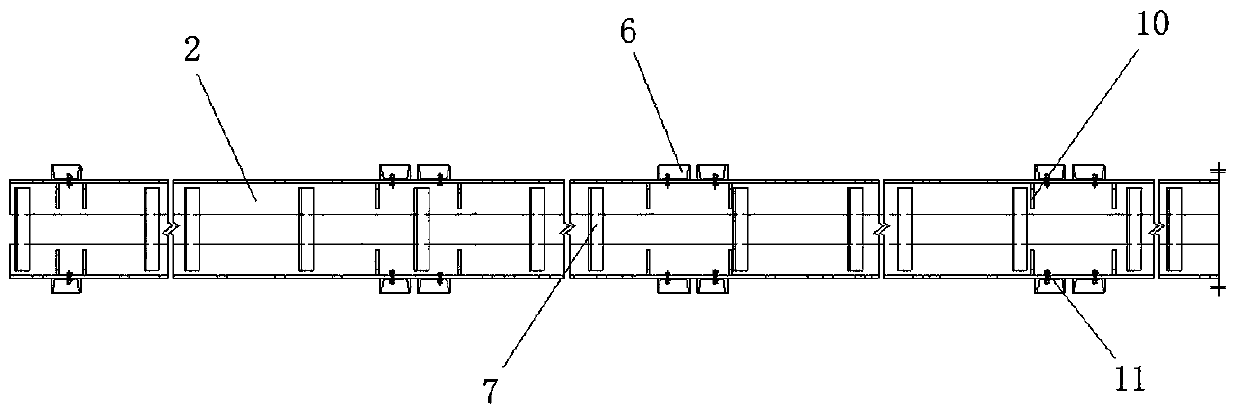

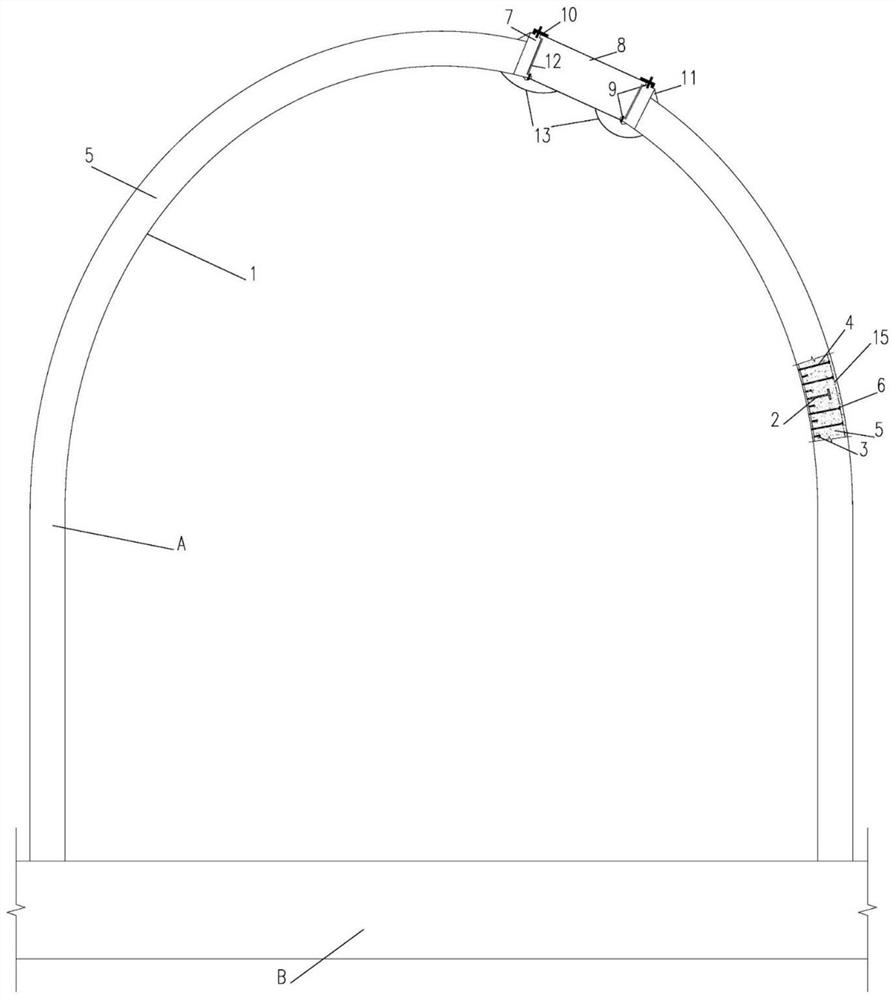

Staged implementation method of multi-bridge-floor-layer suspension bridge for highway and rail

ActiveCN104195946AImprove leaping abilityReduce the impactSuspension bridgeBridge erection/assemblyTerrainBridge deck

The invention discloses a staged construction method of a multi-bridge-floor-layer suspension bridge for a highway and a rail. The suspension bridge is a three-bridge-floor-layer suspension bridge composed of a double-layer parallel main truss structure, rail transit is located on the uppermost layer, and highway traffic is located on the middle layer and the lower layer. The staged construction method of firstly constructing the highway traffic and then constructing the rail transit is adopted, construction on the rail transit can be carried out in the running process of the highway traffic, the scheme of the three-bridge-floor-layer suspension bridge is adopted, structural efficiency can be improved, the adaptive capacity of the structure on terrain is enhanced, the structure can adapt to the requirement for staged construction of the rail transit and the highway traffic, the recent engineering construction investment is effectively reduced, idle resources are avoided, meanwhile, the requirement that existing traffic circulation is not interrupted in the long-term construction period can be met, and the influence of construction on traffic is reduced to the largest extent.

Owner:林同棪国际工程咨询(中国)有限公司

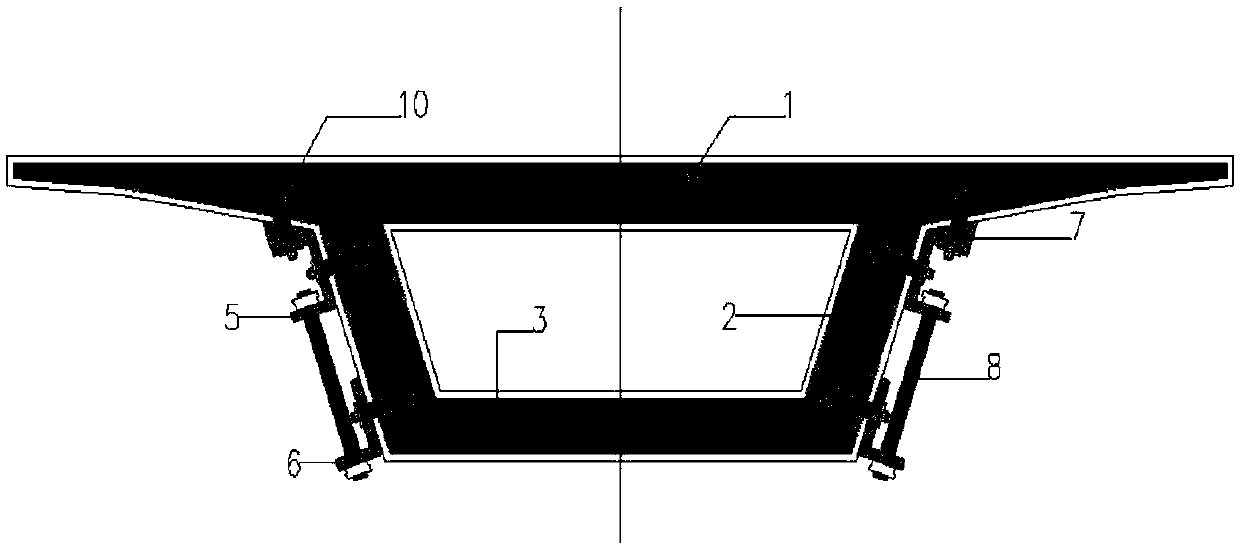

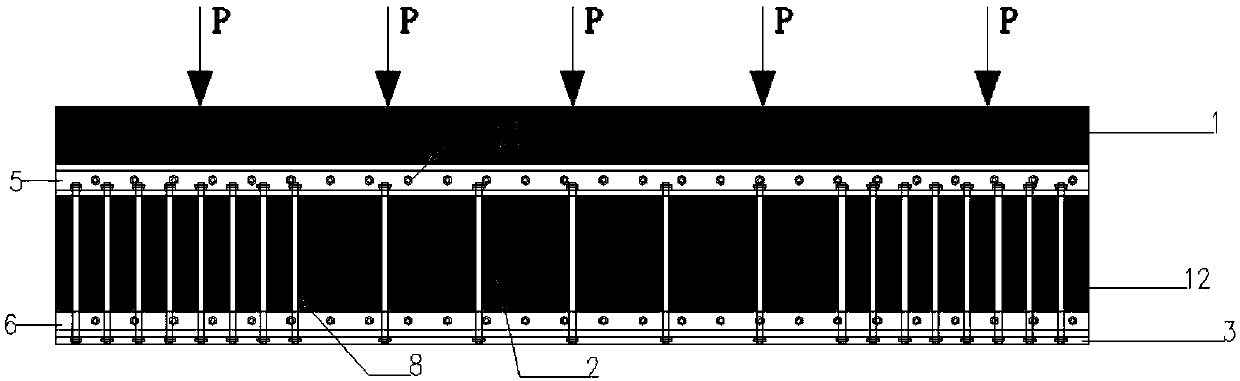

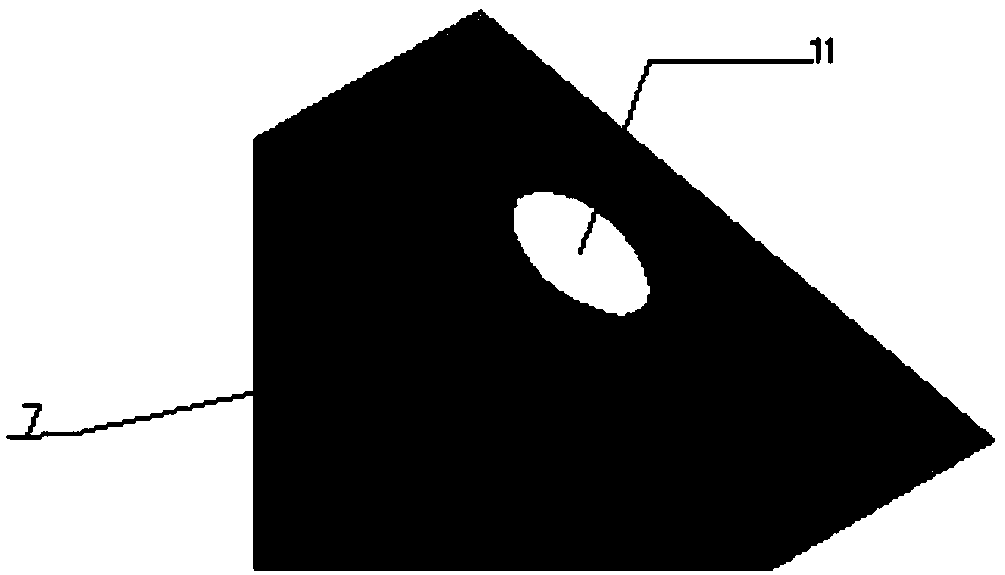

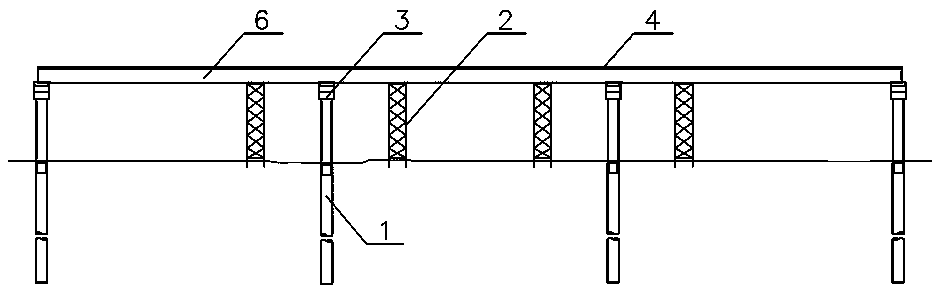

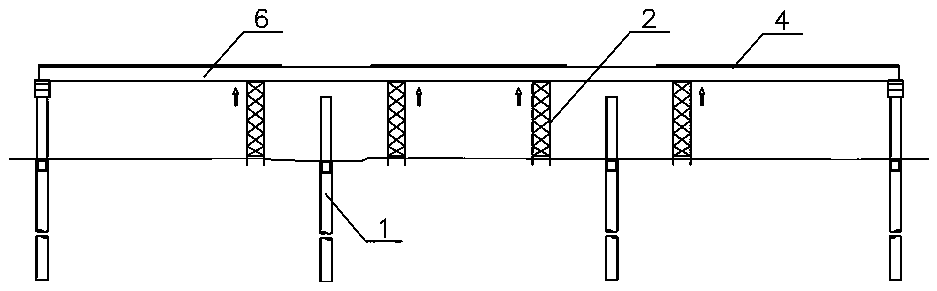

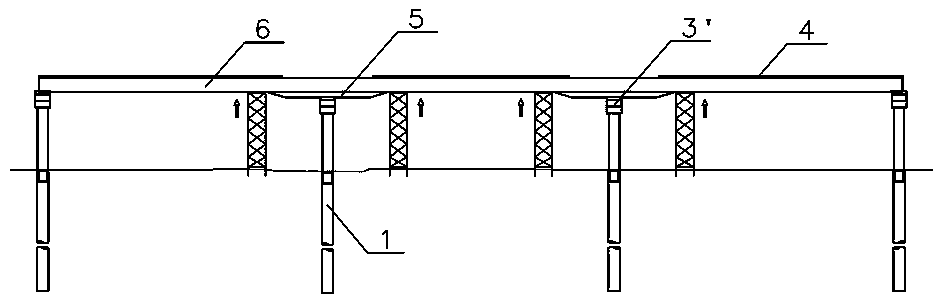

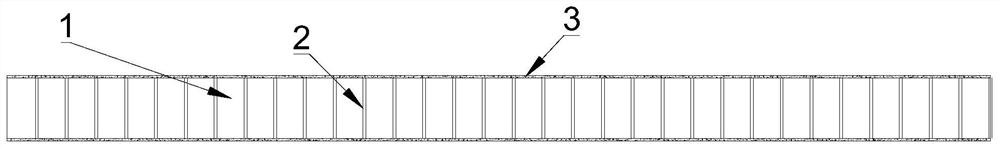

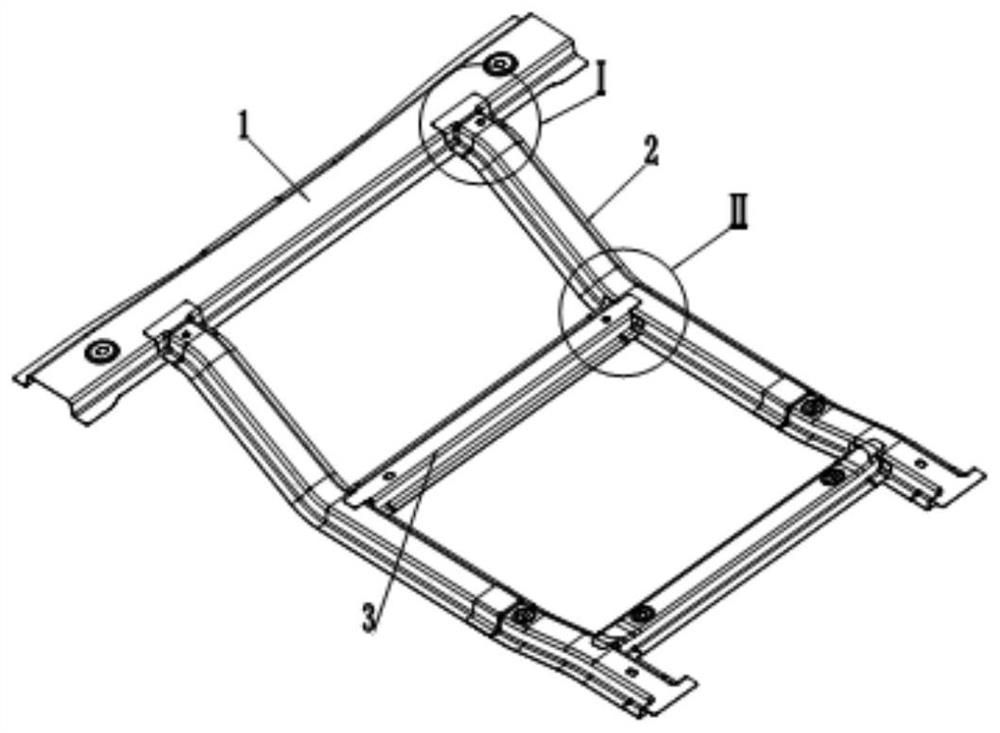

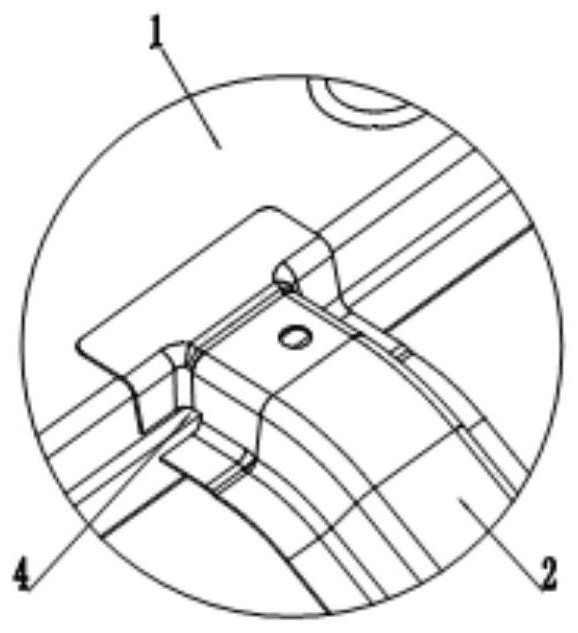

Reinforcing structure and method for assembled continuous box girders

ActiveCN107938525AThe maximum vertical displacement is reducedReduce disturbanceClimate change adaptationBridge erection/assemblyArchitectural engineeringBox girder

The invention specifically relates to a reinforcing structure and method for assembled continuous box girders and solves the problem that the existing reinforcing of the assembled continuous box girders is high in disturbance degree to the original girders, low in construction efficiency and poor in overall rigidity. The reinforcing structure comprises two upper chords and a channel-steel-shaped lower chord and is characterized in that the channel-steel-shaped lower chord is provided with a plurality of anchor bolt holes, anchor bolts are arranged in the anchor bolt holes, web members are arranged between the outer sides of the two upper chords and the front and rear sides of the lower chord, a lacing bar is arranged between the middles of each pair of front-rear-corresponding web members,node plates are arranged between the lower ends of the web members and the front and rear walls of the lower chord, and lower reinforcing ribs are arranged in the channel-steel-shaped lower chord. The reinforcing structure has the advantages that the maximum vertical displacement of the upper box girders is reduced to a certain extent, overall section rigidity is increased to a certain extent, uniform stress of the transverse girders is achieved, the transverse partition girders can play the role of rigid support, the overall stress performance of the structure is increased, and the stress state of the single girder is improved evidently.

Owner:SHANXI TRAFFIC PLANNING PROSPECTING & DESIGN INST

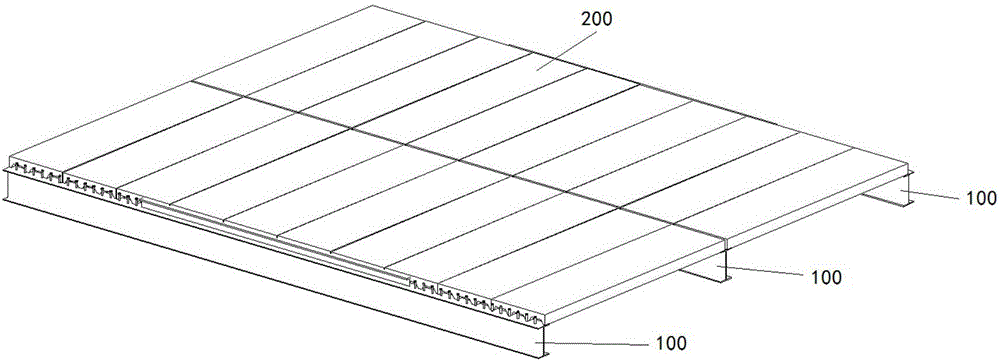

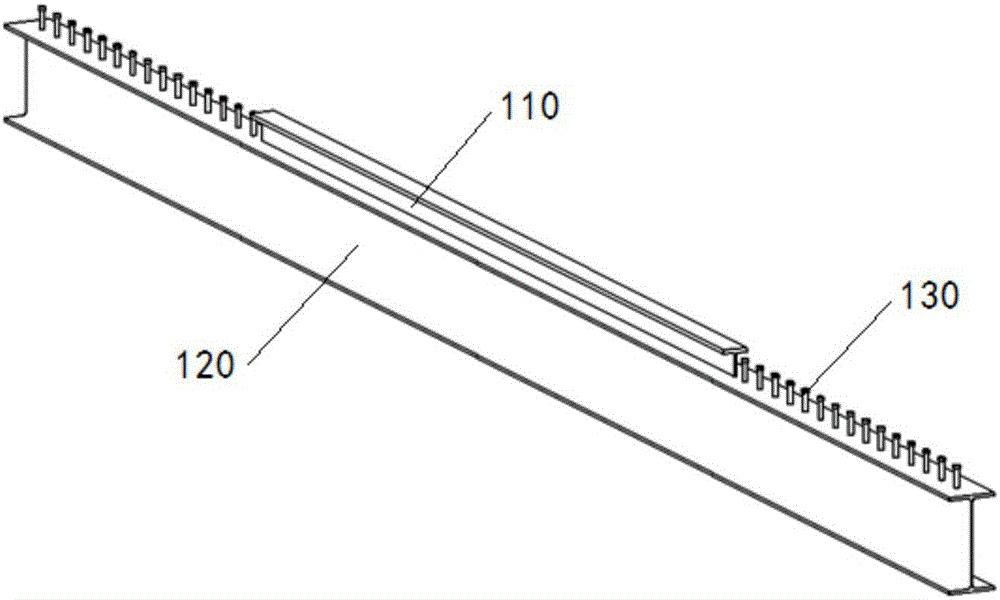

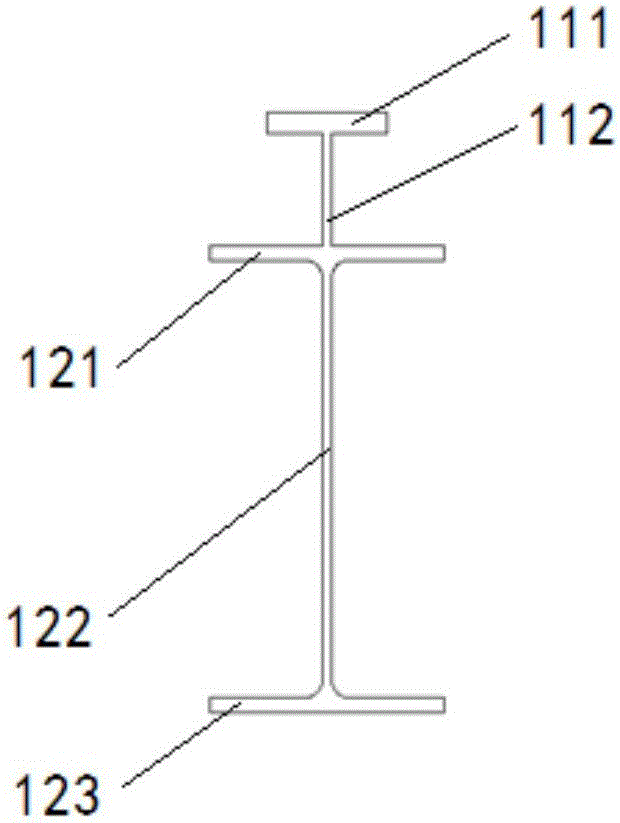

H+T type component and combination beam of H+T type component and floor

InactiveCN106401035AIncreased bending stiffnessImprove the bending capacityFloorsArchitectural engineeringRebar

The invention provides an H+T type component which comprises T type proximate matter and H type proximate matter. The flange of the T type proximate matter is parallel to the two flanges of the H type proximate matter, a web of the T type proximate matter and a web of the H type proximate matter are located in one straight line, the T type proximate matter is fixed to the H type proximate matter, or the T type proximate matter and the H type proximate matter are integrally molded. The invention further provides a combination beam of the H+T type component and a floor. The combination beam comprises the H+T type component and a floor assembly; and the floor assembly comprises at least one layer of reinforcing steel bars, and the reinforcing steel bars are fixed to the T type proximate matter. The H+T type component and the combination beam have the beneficial effects that under the condition that the building layer height, the beam span and the load are the same, the effective section depth is larger than that of a traditional H type cross section, and the flexural rigidity and the flexural capacity of beams can be effectively improved; and the beam height is reduced, the indoor using clear height is increased, the steel using amount of the beams is reduced, and the aims of being economical and applicative can be achieved.

Owner:江苏拓特智能制造有限公司 +1

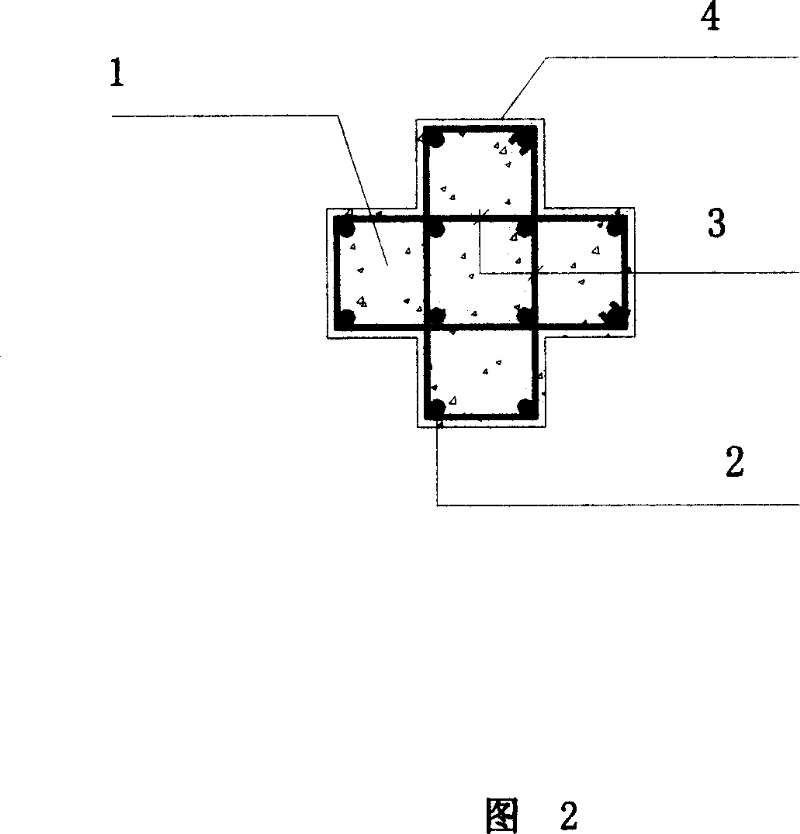

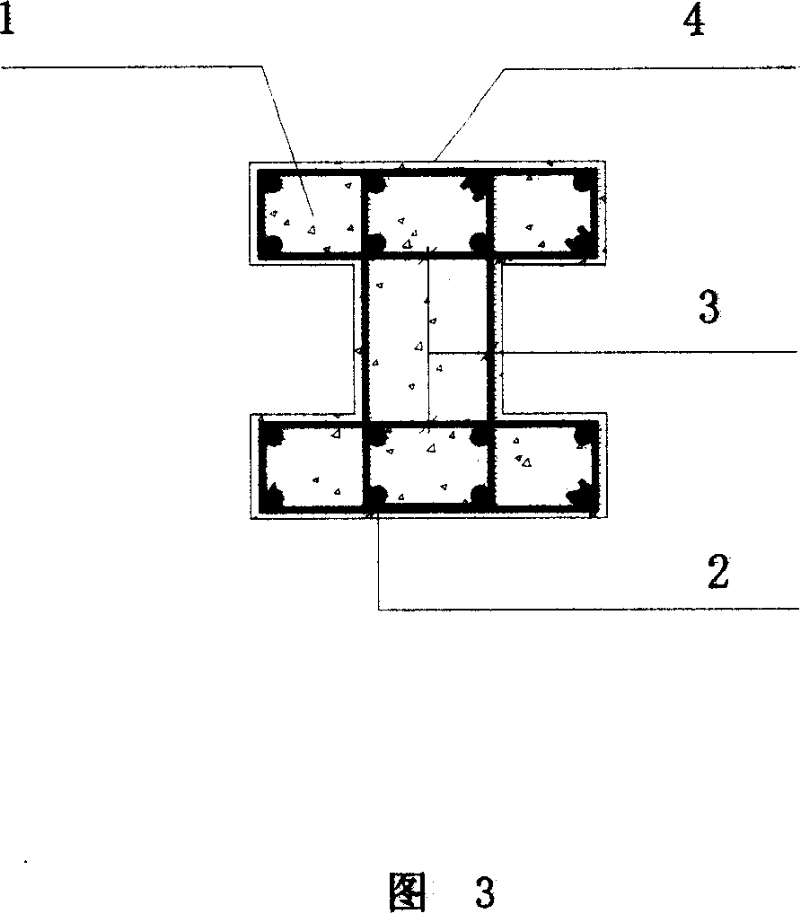

Prefabricated reinforced concrete odd-shaped cross-section pile

InactiveCN101041963AImprove horizontal bearing capacityImprove pile side frictionBulkheads/pilesReinforced concreteRebar

The invention discloses a preformed steel bar concrete special-section post, belonging to construction technique, comprising concrete, main bar and hoop reinforcement, while its section is in cross shape, I-shape, or gear shape. Compared with square post and tube post in same section, the special-section post changes the geometry physical character of section, improve section rigidity, increase the side area of post circumference, and improve the friction resistance and horizontal bearing force of post.

Owner:凌国智

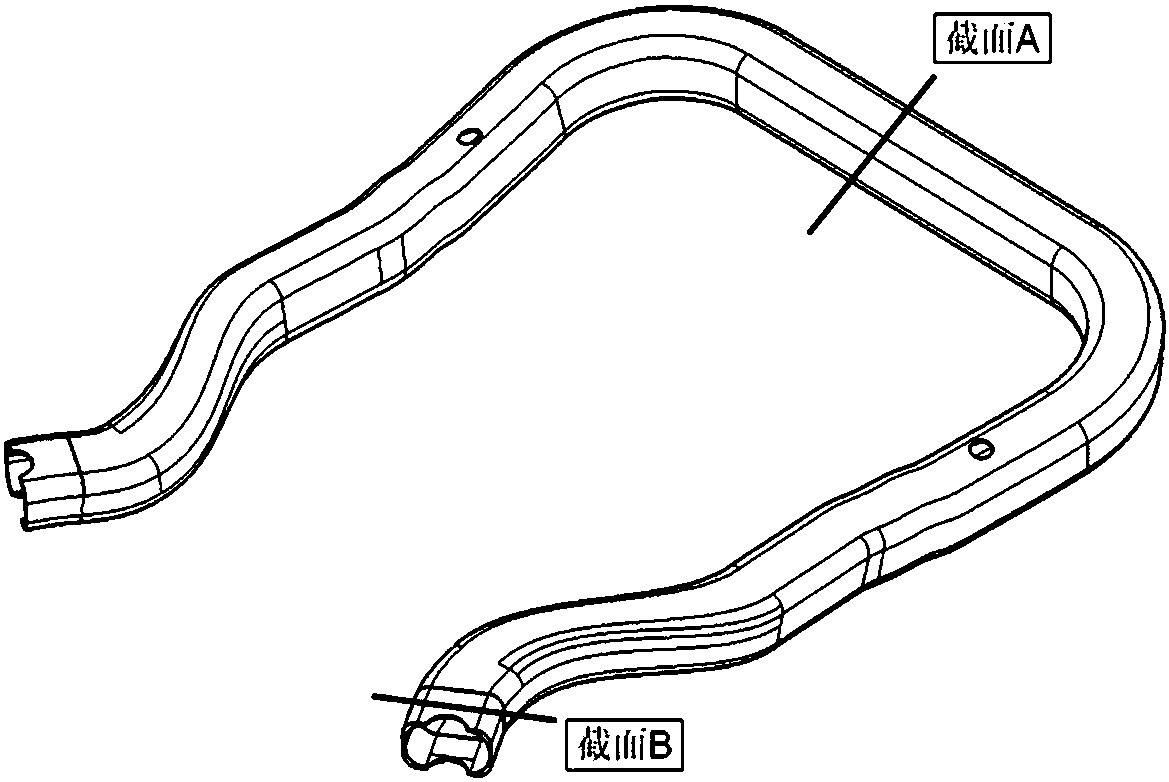

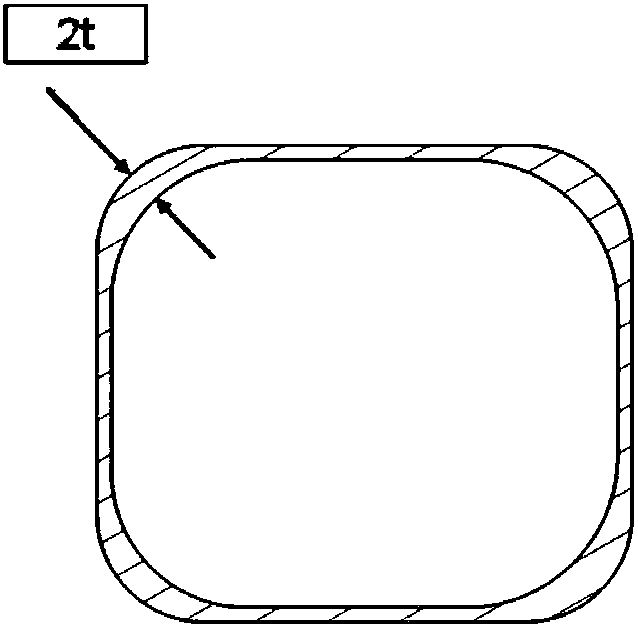

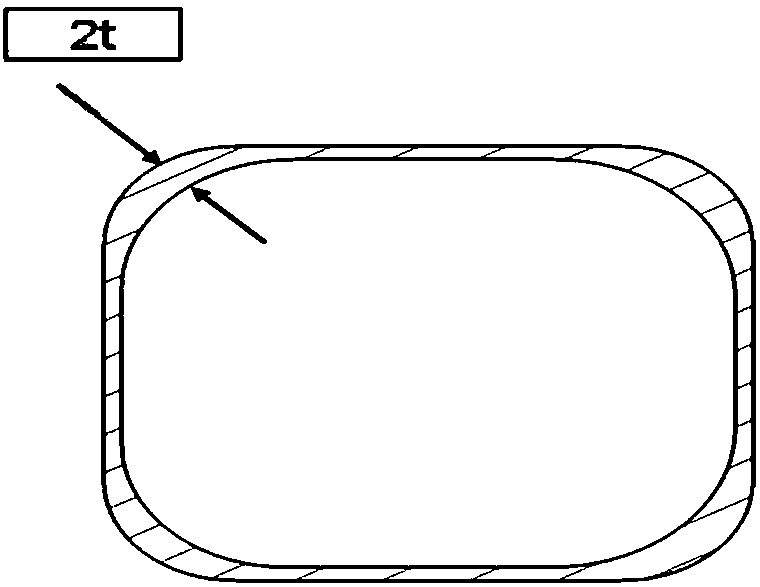

Hydraulic bulging tube with partially thickened wall thickness and forming method of hydraulic bulging tube

InactiveCN108655249AImprove section stiffnessImprove stress concentrationUnderstructuresRigid pipesStress concentration

The invention relates to a hydraulic bulging tube with the partially thickened wall thickness and a forming method of the hydraulic bulging tube. The tube is characterized in that the wall thickness of the upper part or all R angle positions of the circumferential direction of the section of a hydraulic bulging tube body perpendicular to the axis and in the axial direction is larger than the wallthickness of the side wall of the tube body, or / and, the wall thickness of the tube body in the stress concentration position is increased, and the thickened wall thickness is continuous in the axialdirection of the tube body; and the wall thickness of the R angle position is 1.2t to 6.0t, wherein t is the wall thickness mm of the side wall of the tube body. Through the design of the hydraulic bulging tube with the partially thickened wall thickness, the rigidity of the section of a part can be improved, the stress concentration can be improved, and the thickness of a tube blank in the R angle and the corresponding stress concentration position is increased, and therefore, the phenomenon that the wall thickness is excessively thinned and crack occurs due to the fact that the local bulging amount is relatively large can be effectively avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

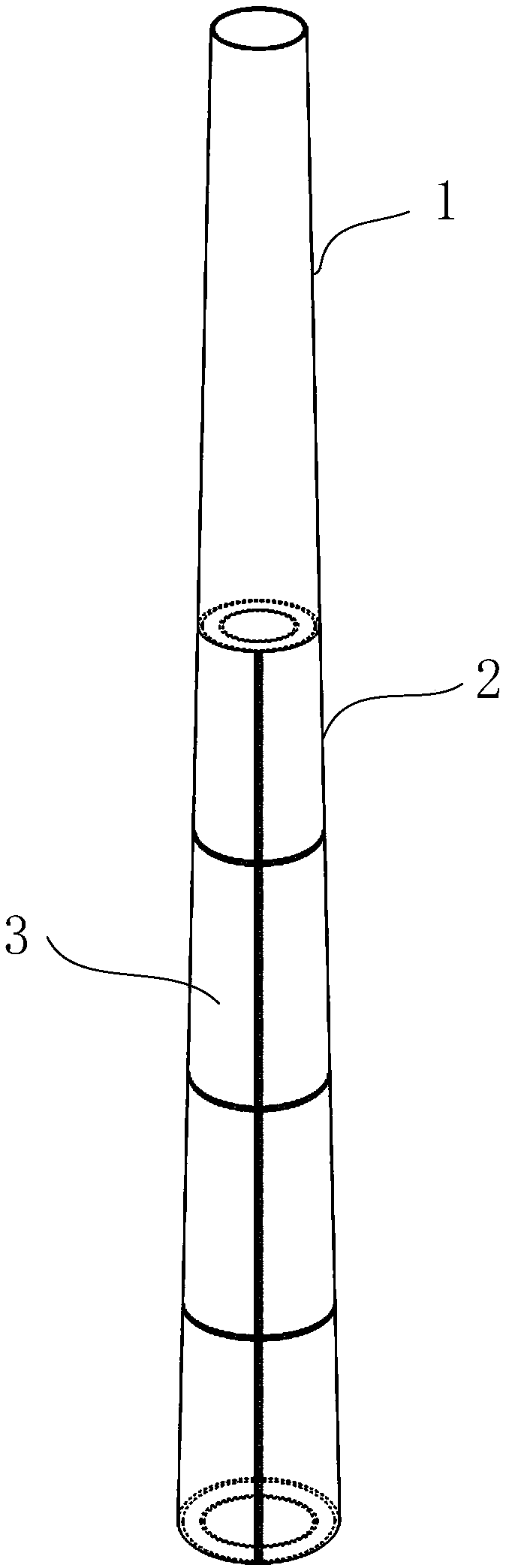

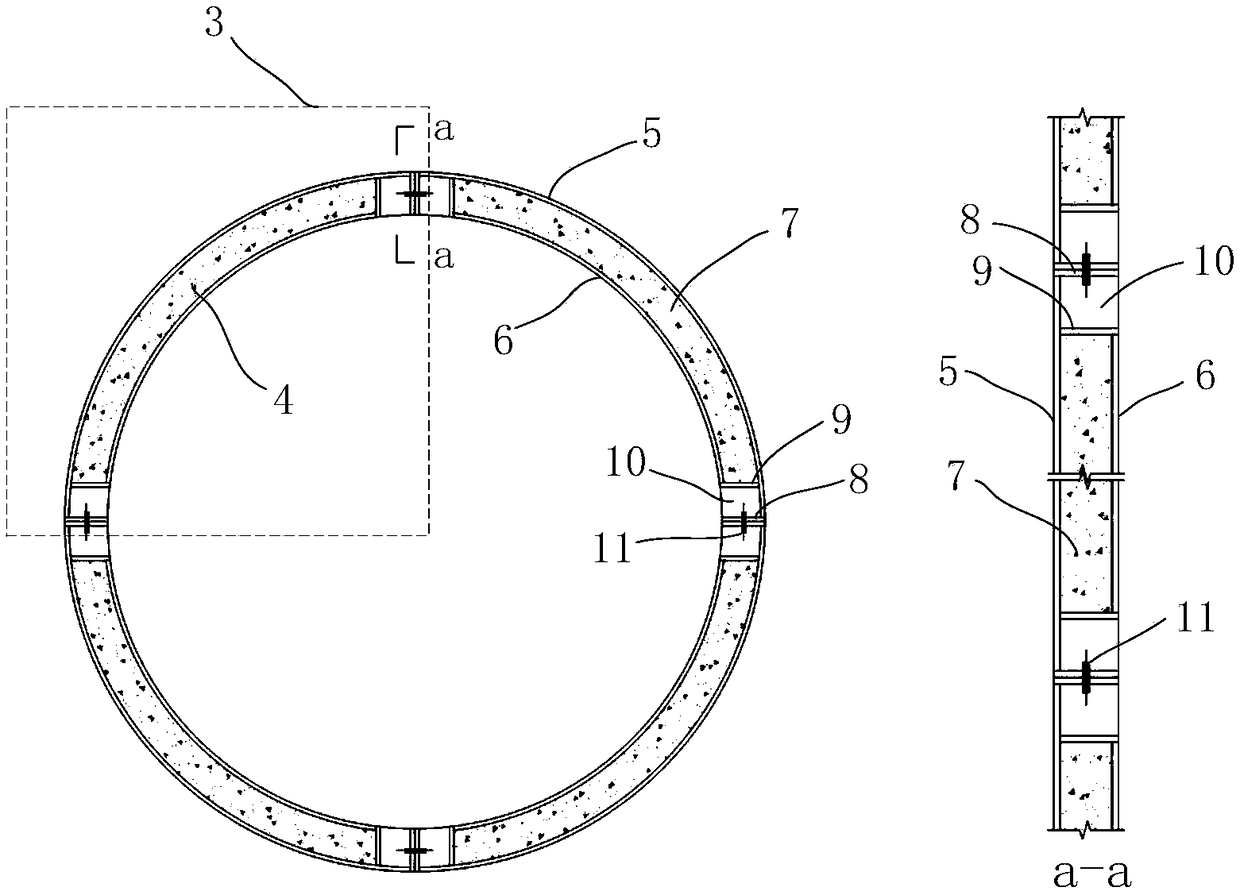

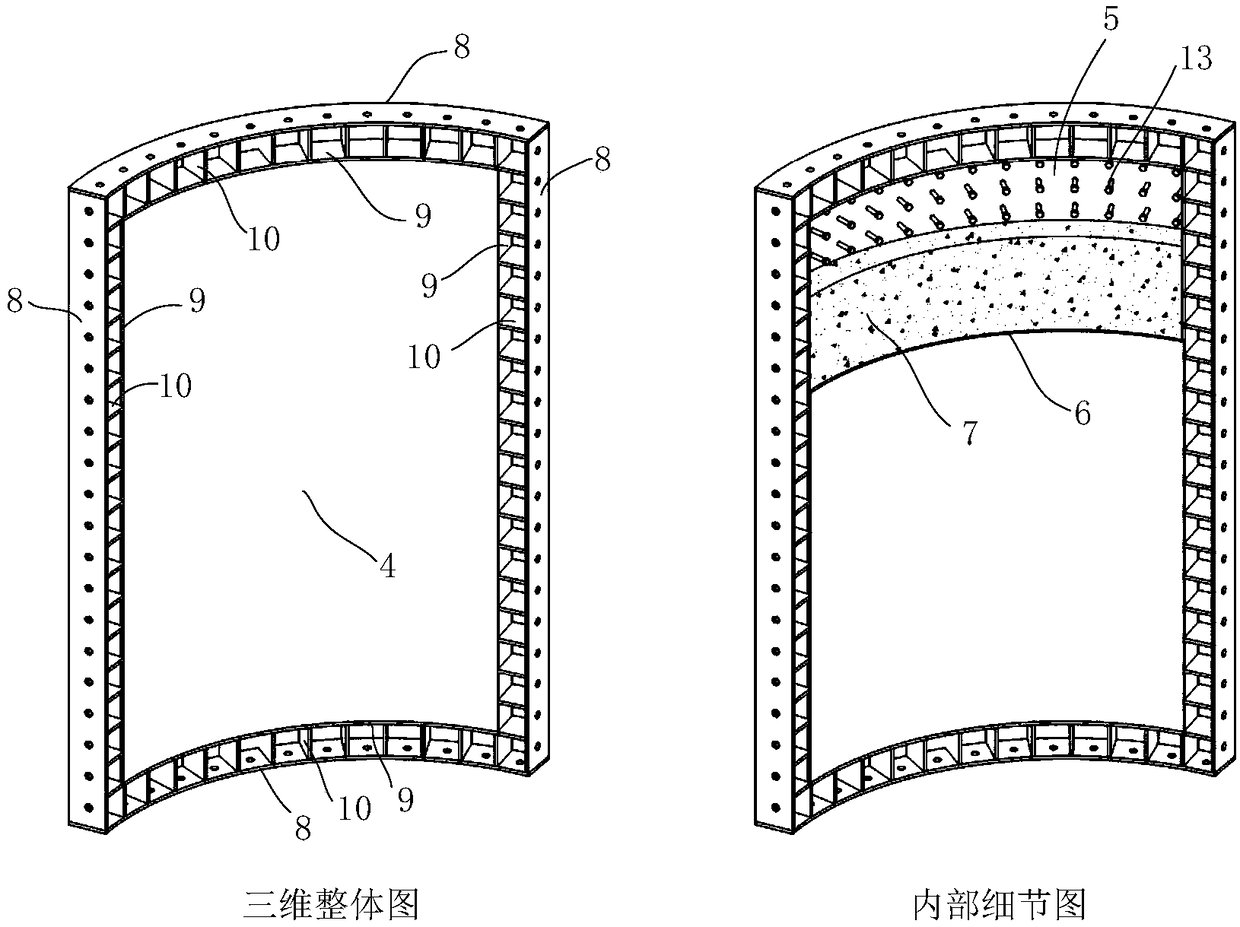

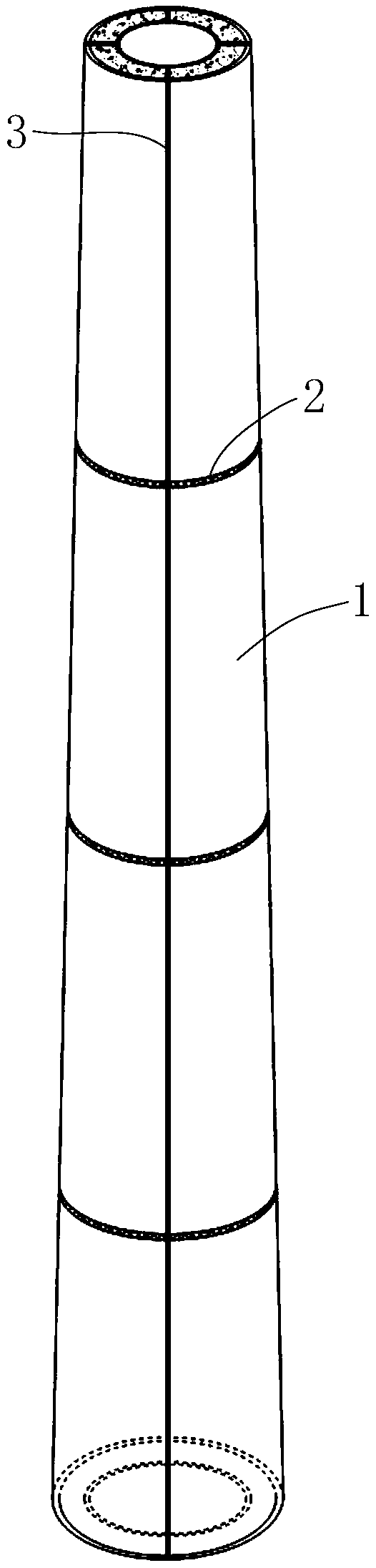

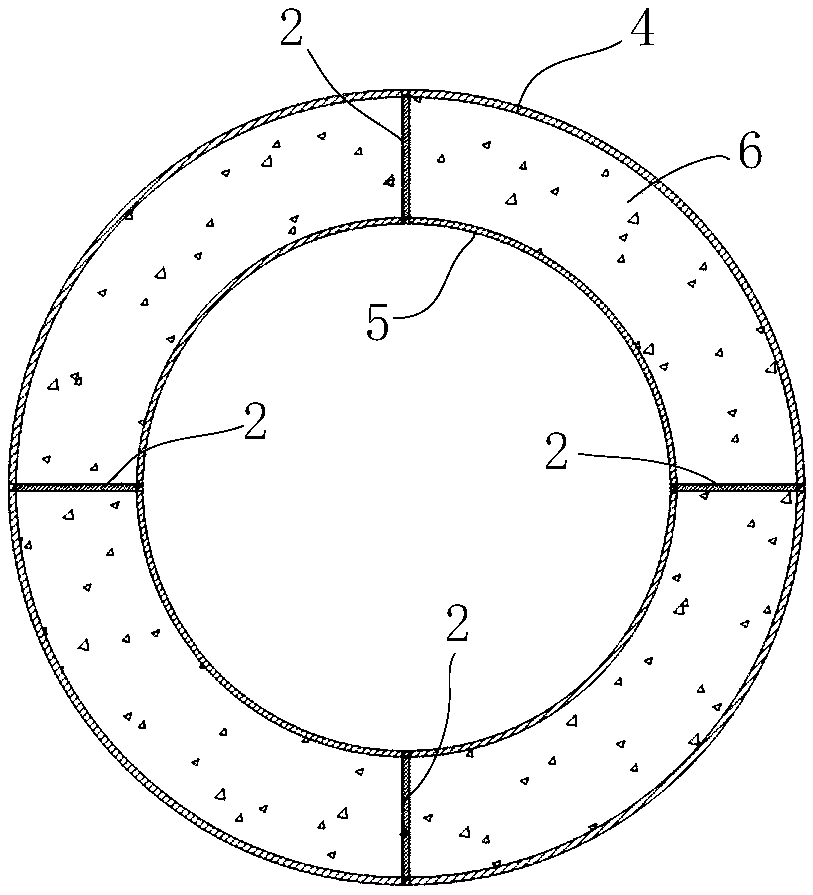

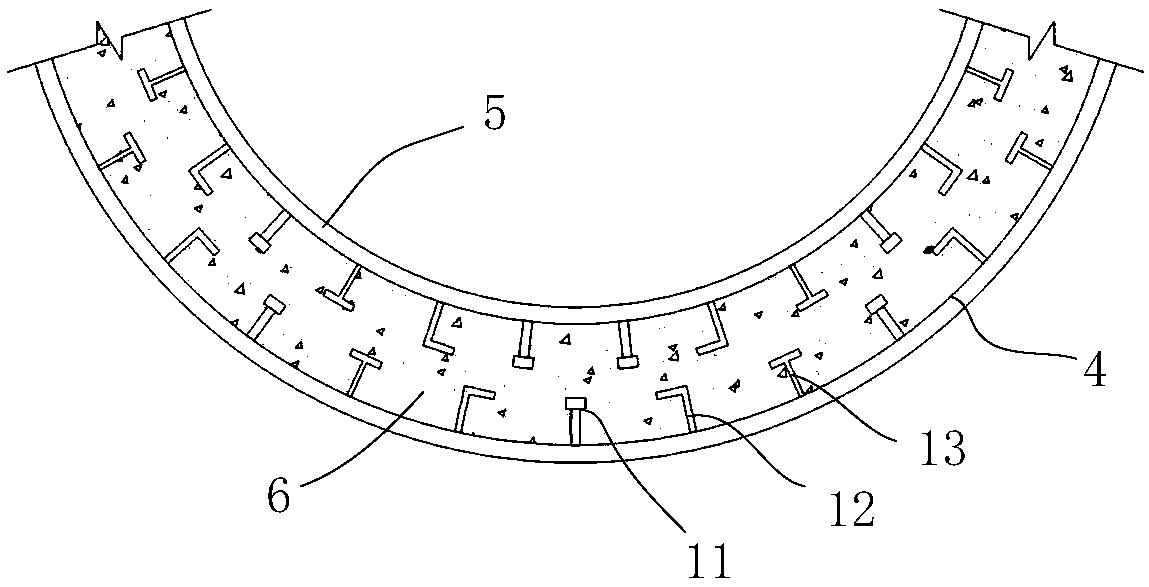

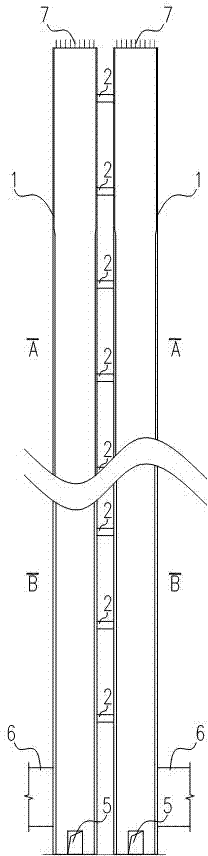

Wind power mixing tower barrel based on edge stiffening combined shell

PendingCN109404224AEasy constructionIncrease productivityWind motor supports/mountsMachines/enginesElectricityTower

The invention discloses a wind power mixing tower barrel based on an edge stiffening combined shell, and relates to the technical field of wind power generation. The upper portion of the wind power mixing tower barrel is a pure steel tower barrel, and the lower portion of the wind power mixing tower barrel is a combined tower barrel. The combined tower barrel is formed by splicing two to eight edge stiffening combined shells along the circumferential direction, and is assembled along the vertical section. The edge stiffening combined shell is composed of hollow interlayer steel tube concrete and outer end plates, inner end plates and stiffening plates arranged along the periphery of the hollow interlayer steel tube concrete. The hollow interlayer steel tube concrete is composed of an outerlayer steel tube, an inner layer steel tube and concrete. Bolts, steel angles, T-shaped steel parts or a combination of the three steel parts are welded on one side of the steel pipe in advance, andthen concrete is poured. According to the wind power mixing tower barrel, the advantages of the combined structure are brought into full play, the stress form is reasonable, the connection is reliable, all the components can be prefabricated in advance and assemblied in filed, the construction efficiency is high, the material consumption is saved, the transport is convenient, and the engineering application prospect is wide.

Owner:CHONGQING UNIV

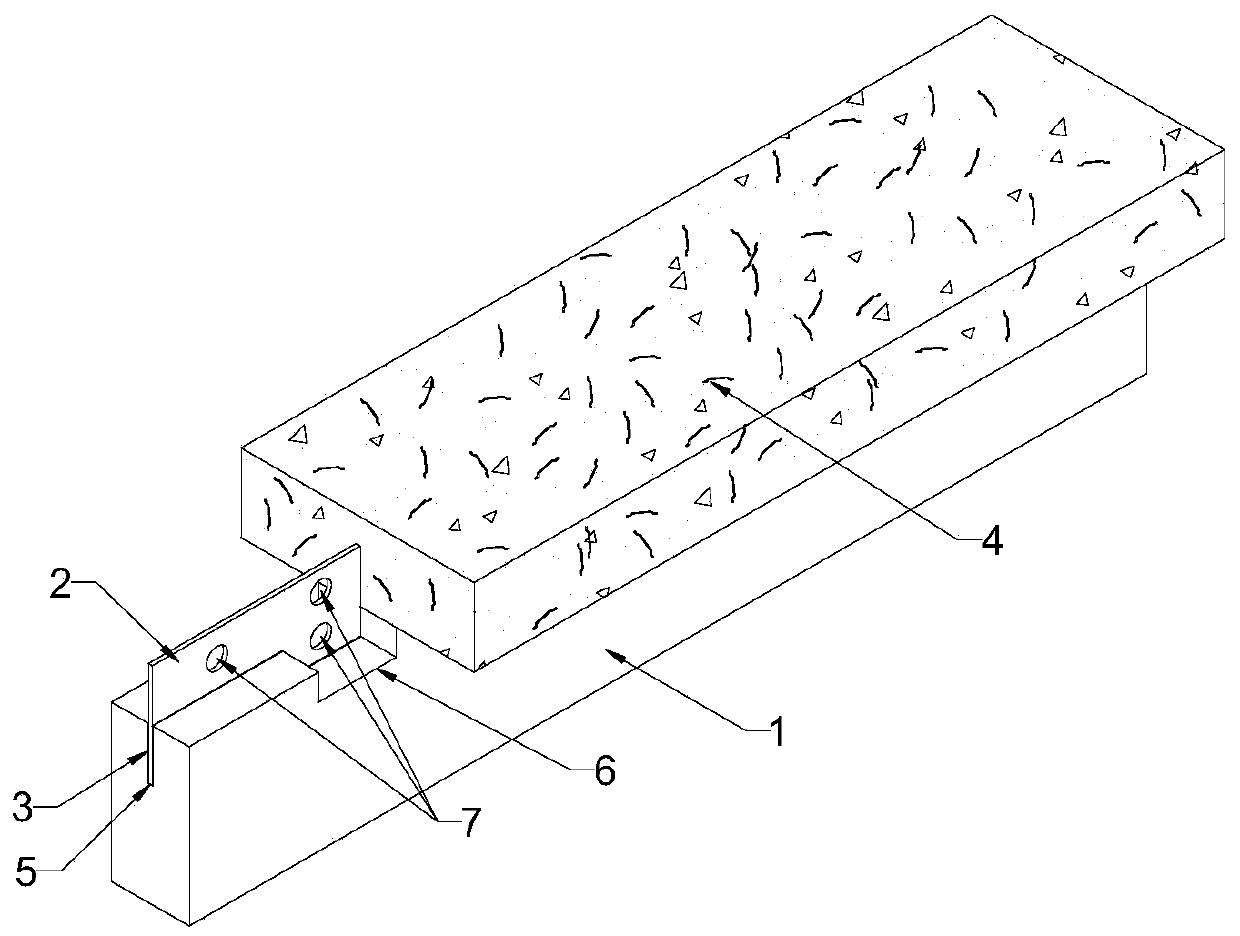

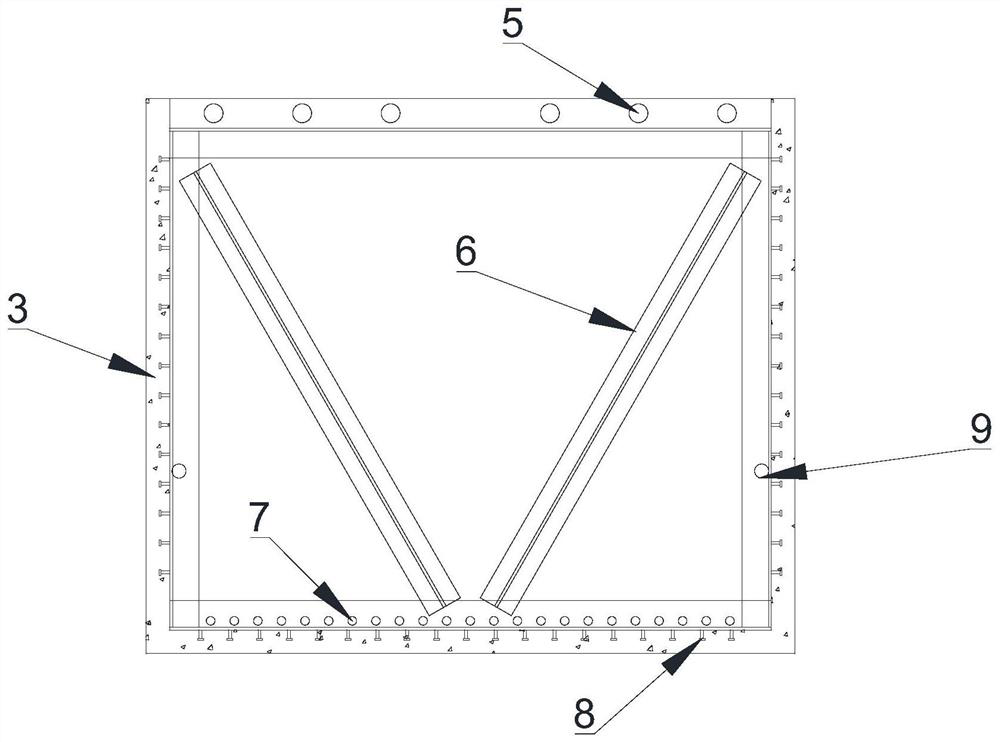

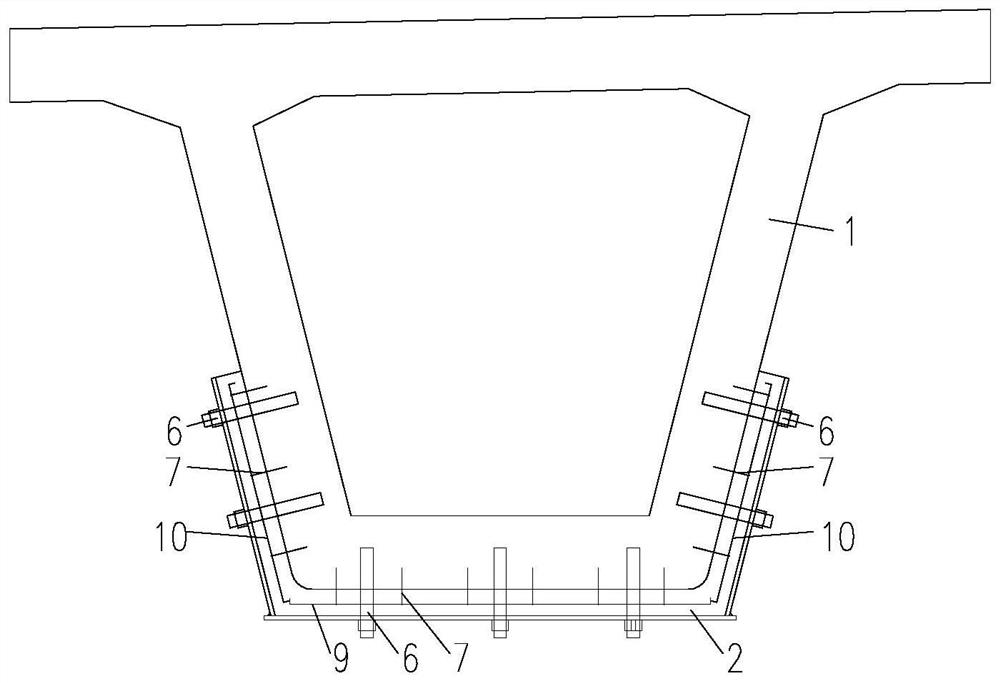

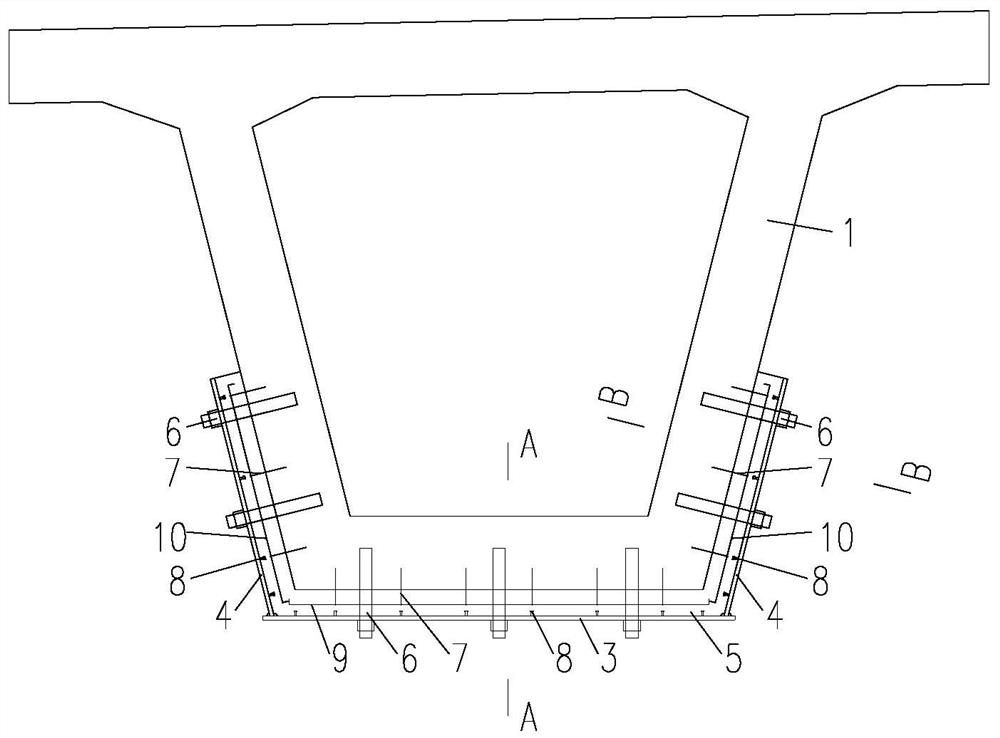

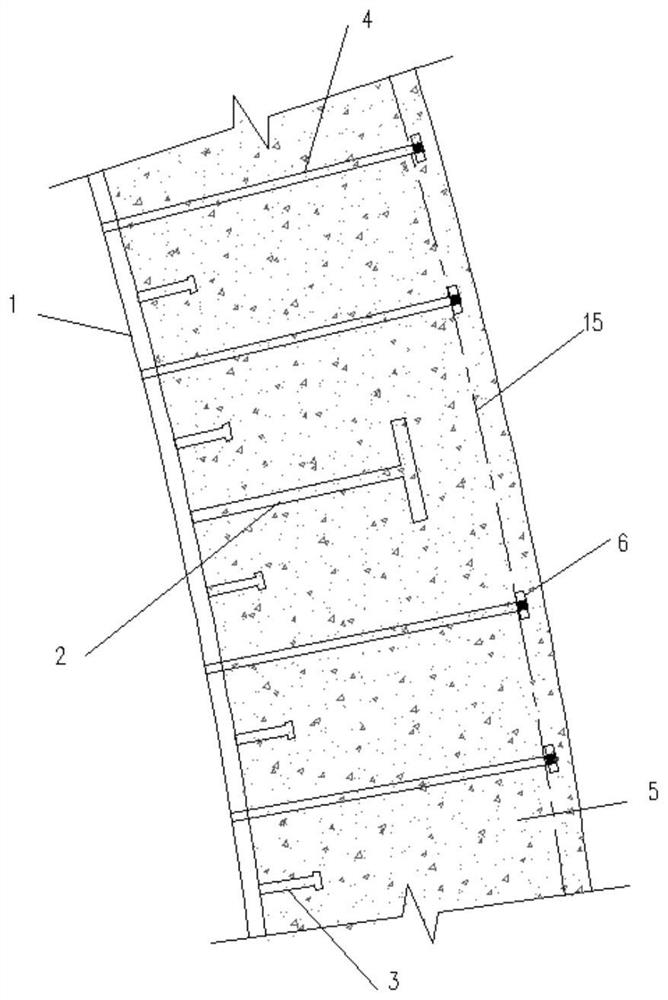

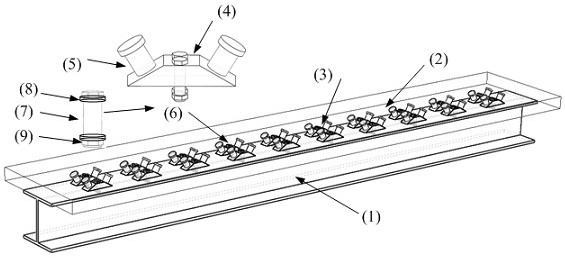

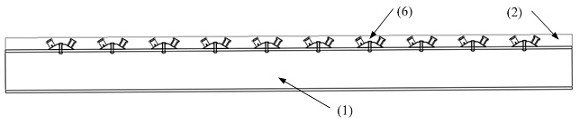

Anti-shearing reinforcement device and method for concrete box girder web

ActiveCN109537478ASolve the problem of excessive main tensile stressAvoid corrosionBridge erection/assemblyBridge strengtheningPre stressRebar

The invention relates to an anti-shearing reinforcement device and method for a concrete box girder web. In order to solve the problem that in existing engineering technologies, the concrete box girder web has cracking inclined cracks and insufficient anti-shearing bearing capacity, an external vertical prestressing tendon reinforcement device and method are provided. The device comprises groove-shaped steel, L-shaped steel, vertical prestressing tendons, wedge-shaped steel cushion blocks and an anti-corrosion coating at the outer side of the web. The groove-shaped steel is horizontally fixedto the junction of the upper end of the web and a top plate in the girder length direction. The L-shaped steel (6) is horizontally fixed to the lower end of the web in the girder length direction andis parallel to the groove-shaped steel (5). The vertical prestressing tendons are vertically mounted on the groove-shaped steel and the L-shaped steel, and it is ensured that the vertical prestressingtendons are parallel to the plane of the web. According to the anti-shearing reinforcement device and method, the web is connected with the top plate and a bottom plate through finish rolling twistedsteel, the force transmission path is definite, the risk that web concrete is pulled broken is reduced, and meanwhile, midspan deformation is reduced; the problem of insufficient main tensile stressof the web concrete is effectively solved, and the situations of continuous extension of the inclined cracks of the web or new inclined cracks are prevented.

Owner:BEIJING UNIV OF TECH

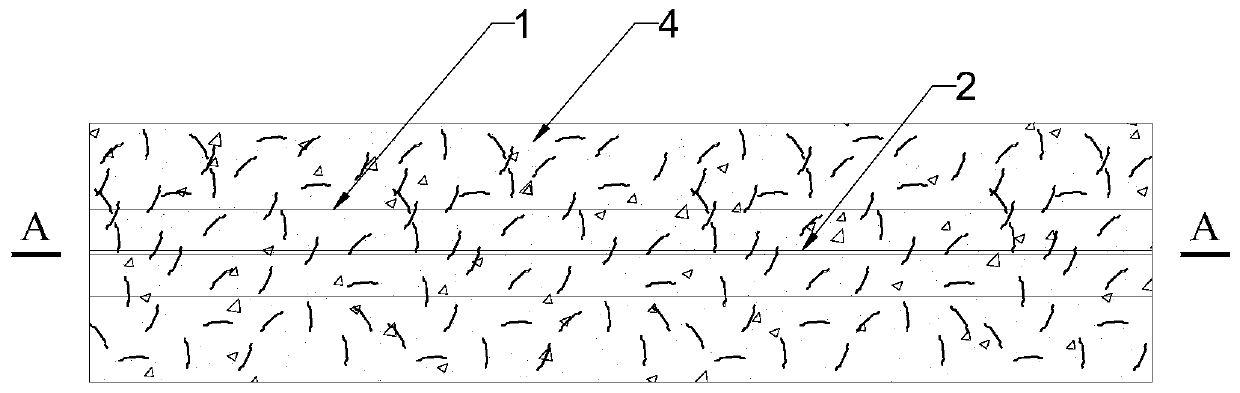

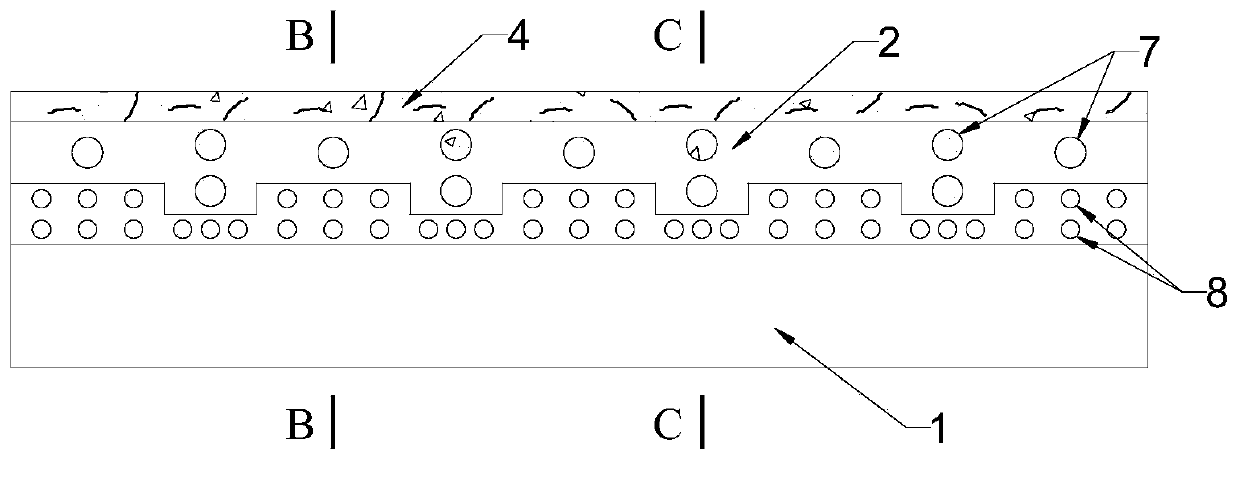

Bamboo-steel fiber reinforced concrete composite beam

InactiveCN109914691AImprove bending resistanceAvoid separationGirdersJoistsAdhesive gluePerforated metal

The invention discloses a bamboo-steel fiber reinforced concrete composite beam, comprising a bamboo beam, a perforated metal plate, adhesive glue and a cast-in-place steel fiber reinforced concrete layer. The bamboo beam is provided with a reserved seam in the length direction and provided with grooves at intervals; the bamboo beam and the cast-in-place steel fiber reinforced concrete layer are connected through the perforated metal plate; the lower part of the perforated metal plate is embedded into the reserved seam; the upper part and the lower part of the perforated metal plate are respectively provided with a circular upper hole and a circular lower hole; the reserved seam and the lower hole of the bamboo beam are filled with the bonding glue; the cast-in-place steel fiber reinforcedconcrete layer and the bonding glue respectively form an upper pin bolt and a lower pin bolt in the upper hole and the lower hole of the perforated metal plate; and the cast-in-place steel fiber reinforced concrete layer forms shear tenons at the positions of the grooves. Compared with a common bamboo structure, the bending rigidity of the section of the bamboo structure is greatly improved, theadverse situation of rigidity control design of the bamboo structure is thoroughly changed, and the bamboo-steel fiber reinforced concrete composite beam has the advantages of being high in bearing capacity and large in rigidity.

Owner:HOHAI UNIV

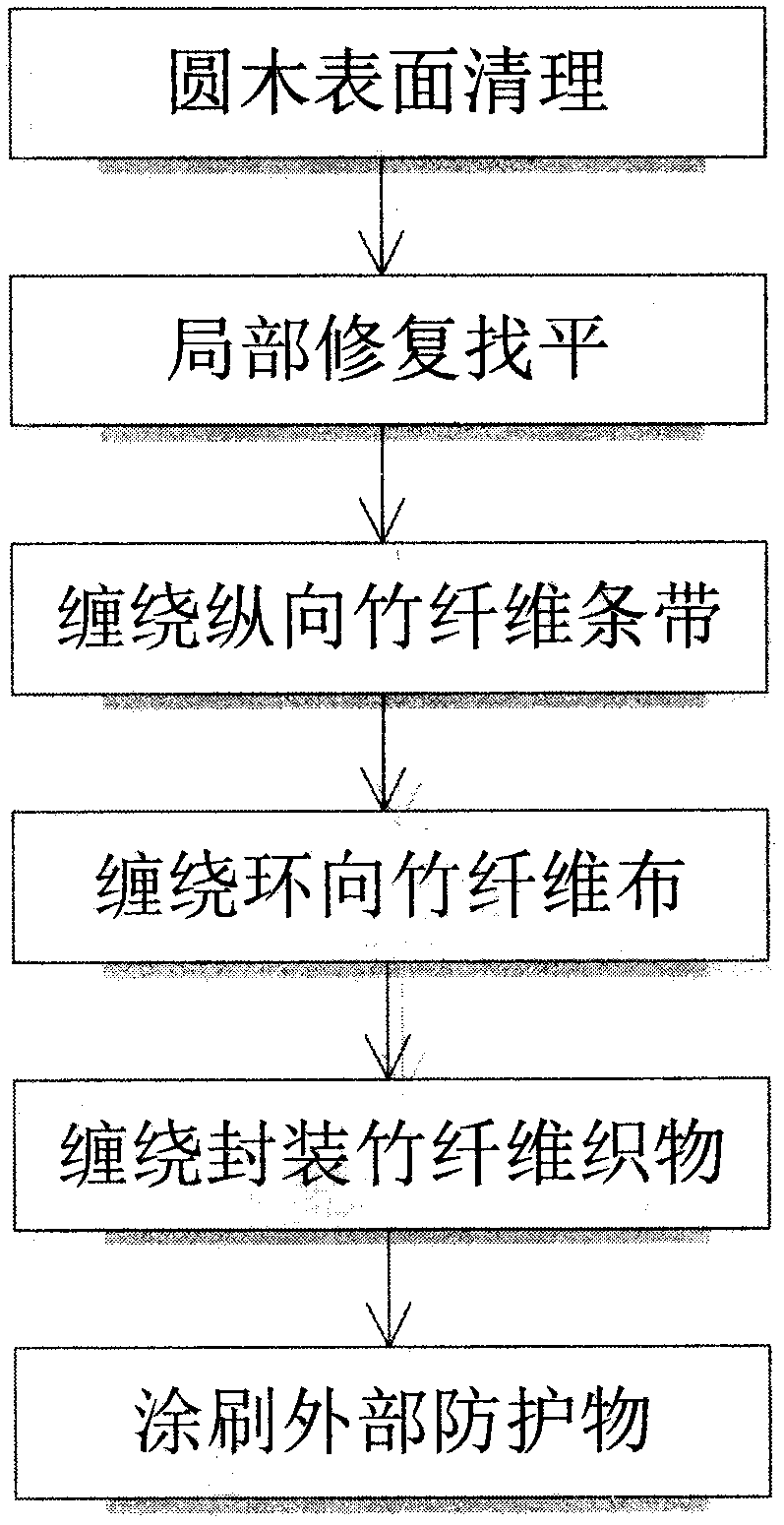

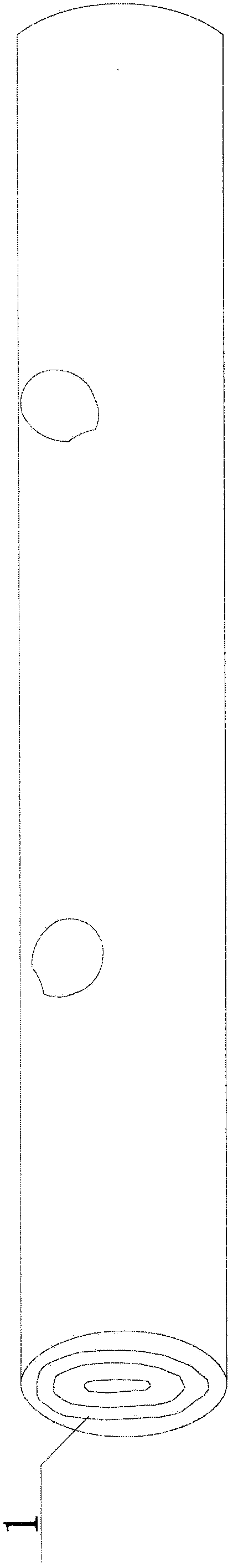

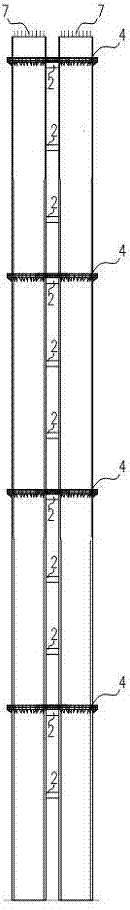

Method for reinforcing round-log bending member through bamboo wood

PendingCN107869254AStrong maneuverabilityLow energy consumptionBuilding repairsRettingSustainable development

A method for reinforcing a round-log bending member through bamboo wood includes the following steps that, firstly, the surface of a round log (1) is cleaned, the defects on the surface of the round log (1) is subjected to gum dipping through compound bamboo fragments (2), longitudinal bamboo fiber strips (3) are wound in the length direction of the round log (1), circumferential-direction bamboofiber cloth (4) are wound in the circumferential direction of the round log (1), then packaging bamboo fiber fabrics (5) are wound in the circumferential direction, an external protection material (6)is brushed, the round log (1), the compound bamboo fragments (2), the longitudinal bamboo fiber strips (3), the circumferential-direction bamboo fiber cloth (4), the packaging bamboo fiber fabrics (5) and the external protection material (6) form a whole, and bending reinforcement of the round log (1) is achieved. The invention aims to provide the method for reinforcing the round-log bending member through bamboo wood, the advantages, such as good toughness and high tensile strength, of the bamboo wood are made full use of, the reinforcement of the round-log bending member is achieved, the core goal that ancient buildings are repaired as before is reached, meanwhile abundant bamboo resources in our country are made full use of, and the method is in line with the existing sustainable development concept in our country.

Owner:NANJING FORESTRY UNIV

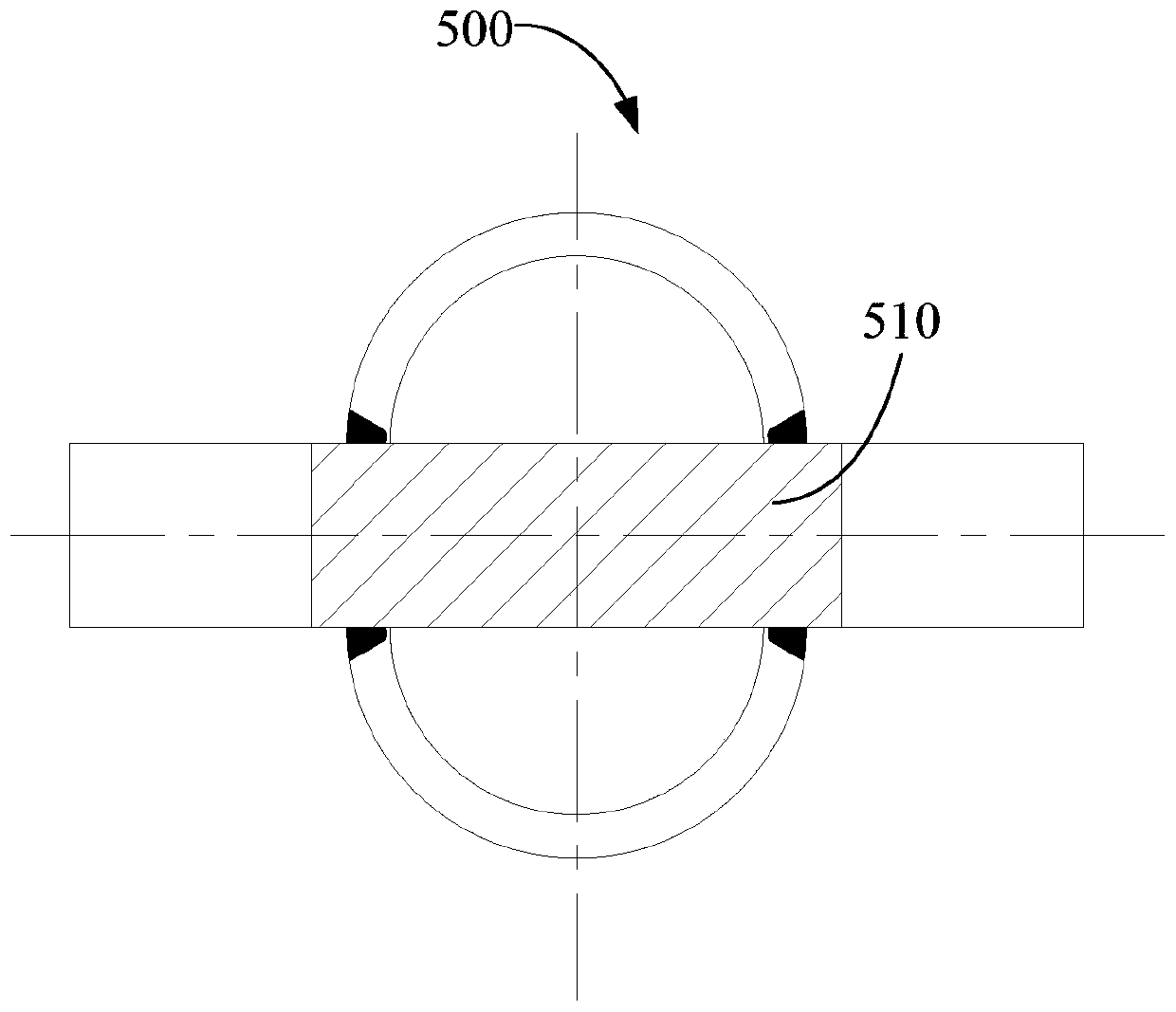

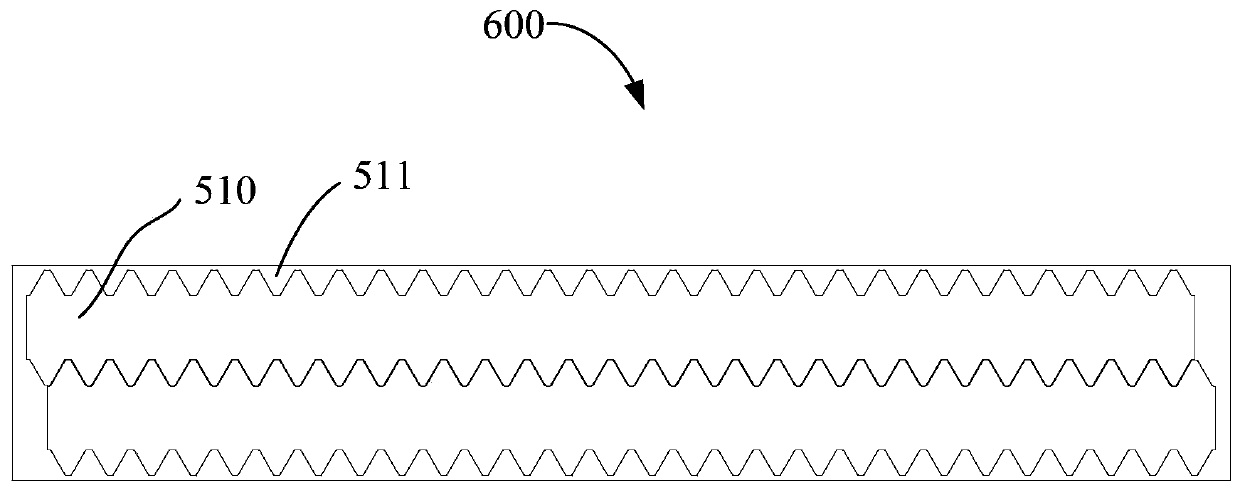

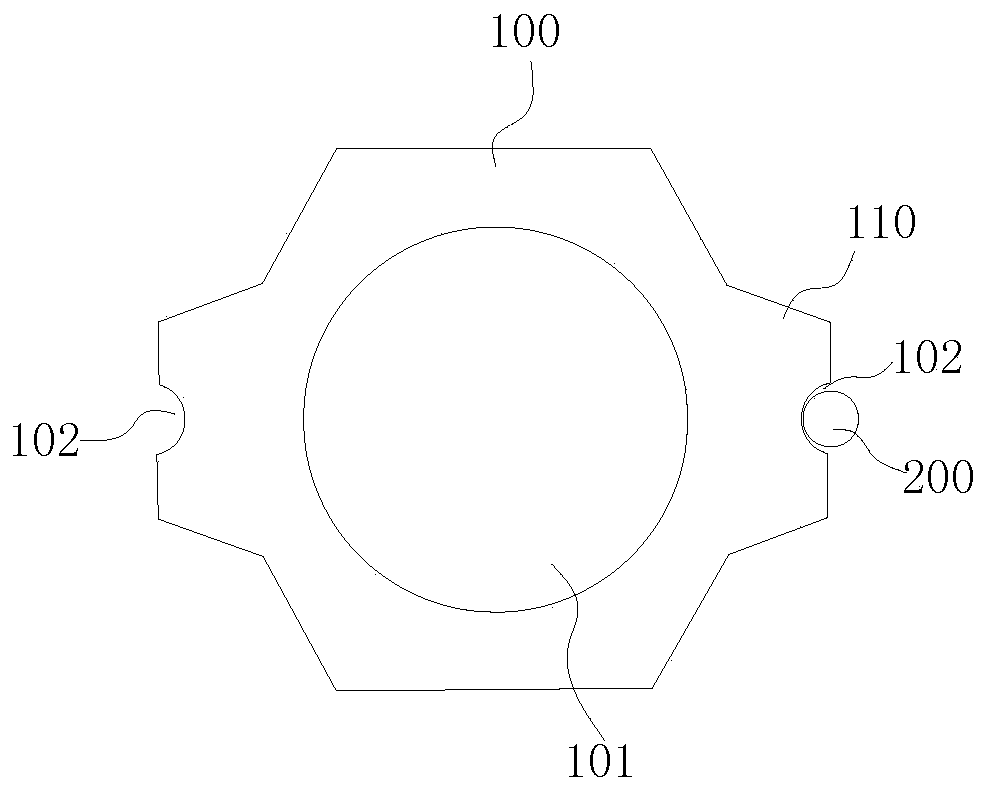

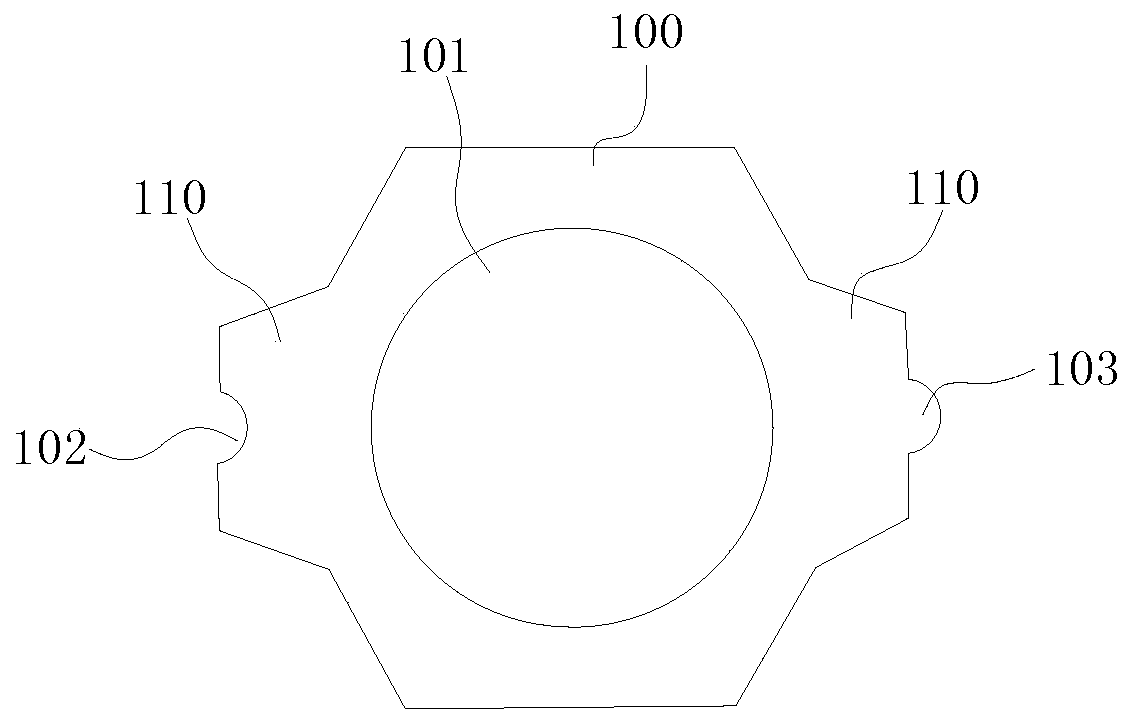

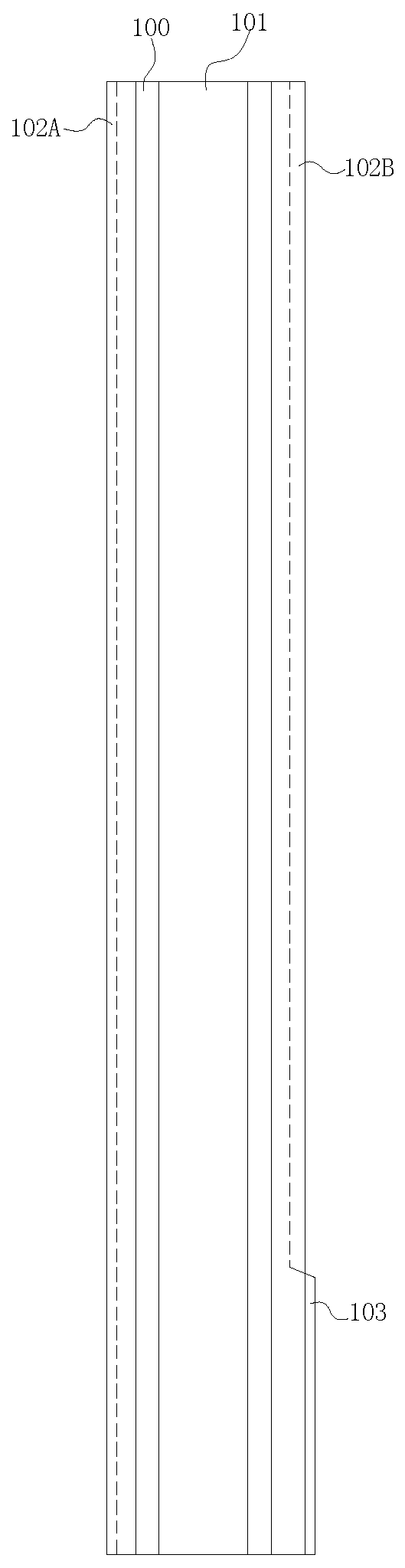

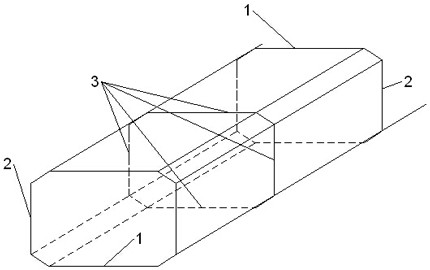

Main chord pipe and design method thereof and pile leg

ActiveCN110306513AImprove section stiffnessGuaranteed structural strengthArtificial islandsUnderwater structuresEngineeringUltimate tensile strength

The invention discloses a main chord pipe, a design method of the main chord pipe, a pile leg and a design method for an open-spandrel type main chord pipe by which a solid-web type main chord pipe can be replaced. The main chord pipe comprises a rack plate and semi-chord pipes connected with the rack plate. The rack plate comprises two or more racks and a connection assembly. Each rack comprisesa toothed plate and teeth. The side face, deviating from the teeth, of each toothed plate is the connection face. The connection assembly is connected between the two racks along the width direction of the racks. Thus waste of a tooth-shaped material excised can be effectively saved by the rack structure. In addition, the connection assembly is arranged and connected between the two racks so thatmeshing force coming from the teeth can be conducted, and section rigidity of the rack plate is improved. In this way, by means of the technical scheme of the main chord pipe, saving of materials is achieved, and meanwhile, structural strength of the main chord pipe is effectively guaranteed.

Owner:YANTAI RAFFLES SHIPYARD +4

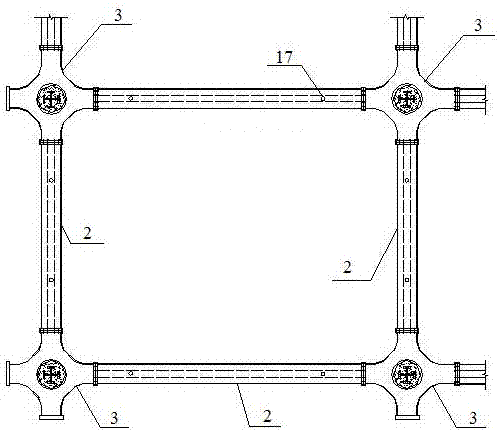

Totally-assembled type hollow interlayer steel pipe concrete combined tower barrel and joints

PendingCN109322793AReduce dosageThe form of force is reasonableWind motor supports/mountsMachines/enginesTowerMaterials science

The invention discloses a totally-assembled type hollow interlayer steel pipe concrete combined tower barrel and joints, and relates to the technical field of wind power generation. The system comprises a hollow interlayer steel pipe concrete barrel body, transverse joints, longitudinal joints and corresponding structures. The hollow interlayer steel pipe concrete barrel body is composed of an outer-layer steel pipe, an inner-layer steel pipe and concrete, studs, angle iron, T-shaped steel or the combination of the studs, the angle iron, the T-shaped steel is welded to one side of each steel pipe in advance, and then concrete pouring is conducted. The hollow interlayer steel pipe concrete barrel body is divided into 2-8 sheets in the ring direction, connection is conducted through the transverse joints, and two forms are adopted in the transverse joints. Segmented assembling of the hollow interlayer steel pipe concrete barrel body in the height direction is achieved, various segments are connected through the longitudinal joints, and two forms are adopted in the longitudinal joints. According to the system, the advantages of a combined structure are brought into full play, the stress form is reasonable, and joint connection is reliable. All the components can be prefabricated in advance, field assembling is adopted, transportation is convenient, the construction efficiency is improved, the material usage amount is reduced, and wide project application prospects are achieved.

Owner:CHONGQING UNIV

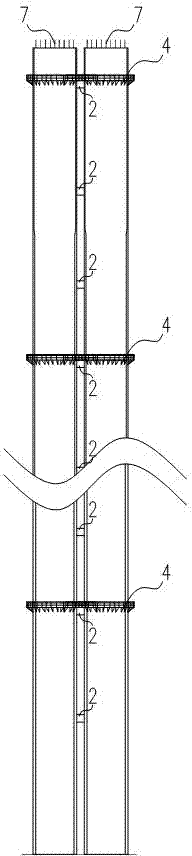

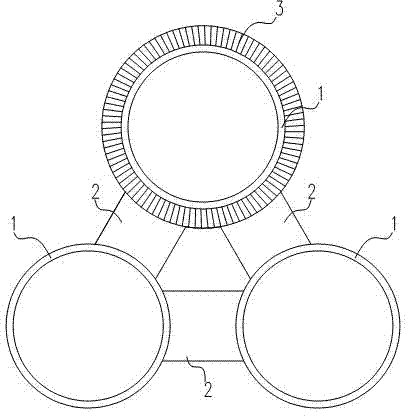

Three-pipe conjoint chimney

InactiveCN103924821AReduce construction costsUniform bending stiffnessTowersReinforced concreteIsoetes triquetra

The invention discloses a three-pipe conjoint chimney comprising three round-section reinforced concrete cylinders and reinforced concrete connecting beams. The round-section reinforced concrete cylinders are arranged at three apexes of an equilateral triangle; each two cylinders are connected through the reinforced concrete connecting beams arranged in the height-wise direction at certain intervals. A steel inner cylinder is omitted, and building cost of the whole chimney structure is greatly reduced accordingly; the cylinders are connected in a whole through the reinforced concrete connecting beams, flexural rigidities of the whole structure in all directions are uniform, the whole structure is evenly stressed in all directions, and the whole structure is reasonable; the use of the reinforced concrete connecting beams decreases lateral displacement of the structure. The wall thickness of the cylinders gradually increases from top to bottom in the height-wise direction of the chimney, sectional rigidity also gradually increases from top to bottom, and stress is reasonable. A steel ladder between each two cylinders is safer and more reliable than the steel ladder in the traditional multi-pipe chimney with the steel inner cylinder, and using is more facilitated. By the use of the three-pipe conjoint chimney which is continuously cast, the problem that a chimney connector of the steel inner cylinder expands is solved.

Owner:中国电建集团江西省电力设计院有限公司

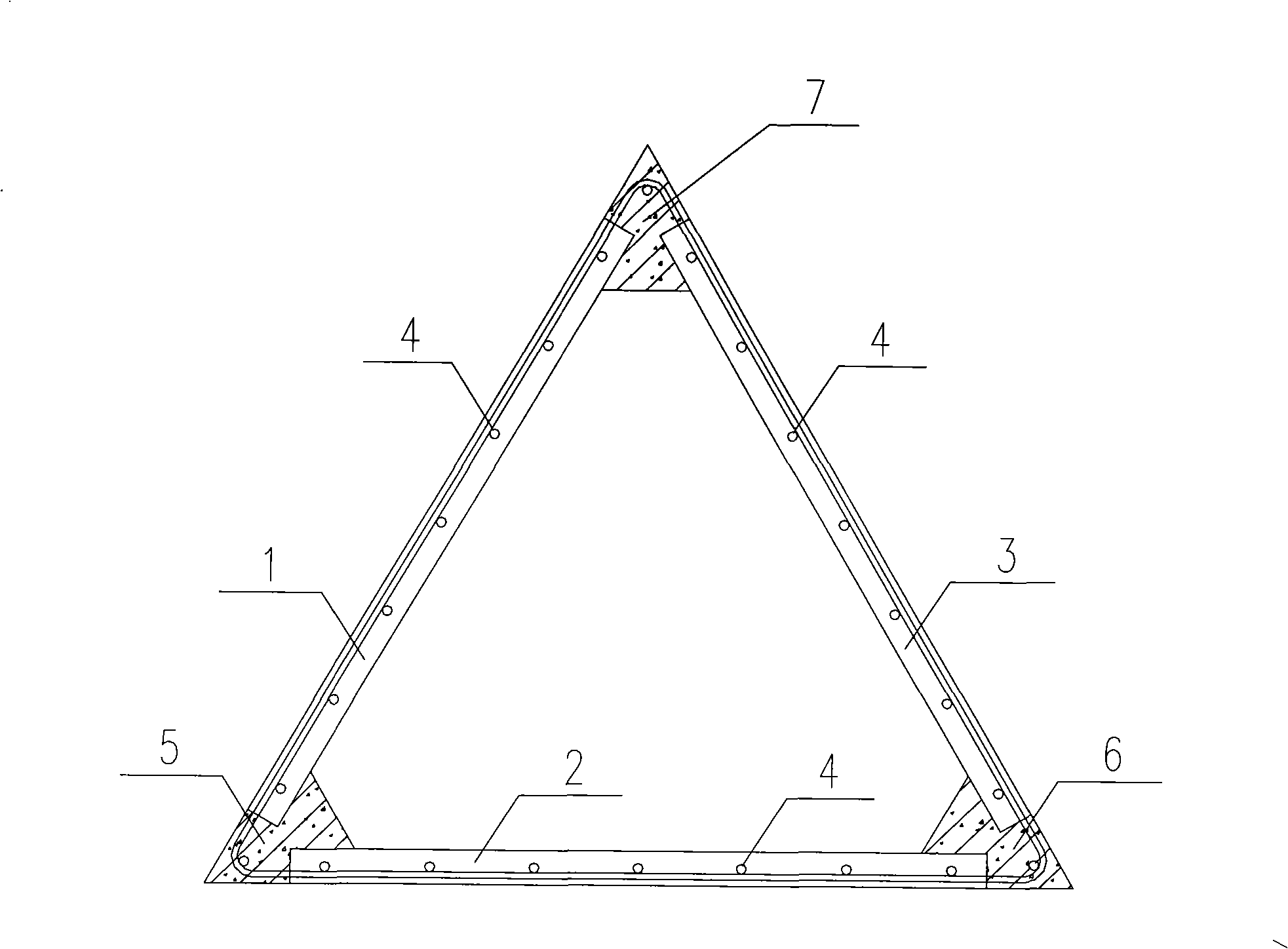

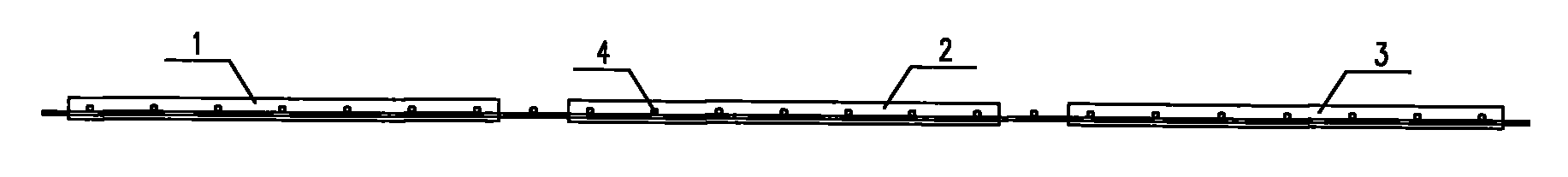

Triangular concrete thin-wall folded plate pile and preparation method thereof

InactiveCN101550690BEasy constructionLow costExcavationsBulkheads/pilesRebarUltimate tensile strength

The invention relates to a triangular concrete thin-wall folded plate pile; end-to-end connection is conducted on a concrete left plate, a concrete middle plate and a concrete right plate so as to bend and form a triangular drum shape; the three angles of the triangular drum are respectively provided with a first bottom angle joint-pouring concrete zone, a second bottom angle joint-pouring concrete zone and a top angle joint-pouring concrete zone which cover part of steel bars of a steel bar mesh. A preparation method comprises the following steps: the concrete left plate, the concrete middleplate and the concrete right plate which are flatly horizontal are simultaneously poured and stretched to form a concrete flat plate of which three steel bar meshes are connected; the concrete left plate and the concrete right plate are symmetrically bent to form an angle; when the angle reaches 90 degrees, harsh concrete is adopted to cast the bottom angle joint-pouring concrete zones; the symmetrical bending is conducted continuously so as to lead the concrete left plate, the concrete middle plate and the concrete right plate to form a triangular drum shape; short connecting bars on the toppart are welded, the top angle joint-pouring concrete zones are cast, simultaneously adjustment and repairing are conducted on the bottom angle joint-pouring concrete zones, and when the joint-pouringconcrete reaches design strength, the triangular concrete thin-wall folded plate pile is formed.

Owner:NANTONG ZHONGRUN CONCRETE +1

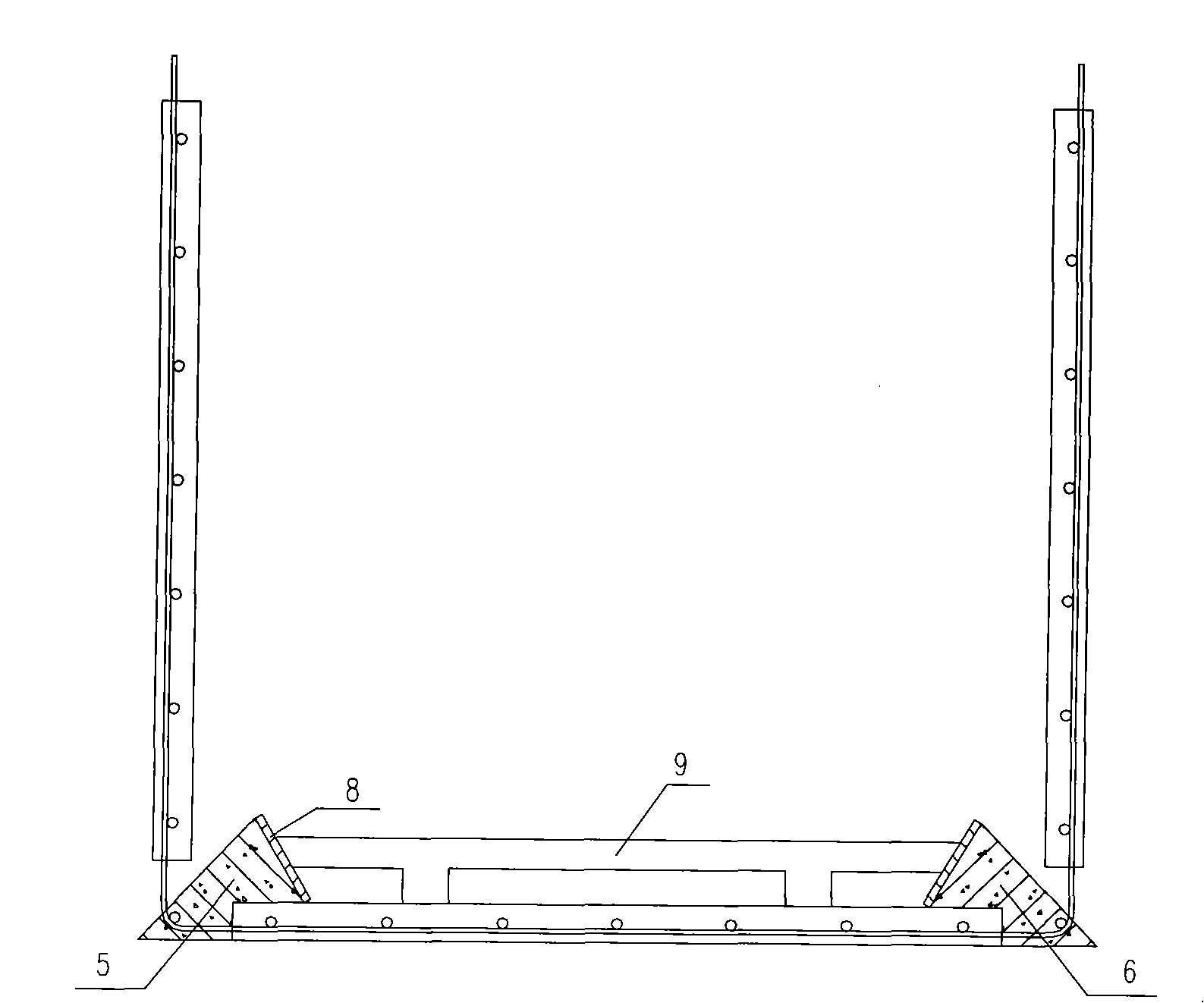

Water-stopping type prefabricated assembly type foundation pit supporting construction mode

InactiveCN110644500AFirmly connectedClosely connectedExcavationsBulkheads/pilesArchitectural engineeringStructural engineering

The invention discloses a water-stopping type prefabricated assembly type foundation pit supporting construction mode. The mode comprises the following steps of carrying out integral construction budget, prefabricating supporting piles, mounting one-way grouting valve pipes, carrying out supporting pile construction, carrying out subsequent pile-among grouting water stop belt construction, carrying out cement soil stirring embedding fixing layer construction and the like. According to the mode, mortise groove structures are arranged on pile bodies of the supporting piles, a grouting space is formed between every two adjacent mortise grooves of the pile bodies, cement slurry or mixture of water glass and cement slurry are injected into grouting channels in foundation pit supporting engineering, the adjacent pile bodies can be stably connected, water stop belts can be prepared, and the tight connection between every two adjacent pile bodies can be ensured; and the prefabricated supporting piles are used as structural stiffeners and has the characteristics of high strength and high compactness, and meanwhile, the prefabricated supporting pile has the characteristics of large section rigidity, excellent bending resistance and no field maintenance. The construction installation of the prefabricated supporting piles adopts mechanical chemical methods such as a static pressure method,an impact method and the like, the construction speed is extremely rapid, and the construction period can be greatly saved.

Owner:广东卓安特岩土建筑科技有限公司

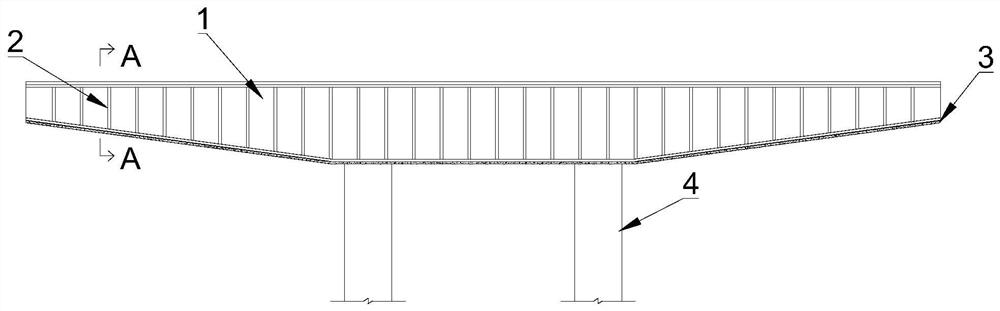

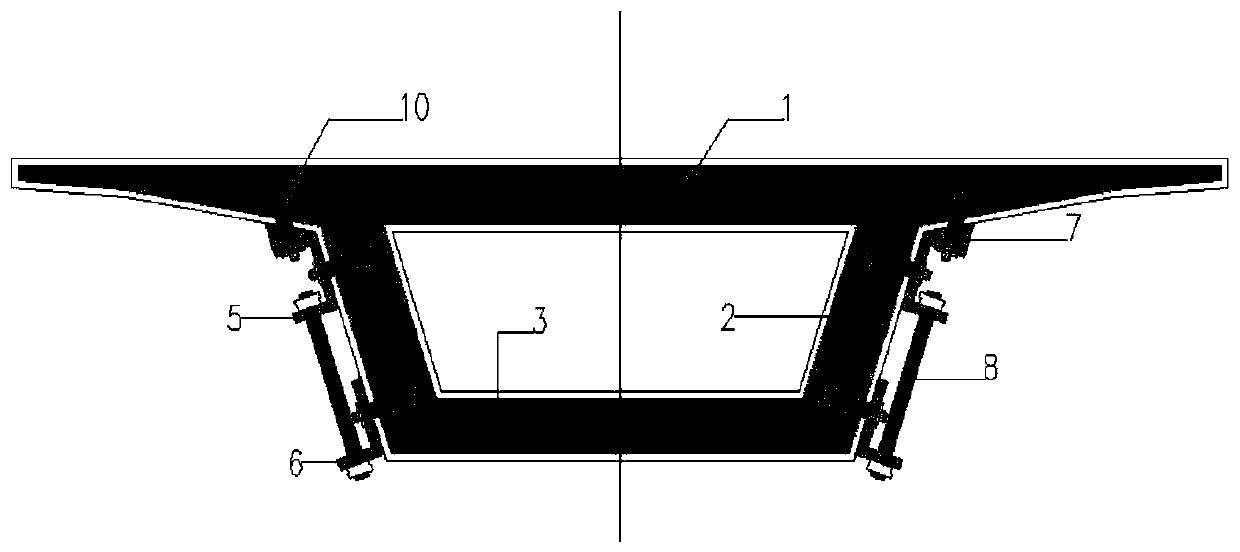

Large-amplitude load increasing and reinforcing method for existing steel plate combined continuous beam bridge

InactiveCN109505269AIncreased moment of inertiaImprove carrying capacityBridge erection/assemblyBridge strengtheningSheet steelBridge deck

The invention discloses a large-amplitude load increasing and reinforcing method for an existing steel plate combined continuous beam bridge. The method comprises the steps of putting up a temporary support nearby a combined beam bending moment zero point; then conducting first-time jacking on a combined beam, and chiseling damaged concrete on a middle bridge pier cap and a pier top hogging momentregion bridge deck slab; then conducting second-time jacking, hoisting a prefabricated trough beam, welding an upper flange of the prefabricated trough beam to a lower flange of a steel girder, and then constructing the bridge pier cap; casting concrete to the hogging moment region bridge deck slab; after the concrete reaches the designed intensity, unloading a jack, and dismantling the temporarysupport to complete construction. By means of the method, on one hand, the bearing capacity of the steel plate combined continuous beam can be greatly improved; on the other hand, the problem that the concrete of the hogging moment region bridge deck slab of the steel plate combined continuous beam cracks can be effectively solved, and the purpose of conducting load increasing and reinforcing onthe existing steel plate combined continuous beam is achieved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

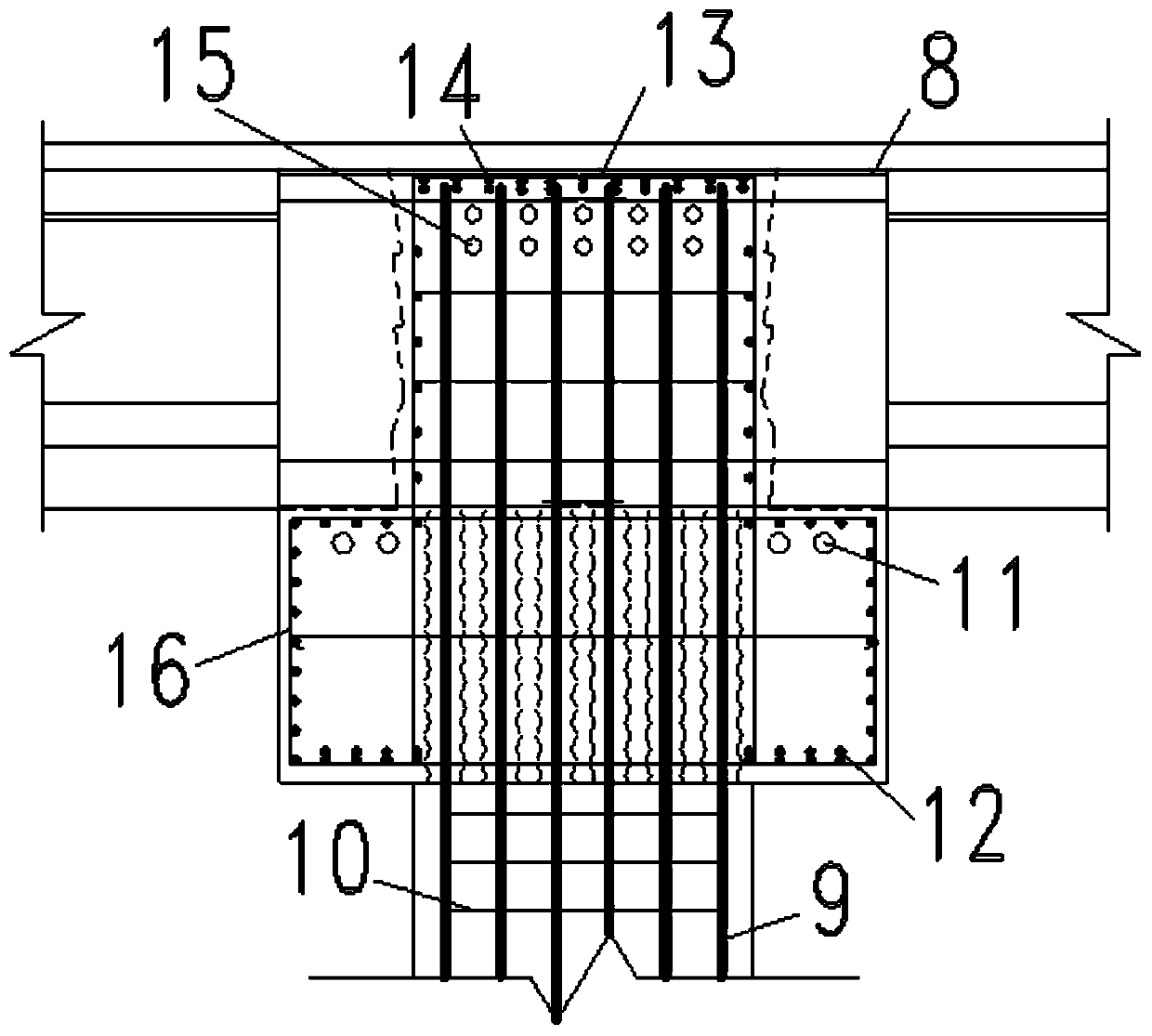

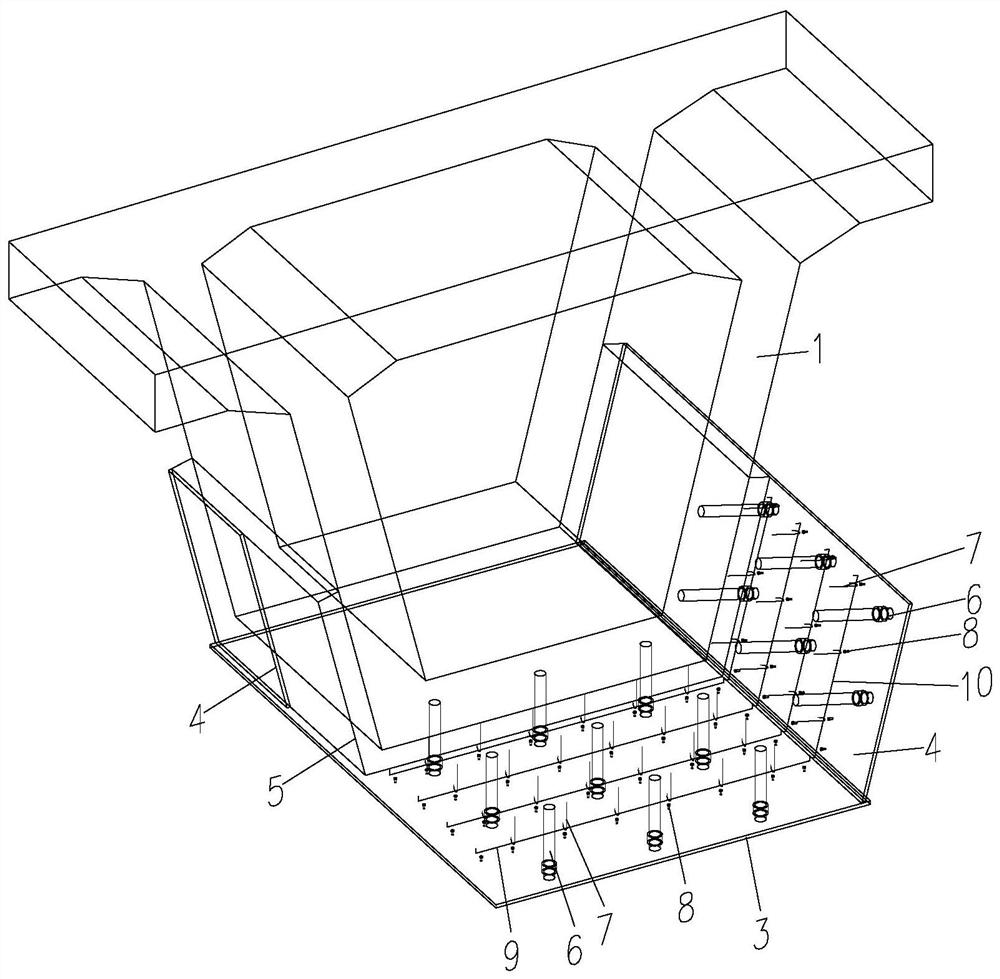

Prestressed UHPC shell-concrete inner core combined cover beam structure and construction method thereof

InactiveCN113605246AReduce usageSmall sizeBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a prestressed UHPC shell-concrete inner core combined cover beam structure which comprises a cover beam shell, the cover beam shell comprises webs and a bottom plate, multiple webs are connected to the bottom plate, an inner cavity with an upward opening is defined by the webs and the bottom plate, the cover beam shell is a prefabricated UHPC shell, a plurality of reinforcing frames are vertically arranged in the inner cavity, multiple reinforcing frames are arranged in the length direction of the bent cap shell at intervals, and the inner cavity is filled with common concrete inner cores in a pouring mode. The structure has the advantages of being low in self weight, good in durability and high in bearing capacity.

Owner:HUNAN UNIV

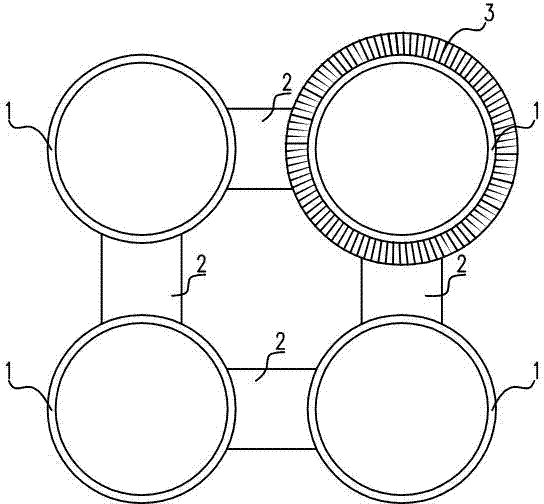

Four-tube conjoint chimney

InactiveCN103924824AReduce construction costsUniform bending stiffnessTowersReinforced concreteRebar

The invention discloses a four-tube conjoint chimney comprising four round-section reinforced concrete cylinders and reinforced concrete connecting beams. The round-section reinforced concrete cylinders are arranged at four apexes of a square; each two adjacent cylinders are connected through the reinforced concrete connecting beams in the height-wise direction. The four-tube conjoint chimney has the advantages that a steel inner cylinder is omitted so that building cost of the whole chimney structure is greatly lowered; the chimney is integrated and centrally arranged, the floor area is decreased as compared with that of the independent chimney, the cylinders are connected in a whole through the reinforced concrete connecting beams, the whole structure has uniform flexural rigidities in all directions and is evenly stressed in all directions, the whole structure is reasonable, and lateral displacement of the whole structure can be decreased by the use of the connecting beams; the wall thickness and size of the cylinders gradually increase from top to bottom in the height-wise direction of the chimney, sectional rigidity of the chimney gradually also increases from top to bottom, and stress is reasonable; a ladder between each two cylinders is safer and more reliable than the steel ladder in the traditional many-tube chimney with the steel inner cylinder, and using is more facilitated; by the use of the four-tube conjoint chimney which is continuously cast, the problem that a chimney connector of the steel inner cylinder expands is avoided.

Owner:中国电建集团江西省电力设计院有限公司

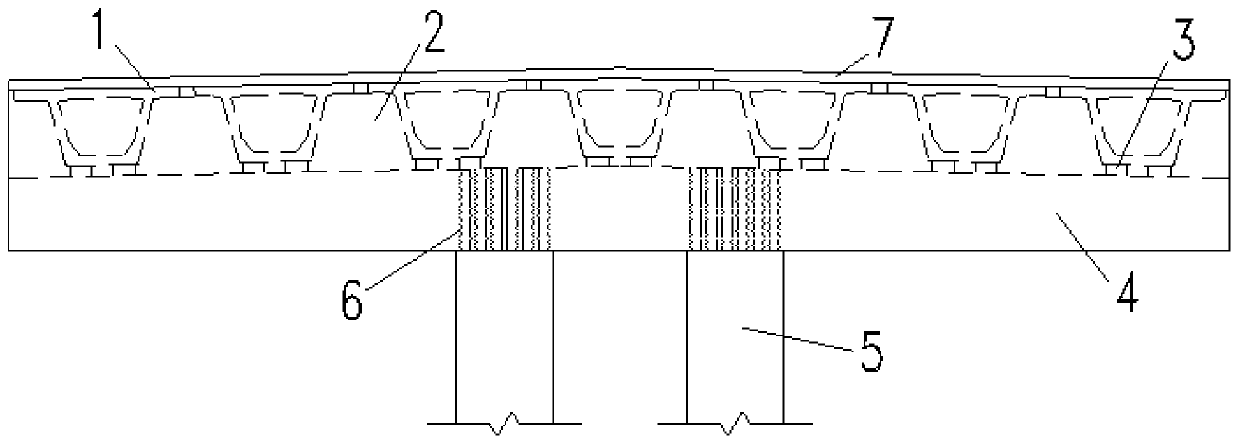

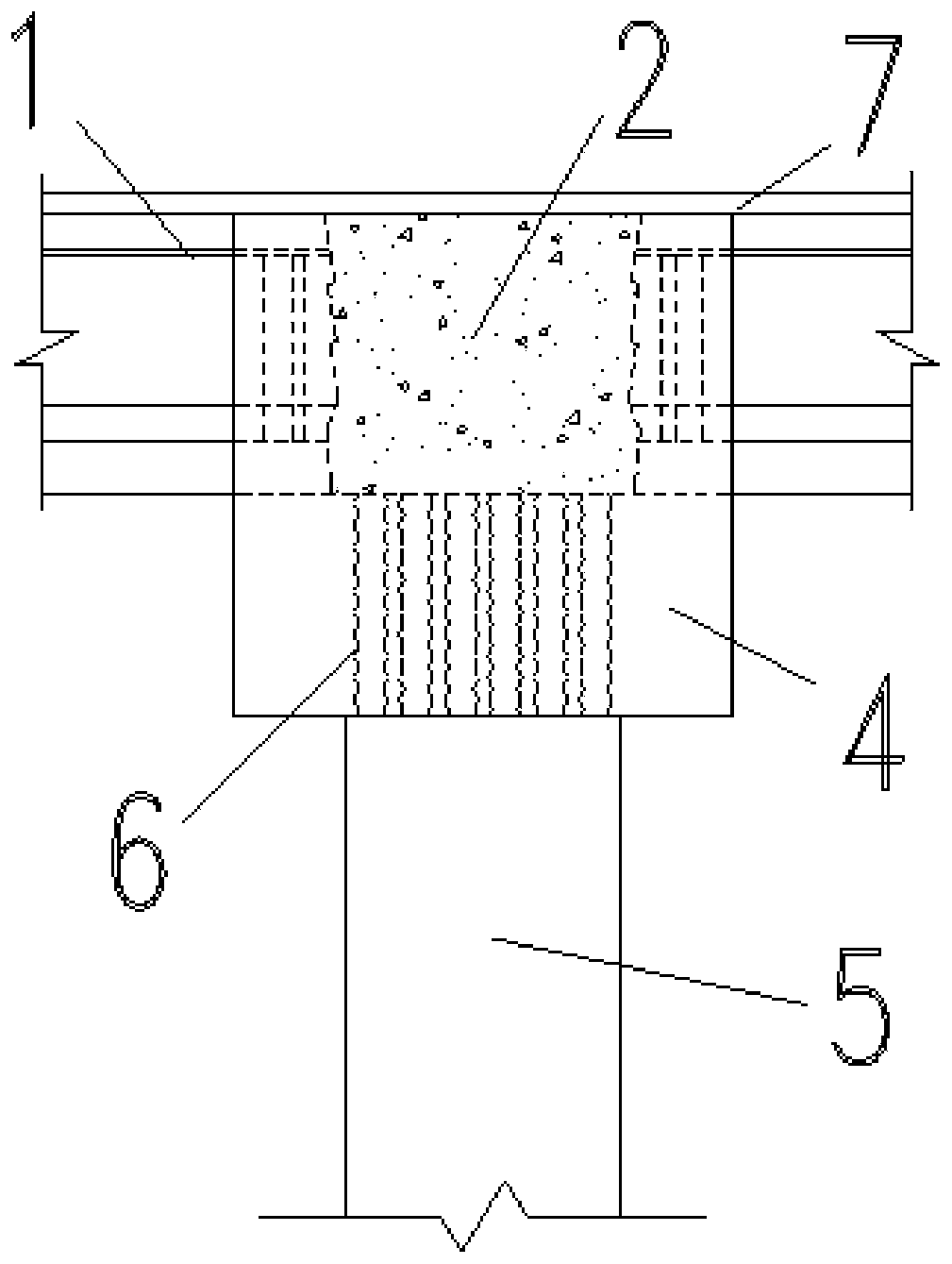

Prefabricated assembly pier and beam fixing structure and construction method thereof

PendingCN109868753AReduce weightSmall amount of workBridge structural detailsBridge erection/assemblyRebarBending moment

The invention discloses a prefabricated assembly pier and beam fixing structure and a construction method thereof. The prefabricated assembly pier and beam fixing structure comprises girders, prefabricated pier columns and a bent cap. The bent cap comprises an upper layer cast-in-place structure and a lower layer prefabricated structure. Multiple welding reinforcing steel bars arranged on the upper layer cast-in-place structure are connected with corresponding girder longitudinal main ribs of the two girders located on the two sides of the bent cap. The position, correspondingly connected witheach prefabricated pier column, of the lower layer prefabricated structure is provided with multiple parallel vertically-arranged metal corrugated pipes. Each prefabricated pier column comprises multiple vertically-arranged pier column main ribs. The upper ends of the multiple pier column main ribs extend upwards out of the upper faces of the corresponding prefabricated pier column. The extend-out portions of the multiple pier column main ribs are matched with the multiple metal corrugated pipes. In the installation process, each pier column main rib penetrates through the corresponding metalcorrugated pipe. The bending moment load of each pier bottom in the bridge axis direction is reduced, the weight of the prefabricated bent cap is greatly reduced, and the requirements for local transportation and elevating capacity can be easily met.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

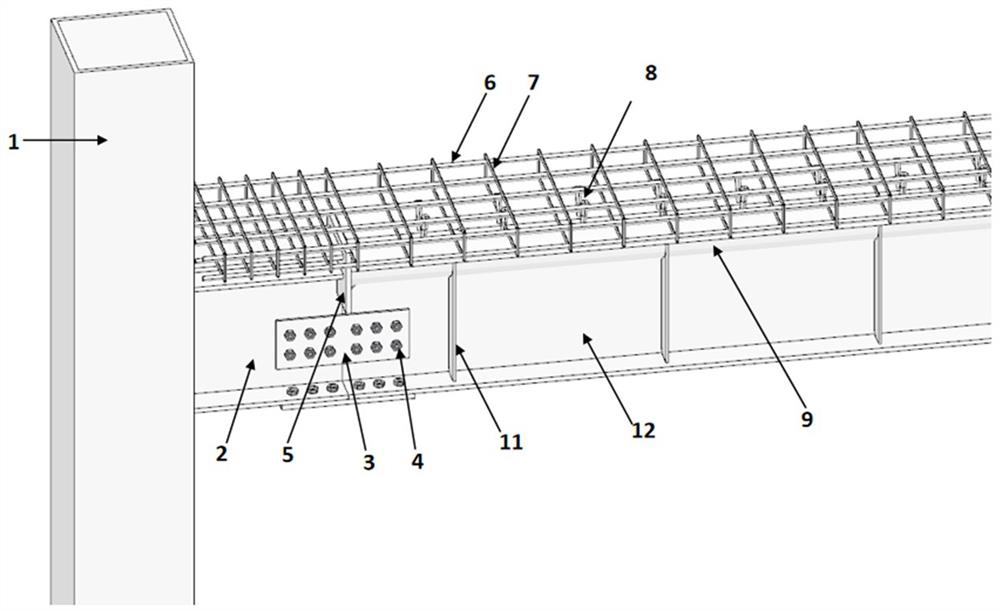

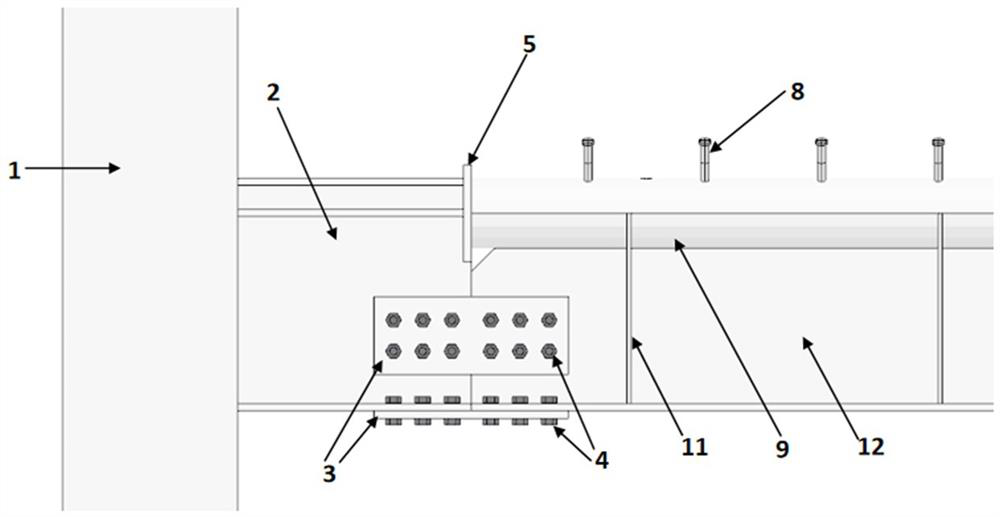

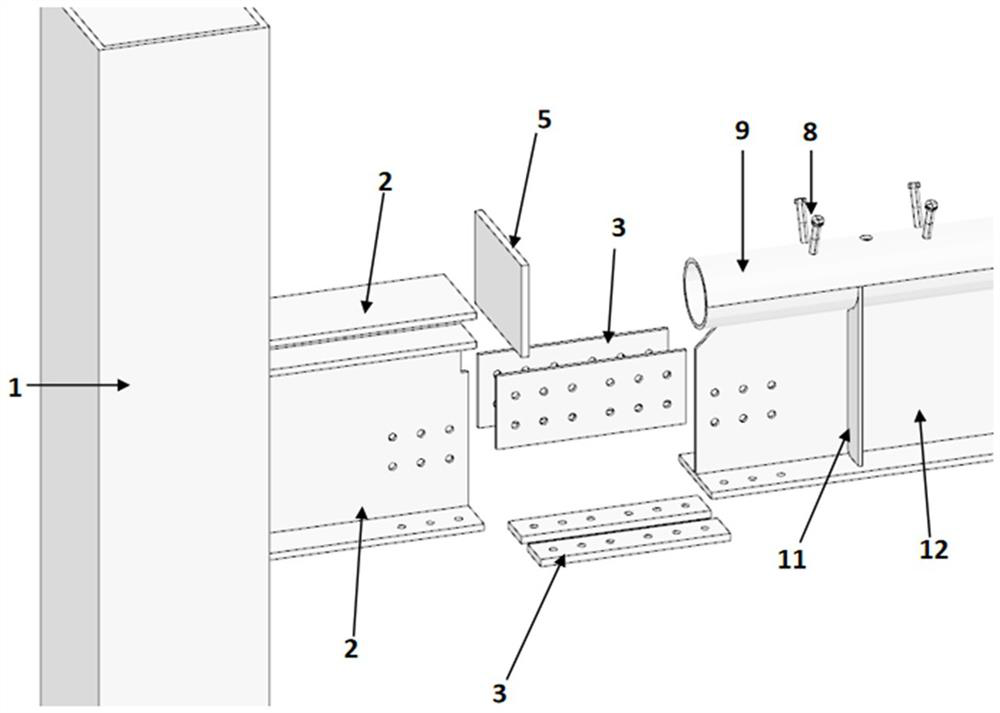

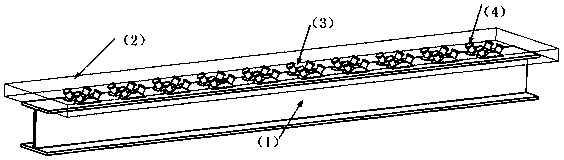

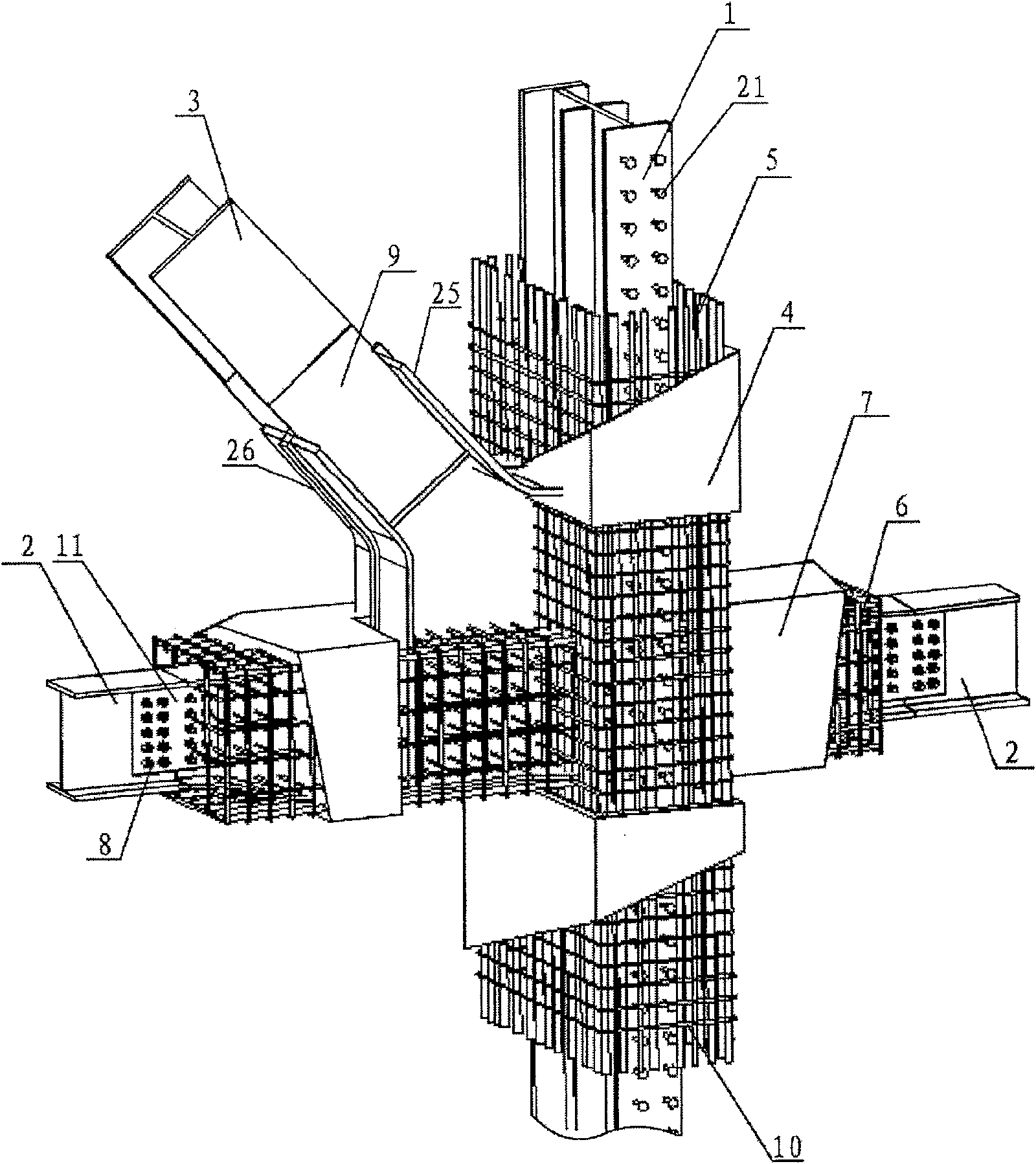

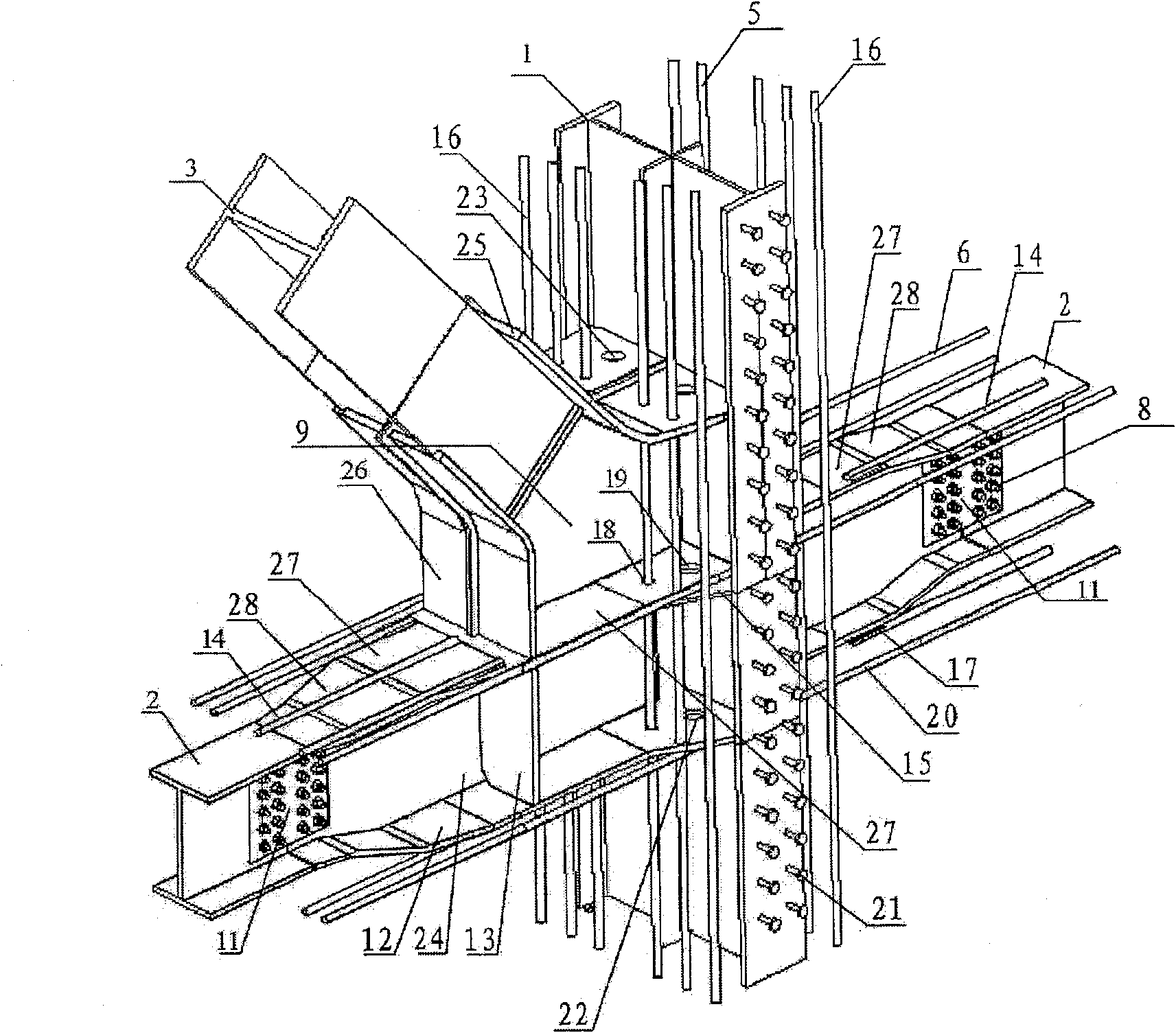

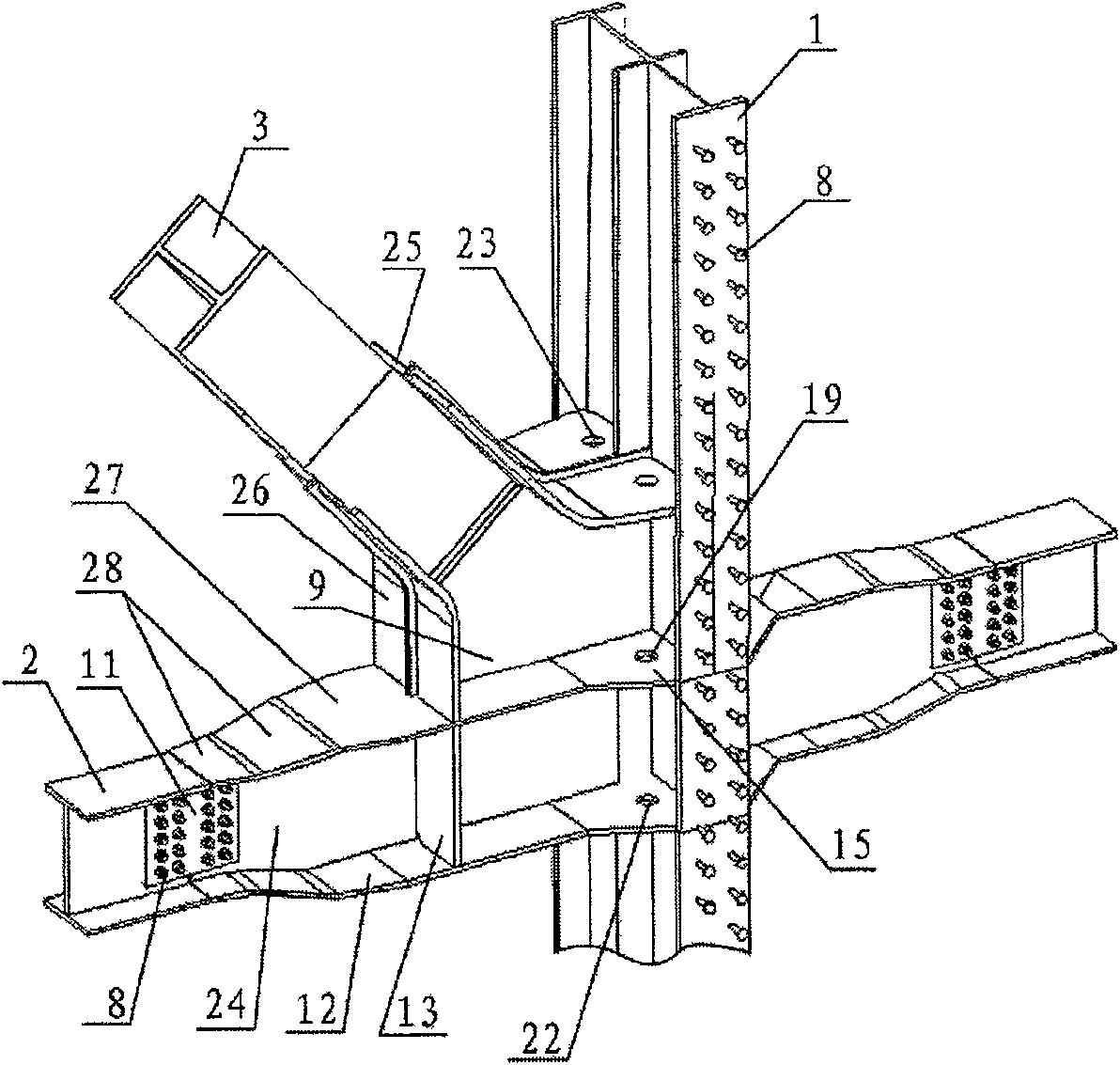

Heavy-load large-span composite beam-column structure and construction method

ActiveCN113062476AIncrease stiffnessClear load transmissionBuilding constructionsReinforced concrete columnCantilevered beam

The invention relates to a heavy-load large-span composite beam-column structure and a construction method. The structure comprises a stand column, a cantilever beam, an end plate and a large-span composite beam, wherein the stand column is a steel column or a steel-reinforced concrete column; the cantilever beam is made of H-shaped steel, one end of the cantilever beam is welded to the stand column, and a notch is formed in the upper side of the other end of the cantilever beam; the end plate is vertically arranged in the notch and is connected with a web and an upper flange of the H-shaped steel in a welded mode; and the large-span composite beam is connected with the cantilever beam in a bolted and welded combined mode and is composed of a circular steel pipe and T-shaped steel, the circular steel pipe is arranged above a web of the T-shaped steel and is welded to the web, the end face of the circular steel pipe is connected with the outer surface of the end plate in a welded mode, and the web and a lower flange of the T-shaped steel are connected with the web and the lower flange of the H-shaped steel through connecting plates and high-strength bolts. The large-span composite beam-column structure is particularly suitable for bearing roof heavy loads, and is high in rigidity, clear in load force transmission, low in mid-span deflection, high in bearing capacity and good in integrity. The structure is simple, the height and width of the section are small, and materials are saved.

Owner:CSIC INT ENG CO LTD +2

Steel plate holder and skew spike combined interface connection steel and UHPC (ultrahigh performance concrete) thin slab combination structure system

ActiveCN109487699AIncreased shear strengthImprove integrityBridge structural detailsBridge erection/assemblySheet steelStructure system

The invention discloses a steel plate holder and skew spike combined interface connection steel and UHPC (ultrahigh performance concrete) thin slab combination structure system. According to the system, the ultra-thin deck slab is made from UHPC so that dead weight of the structure can be reduced while the bridge capacity of the structure can be improved; steel plate holder and skew spike combinedconnectors are used for interface connection at the interface, so that comprehensive advantages of the steel plates serving as the rigid connectors and the spikes serving as the flexible connectors can be achieved well, interface slippage can be reduced under action of rigid connection of the steel plate holders in the normal application state, and the defect in ductility of the steel plate holders which serve as the rigid connectors can be overcome according to characteristic of the spikes serving as the flexible connector in an ultimate state. The short skew spikes are in staggered arrangement to form the reinforcing truss web member of the UHPC slab, so that rigidity of the UHPC slab is increased and further the integral rigidity of the combined section is increased.

Owner:SOUTHEAST UNIV

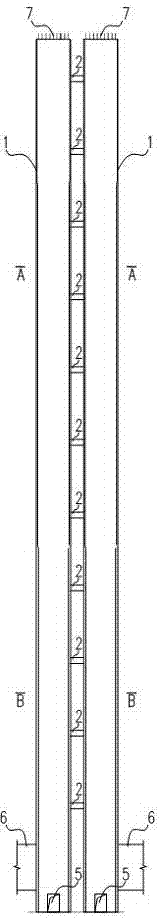

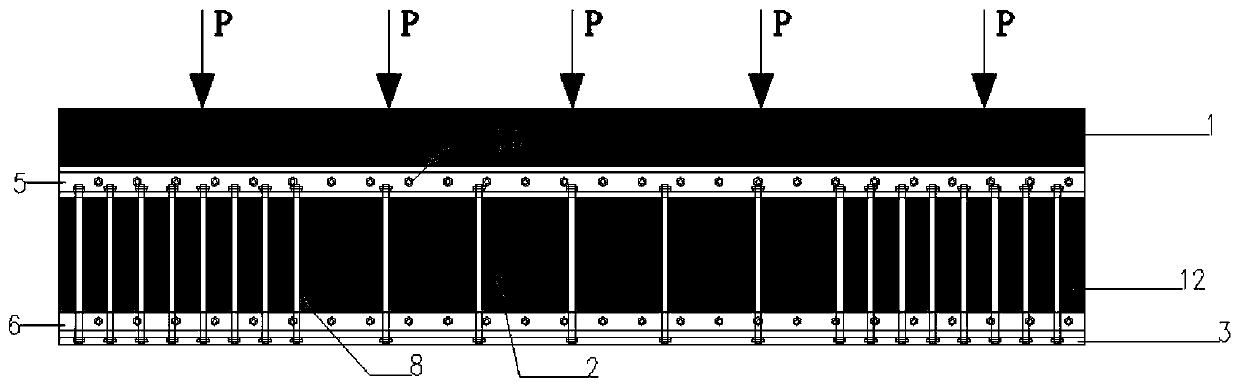

Steel-encased-ultra-high-performance concrete reinforcing method for box girder

InactiveCN113216017AImprove section stiffnessImprove carrying capacityBridge erection/assemblyBridge strengtheningFillet weldPre stress

The invention discloses a steel-encased-ultra-high performance concrete reinforcing method for a box girder. The method comprises the following steps of setting out the positions of bolts and embedded steel bars on the box girder, and drilling at the position of the box girder; mounting and maintaining the embedded steel bars, and embedding steel bar hooks along the longitudinal direction of the bridge; bottom plate stirrups and web stirrups being installed and bound with the embedded steel bars; the positions of the studs being lofted, and the studs being welded to the bottom steel plate and the side steel plates; the bottom steel plate and the side steel plates being fixed to the box girder through bolts, and the bottom steel plate and the side steel plates being welded through fillet welds; and ultra-high performance concrete being poured and cured. The method steel-encased ultra-high performance concrete of the box girder is reinforced, the steel plate-ultra-high performance concrete can effectively improve section rigidity of the original structure, the bearing capacity of the structure is greatly improved, the size of the reinforced section of the structure is small, and reinforcing efficiency is high. According to the steel-ultra-high performance concrete reinforcing design, common load-bearing steel bars and prestressed steel strands are not configured, and the site construction process is simple.

Owner:山西省交通科技研发有限公司

Shaped-steel concrete frame-steel supporting structure section-changeable conversion node

ActiveCN100558996CConvenience constraintsIncrease the moment of resistance of the sectionBuilding constructionsReinforced concreteSteel bar

A type of steel concrete frame-steel support structure variable cross-section conversion node, which is connected and poured into one by the medium-shaped steel in the column, the medium-shaped steel in the beam, the steel support, the reinforced concrete in the column, and the reinforced concrete in the beam. The section steel and the beam medium-section steel flange plate are connected orthogonally, the web of the beam medium-section steel at the node junction is converted into a web with increased height and variable section, and the upper side of the web with increased height and variable section is welded to the upper flange with increased width and variable section, and the height and variable section The underside of the web plate is welded with the lower flange of the widened and variable section; the shape of the steel support at the junction of the nodes is converted into a structure in the transition zone of the variable section node, and the two flange plates of the steel support in the transition zone of the variable section are respectively connected with the steel in the column and the The beams are connected orthogonally in steel sections. The invention enhances the stress performance of the section steel concrete frame-steel support structure joint area and the synergistic effect ability of the section steel and reinforced concrete.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

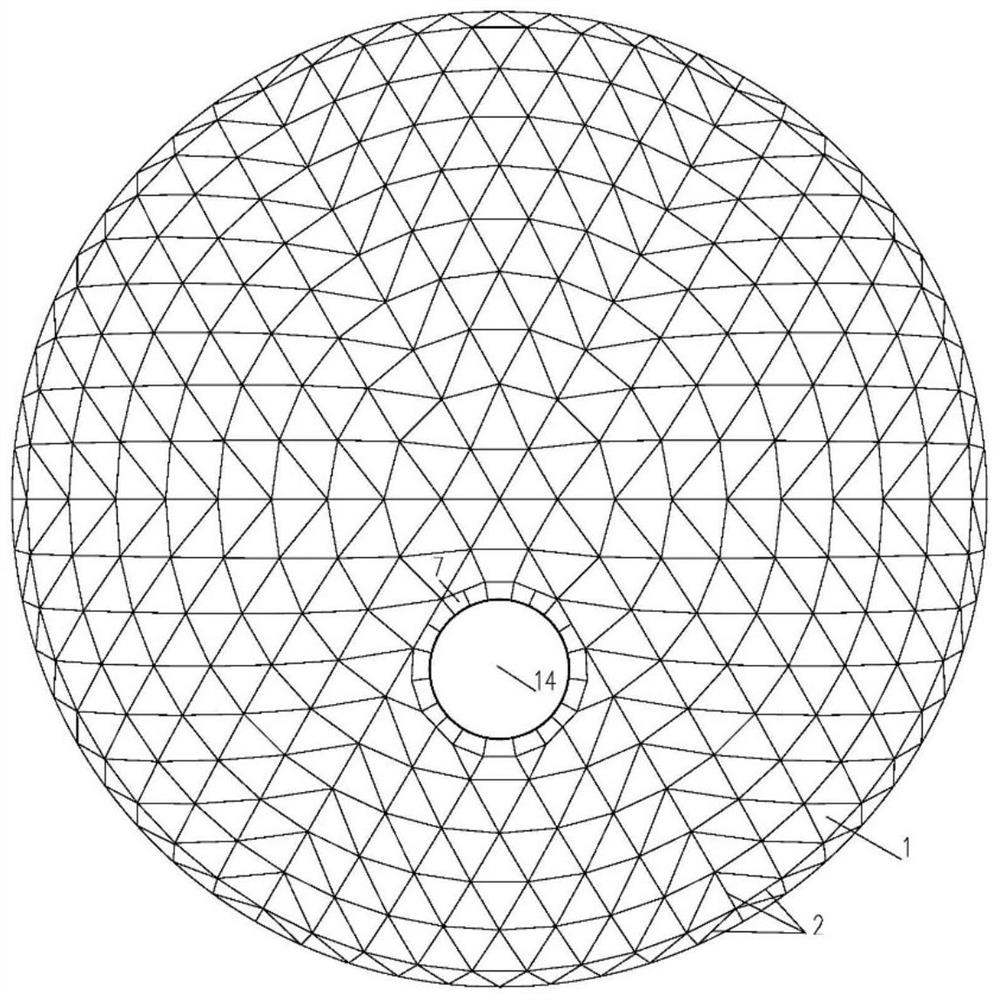

Reactor single-side steel plate ultra-high performance concrete single-layer containment and its construction method

ActiveCN111561194BAvoid crackingAvoid instabilityBuilding roofsNuclear energy generationArchitectural engineeringMesh reinforcement

The invention provides a one-sided steel plate ultra-high-performance concrete single-layer containment vessel, which belongs to the technical field of nuclear power engineering structures. The containment structure includes the cylinder body and the dome, both of which adopt a single inner steel plate ultra-high performance concrete structure, and a plurality of T-shaped stiffeners, studs and shear bars arranged obliquely or orthogonally are evenly fixed on the outer surface of the steel plate by welding. The T-shaped stiffener web can be solid web or empty web, and the shear reinforcement is fixed by the two-way reinforcement intersection of the straight thread anchor plate on the top and the reinforcement mesh on the outside of the containment wall. The dome considers the design of Yonglin combined with reserved holes, and the cover plate and the opening are connected and disassembled by ring flanges and high-strength bolts. The containment adopts a modular design and construction method, and the single-sided steel plate and T-shaped stiffener can replace part of the ultra-high performance concrete pouring formwork. Adopting the invention can ensure the pressure bearing and sealing requirements in the containment vessel, prevent external events and large aircraft collisions, and has remarkable engineering economy.

Owner:CHINERGY CO LTD

Device and method for shear reinforcement of concrete box girder web

ActiveCN109537478BSimple structureReasonable designBridge erection/assemblyBridge strengtheningDiagonal crackPre stress

Owner:BEIJING UNIV OF TECH

Large-span underground structure externally-wrapped U-shaped steel reinforced concrete beam and manufacturing method thereof

PendingCN113216514AHigh tensile strengthImprove stress resistanceArtificial islandsLoad-supporting elementsConcrete beamsArchitectural engineering

The invention provides a novel large-span underground structure externally-wrapped U-shaped steel reinforced concrete beam and a manufacturing method thereof. The concrete beam structurally comprises a concrete beam body, U-shaped section steel, shear connectors and steel bars; the U-shaped section steel is externally wrapped outside the concrete beam and located on the lower middle side of the concrete beam; the shear connectors are welded to the inner side of the U-shaped section steel and used for connecting the U-shaped section steel and the concrete beam and transmitting shear force; and a steel bar frame is arranged in the concrete beam and is not in contact with the U-shaped section steel and the shear connectors. The externally-wrapped U-shaped steel reinforced concrete beam structure can remarkably improve the tensile bending resistance of the beam, improve the bearing capacity of the structure and reduce the cross section size of the beam, can be widely applied to building structures, bridge structures and other engineering structures, and is particularly suitable for large-span underground structures with the large-load characteristic.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

A steel plate support-diagonal nail combined quick-connect steel-uhpc combined structural system

ActiveCN109487698BIncreased shear strengthImprove integrityBridge structural detailsBridge erection/assemblyIsosceles trapezoidThin slab

The invention discloses a steel plate holder and skew spike combined rapid connecting steel and UHPC (ultrahigh performance concrete) combination structure system, comprising a steel beam, an UHPC thin slab, steel plate holders and short spikes; the steel plate holders are of isosceles-trapezoid structure, and are connected with the steel beam through high-strength bolts; the short spikes are vertically arranged on bevels of two sides of each steel plate holder; the UHPC thin slab is cast on the upper side of the steel beam; combinations of the steel plate holders and the short spikes are uniformly distributed inside the UHPC thin slab. As the deck slab is made of UHPC, dead weight of the structure can be reduced while bridge capacity of the structure can be improved; steel plate holder and skew spike combined connectors are used for interface connection at the interface, so that comprehensive advantages of the steel plates serving as the rigid connectors and the spikes serving as theflexible connectors can be achieved well, and interface slippage can be reduced under action of rigid connection of the steel plate holders in the normal application state; in the UHPC slab, the shortskew spikes are in staggered arrangement to form the reinforcing truss of the UHPC, and accordingly rigidity of the UHPC slab is increased and the integral rigidity of the combination section is increased.

Owner:SOUTHEAST UNIV

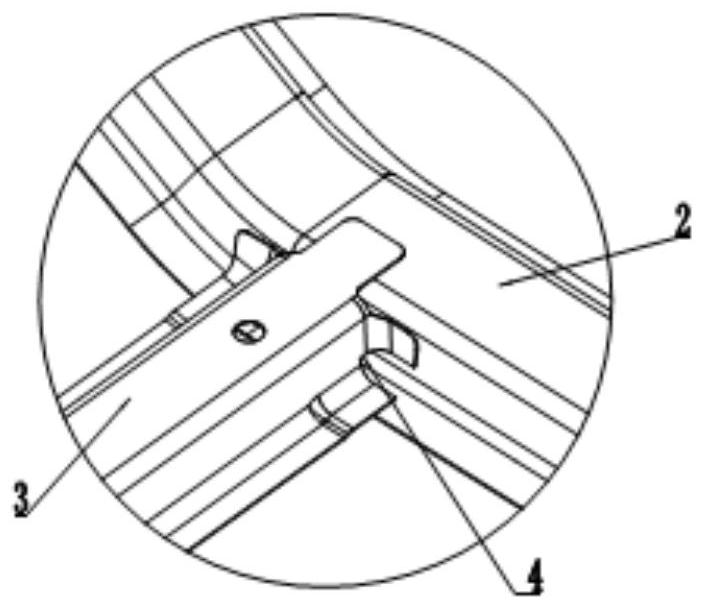

Connecting structure of automobile aluminum alloy floor beam

PendingCN114802482AFirmly connectedImprove section stiffnessSuperstructure subunitsStringerSpot welding

An automobile aluminum alloy floor beam connecting structure is provided with a first connecting piece and a second connecting piece. The first connecting piece is of a hollow cavity structure, is provided with an arc-shaped top face extending towards the front side and the rear side, is connected with the first cross beam in a spot welding mode through an arc-shaped top face front side extending part, a cavity front side wall and a cavity bottom face, and is connected with the end of the longitudinal beam in a spot welding mode through an arc-shaped top face rear side extending part and a cavity rear side wall. The second connecting piece is a T-shaped hollow shell, the upper end and the lower end of the second connecting piece are of an open structure, a longitudinal beam penetrating groove and a cross beam penetrating groove are formed in the side wall of the second connecting piece, the longitudinal beam penetrates through the longitudinal beam penetrating groove, the left side wall and the right side wall of the longitudinal beam are connected with the longitudinal inner wall of the T-shaped hollow shell in a spot welding mode, and the end of the second cross beam penetrates through the cross beam penetrating groove. The front side wall and the rear side wall of the second cross beam are in spot welding connection with the transverse inner wall of the T-shaped hollow shell. Reliable connection of parts in the aluminum alloy floor beam assembly is achieved, and the purposes of meeting the requirements of automobile floor beam connection strength, light weight and low cost are achieved.

Owner:SHANGHAI LINGYUN IND TECH CO LTD +1

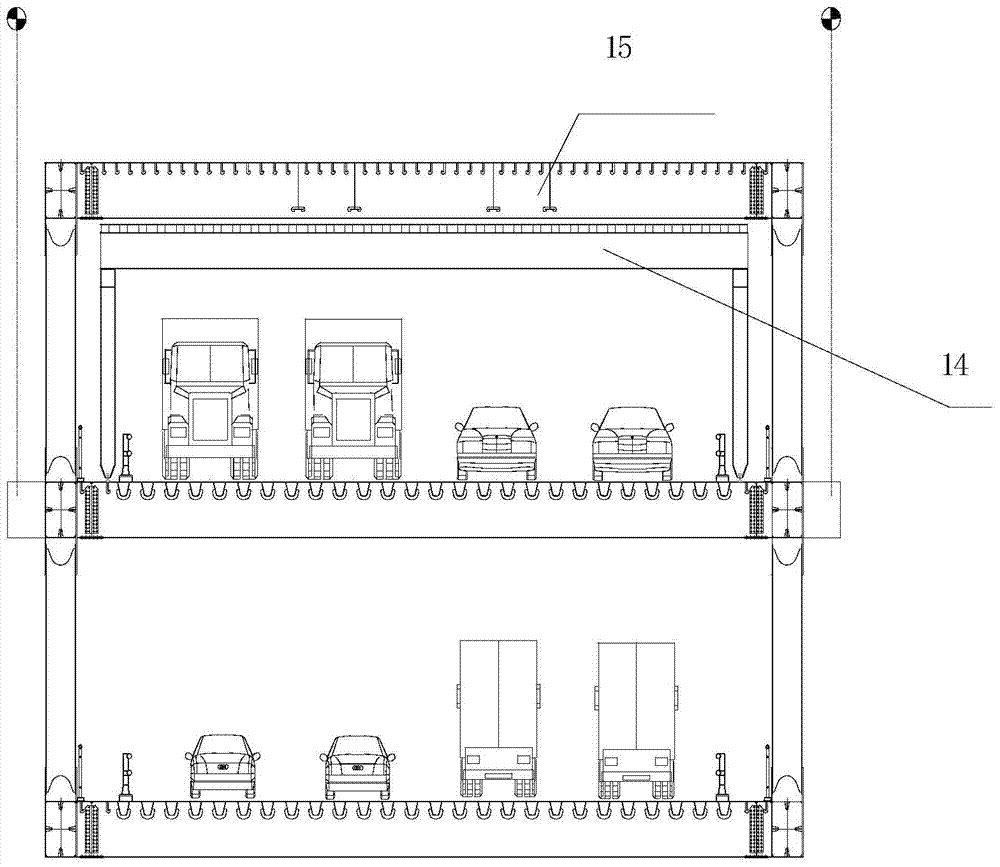

Concrete shrinkage stress restraint system of subway underground long longitudinal structure

PendingCN111809659AIncreased longitudinal stiffnessImprove the crack resistance of the sectionArtificial islandsUnderwater structuresArchitectural engineeringEconomic benefits

The invention discloses a concrete shrinkage stress restraint system of a subway underground long longitudinal structure. Supporting transverse beams and side columns are arranged at certain intervalsadditionally in the longitudinal direction of the long longitudinal structure, the transverse beams are arranged on a top plate and a bottom plate respectively, the side columns are arranged on sidewalls on both sides, and the transverse beams are connected with the side columns end to end to form a closed frame. According to the system, through the arrangement that the beams, the columns and the closed frame are arranged on the long longitudinal structure additionally, and anti-cracking steel bars are arranged additionally at the same time, on the one hand, the cross-sectional area and reinforcement ratio of a beam-column structure are increased, the longitudinal rigidity and tensile stress of the structure are improved, on the other hand, the shrinkage stress accumulates at the late stage of truncated structure closing, and the shrinkage effect length is shortened, so as to avoid structural cracks of the long longitudinal structure caused by the shrinkage stress, the safety and durability of a main structure are ensured, safe operation is ensured, a lot of plugging and repair costs of concrete cracks are saved, and economic benefits are good.

Owner:深圳市居安建筑科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com