Steel-encased-ultra-high-performance concrete reinforcing method for box girder

A concrete reinforcement, ultra-high performance technology, applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of limited crack development effect, complicated construction procedures of anchoring devices, and inability to operate economically and durable, so as to avoid the risk of concrete cracking. , The construction is simple and fast, and the effect of improving the reinforcement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

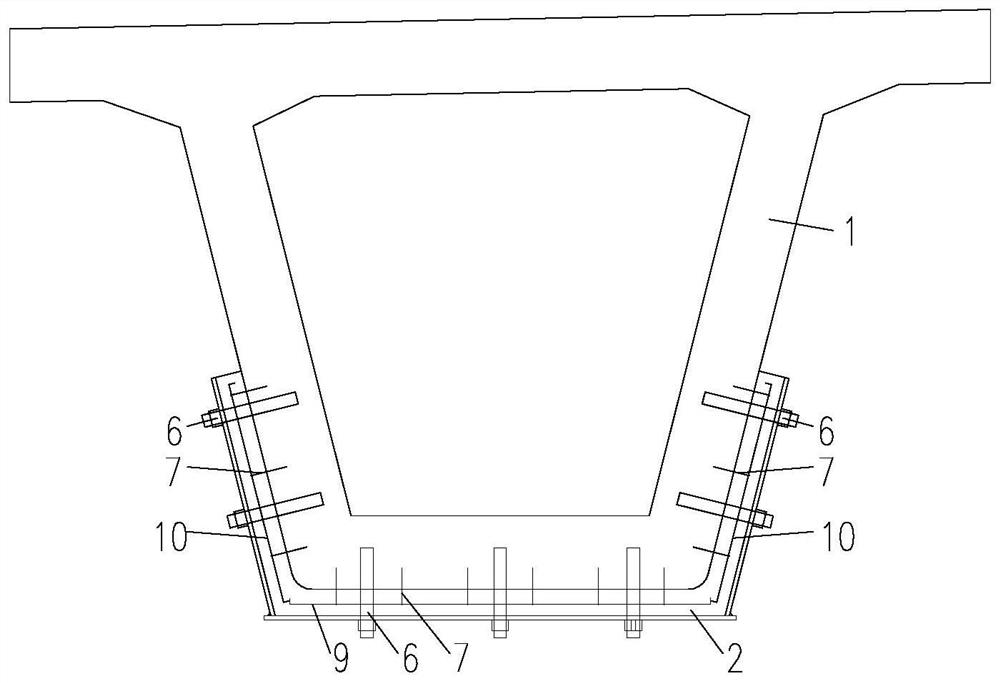

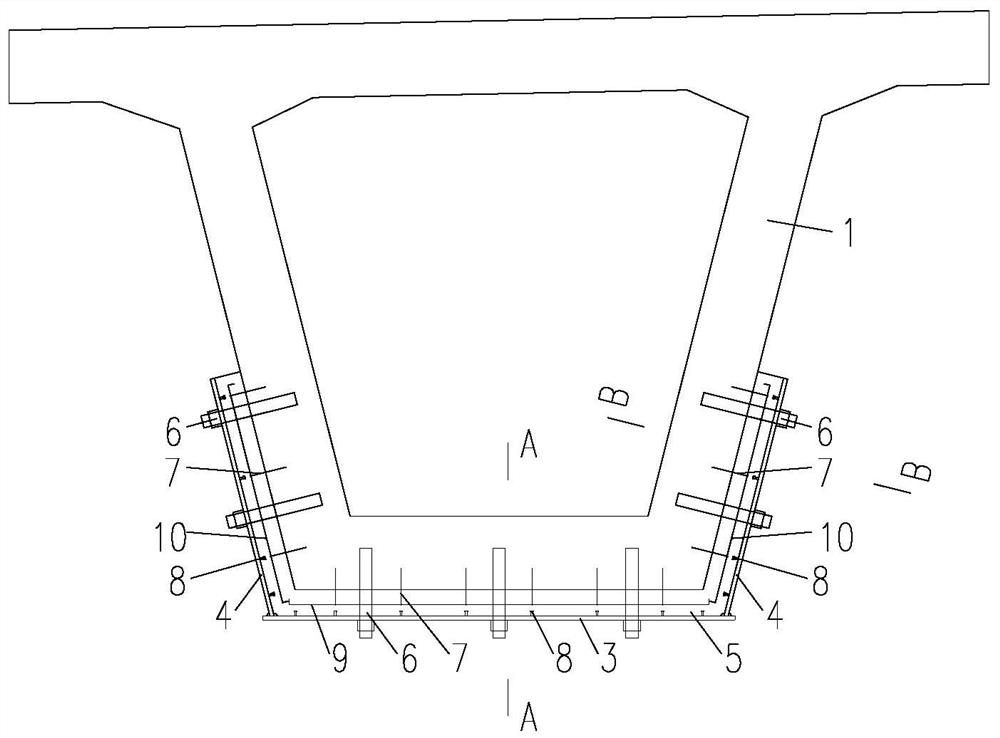

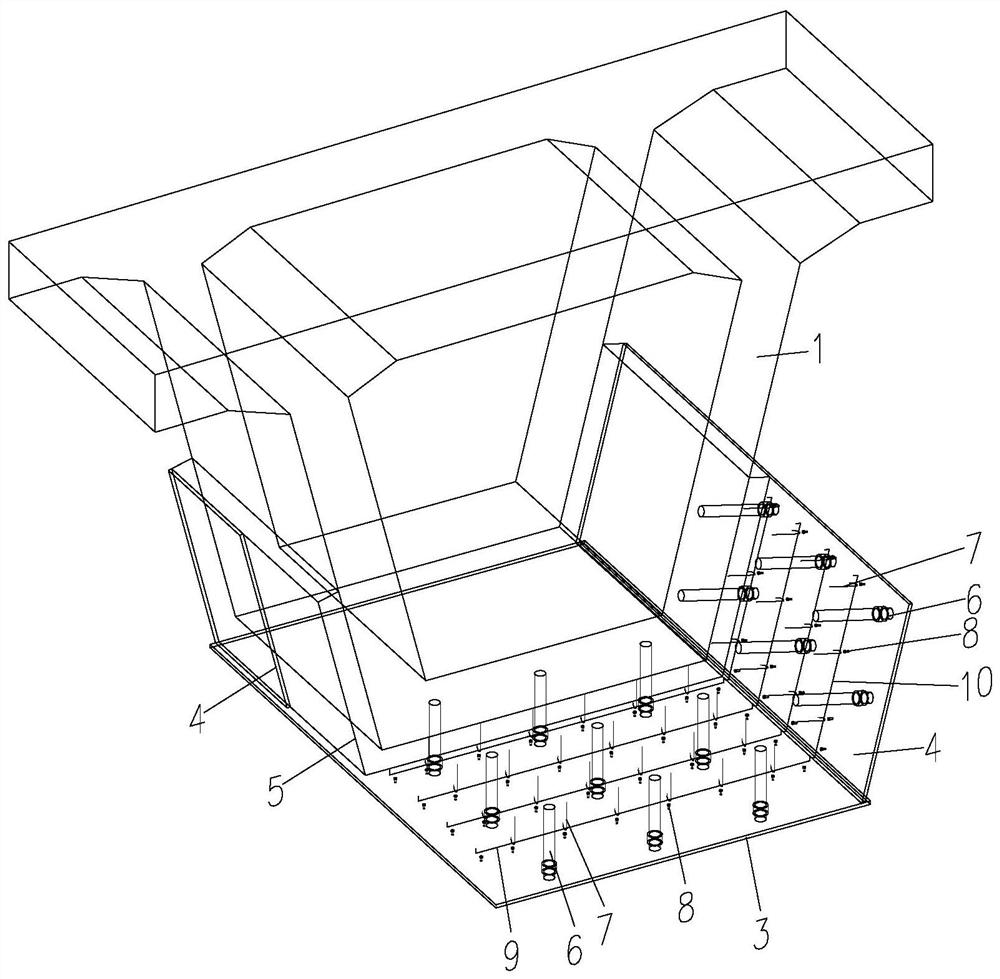

[0036] Such as figure 1 As shown, the steel-ultra-high-performance concrete reinforcement structure of the box girder in this embodiment includes a box girder 1, a steel-ultra-high performance concrete structure 2, bolts 6, implanted steel bars 7, floor stirrups 9, and webs Stirrup 10.

[0037] Such as figure 2 As shown, the steel-ultra-high-performance concrete structure 2 of the above-mentioned embodiment includes a bottom steel plate 3, a side steel plate 4, studs 8, and an ultra-high performance concrete 5. The bottom steel plate 3 is parallel to the bottom plate of the box girder 1, and the side steel plate 4 and the box Beam 1 web is parallel.

[0038] In this embodiment, the bottom steel plate 3 and the side steel plates 4 are welded by fillet welds, and the frame formed by the bottom steel plate 3 and the side steel plates 4 is U-shaped.

[0039] In this embodiment, the studs 8 are short studs, the studs 8 are welded to the bottom steel plate 3 and the side steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com