Patents

Literature

136results about How to "Improve reinforcement efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

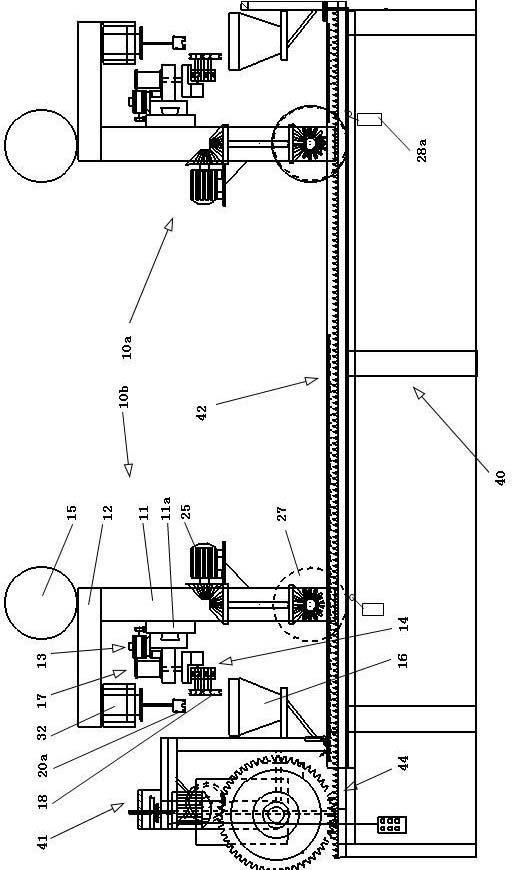

In-situ carbonization curing treatment method for shallow soft ground

ActiveCN104912055AEasy to adjust the depth of mixingImprove uniformityOrganic fertilisersSoil preservationResource utilizationCarbonization

The invention discloses an in-situ carbonization curing treatment method for a shallow soft ground, and belongs to the field of civil engineering ground stabilization. The method includes the steps that pretreated ground soil is broken and stirred through a crawler-type stirrer; a first curing agent and a second curing agent are mixed, the mixed curing agents are sprayed into the ground soil, and the mixed curing agents and the ground soil are evenly stirred; U-type drain boards are inserted at intervals through a board inserting device; a compacting device and a film laying device are started, and films are laid while the treated ground soil is rolled; carbon dioxide gas is injected to carry out ventilating carbonization on the compacted ground soil; the steps are repeated, and the steps of mixing the curing agents for the pretreated ground soil, inserting the drain boards, and compacting, sealing and stabilizing the treated ground soil in a carbonization mode are completed continuously. The treatment system and method are simple and reliable and capable of adapting to a complex environment, construction is safe and efficient, and quantification of the curing agents in ground treatment and resource utilization of carbon dioxide are achieved.

Owner:SOUTHEAST UNIV

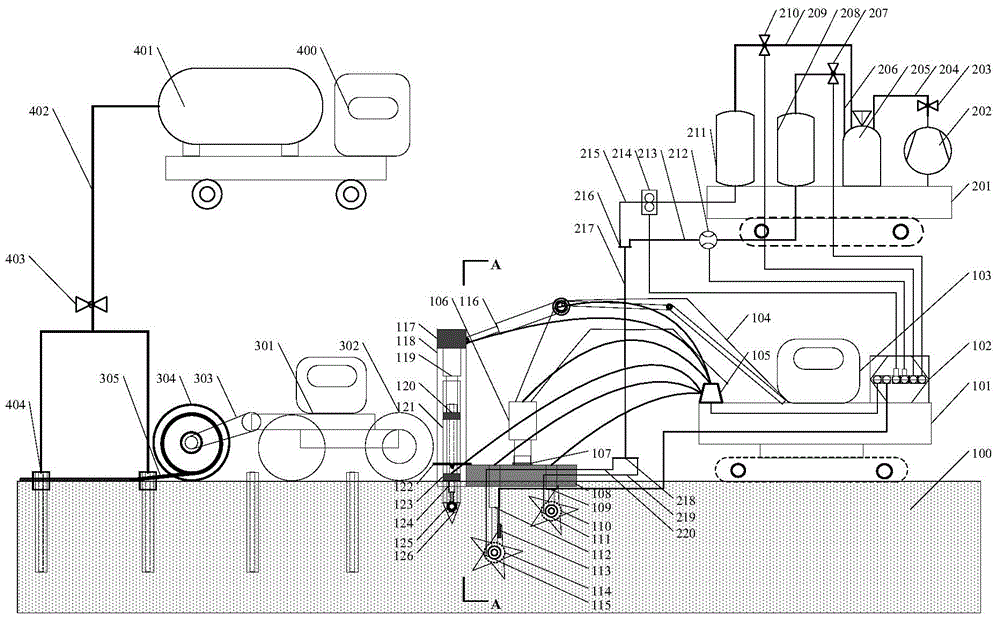

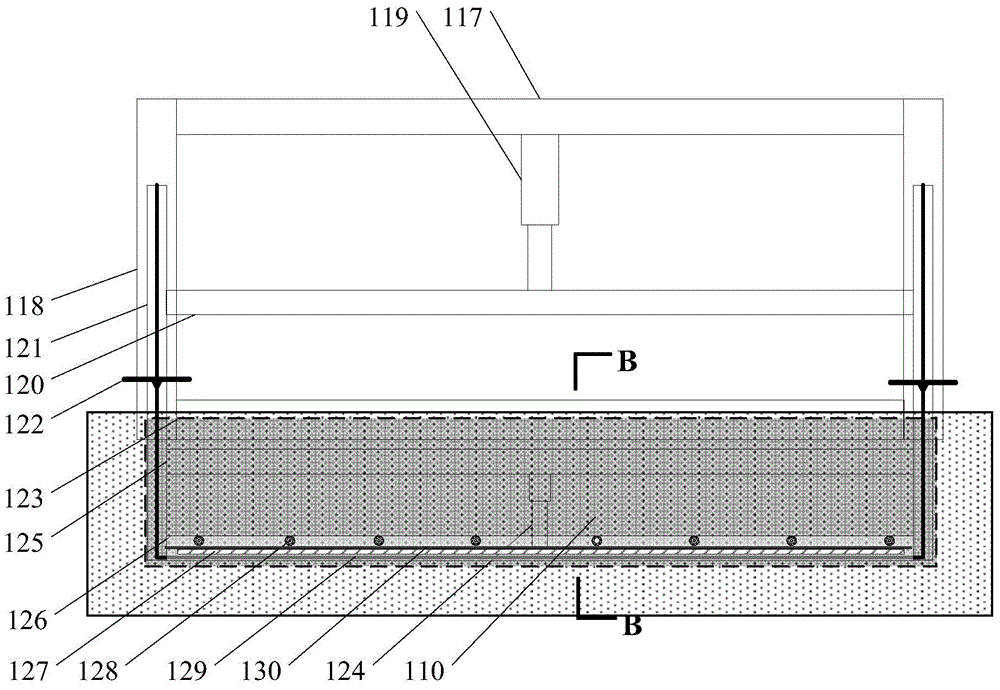

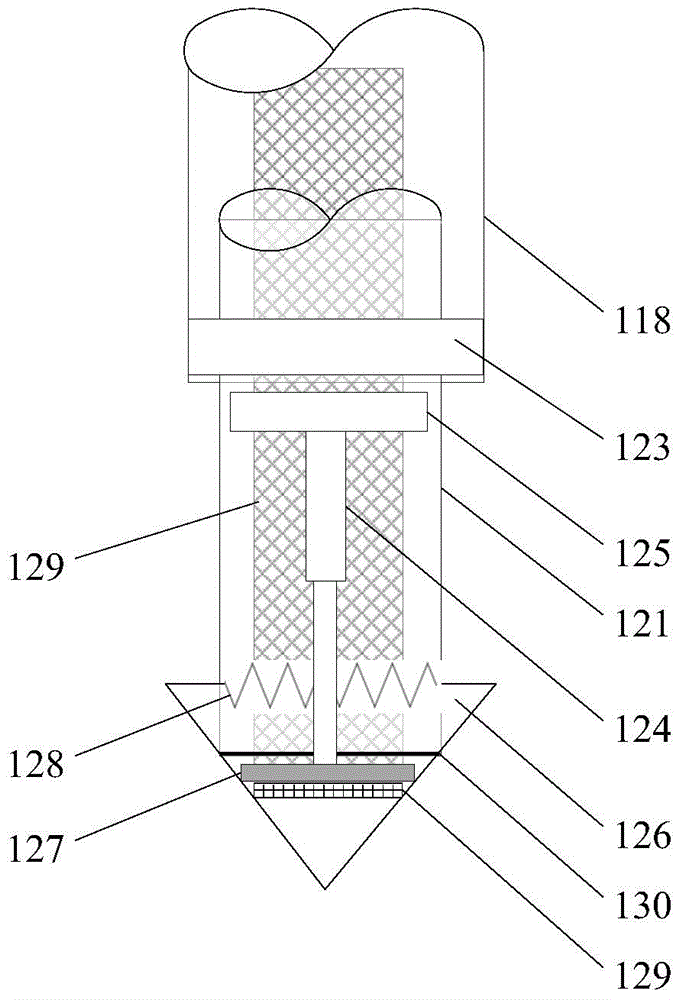

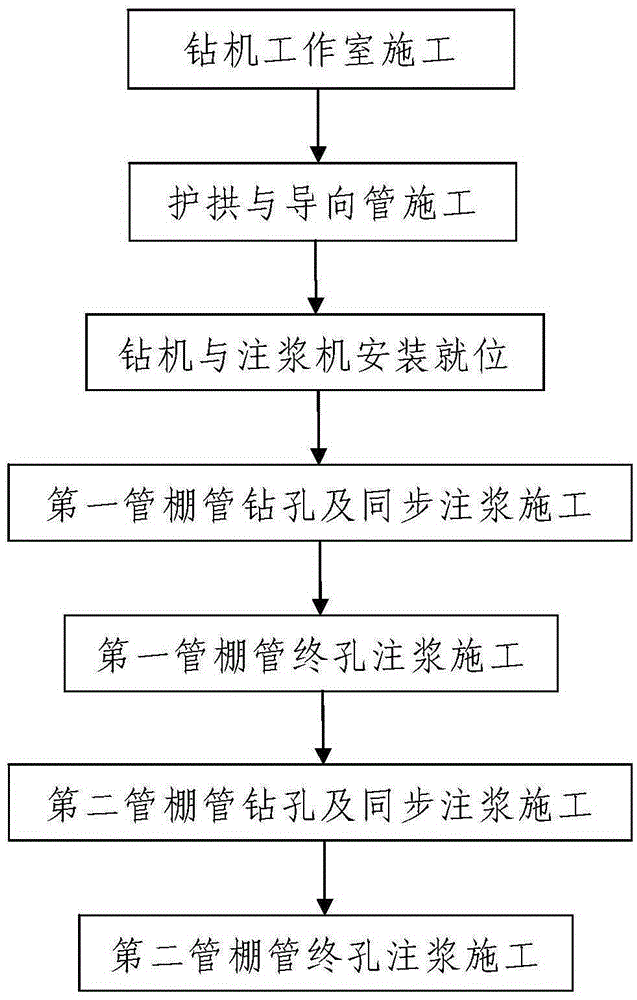

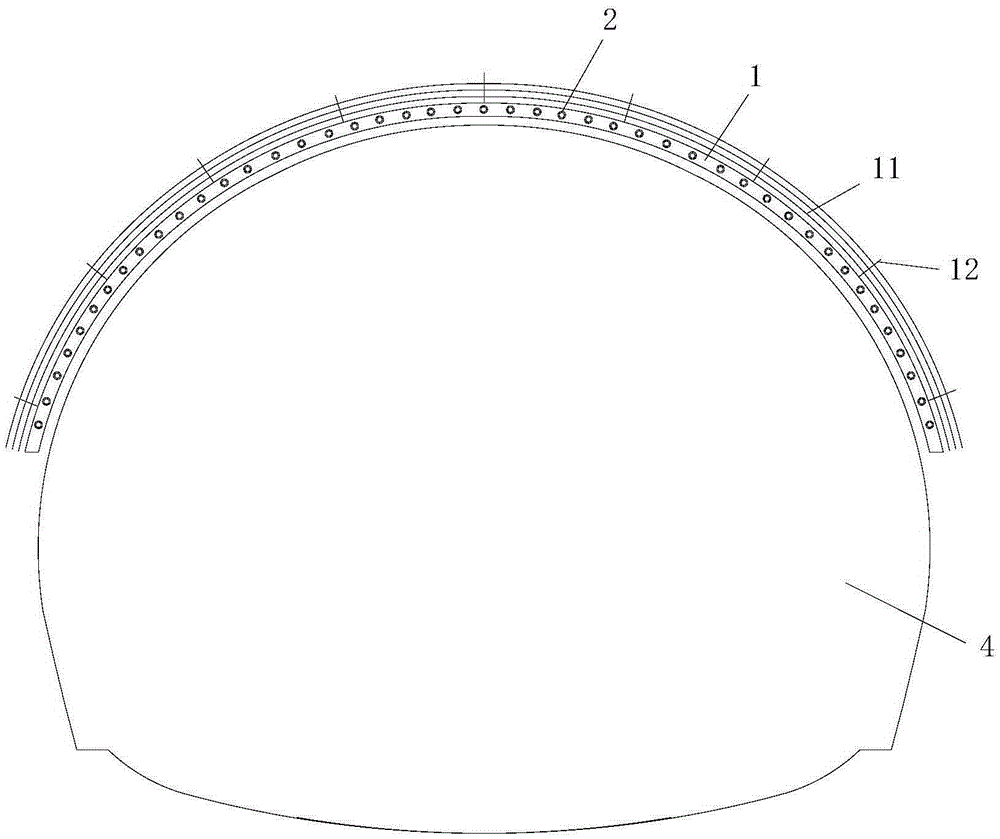

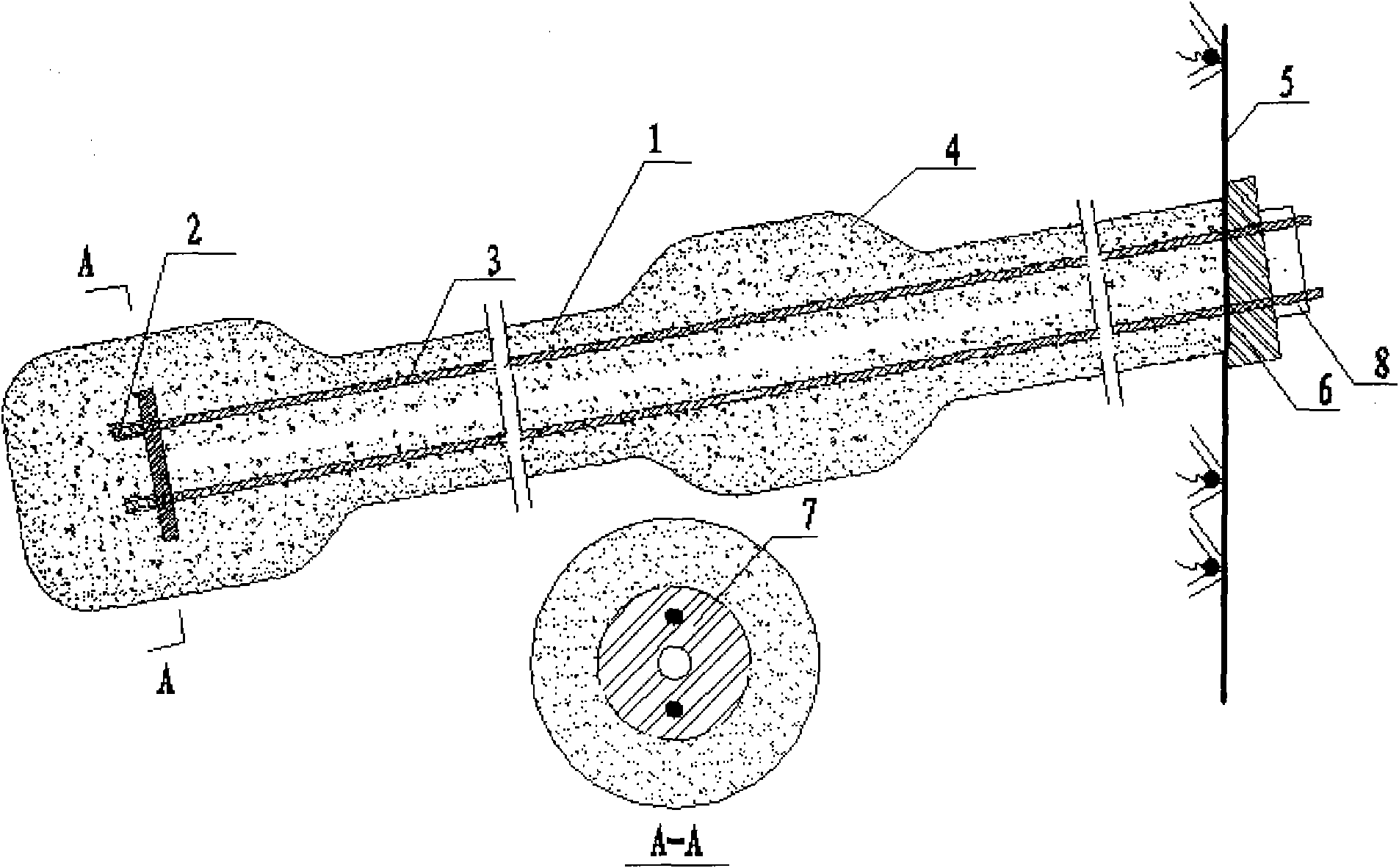

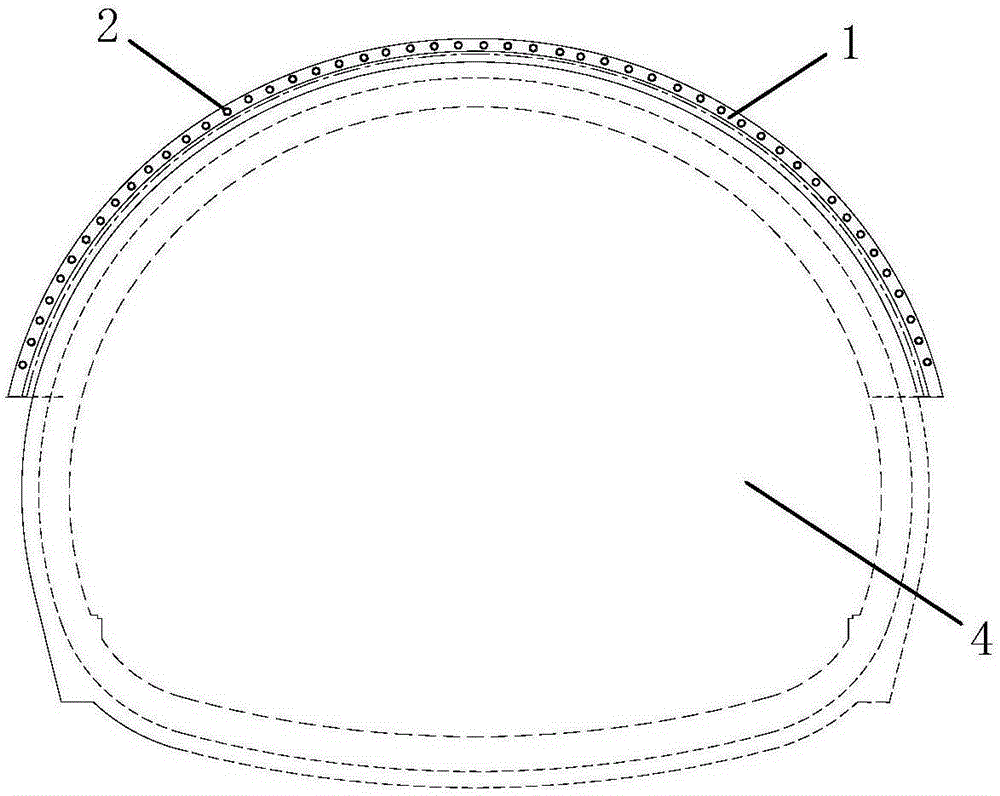

Soft and weak wall rock tunnel advance reinforced support construction method

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

Reactive powder fiber concrete reinforced concrete column and reinforcement method

InactiveCN103590616ALight weightSelf-respect and high strengthBuilding repairsReinforced concrete columnFiber

The invention discloses a method for reinforcing a reactive powder fiber concrete reinforced concrete column. The method includes the steps that firstly, cleaning treatment is carried out on the surface of an original concrete column so that a concrete structure layer of the original concrete column can be exposed, and then impurity removal and dabbing are carried out till a new surface is exposed and an aggregate surface of the concrete structure layer is reached; secondly, positioning, lining and drilling are carried out on the surface of the column, shear pins are embedded into drilled holes through rib embedding glue, and a reinforcing mesh is bound at the lining position; thirdly, interface agents are applied, specifically, reactive powder fiber concrete is applied with the interface agents in a layered mode, joints between the layers are made staggered, and reinforcement of the concrete column is completed after the processes of flattening, burnishing and maintenance. The reinforced concrete column obtained through the method mainly comprises the original concrete column structure layer and a reactive powder fiber concrete reinforced layer, and the reactive powder fiber concrete reinforced layer is formed by mutually overlaying multiple unit reinforced layers with the reactive powder fiber concrete as a base material and the reinforcing mesh as a reinforcing material. The reactive powder fiber concrete reinforced concrete column has the advantages of being small in sectional dimension change, good in durability, long in service life, easy and convenient to construct, high in construction efficiency and the like.

Owner:湖南大兴加固改造工程有限公司

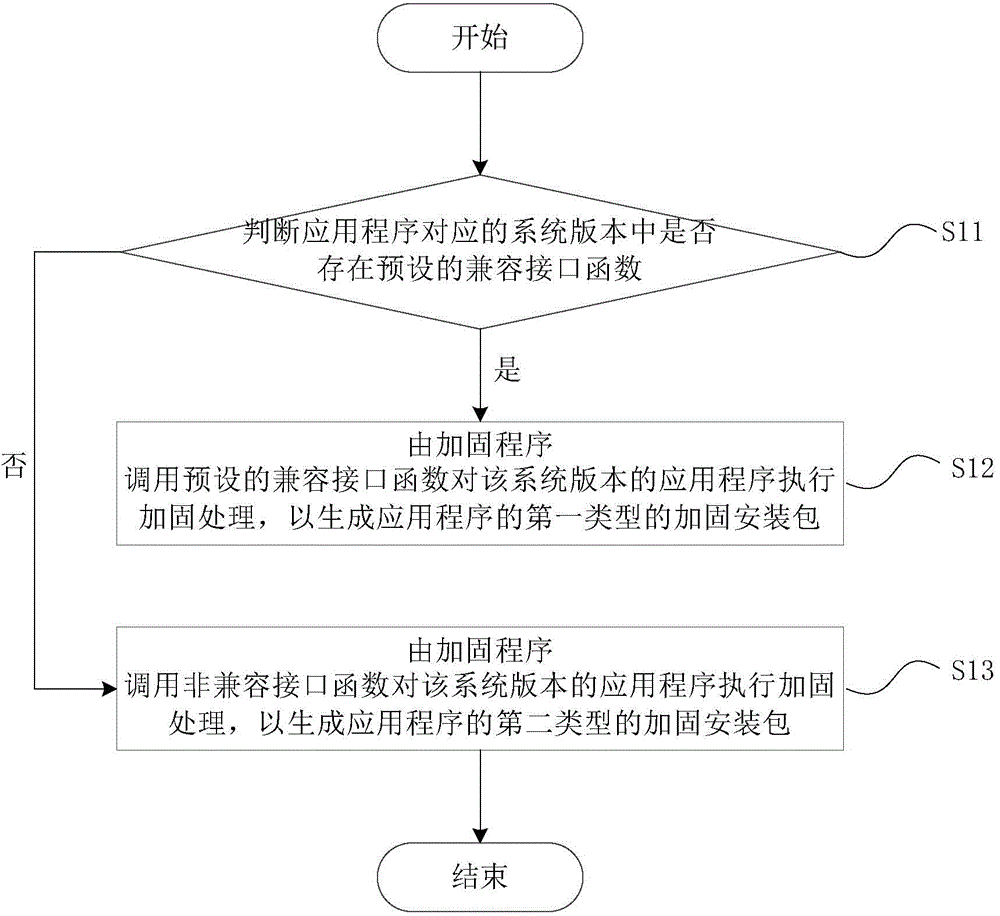

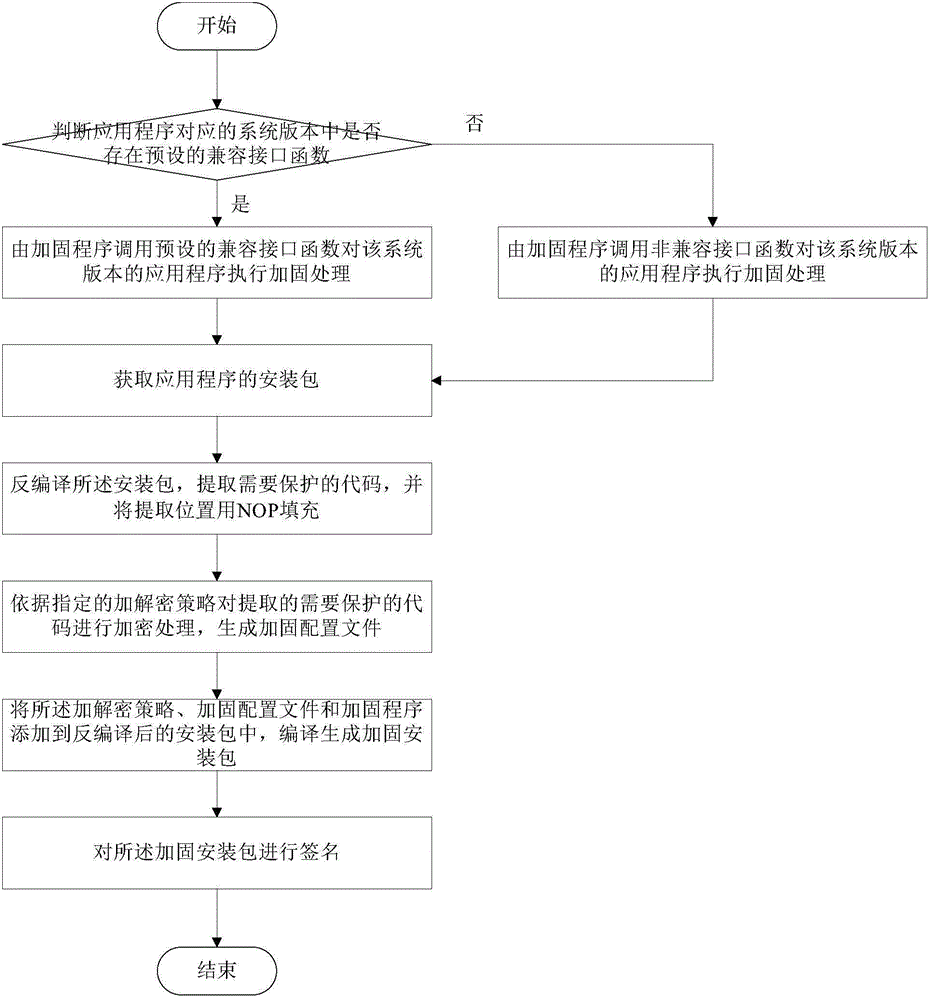

Application reinforcing protection method and apparatus and mobile terminal

ActiveCN104965712AHigh-quality reinforcement experienceFix compatibility issuesSpecific program execution arrangementsComputer compatibilitySoftware engineering

The present invention provides an application reinforcing protection method. The method comprises the following steps of: determining whether a system version corresponding to an application has a preset compatible interface function; if yes, a reinforcing program calling the preset compatible interface function to reinforce the application of the system version, so as to generate a first-type reinforcement installation package of the application; and if no, the reinforcing program calling a non-compatible interface function to reinforce the application of the system version, so as to generate a second-type reinforcement installation package of the application. Meanwhile, the present invention further provides an application reinforcing apparatus and a mobile terminal. The method and the apparatus provided by the present invention can reinforce applications of different system versions, so that a reinforced application is compatible with a corresponding system version thereof, solving the compatibility problem between a reinforced application and a system.

Owner:BEIJING QIHOO TECH CO LTD

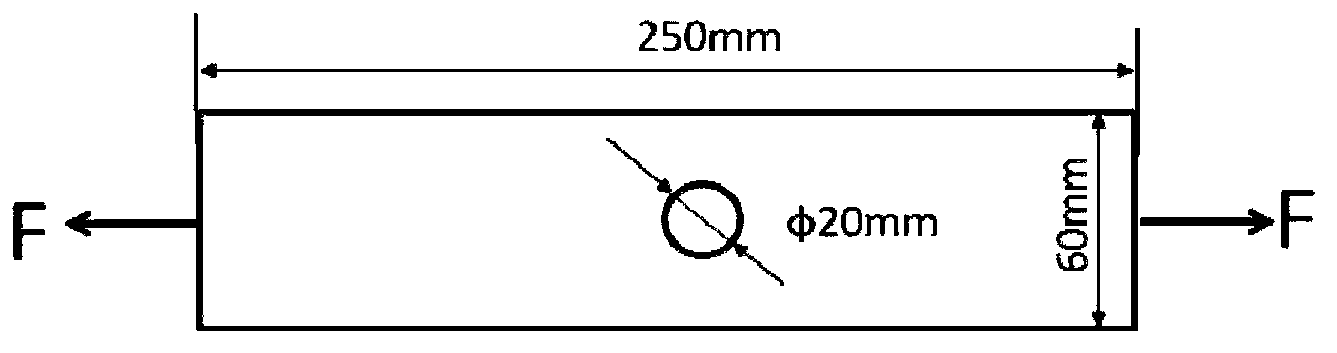

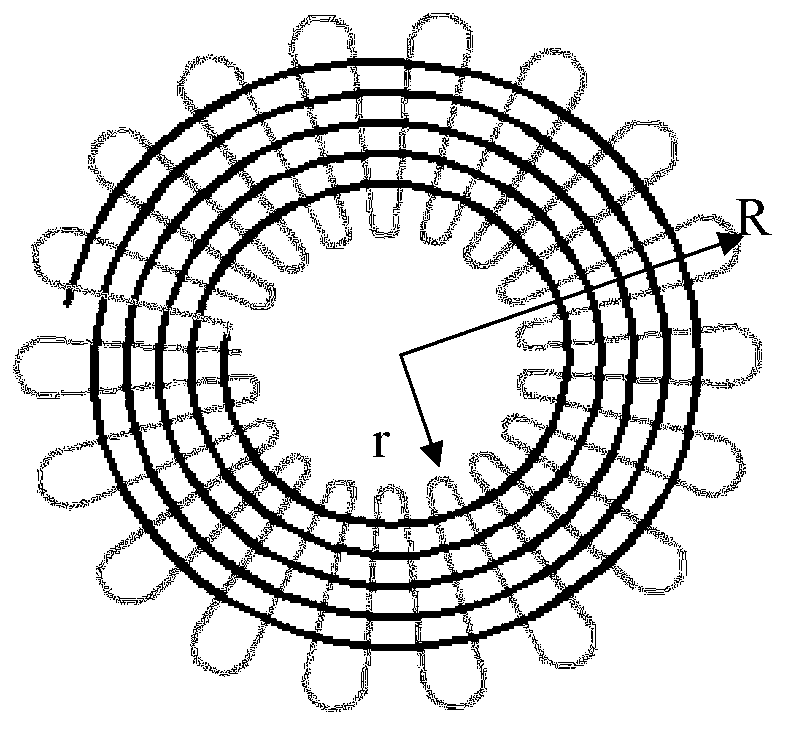

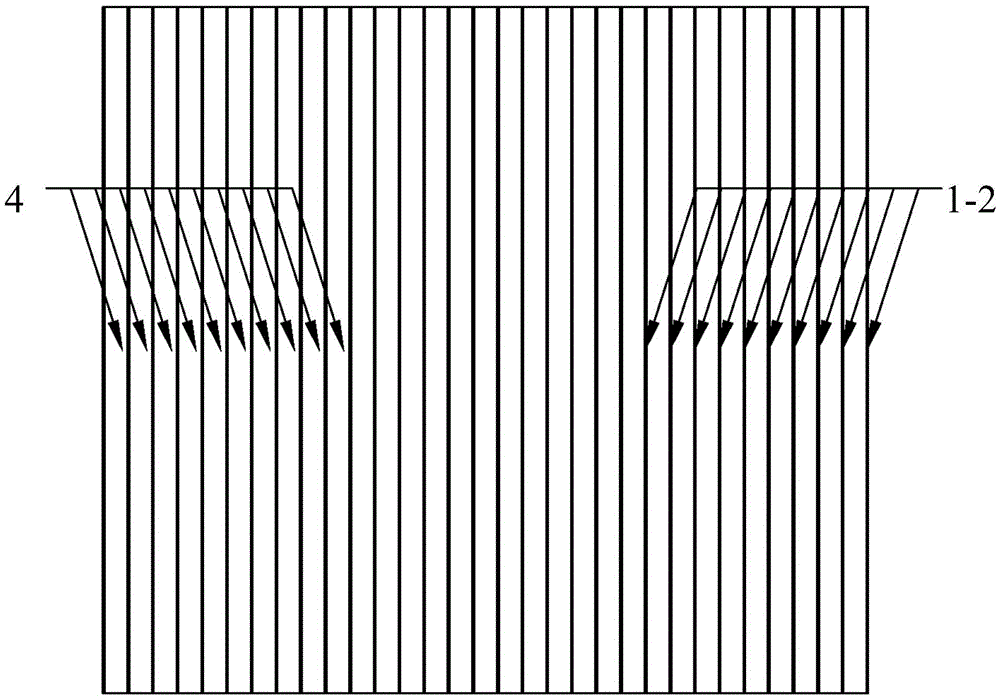

Reinforcing sheet design and reinforcing method for fiber composite material opening workpiece

The invention discloses a reinforcing sheet design and a reinforcing method for a fiber composite material opening workpiece. A matched reinforcing sheet is designed in accordance with the shape and the size of the opening portion of the workpiece. The fiber trajectory of the reinforcing sheet consists of a radial trajectory layer and an annular fiber trajectory layer, presoaked or unsoaked fiber bundles are used for preparing the reinforcing sheet in accordance with the designed fiber trajectory, the reinforcing sheet is laid on the reinforcing portion of an opening, the reinforcing sheet is cured to the opening portion through an integral curing process or a secondary curing process, and the opening reinforcement of the fiber composite material opening workpiece is achieved. The reinforcing sheet has the advantages of being simple in design, good in reinforcing effect, free from cutting, suitable to mass production and wide in application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

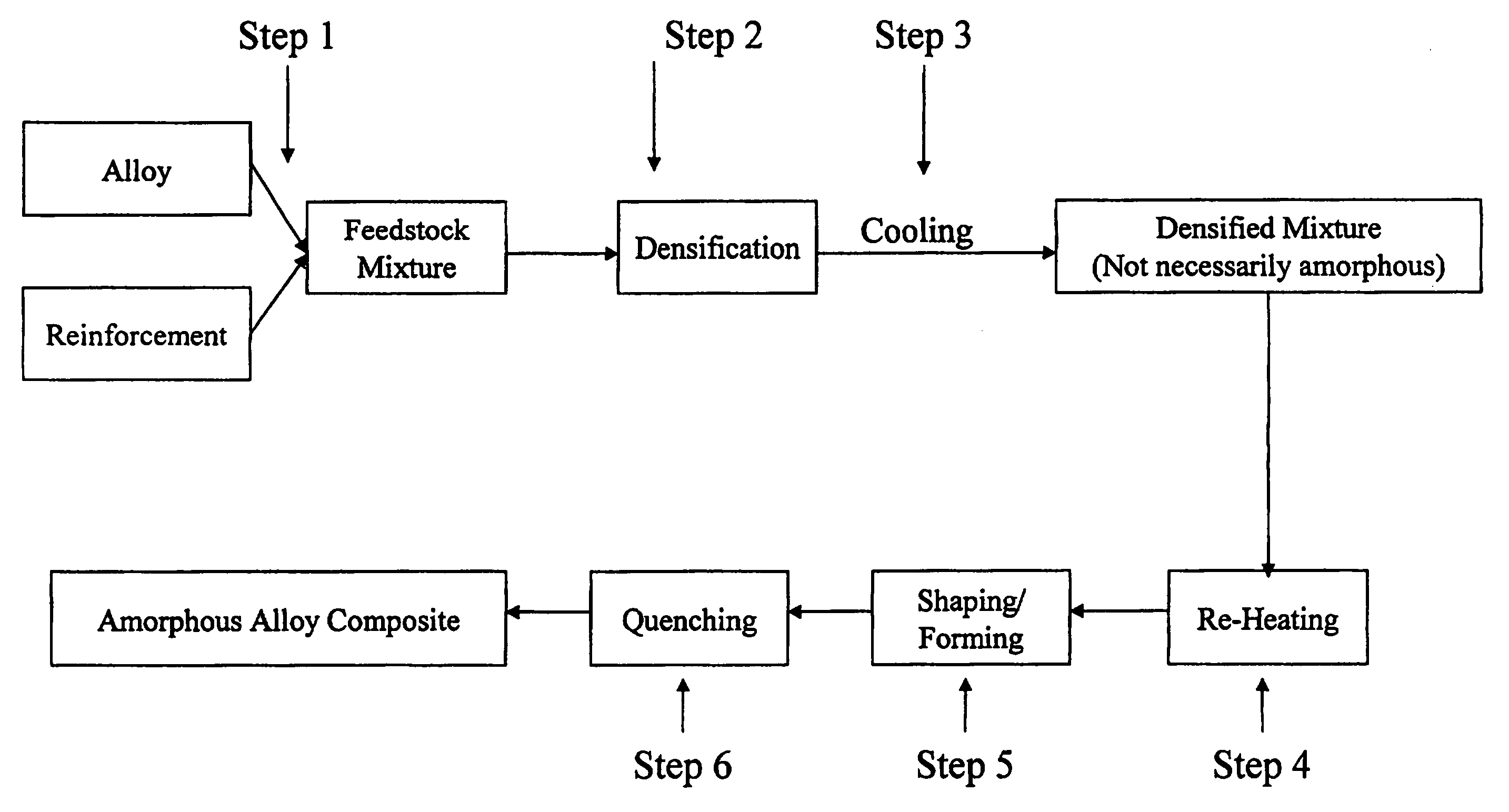

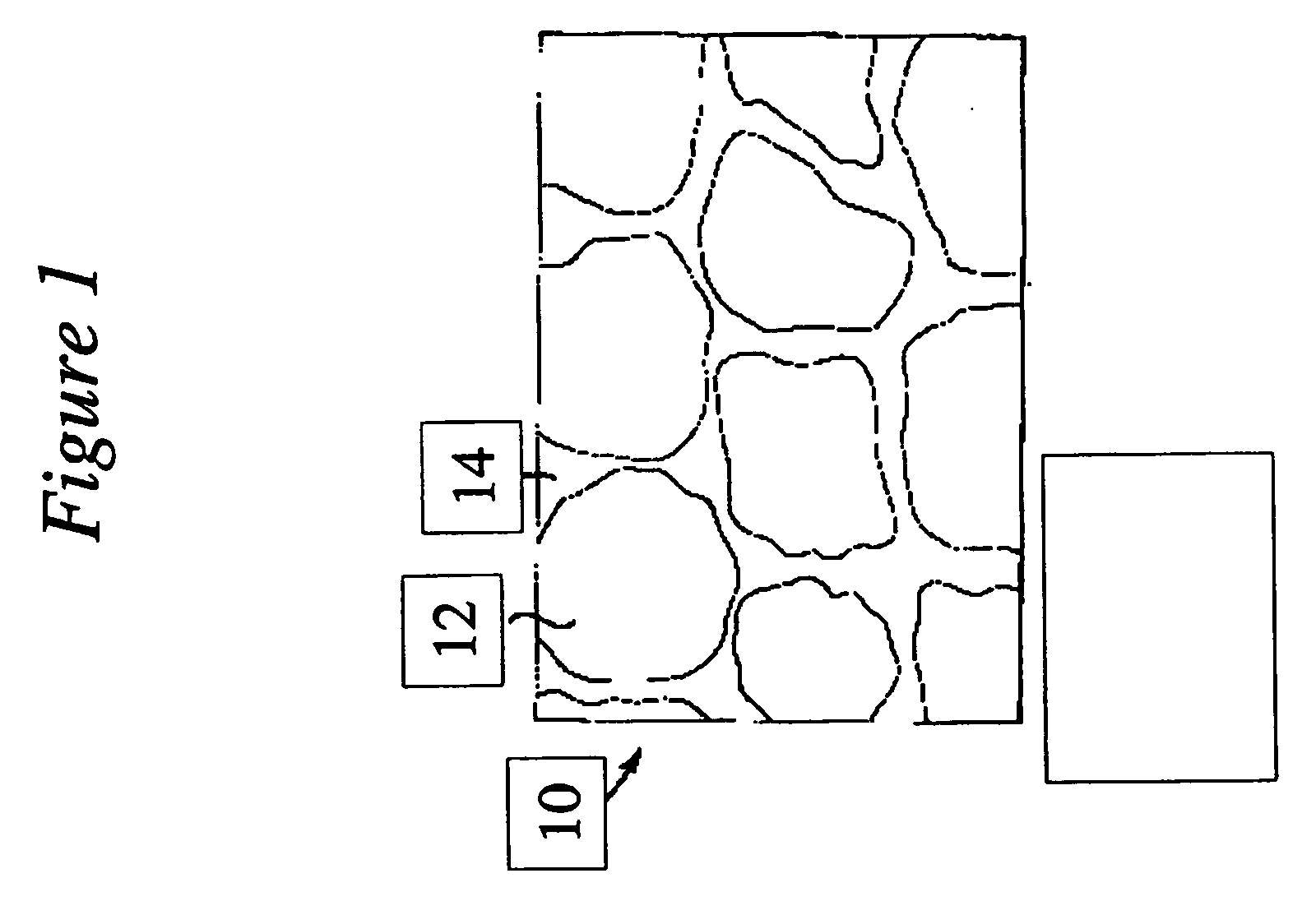

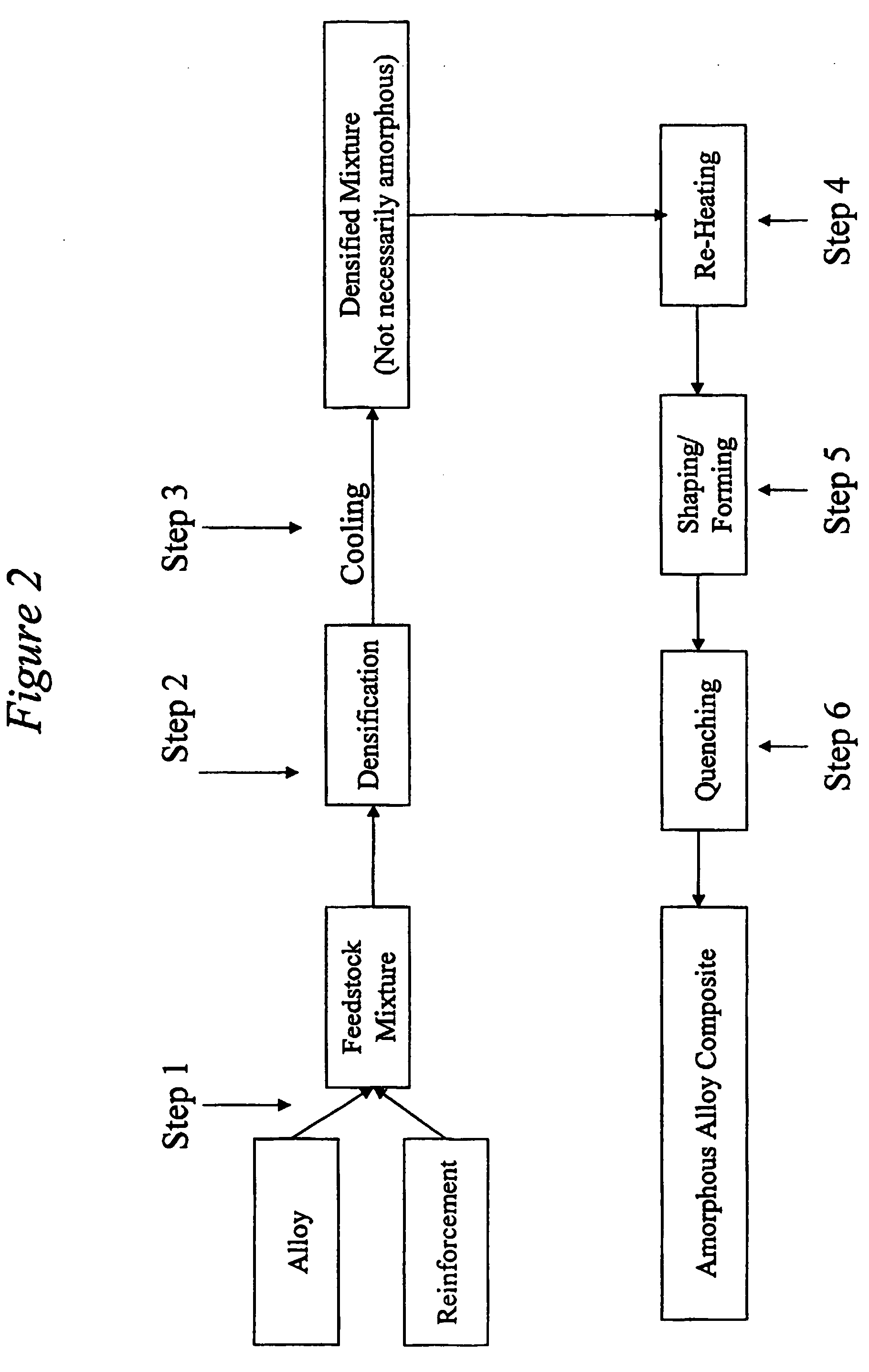

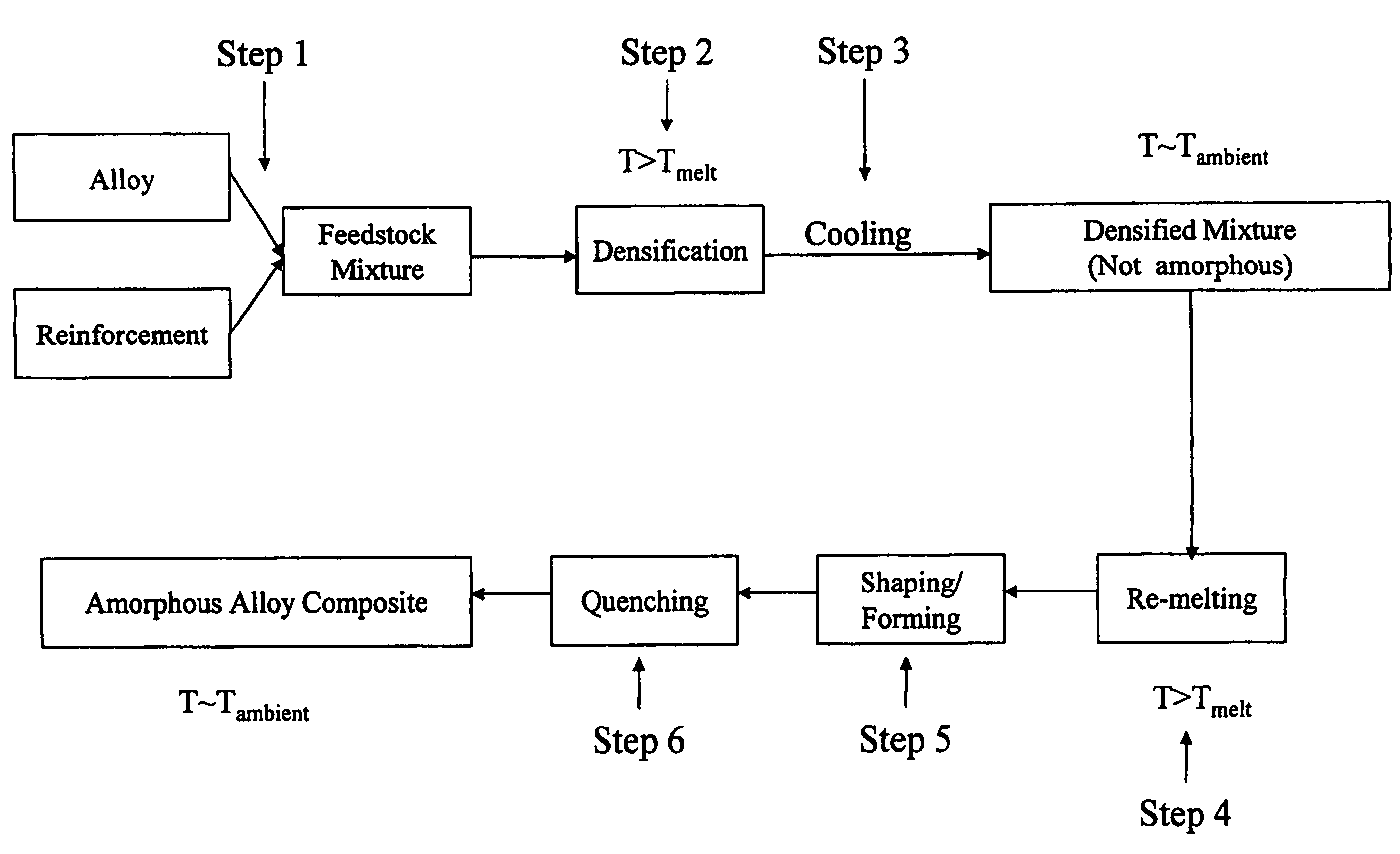

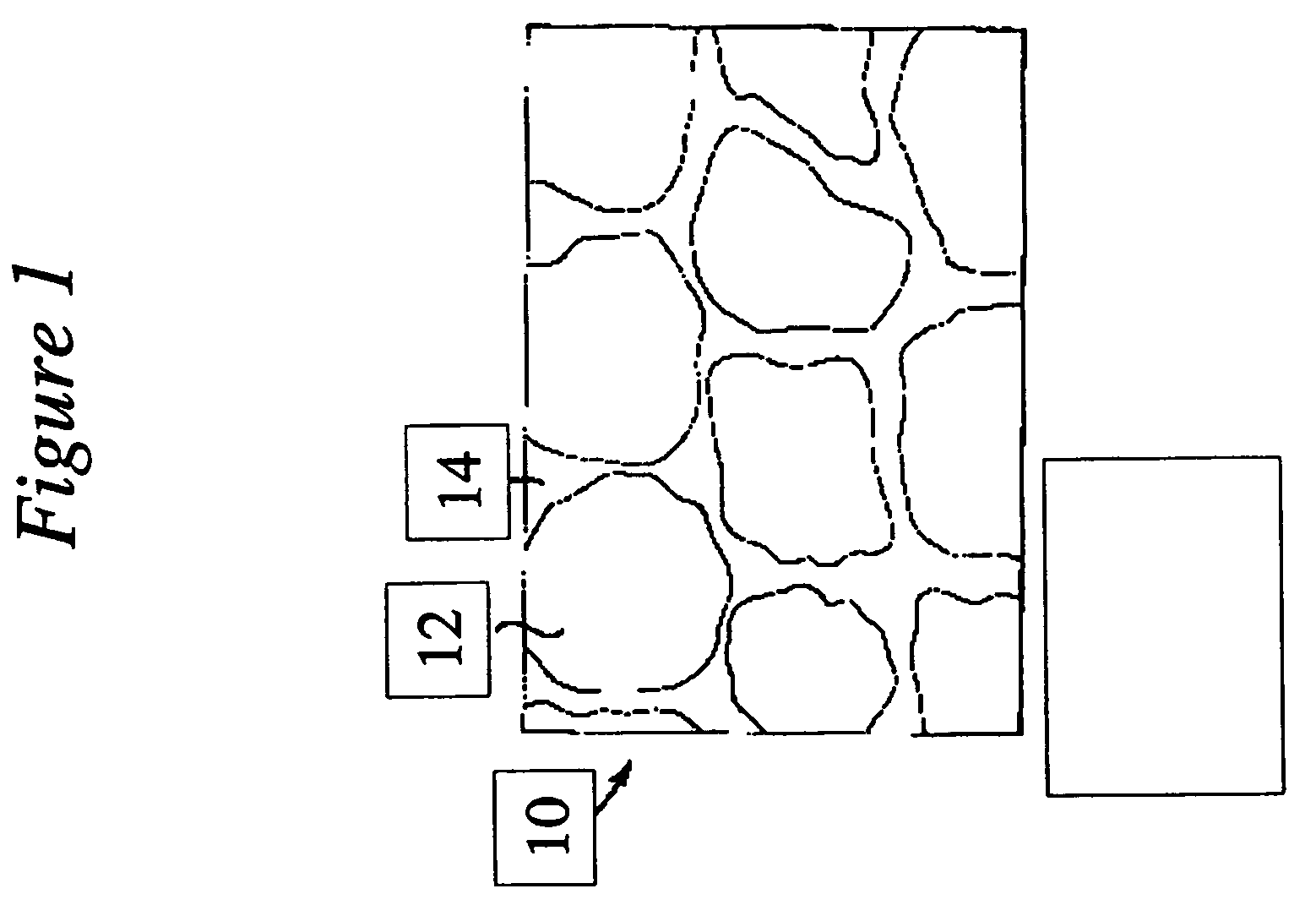

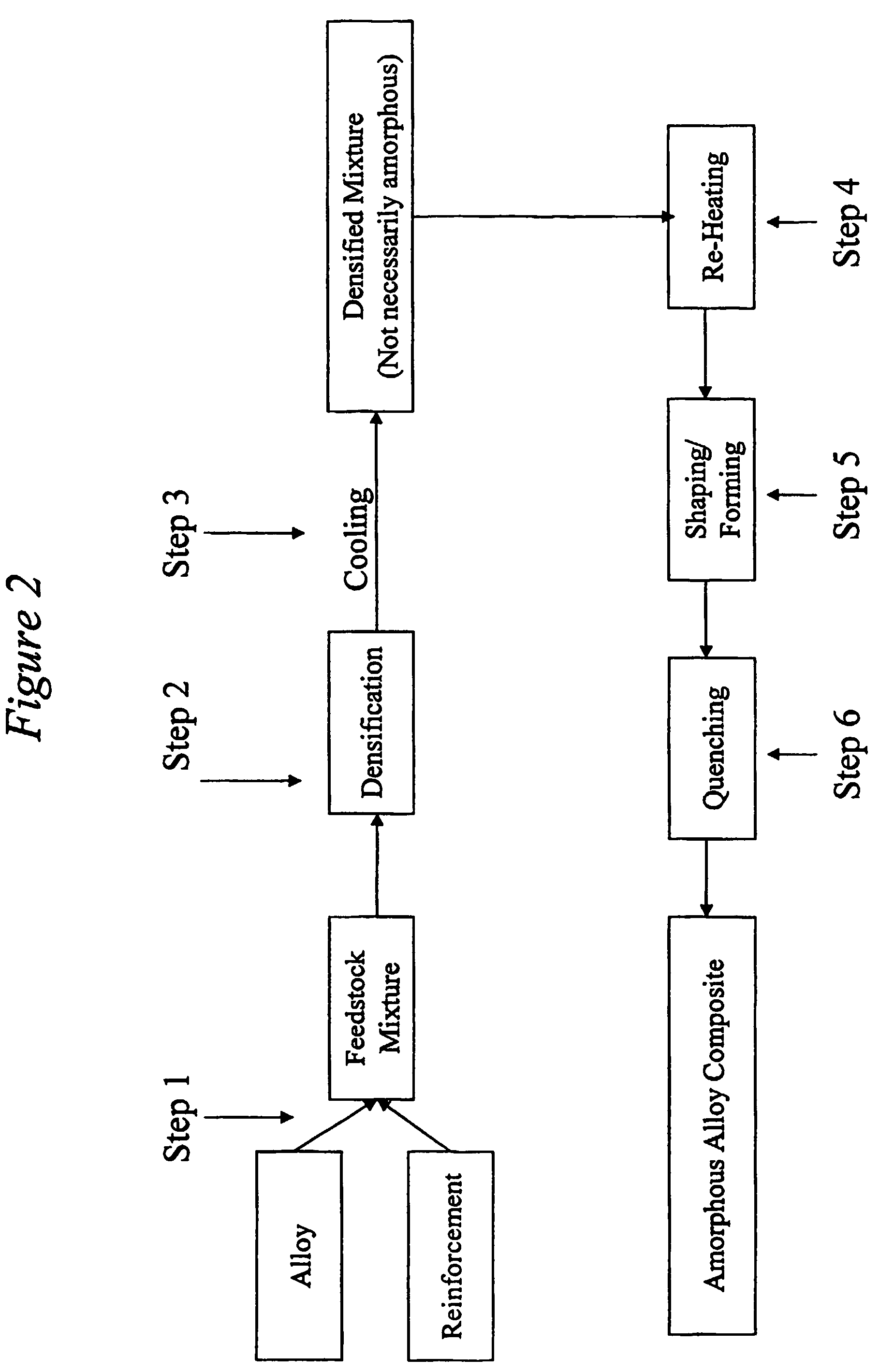

Method of making dense composites of bulk-solidifying amorphous alloys and articles thereof

ActiveUS20060130943A1Improve package efficiencyImprove reinforcement efficiencyPorosityVolume fraction

A method of making composites of bulk-solidifying amorphous alloys, and articles made thereof, containing at least one type or reinforcement material, wherein the composite material preferably comprises a high volume fraction of reinforcement material and is fully-dense with minimum porosity are provided.

Owner:CRUCIBLE INTPROP LLC

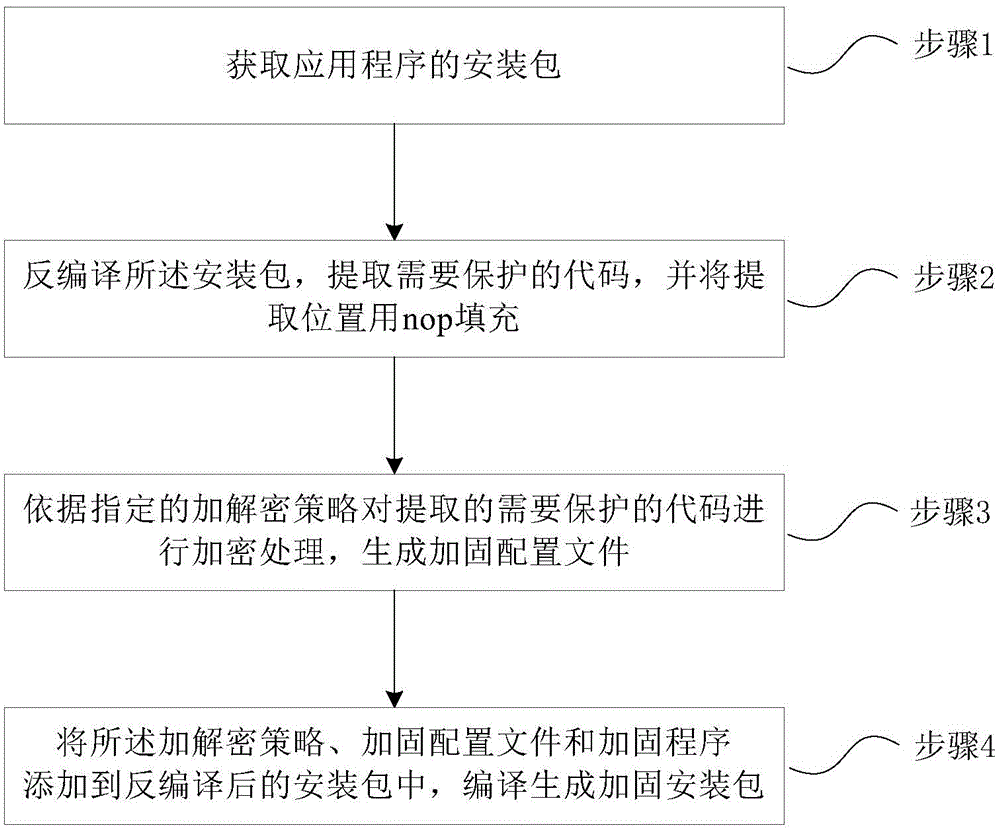

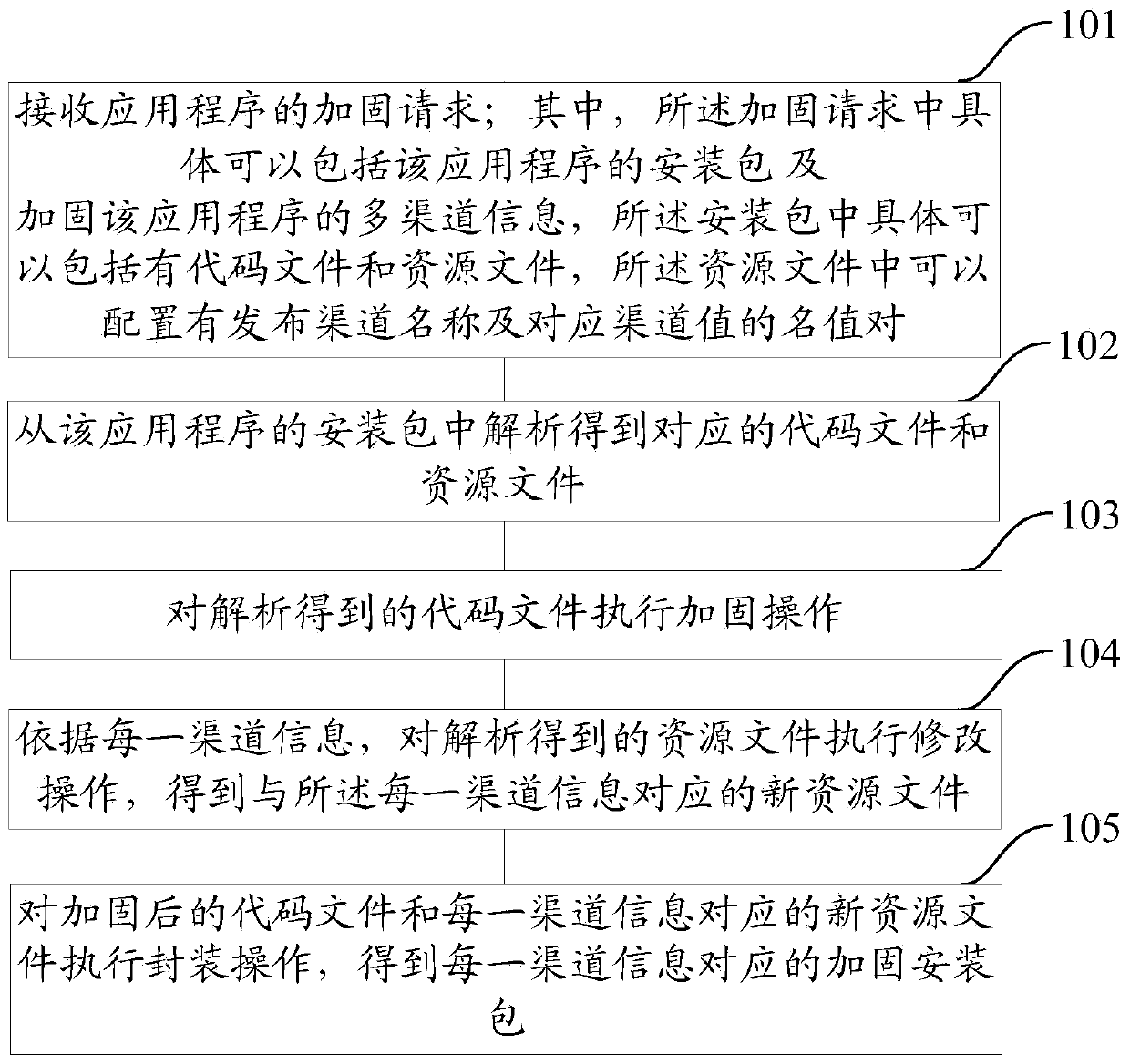

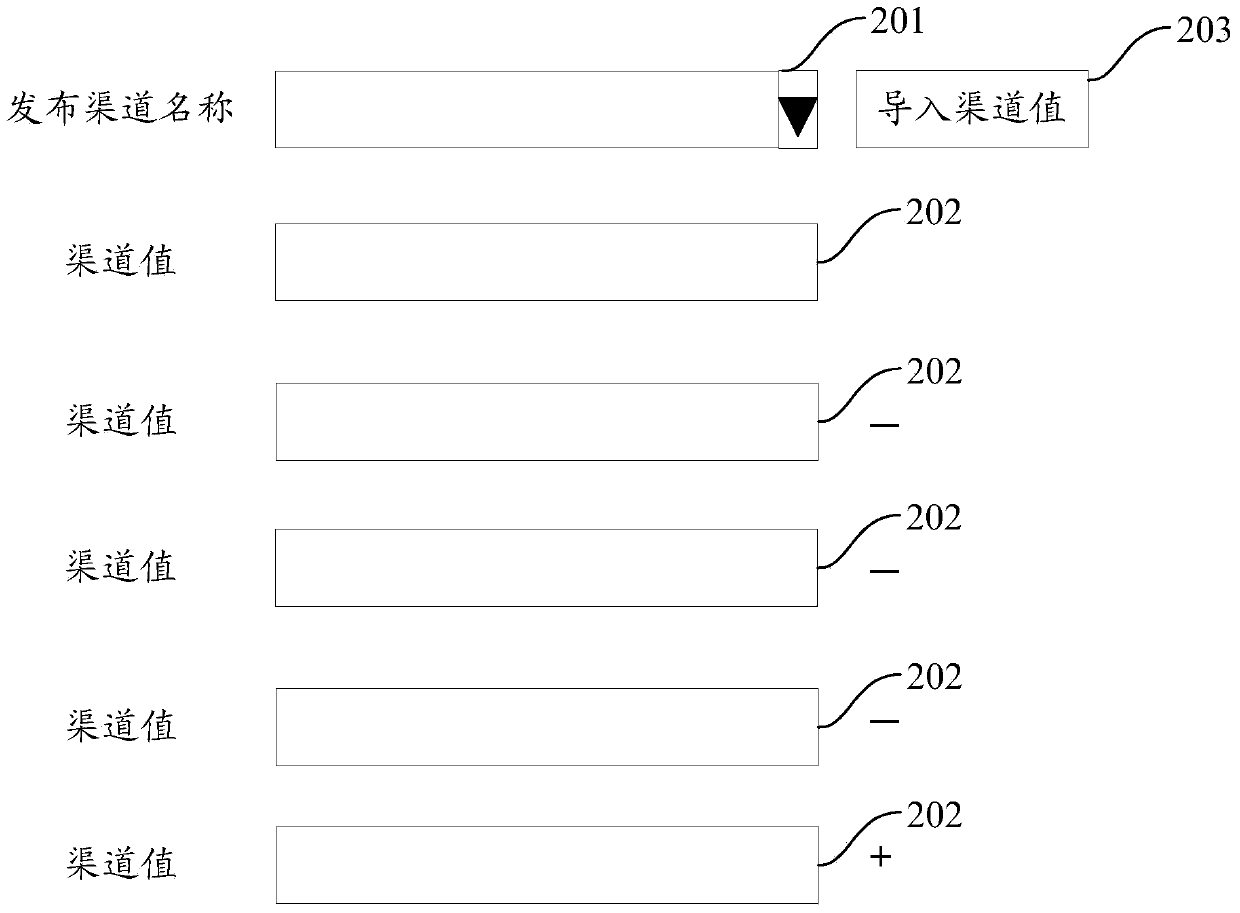

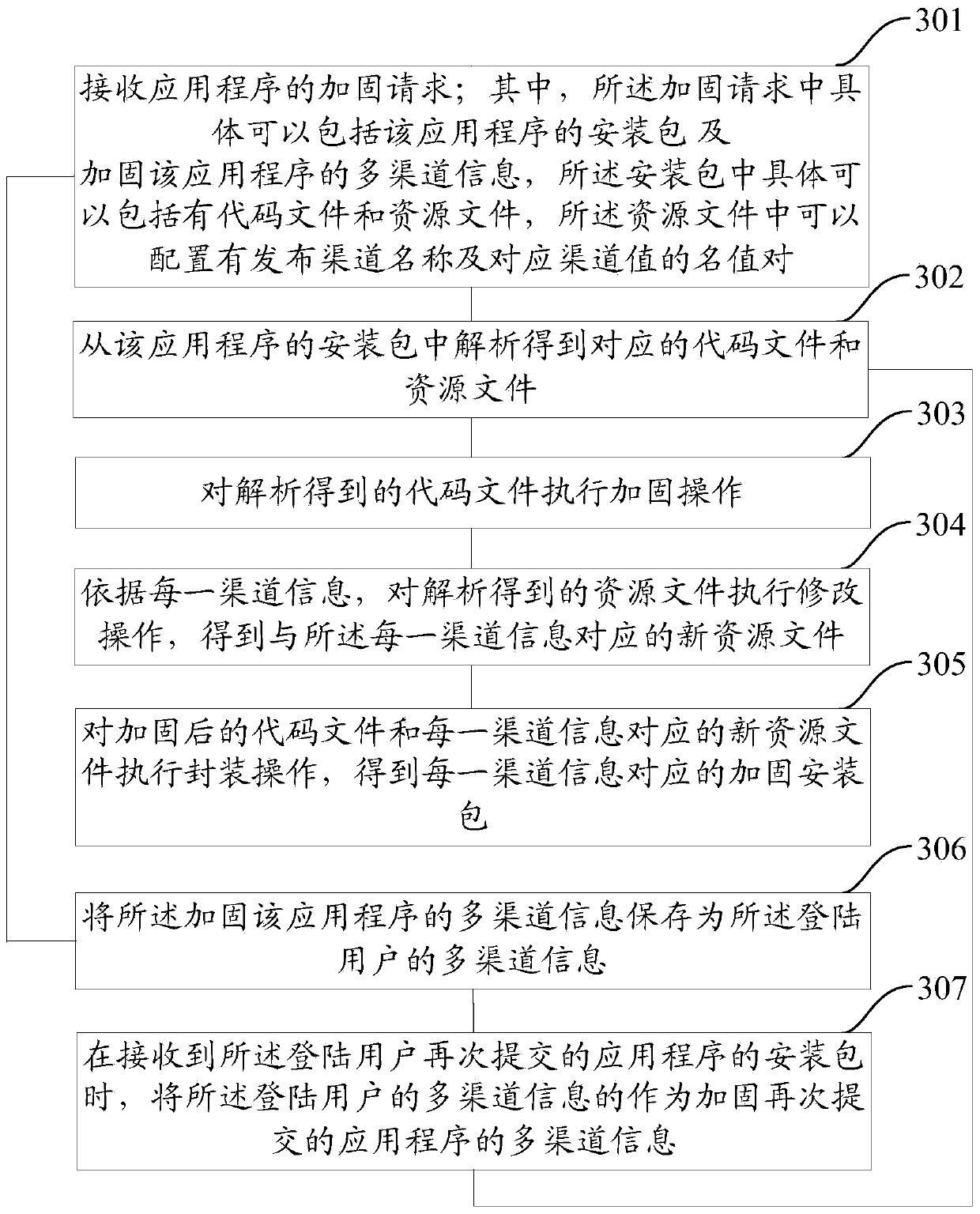

Method and device for reinforcing application program

ActiveCN104217140AImprove securityPrevent decompilationProgram/content distribution protectionOperating systemResource file

The embodiment of the invention provides a method and a device for reinforcing an application program. The method comprises the following steps of receiving a reinforcing request of the application program, wherein the reinforcing request comprises an installation package of the application program and multi-channel information for reinforcing the application program, the installation package comprises code files and resource files, and release channel names and corresponding channel values are configured in the resource files; analyzing to obtain corresponding code files and resource files from the installation package of the application program; executing reinforcing operation on the code files obtained through analysis; executing retouching operation on the resource files obtained through analysis according to each piece of channel information to obtain a new resource file corresponding to each piece of channel information; executing packaging operation on the reinforced code files and the new resource file corresponding to each piece of channel information to obtain a reinforced installation package corresponding to each piece of channel information. According to the method and the device, the safety of the application program can be improved and the efficiency of reinforcing multiple release channels is improved.

Owner:BEIJING QIHOO TECH CO LTD

Method of making dense composites of bulk-solidifying amorphous alloys and articles thereof

A method of making composites of bulk-solidifying amorphous alloys, and articles made thereof, containing at least one type or reinforcement material, wherein the composite material preferably comprises a high volume fraction of reinforcement material and is fully-dense with minimum porosity are provided.

Owner:CRUCIBLE INTPROP LLC

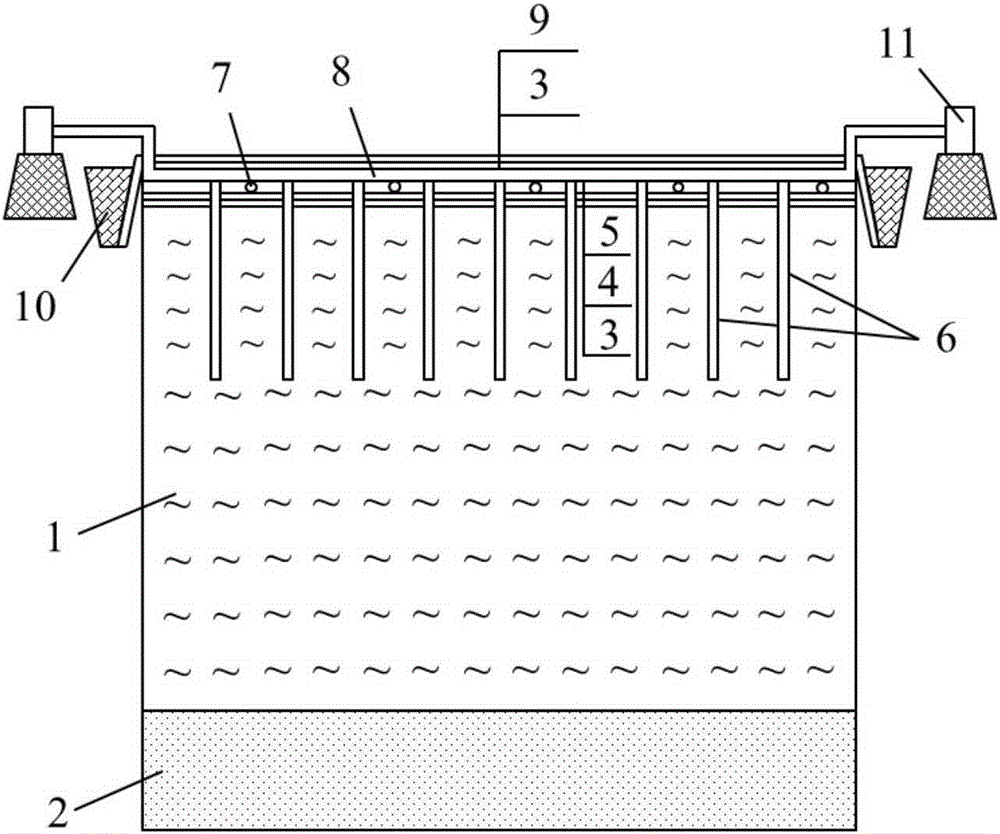

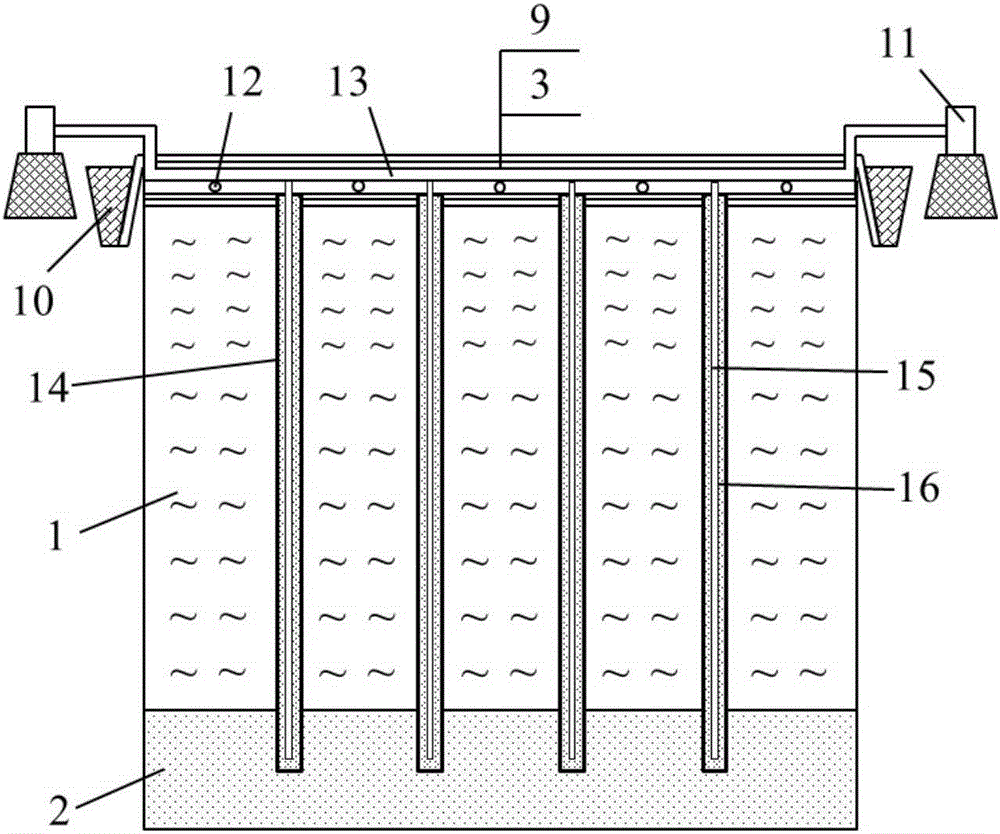

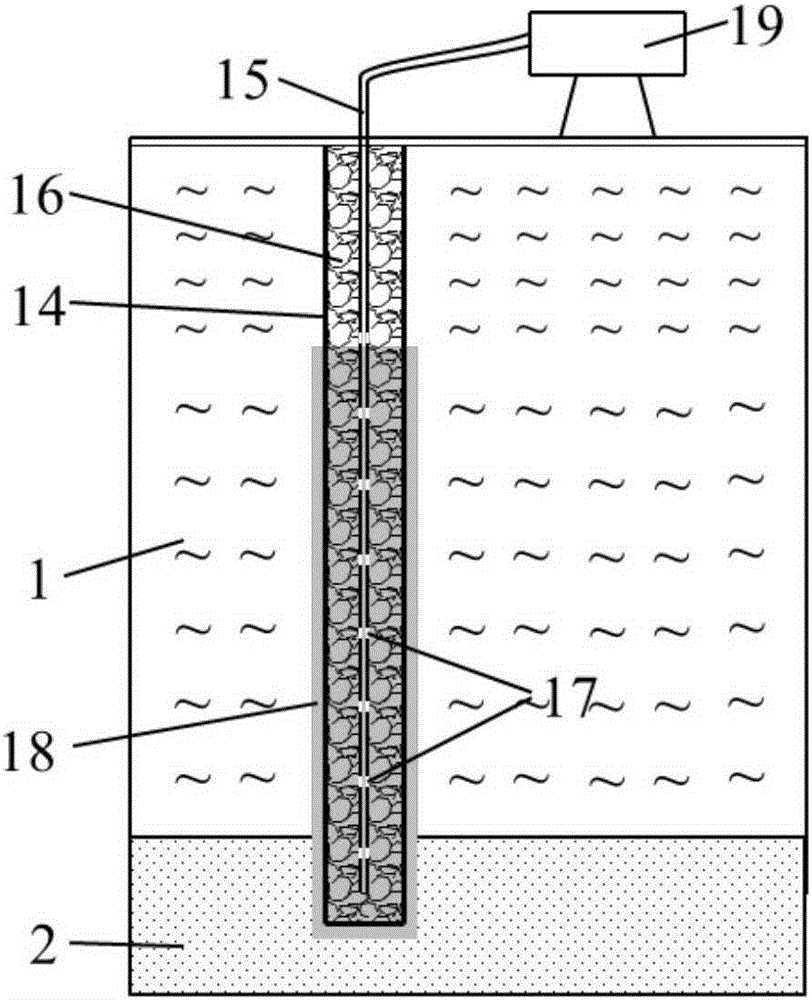

Method for treating soft soil foundation through combination of bagged grouting gravel pile and vacuum preloading

The invention provides a method for treating a soft soil foundation through combination of a bagged grouting gravel pile and vacuum preloading. The method comprises the steps that (1) shallow vacuum drainage pretreatment is conducted on the soft soil foundation to form a construction machinery work platform with a certain strength and bearing capacity; (2) bagged grouting gravel pile construction is carried out through an immersed tube method, and grouting tubes are embedded in the pile; (3) the bagged grouting gravel pile serves as a vertical drainage channel, and the deep soft soil foundation is treated through directly draining type vacuum preloading; and (4) grouting is conducted on the bagged grouting gravel pile through the embedded grouting tubes, the strength of a pile body is improved, and a rigid pile composite foundation is formed. By means of the method for treating the soft soil foundation through combination of the bagged grouting gravel pile and vacuum preloading, the purposes of economy and environmental protection are achieved, construction is easy and convenient, and a sand cushion is omitted; the method is applicable to treatment of a large-area ultra-soft clay foundation with the very high moisture content or a large-area new hydraulic fill mud foundation with the very high moisture content; the reinforcing efficiency is remarkable, the foundation treatment period can be substantially shortened, and the cost of construction is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Historic building timberwork beam-column system house composite strengthening method

The invention discloses a historic building timberwork beam-column system house composite strengthening method. The method comprises the steps that wooden columns are included. After transverse fiber cloth extend and are wound on the wooden columns, spiral fiber cloth on pasting columns are hooped on the transverse fiber cloth, beam columns are connected into a beam-column system through mortises and tenons, mortise-tenon joints of the beam columns are strengthened through the transverse fiber cloth pasted to wooden beams and the wooden columns and single-opening iron parts or double-opening iron parts hooped on the wooden columns, and the transverse fiber cloth is compacted and anchored on the wooden beams through the spiral fiber cloth pasted to the wooden beams and the single-opening iron parts or the double-opening iron parts. The strengthening defects of existing historic timberwork systems are overcome, the connection reliability of the fiber cloth and the wooden beams is ensured, the bearing capacity of the beam-column components and connection joints can be effectively improved, meanwhile, the repair principles of restoration of the old as the old, restoration of the building original forms and reversibility are met, and the method can be widely used for repair and strengthening of historic building timberwork beam-column systems.

Owner:SOUTHWEAT UNIV OF SCI & TECH

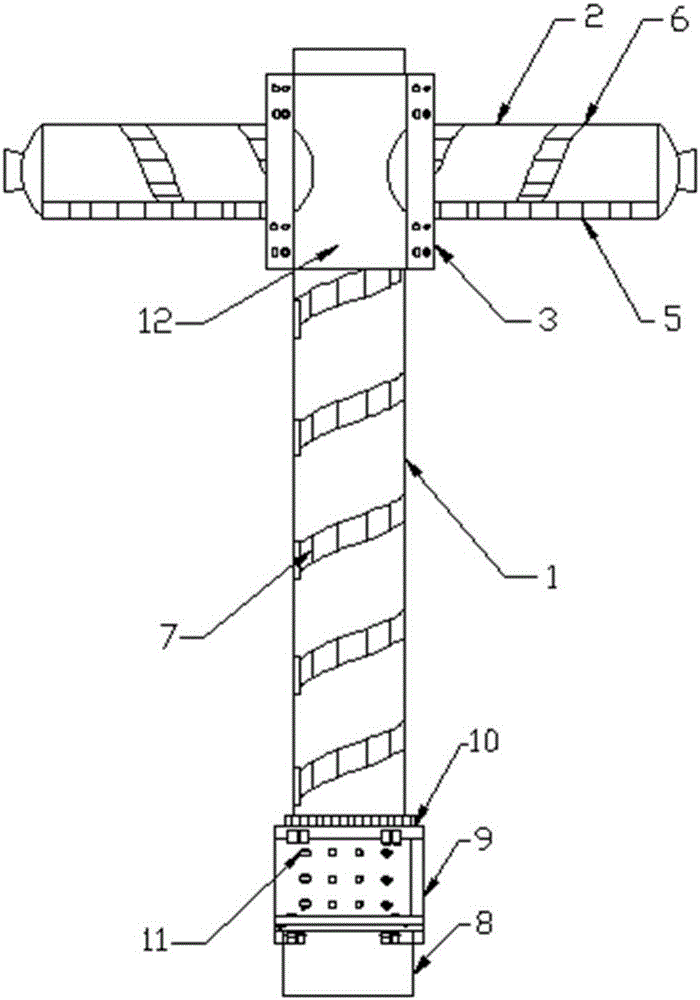

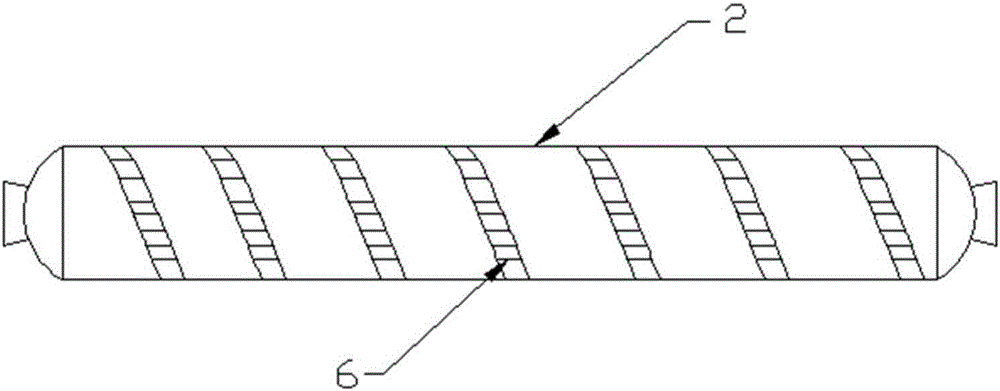

Variable-diameter multi-direction anchor pile

InactiveCN101649614ARapid enhancementImprove integrityBulkheads/pilesCement slurryStructural engineering

The invention provides a variable-diameter multi-direction anchor pile, which is an anchor body for reinforcing and supporting soft rock and soil in geotechnical engineering. As the bond force betweensoft rock-soil masses and the anchor body is limited, only grouting, rotary jet, stirring or anchor pull is not big in effect of improving the strength and stability of the soft rock-soil masses, lowin reinforcing speed, difficult to control reinforcing effect and the like, thus the application range of the soft rock-soil masses is often limited. Therefore, the variable-diameter multi-directionanchor pile is invented and has the specific characteristics that a soft rock-soil layer is drilled through special equipment, and cement slurry and other cementitious materials are sprayed to be mixed well with cut broken rock-soil masses; quick strengthener is added at the same time; stirring-rotating direction and rotary jet pressure are controlled; and a special anchor part is added so as to form a variable-diameter multi-direction anchor body. The diameter of the formed anchor pile can reach 300 to 15,000 millimeters.

Owner:SHANGHAI STRONG FOUND ENG

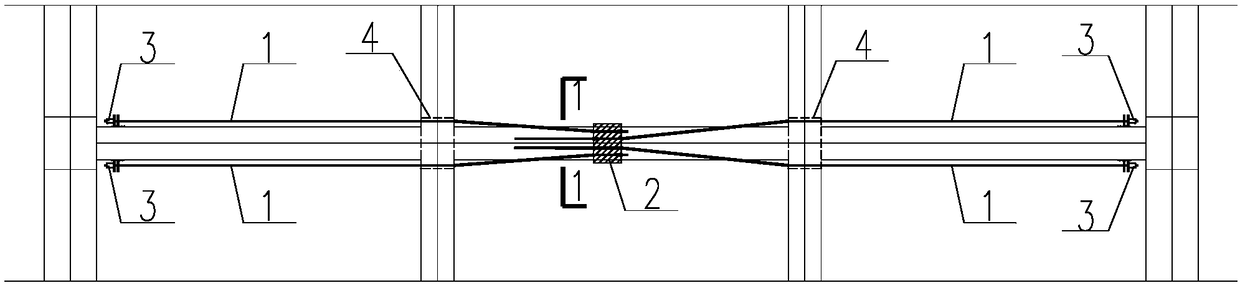

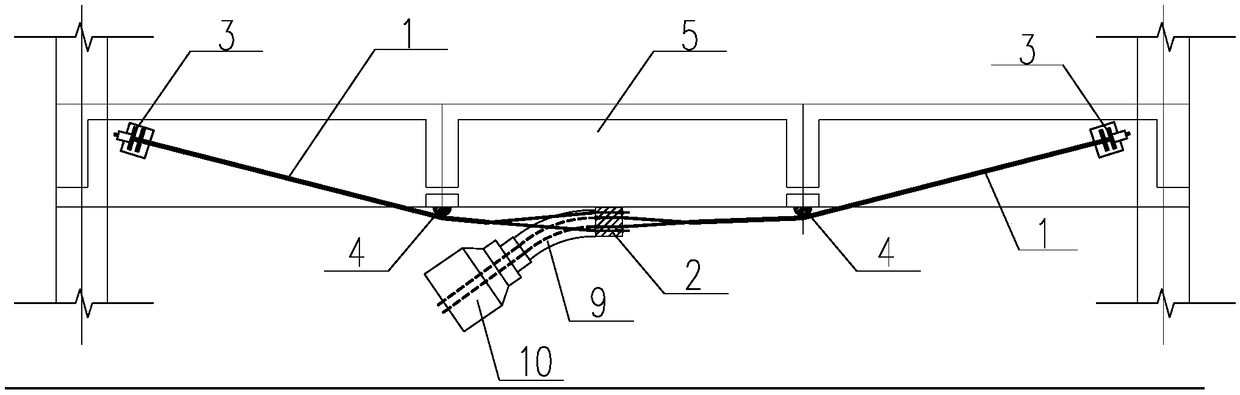

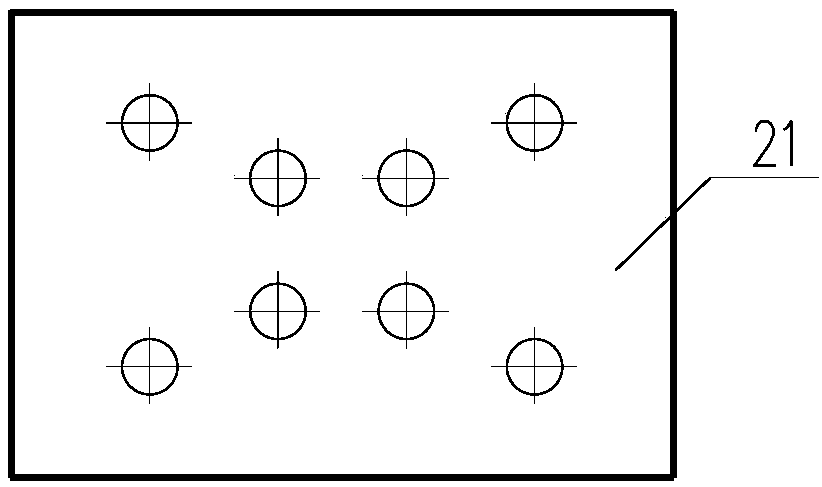

External prestressing reinforced concrete framework beam structure and construction method

PendingCN108708498AReduce in quantitySimple structureBuilding repairsGirdersReinforced concreteFloor slab

The invention provides an external prestressed reinforced concrete framework beam structure and a construction method thereof, which belong to the technical field of construction engineering. The structure comprises at least two groups of external prestressed tedons, a tension end structure, a fixed end structure and a steering apparatus. The tension end structure is located below the bottom of amiddle beam of each span of the framework-crossing beam, each group of the external prestressed tedons pernerates through the tension end structure in the middle of a span after being directionally changed by the respective steering apparatus, and the tension end structure adopts an annular anchorage device to join and stretch the two groups of external prestressed tedons; and the tension end structure is only arranged below the bottom of the middle beam of each span of the framework beam, so that the number of the tension end structure can be effectively reduced. In addition, the tension endstructure is arranged below the bottom of each span of the framework beam, so that not only can the occupation of an application space on a floor or a roof be avoided, but also when in the external prestressing installation construction, a floor slab or a roof slab does not need to be perforated; and moreover, when the external prestressed tedon is loosened when in use, the prestressed tedon can be subjected to supplementary tension or replacement.

Owner:SHANGHAI CONSTRUCTION GROUP +1

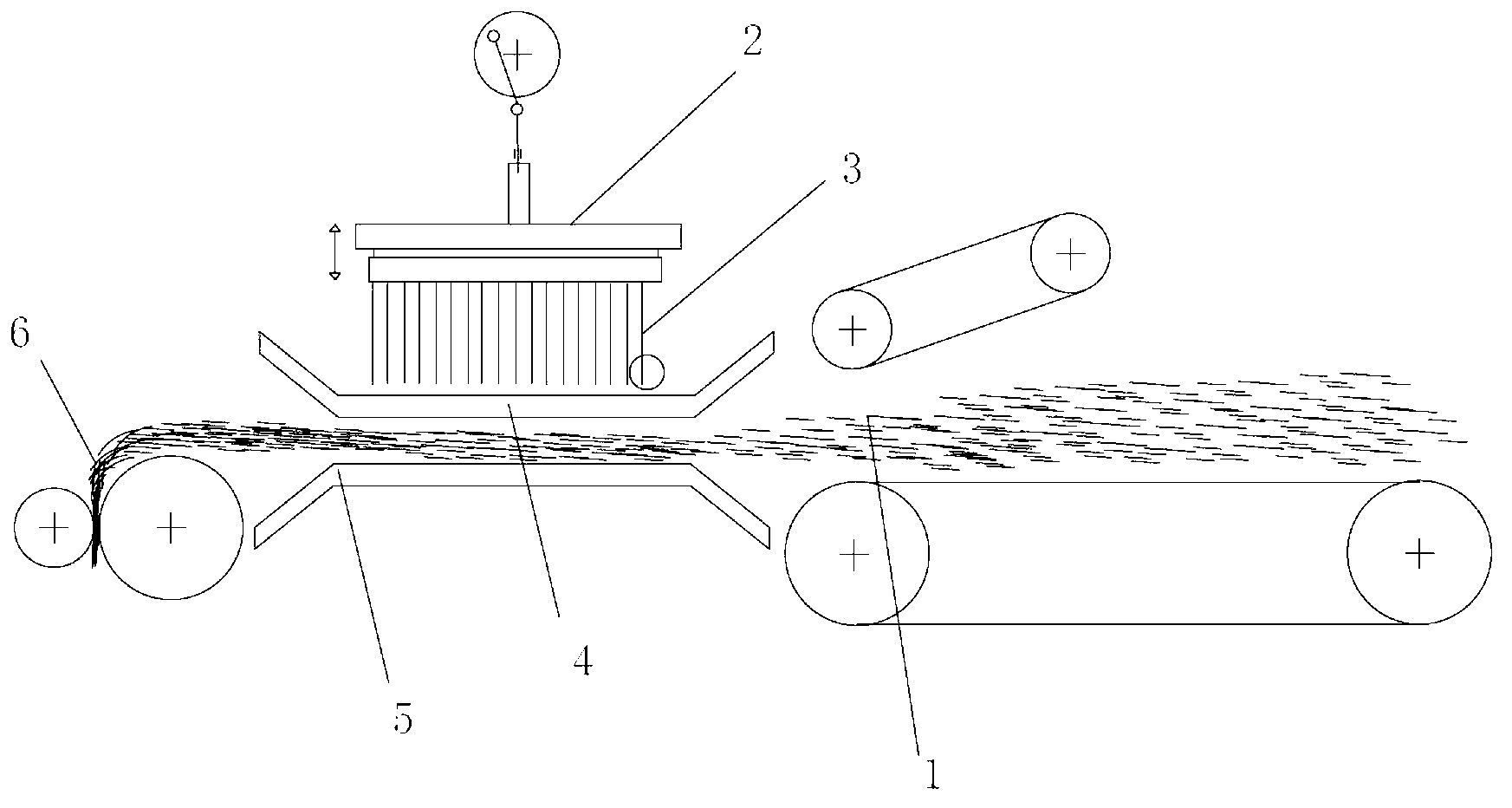

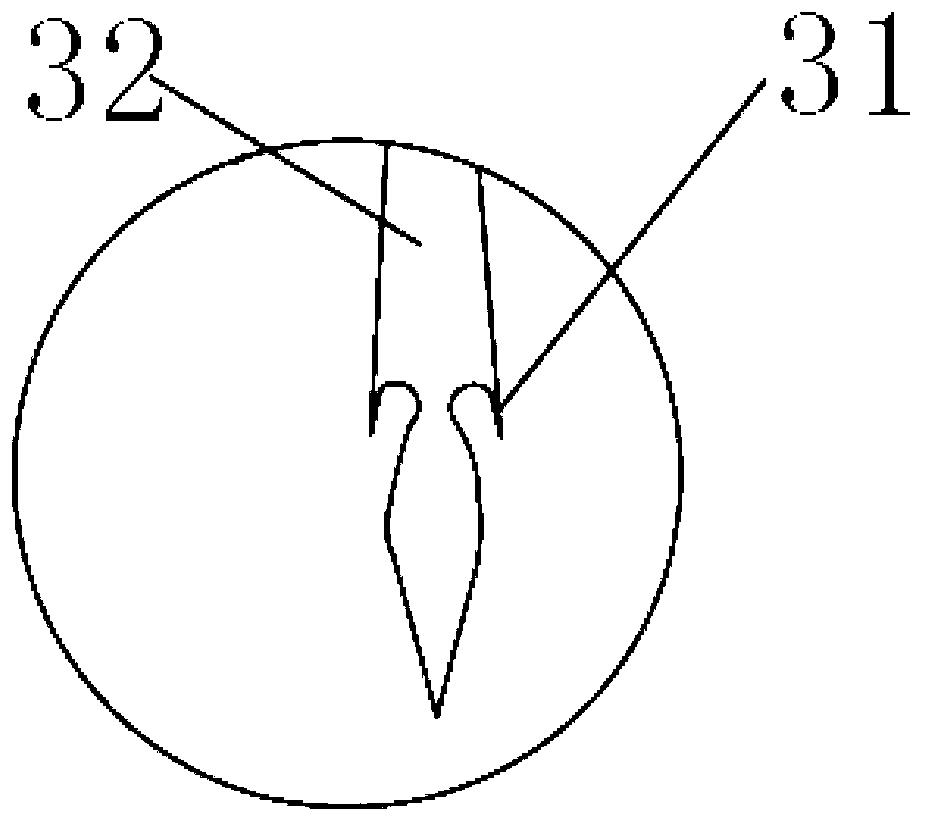

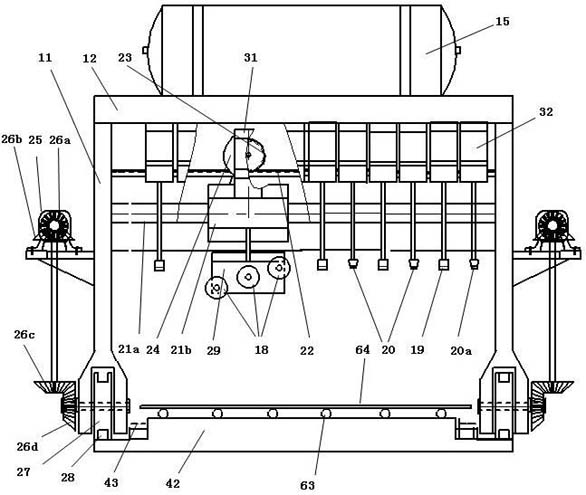

Manufacturing method and special needling equipment for collagen fiber regenerated bark

InactiveCN103233322ASimple processReduce manufacturing costNeedling machinesState of artVolumetric Mass Density

The invention relates to a manufacturing method for collagen fiber regenerated bark, which comprises the steps of dissolving fiber, lapping, needling, cutting edge, rolling, packaging and the like in sequence, wherein the needling process is carried out in a special needling machine or a special needling machine unit; 1 to 3 hooked stabs are arranged on each pricking needle of the special needling machine; the included angle between each hooked stab and each pricking needle is 5 to 32 degrees; the pricking needle density is 50 to 200 pricking needles per square meter; 2 to 5 times of needling treatments of the fibre web are carried out during the needling process; the density of the needles is gradually improved in the needling process carried out in sequence; and needle handles of the pricking needles turn thinner in sequence. Compared with the prior art, the manufacturing method for collagen fiber regenerated bark, provided by the invention, has the advantages that the technology is simple; the equipment cost is low; and the gained regenerated bark is stable in property, high in strength, and is not easy to be damaged. The invention further relates to the special needling machine and the special needling machine unit used for manufacturing collagen fiber regenerated bark.

Owner:JIANGYIN JUNHUA TEXTILE TECH

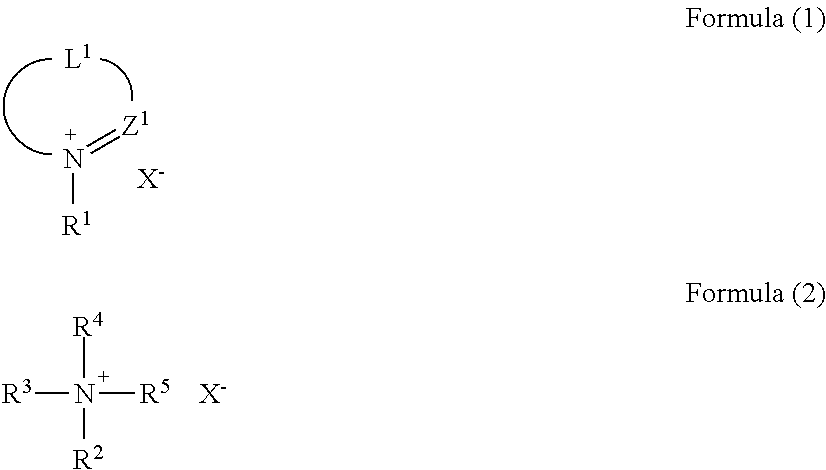

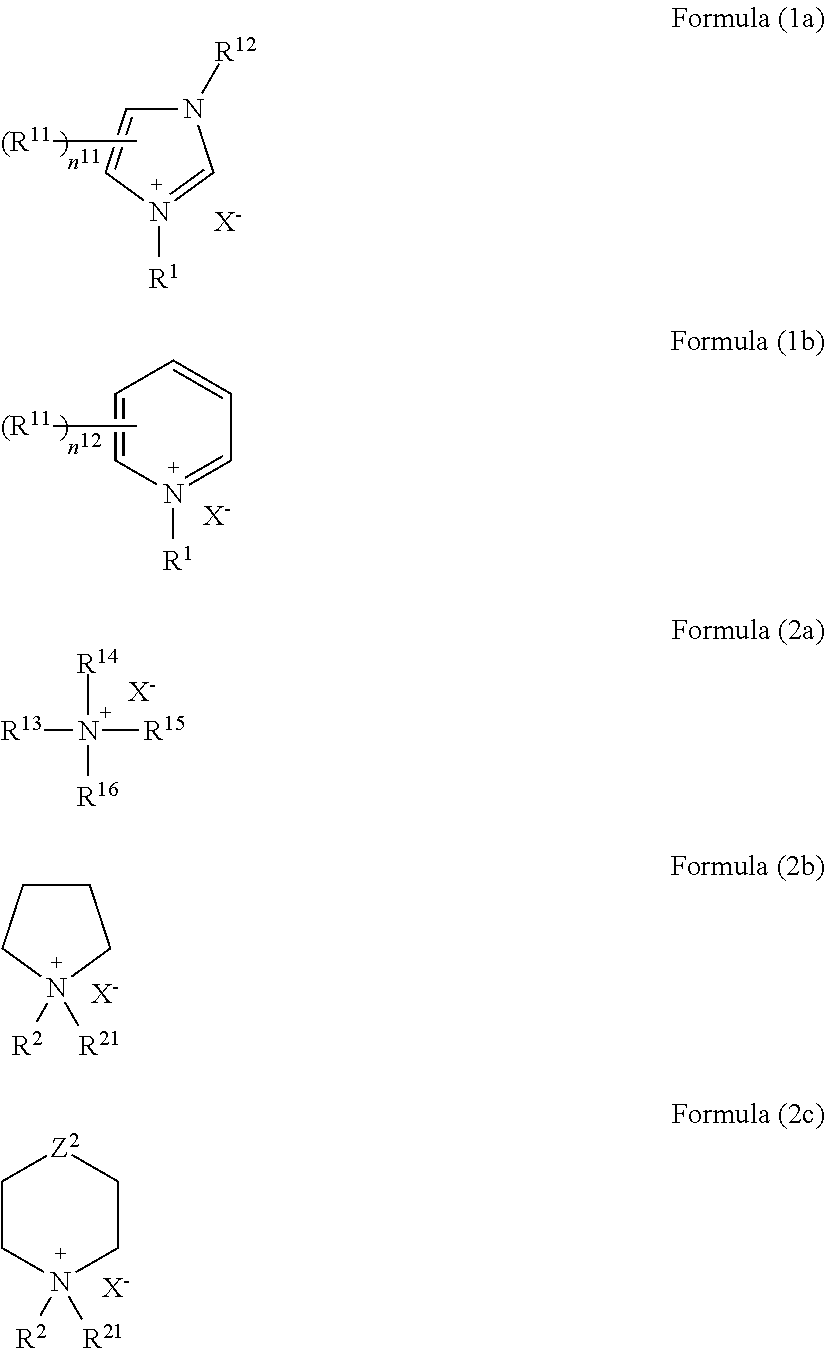

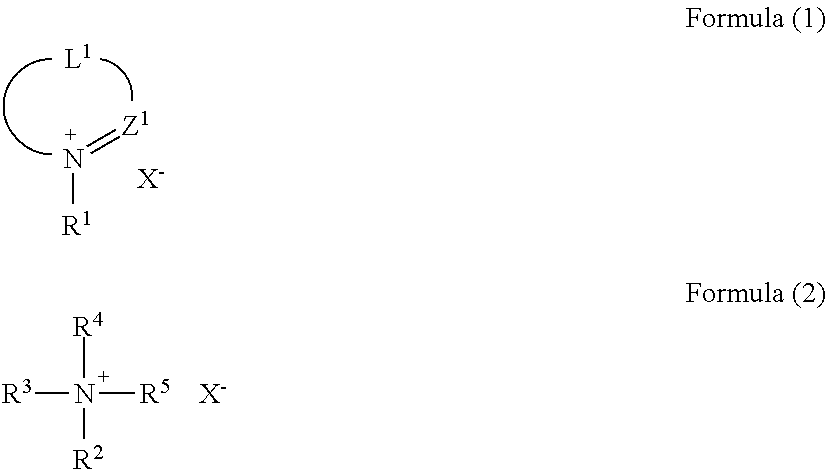

Thermoplastic resin composition, method of producing thermoplastic resin composition, molded article of cellulose-reinforced resin, and method of producing molded article of cellulose-reinforced resin

A thermoplastic resin composition, containing a thermoplastic synthetic resin, a cellulose and an ionic compound; in which a content of the cellulose is from 1 to 100 parts by mass, with respect to 100 parts by mass of the thermoplastic synthetic resin, and a content of the ionic compound is 0.001 times or more and less than 1.000 time of the content of the cellulose;a method of producing a thermoplastic resin composition;a molded article of a cellulose-reinforced resin; anda method of producing a molded article of a cellulose-reinforced resin.

Owner:FURUKAWA ELECTRIC CO LTD

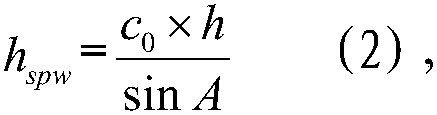

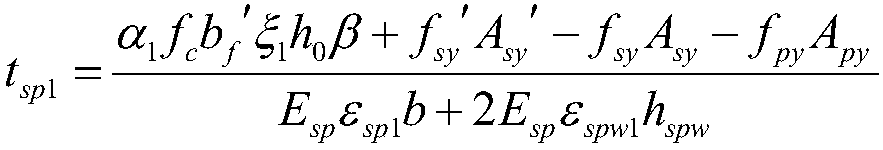

Design method for unbonded prestress and steel-concrete combined reinforcement of concrete box girder

ActiveCN106120574AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSteel jacketPre stress

The invention discloses a design method for unbonded prestress and steel-concrete combined reinforcement of a concrete box girder. The design method comprises the following steps of I, determining a combined reinforcing structure: determining the unbonded prestress and steel plate-concrete combined structure of the box girder to be reinforced wherein the combined reinforcing structure comprises a steel jacket box formed by a base steel pate, two longitudinal side steel plates and two end part plugging steel plates, and a plurality of unbonded prestressed reinforcing bars are arranged in the steel jacket box; II, determining structural parameters for reinforcing the front box girder; and III, determining structural parameters of the combined reinforcing structure in the process comprising the following steps of initializing the parameters, calculating theoretical maximum thickness of the reinforcing steel plates, determining the thickness of the reinforcing steel plates and the thickness of concrete, and determining the height of the longitudinal side steel plates and the width of the base steel plate. The method disclosed by the invention is simple in steps, reasonable in design, convenient to realize, and good in using effect, the structural parameters of the combined reinforcing structure of a bridge can be simply, conveniently and quickly determined, and the designed combined reinforcing structure of the bridge is economical and practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

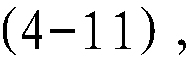

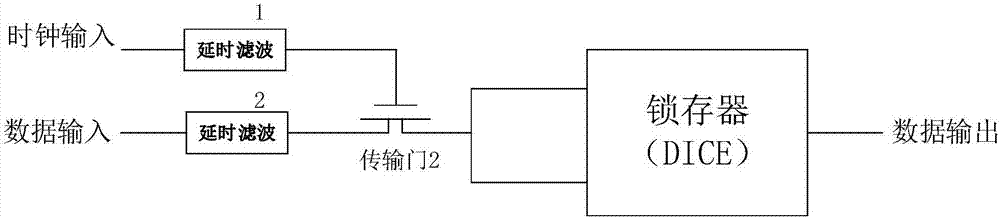

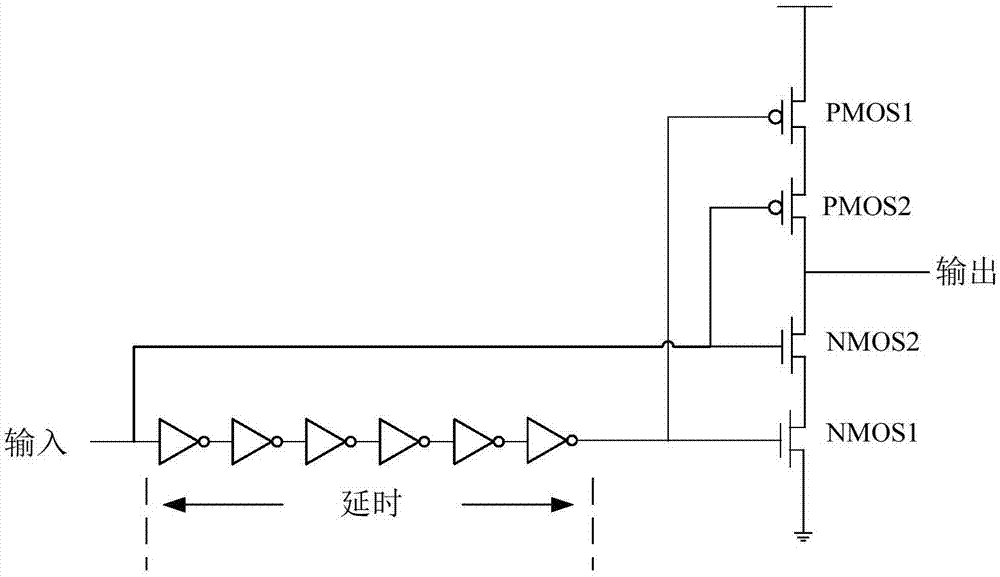

Single event transient disturbance reinforced latch circuit

InactiveCN107124176ADoes not affect the working frequencySimple structureReliability increase by circuit redundancyEngineeringOperating frequency

The invention relates to a single event transient disturbance reinforced latch circuit and belongs to the field of circuit design. The single event transient disturbance reinforced latch circuit comprises a first lowpass filter unit and a latch. First way data input of a data input end is connected with a first input end of the latch. Second data input of the data input end is connected with a second input end of the latch through the first lowpass filter unit. The first lowpass filter unit is a circuit unit which is composed of a passive device and is used for removing a high-frequency signal. The first lowpass filter unit for removing the high-frequency signal is composed of the passive device, the filter capacity only needs to be greater than the maximum pulse width produced by single event transient disturbance, the working frequency of the latch circuit is not influenced, and a circuit structure is simple. The passive device itself does not produce the single event transient disturbance and an area and the power consumption of a storage unit are not increased, so the single event effect resistance of logic circuits such as the latch and a trigger can be effectively improved.

Owner:58TH RES INST OF CETC

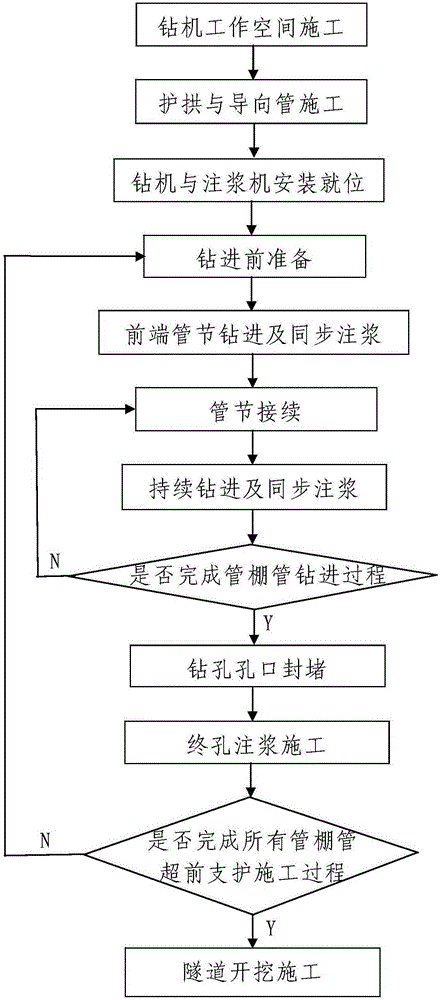

Advance support construction method for high-strength pipe shed of tunnel

InactiveCN105201517AShort construction periodImprove construction efficiencyUnderground chambersTunnel liningDrill holeHigh intensity

The invention discloses an advance support construction method for a high-strength pipe shed of a tunnel. A process for carrying out advance support construction on a pipe shed of one segment of a constructed tunnel comprises the following steps: (1) constructing support arches and guide pipes; (2) installing a drilling machine and a grouting machine in place; (3) carrying out advance support construction on the pipe shed: (301) preparing before drilling; (302) drilling pipe joints at front ends and synchronously grouting; (303) connecting the pipe joints; (304) continuously drilling and synchronously grouting; (305) repeating the steps (303) and (304) many times until the drilling processes of pipes of the current constructed pipe shed are finished; (306) blocking drill holes; (307) carrying out grouting construction on final holes; (308) repeating the steps (301) to (307) many times until all advance support construction processes of the pipes of the pipe shed are finished; and (4) carrying out excavation construction on the tunnel. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient in construction and good in support effect; and by adopting automatic drilling type high-strength pipes of the pipe shed, the advance support process of the tunnel can be simply, conveniently and quickly finished.

Owner:CHINA RAILWAY 20 BUREAU GRP

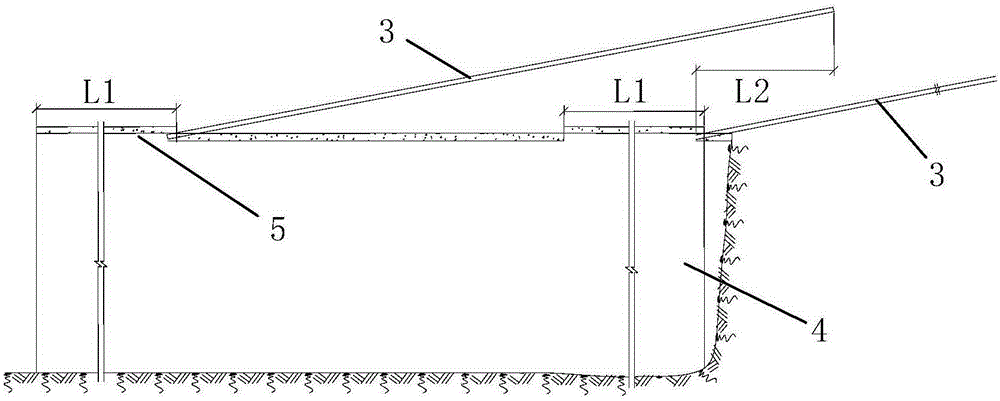

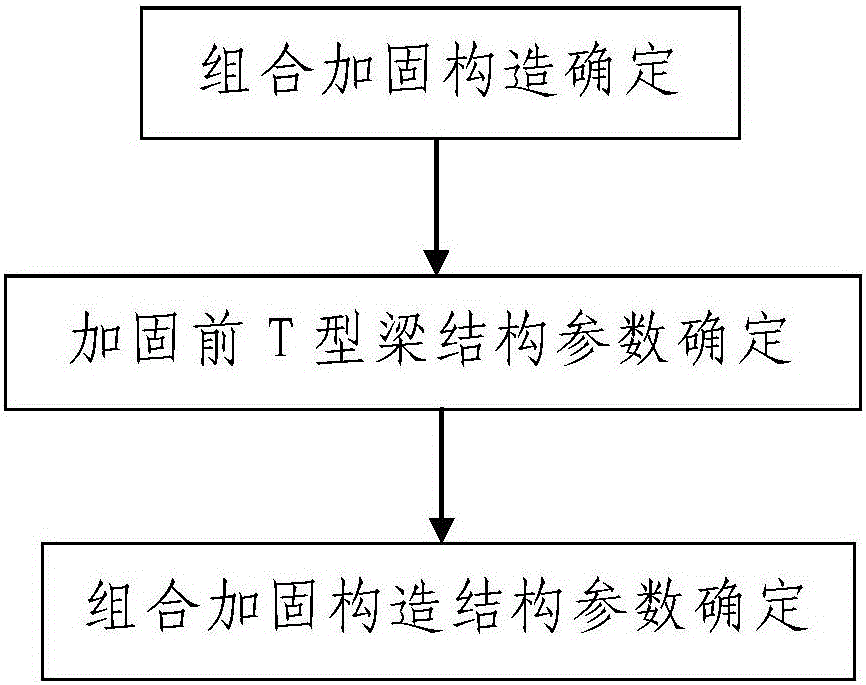

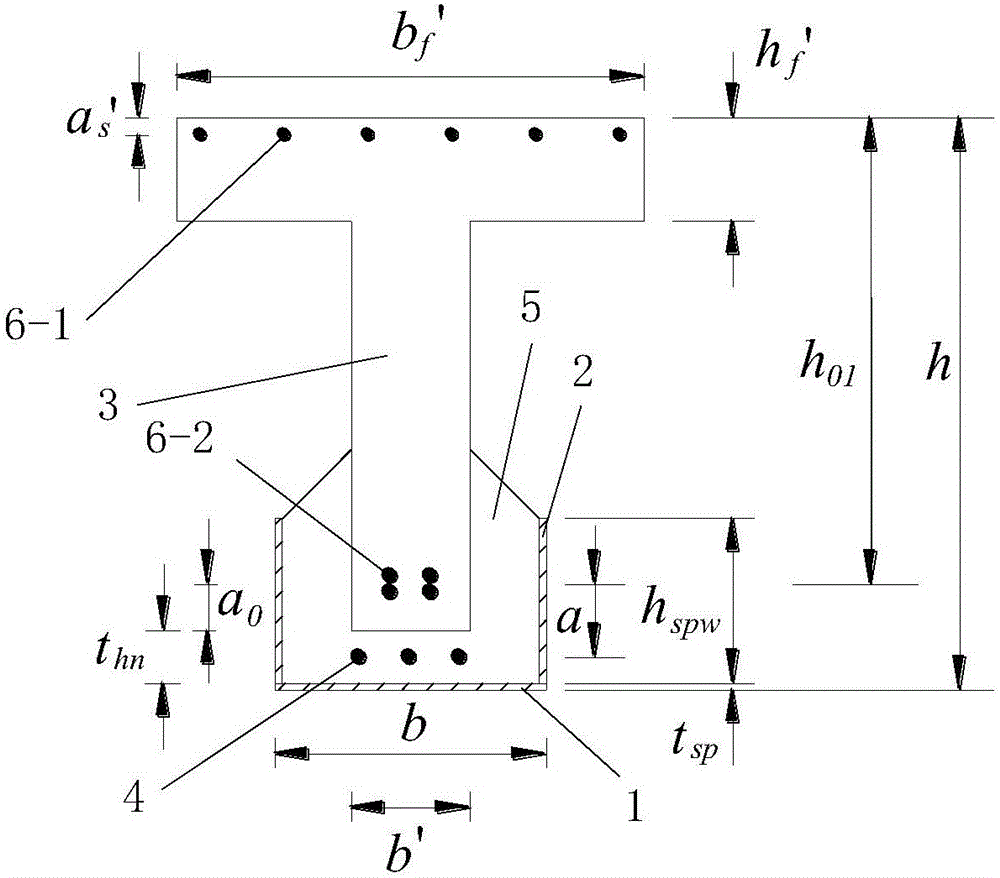

Unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams

ActiveCN105839551AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningRebarSteel plates

The invention discloses an unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams. The unbonded prestress and steel-concrete composite reinforcement design method includes steps of firstly, determining unbonded prestress and steel plate-concrete composite reinforcement structures for the reinforcement T-shaped beams; secondly, determining structural parameters of the T-shaped beams prior to reinforcement; thirdly, determining structural parameters of the composite reinforcement structures, to be more specific, initializing the parameters, computing the maximum theoretical thicknesses of reinforcement steel plates, determining the thicknesses of the reinforcement steel plates and the thickness of concrete and determining the heights of longitudinal side steel plates and the widths of bottom steel plates. Each composite reinforcement structure comprises the corresponding bottom steel plate, the two longitudinal side steel plates and a steel bushing case, each steel bushing case comprises two end blocking steel plates, and a plurality of unbonded prestress reinforcing steel bars are arranged in each steel bushing case. The unbonded prestress and steel-concrete composite reinforcement design method has the advantages that the steps are simple, the unbonded prestress and steel-concrete composite reinforcement design method is reasonable in design and convenient to implement, good service effects can be realized, the structural parameters of the bridge composite reinforcement structures can be easily, conveniently and quickly determined, the bridge composite reinforcement structures designed by the aid of the unbonded prestress and steel-concrete composite reinforcement design method are economical and practical, and good reinforcement effects can be realized by the bridge composite reinforcement structures.

Owner:XIAN HIGHWAY INST

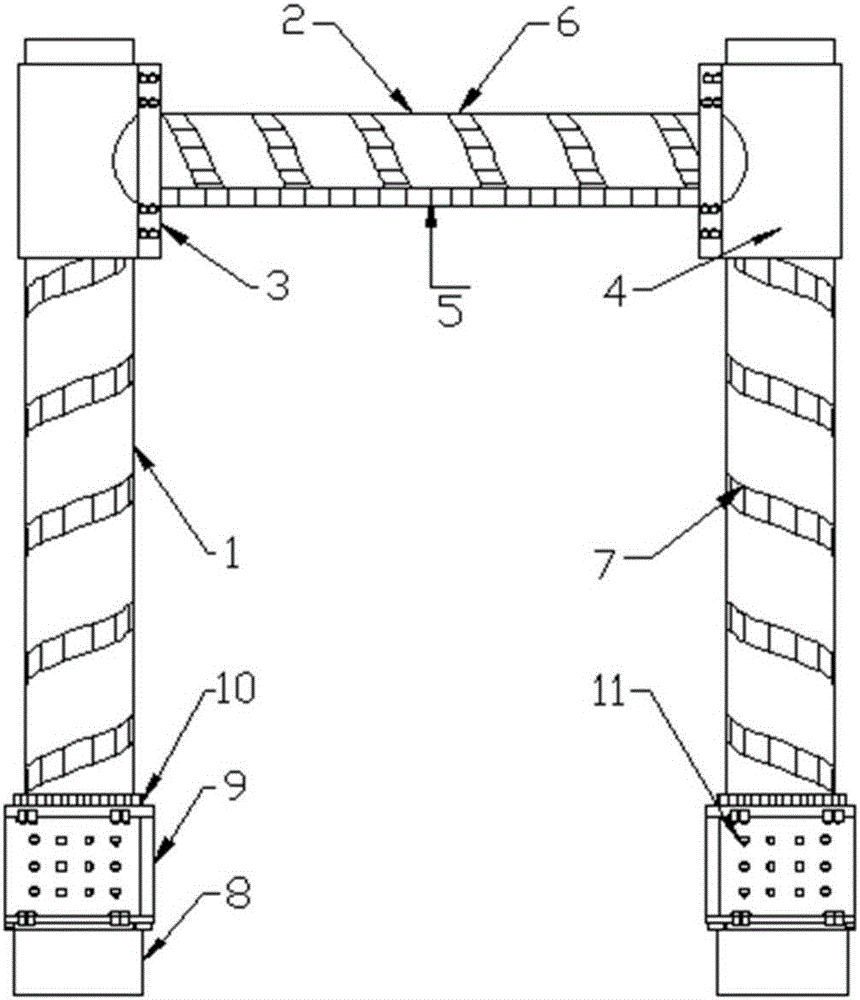

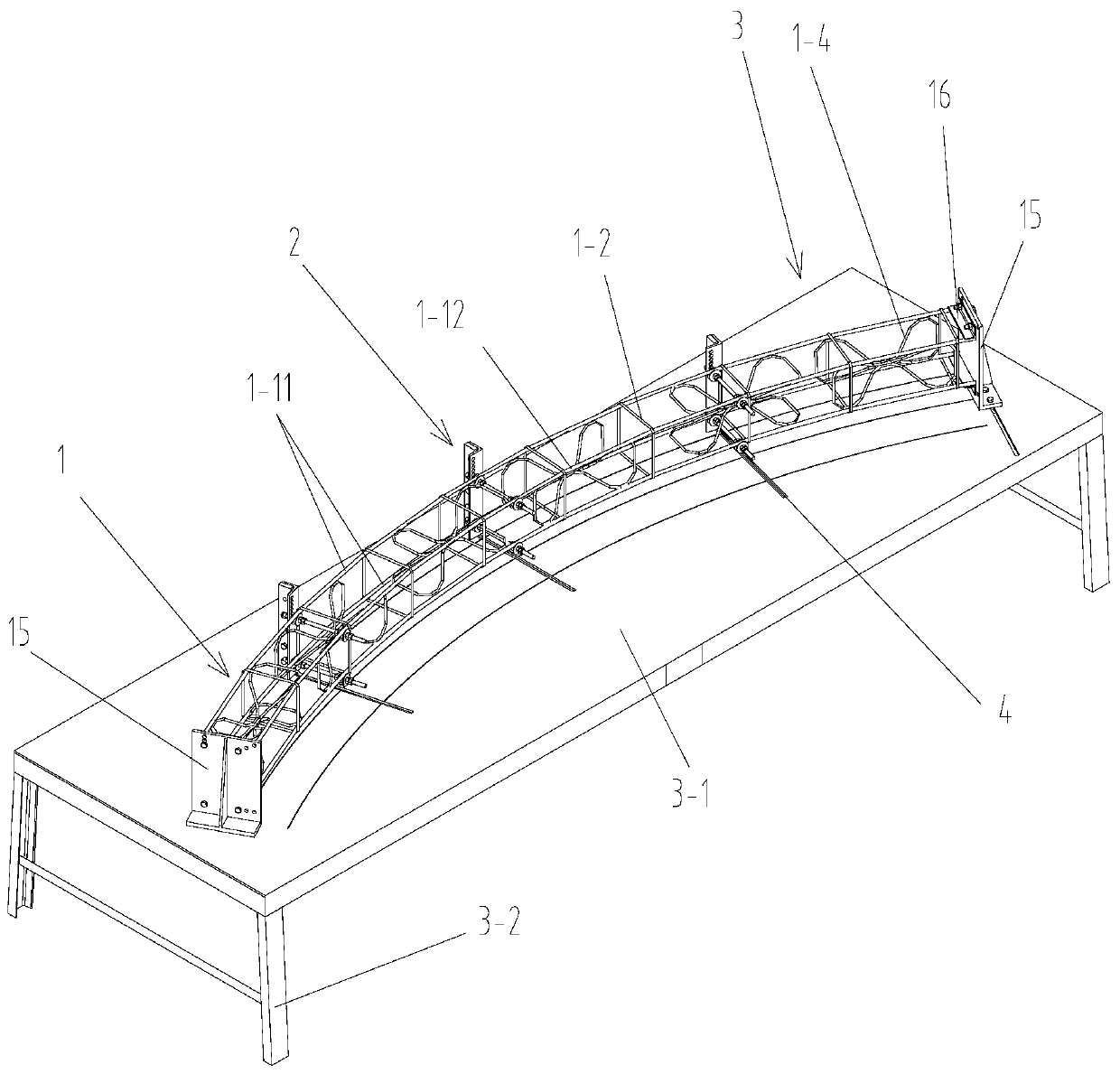

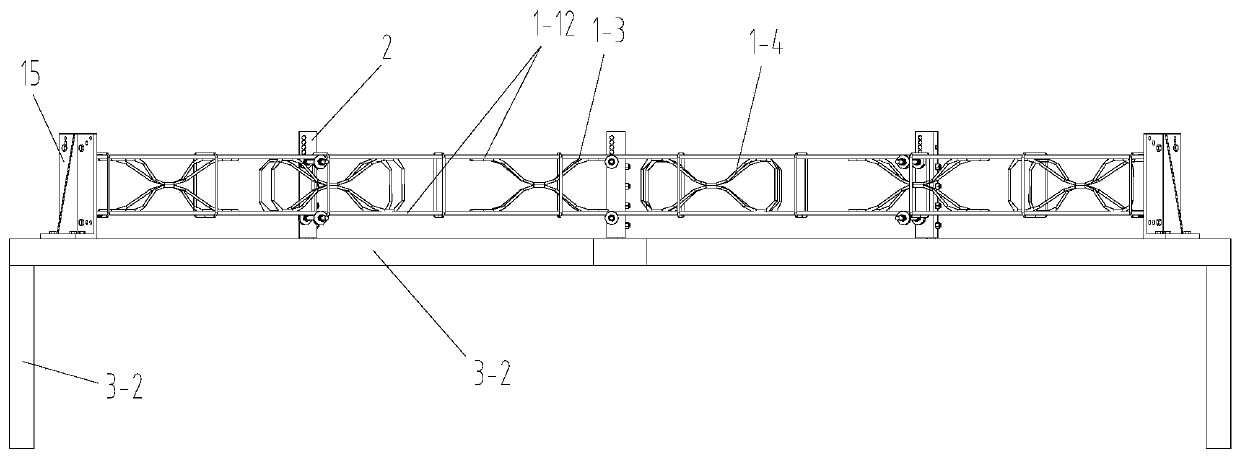

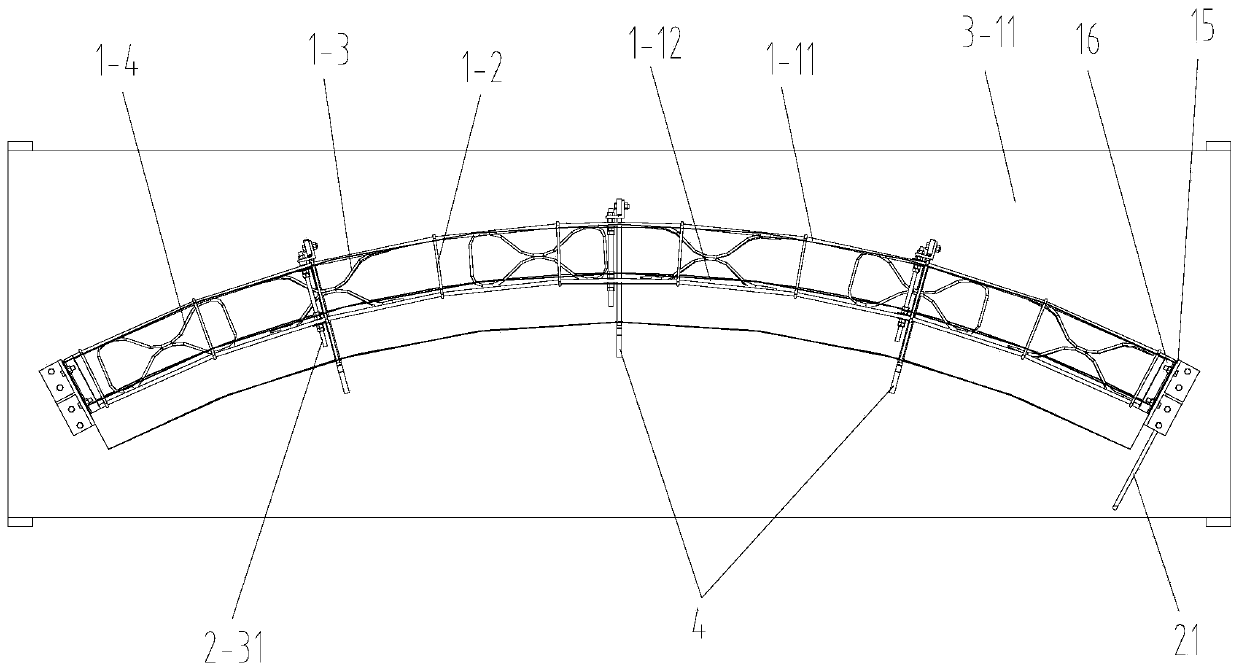

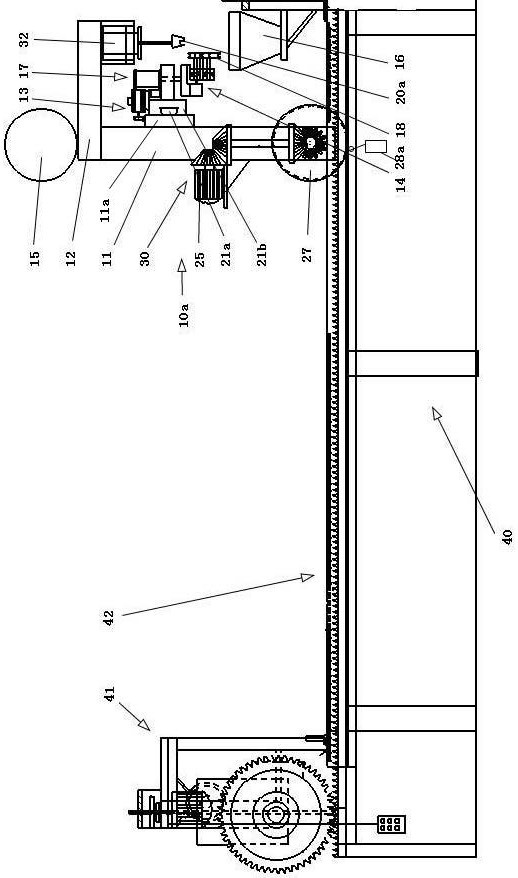

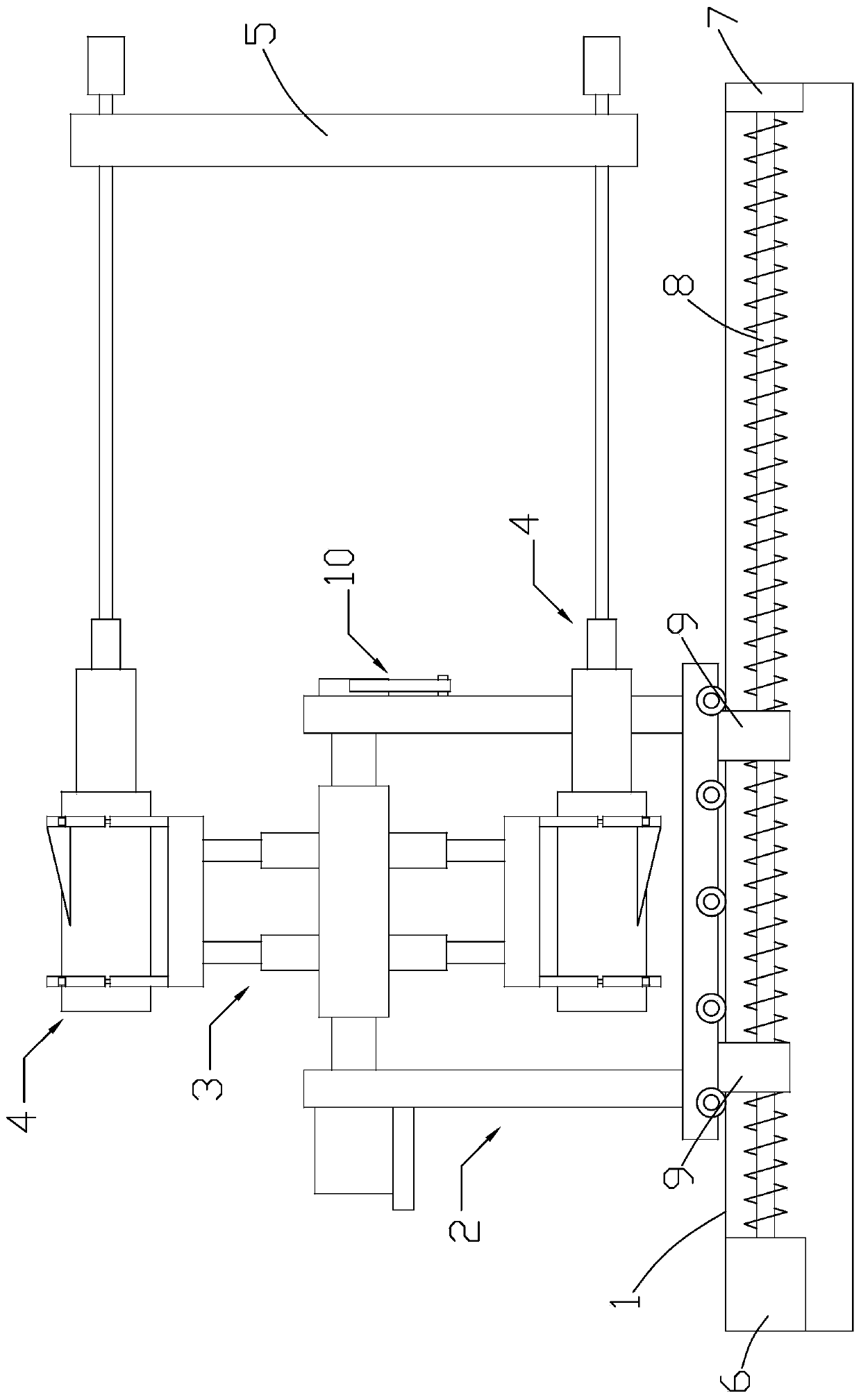

Rapid machining platform and method for grid steel frames

PendingCN110744219ASimple structureReasonable designUnderground chambersWelding/cutting auxillary devicesSteel frameRapid tooling

The invention discloses a rapid machining platform and method for grid steel frames. The machining platform comprises a horizontal support platform and a plurality of main reinforcement positioning moulds, wherein the plurality of main reinforcement positioning moulds are laid in the circumferential direction and all mounted on the horizontal support platform; the plurality of main reinforcement positioning moulds form a main reinforcement positioning device for positioning four main reinforcements in a to-be-machined steel frame segment; and each main reinforcement positioning mould comprisesa sliding seat, a connection seat and a main reinforcement positioning mechanism. The method comprises the steps of 1, adjusting the main reinforcement positioning mechanisms; 2, adjusting the positions of the main reinforcement positioning moulds; 3, mounting the main reinforcements; 4, fixing dowels of the main reinforcements; and 5, fixing rectangular stirrups. The machining platform and method are reasonable in design, simple and convenient in strengthening and good in using effect; and the plurality of movable main reinforcement positioning moulds are adopted to position the steel framesegments and the main reinforcement positioning mechanism on each main reinforcement positioning mould can be adjusted according to the widths and thicknesses of the machined steel frame segments, sothat the machining demands of the steel frame segments with different specifications can be satisfied.

Owner:CHINA RAILWAY 20 BUREAU GRP

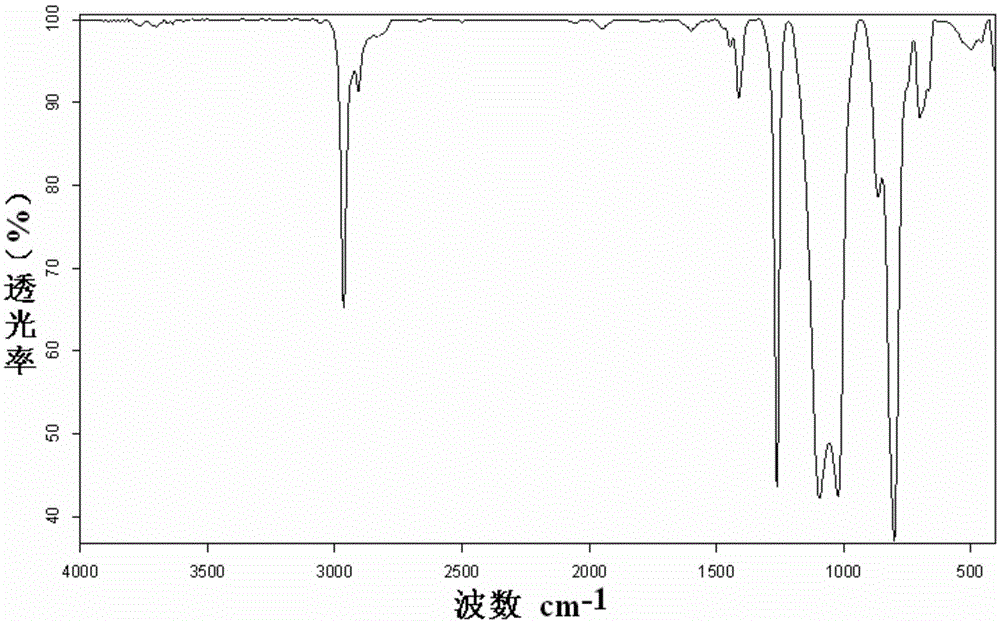

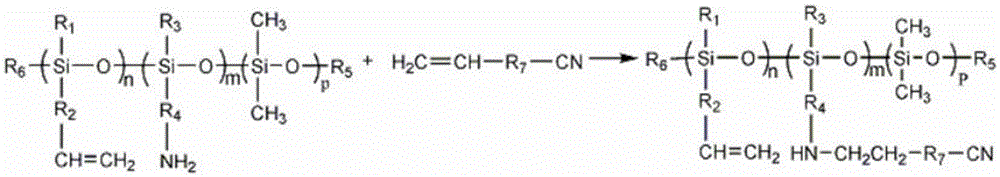

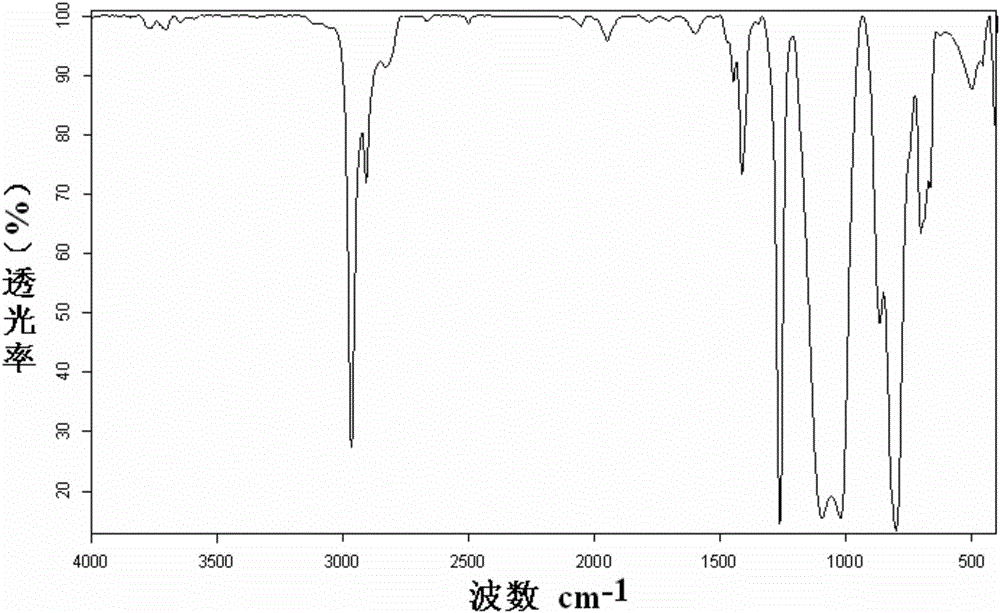

Synthesis method of high molecular weight polysiloxane containing nitrile group and vinyl at the same time and preparation method of addition type heat vulcanized nitrile silicone rubber

The invention relates to a synthesis method of high molecular weight polysiloxane containing nitrile group and vinyl at the same time and a preparation method of addition type heat vulcanized nitrile silicone rubber. The high molecular weight polysiloxane containing nitrile group and vinyl at the same time is prepared by performing amino group and double bond addition reaction on polysiloxane containing amino group and vinyl at the same time and compound containing unsaturated bonds and nitrile group. The addition type heat vulcanized nitrile silicone rubber is prepared through the synthesized high molecular weight polysiloxane containing nitrile group and vinyl at the same time. The synthesis method is simple and controllable, and high in synthesis efficiency; as the synthesized polysiloxane containing nitrile group and vinyl at the same time contains nitrile groups, the polarity and solubility parameters of polysiloxane are changed, and the prepared addition type heat vulcanized nitrile silicone rubber can have the performance of solvent oil resistance, and can be applied to various oil resistance and low temperature resistance places.

Owner:SHANDONG UNIV

Synthesis of siloxane containing nitrile group and vinyl group at same time and preparation method of room-temperature addition type nitrile silicone rubber

ActiveCN105778105AGood storage stabilityReduces prone to yellowingGroup 4/14 element organic compoundsSynthesis methodsRoom temperature

The invention relates to synthesis of siloxane containing nitrile group and vinyl group at same time and a preparation method of room-temperature addition type nitrile silicone rubber. The siloxane containing the nitrile group and the vinyl group is prepared from the siloxane containing amino group and the vinyl group at the same time, and a vinyl-group-containing compound with unsaturated bonds through an addition reaction of the amino group and the double bonds; the synthesized siloxane containing the nitrile group and the vinyl group at same time is used for preparing the room-temperature addition type nitrile silicone rubber. The synthesis method is simple and controllable, and high in synthesis efficiency. The synthesized siloxane containing the nitrile group and the vinyl group at same time contains the vinyl group so that the polarity and the dissolvability parameters of the siloxane are improved; the room-temperature addition type nitrile silicone rubber prepared from the siloxane containing the nitrile group has a property of resisting solvent oil and can be widely applied to various oil-resisting and low-temperature-resisting fields.

Owner:SHANDONG UNIV

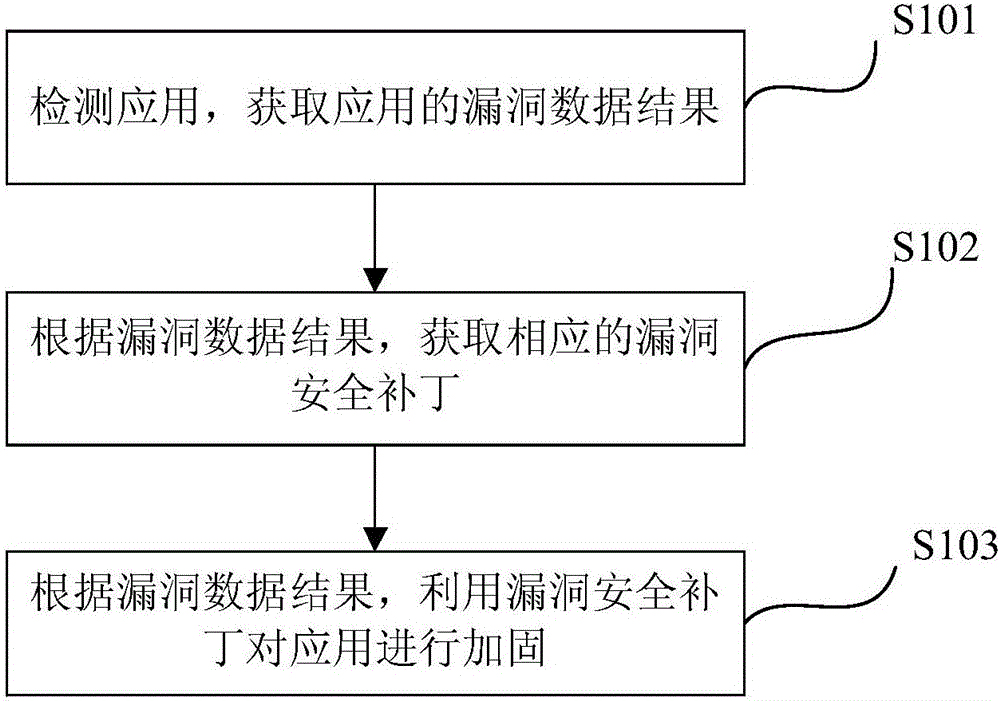

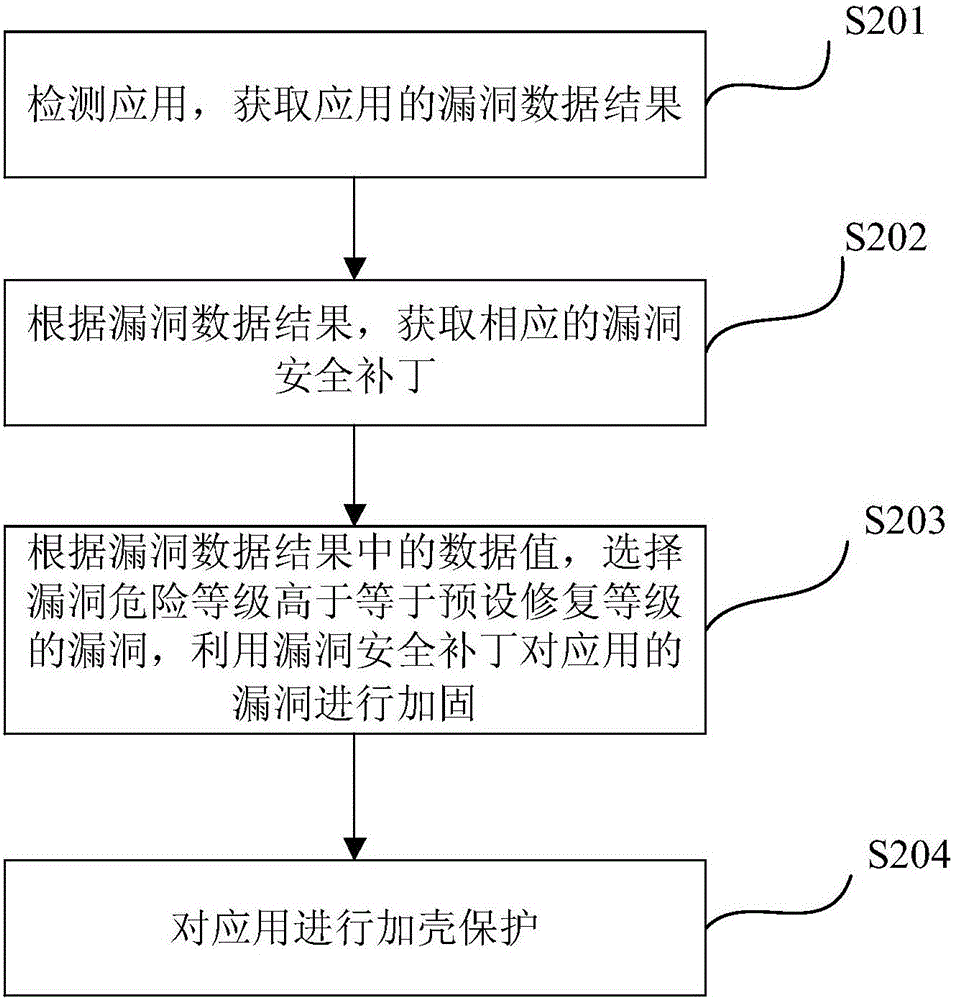

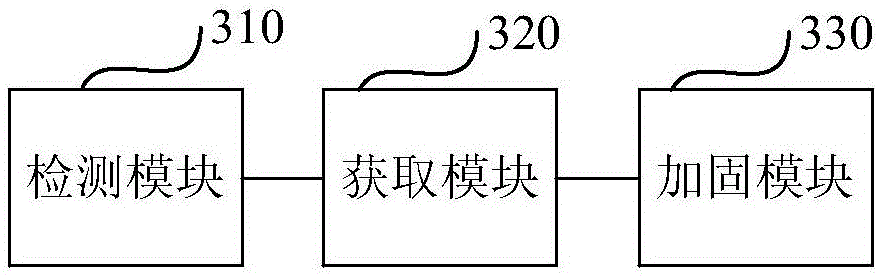

Method and device for automatically reinforcing application vulnerabilities

PendingCN106529287AAutomatic reinforcementAutomatic hardening processPlatform integrity maintainanceComputer scienceOperating system

The invention discloses a method and device for automatically reinforcing application vulnerabilities. The method comprises the following steps: detecting an application, and acquiring a vulnerability data result of the application; according to the vulnerability data result, acquiring a corresponding vulnerability security patch; and according to the vulnerability data result, using the vulnerability security patch to reinforce the application. By using the scheme of the invention, after detecting the application vulnerabilities, targeted reinforcement can be performed on the vulnerabilities automatically according to the vulnerability data result obtained by detecting. The whole reinforcement process is more automatic and intelligent, and the reinforcement efficiency is higher.

Owner:JIANGSU PAYEGIS TECH CO LTD

Novel steel wire rope clamp

The invention provides a novel steel wire rope clamp. The novel steel wire rope clamp is formed by connecting a rope clamp sleeve and a propping bolt, wherein the rope clamp sleeve is formed by precise casting; the steel wire rope is fixed by lapping or through an end head; when in use, the steel wire rope is fixed by lapping, two end heads of the steel wire rope oppositely pass through a steel wire rope hole in the rope clamp sleeve, the elasticity of the steel wire rope is properly adjusted, the steel wire rope is tensioned through a specially-developed tensioning tool, then the propping bolt is pinched through a wrench to compress the steel wire rope, and thus the effects of tensioning, binding and reinforcing can be achieved; the end heads of the steel wire rope are fixed, pass through the steel wire rope hole in the rope clamp sleeve and then are returned through the rope clamp sleeve, so as to form a closed ring which sleeves a T-shaped iron, the elasticity of the steel wire rope is properly adjusted, the steel wire rope is tensioned through a specially-developed tensioning tool, then the propping bolt is pinched through a wrench to compress the steel wire rope, and thus the effects of tensioning, binding and reinforcing can be achieved. The novel steel wire rope clamp can replace the traditional steel wire rope clamp and is applicable to binding and reinforcing of steel, mechanisms and wheel type devices in railway transportation.

Owner:郑元明 +1

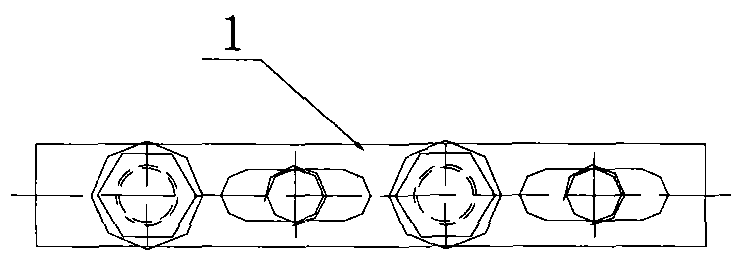

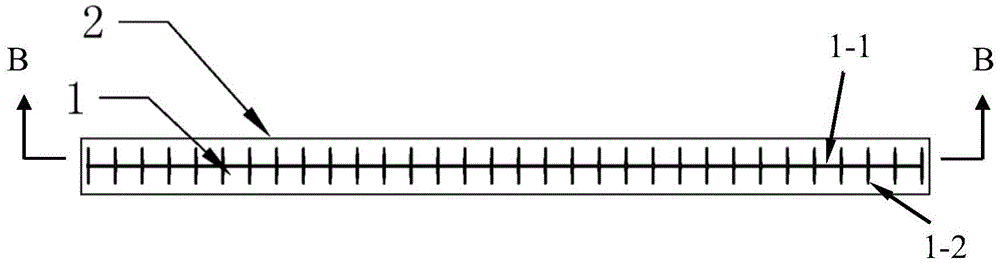

Improved draining plate

Owner:TIANJIN UNIV

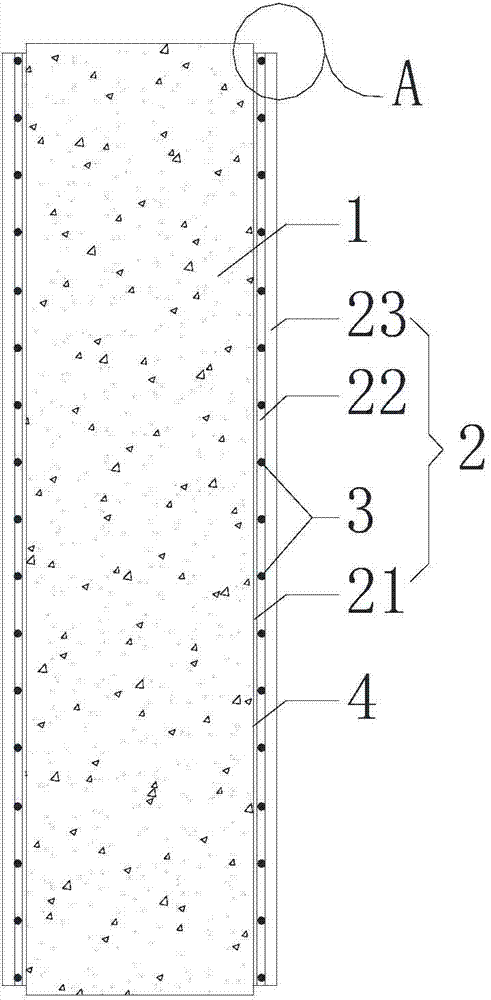

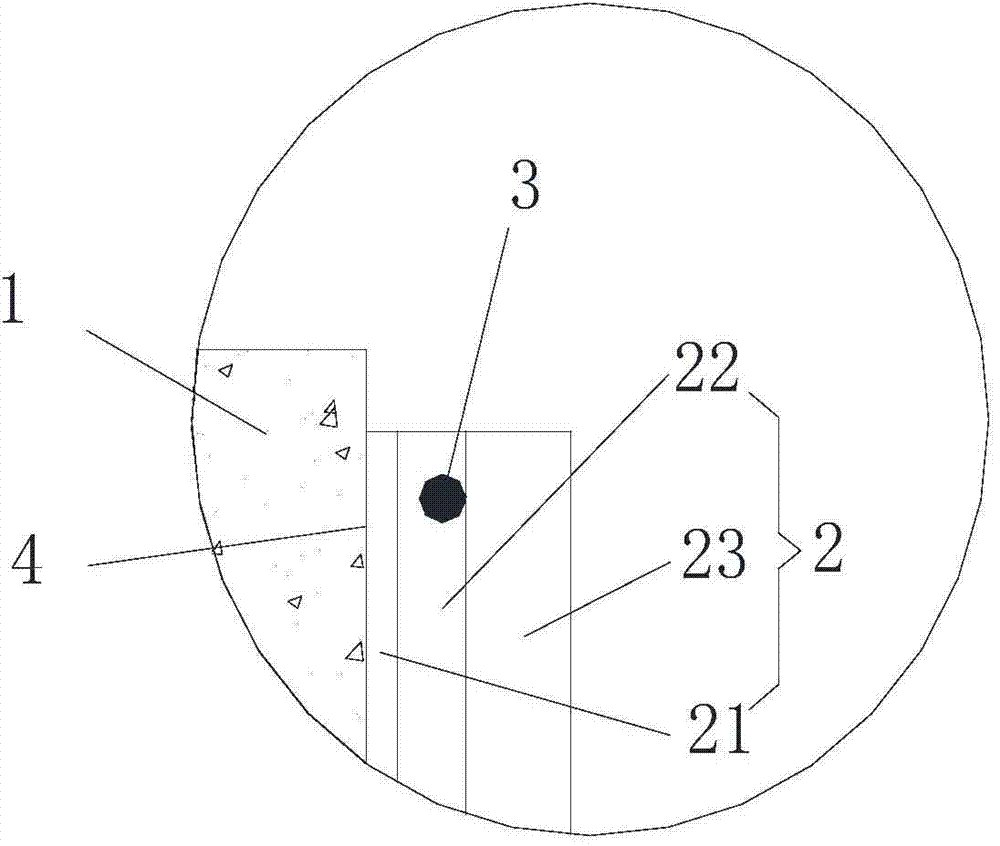

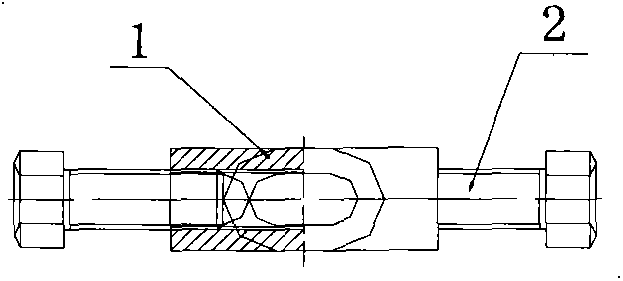

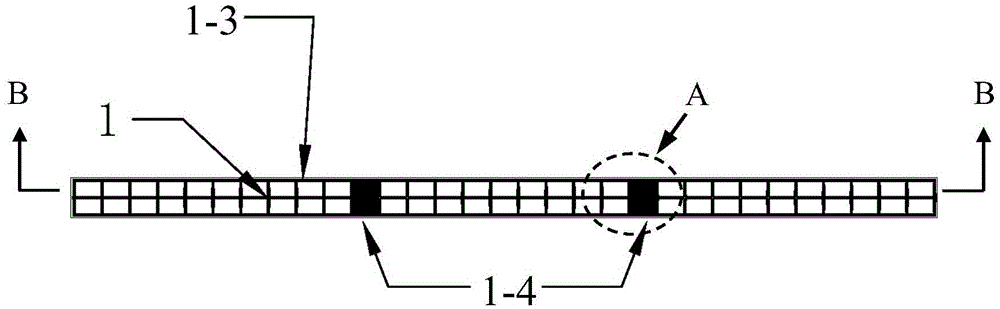

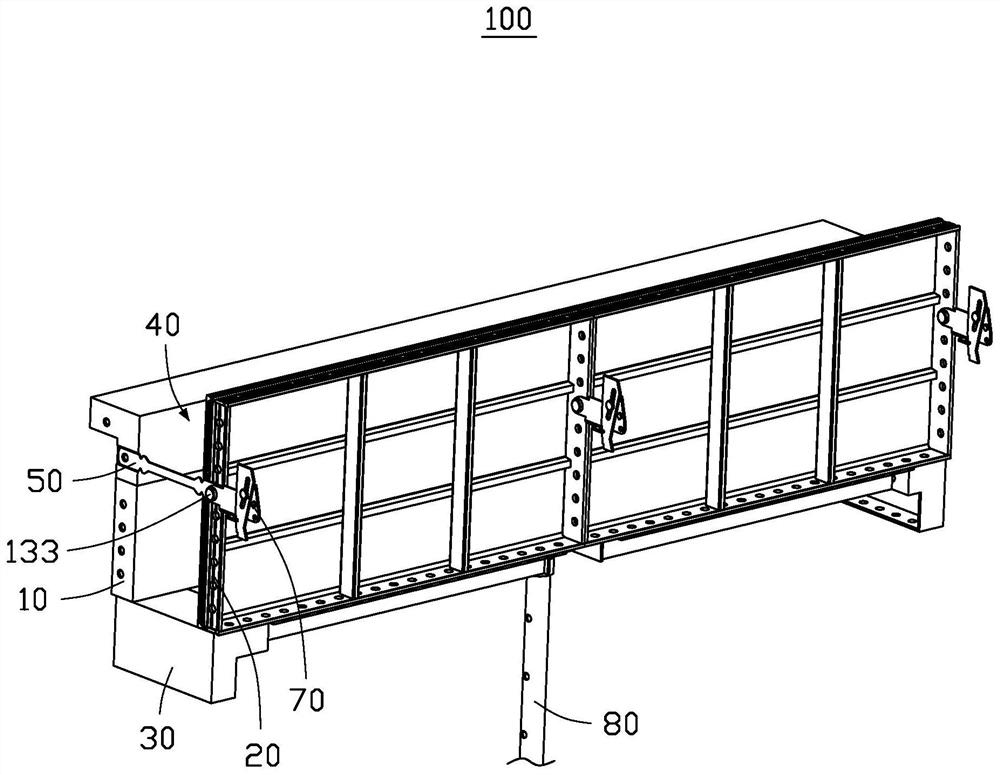

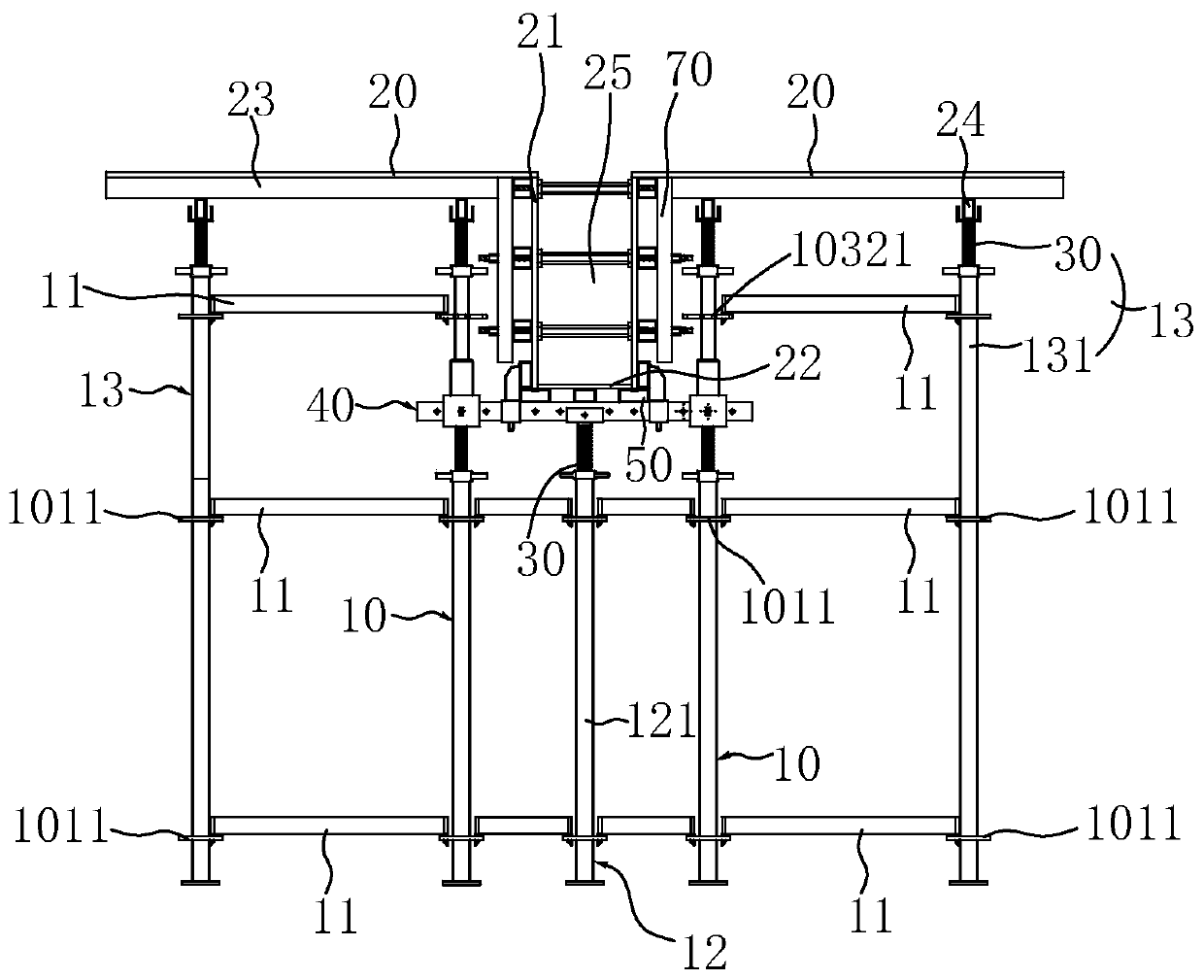

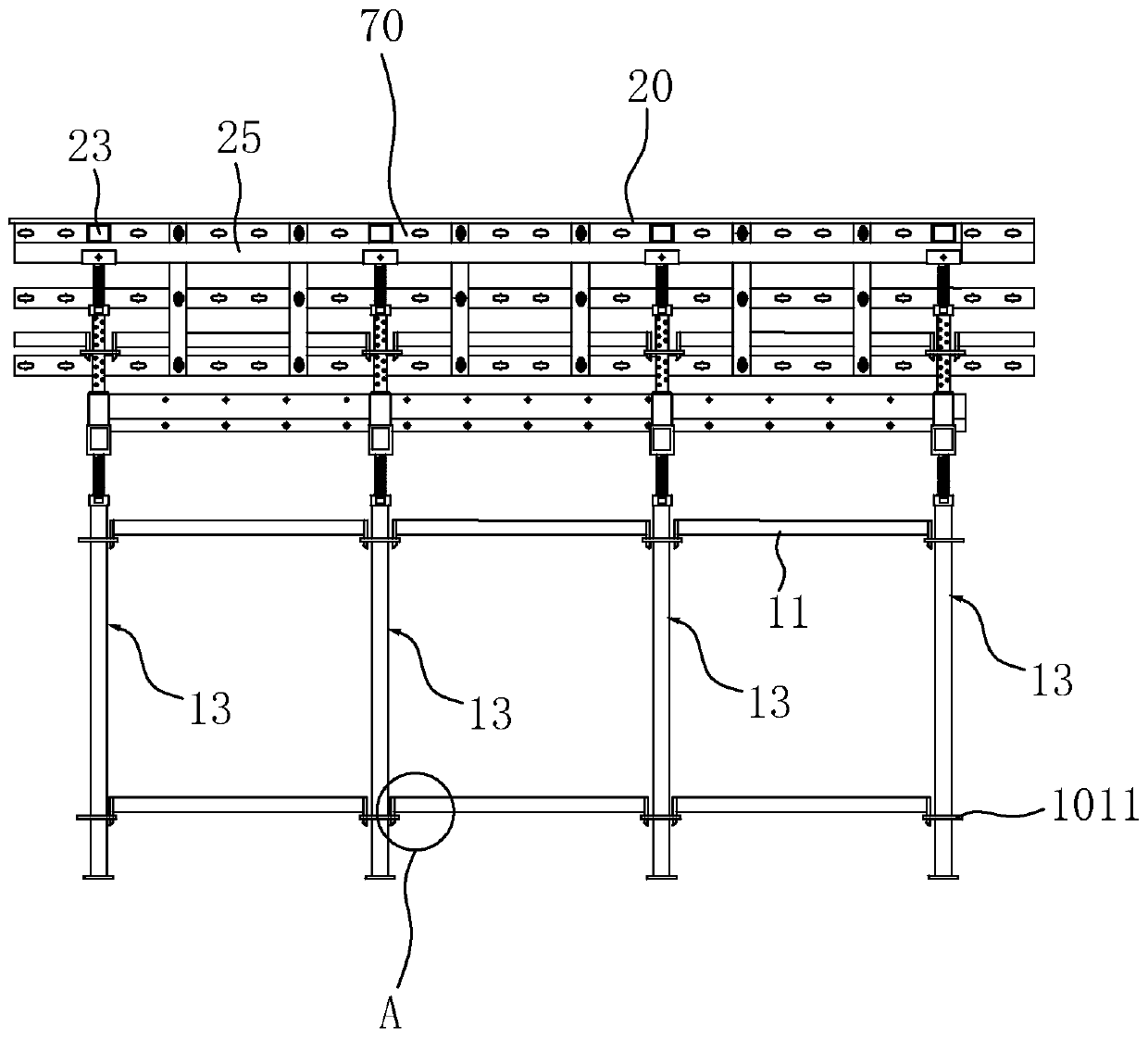

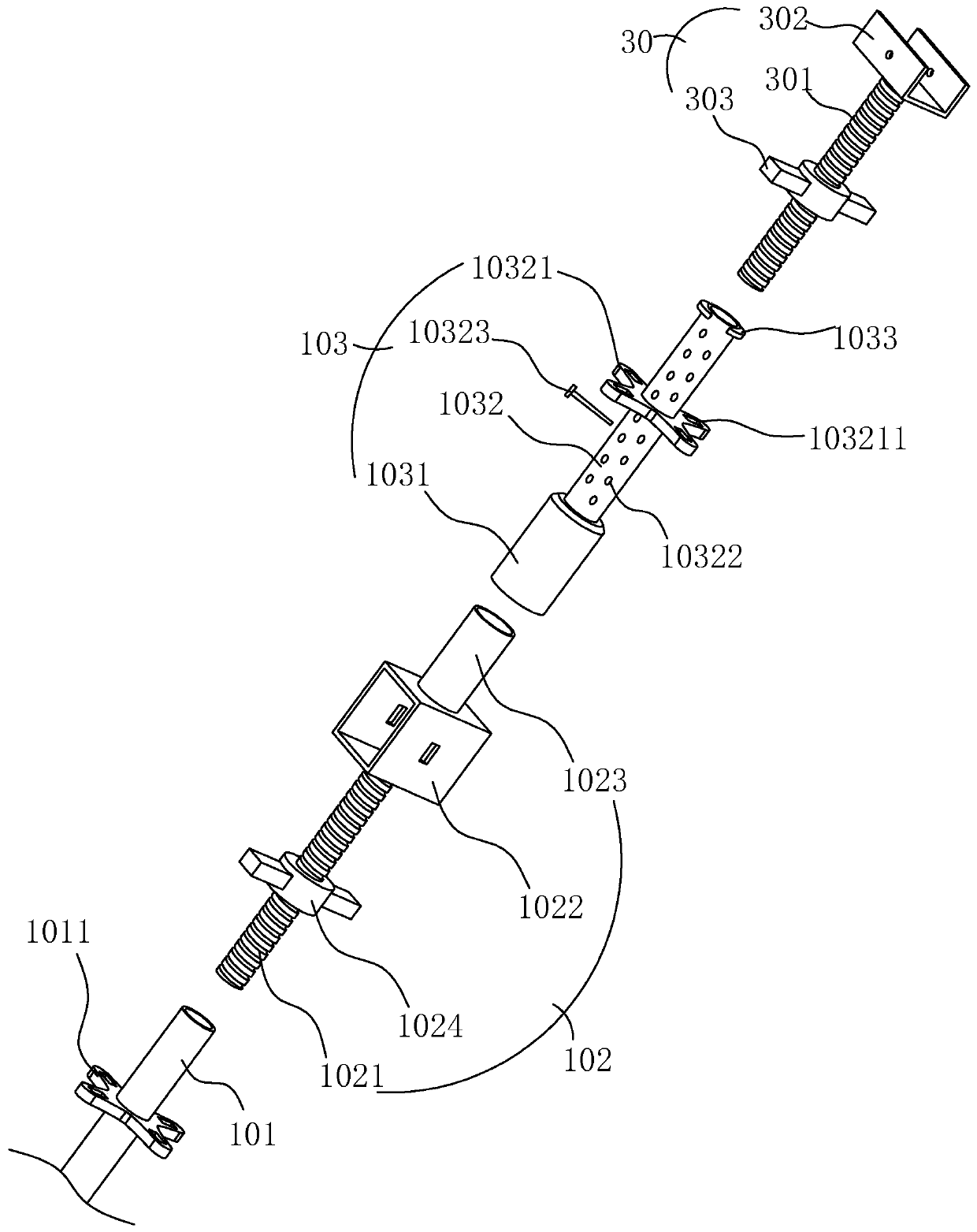

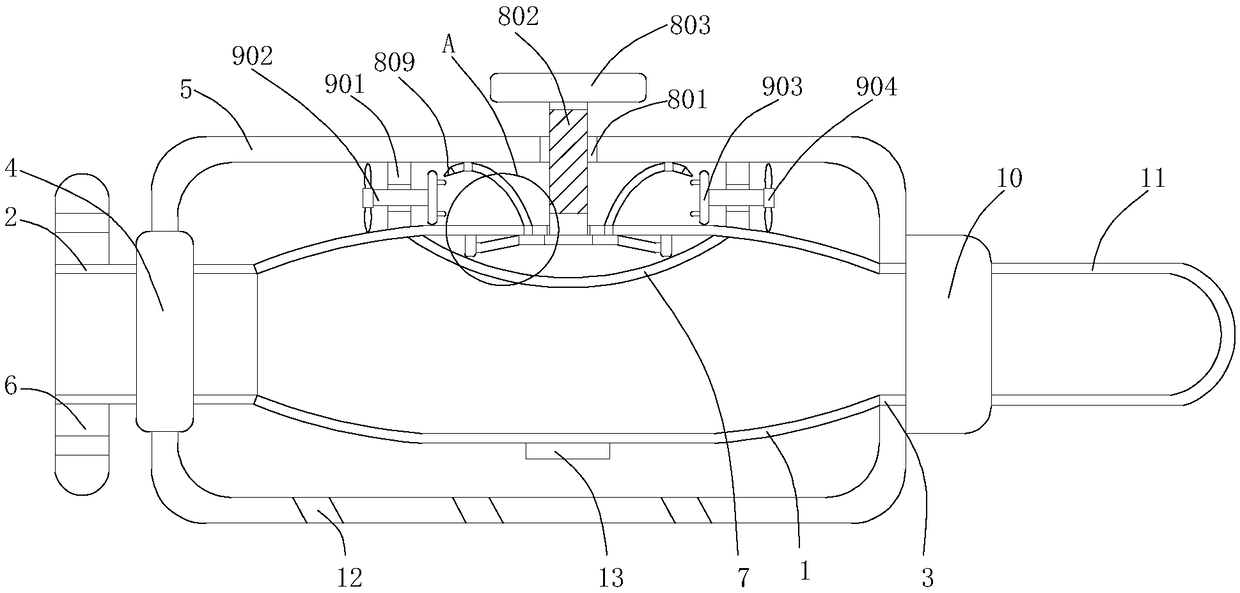

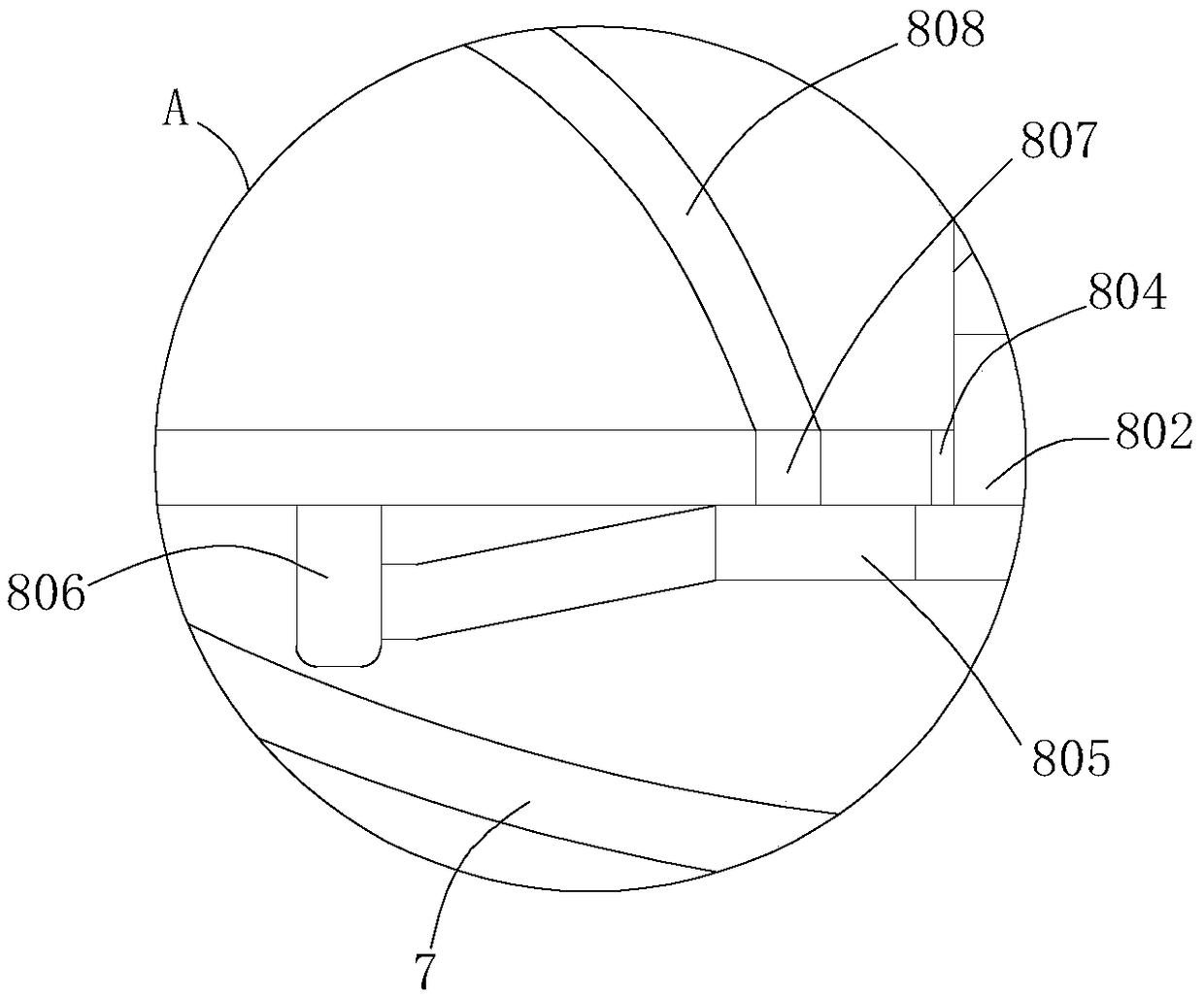

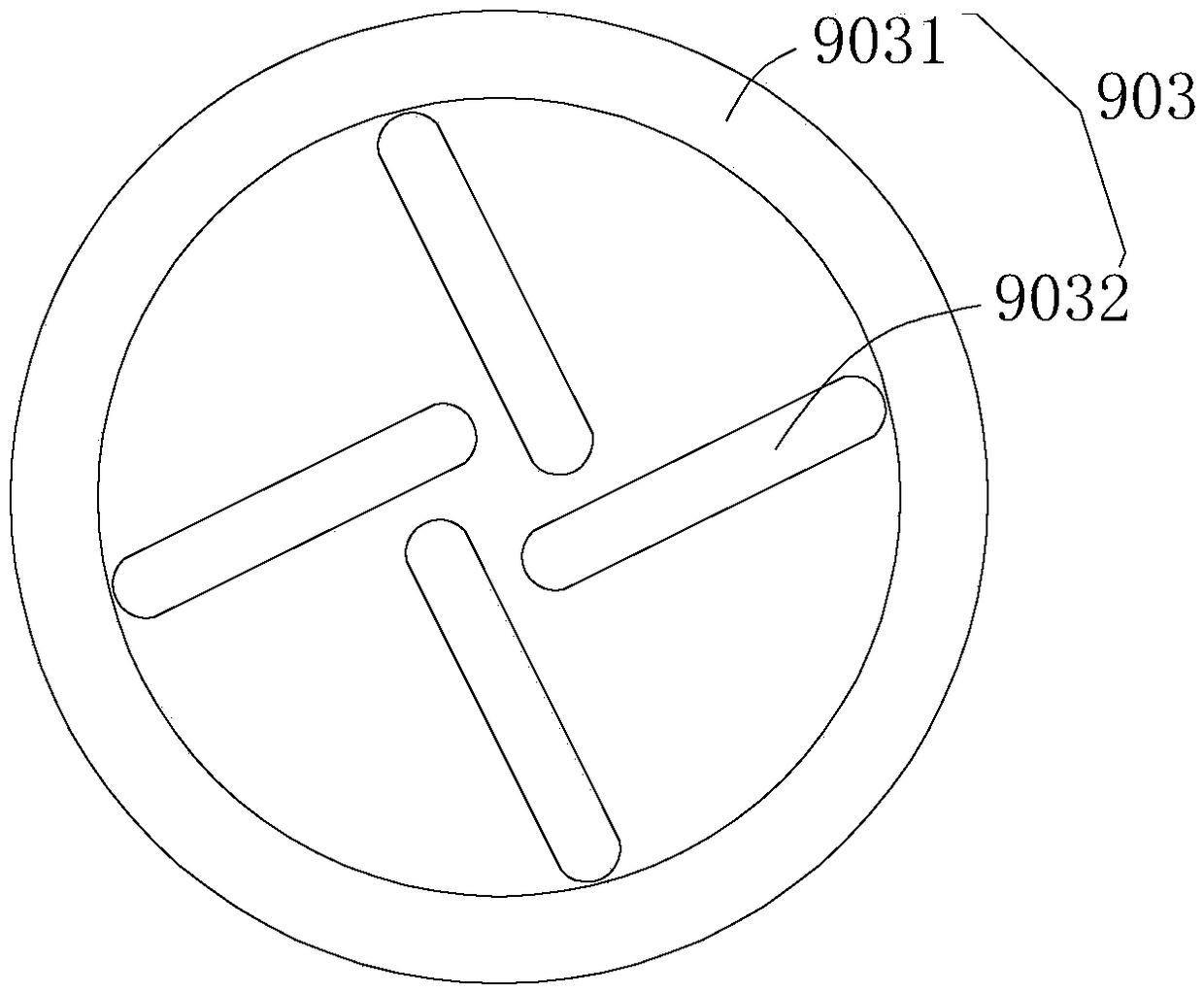

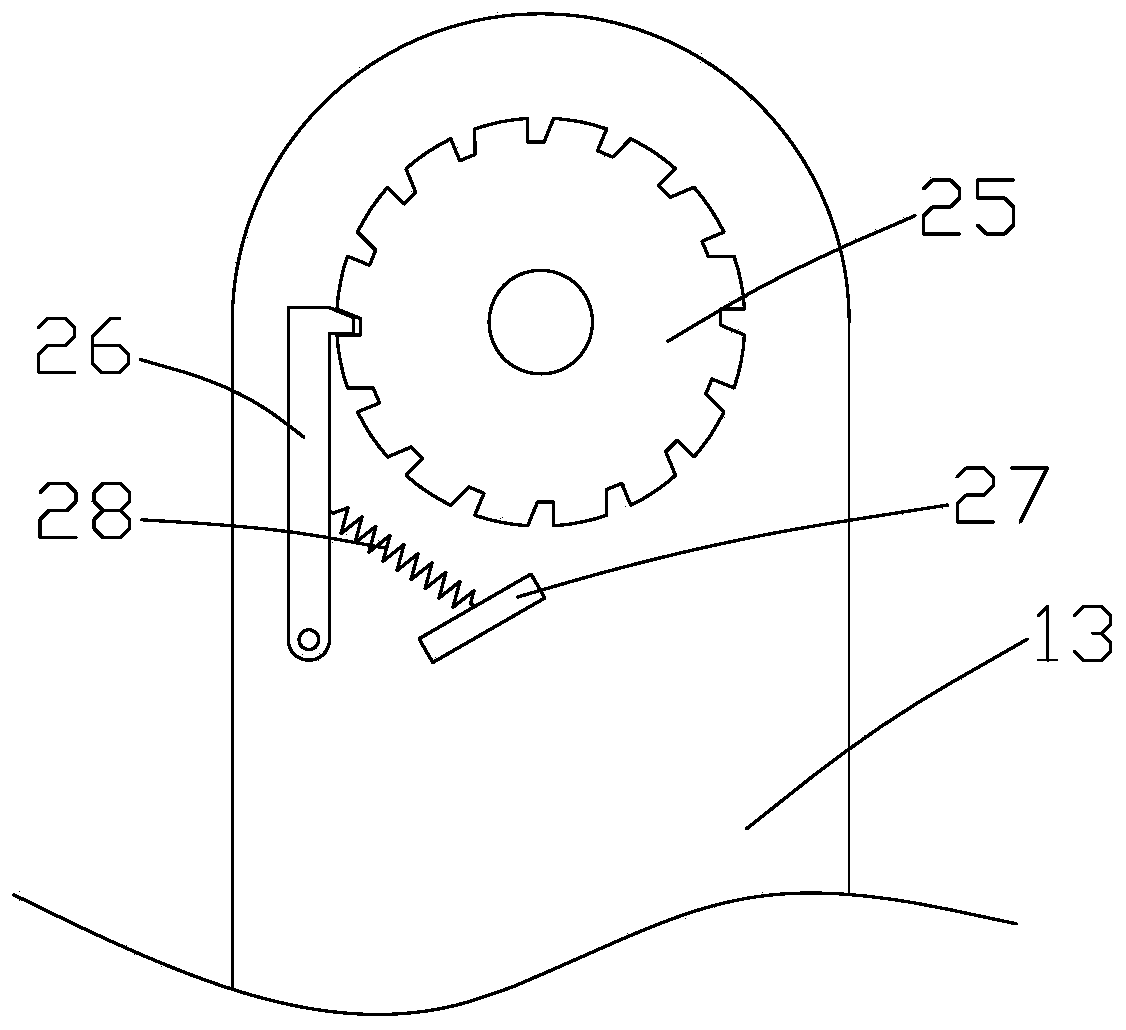

Pull piece fixing structure

InactiveCN111779269AAvoid tiltingImprove reinforcement efficiencyAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

The invention provides a pull piece fixing structure. The pull piece fixing structure comprises at least one first functional piece, at least one second functional piece, a third functional piece anda pull piece, wherein the first functional piece and the second functional piece are arranged at an interval and are connected with the third functional piece; the first functional piece, the second functional piece and the third functional piece jointly define an accommodating space; the accommodating space is used for pouring concrete; and the pull piece penetrates through the first functional piece and the second functional piece separately and is used for fixedly connecting the first functional piece and the second functional piece together, so that opposite-pull fastening is realized. Thepull piece fixing structure adopts a vertical pull piece reinforcing mode, so that an outer beam is effectively prevented from inclining and expanding a mold; and compared with a traditional screw back ridge reinforcing mode, the reinforcing efficiency is high, and potential safety hazards are reduced.

Owner:SNTO TECH GRP

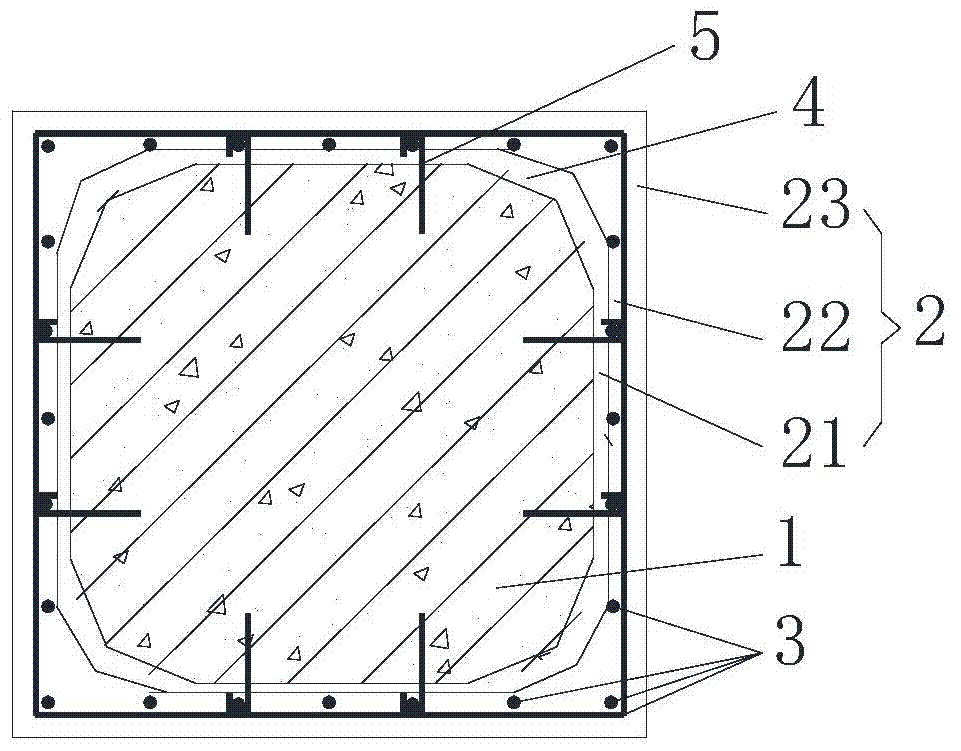

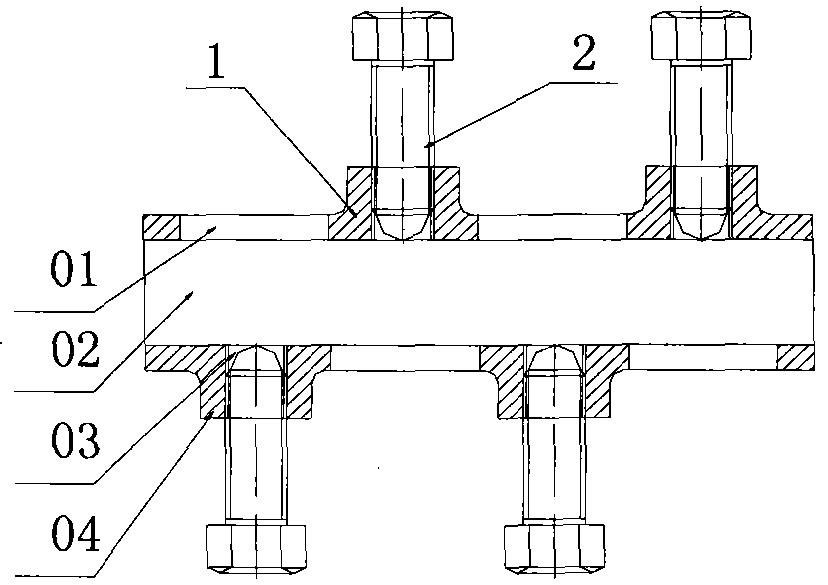

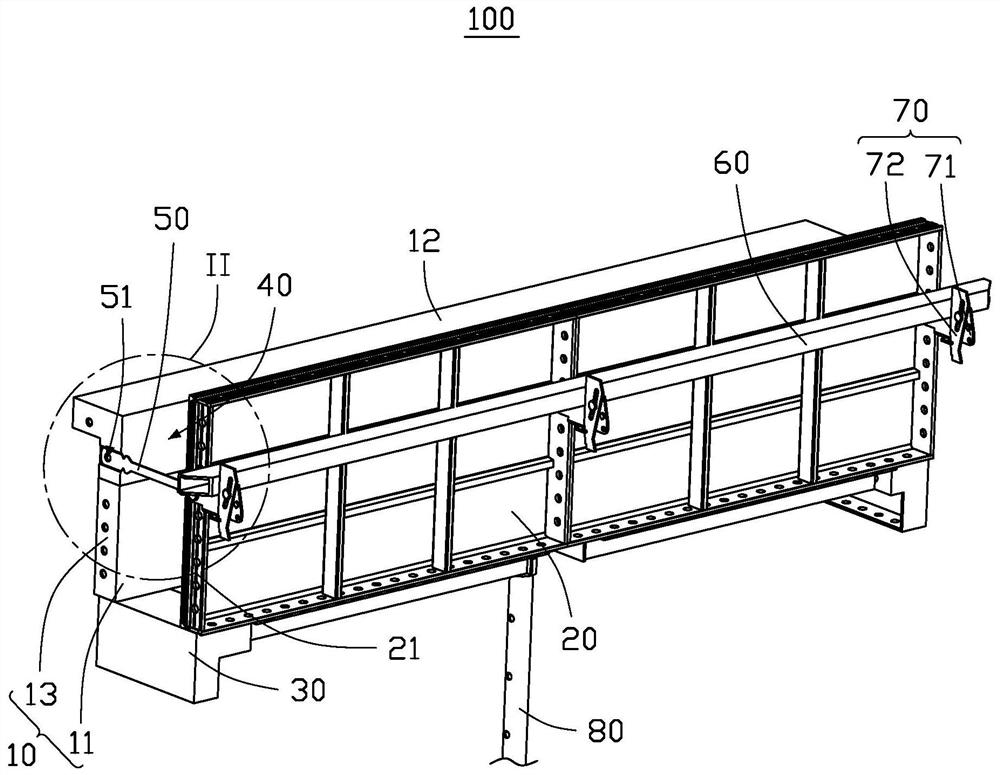

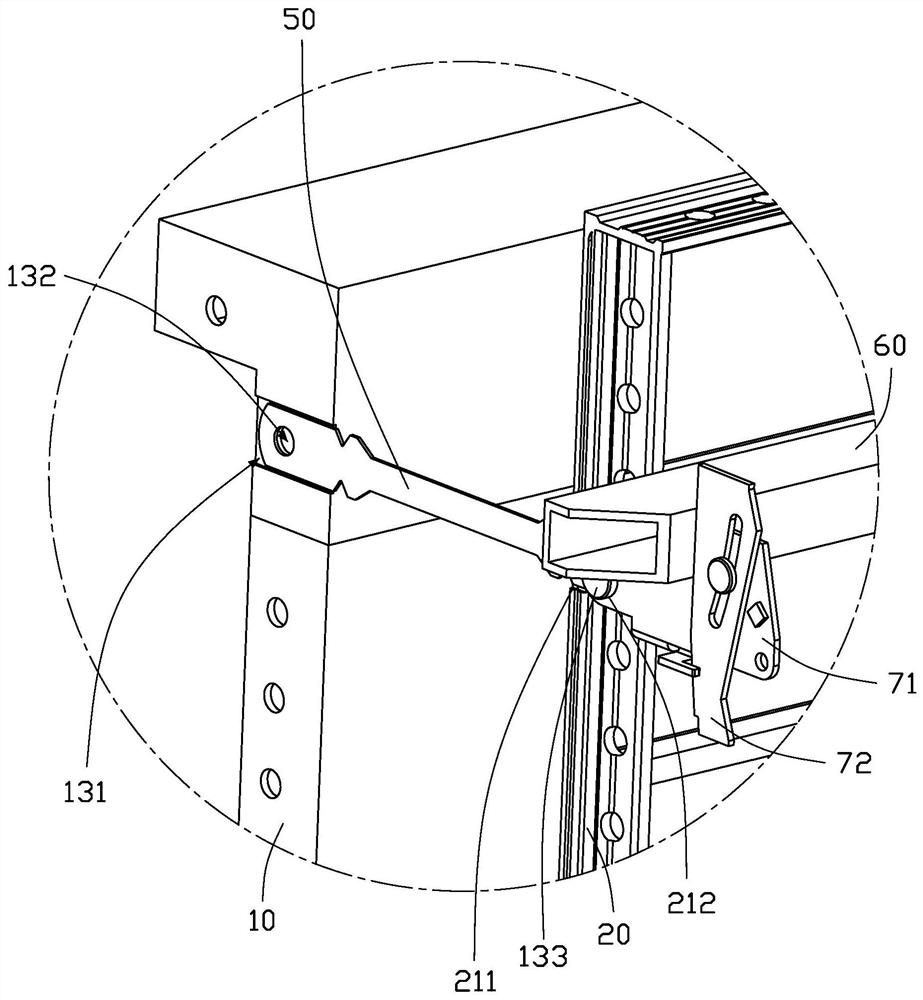

Building wood formwork beam and slab steel keel support system and reinforcing method thereof

ActiveCN110792257APrevent common problemsImprove reinforcement efficiencyForms/shuttering/falseworksShoresSupporting systemKeel

The invention relates to a building wood formwork beam and slab steel keel support system and a reinforcing method thereof. The building wood formwork beam and slab steel keel support system comprisesa beam formwork groove-shaped structure and a plurality of groups of support rod assemblies, wherein the beam formwork groove-shaped structure is arranged on the top of the plurality of groups of support rod assemblies; beam bottom corner L-shaped squares and multi-rod dual-purpose support beam assemblies are arranged on the support rod assemblies; the beam bottom corner L-shaped squares are clamped and fixed to the outer side of the bottom of the beam formwork groove-shaped structure; the multi-rod dual-purpose support beam assemblies are clamped and fixed at the bottoms of the beam bottom corner L-shaped squares; and beam side plate steel main and sub beams tightly covering the outer sides of the two side walls of the beam formwork groove-shaped structure are arranged on the beam formwork groove-shaped structure. The building wood formwork beam and slab steel keel support system has the effects that the installation is convenient; the structure is firm; and the formwork bursting andexpansion is prevented.

Owner:深圳市华力坚建筑科技有限公司

High-pressure grouting device for bridge bottom reinforcement in high temperature environment

ActiveCN109056550AImprove reinforcement efficiencyExtended service lifeBridge erection/assemblySlurryEngineering

The invention relates to the technical field of bridge maintenance, and discloses a high-pressure grouting device for bridge bottom reinforcement under high temperature environment, Including groutingchamber, Slurry inlet pipe, slurry guide pipe, casing, surge chamber, breathable diaphragm, pressure regulator, Two cooling mechanisms, a metering chamber, a slurry outlet pipe and a circulation hole, wherein the slurry inlet pipe is fixedly communicated with the left end of the slurry injection chamber, the slurry guide pipe is fixedly communicated with the right end of the slurry injection chamber, the sleeve is fixedly sleeved on the outer surface of the slurry inlet pipe, the surge chamber is fixedly sleeved on the outer surface of the sleeve and the slurry guide pipe, and the air permeable diaphragm is fixed on the middle of the top wall of the slurry injection chamber. The air pressure in the grouting chamber can be dredged from the two exhaust holes, the air intensity difference inside and outside the grouting chamber can be reduced, the grouting chamber can be prevented from cracking due to the larger pressure difference, the airflow flow rate between the grouting chamber andthe surge chamber can be accelerated, the temperature on the outer surface of the grouting chamber can be rapidly evaporated, and the effect of lowering the temperature of the grouting chamber can beachieved.

Owner:安徽升建工程管理有限公司

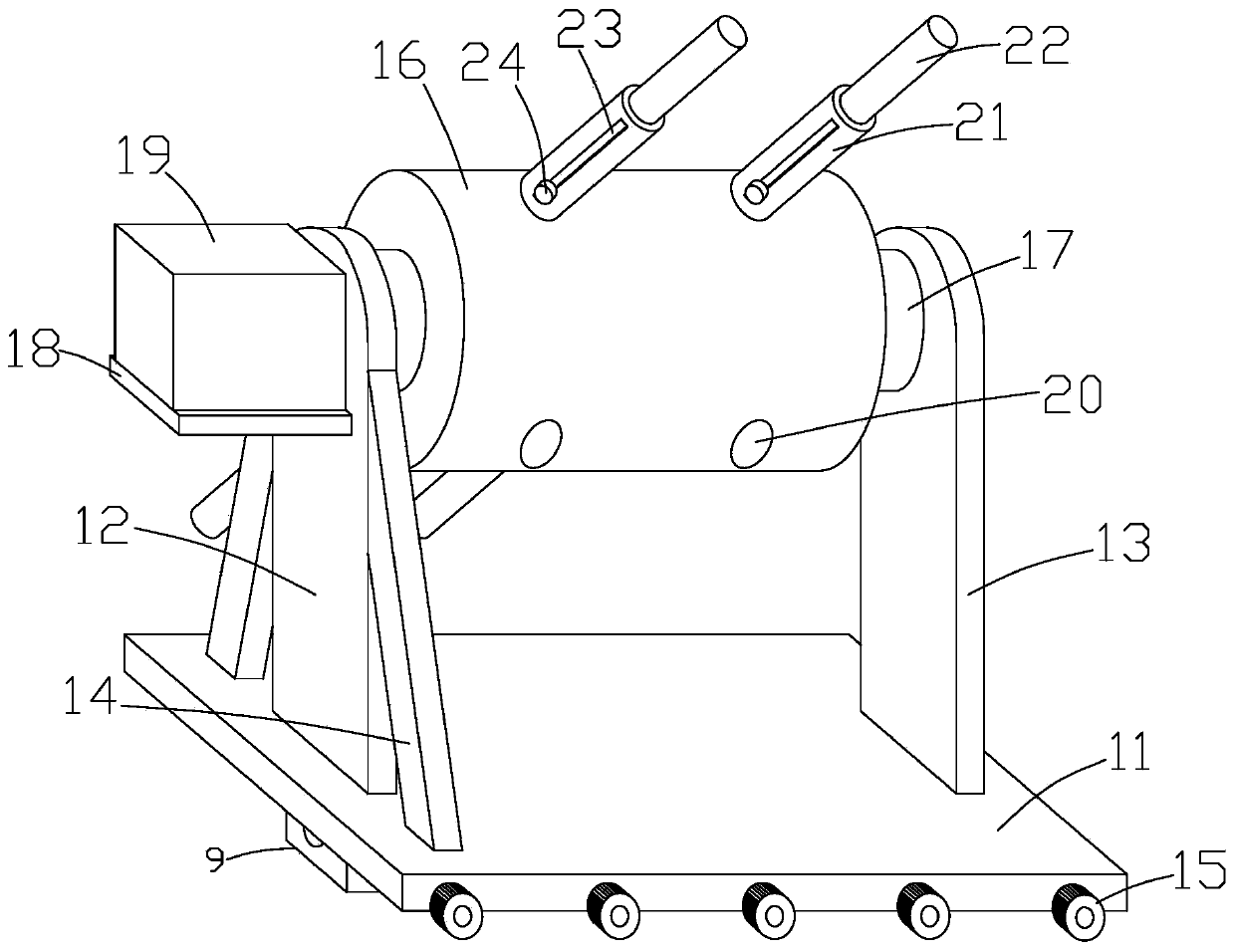

Transverse reinforcement arranging and welding device for four-side ribbed reinforcement net and reinforcement arranging and welding method

ActiveCN111889905AIncrease heightEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesMesh reinforcementTransverse reinforcement

The invention provides a transverse reinforcement arranging and welding device for a four-side ribbed reinforcement net and a reinforcement arranging and welding method and belongs to the field of thereinforcement. According to the transverse reinforcement arranging and welding device, one or two reinforcement arranging and welding racks moving along longitudinal guide rails are arranged on a reinforcement arranging table, a transverse reinforcement bin is arranged on the side of each reinforcement arranging and welding rack, a transverse sliding device is arranged on a vertical plate of thereinforcement arranging and welding rack, a lifting device is suspended on a top plate and arranged on the transverse sliding device, a longitudinal moving device is arranged below the transverse sliding device, the lifting device comprises multiple lifting suckers including transverse reinforcement end lifting suckers as well as top electrodes, and moving rollers are arranged on the side, close to the transverse reinforcement bin, of the longitudinal moving device and can extend to the positions below the multiple lifting suckers and the top electrodes. The device can improve reinforcement arranging accuracy, reduces alarm frequency, prevents intertwining of the reinforcements and can guarantee normal production.

Owner:河南省鼎鼎实业有限公司

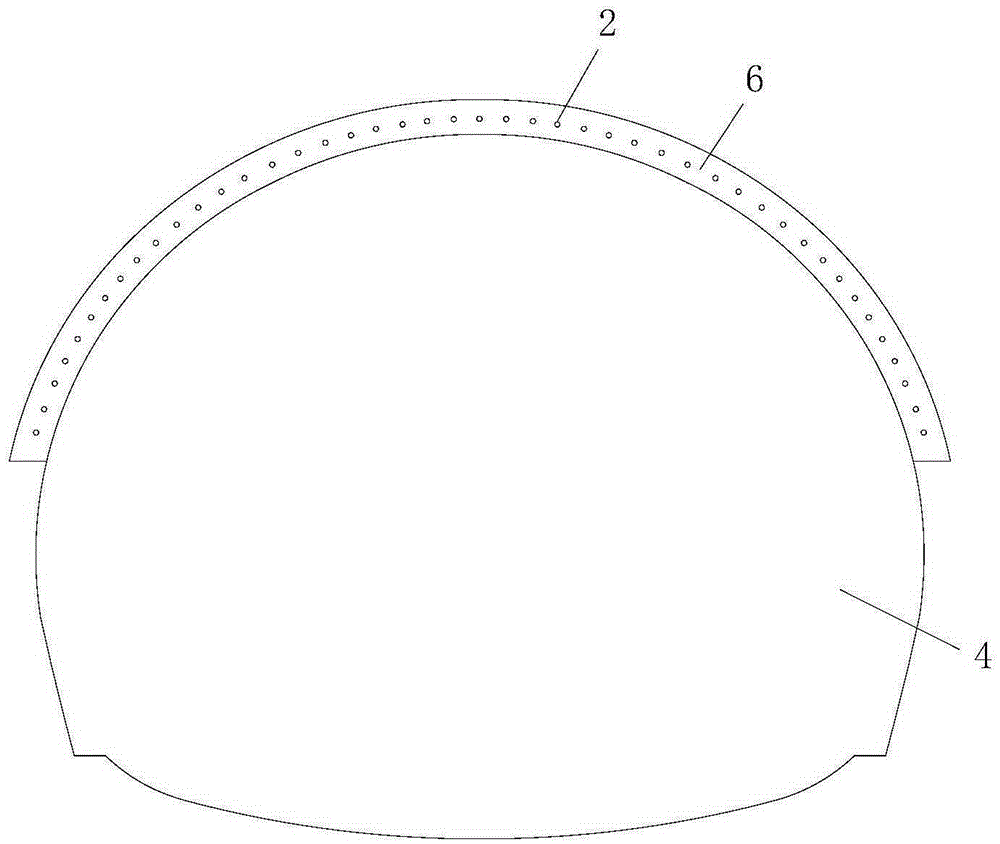

Reinforcing method of ultra-deep stratum shield breaking-in and breaking-out

ActiveCN110056361AImprove reinforcement efficiencyQuality improvementUnderground chambersDerricks/mastsProof constructionMachining

The invention discloses a reinforcing method of ultra-deep stratum shield breaking-in and breaking-out. The reinforcing method comprises the following steps of (1) construction preparation, (2) launching shaft breaking-in opening reinforcing construction, (3) receiving shaft breaking-out opening reinforcing construction, (4) grouting construction, (5) water-proof construction and (6) drilling equipment detachment. The reinforcing method of ultra-deep stratum shield breaking-in and breaking-out is simple in steps, improves the reinforcing efficiency of breaking-in and breaking-out, simplifies steps of a machining technology, and greatly improves the reinforcing quality, the construction difficulty and cost are reduced, and the requirements of shield machining of tunnels in different depthscan be met.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Carbon fiber winding reinforcing slice and manufacturing method thereof

ActiveCN101921459AImprove continuityIncreased longitudinal/hoop design stress ratioFiberCarbon fibers

The invention relates to a carbon fiber winding reinforcing slice and a manufacturing method thereof, relating to a reinforcing slice and a manufacturing method thereof. The invention solves the problem that the reinforcing effect of the existing reinforcing material is inferior. The carbon fiber winding reinforcing slice is made of carbon fiber and base resin. The method comprises the steps of weighting raw materials and annularly winding continuous fibers so as to form the carbon fiber winding reinforcing slice. The reinforcing slice of the invention is molded through pre-casting process, has proper hardness and can be stored for a long time. When in use, a user only needs to take the slice out from an ice tank, take off a de-molding slice and pave the slice on an end socket of a carbon fiber winding shell. The use method is simple. Compared with the existing reinforcing material, the reinforcing slice of the invention has better reinforcing effect.

Owner:HARBIN FRP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com