Patents

Literature

37results about How to "Large diffusion radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

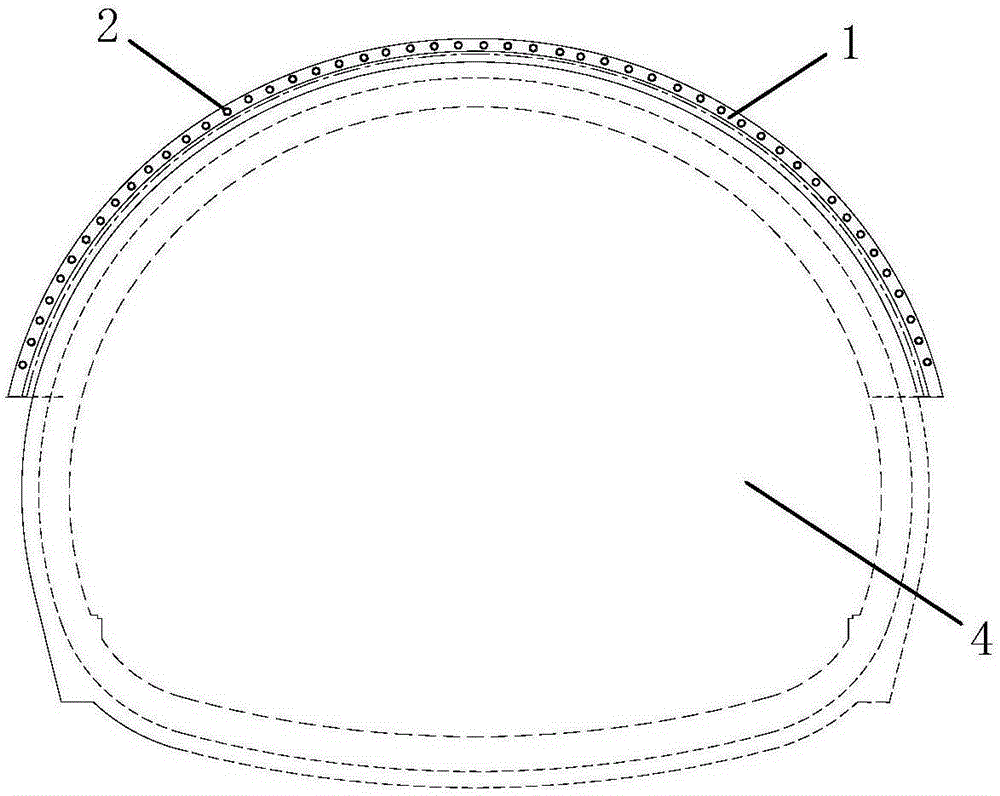

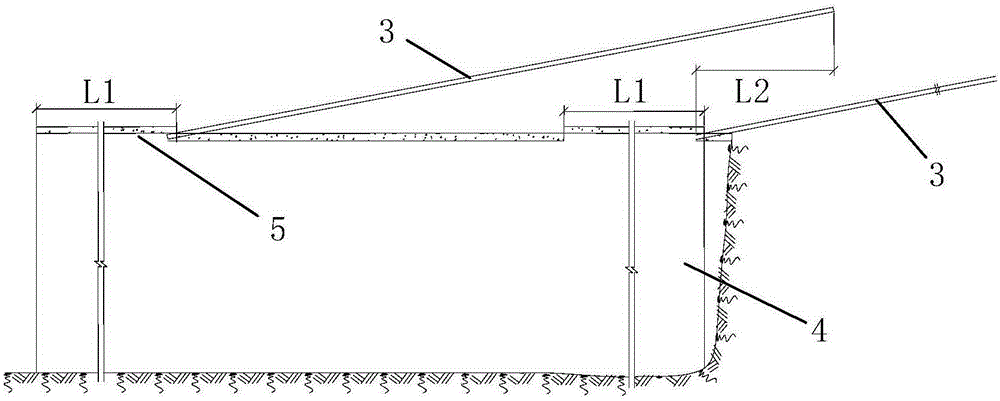

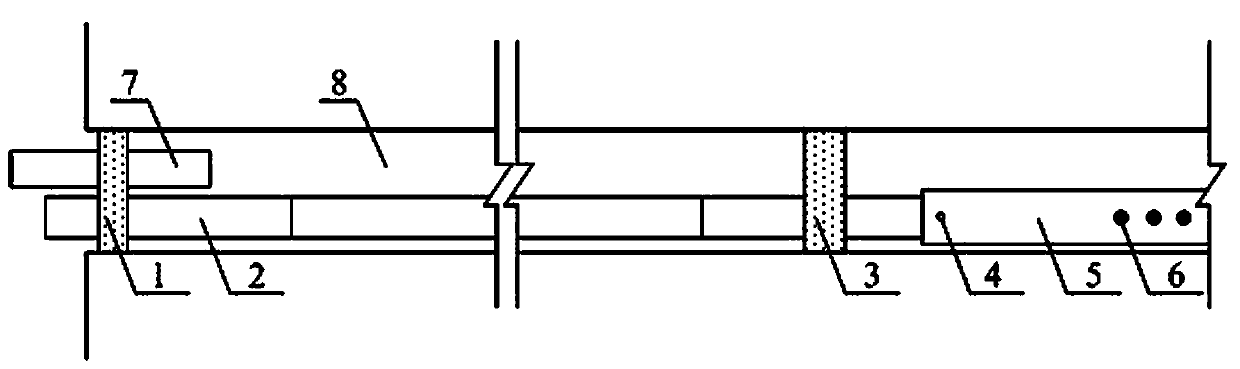

Soft and weak wall rock tunnel advance reinforced support construction method

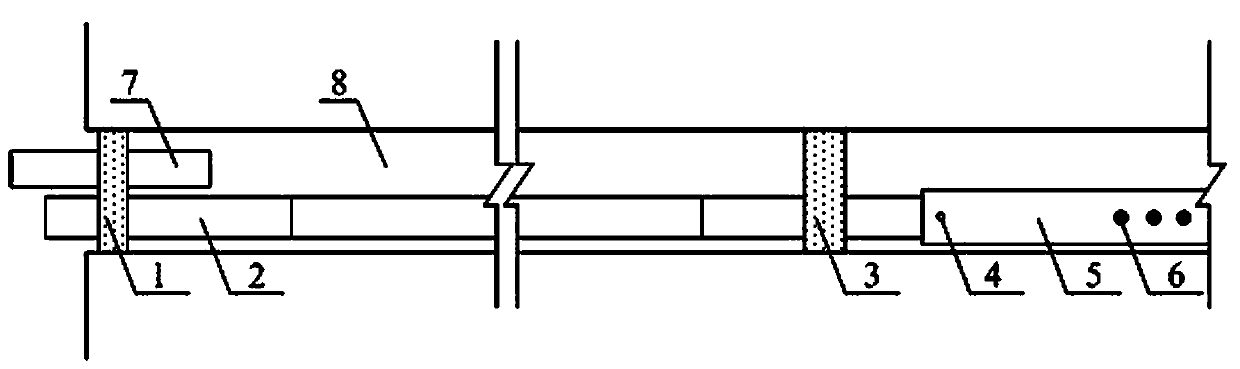

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

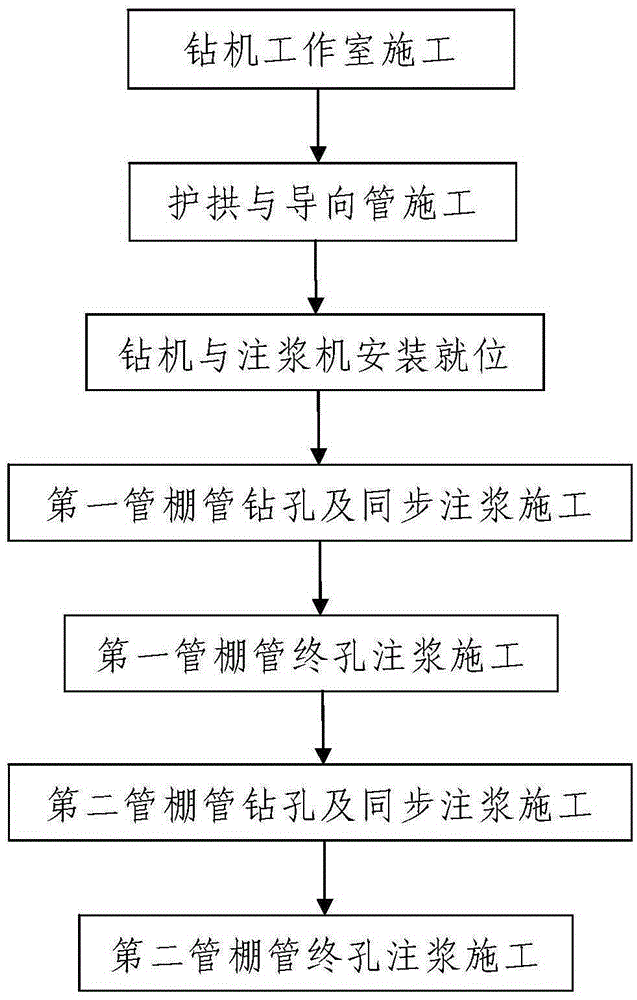

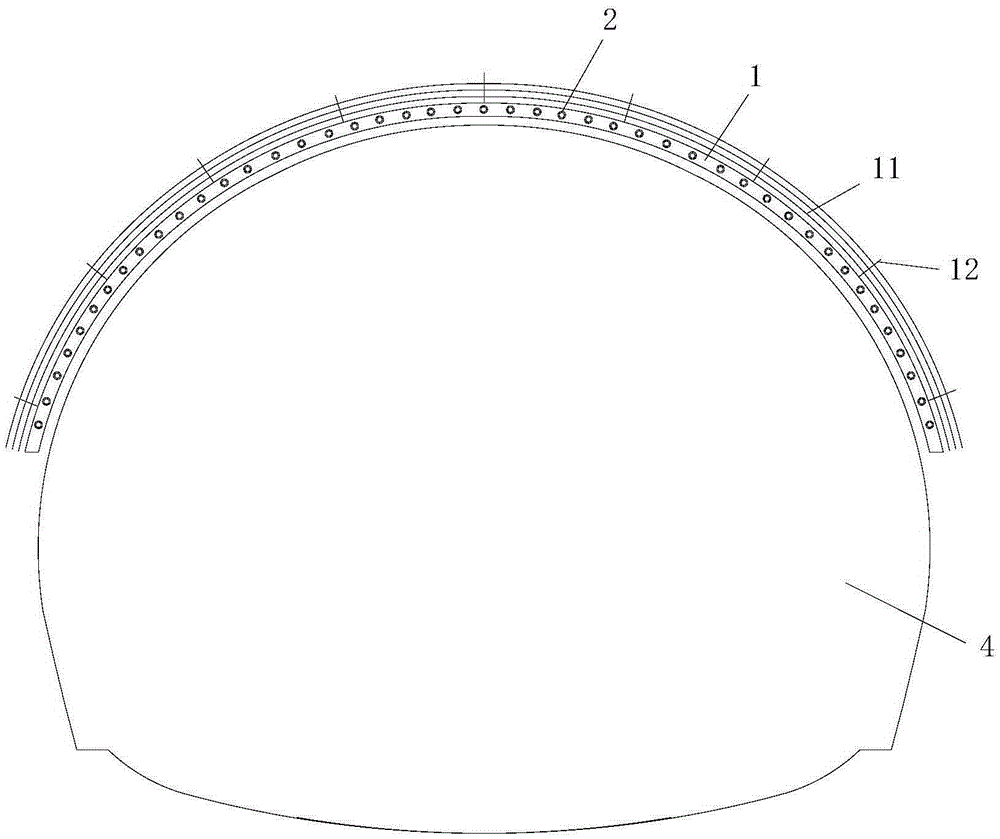

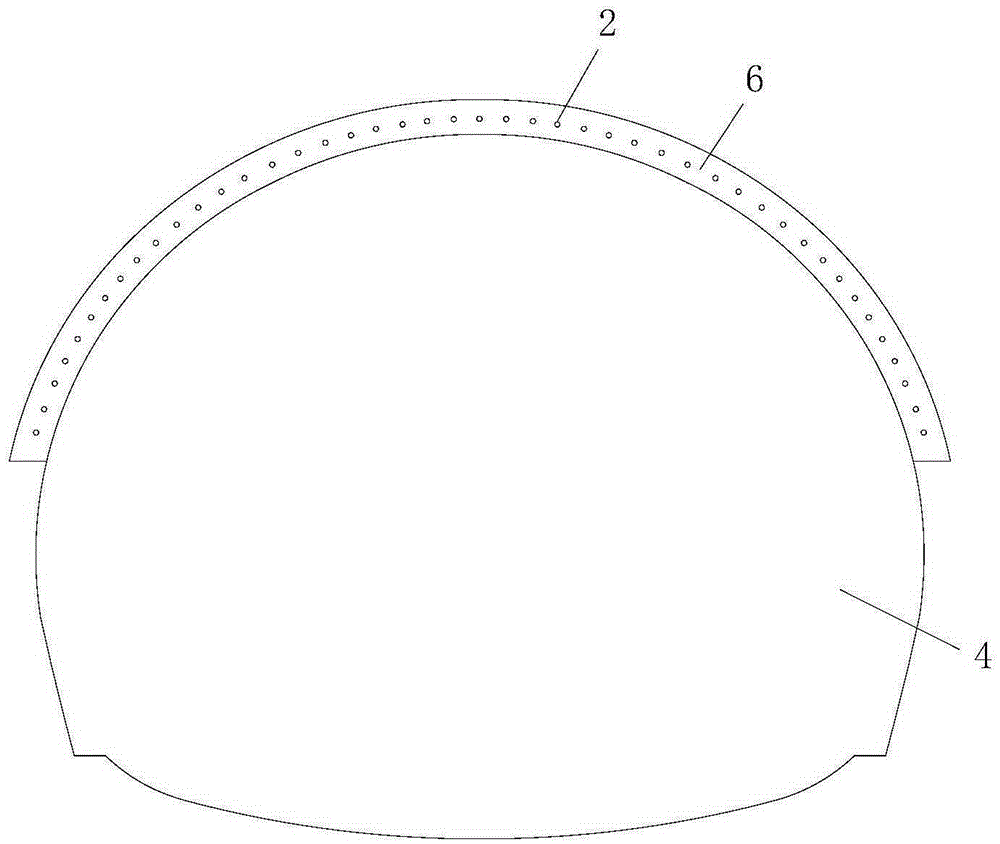

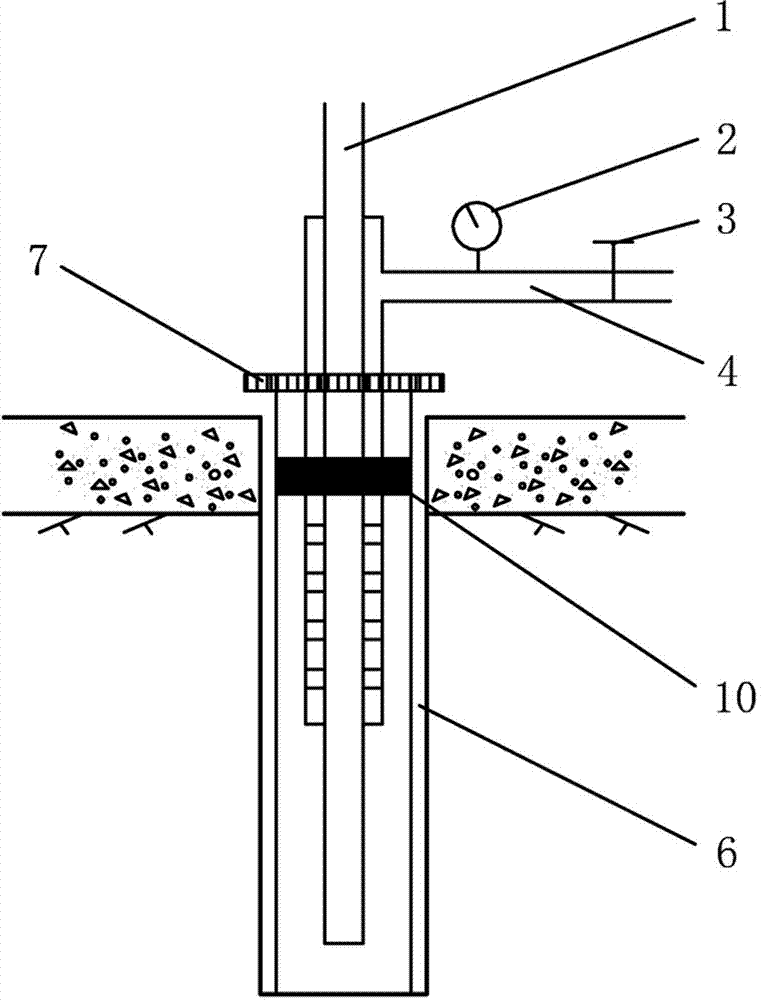

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

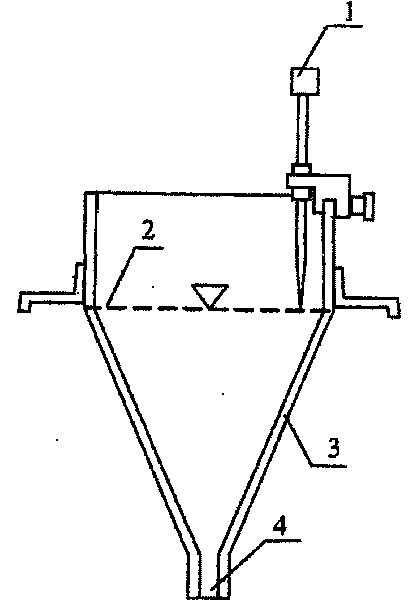

Construction method for covering layer closed porthole high-pressure curtain grouting

InactiveCN103485345ASolve the difficulty of forming holesIncrease drilling speedFoundation engineeringHigh pressureInjection rate

The invention relates to a construction method for covering layer closed porthole high-pressure curtain grouting. The method includes following steps: (1), non-grouting section construction; (2), grouting section hole-creating; (3), grouting section long division; (4), grouting pressure determination; and (5), grouting way determination. A casing pipe is used for following up to the non-grouting section, and mud fixes walls and creates holes, so drilling speed and hole-forming rate can be greatly improved, and the problem of difficulty in hole-forming of a ground layer of a deep covering layer is solved. On the deep covering layer, higher grouting pressure is adopted, grouting injection rate increases obviously, diffusion radius enlarges, and grouting effect is fine. On the covering layer, the closed porthole curtain grouting construction method is adopted, grouting quality is guaranteed, frequent 'pipe hugging'drilling accidents during grouting are basically avoided, and construction efficiency is improved.

Owner:GEZHOUBA GROUP FOUND ENG

Single-side water-proofing and dirt-resisting and single-side 3-dimensional moisture-absorbing and quick-drying process for terylene/chinlon fabric

ActiveCN104074055AImprove hydrophilicityImprove washabilitySucessive textile treatmentsFibre typesPolyesterCustomer requirements

The invention relates to a single-side water-proofing and dirt-resisting and single-side 3-dimensional moisture-absorbing and quick-drying process for terylene / chinlon fabric. The process is characterized in that a polyester-polyether hydrophilic finishing agent DM-3741 is firstly used for carrying out hydrophilic finishing to the terylene / chinlon fabric, so as to enable the terylene / chinlon fabric to have excellent hydrophilicity, then a one-way wet guiding agent DM-3420 is used for full bottom printing of the front side of the fabric, drying is performed, then a one-way wet guiding agent dot matrix is printed on the reverse side of the fabric, and drying, baking, water washing, dewatering and drying are performed. Thus, the single-side water-proofing and dirt-resisting and single-side moisture-absorbing and quick-drying effects can be achieved. The process provided by the invention has the advantages that the operability is strong, the fabric treated with the process is excellent in washing resistance and comfortableness during wearing; after 30 times of washing, the effects of water proofing, dirt resisting, moisture absorbing and quick drying are hardly lowered, so that customer requirements are satisfied, and the process has remarkable significance in improving product wearing properties, added values and the like.

Owner:DYMATIC CHEM

Method for widening grouting reinforcement and seepage and blockage prevention range of rock and soil

The invention discloses a method for widening the grouting reinforcement and seepage and blockage prevention range of rock and soil. Grouting holes and water drainage holes are distributed in the place where reinforcement and seepage prevention need to be conducted at intervals according to a certain form through combination of static pressure grouting and vacuum negative pressure water drainage. By means of vacuum negative pressure water drainage, the underground water level is lowered, underground water and air in holes of rock and soil are discharged, and dilution of underground water on grouting fluid is reduced. Negative pressure is formed at the water drainage positions, under the same grouting pressure condition, a forward pressure field is formed, the grouting speed is increased, and the grout expansion radius is increased. When a vacuum negative pressure pump works, underground water in holes of rock and soil surrounding the water drainage holes is collected towards the water drainage holes, dynamic water pressure is formed, and the grouting expansion radius is further increased. The grouting reinforcement and seepage and blockage prevention range of rock and soil is widened, the grouting effect is improved, the grouting quality is improved, and the grouting speed is increased. The method has the remarkable beneficial effects of being small in work amount, high in safety, good in grouting effect, wide in reinforcement and seepage prevention range, and the like.

Owner:CENT SOUTH UNIV

Road engineering base course and soil road base polymer grouting material

The invention provides a road engineering base course and soil road base polymer grouting material. The material is characterized by comprising the following components in parts by weight: 100 parts of metallurgical slag, 30 parts of high-lime fly ash, 10 parts of metakaolin, 1-3 parts of thickening water-retaining agent, 30 parts of alkaline exciting agent and 2-4 parts of additive. The material has the advantages of quick setting, early strength, large fluidity and good permeability.

Owner:上海城西城建工程勘测设计院有限公司

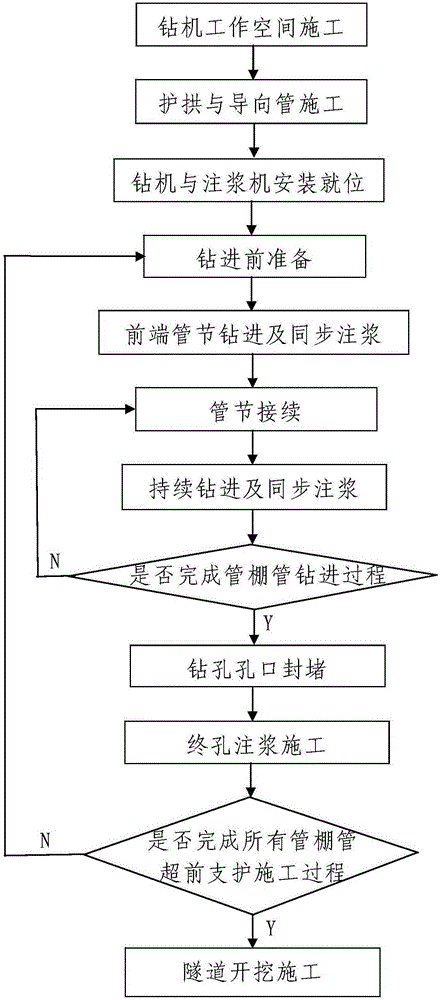

Advance support construction method for high-strength pipe shed of tunnel

InactiveCN105201517AShort construction periodImprove construction efficiencyUnderground chambersTunnel liningDrill holeHigh intensity

The invention discloses an advance support construction method for a high-strength pipe shed of a tunnel. A process for carrying out advance support construction on a pipe shed of one segment of a constructed tunnel comprises the following steps: (1) constructing support arches and guide pipes; (2) installing a drilling machine and a grouting machine in place; (3) carrying out advance support construction on the pipe shed: (301) preparing before drilling; (302) drilling pipe joints at front ends and synchronously grouting; (303) connecting the pipe joints; (304) continuously drilling and synchronously grouting; (305) repeating the steps (303) and (304) many times until the drilling processes of pipes of the current constructed pipe shed are finished; (306) blocking drill holes; (307) carrying out grouting construction on final holes; (308) repeating the steps (301) to (307) many times until all advance support construction processes of the pipes of the pipe shed are finished; and (4) carrying out excavation construction on the tunnel. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient in construction and good in support effect; and by adopting automatic drilling type high-strength pipes of the pipe shed, the advance support process of the tunnel can be simply, conveniently and quickly finished.

Owner:CHINA RAILWAY 20 BUREAU GRP

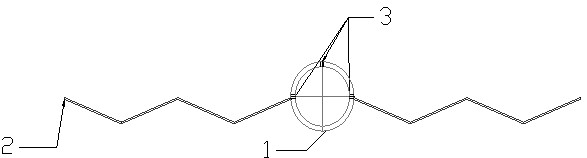

Support method for coal seam roadway to cross gob

ActiveCN102505949ALarge diffusion radiusHigh strengthUnderground chambersElectrophoretic coatingsCoal measuresSlurry

A support method for a coal seam roadway to cross a gob belongs to the technical field of roadway supporting for coal measure strata and utilizes combination of temporary support and permanent support. The support method is characterized in that the temporary support includes applying an alternating-current field after double-slurry is grouted into small ducts, increasing scattering radius of the slurry under electric effect of electro-osmosis and electrophoresis, filling the double-slurry into holes and slits inside regenerated surrounding rock of the gob sufficiently so as to reinforce of the regenerated surrounding rock of the gob again, and finally forming the integrated surrounding rock. The support method aims to increase integral strength, stability and self-bearing capacity of the regenerated surrounding rock of the gob. The integral strength of the regenerated surrounding rock of the gob is increased by at least 230% by using the support method as compared with the existing support method for the coal seam roadway to cross the gob.

Owner:SCI & TECH RES OF SHANXICOAL TRANSPORTATION & SALES GROUP

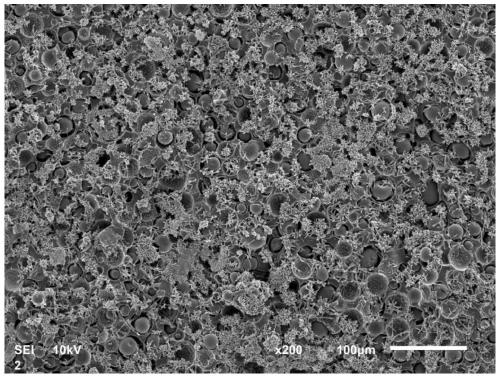

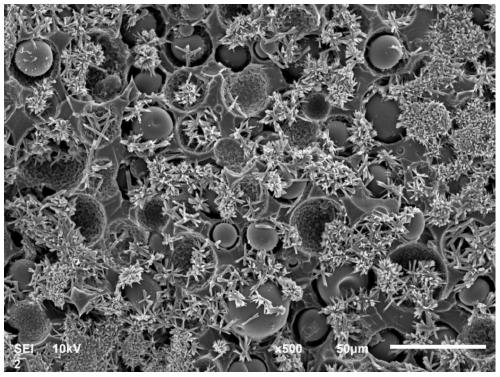

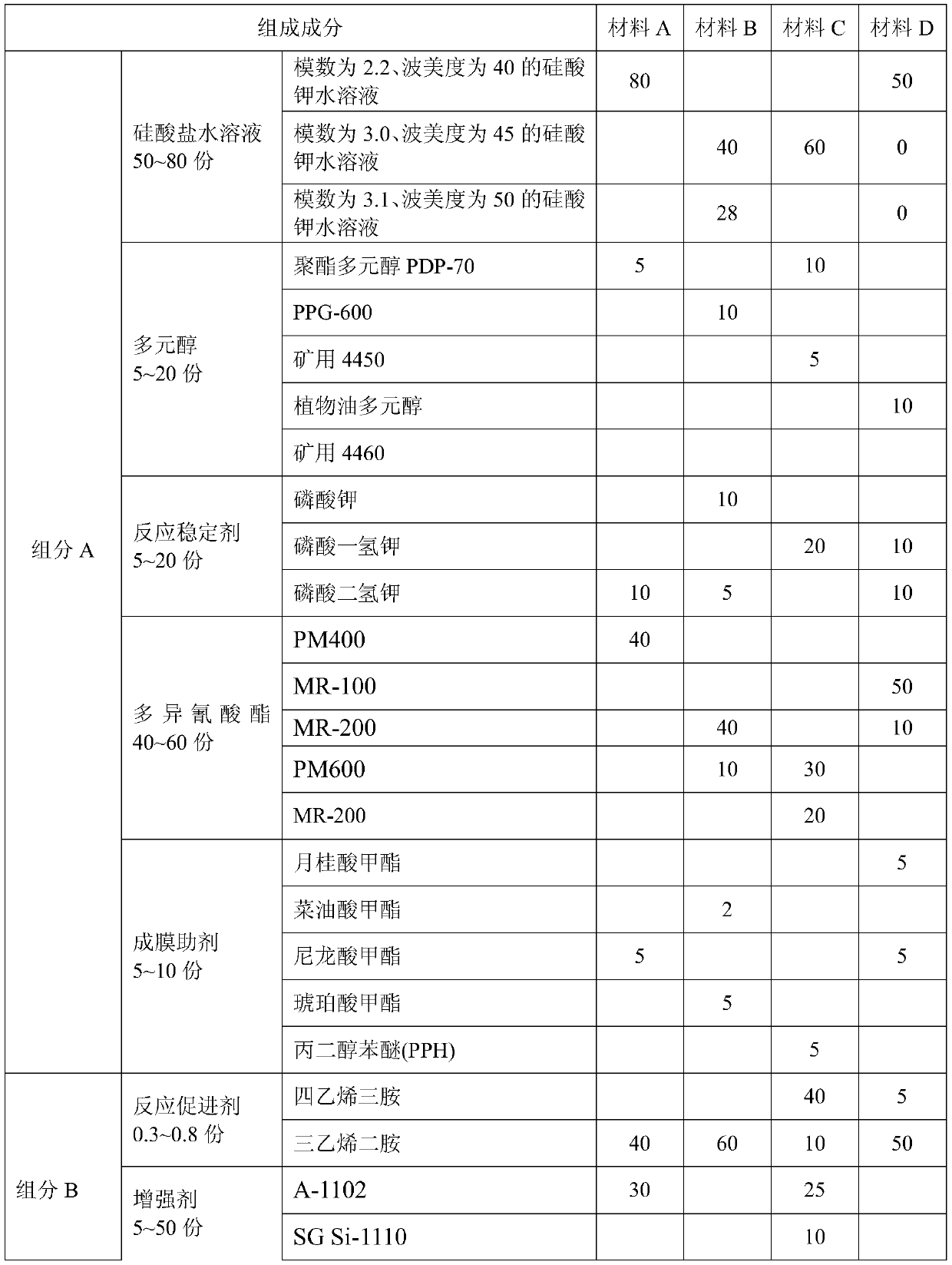

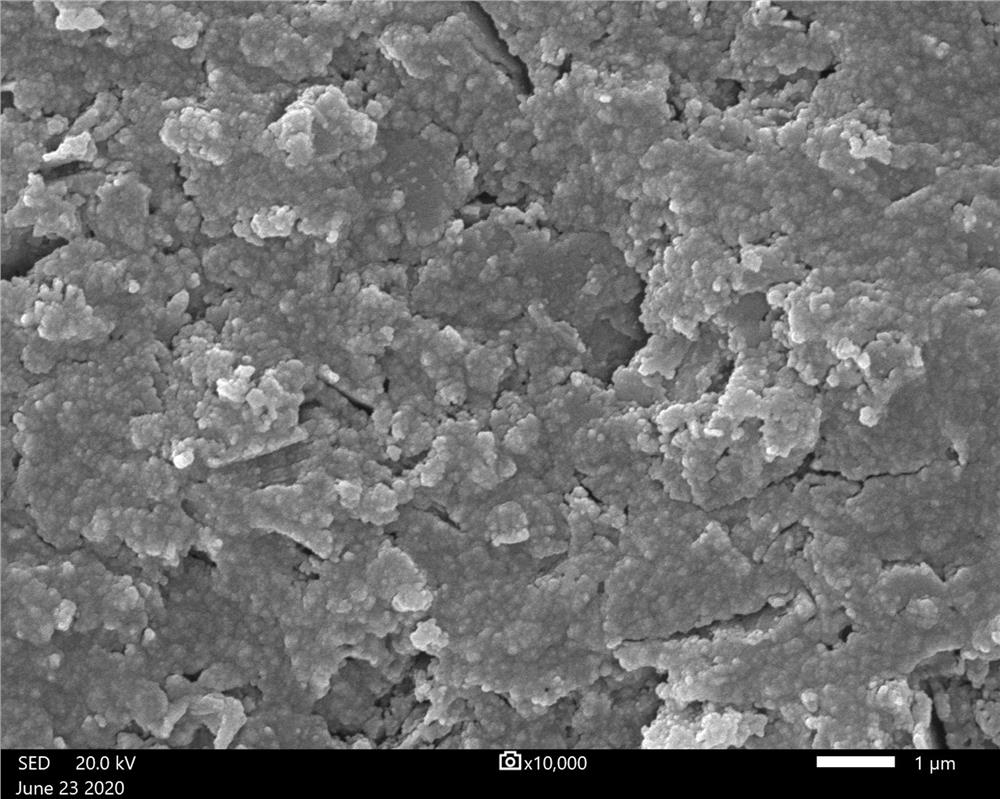

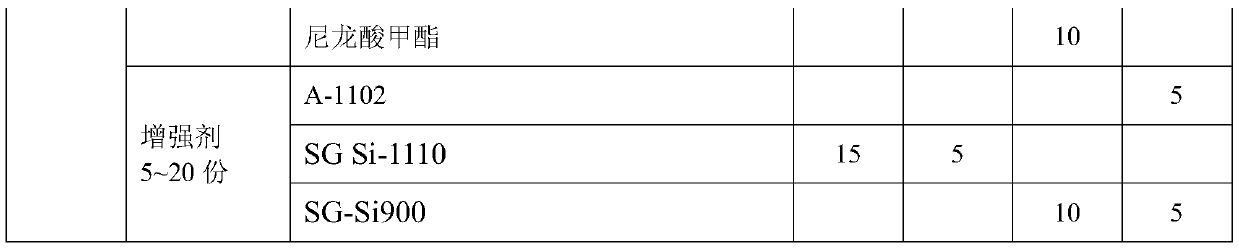

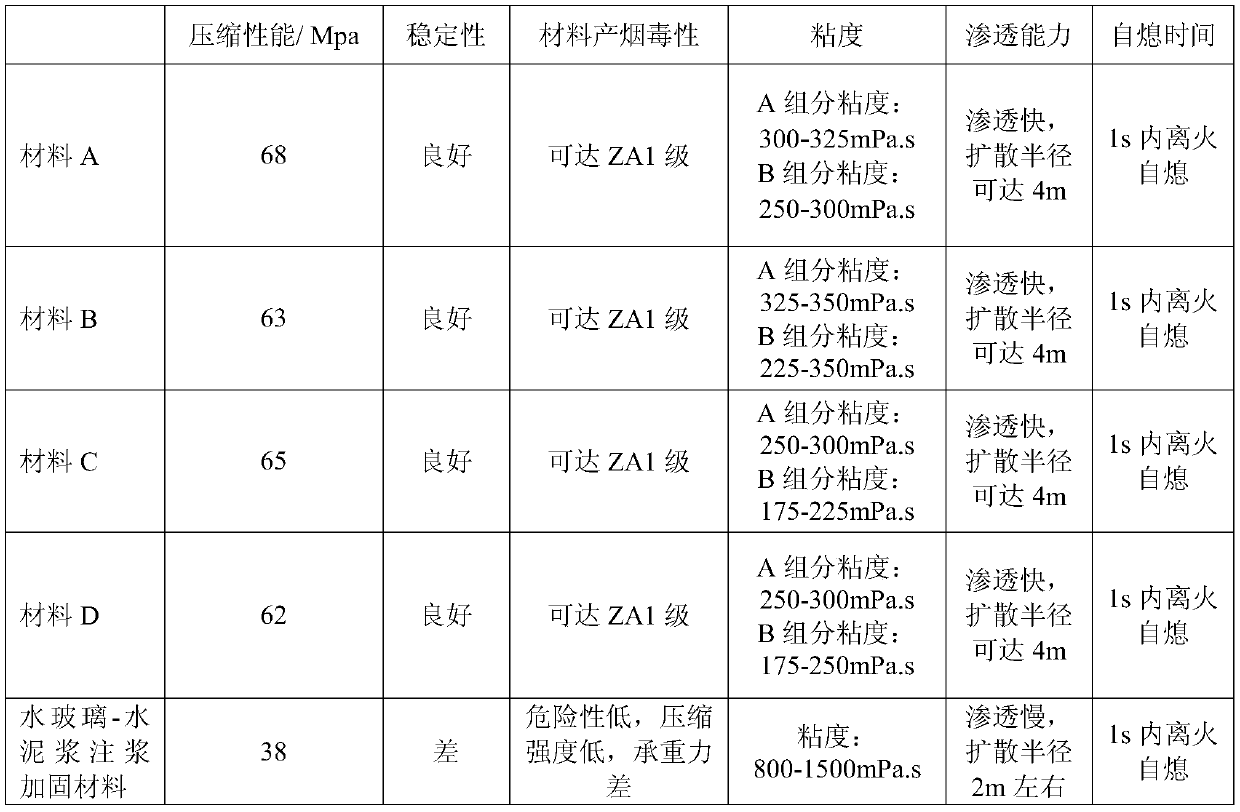

High-strength composite grouting reinforcement material with island structure and preparation method thereof

The invention relates to a high-strength composite grouting reinforcement material with an island structure and a preparation method thereof, which belong to the field of engineering grouting reinforcement. The material comprises components A (silicate aqueous solution, polyisocyanate, polyol, a reaction stabilizer and a coalescing agent) with the viscosity of less than 300 mpa.s and components B(a reaction promoter, a reinforcing agent and a cooling agent) with the viscosity of less than 200 mpa.s, and through content adjustment of proper components, the material has an island structure. Thecompressive strength of the material can reach 65 Mpa or above, self-extinguishing can be achieved within 1 s after fire is removed, safety is high, stability is good, viscosity is low, infiltrationcapacity is high, the diffusion radius is large, the material is applied to the fields of coal mine roof and floor reinforcement, roadway reinforcement, slope reinforcement, soft soil foundation reinforcement and the like, the mechanical structure of a working face can be effectively improved, and the bearing capacity of the working face is improved; meanwhile, the preparation method is simple andeasy to operate, and the preparation cost of the reinforcing material can be further reduced.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Compound micro iron agent facilitating in-situ injection and preparation method of compound micro iron agent

InactiveCN107473315AImprove stabilityGuaranteed stabilityOther chemical processesAlkali metal oxides/hydroxidesMaterials scienceIon

The invention discloses a compound micro iron agent facilitating in-situ injection and relates to the technical field of in-situ remediation of soil and underground water. The compound micro zero-valent iron agent is prepared from zero-valent ion powder, a dispersant, a thickener and water through uniform mixing in a high-speed stirring manner. The zero-valent iron powder, the dispersant and the thickener account for 5%-40%, 0.3%-1% and 2%-6% of the total water quantity respectively in percentage by weight. Compared with existing commercially available micro iron compound agents, the compound micro zero-valent iron agent has very high stability and excellent migration liquidity, facilitates in-situ injection of the agent during remediation, can be injected into a target remediation layer under lower pressure, has larger diffusion radius and has good removal effects on heavy metals and organic pollutants. The compound micro zero-valent iron agent comprises green and environmentally friendly components, is wide in application range, is beneficial to sustainable development of the enjoinment and cannot exert adverse effects on the underground water environment.

Owner:北京市科学技术研究院资源环境研究所

Side slope grouting slurry for silty-fine sand embankment widening and method for preparing same

The invention discloses side slope grouting slurry for silty-fine sand embankment widening, prepared from the following raw material in parts by weight: 3-15 parts of water glass, 2-10 parts of acetic acid, 1-5 parts of calcium chloride, 0.2-3 parts of disodium hydrogen phosphate, 0.1-5 parts of ferric trichloride, 0.1-5 parts of aluminum chloride, and 0.1-3 parts of phosphoric acid or sulfuric acid. The side slope grouting slurry for silty-fine sand embankment widening has the advantages as follows: (1) the slurry provided by the invention is good in permeability, large in dispersion radius after grouting, high in grouting reinforcement strength and good in homogeneity, and the gelation time of the slurry in the air and the sand layer is long; (2) the rest materials of the raw materials apart from the acetic acid which is an organic matter are all inorganic matters, and all of the raw materials do not belong to the range of hazardous article control, and may not cause pollution on the surrounding environment in the use process; the by-products of the slurry after solidification reaction also has no pollution on the environment, and is environment-friendly and harmless; and (3) the raw materials are low in price and wide in source.

Owner:SHIJIAZHUANG TIEDAO UNIV

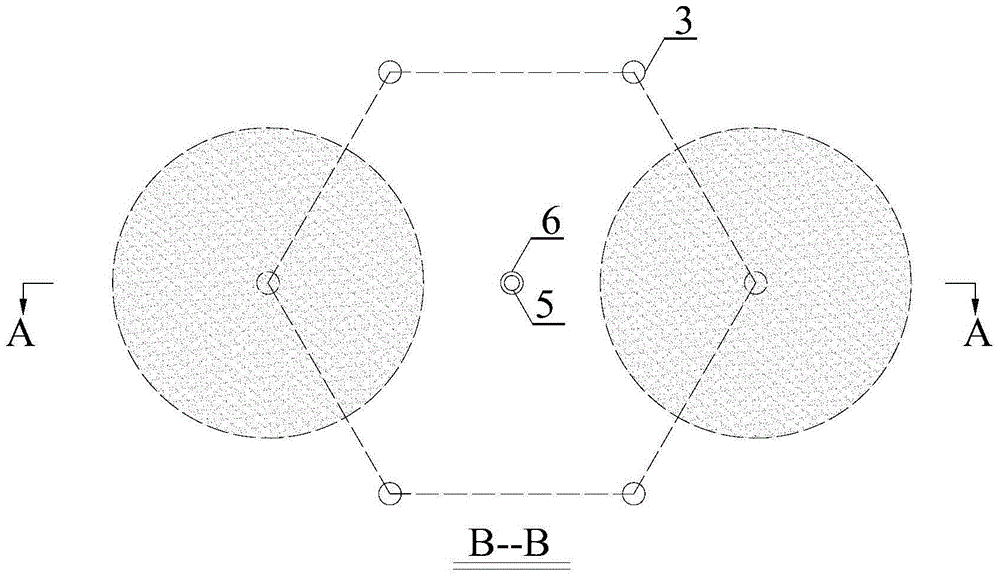

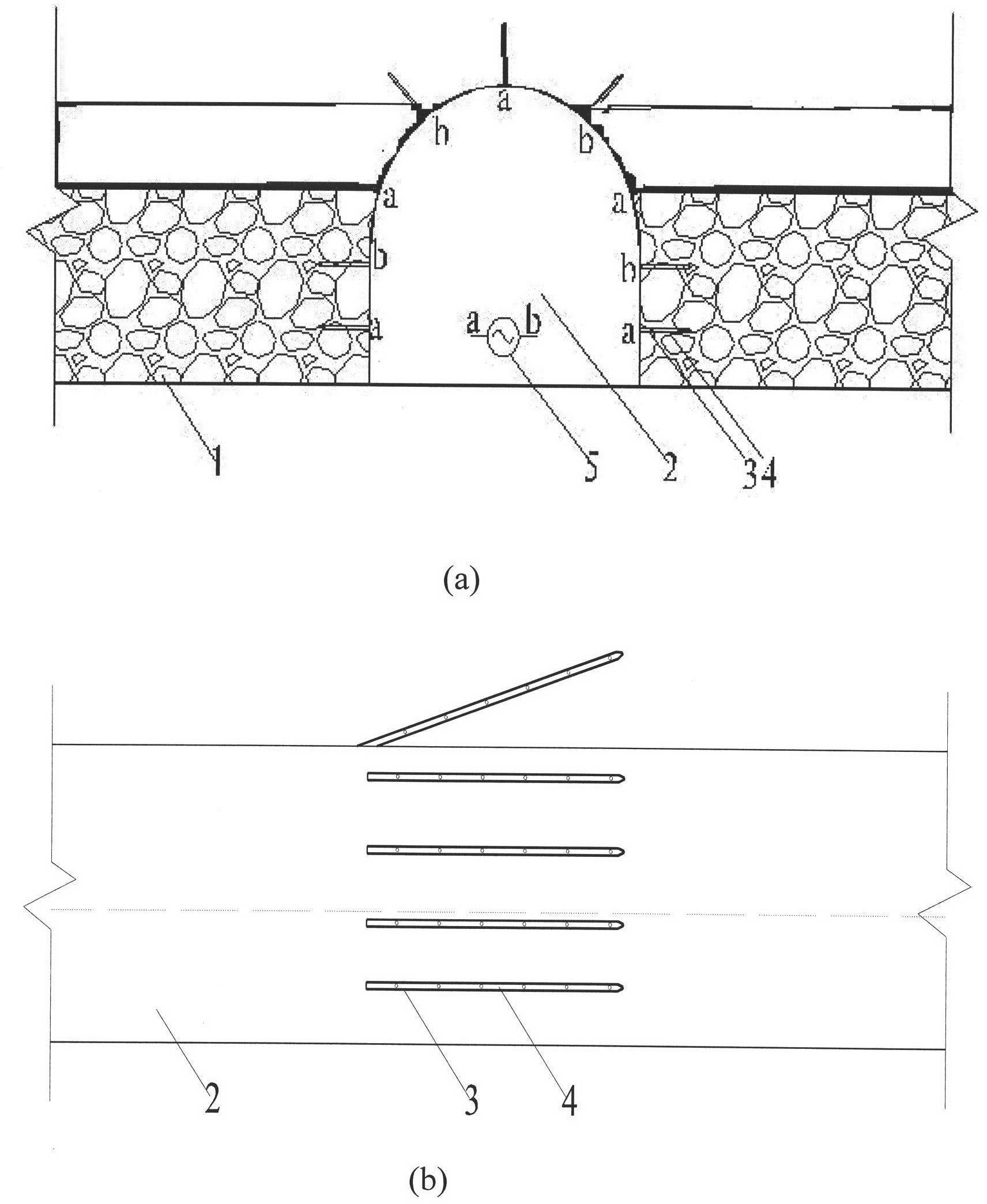

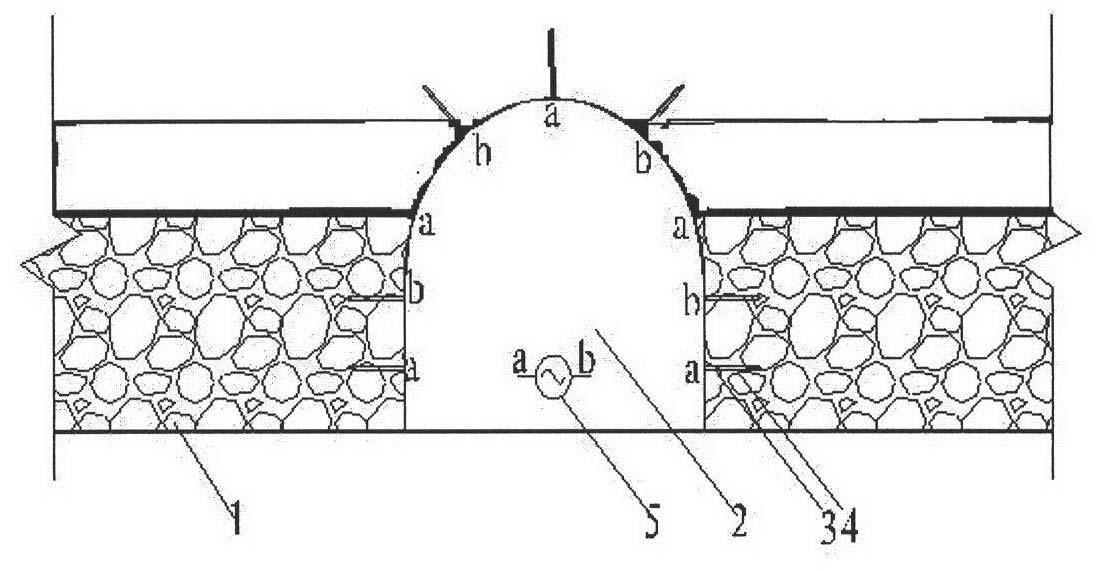

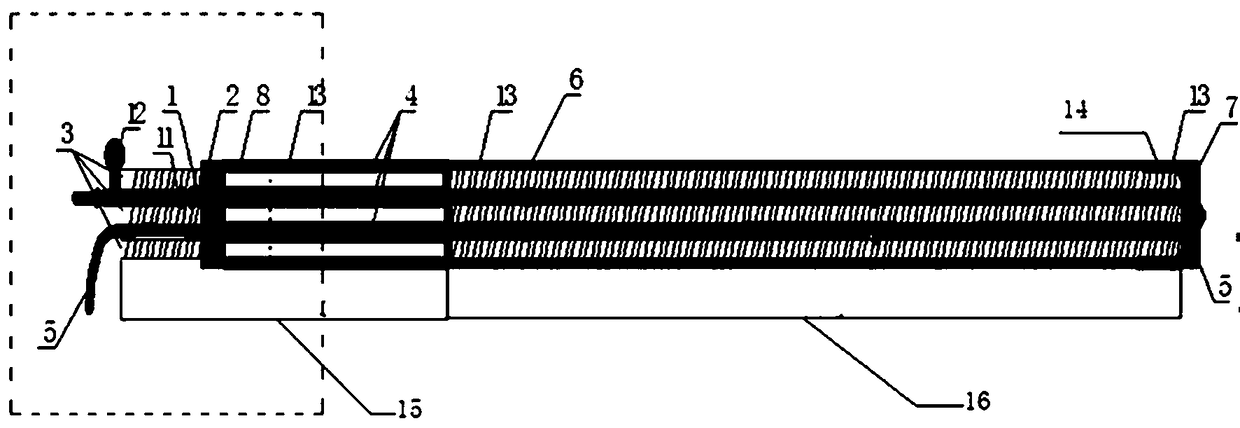

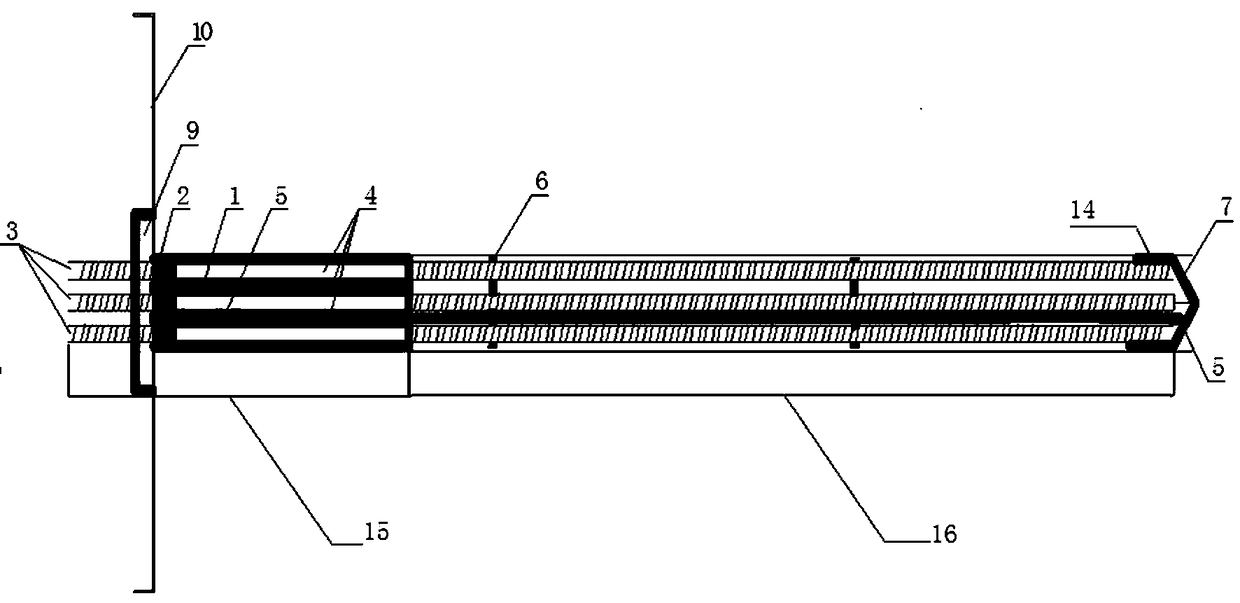

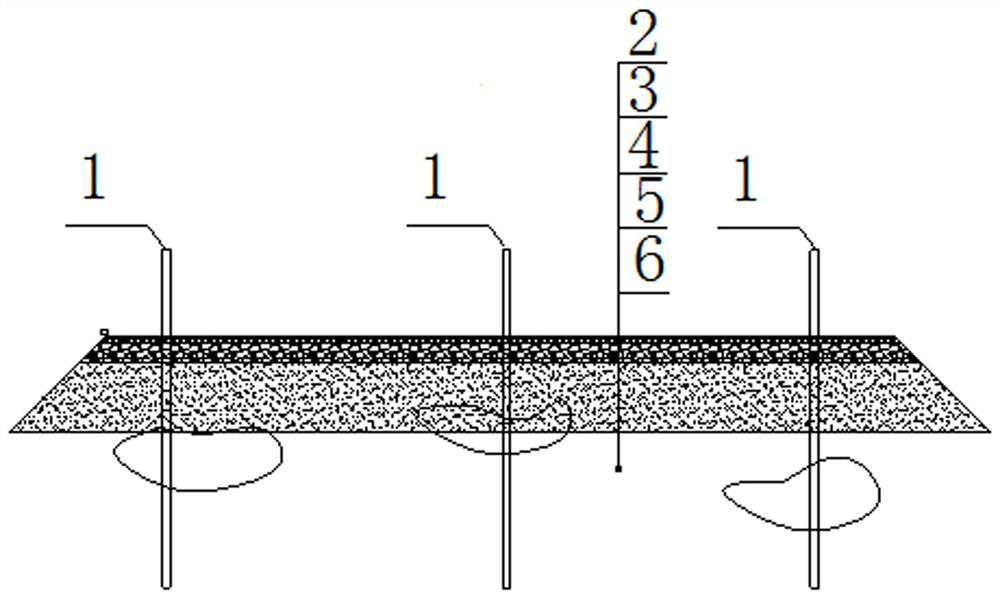

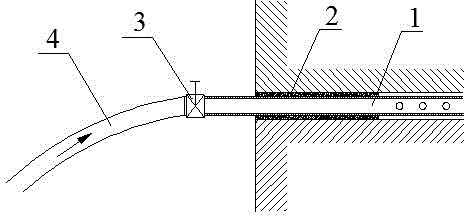

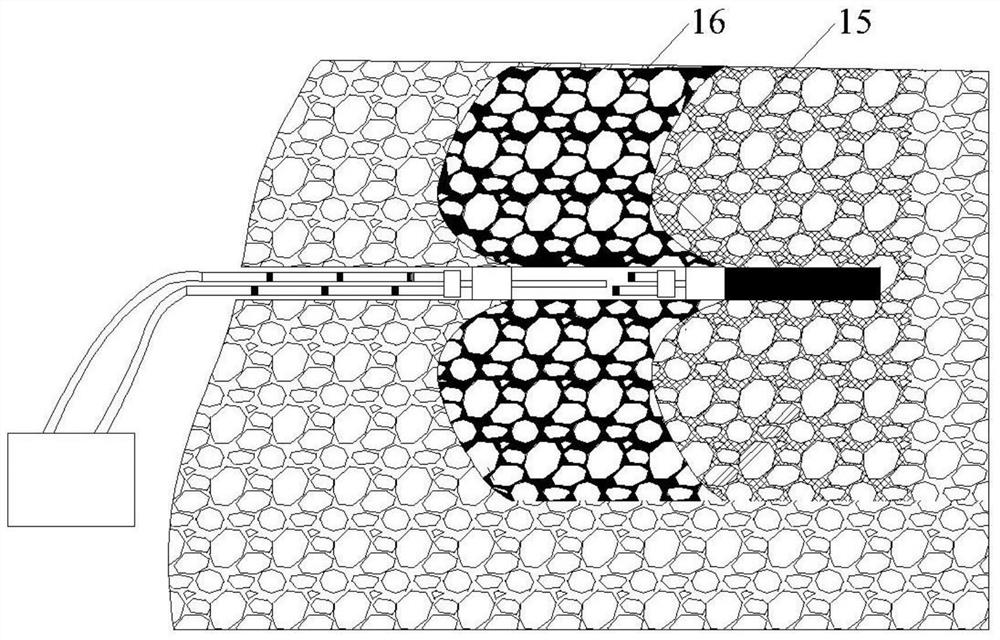

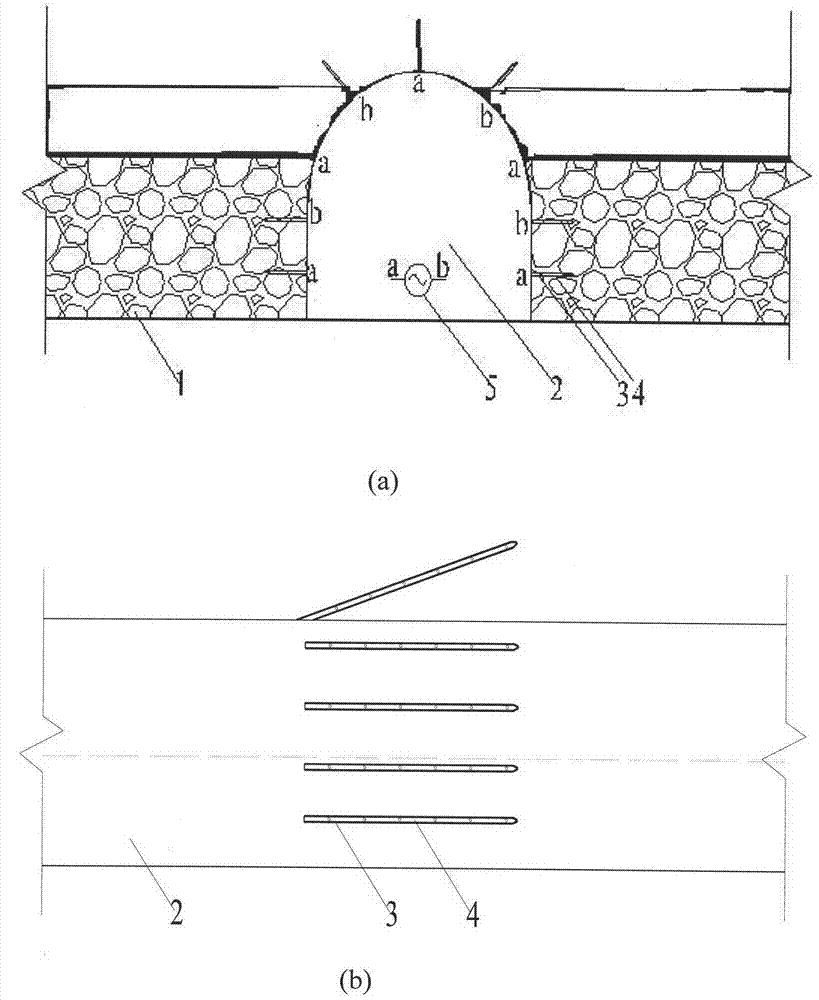

Wing plate type advanced small pipe used for advance support of soft broken surrounding rock tunnel

ActiveCN102619537ALarge diffusion radiusImprove the strength of surrounding rockUnderground chambersTunnel liningRock tunnelSlurry flow

The invention discloses a wing plate advanced small pipe used for advance support of a soft broken surrounding rock tunnel, which comprises small pipes with grouting holes, and both sides of each small pipe are provided with wing plates. The small pipes are pressed into the front broken surrounding rocks at certain inclination angle through a jack or a drill, and the small pipes are buckled together to form a curtain structure during pressing. Slurry is injected into the small pipes, the slurry flows into slots in the wing plates through holes on the pipe walls and is injected into the front surrounding rock cracks along the slots, so that the broken rock bodies are connected into a whole, and the stability of the surrounding rocks is maintained. The wing plate advanced small pipe has easiness in maintenance, high slurry utilization rate and high load bearing, the advance support of loose broken surrounding rocks is truly realized, and the collapse rate of surrounding rocks of a tunnel is greatly reduced. The wing plate advanced small pipe can be machined outside the site and then transported to the site, so that time and labor are saved. Meanwhile, the plate insertion method and the ordinary advanced small pipe are combined to form the wing plate advanced small pipe, so that sufficient supporting counter force can be implemented to the surrounding rocks.

Owner:SHANDONG UNIV

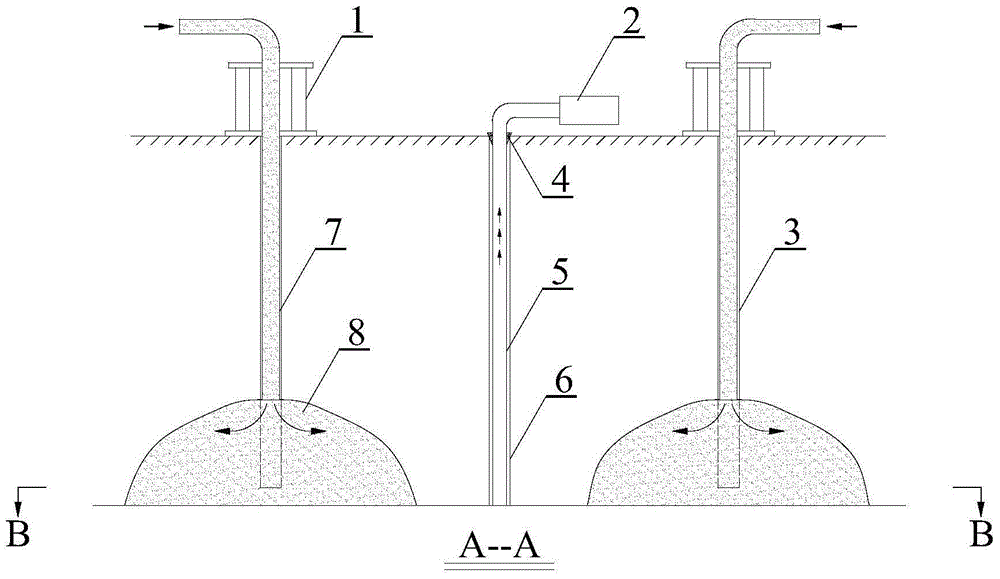

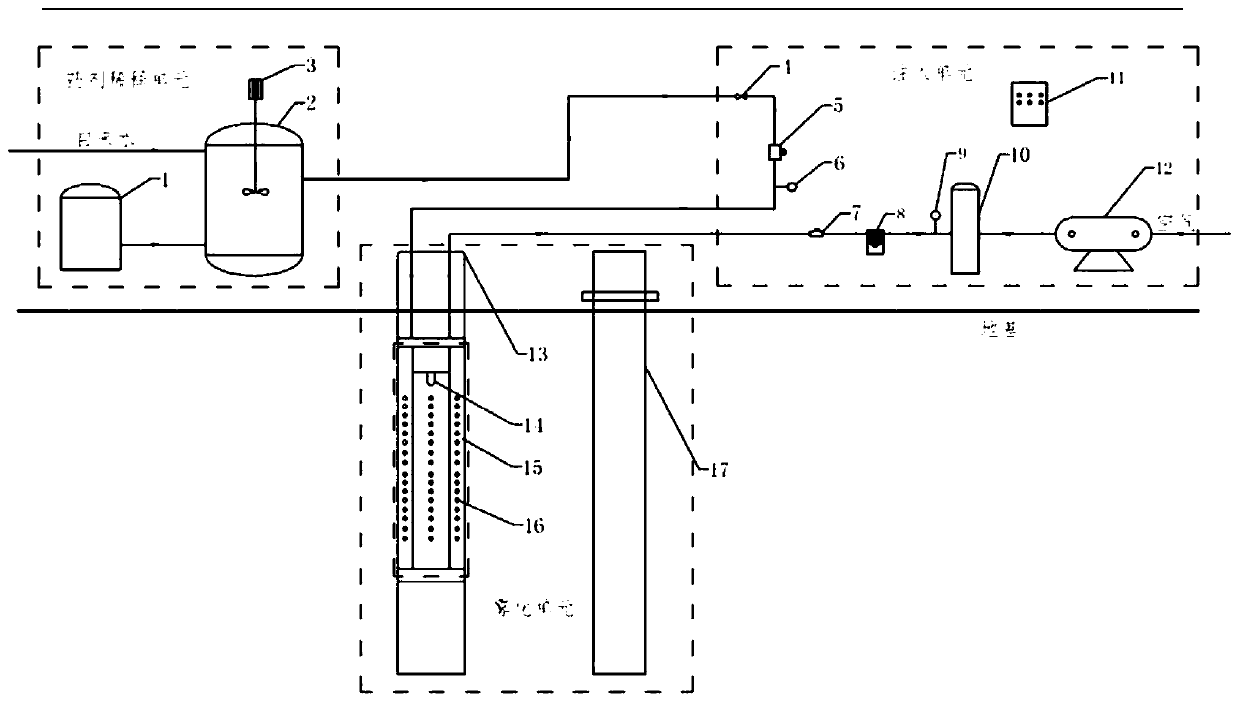

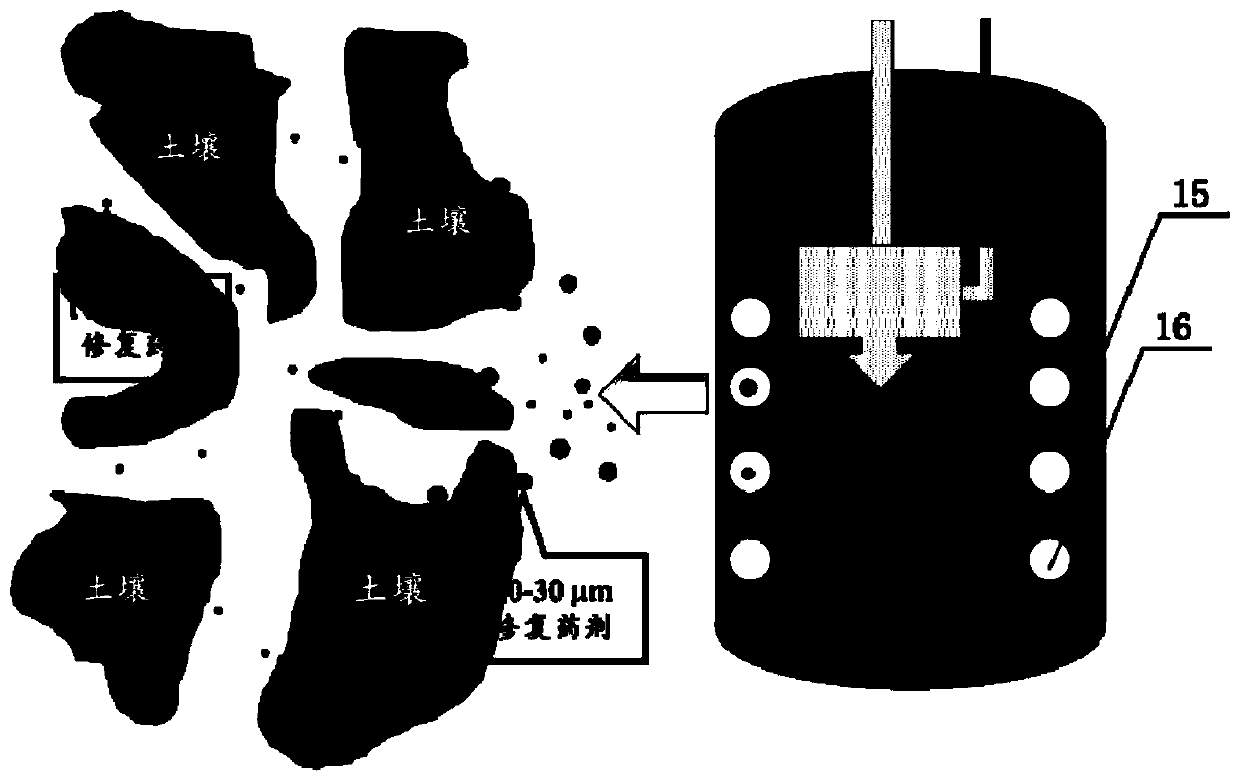

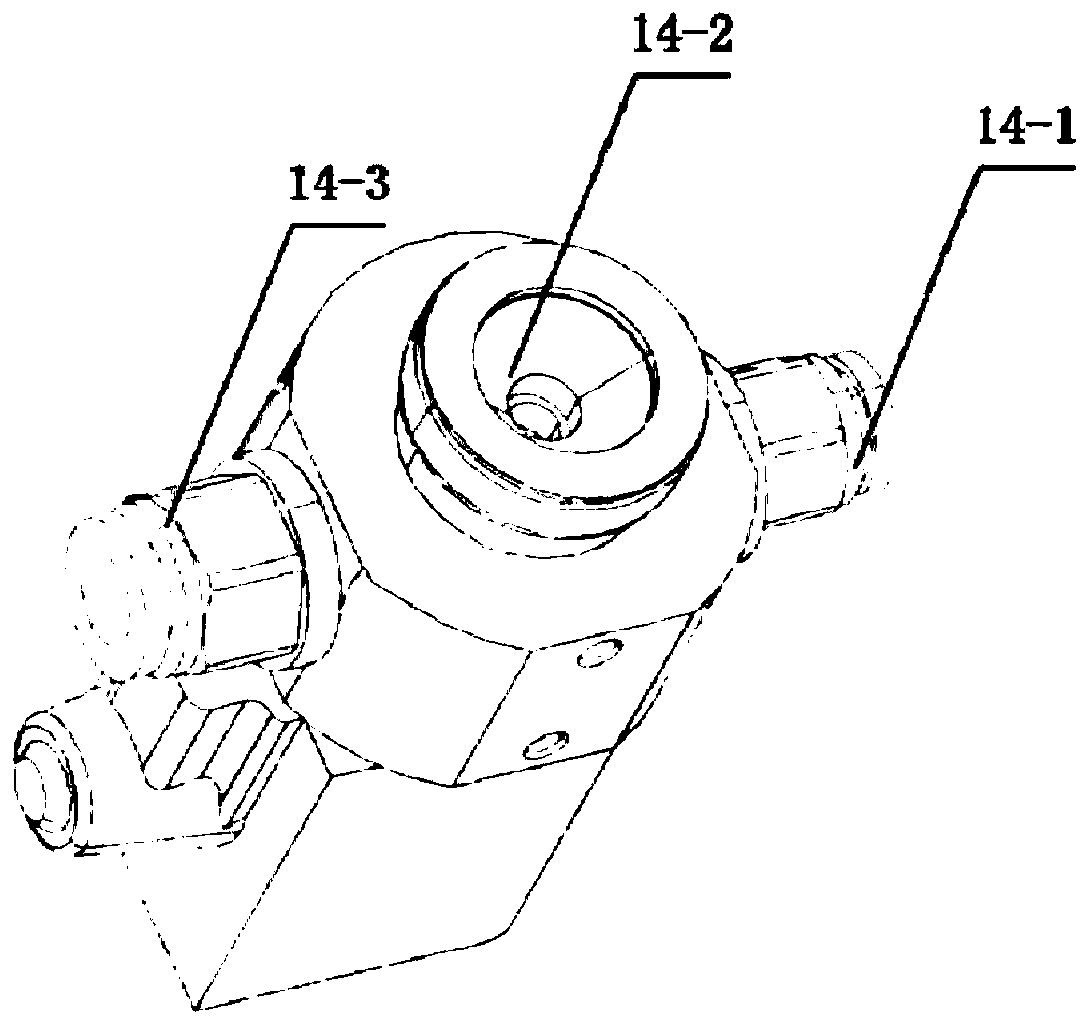

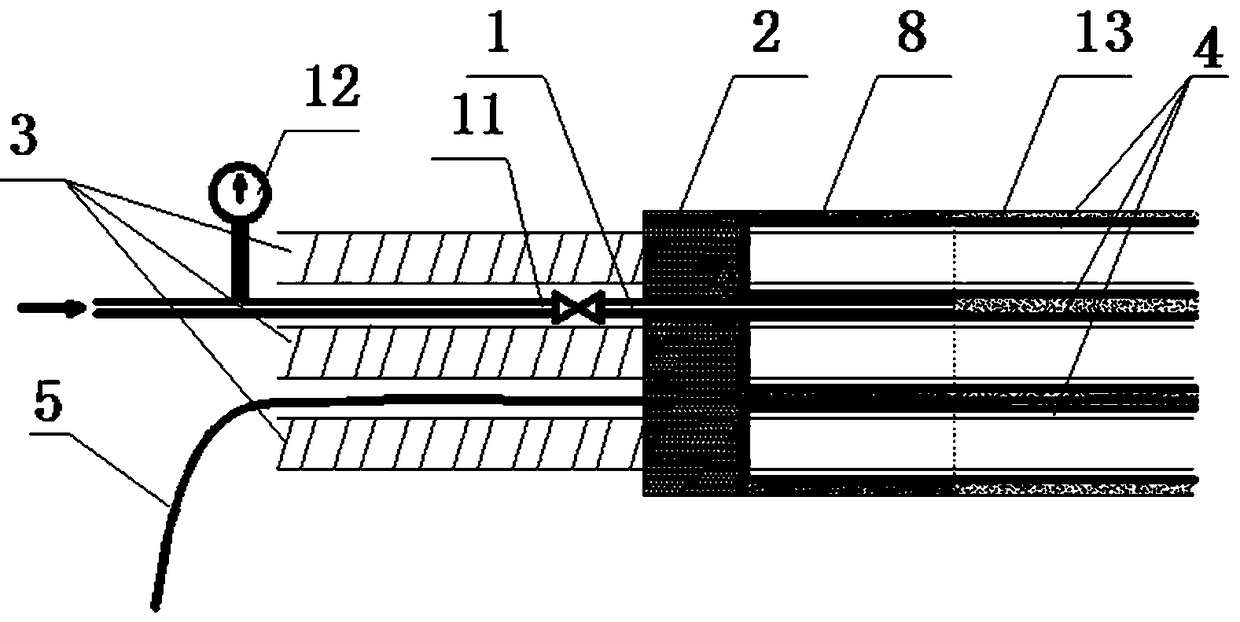

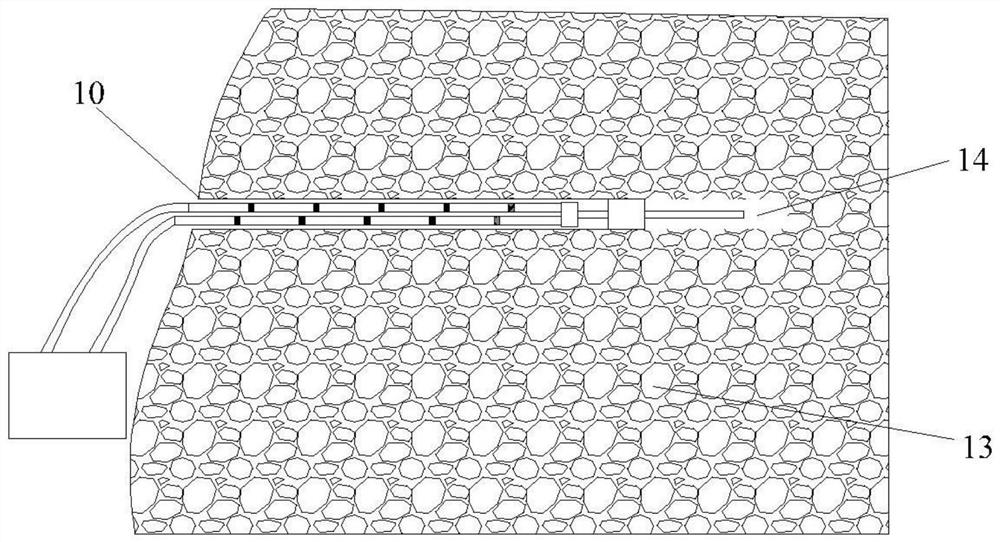

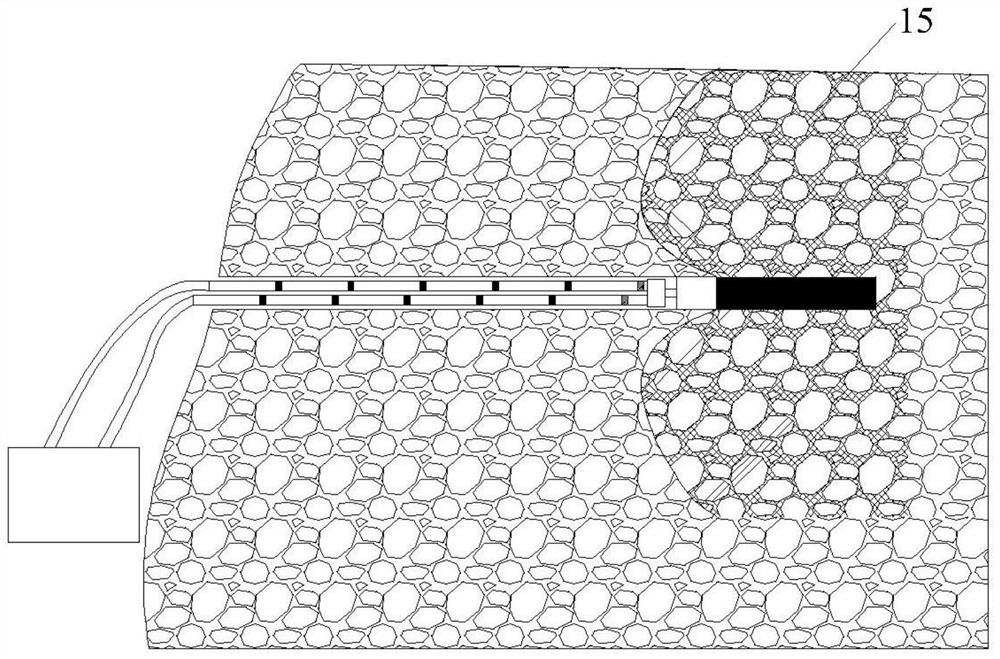

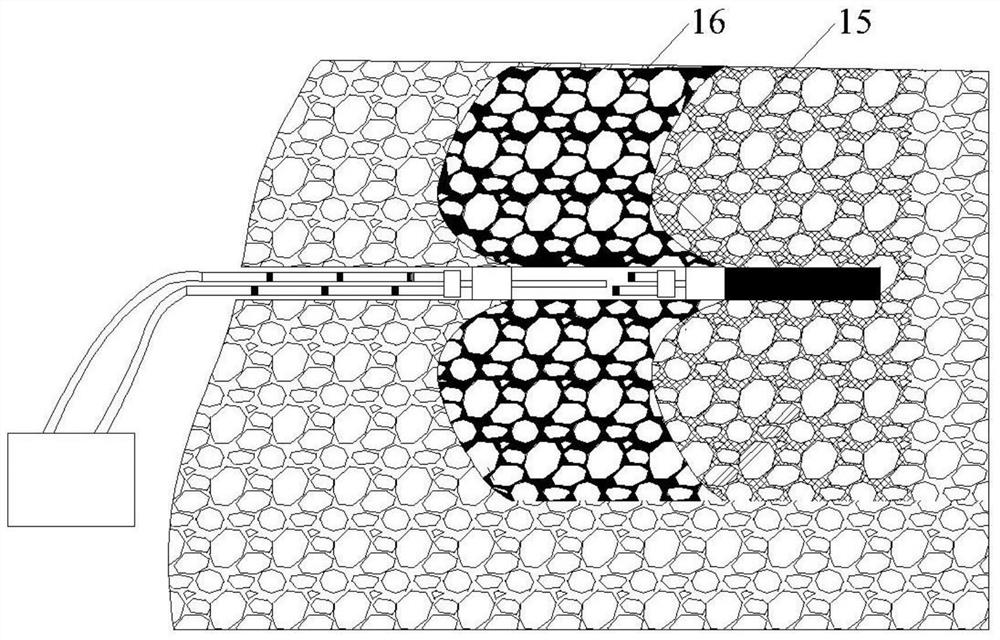

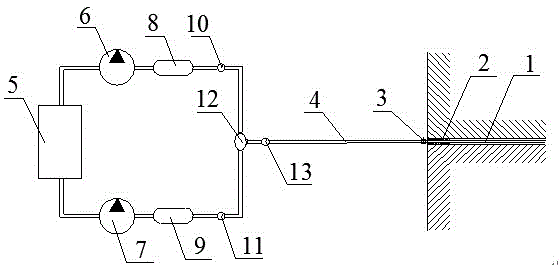

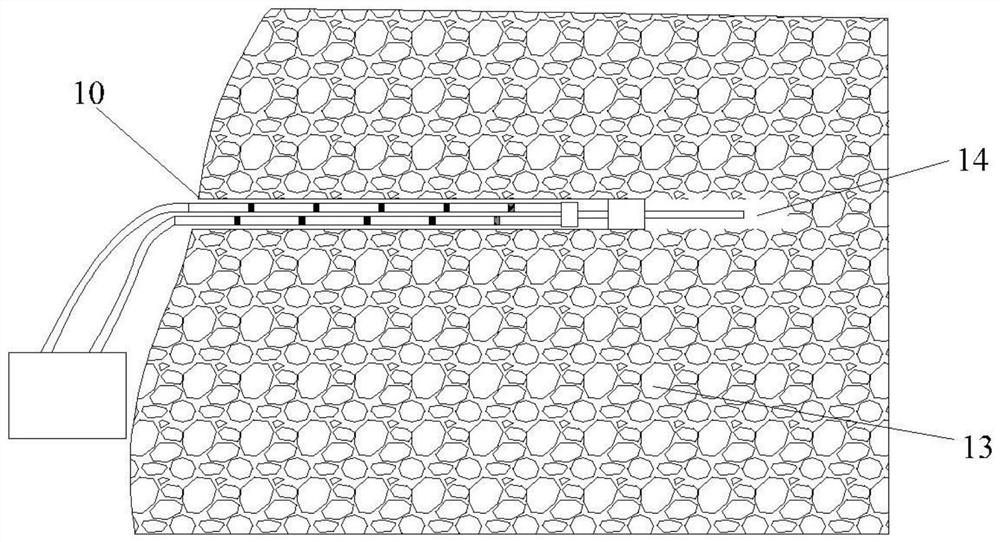

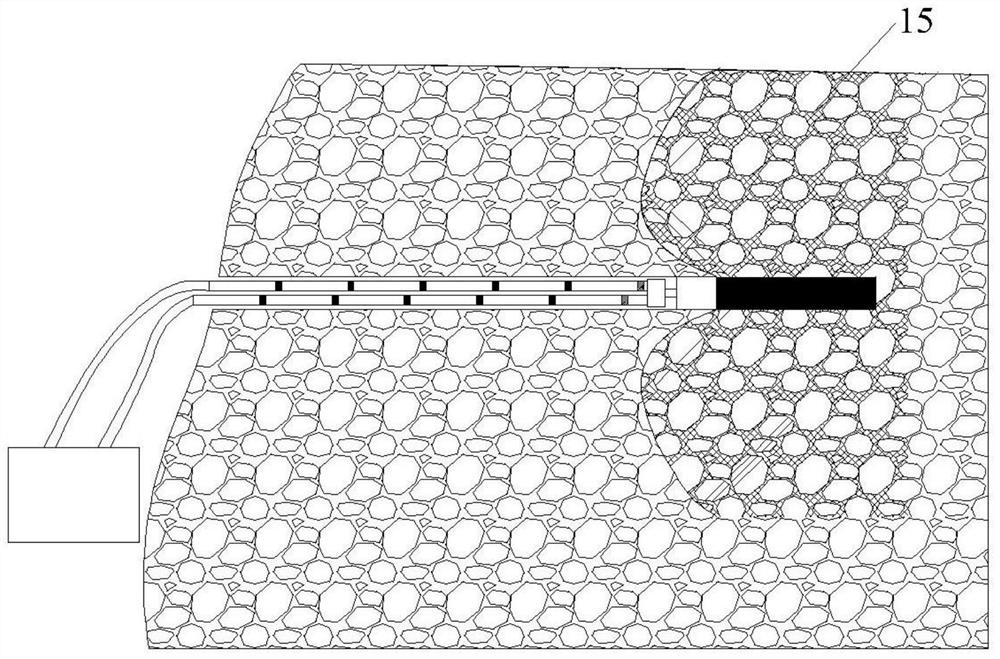

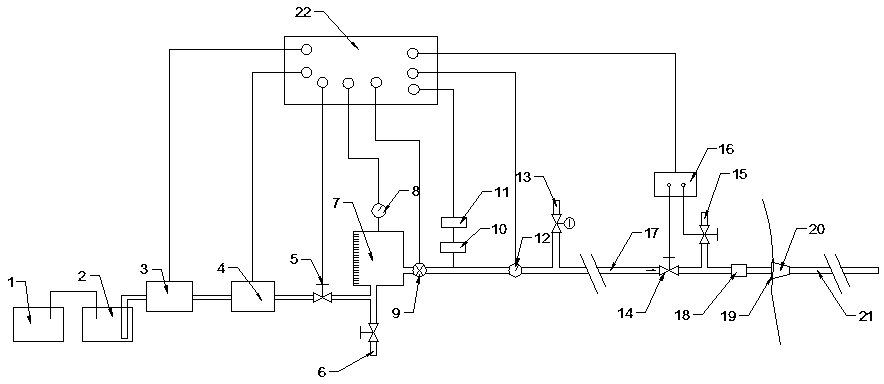

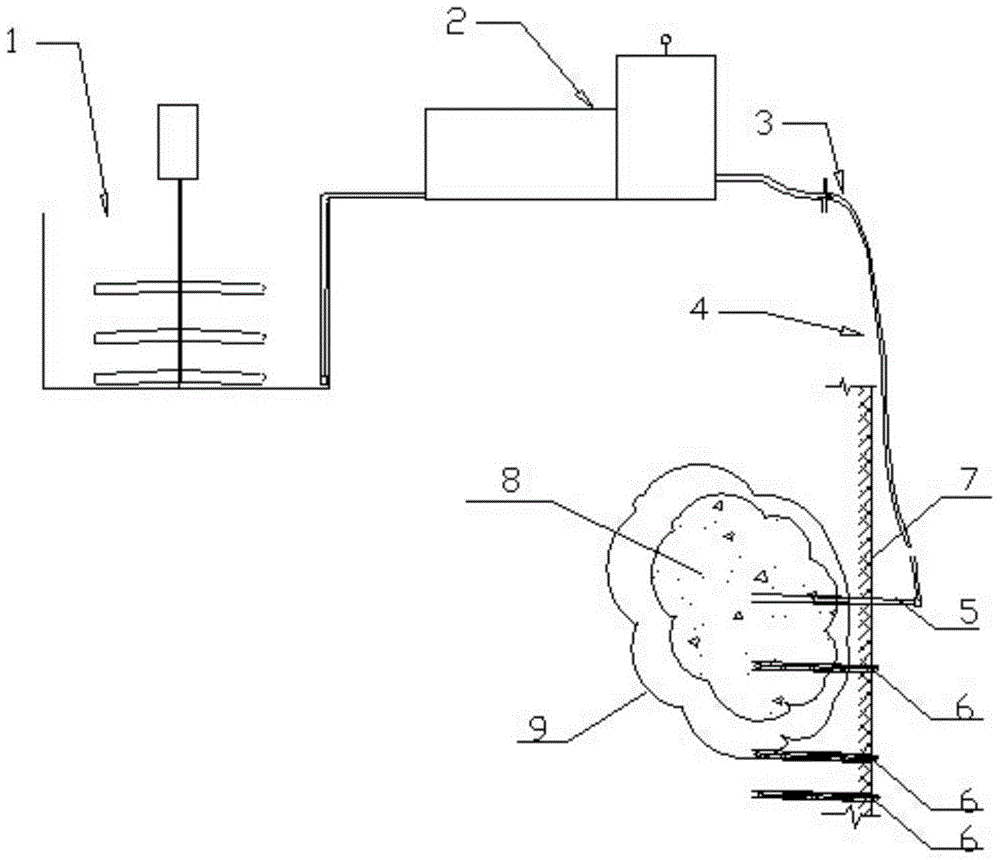

In-situ atomization and injection system for repairing contaminated sites

PendingCN109848200ALarge diffusion radiusPromote decompositionContaminated soil reclamationAir filterBuffer tank

The invention relates to an in-situ atomization and injection system for repairing contaminated sites. The system comprises: a medicament dilution unit, wherein the medicament dilution unit comprisesa medicament stock solution tank, a medicament dilution tank and a mixer; an injection unit, wherein the injection unit comprises an air compressor, a buffer tank, a pressure gauge, an air filter, a flow meter, a check valve, a metering pump, a pressure gauge and a control panel; and an atomization unit, wherein the atomization unit includes an injection well, an atomizing nozzle, a perforated injection tube, spray holes and a monitoring well. The chemical stock solution tank is connected with the medicament dilution tank through a pipeline, and a diluted medicament goes through the check valve and the metering pump and enters the atomizing nozzle; and compressed air goes through the buffer tank, the air filter and the flow meter and enters the atomizing nozzle. The diluted medicament andthe compressed air collide with each other in the atomizing nozzle to form a misty medicament, and the misty medicament enters the soil and groundwater through the spray holes to decompose or stabilize the pollutants in the soil and groundwater.

Owner:上海康恒环境修复有限公司

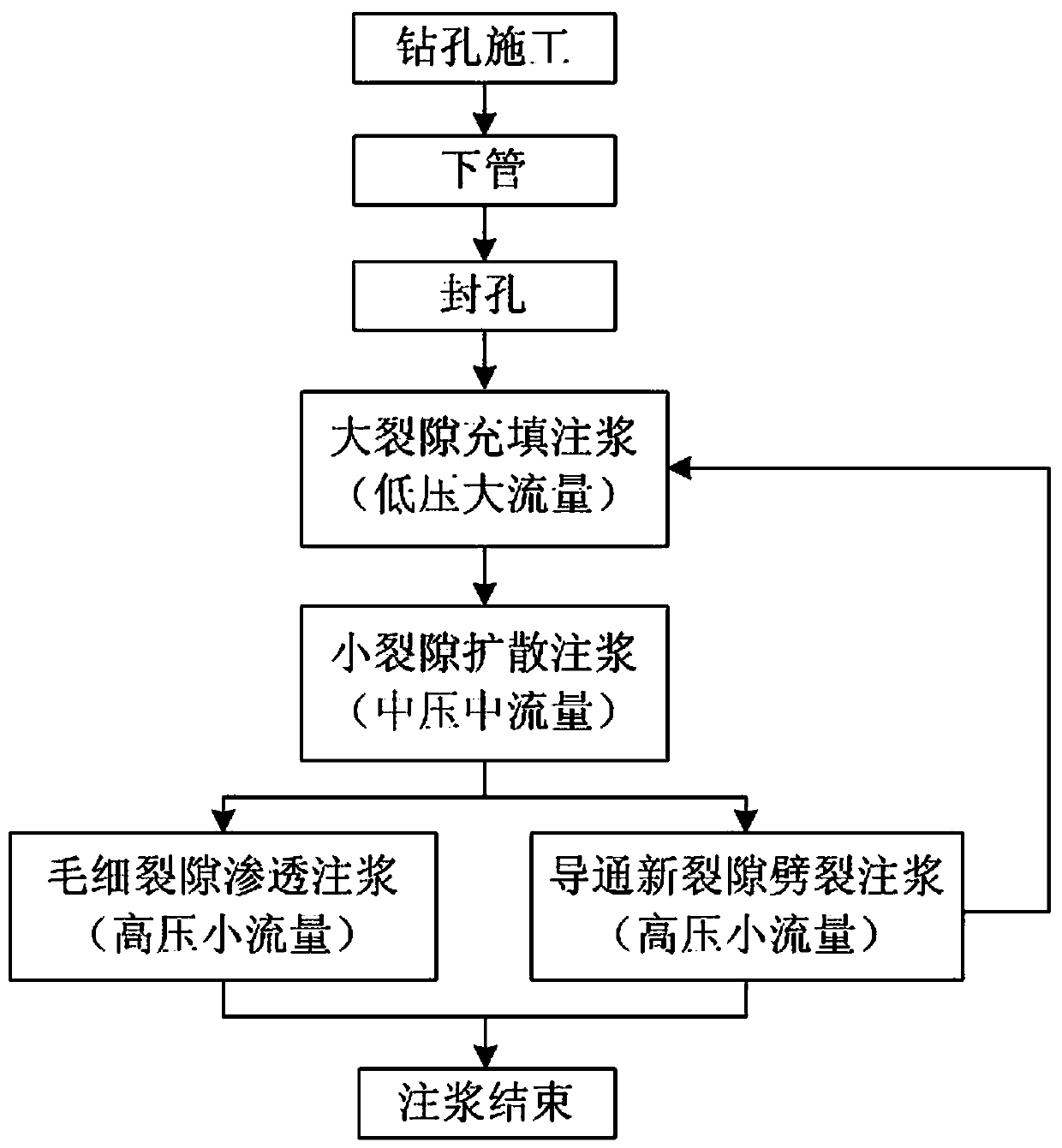

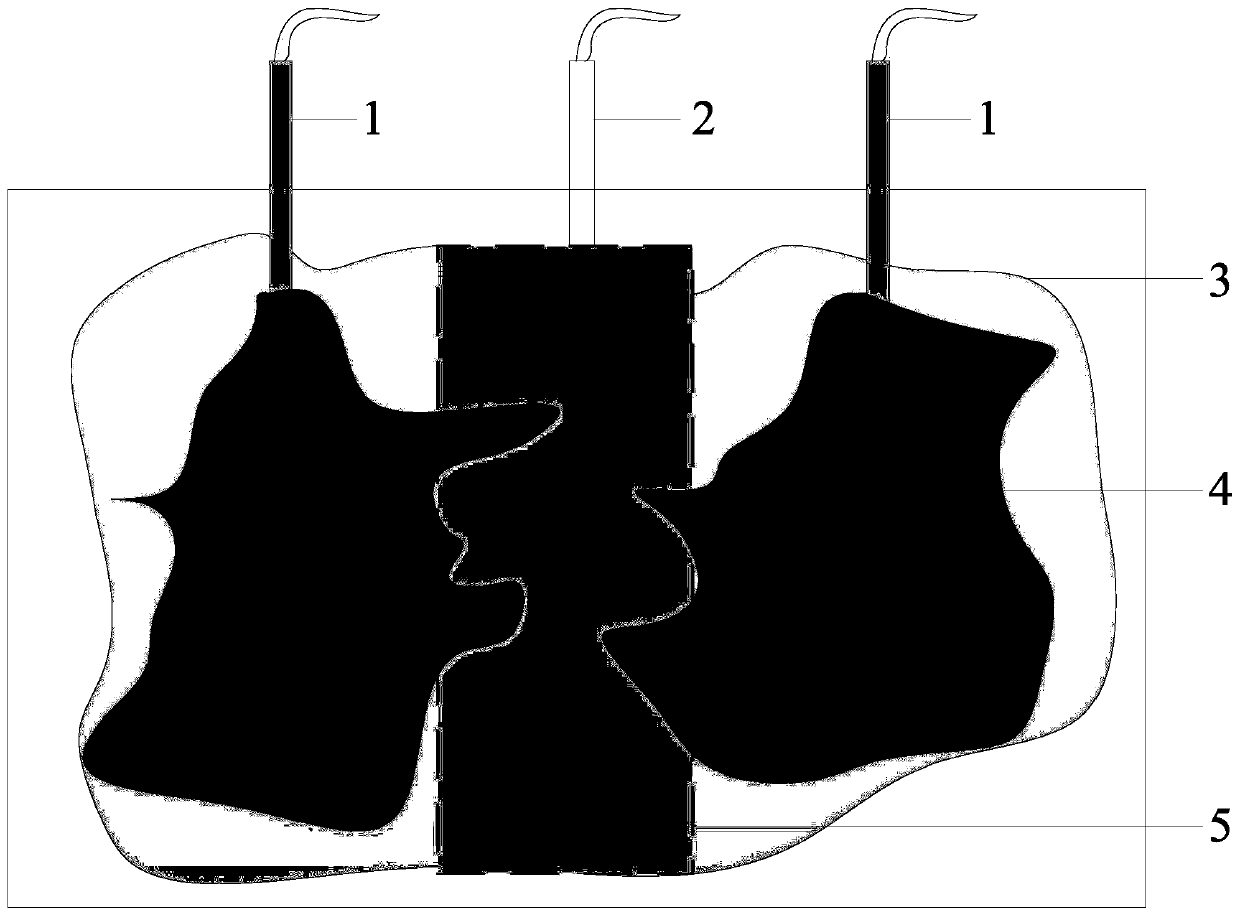

Fully mechanized mining face construction region deep hole staging pressurization grouting method

InactiveCN111156031ADiffuse fullyLarge diffusion radiusUnderground chambersSealing/packingDeep holeDrill hole

The invention relates to a coal mining grouting technology, in particular to a fully mechanized mining face construction region deep hole staging pressurization grouting method. The fully mechanized mining face construction region deep hole staging pressurization grouting method comprises the steps of construction grouting drilling, pipe downward feeding, hole sealing and grouting. According to the fully mechanized mining face construction region deep hole staging pressurization grouting method, the staging pressurization grouting mode is adopted, and therefore the purpose that different grouting pressures and different grouting flow quantities are carried out in different stages can be achieved, fully diffusion of grout is ensured, the grouting effect of the abnormal region of a working face is guaranteed, the single grouted region is prevented from being repeatedly grouted, the grouting efficiency is improved, the grout diffusion radius is increased, and the grouting effect is ensured. Advanced grouting reinforcement is conducted in the abnormal region, and therefore the stability and the bearing capacity of a coal and rock mass in the abnormal region are improved, and the situation that the working face safely and efficiently passes through the abnormal region is ensured.

Owner:SHANXI JINMEI GRP TECH RESEACH INST

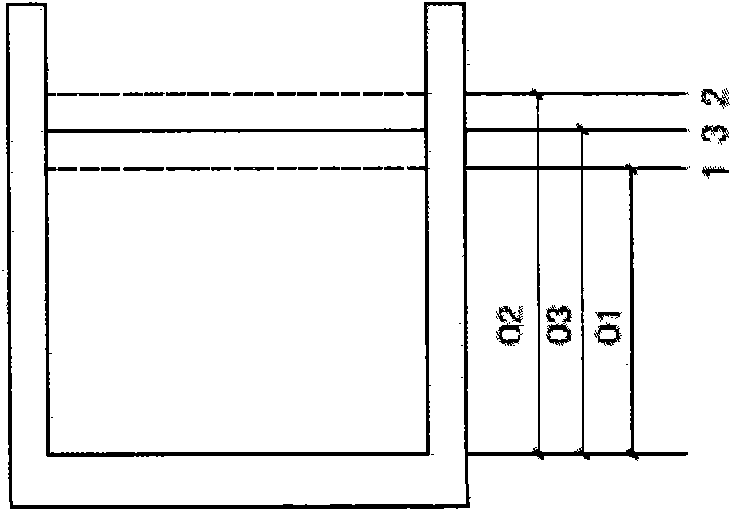

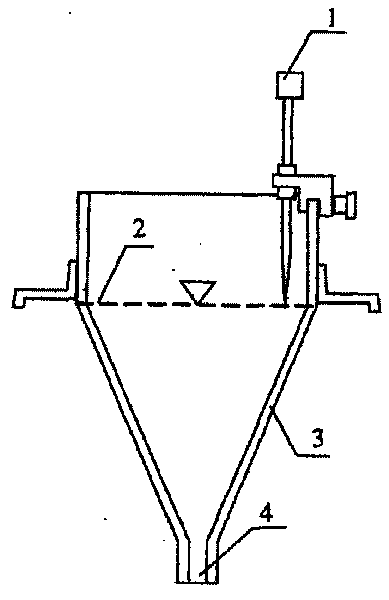

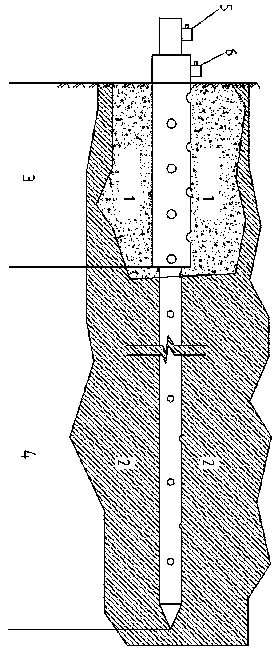

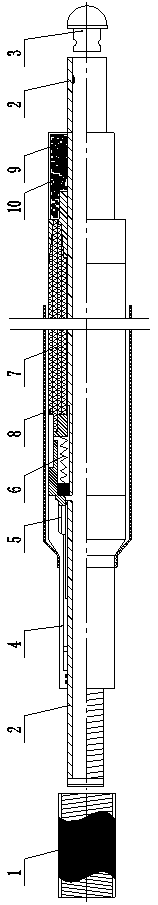

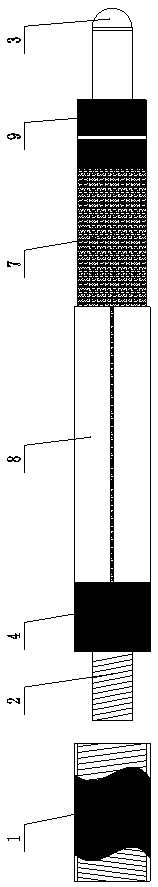

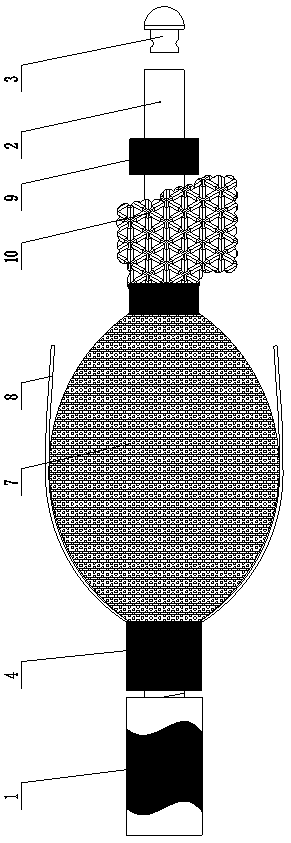

Thousand-meter deep well highland stress combination anchor rope grouting hole sealing device and hole sealing method

InactiveCN108868827AGuaranteed blocking effectLarge diffusion radiusUnderground chambersSealing/packingGeotechnical engineeringPressure increase

The invention relates to a thousand-meter deep well highland stress combination anchor rope grouting hole sealing device and hole sealing method used for grouting accessory of mines, tunnels and underground engineering shoring. The hole sealing device comprises a grouting pipeline which is used for pouring size into a grouting hole, a hole sealing device which seals the grouting hole, and the holesealing device is installed at the mouth of the grouting hole; an anchor rope is installed in the grouting hole through an anchor rope supporting frame, a guiding cap is installed at the head portionof the anchor rope, and a gas guiding pipe is installed in the grouting hole. The device has a simple structure, tight sealing and grouting pressure increasing can be achieved, the grouting diffusionradius can be increased to well fill cracking gaps of wall rock, and therefore the grouting shoring effect is improved; the device and the method can be widely applied to the mines, the tunnels and underground engineering shoring.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

Grouting reinforcement material applied to rapid repair of pavement structure, and preparation method and application

InactiveCN111978022AFast curing rateImprove early strengthCement productionPaving detailsKaolin clayRoad surface

The invention discloses a grouting reinforcement material applied to rapid repair of a pavement structure. The grouting reinforcement material comprises geo-polymer mortar, wherein the formula of thegeo-polymer mortar in mass ratio comprises a component A and a component B, the component A and the component B are mixed in an equal mass ratio, the component A comprises 31.5%-35.5% of a sodium silicate solution, 4.2%-6.2% of sodium hydroxide, 10.9%-14.9% of water and 1.0%-2% of amorphous nano silicon dioxide; the component B comprises 16.9%-20.9% of metakaolin, 11%-14% of cement and 13.5%-17.5%of slag; and the total proportion added up by all the components in the component A and the component B is 100%. The material is simple in preparation technology and low in cost, has the advantages of being environment-friendly and efficiency and capable of resource recycling, and has wide application prospect.

Owner:YANCHENG INST OF TECH

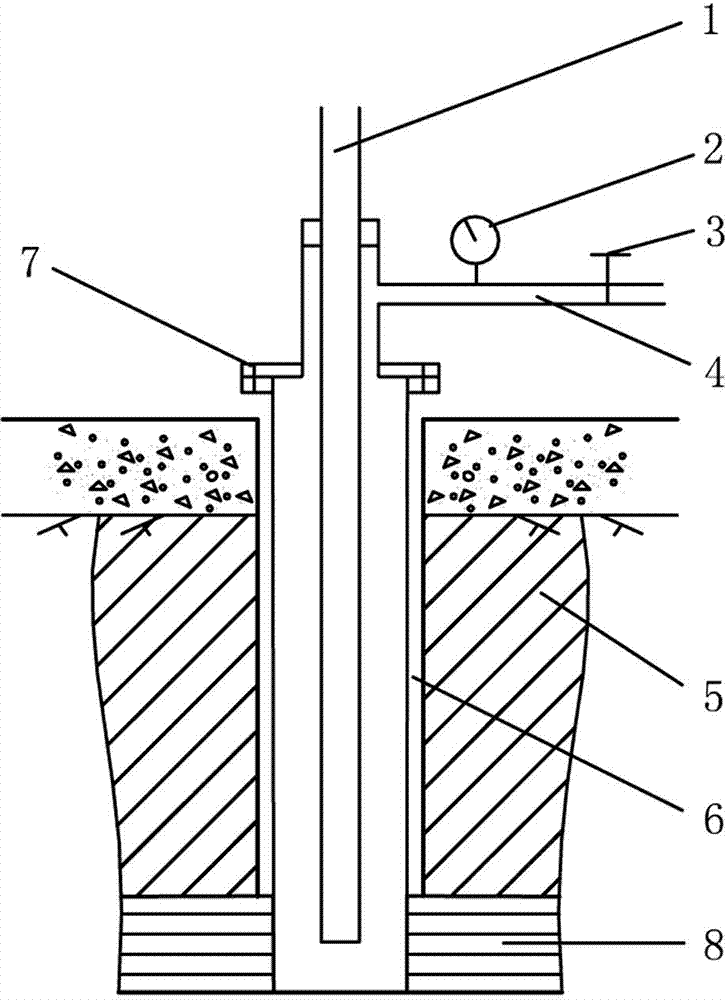

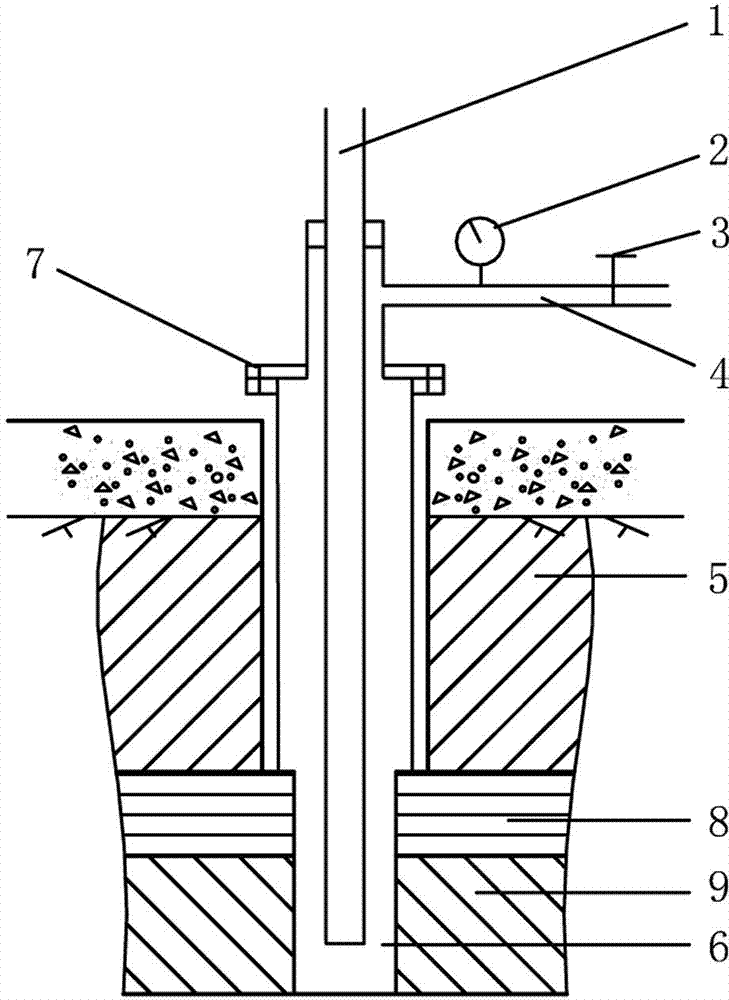

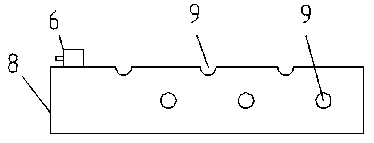

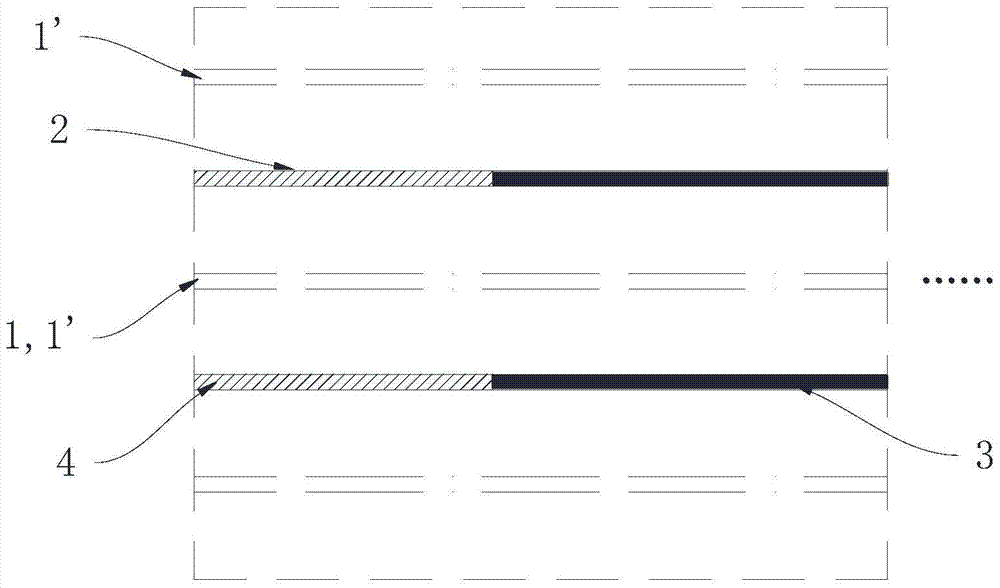

Double-wall small guide pipe grouting device and construction method thereof

PendingCN110454200ALarge diffusion radiusImprove grouting effectUnderground chambersTunnel liningDouble wallEngineering

The invention discloses a double-wall small guide pipe grouting device and a construction method thereof. The double-wall small guide pipe grouting device comprises a first grouting pipe, a second grouting sleeve sleeves the upper end of the first grouting pipe, a first gate valve is arranged at the position, located on the first grouting pipe, of the upper part of the second grouting sleeve, a second gate valve is arranged at the position, located on the second grouting sleeve, close to the first gate valve, first grouting holes are evenly distributed at the position, located on the first grouting pipe, of the lower part of the second grouting sleeve, and second grouting holes are evenly distributed at the position, located on the second grouting sleeve, of the lower part of the second gate valve. The double-wall small guide pipe grouting device has the beneficial effects of high construction speed, good grouting effect, simple structure, convenient use, good grouting effect and low cost.

Owner:GUIZHOU BRIDGE CONSTR GROUP

Coal and rock mass deep hole subsection grouting reinforcement device and reinforcement method

ActiveCN111894632AImproves uniformity of diffusionAchieving bottom-hole mixingUnderground chambersTunnel liningStructural engineeringSlurry

The invention discloses a coal and rock mass deep hole subsection grouting reinforcement device and a reinforcement method. The coal and rock mass deep hole subsection grouting reinforcement device comprise a grouting device and at least two groups of grouting pipeline assemblies, wherein the grouting device is provided with slurry outlets matched with the grouting pipe assemblies one by one, connected with the inlet ends of the grouting pipe assemblies and used for conveying different materials, the outlet end of each grouting pipe assembly is connected with a grouting head and can be detached from the grouting head by rotating on its axis. According to the coal and rock mass deep hole subsection grouting reinforcement device and the reinforcement method, the grouting pipeline assembliescan be separated from the grouting heads, so that grouting pipelines are convenient to disassemble, and the grouting heads are secondarily installed for the second time to realize grouting in the nextstage. The grouting range of the structure can be selected, the problems of small effective grouting range, serious slurry leakage phenomenon, complex grouting construction organization and the likeof an existing method for reinforcing a coal and rock mass through shallow hole grouting with high polymer reinforcing materials can be effectively solved, and meanwhile the problems of large diffusion radius fluctuation, difficulty in hole formation and difficulty in reusing drilling holes of deep hole grouting materials can be overcome.

Owner:PINGDINGSHAN TIANAN COAL MINING +1

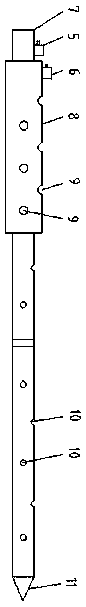

Coal mine underground deep hole quick sealing and grouting device

The invention discloses a coal mine underground deep hole quick sealing and grouting device and belongs to the technical field of coal mine underground grouting and hole sealing. The grouting device is high in engineering timeliness and grouting speed and large in diffusion radius and can achieve the objective of single-hole sectional continuous grouting. A one-way valve joint is of an internal thread structure with a forward thread at one end and a reverse thread at the other end, the reverse thread of the one-way valve joint is connected with the front end of a grouting central pipe, a sealing cover is hermetically mounted at the rear end of the grouting central pipe in a sleeved manner, a top cap, a turnbuckle, a one-way valve and a rubber sleeve are sequentially and fixedly mounted onthe outer wall of the grouting central pipe in a sleeved manner, the front end of the one-way valve is abutted against the top cap and the turnbuckle, each of two ends of the rubber sleeve is clampedand shaped through an iron core and an iron loop, an upper iron core on the rubber sleeve is fixed on the grouting central pipe, a lower iron core movably sleeves the grouting central pipe, and an inlet of the one-way valve is communicated with the inside of the grouting central pipe while an outlet of the same is communicated with the rubber sleeve.

Owner:刘彦俊

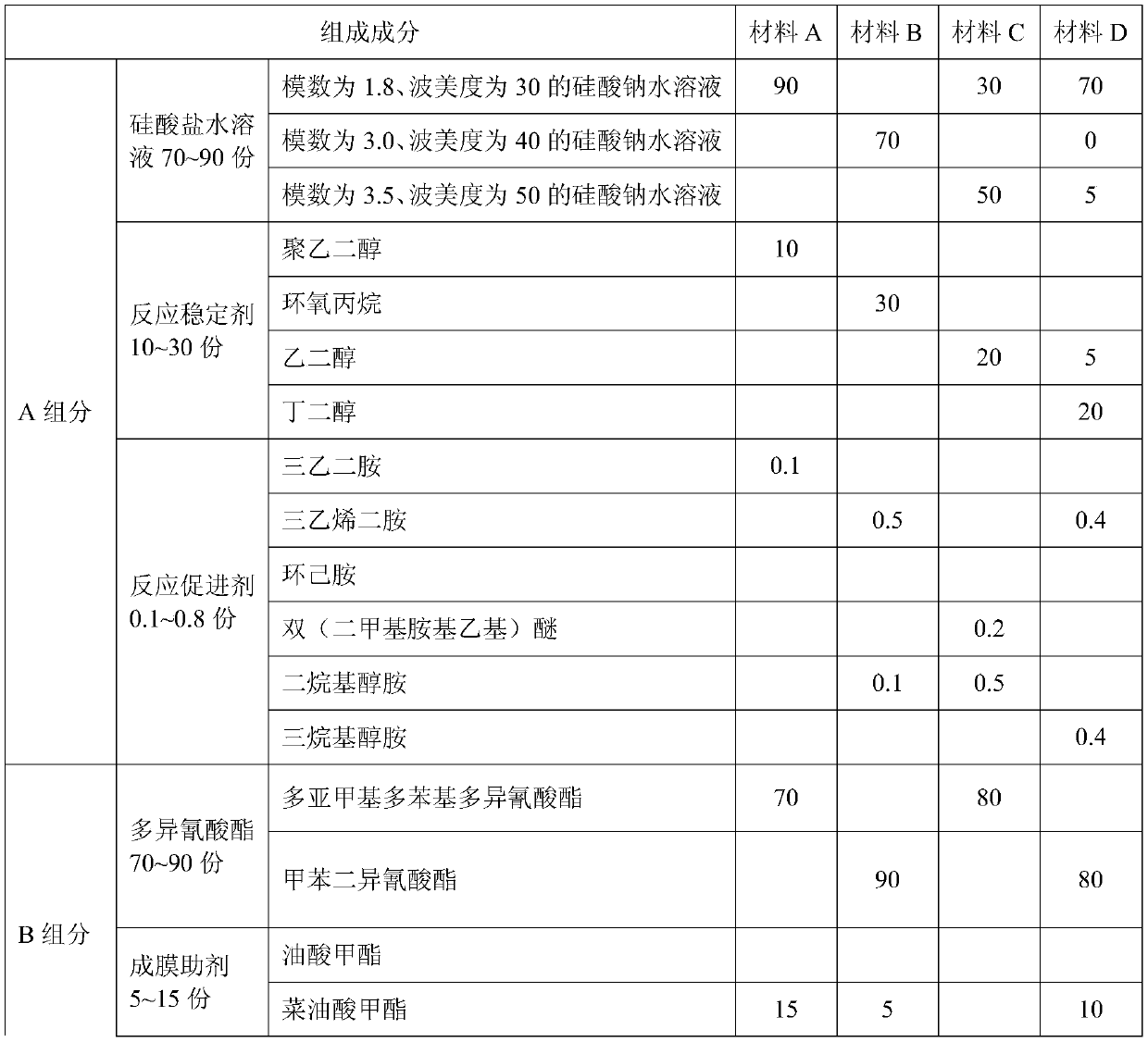

Reactive grouting reinforcement material with low smoke toxicity and high mechanical strength and preparation method thereof

The invention relates to a reactive grouting reinforcement material with low smoke toxicity and high mechanical strength and a preparation method of the reactive grouting reinforcement material, and belongs to the field of mining polymer grouting reinforcement materials. The reactive grouting reinforcement material is prepared from a component A and a component B according to a ratio of 1: 1, wherein the volume ratio of the components is 1. The coating comprises the following components: a silicate aqueous solution, a reaction stabilizer, a reaction promoter, polyisocyanate, a coalescing agentand a reinforcing agent, the obtained reactive grouting reinforcement material has the characteristics of low smoke toxicity and high mechanical strength, the smoke toxicity grade of the material canreach the quasi-safety grade, the compressive strength can reach 60 Mpa, the flame retardant property can realize self-extinguishing 1s away from fire, the safety performance is high, and the stability is good; meanwhile, the characteristics of low viscosity, strong infiltration capacity and large diffusion radius are also realized; in addition, the preparation method of the material is simple and easy to operate, and the preparation cost of the reinforcing material can be further reduced.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

A method of blasting to increase seepage and its application

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Impulse-type grouting method

The invention discloses an impulse-type grouting method, and is applicable to general tunnel and roadway support projects. A grouting pipe with the same depth of a drilling hole is inserted into a well-constructed grouting drilling hole, the inner end of the grouting pipe contacts a hole bottom, and the outer end of the grouting pipe is connected with a grouting flexible pipe through a control valve. An impulse-type grouting system is connected on the grouting flexible pipe. A reversing valve ensures that high-pressure thick liquid and low-pressure thick liquid alternatively pass through, and therefore impulse-type grouting is achieved. As grouting time increases, the injecting speed of thick liquid is reduced, changes of a displayed value on a flow meter is observed, and when the thick liquid stops to flow, grouting is stopped. Impulse pressure is utilized to ensure that the thick liquid is provided with larger flow velocity and impact force; the width of an original cranny gap of a rock mass is enlarged, the closed cranny gap is opened, and therefore the number of channels for the thick liquid to pass through is increased, and strong permeation effect is generated; and the diffusion radius of the thick liquid is enlarged to improve filling rates of the gap.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing side slope grouting slurry for widening silty-fine sand embankment

Owner:SHIJIAZHUANG TIEDAO UNIV

Coal and rock mass deep hole segmented grouting reinforcement device and reinforcement method

ActiveCN111894632BImproves uniformity of diffusionExpand the effective diffusion radiusUnderground chambersTunnel liningStructural engineeringPipe

The invention discloses a deep hole segmented grouting reinforcement device for coal and rock mass and a reinforcement method, comprising a grouting device and at least two groups of grouting pipeline assemblies, wherein the grouting device has a one-to-one matching with each grouting pipe assembly A grouting outlet connected with the inlet end of the grouting pipe assembly for conveying different materials, the outlet end of each grouting pipe assembly is connected with the grouting head, and the grouting pipe assembly can rotate with its own axis to realize the connection with the grouting head. In the present invention, the grouting pipeline assembly can be separated from the grouting head, which facilitates the disassembly of the grouting pipeline and the secondary installation of the grouting head to realize the grouting in the next stage. The grouting range of the structure is optional, which can effectively solve the problem of existing Some shallow hole grouting methods for strengthening coal and rock mass of polymer reinforcement materials have problems such as small effective grouting range, serious grouting phenomenon, and complex grouting construction organization. Difficulty, drilling is difficult to use multiple times and other problems.

Owner:PINGDINGSHAN TIANAN COAL MINING +1

Nanometer silicon-based grouting material and application

The invention belongs to the technical field of grouting, and discloses a nanometer silicon-based grouting material and application. The grouting material comprises a component A and a component B which are independently packaged, wherein the component A comprises 500-800 parts by weight of a main agent, 50-100 parts by weight of a modifier and 50-400 parts by weight of an accelerant, the main agent is sodium silicate and / or potassium silicate, and the component B comprises the following components in parts by weight: 100-200 parts of a cross-linking agent and 200-300 parts of an initiator. According to the invention, the nanometer silicon-based grouting material is good in construction effect, and after grout is injected into a stratum, gel can be rapidly generated to form a high-strength consolidation body with water, gravel and clay in the stratum; and the maximum strength of the gel can reach 1.2 MPa, and the gel has certain elasticity and toughness, can resist stress deformation of strata, and can play a role in long-term water stop and reinforcement.

Owner:东方雨虹建筑修缮技术有限公司

An intelligent circulation increasing-relieving pressure dynamic grouting system and method

ActiveCN108952760BAvoid wastingIncrease the grouting pressureUnderground chambersTunnel liningPressure stabilizationClassical mechanics

The invention relates to an intelligent cyclic supercharging and pressure relief type dynamic grouting system and a method. Under the premise of not destroying the original strength of rock mass, thestatic pressure grouting is carried out first, and by measuring the change of the indication number of a flow meter and a pressure transmitter; when the indication number of the flow meter no longer changes and the indication number of the pressure transmitter increases, the system automatically adjusts a pressure regulating valve to increase the grouting pressure, a valve automatic controller controls a slurry outlet valve and a slurry discharging pipeline valve according to the design frequency to switch on, and the cyclic supercharging and pressure relief grouting is realized; the fracturefilling rate and the grouting effect are improved, and the grouting ending standard is more clear to prevent the incomplete or excessive grouting from destroying the rock mass and wasting the resource. A safety pipeline is added in the system to prevent the pipe explosion and extraordinary accident, and the arrangement of a pressure stabilizing barrel ensures the stability of the grouting pressurein grouting process; the intelligent switch of the grouting mode is realized, the grouting efficiency is improved, and the slurry diffusion radius is increased; the fracture filling rate and the grouting effect are improved, the labor capacity is reduced, and the application prospects are wide.

Owner:CHINA UNIV OF MINING & TECH

Water Surface Spreading Agent and Water Surface Spreading Pesticide

ActiveCN104430325BSpread evenlyImprove diffusivityBiocideAnimal repellantsPhosphateAdditive ingredient

The invention provides a water surface dispersing agent. The water surface dispersing agent comprises the following ingredients by weight percent: 30 to 80 percent of polyarylphenol-polyoxyethylene ether phosphate, 10 to 35 percent of a penetrating agent and 10 to 35 percent of a surfactant. The invention also provides a water surface dispersion-type pesticide. The polyarylphenol-polyoxyethylene ether phosphate is adopted as a main component, so that the water surface dispersing agent is good in dispersing effect, the dispersing speed is high and the dispersing radius is large, uniform dispersion can be realized, the effective utilization rate of the pesticide per unit area can be increased, the consumption of the pesticide per unit area can be reduced, and the effective utilization rate of the pesticide can be increased. Meanwhile, the water surface dispersing agent is relatively low in cost. The experimental result shows that the dispersing speed of the water surface dispersing agent can reach 0.3m / s, the dispersing radius can reach 5m to 10m; compared with similar products, the water surface dispersing agent has the advantages that the dispersing speed can be increased by 10 to 20 times and the dispersing radius can be increased by more than 5 times.

Owner:DALIAN RENBANG CHEM

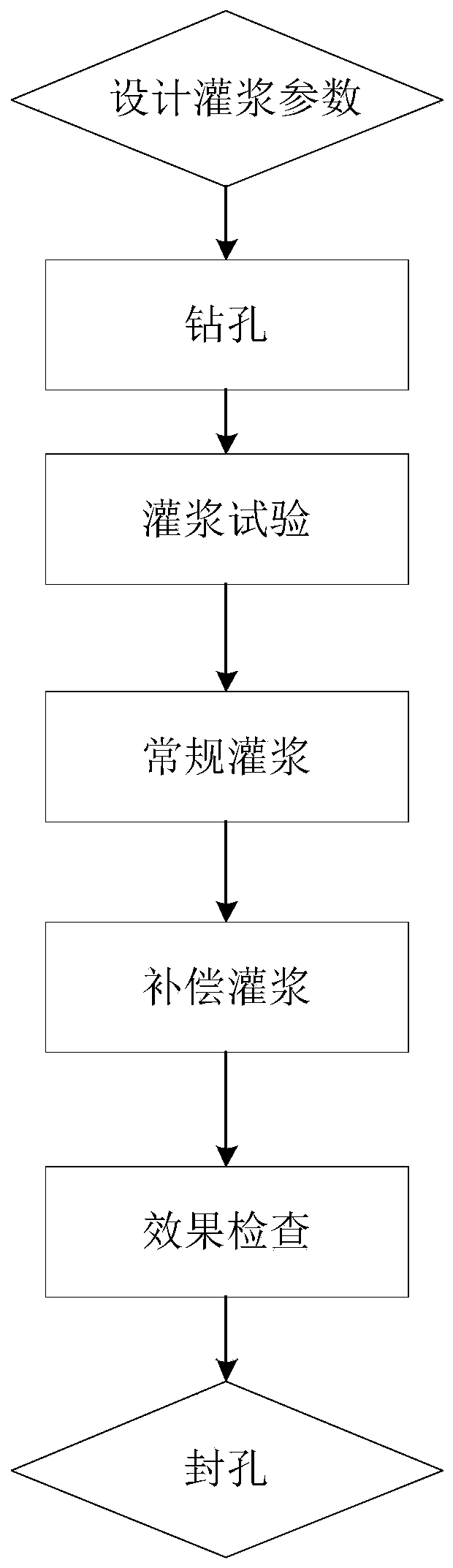

A Grouting Method for Eliminating Grouting Blind Area in Soft Stratum

The invention discloses a grouting method for eliminating grouting blind areas in soft stratum. The grouting method comprises the steps that grouting holes are arranged according to construction grouting design parameters, and one of the grouting holes is randomly selected as a grouting test hole; a grouting test is carried out on the grouting test hole to test grouting quantity and stratum splitting grouting pressure; controlling grouting is carried out in the other grouting holes; when all the grouting holes are grouted, and an inspection hole water pressure test and quality inspection are carried out; and compensation grouting is carried out on inspection holes which do not meet the design requirements. According to the grouting method for eliminating the grouting blind areas of the soft stratum, firstly, the stratum is tightly compacted through a compaction-splitting composite grouting method, and the diffusion radius of cement-based slurry vein is increased, and the existence of the grouting blind areas is reduced; then, blind area compensation grouting is carried out between holes which do not meet the design requirements, and the grouting blind areas are filled in a permeating mode by using the good groutability of chemical grouting materials and biological grouting materials, thus a closed grouting curtain is formed, and the best grouting effect is achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

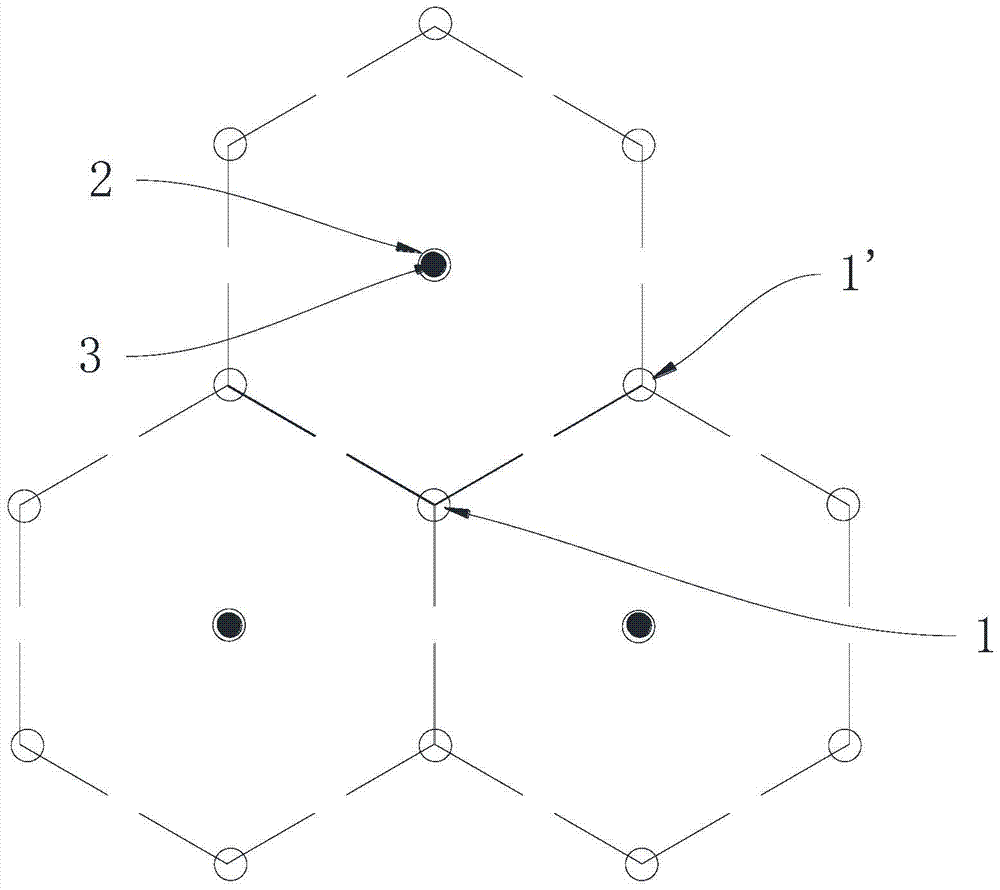

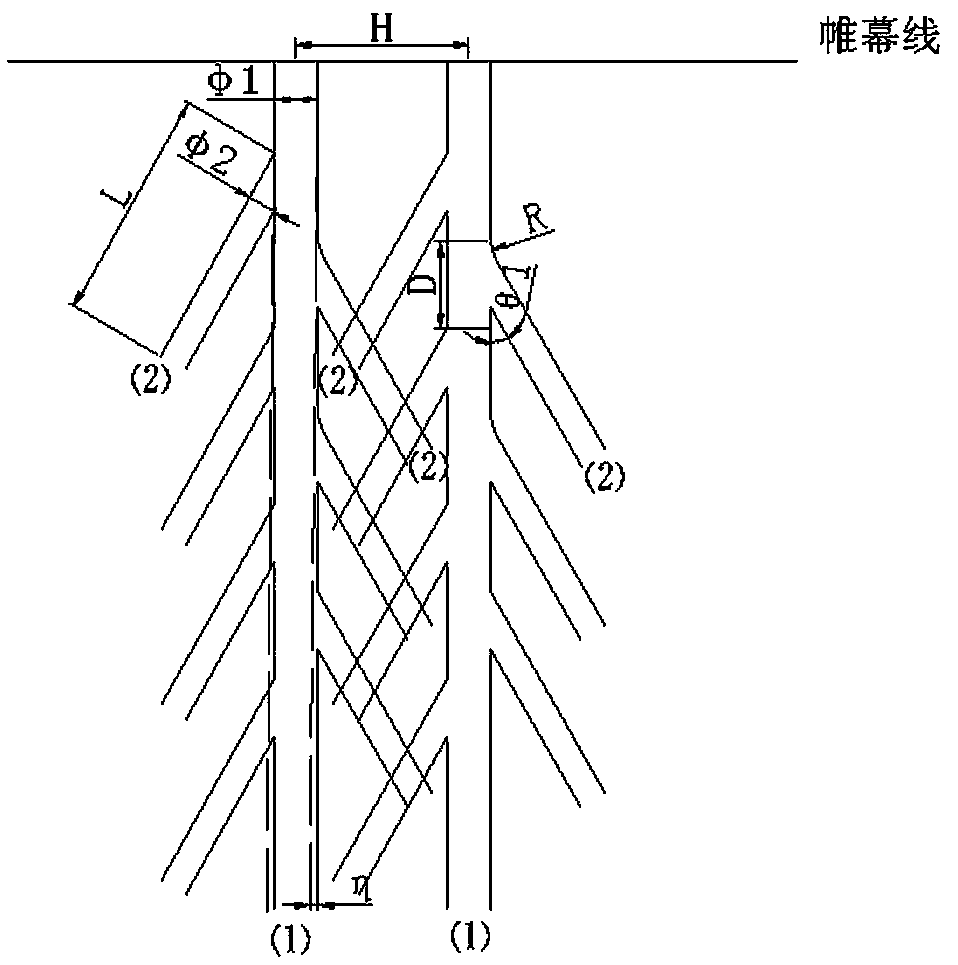

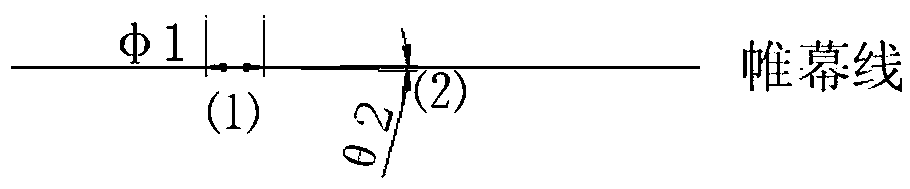

Grouting curtain drilling structure

ActiveCN106545313BIncrease exposure rateLarge diffusion radiusDrainageSealing/packingSocial benefitsStructure of the Earth

The invention provides a grouting curtain drilling structure and a construction process thereof, and relates to the technical field of mine curtain grouting. The grouting curtain drilling structure comprises a plurality of straight grouting holes formed along a curtain line. A plurality of branched grouting holes communicating with the straight grouting holes are further formed in the peripheries, in the height direction, in the straight grouting holes, and the directions of the branched grouting holes radiate and extend towards the peripheries. After grouting, in the curtain line direction, the exposure rate of high-angle water guide cracks can be increased, or water guide cracks in any angle can be exposed. The grouting curtain drilling structure and the construction process have the technical effects that compared with the prior art, the exposure rate of the high-angle water guide cracks can be greatly increased, or the water guide cracks in any angle can be exposed, and therefore the grout dispersion radius is increased, the grouting effect is guaranteed, the number of the straight holes and the drilling workload are greatly reduced, the cost of investment of the mine party is reduced, and great economic benefits and social benefits are achieved. Due to the fact that the distance between the straight holes is increased, it is possible that a tunnel inner curtain grouting manner is adopted for water plugging in mines in lofty mountains and steep hills.

Owner:NORTH CHINA ENG INVESTIGATION INST

A kind of rock and soil grouting method

InactiveCN104612131BLarge diffusion radiusImprove injectable propertiesSoil preservationHeat conductingTemperature difference

Provided is a rock and earth mass grouting method. By changing the temperatures of different components of grout, the temperature difference between the grout and an injected rock and earth mass is improved, the feature that the fluidity of the grout is enhanced when temperature rises is used, the larger diffusion radius of the grout in a rock and earth mass hole and a fracture is obtained, the injecting feature of the grout in an earth mass and broken rocks is improved, the purpose of grouting effect enhancing is achieved, meanwhile, during the process that the grout seeps and carries out heat conducting in the rock and earth mass, the temperature character of a near rock and earth mass is changed, and the temperature monitoring feature of the grouting diffusion range can be obtained. An active temperature rising method is used for achieving the process, the method is simple, the injecting performance of the grout is improved, meanwhile, the injecting range of the grout has temperature measurability, and certain practicability and promoting value are achieved.

Owner:CHINA UNIV OF MINING & TECH

Support method for coal seam roadway to cross gob

ActiveCN102505949BLarge diffusion radiusHigh strengthUnderground chambersElectrophoretic coatingsCoal measuresElectrophoresis

A support method for a coal seam roadway to cross a gob belongs to the technical field of roadway supporting for coal measure strata and utilizes combination of temporary support and permanent support. The support method is characterized in that the temporary support includes applying an alternating-current field after double-slurry is grouted into small ducts, increasing scattering radius of the slurry under electric effect of electro-osmosis and electrophoresis, filling the double-slurry into holes and slits inside regenerated surrounding rock of the gob sufficiently so as to reinforce of the regenerated surrounding rock of the gob again, and finally forming the integrated surrounding rock. The support method aims to increase integral strength, stability and self-bearing capacity of the regenerated surrounding rock of the gob. The integral strength of the regenerated surrounding rock of the gob is increased by at least 230% by using the support method as compared with the existing support method for the coal seam roadway to cross the gob.

Owner:SCI & TECH RES OF SHANXICOAL TRANSPORTATION & SALES GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com