In-situ atomization and injection system for repairing contaminated sites

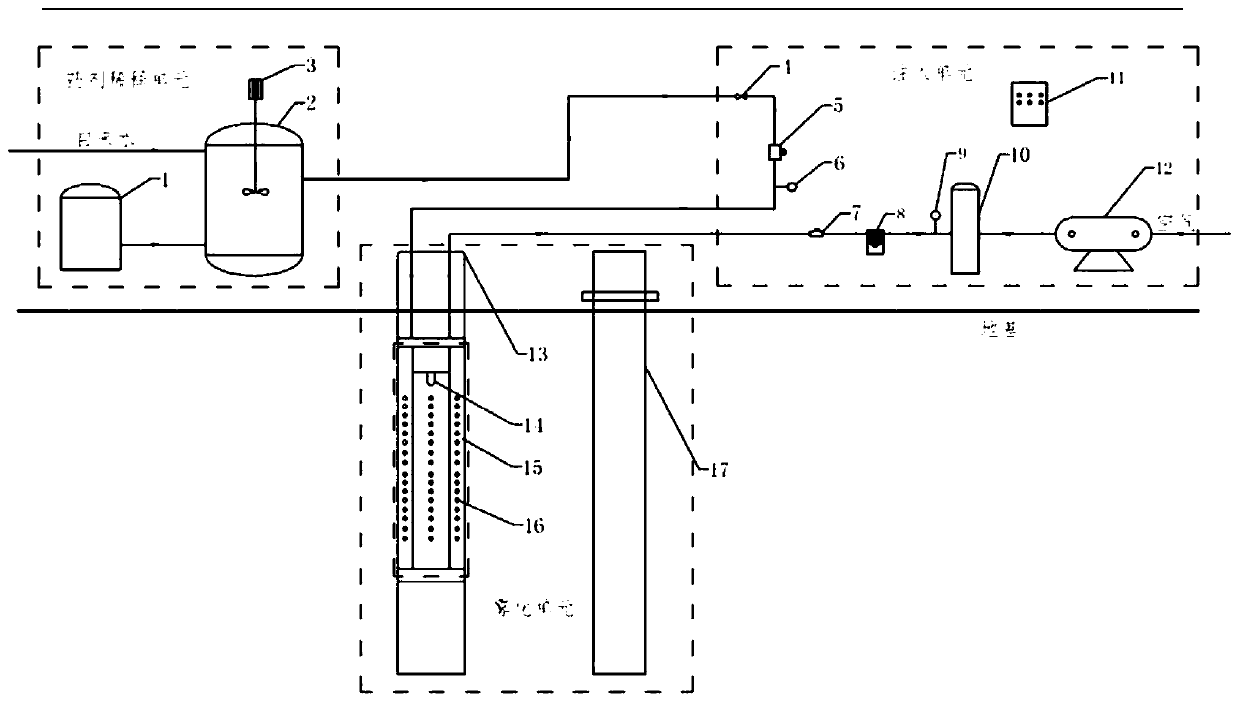

An injection system, in-situ technology, applied in the field of environmental restoration, can solve the problems of cumbersome procedures, increase the diffusion radius of the agent, and complex procedures, and achieve the effects of simplifying the procedure, shortening the repair period, and simplifying the procedure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

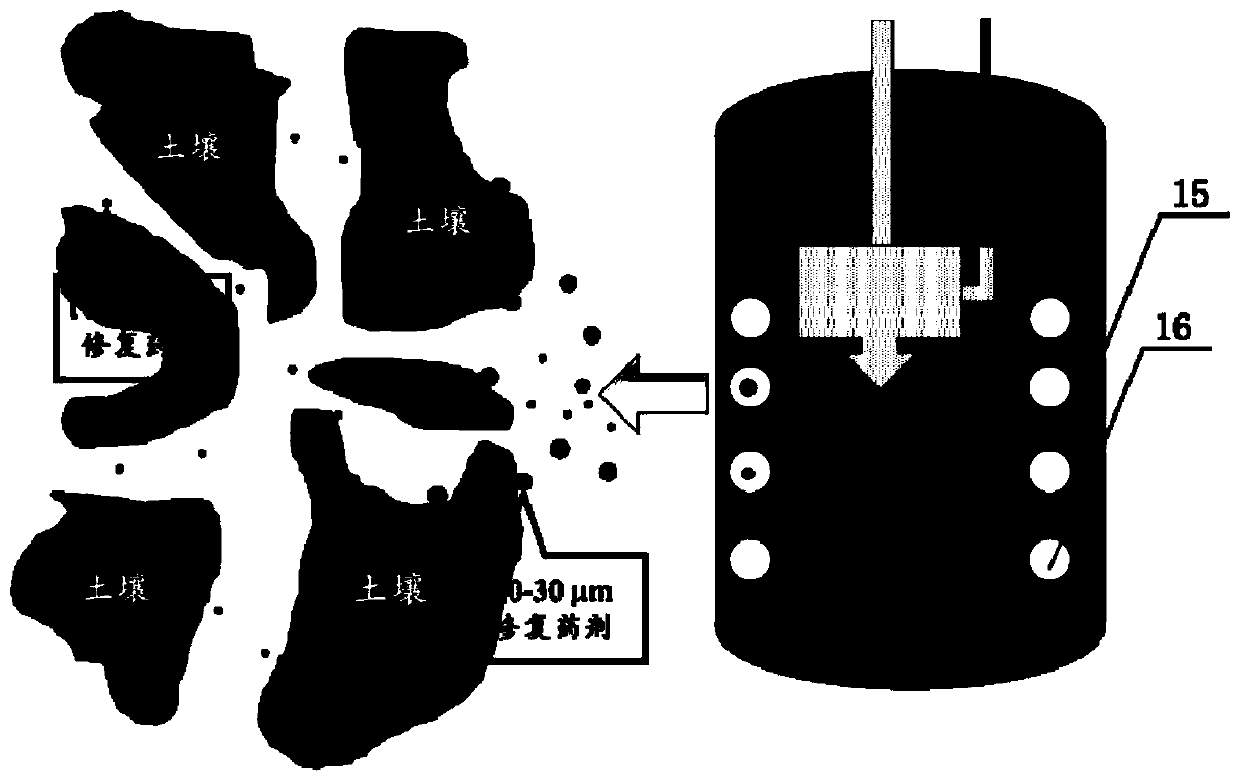

[0026] Location: an abandoned gas station;

[0027] Target pollutants: BTEX and C6-C20;

[0028] Background: The surface soil is clay or silty clay, and the bottom is sandy clay and coarse soil materials. The pollution depth reaches 5m, and the treatment scale is 5000m 3 ;

[0029] Repair method: choose oxidizing agent, inject into the polluted area in different rounds, each round of injection cycle is 10 days for injection, 10 days for reaction, 10 days for detection and analysis, and the cycle is 30 calendar days. After the injection cycle is over, according to the monitoring well The concentration of collected soil pollutants is used to judge whether to continue the injection, and if the restoration target is reached, the next round of injection will be stopped;

[0030] Results: After 180 days of injection of mist oxidant, the average concentration of aliphatic hydrocarbons in the soil decreased by 2500 mg / kg, and the average concentration of BTEX decreased by 62.5 mg / kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com