A kind of rock and soil grouting method

A rock and soil mass and grouting technology, applied in the field of rock and soil mass grouting, can solve the problems of lack of attention to temperature characteristics, and achieve the effects of wide practicability, improved injectability, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

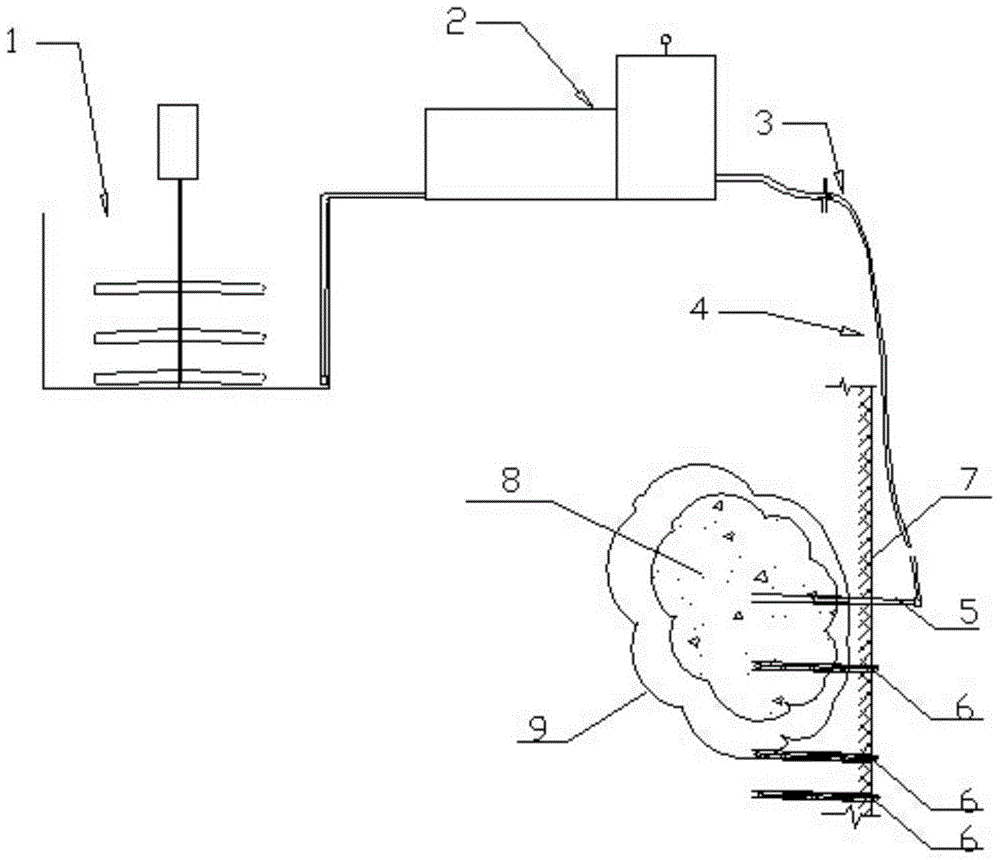

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0019] Rock soil mass grouting method step of the present invention is as follows:

[0020] a. A plurality of temperature measuring points are arranged at intervals in the grouting area 9 and the wall surface 7 of the surrounding grouting space, and the drill holes 6 are constructed for the positions of the arranged multiple temperature measuring points, and at least One grouting borehole 5, according to the actual situation on site, there may be one or more than one grouting borehole 5; the distance between the multiple measuring points of the temperature measuring point arrangement is 200-2000mm.

[0021] b. Arrange temperature sensors in each borehole 6 along the depth direction of the borehole, fill and seal the borehole, and lead the temperature test wire out of the borehole to connect to a temperature tester to measure the temperature of the borehole;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com