Patents

Literature

67results about How to "Increase the grouting pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

InactiveCN101255698AHigh strengthImprove water stabilitySolid waste managementUnderground chambersWater blockCement slurry

The present invention discloses a running sand layer and sandy gravel layer dynamic-water double-liquid high-pressure slurry-injecting water-shutoff construction method which comprises the following construction steps: drilling a hole, flushing the hole, executing double-liquid high-pressure slurry-injecting operation and sealing the hole. The running sand layer and sandy gravel layer slurry-injecting liquid adopts an ordinary portland cement (P.O.42.5) and 40''Be sodium silicate as material for preparing the slurry, according to the weight proportion of water: cement, namely the cement slurry is prepared with the water cement ratio for 0.5-1.2:1. Then the slurry-injecting liquid is prepared with the volume ratio of cement slurry: sodium silicate for 1:0.08-0.15. The sodium silicate is taken as additive for regulating the initial setting time of the slurry-injecting liquid. The cement slurry can also be doped with fly-ash with cement consumption (weight proportion) for 10%-15%. The invention executes water-insulating construction aiming at the characteristics of large pressure of the underground dynamic water and high flowing velocity in the running sand layer and sandy gravel layer, and can obtain the maximal application sphere and optimum water-shutoff effect.

Owner:HUNAN CONSTR ENG GRP COR

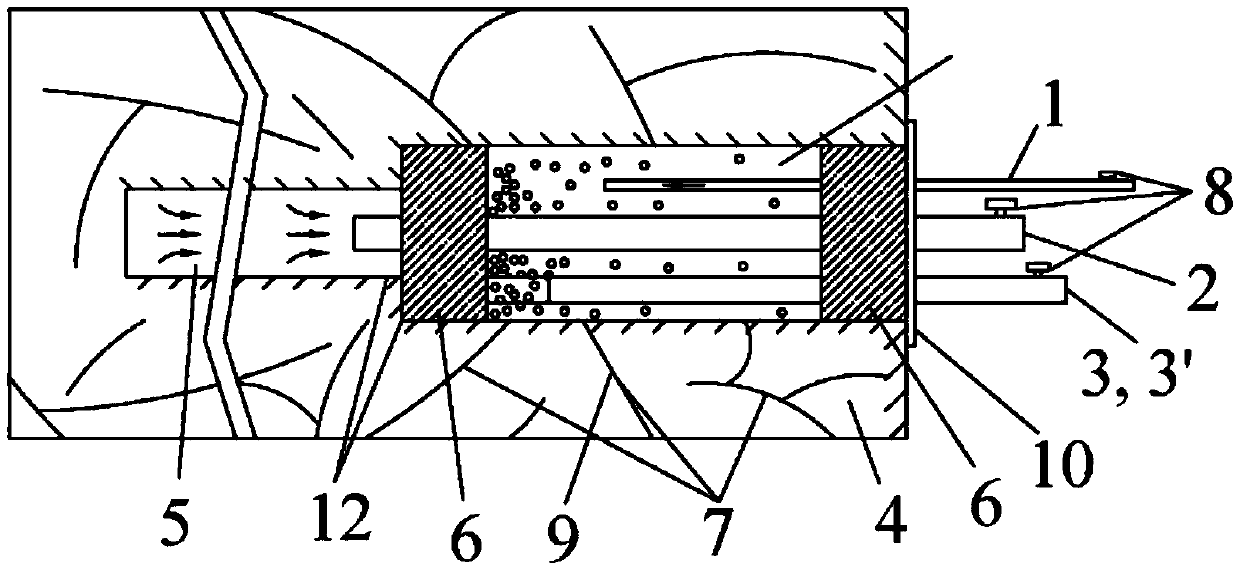

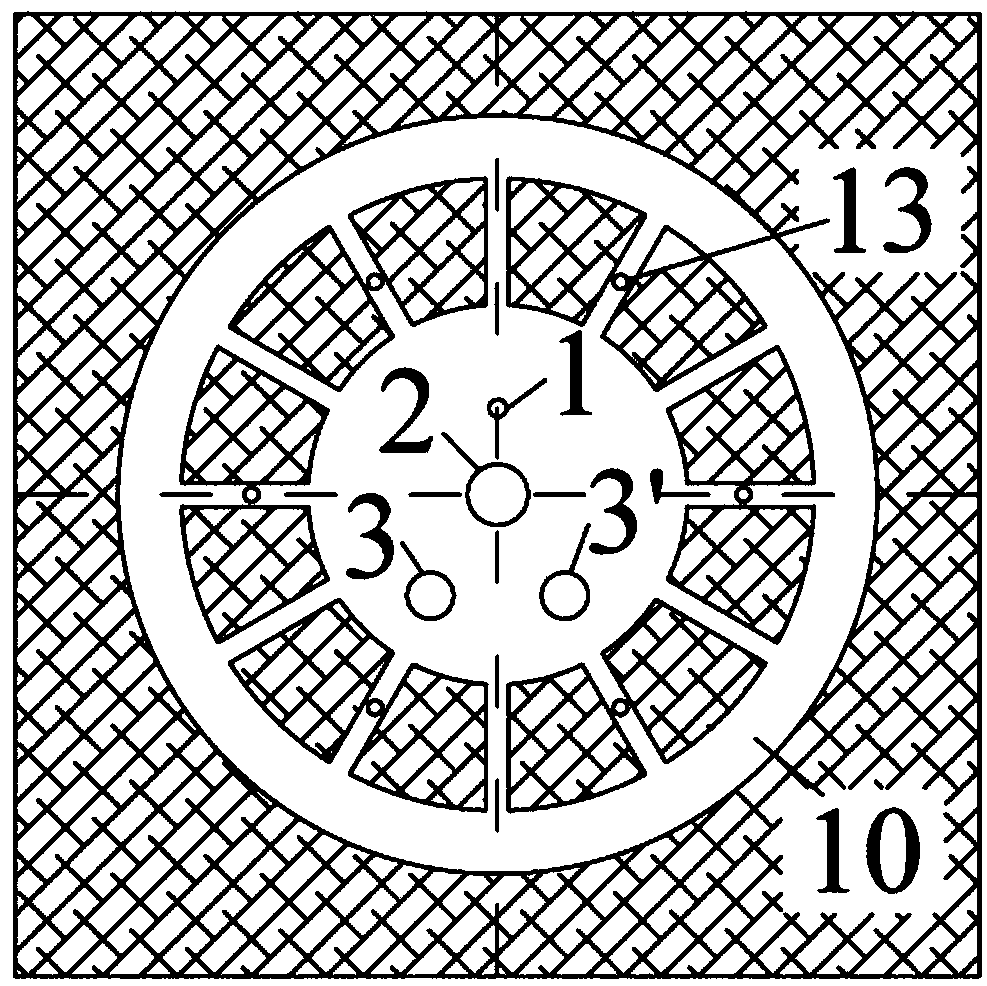

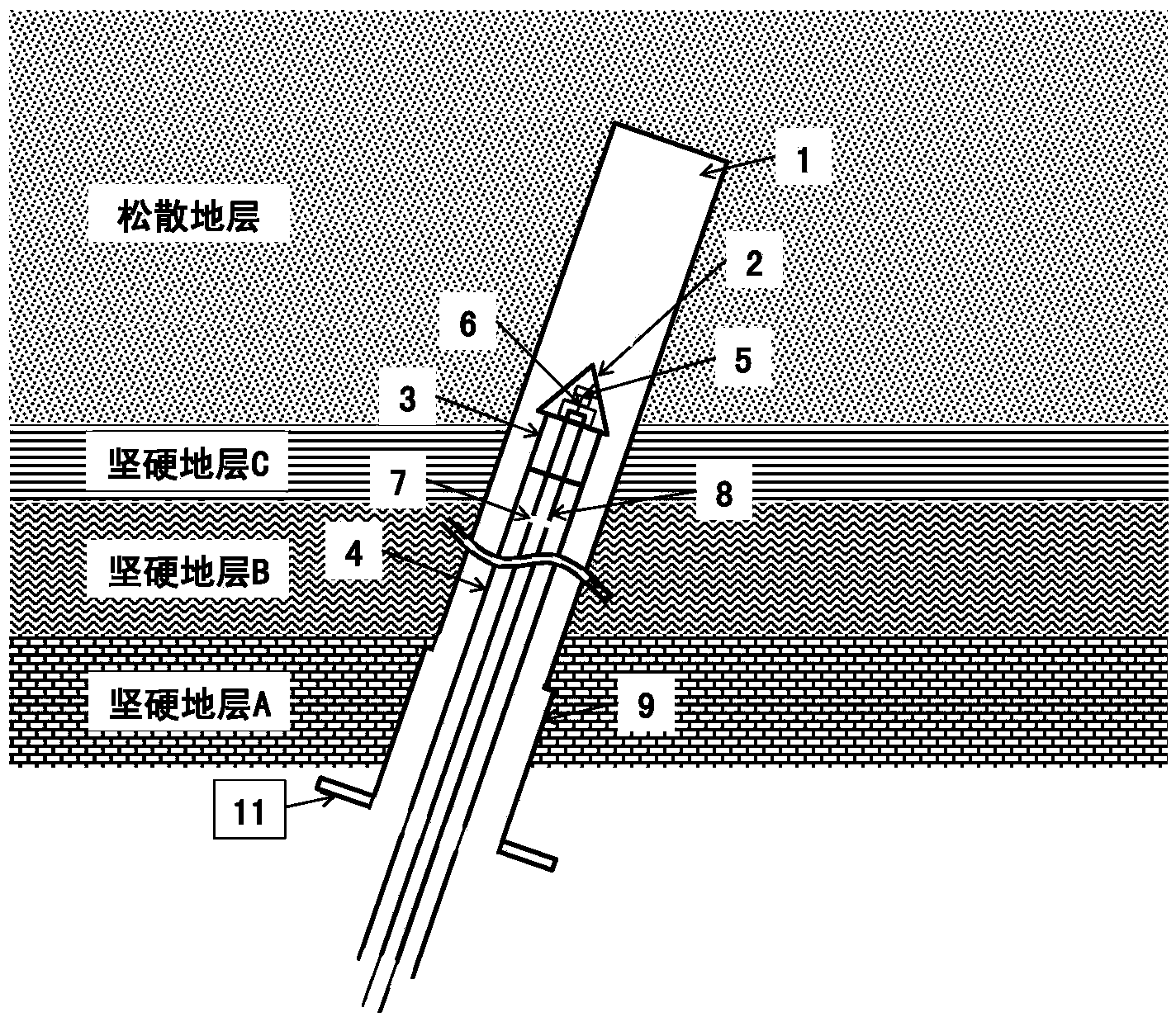

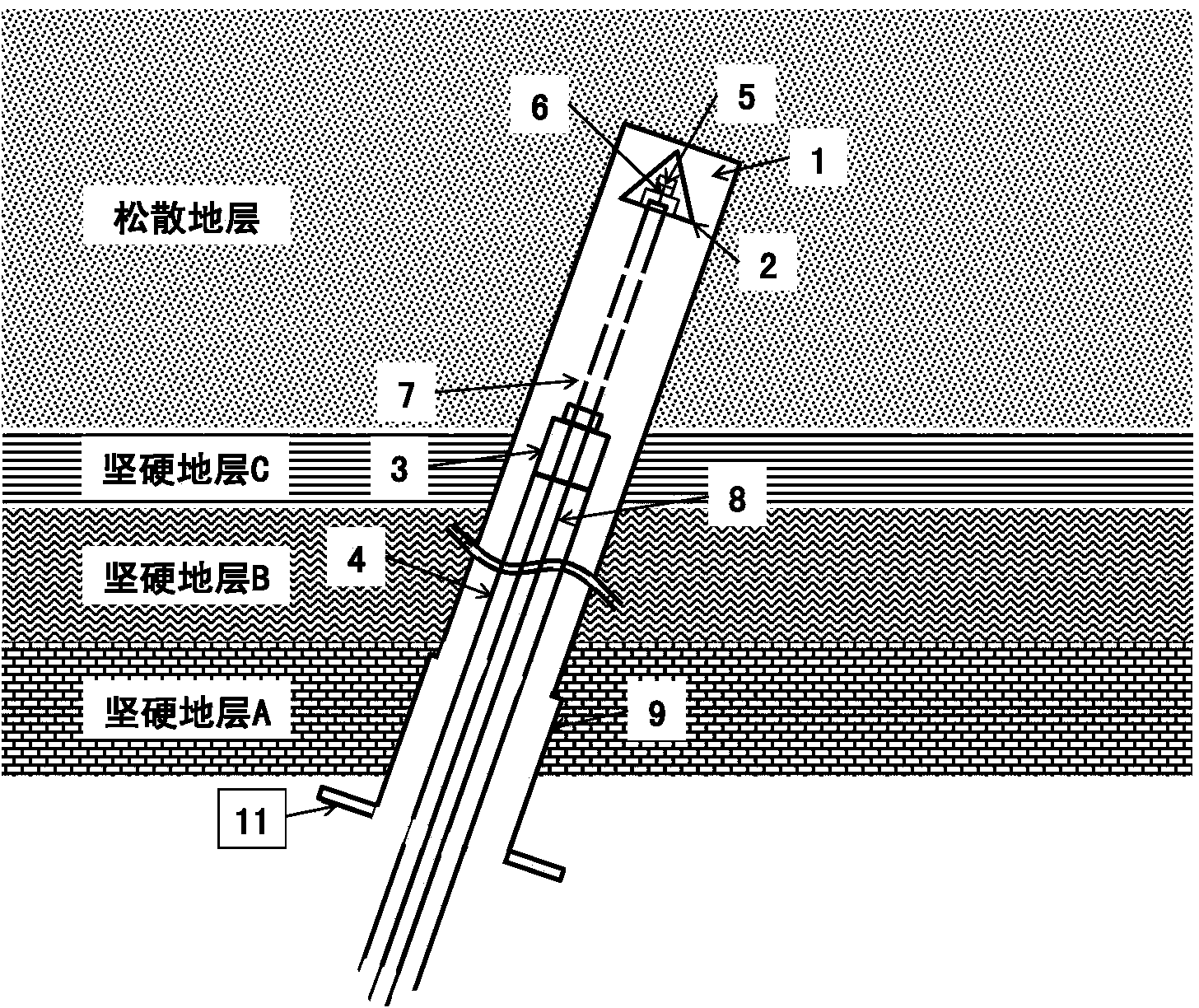

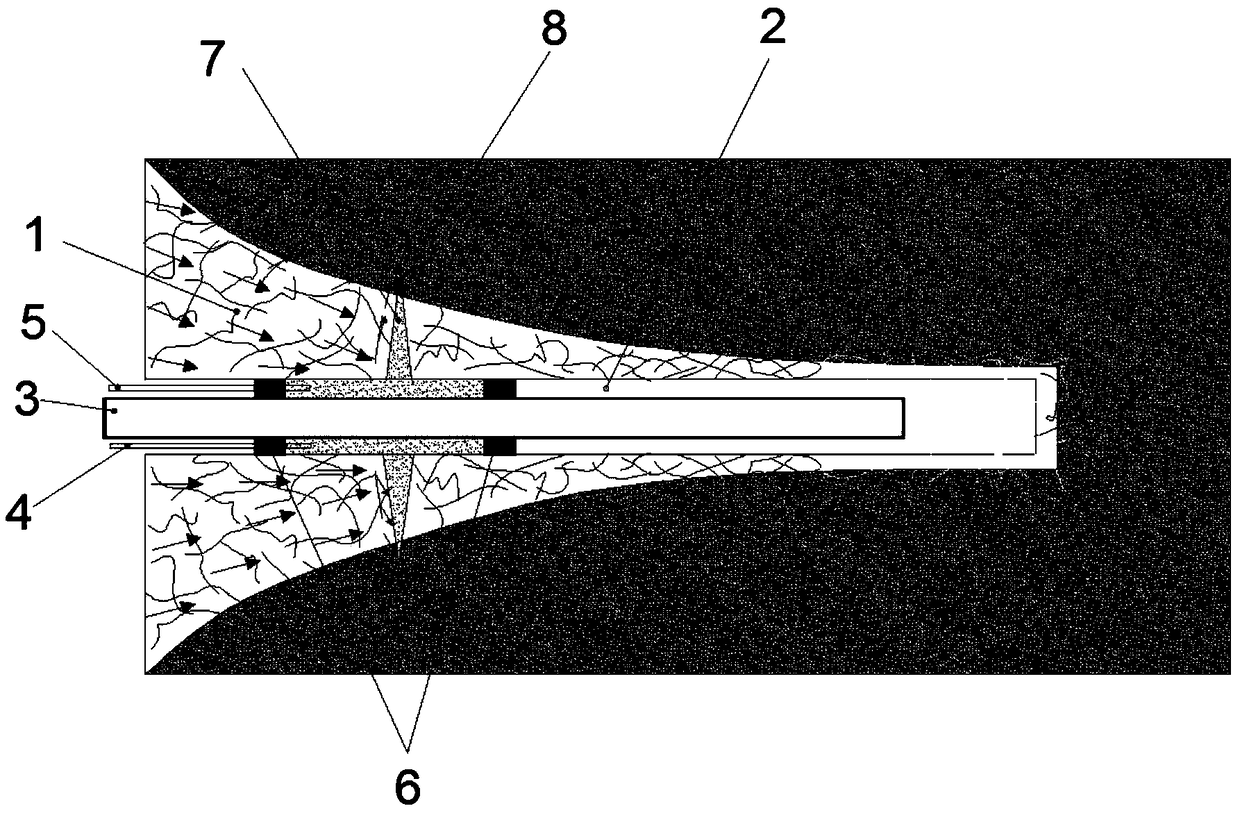

Powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device and method

ActiveCN109577908AImprove radial stabilityEasy to storeFluid removalGas removalPack materialEngineering

The invention provides a powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device and method. The powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device and method is applicable to underground coal mines. The powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device comprises an outer bag and an inner bag, wherein the rear of the outer bag is provided with a fixing unit on a gas extraction pipe; the inner bag is provided with a screen pipe, a bag grouting pipe and a grouting pipe which penetrate through the fixing unit, the tail portions of the screen pipe, the bag grouting pipe and the grouting pipe are arranged at the rear of the outer bag, and the tail ends of the screenpipe, the bag grouting pipe and the grouting pipe are provided with valves; quick lime powder coerced by carbon dioxide is guided into the space among packing materials via the screen pipe to block fractures around a drilled hole through reaction products; cement mortar is filled in by the grouting pipe to achieve the aim of packing cracks and actively supporting the drilled hole. Therefore, thepowder particle-high-pressure grouting crack packing gas extraction drilling and sealing device can effectively reduce the influence of mining damage, prolong the effectively extraction period of drilling gas extraction, increase the concentration of extracted gas, maintain stability of the drilled hole, significantly improve the coal seam gas extracting effects and ensure safety of underground workers.

Owner:CHINA UNIV OF MINING & TECH

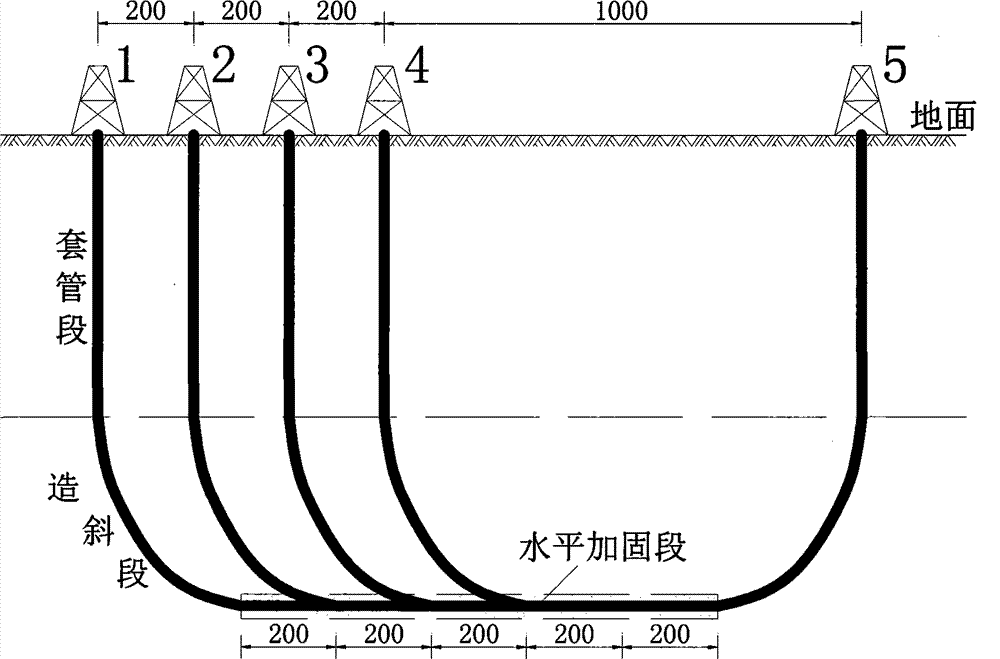

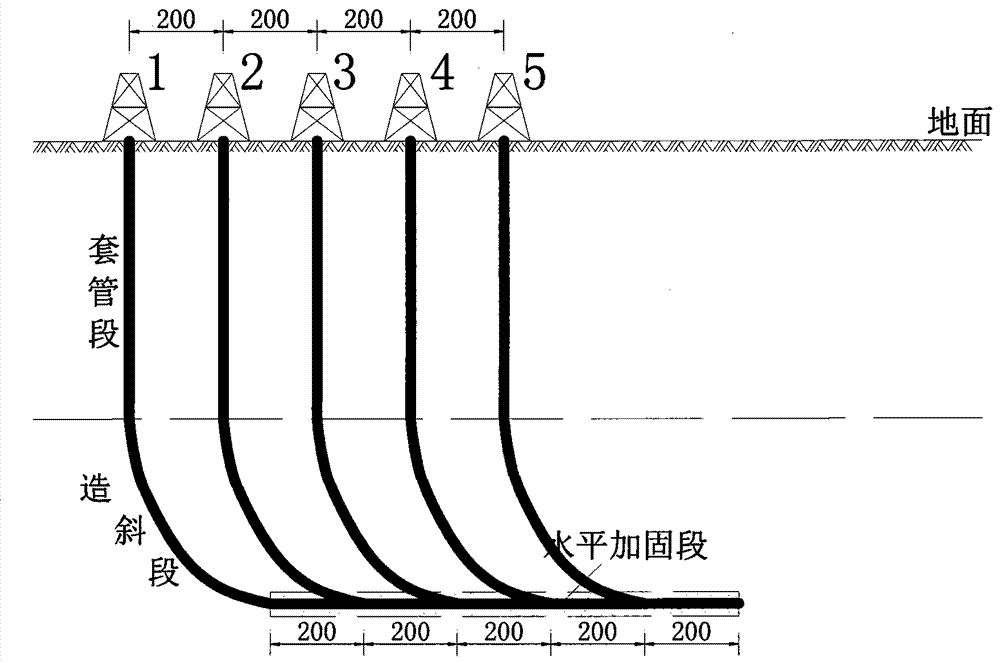

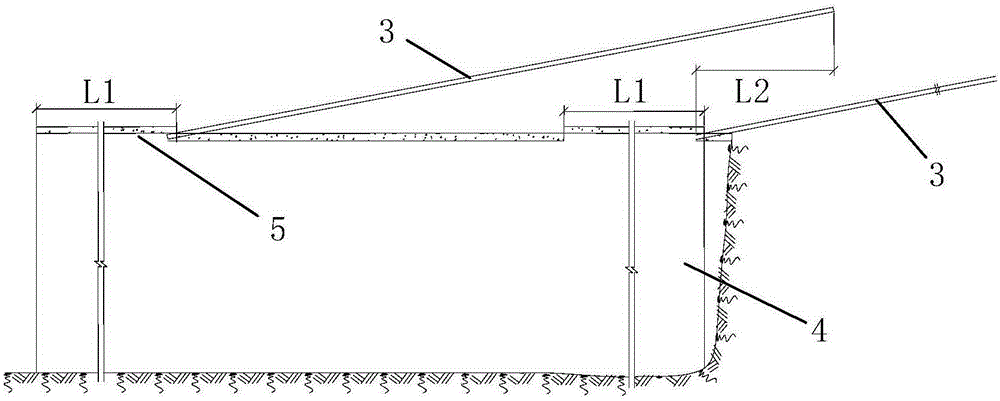

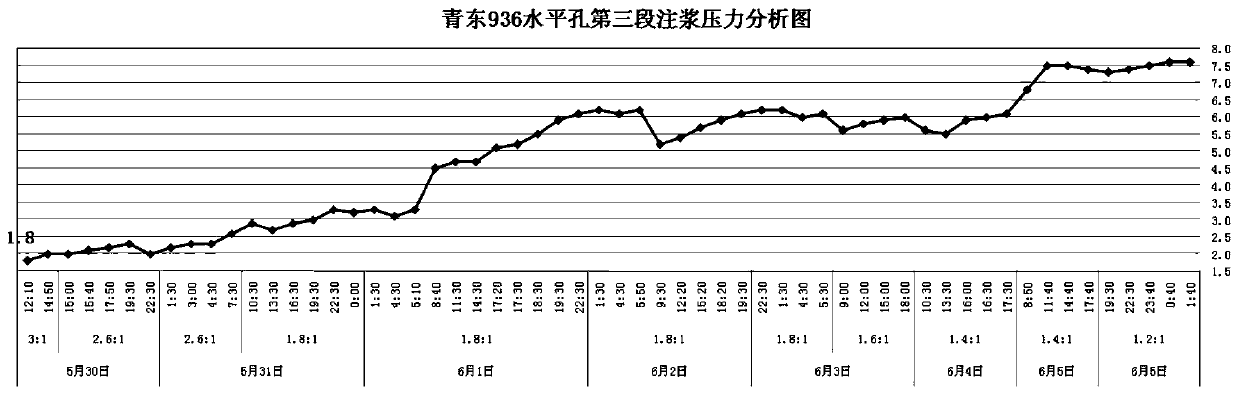

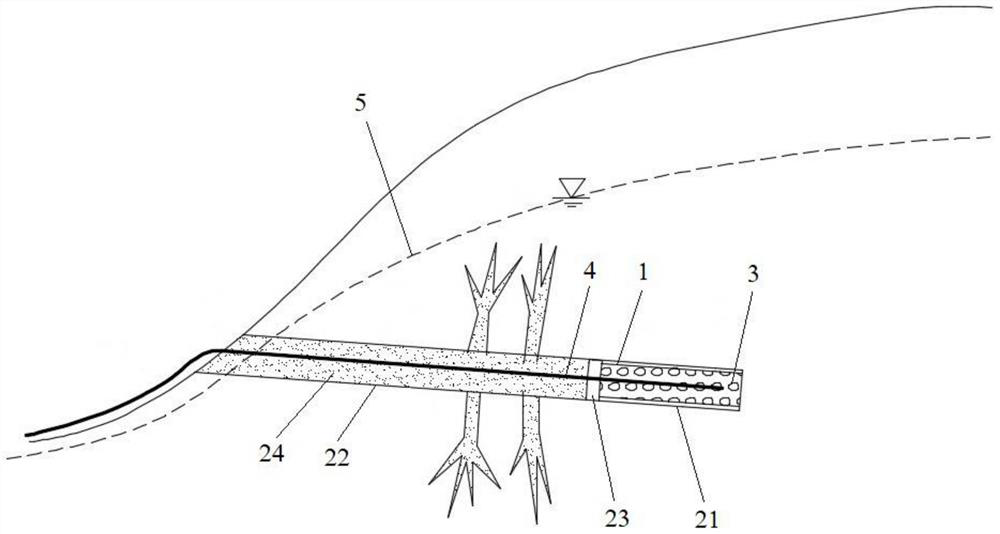

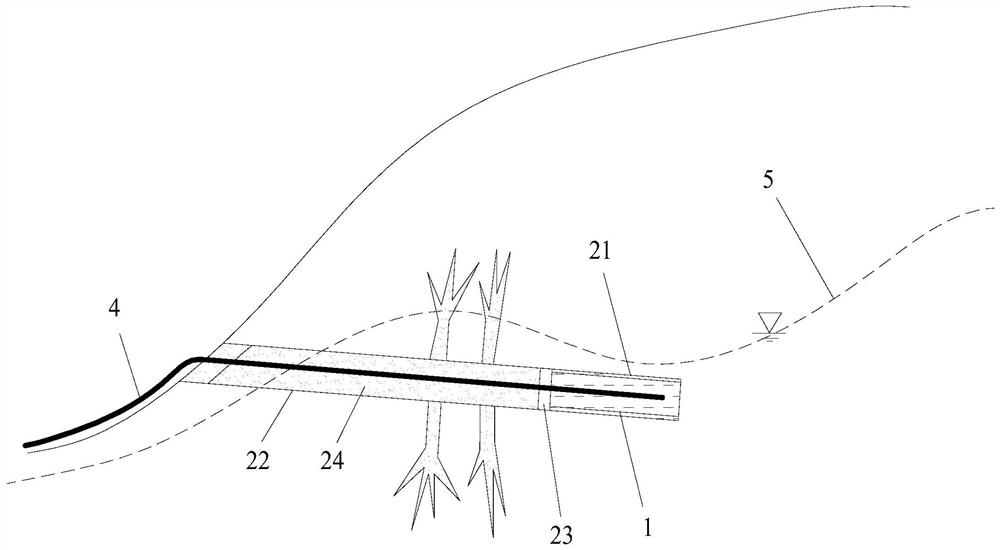

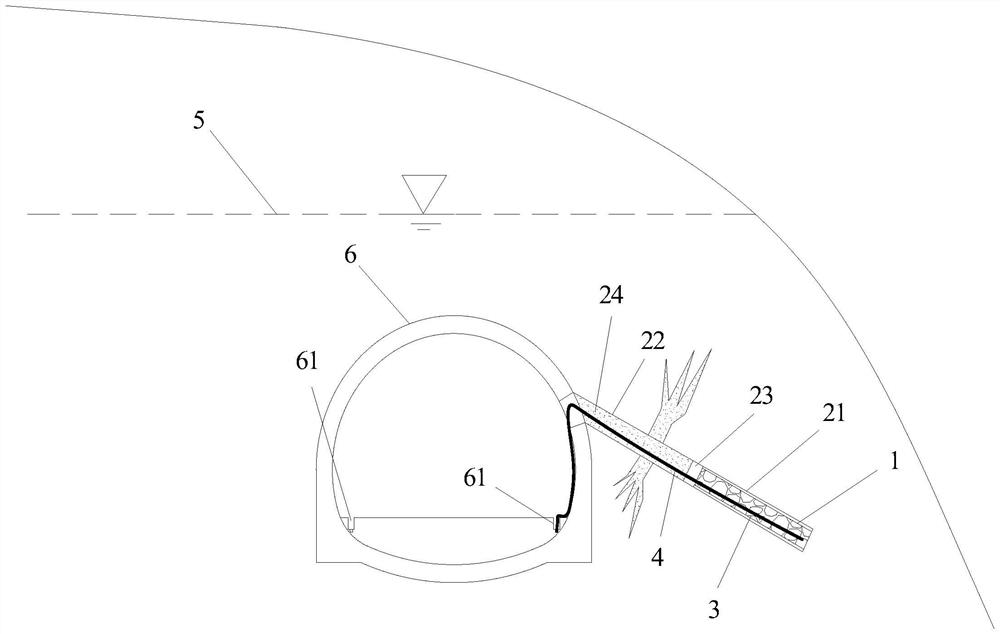

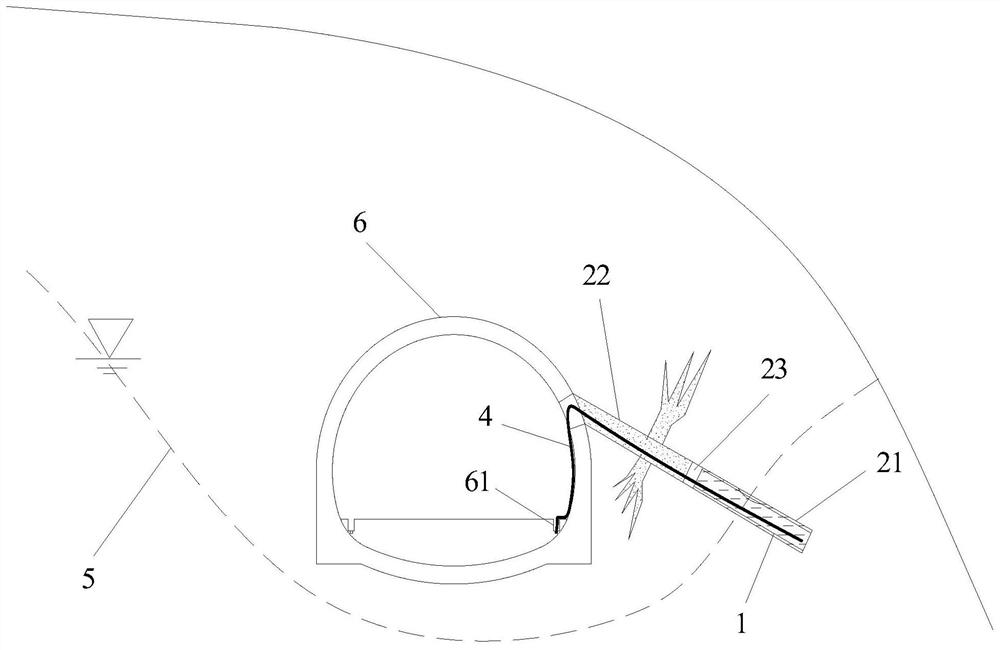

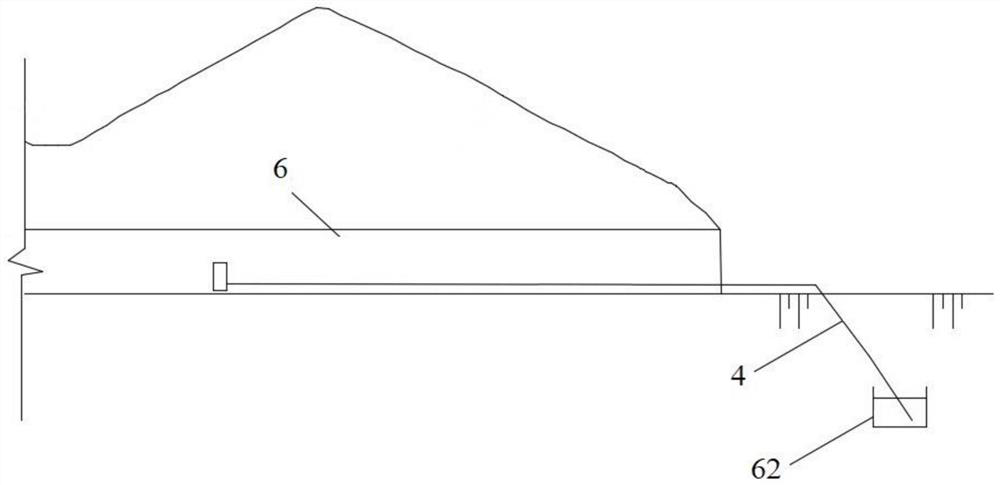

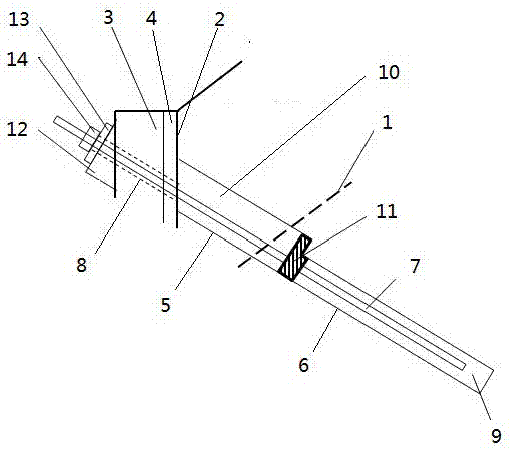

Ground pre-grouting strengthening technology for deep long-distance roadway surrounding rock

ActiveCN103835729AImprove liquidityControllable clotting timeUnderground chambersTunnel liningSlurryLarge range

The invention discloses a ground pre-grouting construction technology suitable for strengthening deep long-distance roadway surrounding rock, and particularly relates to a ground pre-grouting strengthening technology for deep long-distance roadway surrounding rock. The ground pre-grouting strengthening technology for the deep long-distance roadway surrounding rock includes the following steps that firstly, a ground grouting drill hole is formed in the ground through a drilling machine, the ground grouting drill hole comprises a casing pipe segment, a deflecting segment and a horizontal strengthening segment, a casing pipe segment drill hole is internally provided with a casing pipe, the deflecting segment and the horizontal strengthening segment are provided with rock open holes, and ground inlets of the ground grouting drill hole are formed in the walking direction of a roadway; secondly, grout is injected into a stratum rock body where the horizontal strengthening segment exists through a grouting pump located on the ground, and beforehand strengthening government of the roadway surrounding rock is achieved. According to the ground pre-grouting construction technology for strengthening the deep long-distance roadway surrounding rock, strengthening and grouting of the whole roadway surrounding rock can be achieved, and the ground pre-grouting construction technology is suitable for active strengthening of the coal mine large-range roadway surrounding rock and is high in safety and adaptability.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

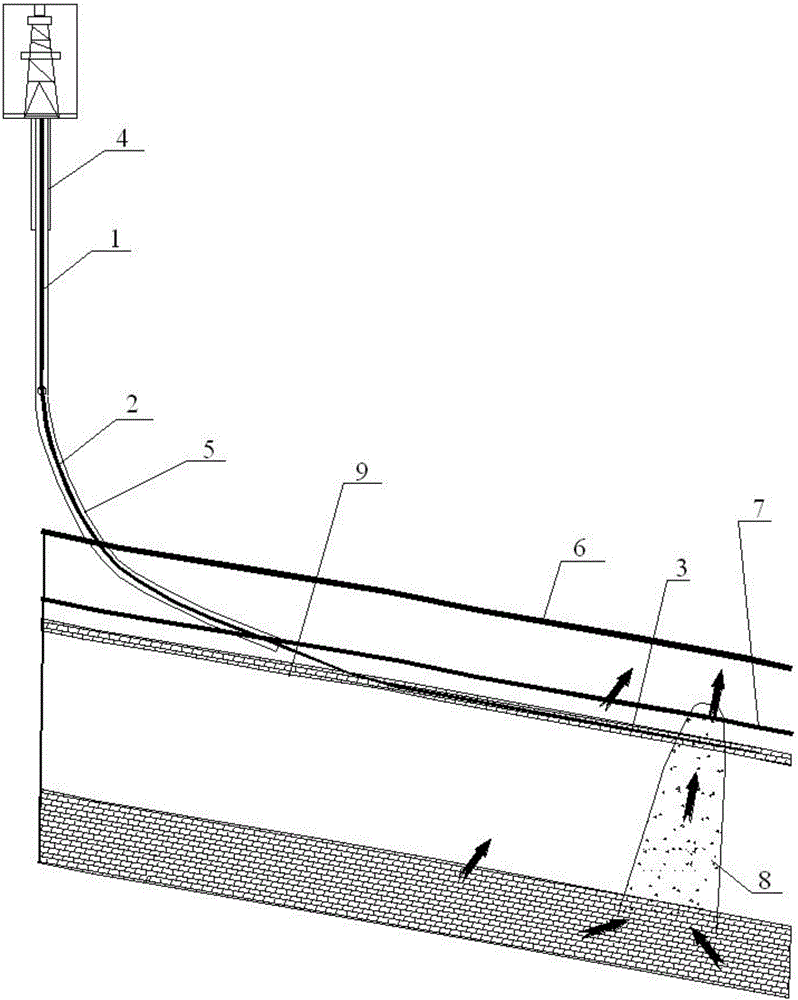

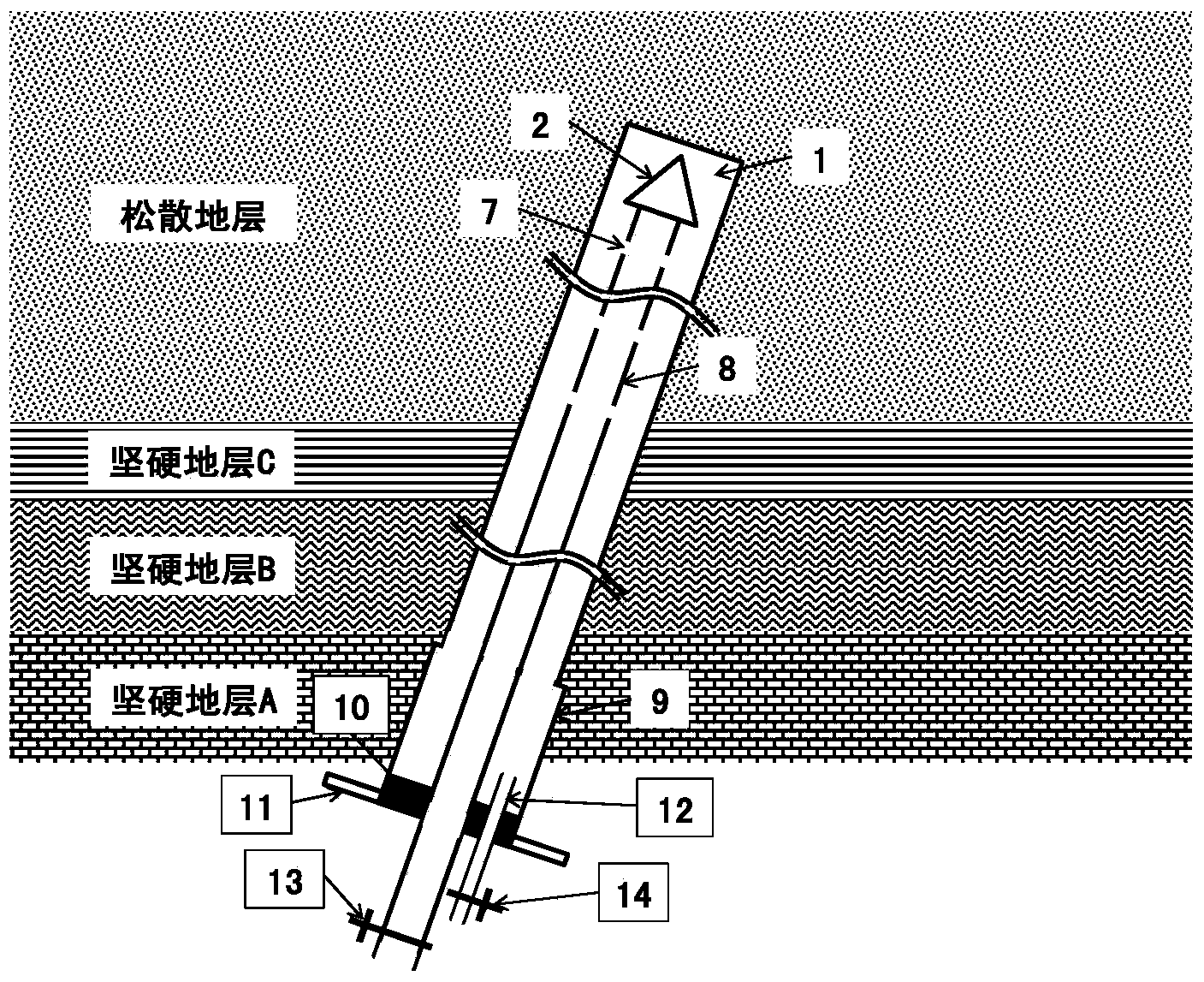

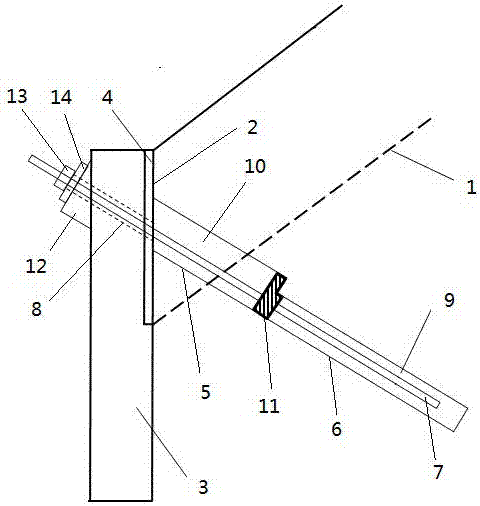

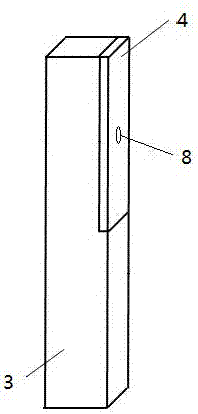

Method using surface orientation bedding drilling grouting to reinforce laminar limestone

InactiveCN106703692AIncrease the grouting pressureReinforcement and reconstruction area is wideDirectional drillingSealing/packingGeomorphologyWater source

The invention discloses a method using surface orientation bedding drilling grouting to reinforce laminar limestone. The method includes: performing surface drilling until a suspected water outlet point is reached, performing drilling grouting, wherein drilled holes include a main hole and branch holes, the main hole is provided with a straight hole section and an oriented bedding section, an oriented slanting-guide section is further arranged between the straight hole section and the oriented bedding section, and the branch holes include primary branch holes and secondary branch holes; a water-bearing stratum is modified through the drilling grouting, grouting pressure is 1.5-3.5 times of the hydrostatic pressure of a to-be-grouted point, grouting termination pressure is 3.5-4 times of the hydrostatic pressure, and the lime-cement-flyash water-bearing stratum is transformed into a water-resisting layer to resist lime, cement and flyash and water of the water-bearing stratum below the lime, cement and flyash. By the method, hidden water guide channels are blocked, a base Ordovician limestone karst powerful water source is blocked, and safety of deep exploitation is guaranteed.

Owner:HUAIBEI MINING IND +1

Method for controlling water inrush and sand inrush under coal mine

The invention discloses a method for controlling water inrush and sand inrush under a coal mine. The method comprises the steps that an injection pipe is arranged below by utilizing a disposable drilling bit device; a disposable drilling bit cap is separated and exited from a drilling body; the injection pipe is fixedly connected; and a special stratum is injected. The method for controlling the water inrush and the sand inrush is high in injection success rate, good in fixed injection pipe connection quality, great in injection pressure, high in drilling and injection combined efficiency and low in injection cost, and safe, quick, cheap and high-quality reconstruction can be achieved for the special stratum. The method achieves that the injection pipe is arranged below a drilling bit, high-pressure injection is performed on the special stratum by utilizing the fixedly connected injection pipe.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

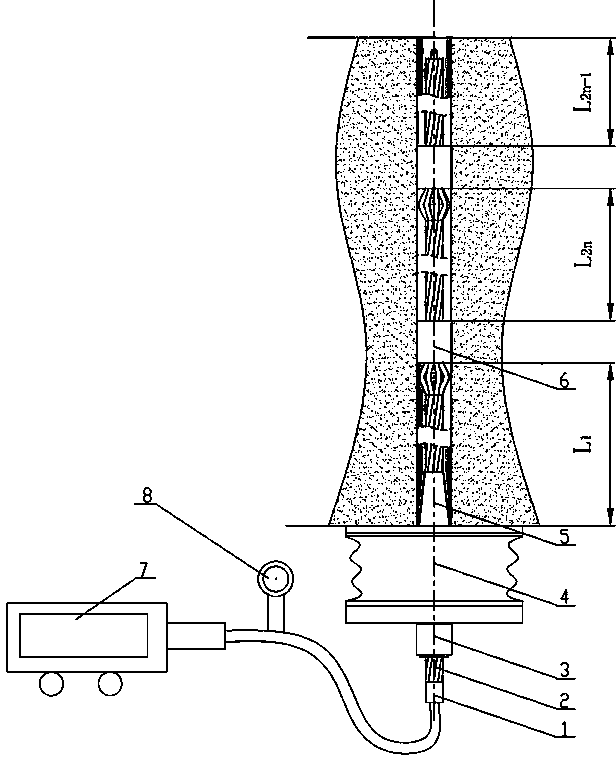

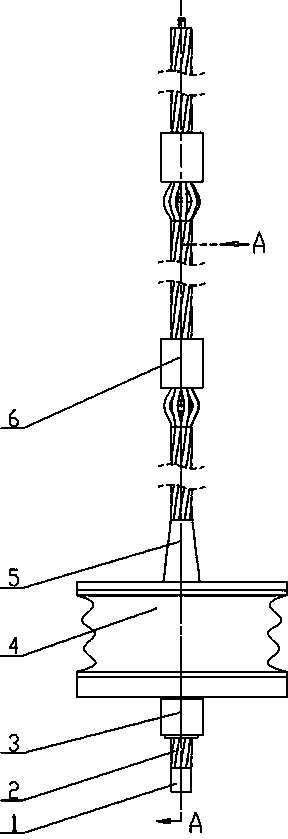

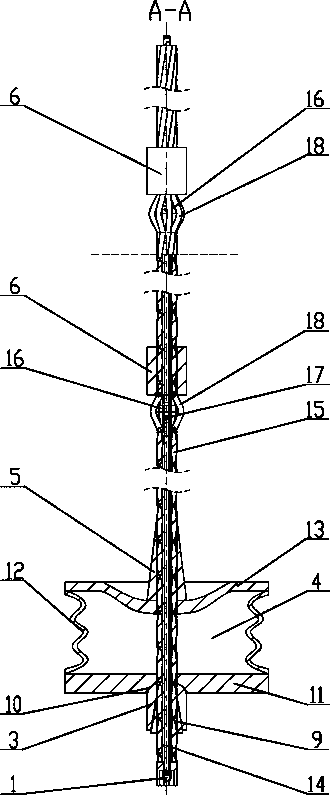

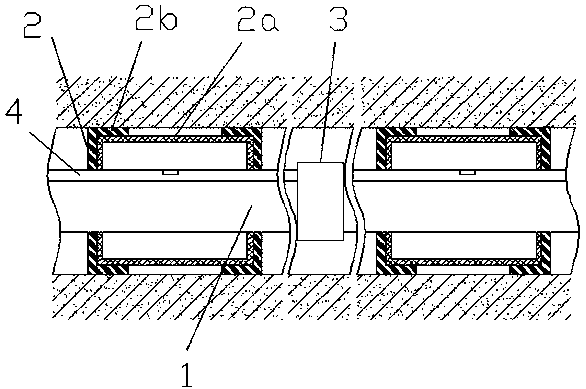

Impact-resistant interval grouting anchor cable and use method thereof

ActiveCN103590845AAlleviate the impact of the momentAvoid High Shear Stress StatesAnchoring boltsSupporting systemHigh stress

The invention discloses an impact-resistant interval grouting anchor cable and a use method of the impact-resistant interval grouting anchor cable. The impact-resistant interval grouting anchor cable comprises a one-way grouting valve, a hollow grouting stranded steel wire, an arc-shaped anchor ring, a sliding pressure yielding retraction ring, a tapered grout blocking plug and a subsection sealing plug, the sliding pressure yielding retraction ring is arranged between the arc-shaped anchor ring and the tapered grout blocking plug, grout discharge valves are arranged on a flexible grouting pipe in the hollow grouting stranded steel wire at certain-length intervals, the subsection sealing plug is arranged at the front end of an expansion area of the stranded steel wire, and interval grouting is achieved. The using method comprises the steps that a grouting section L2n-1 and a non-grouting section L2n are arranged according to coal petrography mechanical parameters of a construction location, initial resin anchoring is carried out on the interval grouting anchor cable, the interval grouting anchor cable is tensioned and pre-tightened, grouting materials are prepared, and a grouting pump is used for achieving the interval grouting on the grouting anchor cable. According to the condition of surrounding rock, the grouting section and the non-grouting section are arranged, the force bearing condition of a supporting system is scientifically improved, the instant high stress state, caused by the intense deformation of the surrounding rock, of the stranded steel wire of the anchoring section is relieved, and an anchor cable support is prevented from losing efficacy.

Owner:HENAN POLYTECHNIC UNIV

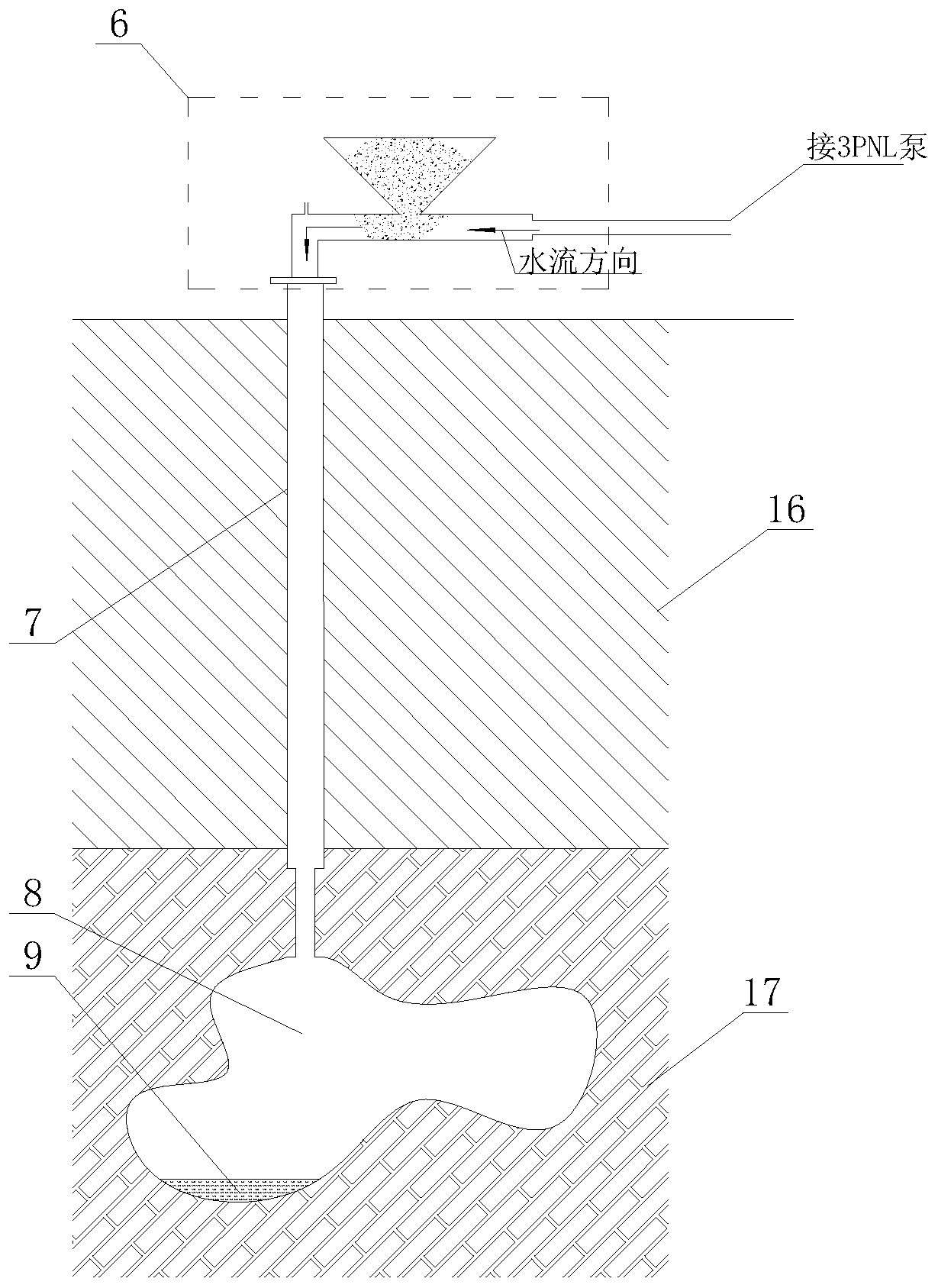

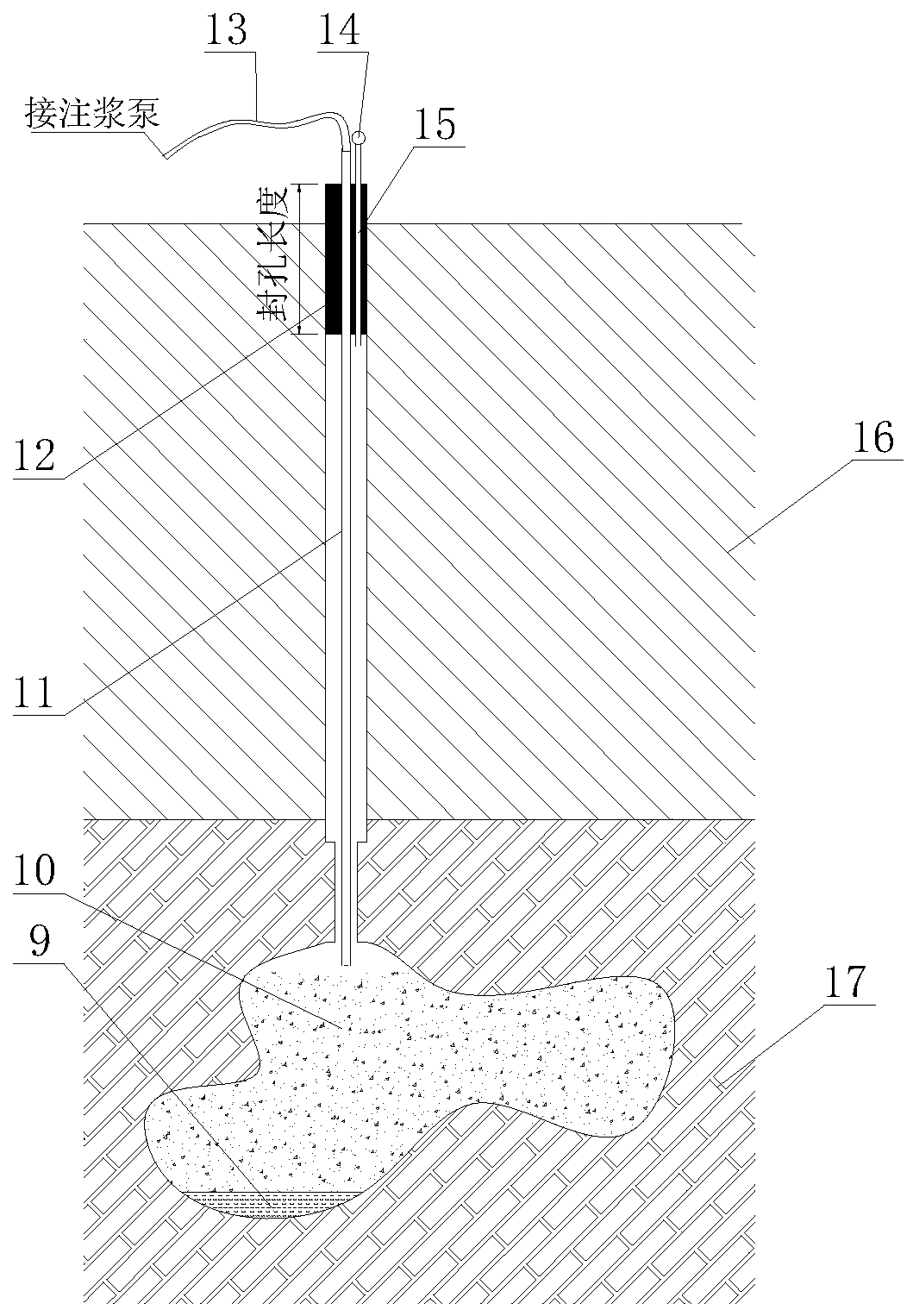

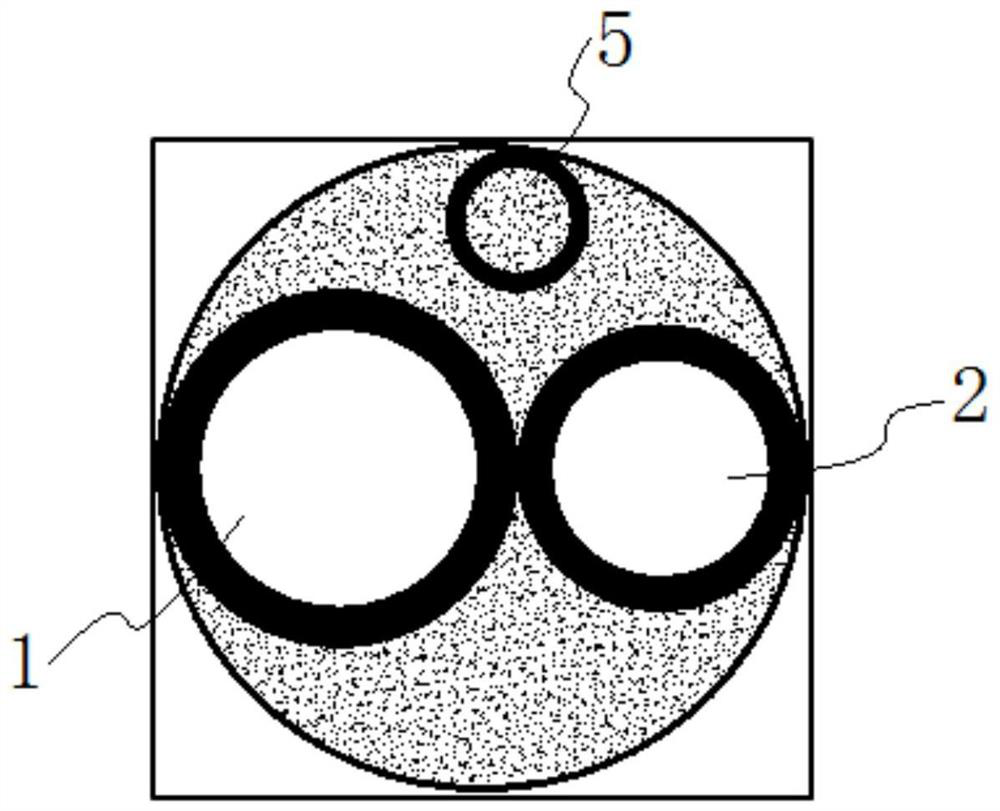

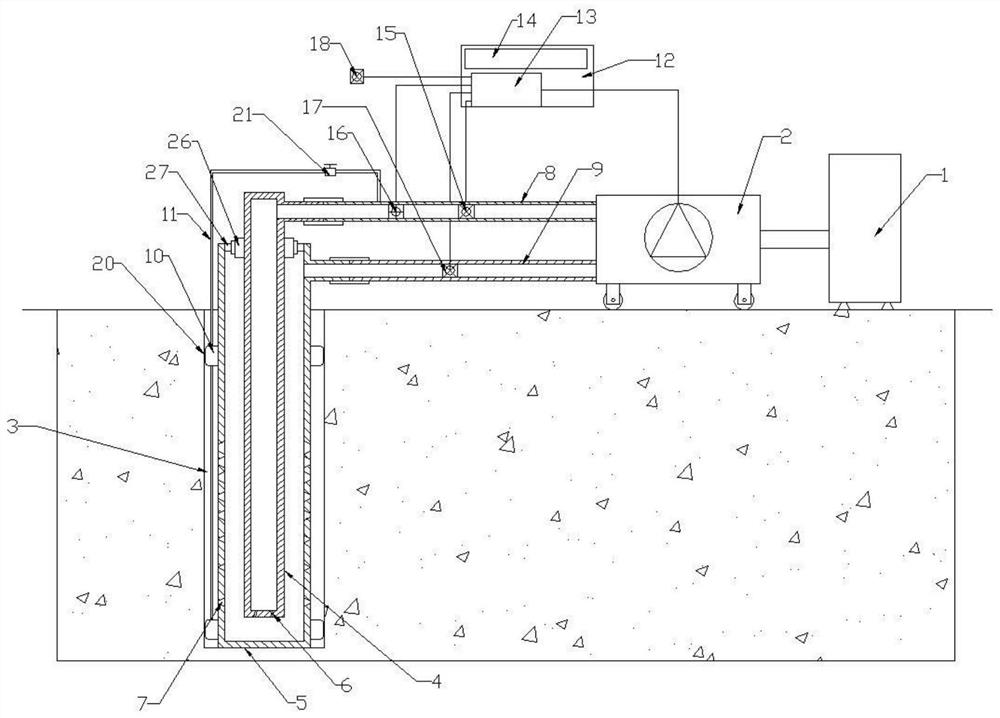

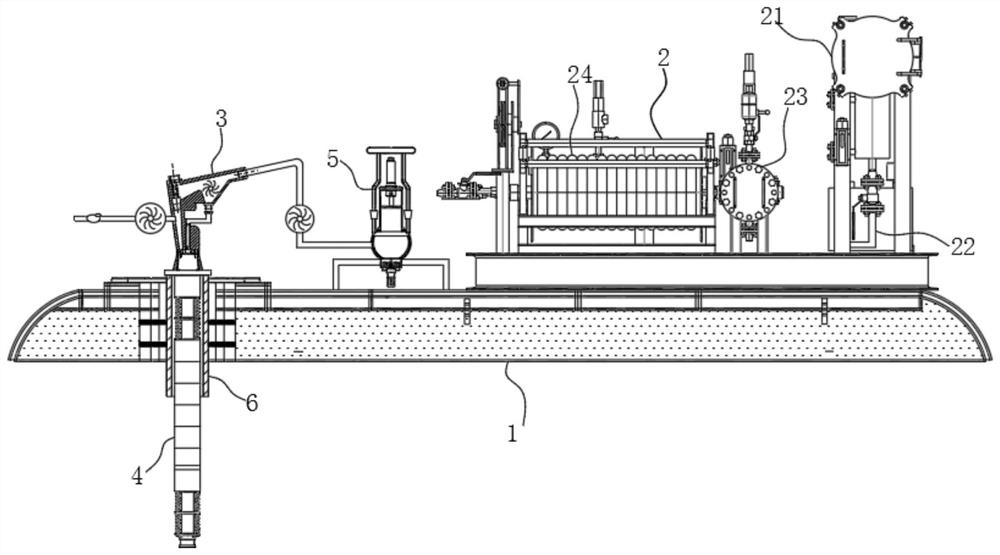

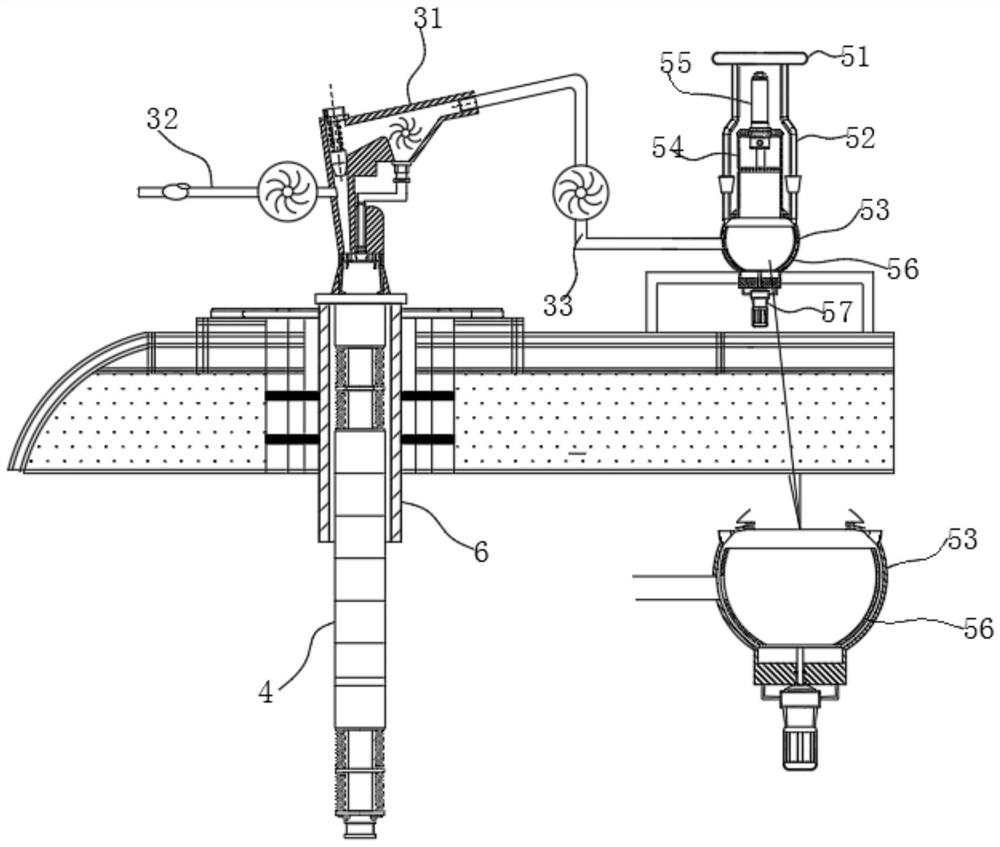

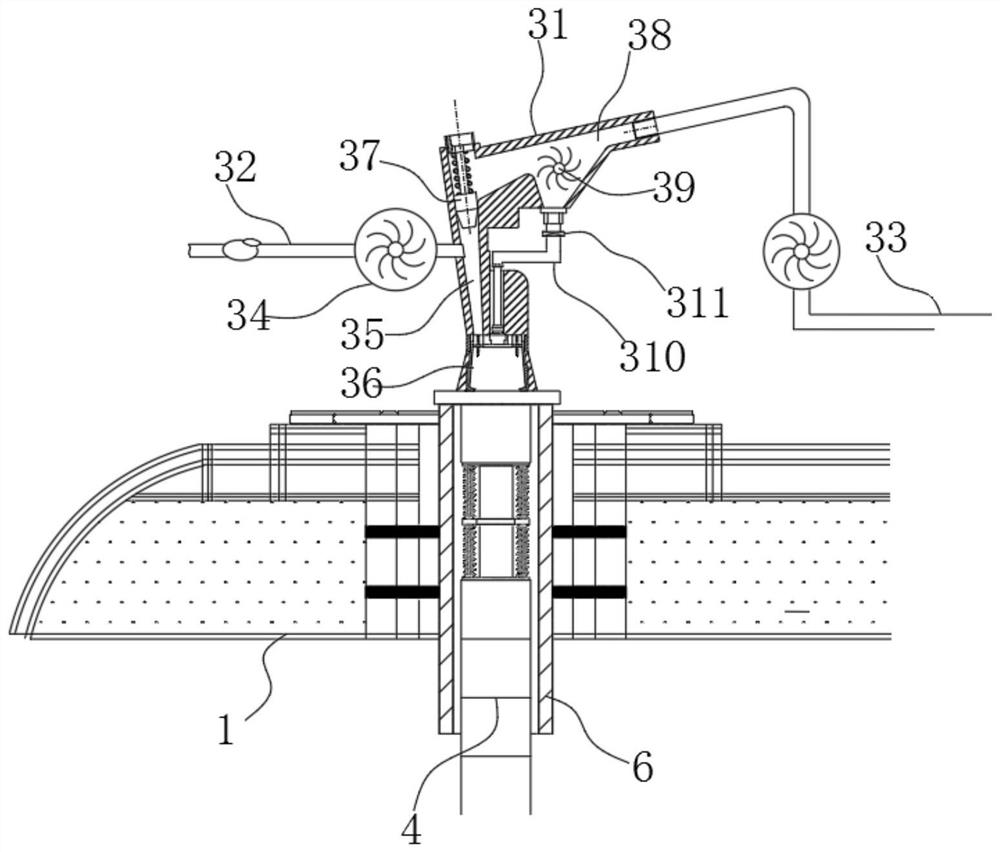

Method for filling underground cavity of bedrock stratum through filler grouting and hydraulic filling device

InactiveCN111535297AReduce the amount of groutReduce processing costsUnderground chambersTunnel liningSoil scienceBedrock

The invention relates to the technical field of karst cave filling, provides a method for filling an underground cavity of a bedrock stratum through filler grouting, and particularly relates to a filling method of a deep-covering type (burial depth is larger than 30.0 meters) large-space karst cave and a roadway. The method comprises the steps of determining a drilling position, drilling a covering soil layer, arranging a conveying casing pipe, drilling a bedrock section, filling by a hydraulic filling method and grouting. According to the method, the underground cavity is filled with the gravel material through the hydraulic filling method, then grouting is conducted, the filled gravel material is solidified, and the integrity of the filling material is improved; and the filled gravel materials can occupy the space in the underground cavity, the grouting amount is greatly reduced, the treatment cost is reduced, a connecting channel between the cavity and the outside of the cavity canbe blocked or reduced, the filling treatment effect of the underground cavity is improved, and the filling treatment problem of the deep covering type large-space karst cave and the roadway is solved.The invention further provides a hydraulic filling device, the hydraulic filling device is used for filling the underground cavity with gravel materials, the filling speed is high, and the filling effect is good.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

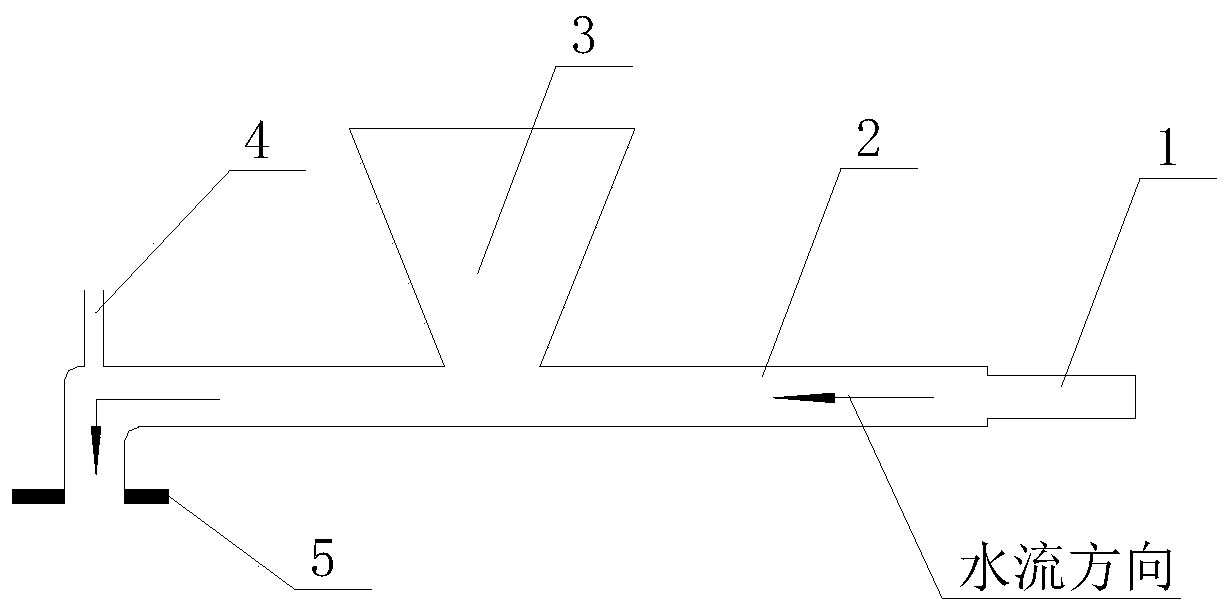

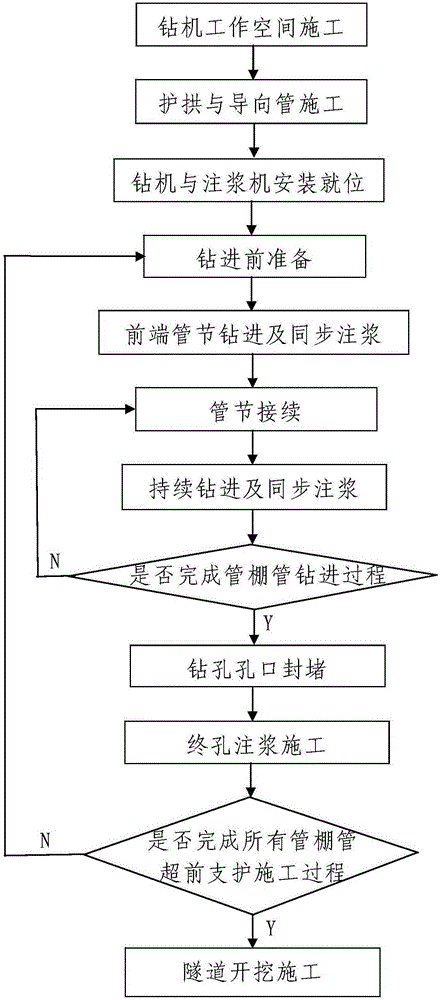

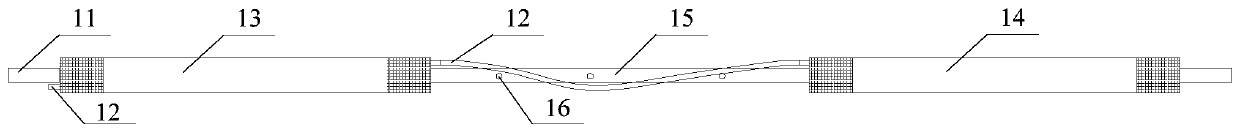

Advance support construction method for high-strength pipe shed of tunnel

InactiveCN105201517AShort construction periodImprove construction efficiencyUnderground chambersTunnel liningDrill holeHigh intensity

The invention discloses an advance support construction method for a high-strength pipe shed of a tunnel. A process for carrying out advance support construction on a pipe shed of one segment of a constructed tunnel comprises the following steps: (1) constructing support arches and guide pipes; (2) installing a drilling machine and a grouting machine in place; (3) carrying out advance support construction on the pipe shed: (301) preparing before drilling; (302) drilling pipe joints at front ends and synchronously grouting; (303) connecting the pipe joints; (304) continuously drilling and synchronously grouting; (305) repeating the steps (303) and (304) many times until the drilling processes of pipes of the current constructed pipe shed are finished; (306) blocking drill holes; (307) carrying out grouting construction on final holes; (308) repeating the steps (301) to (307) many times until all advance support construction processes of the pipes of the pipe shed are finished; and (4) carrying out excavation construction on the tunnel. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient in construction and good in support effect; and by adopting automatic drilling type high-strength pipes of the pipe shed, the advance support process of the tunnel can be simply, conveniently and quickly finished.

Owner:CHINA RAILWAY 20 BUREAU GRP

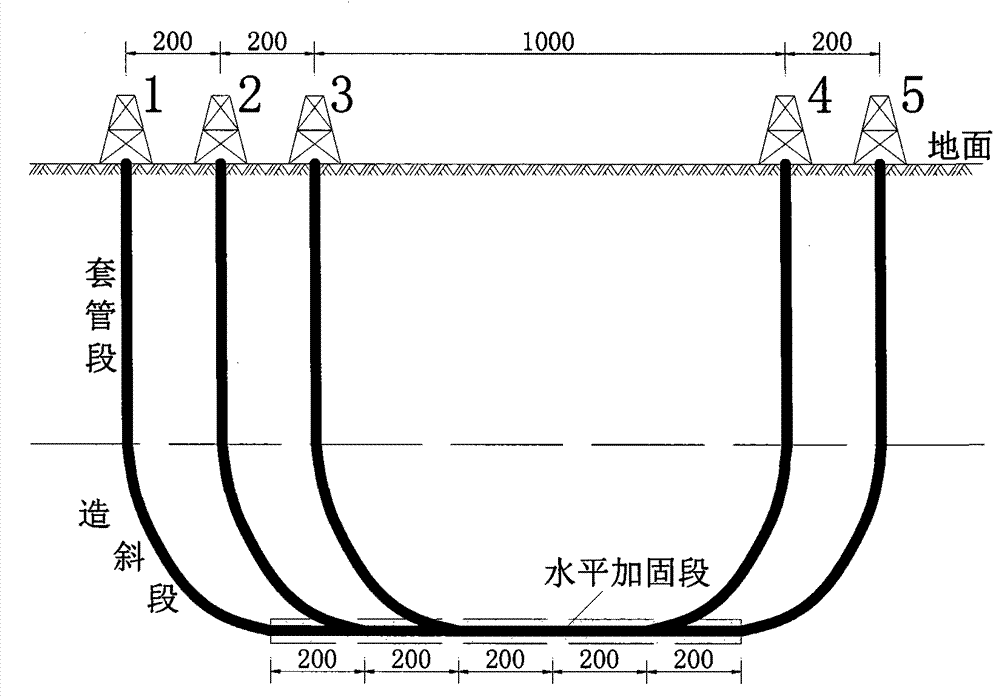

Pre-grouting reinforcement technology for ground construction of structural fracture zone of mining working face

InactiveCN111075478AImplement pre-hardened governanceImprove construction progressSurveyUnderground chambersDrill siteArchitectural engineering

The invention discloses a pre-grouting reinforcement technology for the ground construction of a structural fracture zone of a mining working face. The pre-grouting reinforcement technology comprisesthe following steps of: step (1). performing foundation construction at a drill site; step (2). drilling a straight hole section, and lowering and fixing a first-level casing pipe; step (3). drillinga main branch hole bedding section and grouting, and completing the construction of a main branch hole building angle section and the main branch hole bedding section; and step (4). repeating the step(3) and the step (4), and completing the construction of secondary branch holes one by one. Before the construction of the underground fully mechanized coal mining face, a drilling machine is used onthe ground for drilling, and drills a horizontal grouting hole by using a directional technology; a ground surface grouting pump is used for injecting grout into a stratum rock mass where a fracturedroof of the fully mechanized coal mining face is located, so that the advance reinforcing treatment of the rock mass in the fracture zone of the roof is realized, the construction environment duringthe open-off cut and the working face mining is improved, and the construction progress of the roadway is accelerated. The pre-grouting reinforcement technology has high safety, improves the construction environment of workers, has less pollution to the environment, and is an initiative roof reinforcement technology.

Owner:BEIJING CHINA COAL MINE ENG CO LTD +1

Grouting structure capable of filling soluble crystal and construction method

ActiveCN111794238AReduce crackingImprove negative pressure effectExcavationsBulkheads/pilesSoil scienceOutfall

The invention discloses a grouting structure capable of filling a soluble crystal and a construction method. The structure comprises a water permeating section and a grouting section, wherein a water-stop component is arranged between the water permeating section and the grouting section; a water permeating tube is arranged in the water permeating section; the solid-state soluble crystal is filledin the water permeating section; a water inlet of a water drainage tube is arranged in the water permeating section; and elevation of the water inlet of the water drainage tube is greater than that of the water outlet of the water drainage tube. The grouting structure is beneficial for increasing grouting pressure, reduces cracks of the grouting section, and improves sealing effect, so that negative-pressure effect of the water permeating section is improved; during grouting, the water-stop component can be effectively supported, and slurry is prevented from entering the water permeating section to disturb formation of a negative-pressure environment, so that blockage of the water permeating tube is avoided, the water-stop component is prevented from greater displacement as a result of extrusion, and continuous water drainage effect of a slope deep layer is favorably guaranteed, and therefore, the grouting structure is of great significance on solving the water drainage and control problem of a large slope.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Tunnel water seepage and harmful gas discharge structure and semi-closed ice-filled drilling construction method

ActiveCN111810234AEfficient dischargePrevent escapeMining devicesUnderground chambersOutfallDrainage tubes

The invention discloses a tunnel water seepage and harmful gas discharge structure and a semi-closed ice-filled drilling construction method. The structure includes a permeable pipe arranged in a permeable section of a drilling hole. The drilling hole includes the permeable section and a grouting section, the drilling hole is drilled from the side wall of a tunnel, a water stop member is arrangedbetween the permeable section and the grouting section, the permeable pipe is filled with ice, and the permeable section is internally provided with an water inlet of a drainage pipe; and the elevation of the water inlet of the drainage pipe is higher than the elevation of a water outlet of the drainage pipe, and the lift of the drainage pipe is less than the height of a water column correspondingto the atmospheric pressure. According to the tunnel water seepage and harmful gas discharge structure, harmful gases in the surrounding rock in the drainage link can be effectively discharged, the situation that the harmful gas escapes or is greatly accumulated in the surrounding rock is reduced, the safety risk is reduced, and the water-stop member can be effectively supported during grouting,the structure is beneficial to increase the grouting pressure, the negative pressure effect of the permeable section improved, and the tunnel water seepage and harmful gas discharge structure is conducive to ensuring continuous drainage and exhaust effects and is of great significance to solving the problem of tunnel water seepage and gas leakage.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

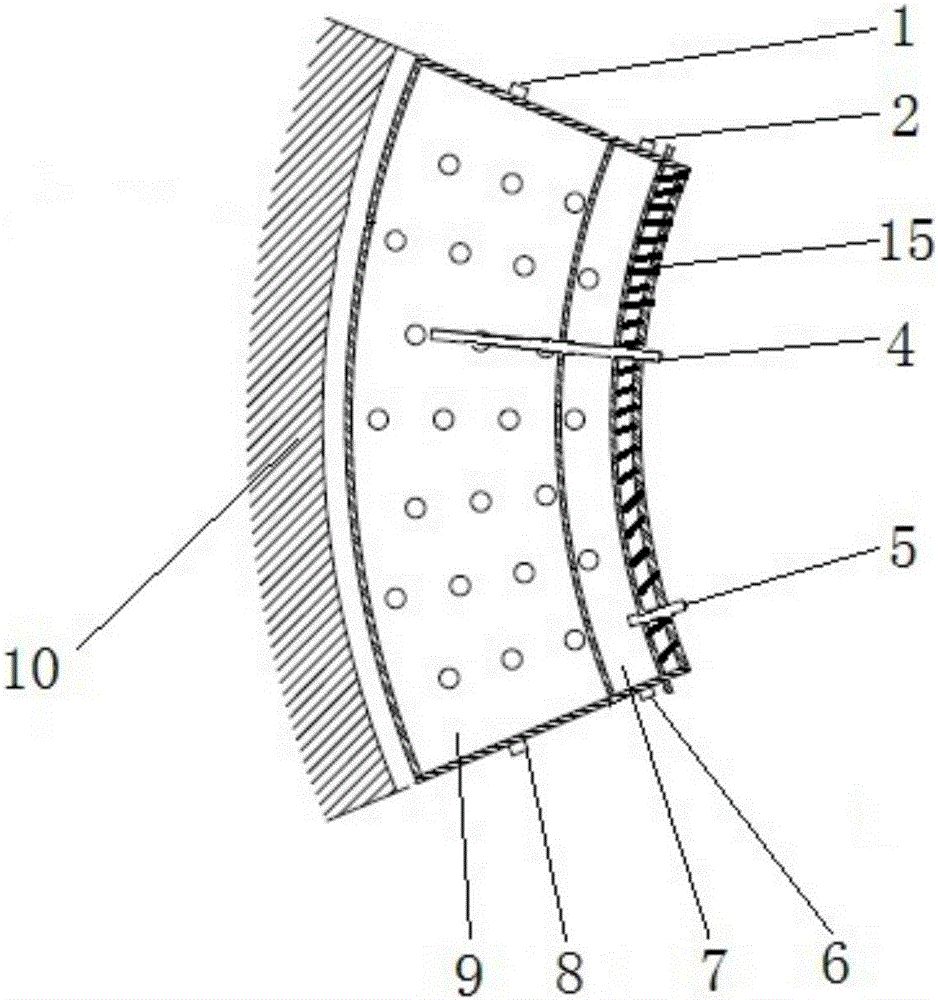

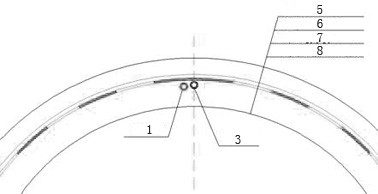

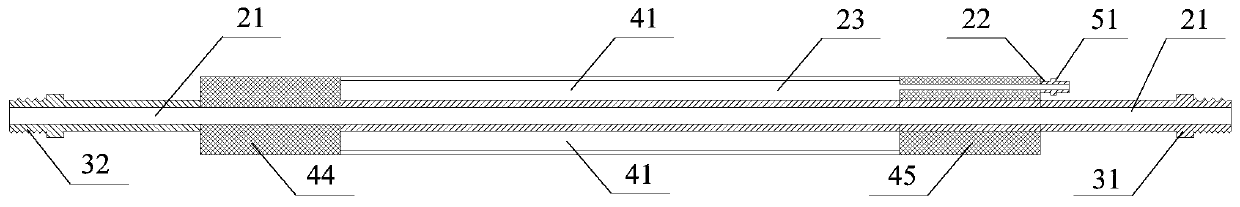

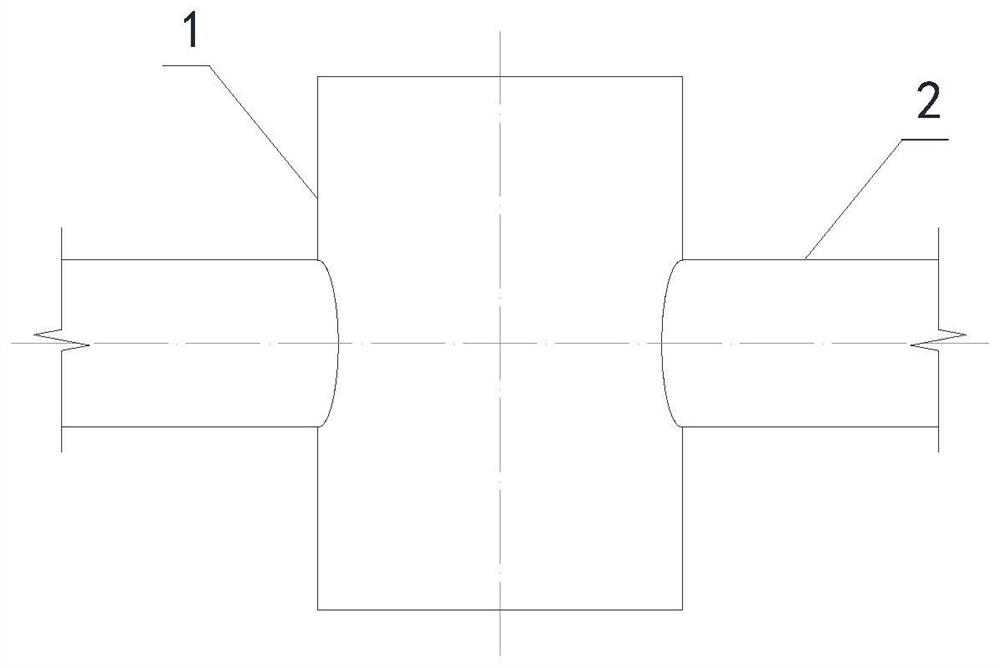

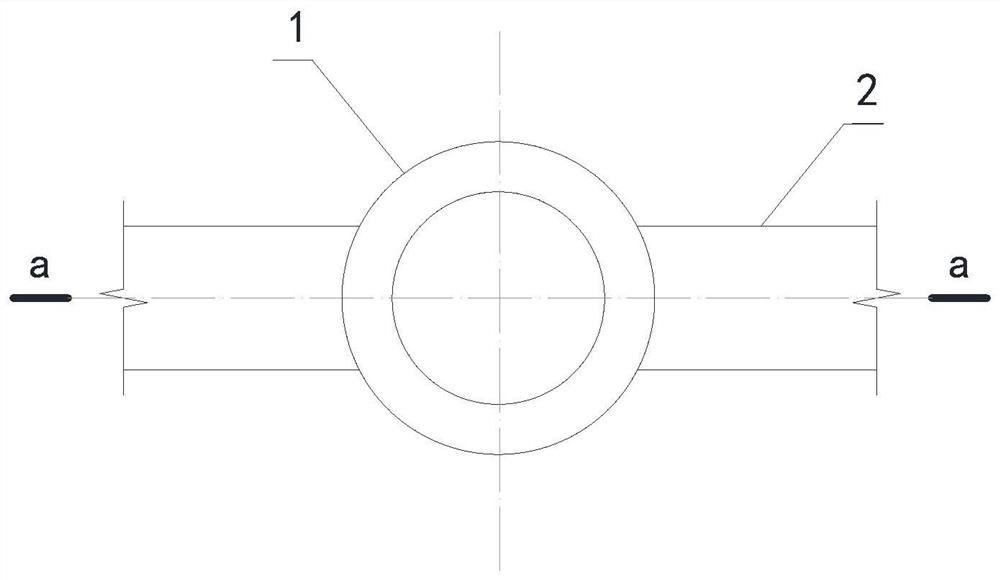

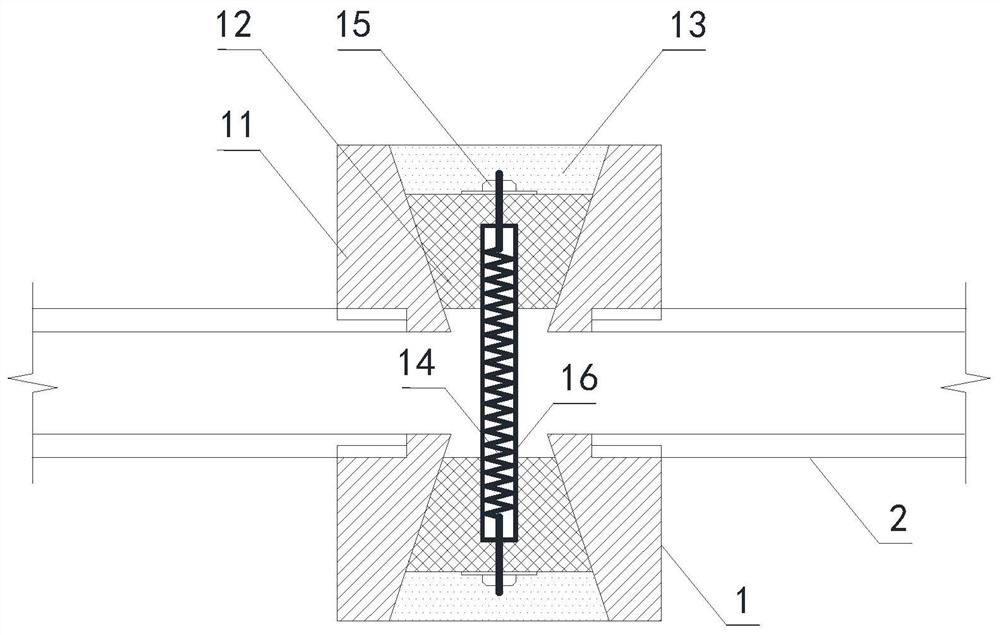

Steel-structure waterproof jointing plate of well wall and construction process of steel-structure waterproof jointing plate

The invention provides a steel-structure waterproof jointing plate of a well wall and a construction process of the steel-structure waterproof jointing plate. The steel-structure waterproof jointing plate is of a multi-cavity annular steel structure laid between cast-in-place concrete of segment construction; the multi-cavity annular steel structure is formed by connecting and surrounding of a plurality of arc sections of multi-cavity annular steel structures in sequence; each arc section of the multi-cavity annular steel structure comprises a grouting cavity, a check valve hole, a water stopping and grout stopping plate and a communication pipe; each multi-cavity annular steel structure is internally provided with a grouting pipe; every two arc sections of the multi-cavity annular steel structures are connected with the water stopping and grout stopping plate through the communication pipe, and a grouting material is injected into each grouting cavity through the grouting pipe; and the grouting material flows to the jointing plate, a connecting surface of upper and lower well walls and an adjacent gap through the check valve hole. According to the steel-structure waterproof jointing plate provided by the invention, the compaction of the jointing plate on a new and old concrete interface and the concrete is increased, and the impervious performance of the new and old concrete interface is improved; and the steel-structure waterproof jointing plate has a good waterproof effect, is simple in structure, convenient to construct and good in sealing performance, and has wider practicability in the technical field.

Owner:CHINA UNIV OF MINING & TECH

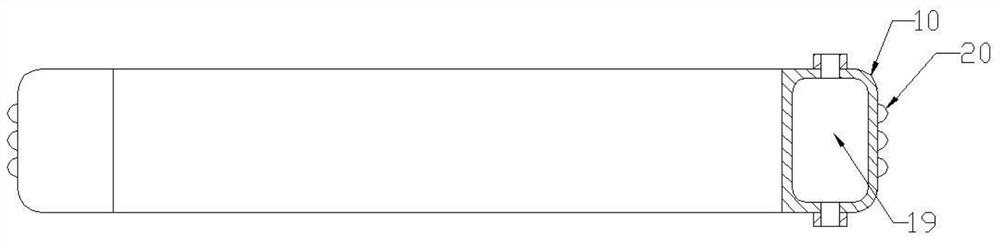

Self-adaptive deformation gas extraction drilled hole sealing device

InactiveCN111852391ARealize adaptive drilling deformationImprove grouting pressure bearing capacityGas removalSealing/packingThermodynamicsStraight tube

The invention relates to a self-adaptive deformation gas extraction drilled hole sealing device, and belongs to the technical field of coal mine downhole gas prevention and governance projects. The device comprises a hole sealing unit and two hole sealing pipes; gas inlet ends of the hole sealing pipes are arranged inside a drilled hole; and the gas inlet ends of the hole sealing pipes penetrate through the hole sealing unit. The device can realize self-adaptive deformation to the drilled hole of the hole sealing pipes, the traditional modes of PVC straight pipe inserting or screw thread connection are not required, and disjointing of inserting between pipes or screw thread connection caused by drilled hole deviation and deformation is avoided; the grouting stress bearing capacity of the hole sealing pipes is further improved, and the situation that the hole sealing pipes are flattened under grouting pressure and grout enters the hole sealing pipes is avoided; and the sealing performance between hole sealing pockets and grouting air chambers is ensured, and grouting stress is improved to ensure that the grout can effectively permeate into seams between coal masses.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

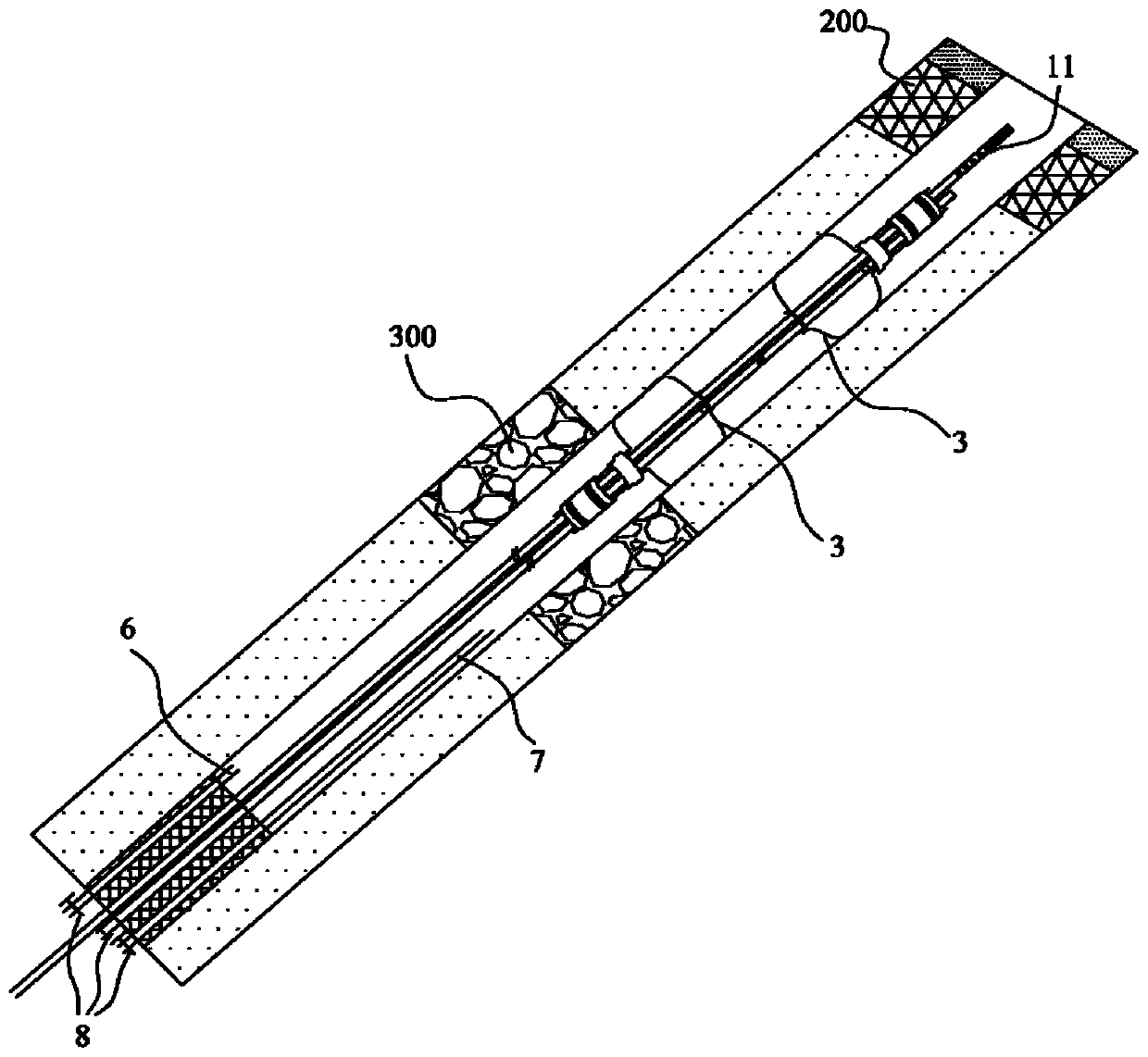

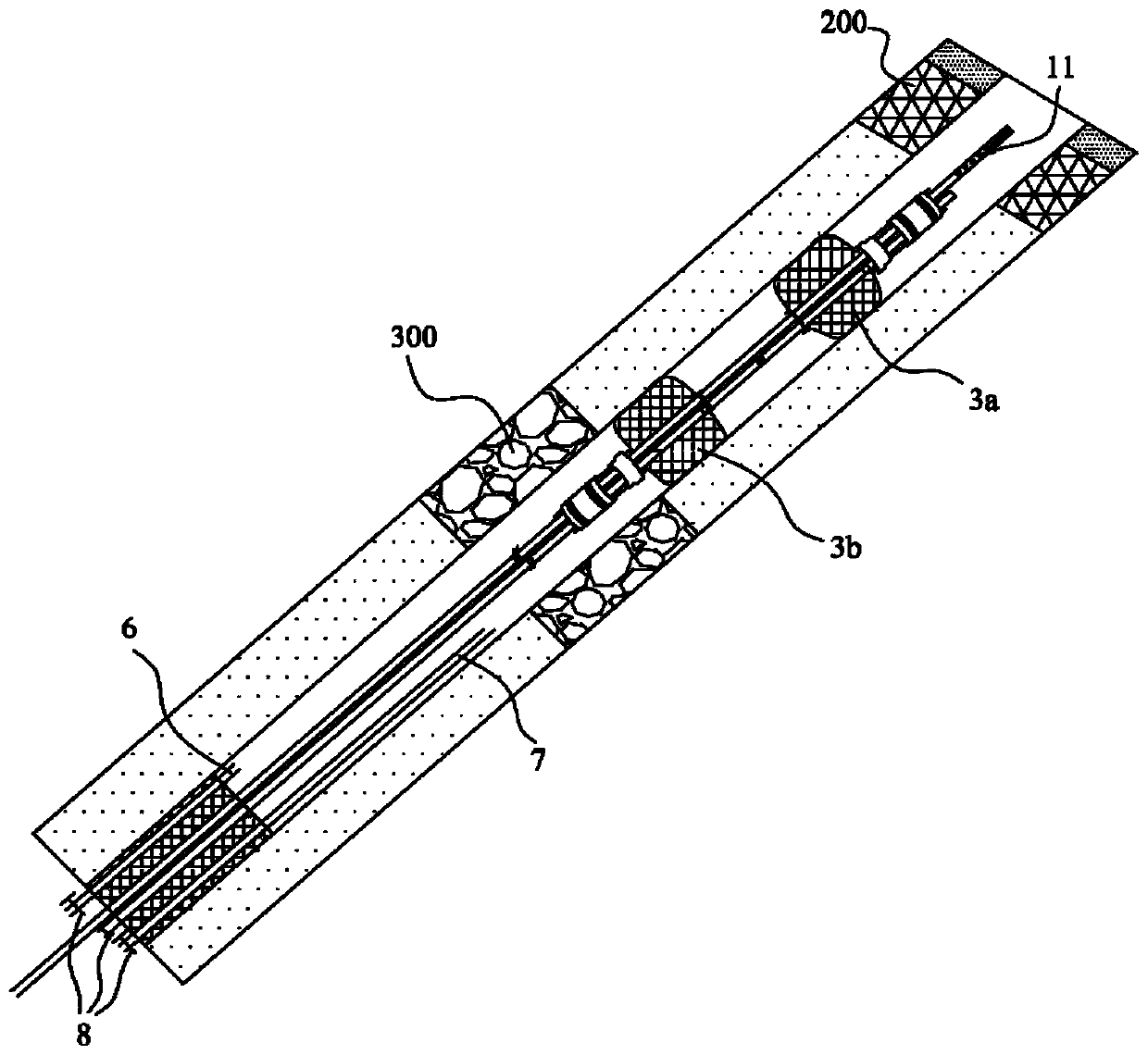

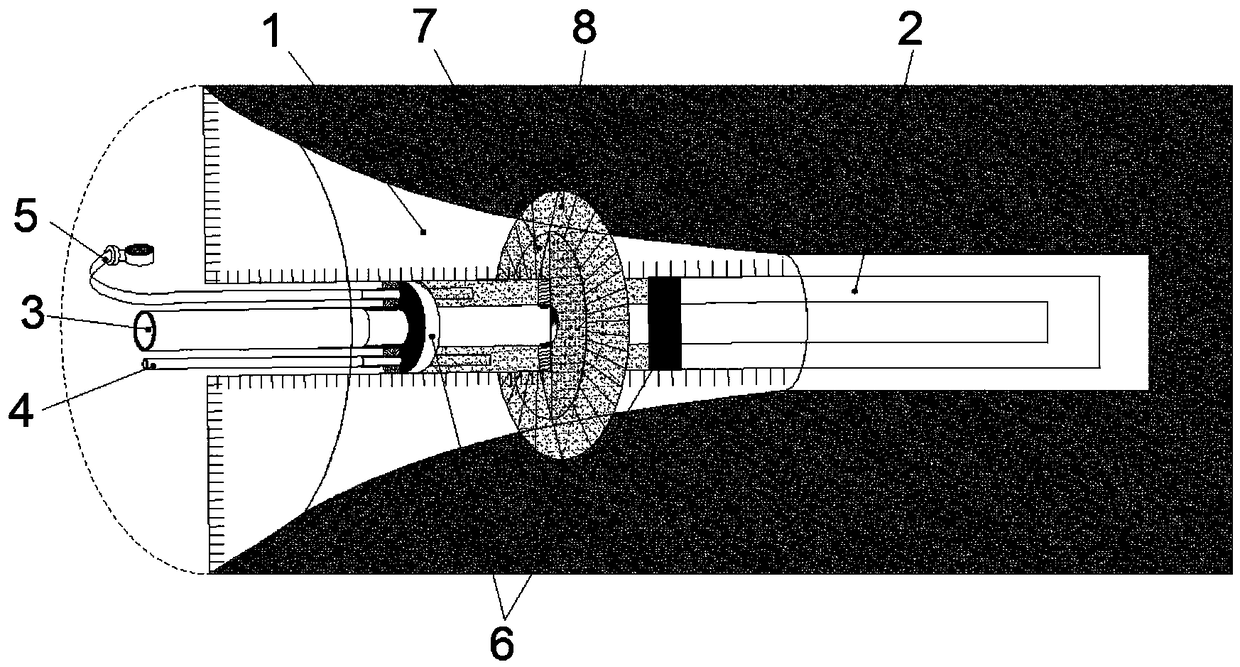

Gas pressure measuring device and gas pressure measuring method

The embodiment of the invention provides a gas pressure measuring device and a gas pressure measuring method, and relates to the technical field of gas pressure detection. The gas pressure measuring device comprises a pressure measuring pipe, a first grouting pipe, grouting bags and a switch device, the head end of the pressure measuring pipe is used for extending into a coal seam, the tail end ofthe pressure measuring pipe is connected with an air pressure detecting device; the first grouting pipe is parallel to the pressure measuring pipe, a plurality of first grouting holes are formed in the first grouting pipe at intervals in the center line direction, a second grouting hole is formed between every two adjacent first grouting holes; the grouting bags wrap the pressure measuring pipe and the first grouting pipes, each first grouting hole is communicated with one grouting bag, each grouting bag is used for being arranged between the coal seam and an aquifer; and the switch device blocks the second grouting hole and is used for opening the second grouting hole when the pressure in the first grouting pipes reaches a preset value. According to the gas pressure measuring device andthe gas pressure measuring method, concrete which flows out of the second grouting hole is in direct contact with the side wall of the pressure measuring drill hole, so that the sealing effect is improved.

Owner:HUAINAN MINING IND GRP +3

Gas extraction hole drilling and hole sealing method for building anti-seepage barrier based on grooving-backfilling method

InactiveCN109236226AImprove extraction qualityIncrease the lengthLiquid/gas jet drillingSealing/packingEngineeringGas concentration

A gas extraction hole drilling and hole sealing method for building an anti-seepage barrier based on a grooving-backfilling method is disclosed. The method comprises the following steps: a wedge-shaped and disc-shaped space is drawn out in a coal body strong air leakage area, positioned at a distance of 6 to 8 m from an orifice of a borehole, around the borehole; a hole sealing capsule is arrangedin each of front and rear boreholes of the wedge-shaped and disc-shaped space, sealing material is injected into the hole sealing capsule and a hole sealing section, and the wedge-shaped and disc-shaped space is fully backfilled; the anti-seepage barrier that blocks an air leakage passageway is formed, and hole sealing operation is completed. Via the hole drilling and hole sealing method disclosed in the invention, the air leakage area around the borehole can be effectively sealed, the air leakage passageway can be blocked, extracted gas concentration and coal seam gas extraction rates can beimproved to an maximum degree, a sealed hole is small in length, excellent hole sealing effects can be realized, injecting paste material can be saved, and engineering work quantities of hole sealingcan be greatly reduced.

Owner:CHINA UNIV OF MINING & TECH

Mining hand hole-sealing pump

InactiveCN1932287AImprove rigorIncrease the grouting pressurePiston pumpsPositive-displacement liquid enginesDrive shaftAgricultural engineering

The present invention relates to a mine manual hole-sealing pump. It is composed of stirring device and slurry-conveying equipment. Said stirring device includes stirrer and bevel gear group connected with said stirrer, said bevel gear group is connected with transmission shaft, on the transmission shaft a power handle is set; the slurry-conveying equipment includes the following several portions: pressure rod, chain gear group, plunger and plunger pump, non-return valve, energy storage device and pressure gauge. Besides, said invention also provides its working principle and concrete application method.

Owner:CHINA UNIV OF MINING & TECH

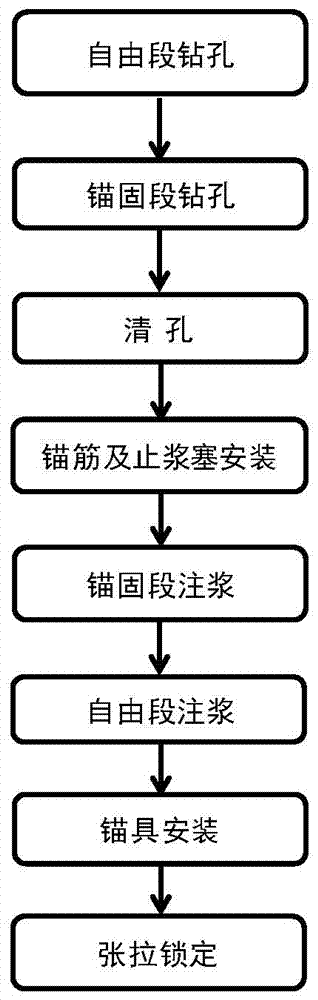

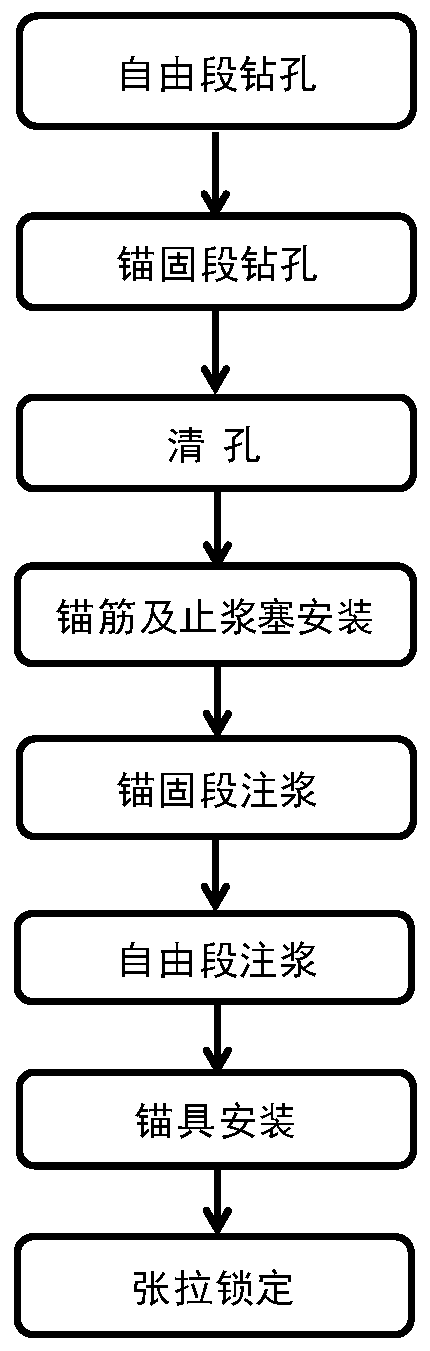

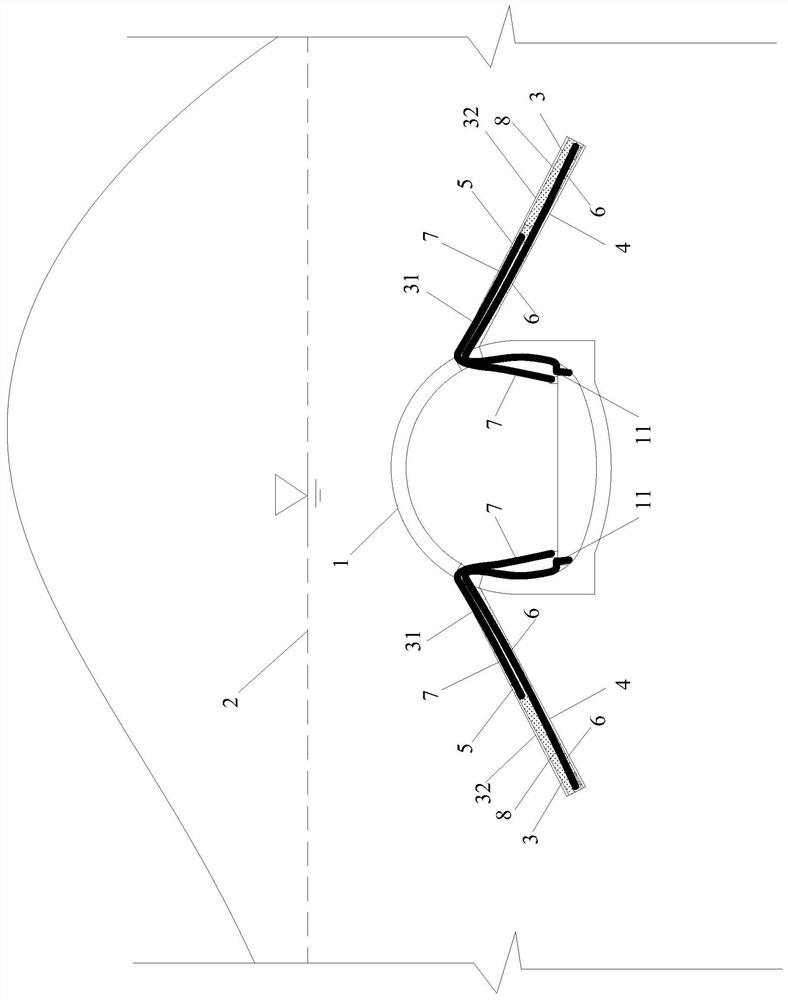

Shear-yielding and pressure-yielding cable-anchored pile structure and construction method thereof

ActiveCN107489156AAchieve pre-hardeningIncreased shear strengthExcavationsBulkheads/pilesStructural engineeringDrill hole

The invention discloses a shear-yielding and pressure-yielding cable-anchored pile structure which comprises a pressure-yielding slide-resistant pile structure and a pile block shear-yielding anchoring structure. The pressure-yielding slide-resistant pile structure comprises an slide-resistant pile, wherein a pressure-yielding layer is arranged on a side face where the slide-resistant pile is in contact with a slope; the pile block shear-yielding anchoring structure comprises a free section drill hole, and an anchoring section drill hole is formed in the bottom face of the inner side of the free section drill hole; the free section drill hole extends inward to the inner side of a potential slip face of the slope, an outer orifice of the free section drill hole is located in a contact face of the slope and the pressure-yielding layer, through holes communicating with the free section drill hole are formed in the slide-resistant pile and the pressure-yielding layer, the inner side end of an anchor bar extends inward to be located in the anchoring section drill hole, and the outer side end of the anchor bar extends outward out of the slide-resistant pile; mortar fills the anchoring section drill hole, a low compression modulus grouting material fills the free section drill hole, and an anchorage device for tensioning and fixing the anchor bar is arranged on the outer orifice of each of the through holes. The invention also provides a construction method of the shear-yielding and pressure-yielding cable-anchored pile structure.

Owner:CHONGQING JIAOTONG UNIVERSITY

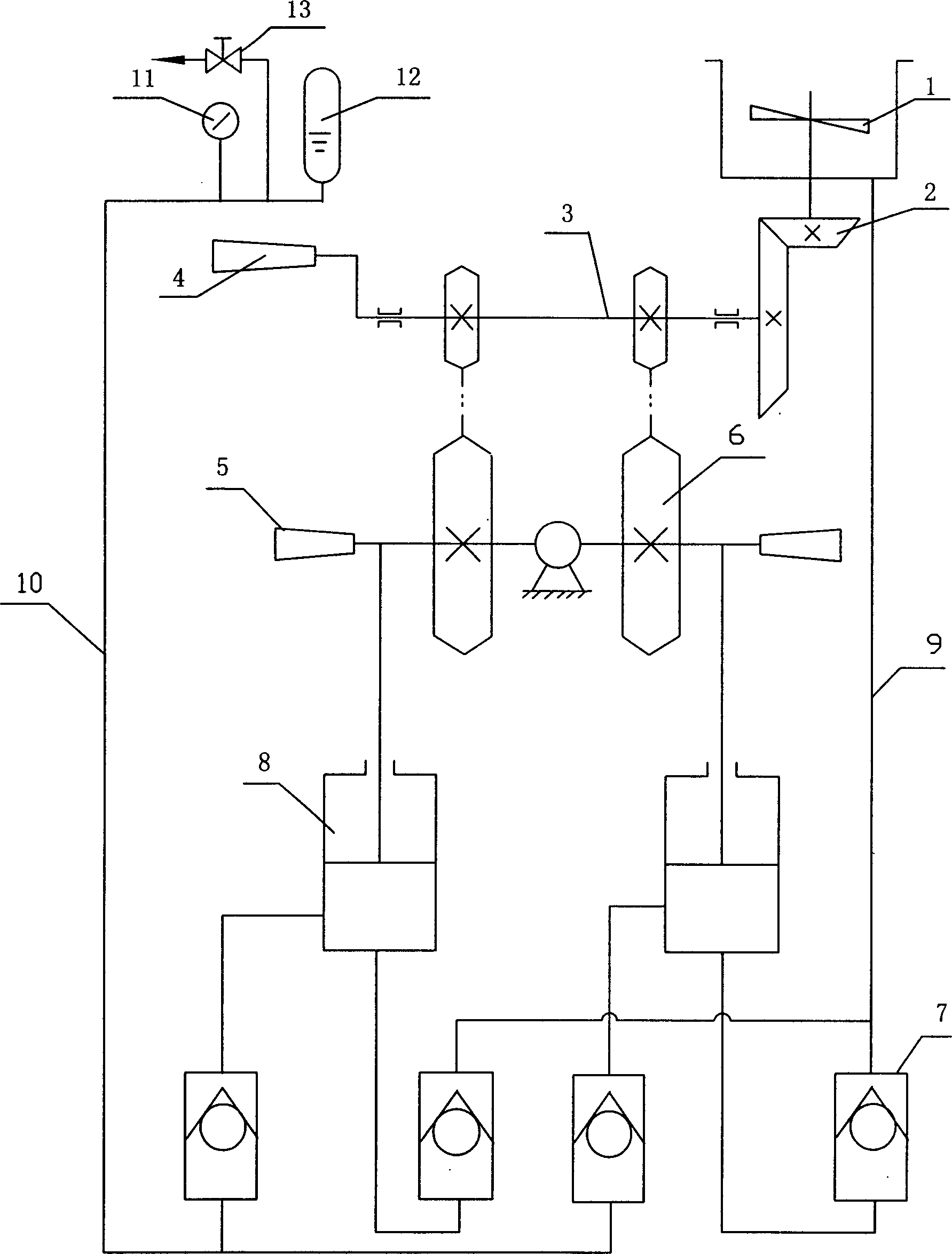

Grouting device for controlling settlement of height railroad bed and grouting method

The invention relates to a grouting device for controlling settlement of a height railway roadbed and a grouting method. The grouting device for controlling the settlement of the height railway roadbed comprises a pulping machine, a grouting pipe and a grouting pump, wherein the grouting pipe comprises an inner pipe and an outer pipe which sleeve with each other, the inner pipe and the outer pipe communicate with each other, and grout outlet holes are formed in the outer pipe; meanwhile, the inner pipe and the outer pipe are connected with the grouting pump through a communicating pipe and a circulating pipe correspondingly; meanwhile, the outer pipe further sleeves with an expansion sleeve, and the expansion sleeve is connected with the communicating pipe through an expansion pipe. According to the grouting device for controlling the settlement of the height railway roadbed, slurry is buffered through the design of the inner pipe and the outer pipe, so that the pressure change amplitude of the slurry is reduced; meanwhile, drainage is conducted to the far end of the grouting pipe through adjustment of the hole diameter and the distribution density of the grout outlet holes, and therefore uniform distribution of grout is guaranteed; the grouting pipe is fixed in a mounting hole after the expansion sleeves at the two ends of the grouting pipe are expanded, so that the vibration of the grouting pipe is further reduced, and the grouting quality is improved; an inlet and an outlet of the grout are formed in the top of the grouting pipe, the grouting pipe can be installed at any angle, and the application range of the grouting pipe is expanded.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

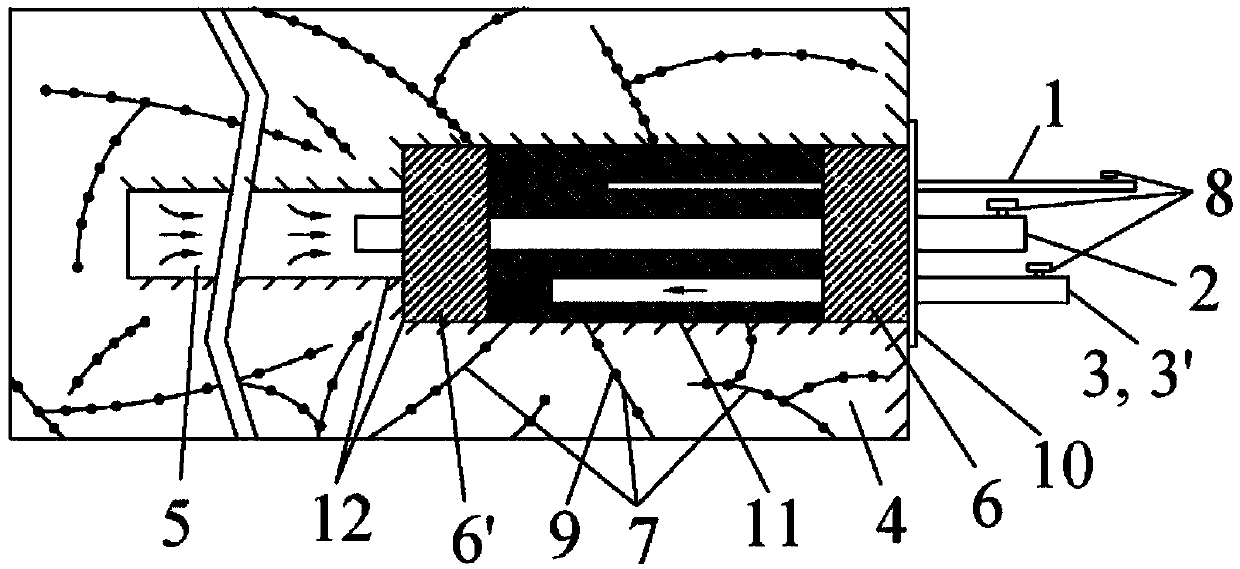

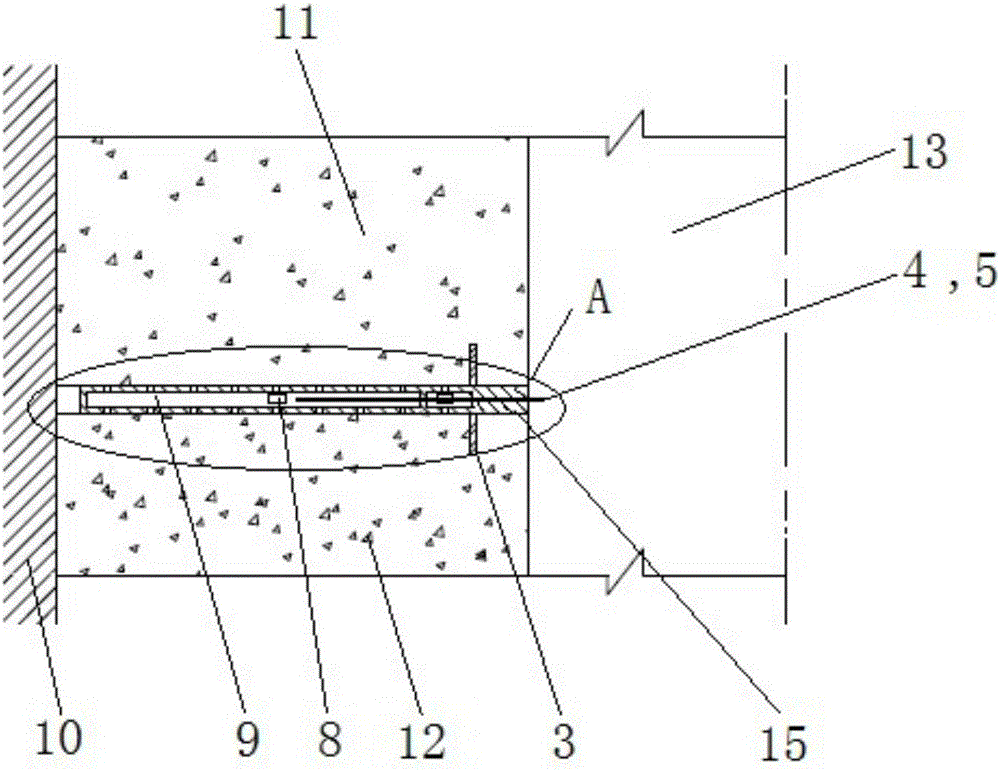

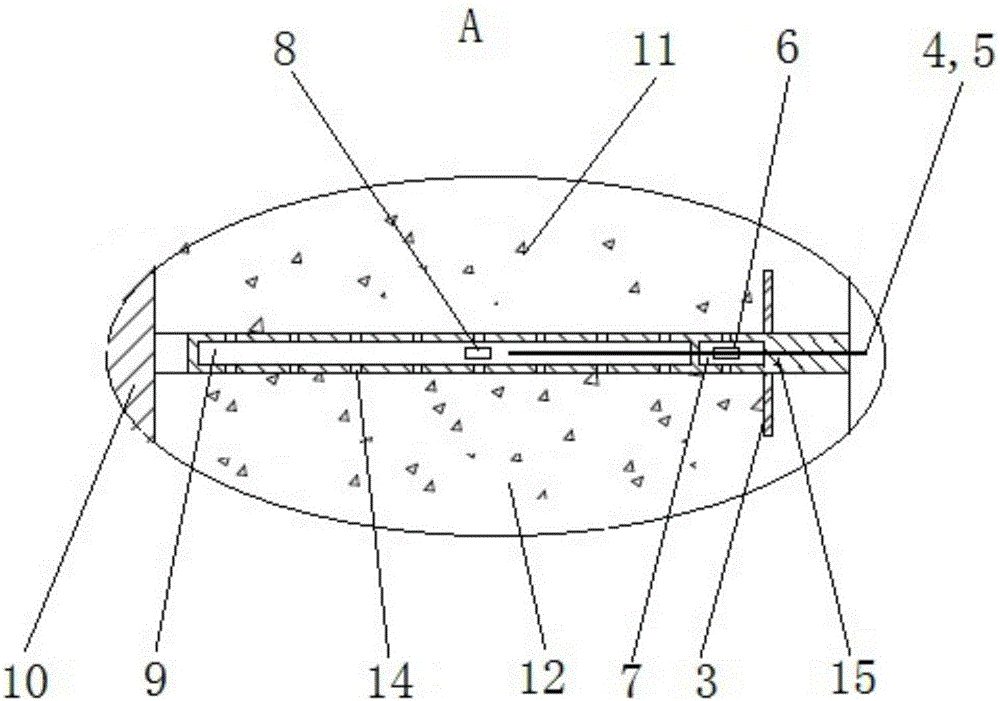

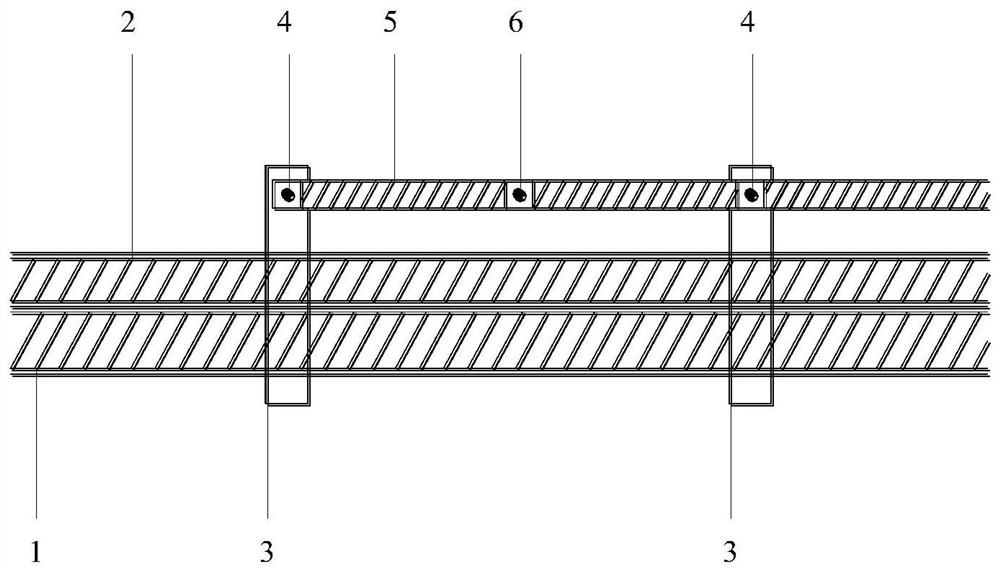

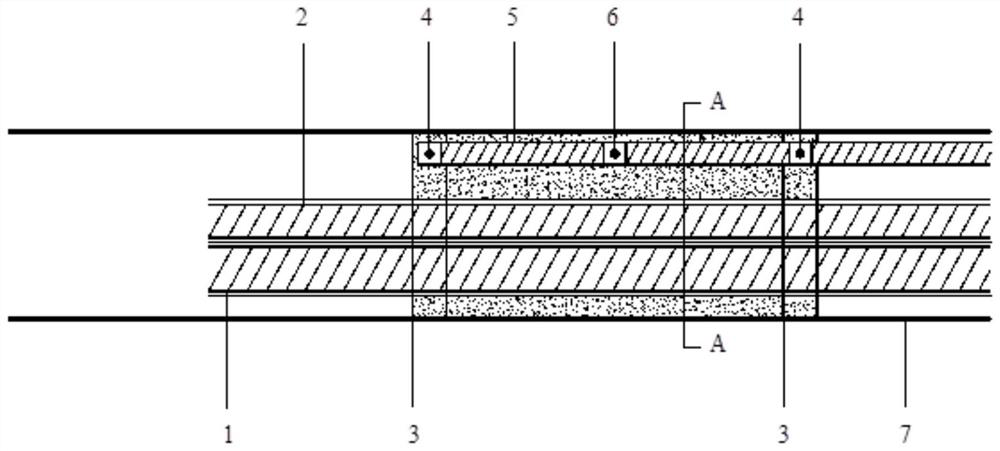

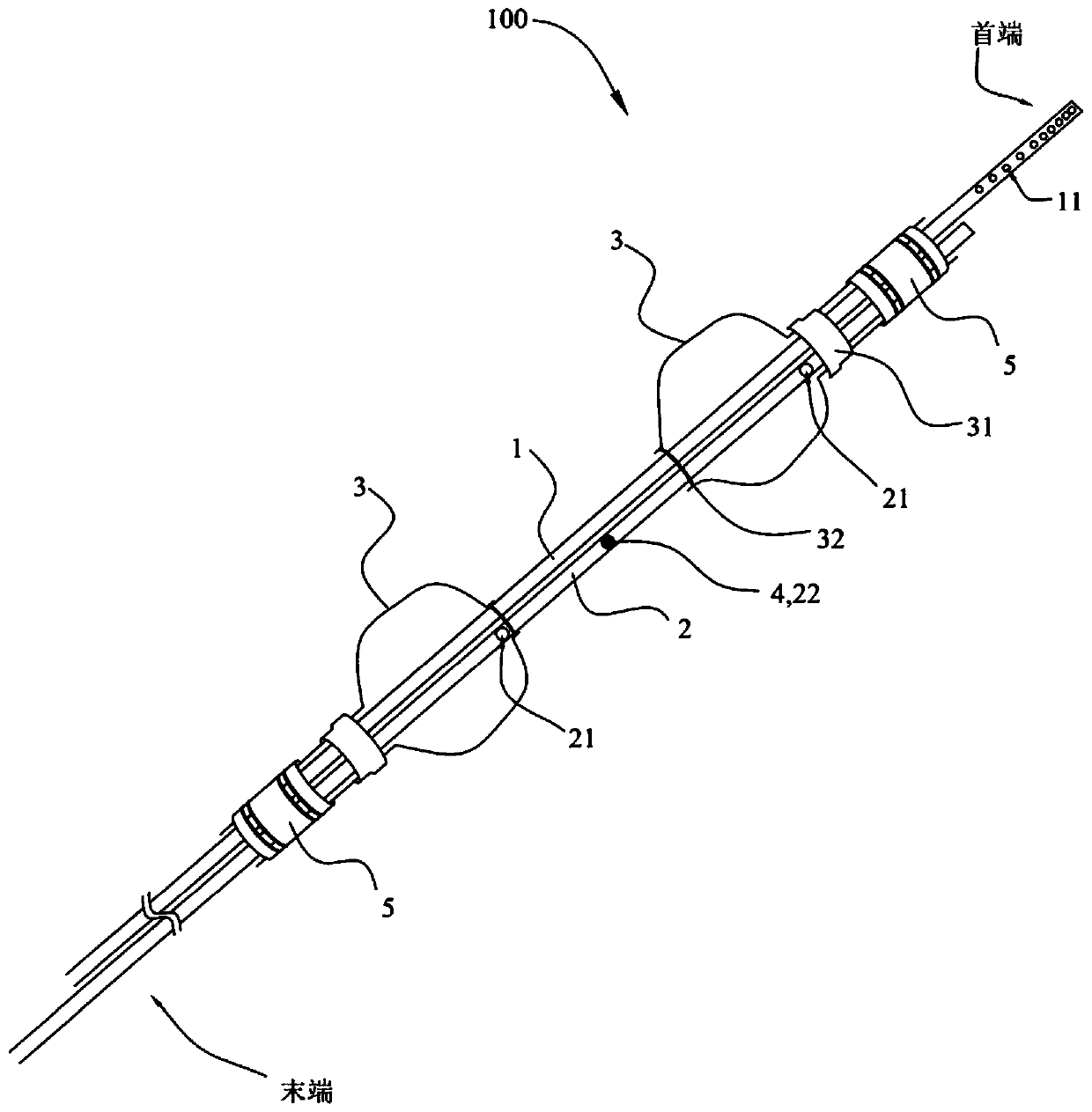

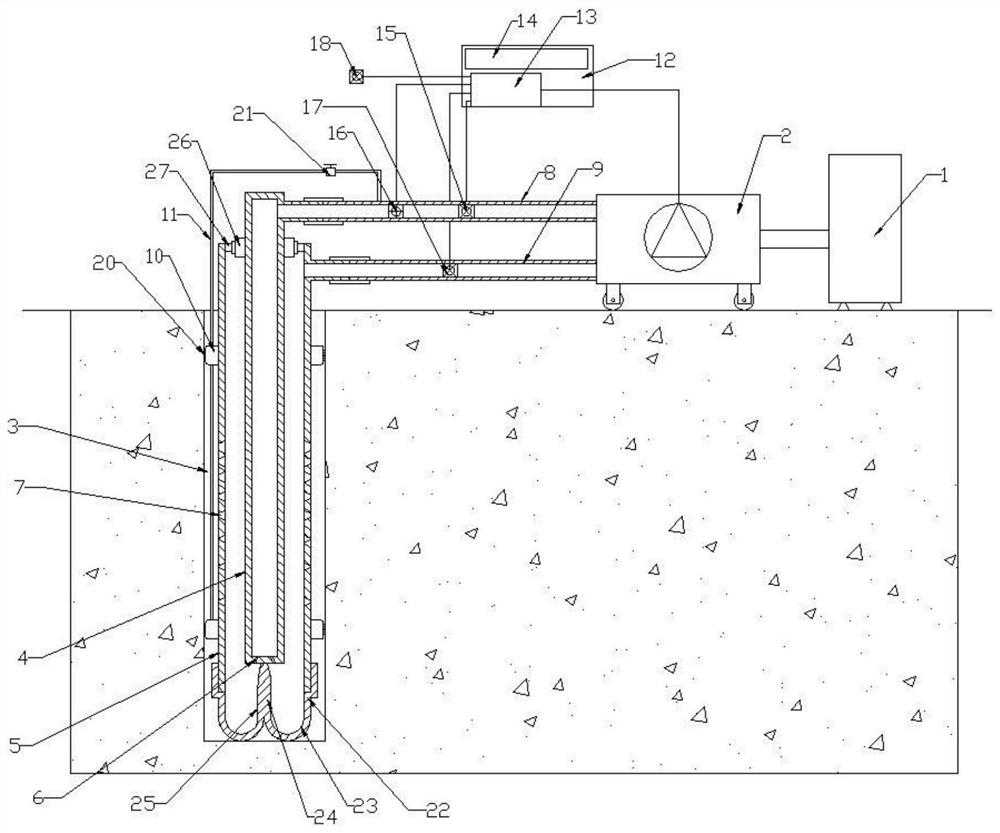

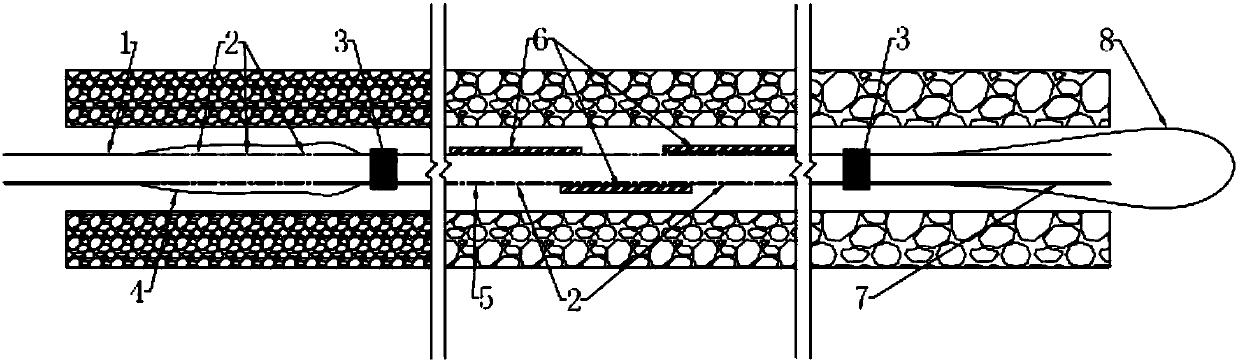

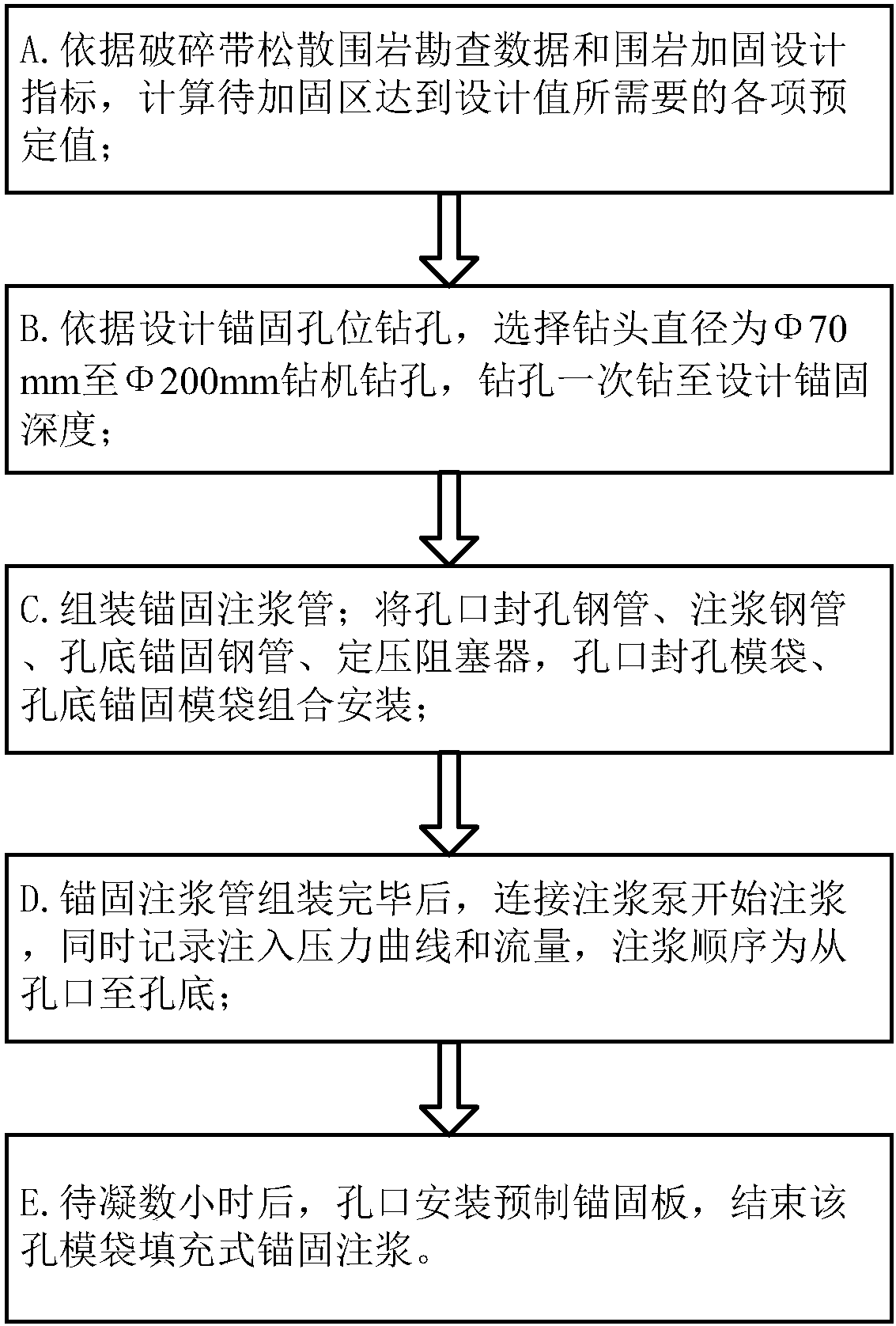

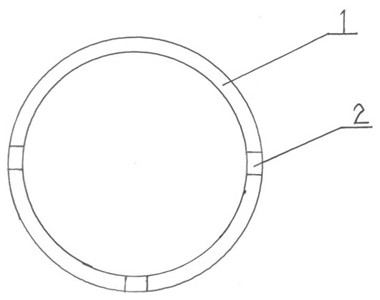

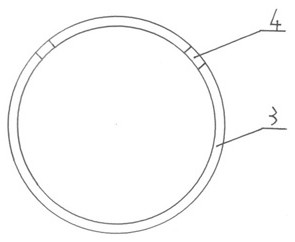

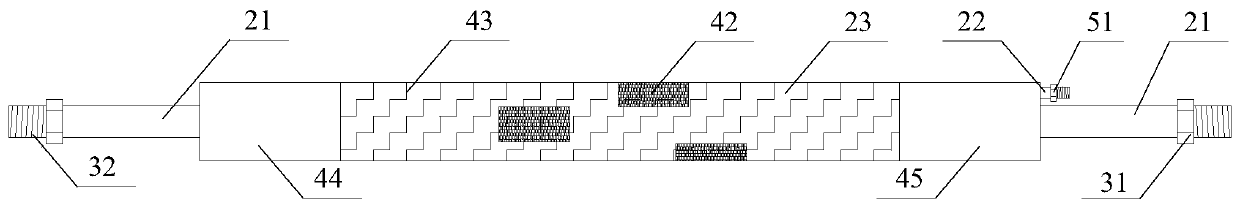

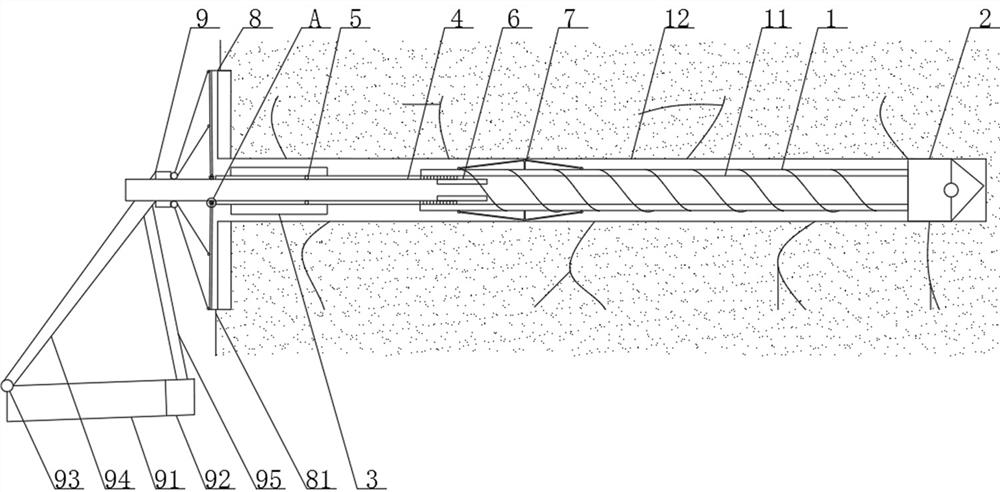

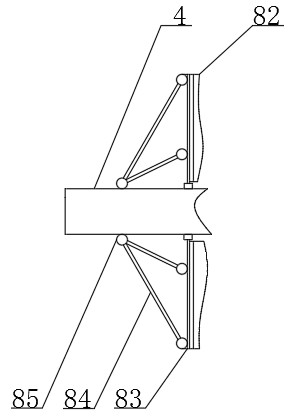

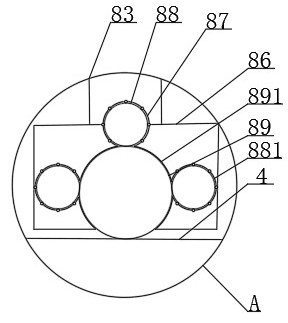

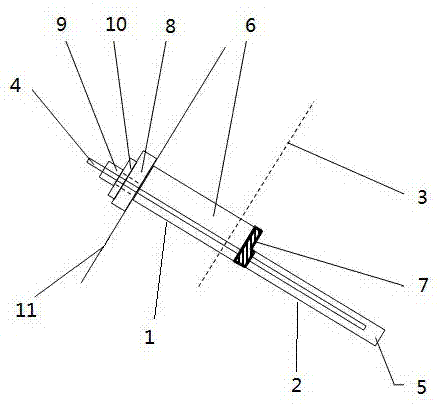

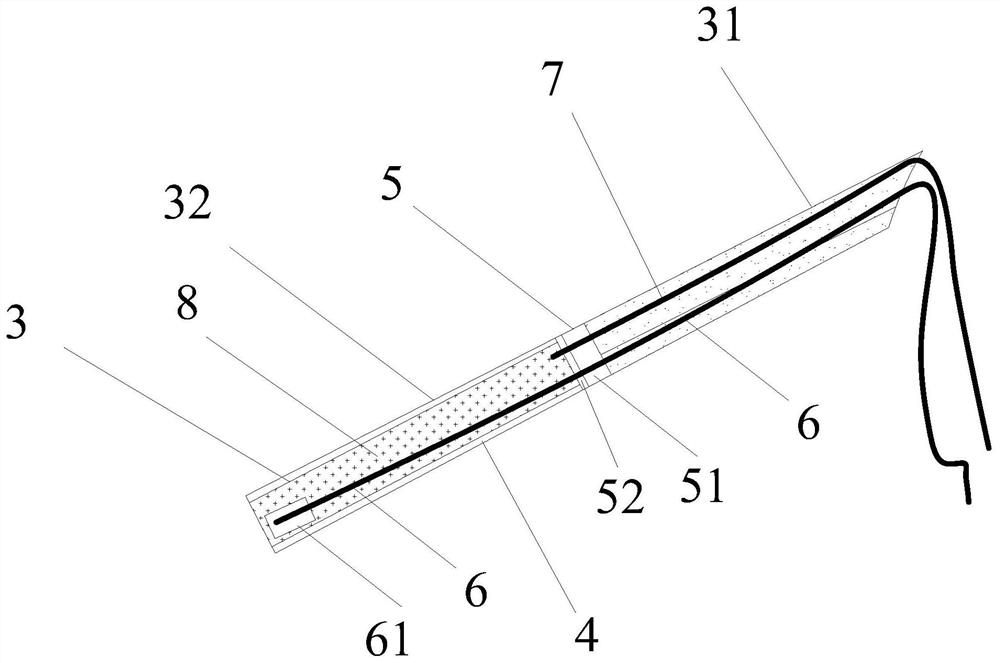

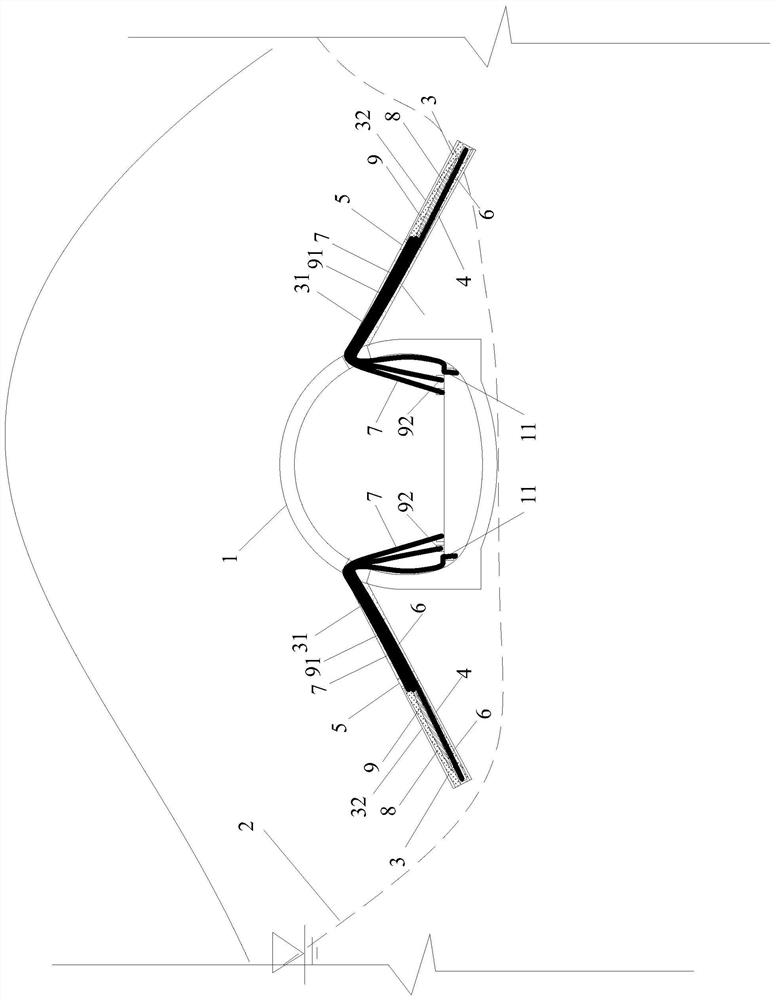

Mold-bag-filling-type anchor grouting device and method

The invention discloses a mold-bag-filling-type anchor grouting device which comprises a hole opening hole sealing steel pipe (1), wall surface patterned holes (2), a constant pressure stopper A (3),a hole opening hole sealing mold bag (4), a grouting steel pipe (5), a constant pressure stopper B (6), reinforcing ribs (7), a hole bottom anchoring steel pipe (8) and a hole bottom anchoring mold bag (9). According to the mold-bag-filling-type anchor grouting device, an anchoring rod is divided into three parts of the hole opening hole sealing steel pipe, the grouting steel pipe and the hole bottom anchoring steel pipe, the mold bags, the reinforcing ribs and the wall surface patterned holes are arranged / formed, and by combining the characteristics that the mold bags are expanded during grouting and grout leakage is not prone to occurring, hole bottom anchoring and hole opening filling closing are achieved; through the wall surface patterned holes, cement grout and solidification grout are effectively grouted into loose wall rock; and thus, the grouting pressure is effectively increased, the broken loose wall rock is quickly filled, grouting liquid is prevented from being subjected to underground water erosion, and finally the firm mold-bag-filling-type anchor rod is formed, so that the engineering quality and the technical level are comprehensively improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Method and device for treating tunnel secondary lining vault cavity and local loose part

PendingCN113279785AFix bugsImprove integrityUnderground chambersTunnel liningStructural engineeringSlurry

The invention belongs to a method and a device for treating a tunnel secondary lining vault cavity and a local loose part, and the device is characterized in that three slurry outlet holes with the diameter of 4mm are drilled in the positions of 90 degrees, 180 degrees and 270 degrees every 20cm on the pipe wall of a longitudinal grouting pipe, and the outer side of each slurry outlet hole is sealed by a PE (Polyethylene) film. Two exhaust holes with the diameter of 4 mm are drilled in the pipe wall of the longitudinal exhaust pipe at the 45-degree position and the 315-degree position every 20 cm, the outer side of each exhaust hole is sealed through a PE film, and the length of the longitudinal grouting pipe and the length of the longitudinal exhaust pipe are larger than that of a tunnel second lining pouring construction section. The longitudinal grouting pipes in the vertical pipes are communicated. According to the method, when the secondary lining concrete is finally set, the secondary lining concrete poured by the secondary lining is subjected to hole filling treatment grouting through the longitudinal grouting pipe, so that the integrity of the secondary lining concrete and grouting treatment slurry is improved, various concrete defects are repaired, a waterproof plate of a vault can be effectively prevented from being perforated and falling off, and the construction quality is guaranteed.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

Multistage pressure-bearing type penetrating sealing method and device

ActiveCN107939333AImprove airtightnessIncrease penetrationSealing/packingHigh concentrationEngineering

The invention relates to a multistage pressure-bearing type penetrating sealing method and device. The method comprises following steps: 1) performing multistage expansion hole sealing at positions tobe sealed of a borehole, wherein the number of expansion hole sealing segments is no less than four and penetrating sealing segments are kept between adjacent expansion sealing segments; 2) performing multistage interval grouting on the penetrating sealing segments, penetrating sealing segments for grouting of a next level are kept between penetrating sealing segments of grouting of an upper level; performing grouting of the next level after the grouting of the upper level is finished; the pressure of the next level grouting is larger than that of the upper level grouting; 3) after the grouting pressure of the penetrating sealing segment of the final level reaches a preset value, the hole sealing is finished. The invention can increase the grouting pressure on the basis of the traditionaltwo-plugging and one-hole sealing method, thereby improving the sealing quality, solving the problem of low gas concentration in the coal mine, and realizing the high concentration and high quality gas drainage in the mine drainage drilling.

Owner:HENAN POLYTECHNIC UNIV

Combined repairing method for rock mass multi-scale fractures based on microbial mineralization

ActiveCN113250184AGood compatibilityImprove repair rateSoil preservationBacilliEnvironmental chemistry

The invention provides a combined repairing method for rock mass multi-scale fractures based on microbial mineralization. The combined repairing method comprises the following steps that a grouting pipe is placed in a surface main fracture of the millimeter level or the centimeter level or above; a mixed slurry A, a mixed slurry B and microorganism mixed liquid are sequentially injected into the deep fractures by using grouting equipment; the mixed slurry A is obtained by uniformly mixing and stirring in-situ rock sand, magnesite powder, a urea solution and a urease solution in parts by weight; the mixed slurry B is obtained by uniformly mixing and stirring in-situ rock sand, limestone powder, a urea solution and a bacillus pasteurii bacterial solution; and the microorganism mixed liquid is obtained by uniformly mixing and stirring limestone, a urea solution and a bacterial solution. The combined repairing method for the rock mass multi-scale fractures based on the microbial mineralization can repair the multi-scale fractures at high pressure, high efficiency and high repairing rate, and has the advantages that repairing materials are convenient to obtain, and compatibility and weather resistance are good.

Owner:NANJING UNIV

Grout injector

PendingCN110055969ADecentralization smoothlyIncrease frictionFoundation engineeringHigh pressureGrout

The invention provides a grout injector. The grout injector comprises a penetrating steel pipe, a gas feeding pipe and an elastic sleeve pipe; a grout injecting connector is arranged at the upper endof the penetrating steel pipe, and a high-pressure nozzle connector used for being connected with a high-pressure nozzle is arranged at the lower end of the penetrating steel pipe; the elastic sleevepipe is arranged on the outer side of the penetrating steel pipe in a sleeving mode, and the lower end of the elastic sleeve pipe is fixed to the penetrating steel pipe; a gas hollow cavity is formedin the middle of the elastic sleeve pipe; anti-sliding patches are arranged on the outer side of the elastic sleeve pipe; and the gas feeding pipe is arranged at the upper end of the elastic sleeve pipe, a gas feeding connector is arranged at the upper end of the gas feeding pipe, and the gas hollow cavity of the elastic sleeve pipe is connected with the lower end of the gas feeding pipe. The grout injector can be applied to improve the grout injecting effect of the grout injector.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

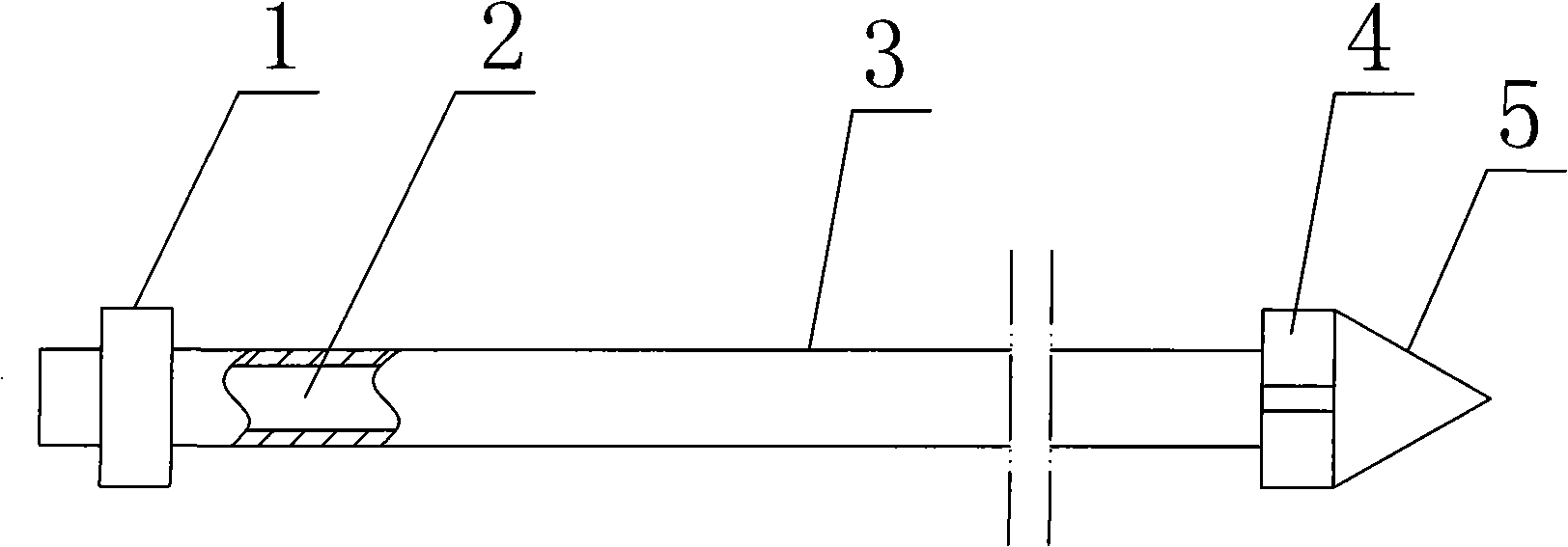

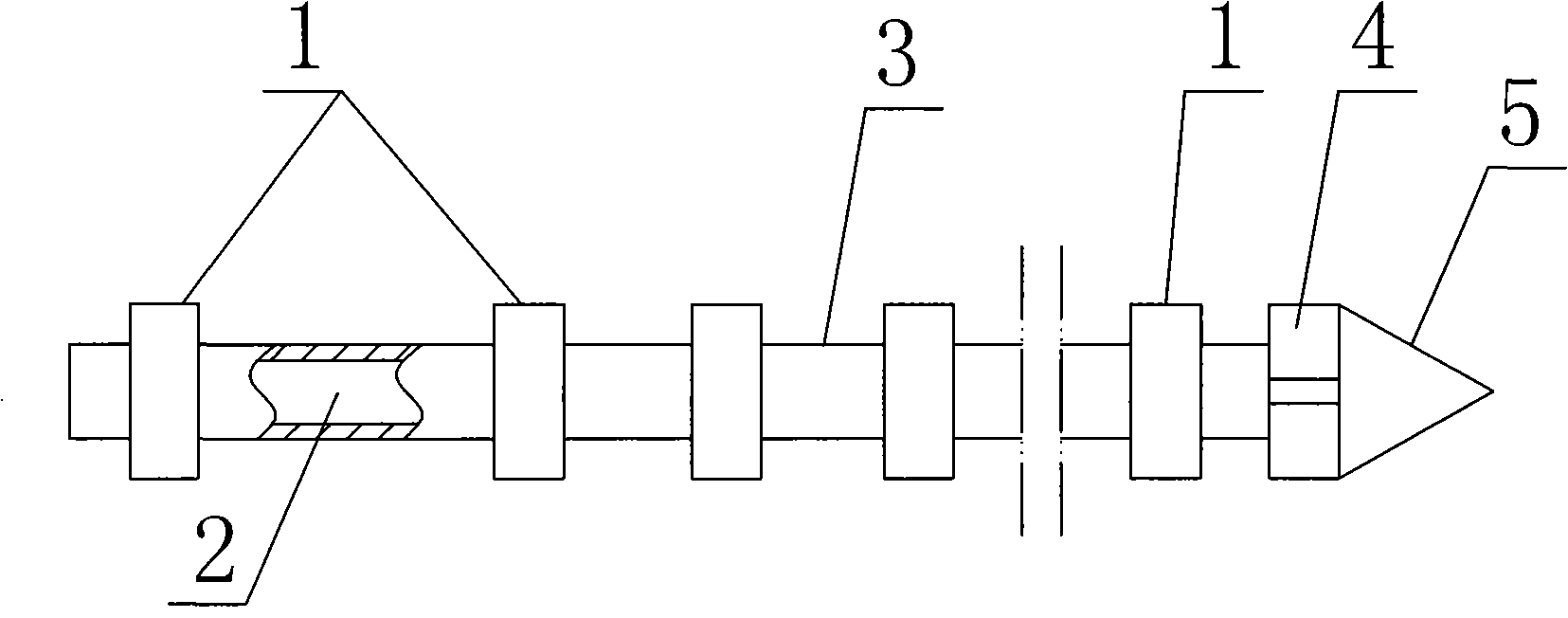

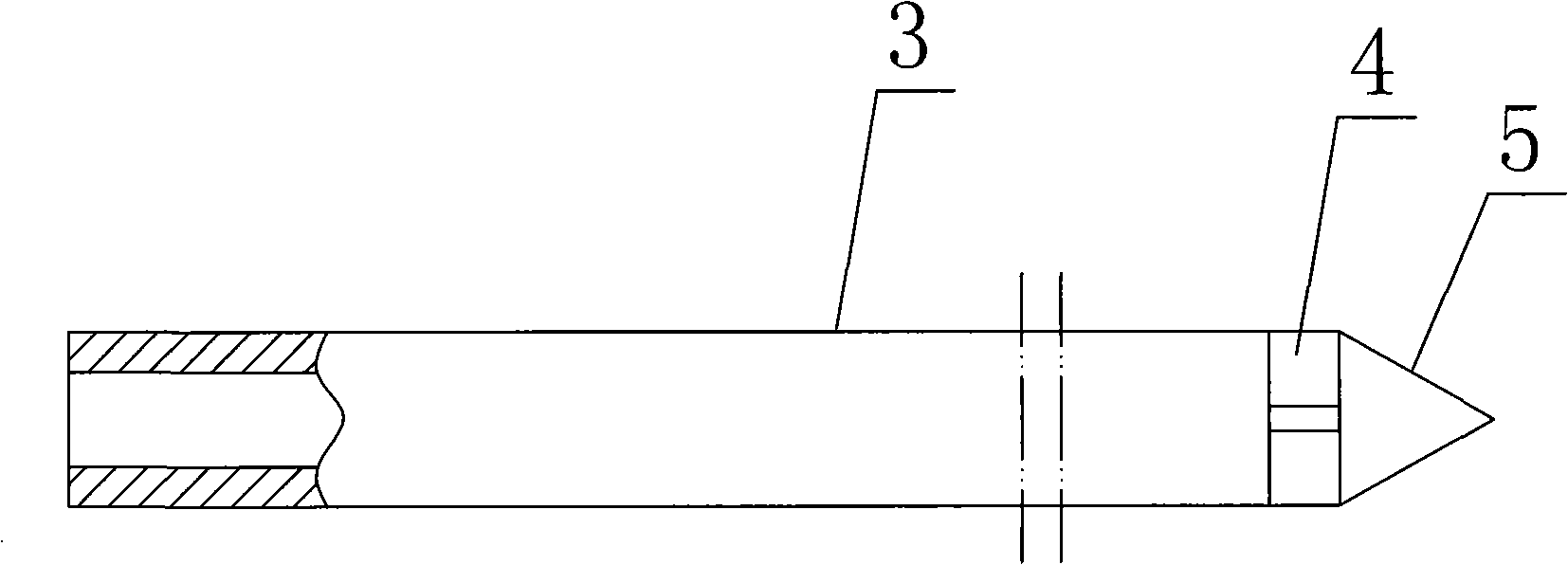

Self-drilling type combined grouting anchor rod with grout-stopping plug and suitable for soft rock stratum

ActiveCN113107561AAvoid difficulty in delegatingIncrease the grouting pressureAnchoring boltsRock boltDrill bit

The invention belongs to the technical field of geotechnical engineering anchoring, and particularly relates to a self-drilling type combined grouting anchor rod with a grout-stopping plug and suitable for a soft rock stratum. The self-drilling type combined grouting anchor rod comprises a grouting anchor rod body, a drill bit mounted at the top end of the grouting anchor rod body and an expansion rubber grout-stopping pipe mounted at the tail part of the grouting anchor rod body; a grouting cavity is formed in the grouting anchor rod body; a grouting pipe is connected to the interior of the grouting cavity; an outer side grout-stopping mechanism is installed at the end, away from the drill bit, of the grouting anchor rod body; and a supporting mechanism is installed on one side of the outer side grout-stopping mechanism. The grouting anchor rod body is matched with the drill bit to drill the anchor rod into the rock stratum, and the expansion rubber grout-stopping pipe and the grouting cavity are matched, so that the grouting anchor rod body does not need to be pulled out, hole sealing grouting is directly conducted, the situation that the grouting pipe is difficult to descend due to the fact that the interior of a drilled hole collapses again after drilling is avoided; and through cooperation of the outer side grout-stopping mechanism and the supporting mechanism, when the crushing degree of surrounding rock where the drilled hole is located is relatively high and cracks are relatively more, the drilled hole is well sealed, relatively high grouting pressure is guaranteed, and the anchoring effect is guaranteed.

Owner:CHINA UNIV OF MINING & TECH +1

A tunnel disease control method that can repeat grouting and is applicable to special grout

ActiveCN112901212BEasy groutingAvoid working at heightsUnderground chambersTunnel liningDiseaseWater leakage

The invention discloses a tunnel disease treatment method that can be repeatedly grouted and is applicable to special grout. The treatment method is as follows: Step 1. In the section where the water leakage disease is prone to occur in the tunnel and before and after, the initial support and waterproof layer of the tunnel In between, multiple groups of repeatable grouting component groups are arranged at intervals along the longitudinal direction of the tunnel. Step 2. Connect the two adjacent connecting pipes of the two adjacent overflow tanks near the tunnel ground to a horizontal pipe, penetrate the waterproof layer and the second lining lining horizontally, and extend into the tunnel. The upper connecting pipe serves as The discharge end, the lower connecting pipe is used as the grouting end, which is used to connect with the grouting machine; step 3, close the discharge end, start the grouting machine, the grout is injected from the grouting end, and the grout is delivered through the ring Channel conveying, filling each overflow tank in turn. The method realizes repeated grouting at low cost and high efficiency, and overcomes the problems of poor durability of the slurry material and repeated treatment of diseases.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

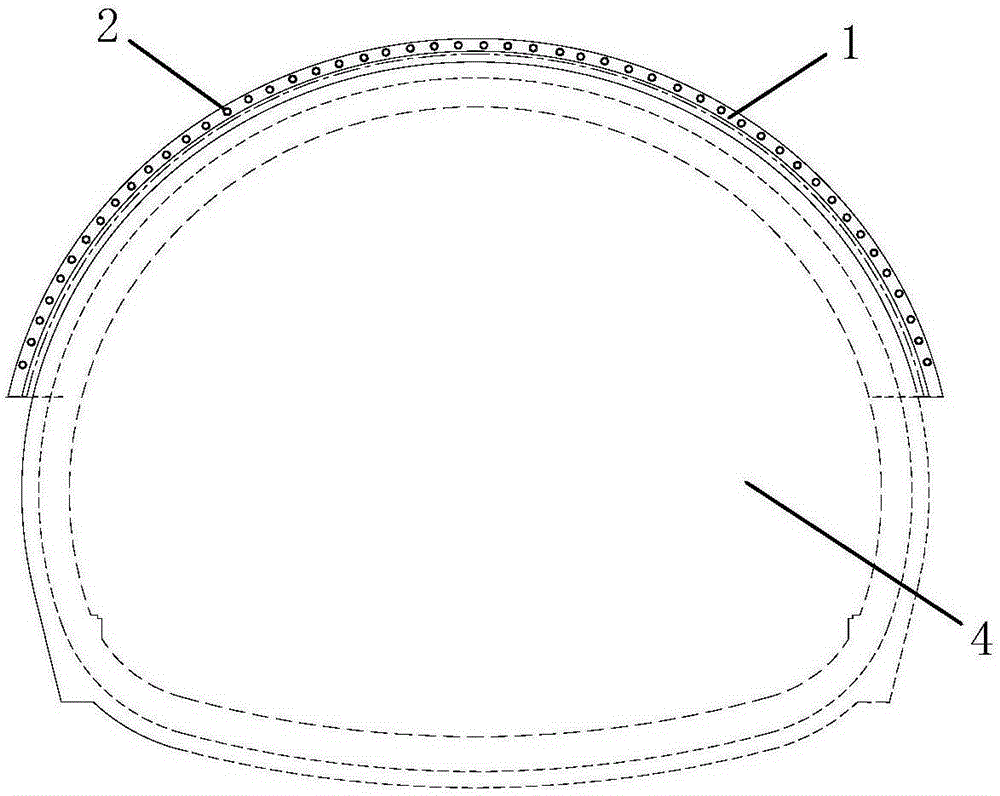

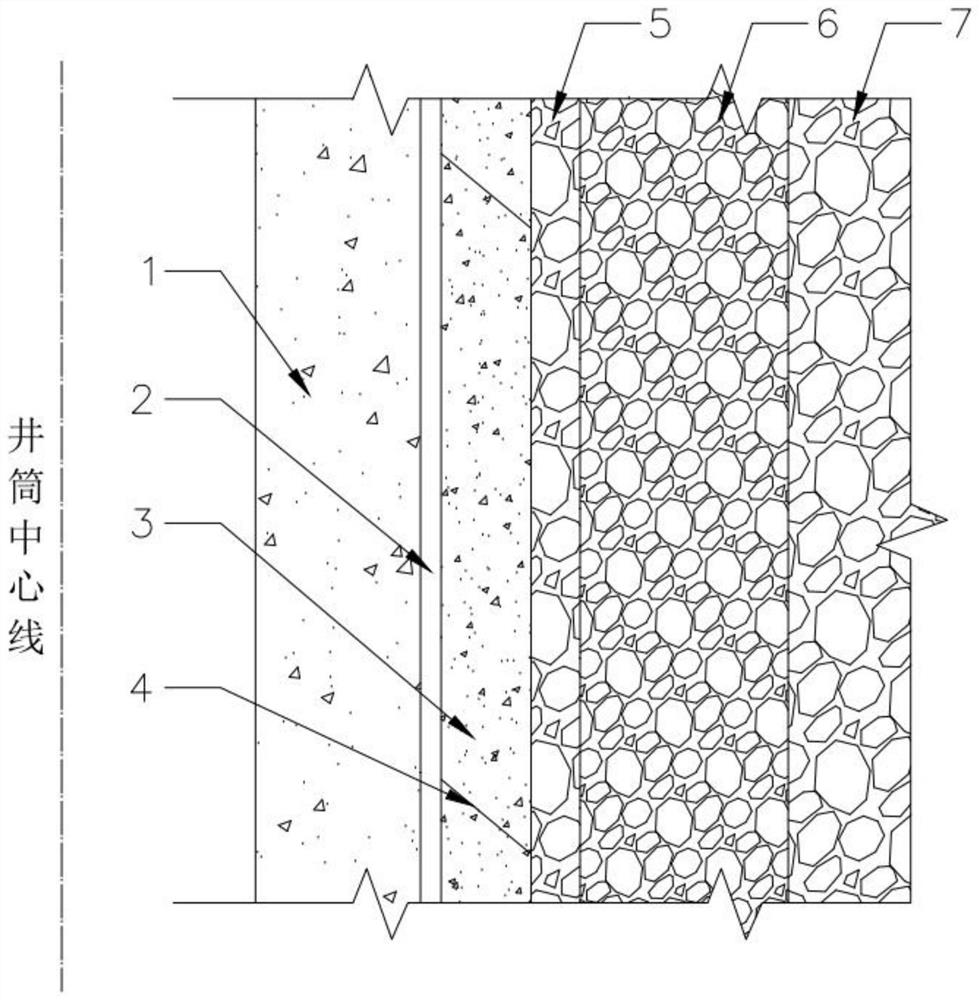

Combined bearing double-layer well wall and construction method thereof

The invention discloses a combined bearing double-layer well wall and a construction method thereof, and belongs to the technical field of double-layer well wall construction. The combined bearing double-layer well wall comprises an inner-layer well wall and an outer-layer well wall, the outer-layer well wall is formed by tunneling and pouring in sections, and construction joints exist between the sections of the outer-layer well wall; the inner-layer well wall is formed by continuous casting; and a gap is formed between the inner-layer well wall and the outer-layer well wall, and a micro-expansion grouting material is injected into the gap to form a micro-expansion interlayer. The micro-expansion grouting material is adopted for grouting between the inner-layer well wall and the outer-layer well wall, and the solidified slurry can tightly bond the inner-layer well wall and the outer-layer well wall and compactly fill water seepage channels in the outer-layer well wall and the stratum close to the well wall.

Owner:CHINA UNIV OF MINING & TECH

Constructional engineering complex foundation grouting equipment

InactiveCN113152428AIncrease the grouting pressureImprove grouting efficiencySoil preservationPulsed modeStructural engineering

The invention discloses constructional engineering complex foundation grouting equipment, and relates to the technical field of foundation grouting. The constructional engineering complex foundation grouting equipment comprises a base, a grouting pipe, a double-liquid double-pressure grouting assembly and a slurry supply assembly, and the grouting pipe penetrates through the base and extends into the stratum; the double-liquid double-pressure grouting assembly is provided with a first grouting pipe, a second grouting pipe and a liquid outlet end, grout components in the first grouting pipe and the second grouting pipe are different, and the liquid outlet end communicates with the grouting pipes; and the slurry supply assembly can supply slurry to the double-liquid double-pressure slurry supply assembly, and a pulse slurry supply assembly is arranged between the second grouting pipe and the slurry supply assembly so that the grouting pressure can be increased in a pulse mode. In the grouting process, grouting is carried out through the first grouting pipe at the first grouting pressure; and then, the second grouting pipe is used for grouting at the second grouting pressure, so that the grouting effect is improved.

Owner:GUANGZHOU CITY CONSTR COLLEGE

Shear-stress-reduction anchoring structure and construction method thereof

ActiveCN107401162AEasy to transformAvoid breakingExcavationsBulkheads/pilesShear stressStructural engineering

The invention discloses a shear-stress-reduction anchoring structure. The shear-stress-reduction anchoring structure comprises a free section drill hole. The inner bottom surface of the free section drill hole is provided with an anchoring section drill hole. The free section drill hole extends inwards to the inner side of a potential slip plane of a slope. An anchor bar is arranged in the free section drill hole and the anchoring section drill hole. The outer end of the anchor bar extends out of the free section drill hole. The anchoring section drill hole is filled with mortar wrapped outside the anchor bar. The free section drill hole is filled with a low-compression-modulus grouting material wrapped outside the anchor bar. An anchorage device which is arranged on the anchor bar in a sleeving mode and used for tensioning and fixing the anchor bar is arranged at an orifice on the outer side of the free section drill hole. The invention further discloses a construction method of the shear-stress-reduction anchoring structure. According to the shear-stress-reduction anchoring structure and the construction method thereof, the technical purpose of stabilizing the slope is achieved by means of the shearing strength between layers of rock stratums.

Owner:CHONGQING JIAOTONG UNIVERSITY

Shear anchor structure and its construction method

ActiveCN107401162BEasy to transformAvoid breakingExcavationsBulkheads/pilesStructural engineeringUltimate tensile strength

The invention discloses a shear-stress-reduction anchoring structure. The shear-stress-reduction anchoring structure comprises a free section drill hole. The inner bottom surface of the free section drill hole is provided with an anchoring section drill hole. The free section drill hole extends inwards to the inner side of a potential slip plane of a slope. An anchor bar is arranged in the free section drill hole and the anchoring section drill hole. The outer end of the anchor bar extends out of the free section drill hole. The anchoring section drill hole is filled with mortar wrapped outside the anchor bar. The free section drill hole is filled with a low-compression-modulus grouting material wrapped outside the anchor bar. An anchorage device which is arranged on the anchor bar in a sleeving mode and used for tensioning and fixing the anchor bar is arranged at an orifice on the outer side of the free section drill hole. The invention further discloses a construction method of the shear-stress-reduction anchoring structure. According to the shear-stress-reduction anchoring structure and the construction method thereof, the technical purpose of stabilizing the slope is achieved by means of the shearing strength between layers of rock stratums.

Owner:四川钦耀炜岳建设工程有限公司

Acid-soluble borehole drainage structure and construction method for karst or faulted tunnels and slopes

ActiveCN113323723BPrevent grout from enteringImprove fill rateUnderground chambersDrainageKarstStructural engineering

The invention relates to the field of civil engineering, and discloses a drainage structure and a construction method for karst or fault tunnels and side slopes. The acid-soluble borehole drainage structure of the present application includes a hollow section and a grouting section. A water-stop member is arranged between the grouting section, and a water-permeable pipe is provided in the permeable section, and a cavity is provided in the water-permeable pipe, and a drain pipe extending outward through the water-stop member is arranged in the water-permeable pipe. The water-permeable pipe is filled with acid-soluble and water-insoluble solid filling materials, and the lower part of the water-stop component, the water-permeable pipe and the drain pipe are all acid-resistant materials or have acid-resistant surface layers. Through the drainage structure and the construction method, the controllability of construction of the drainage structure can be improved while ensuring the grouting pressure.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com