Gas extraction hole drilling and hole sealing method for building anti-seepage barrier based on grooving-backfilling method

A technology of gas drainage and grooving, which is applied in the fields of gas drainage drilling and sealing and bedding drilling, which can solve problems such as insufficient construction volume, limited penetration distance of grouting pressure, and increased engineering difficulty. Achieve the effects of reducing the amount of sealing work, wide applicability, and saving grouting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

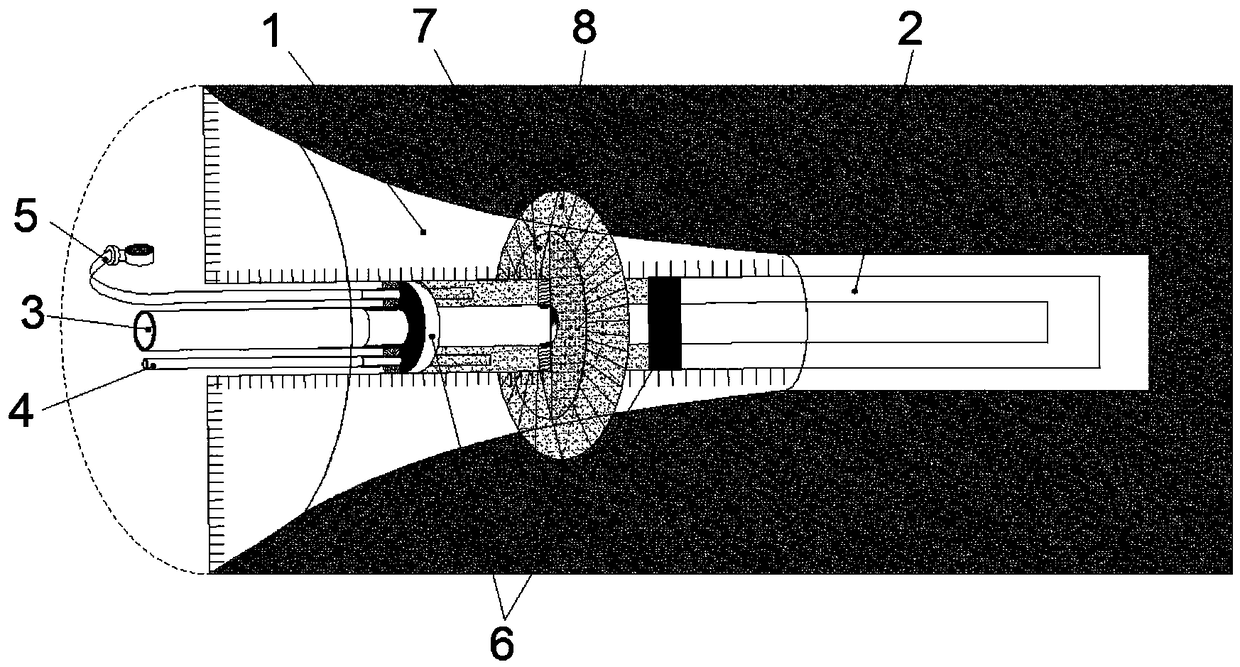

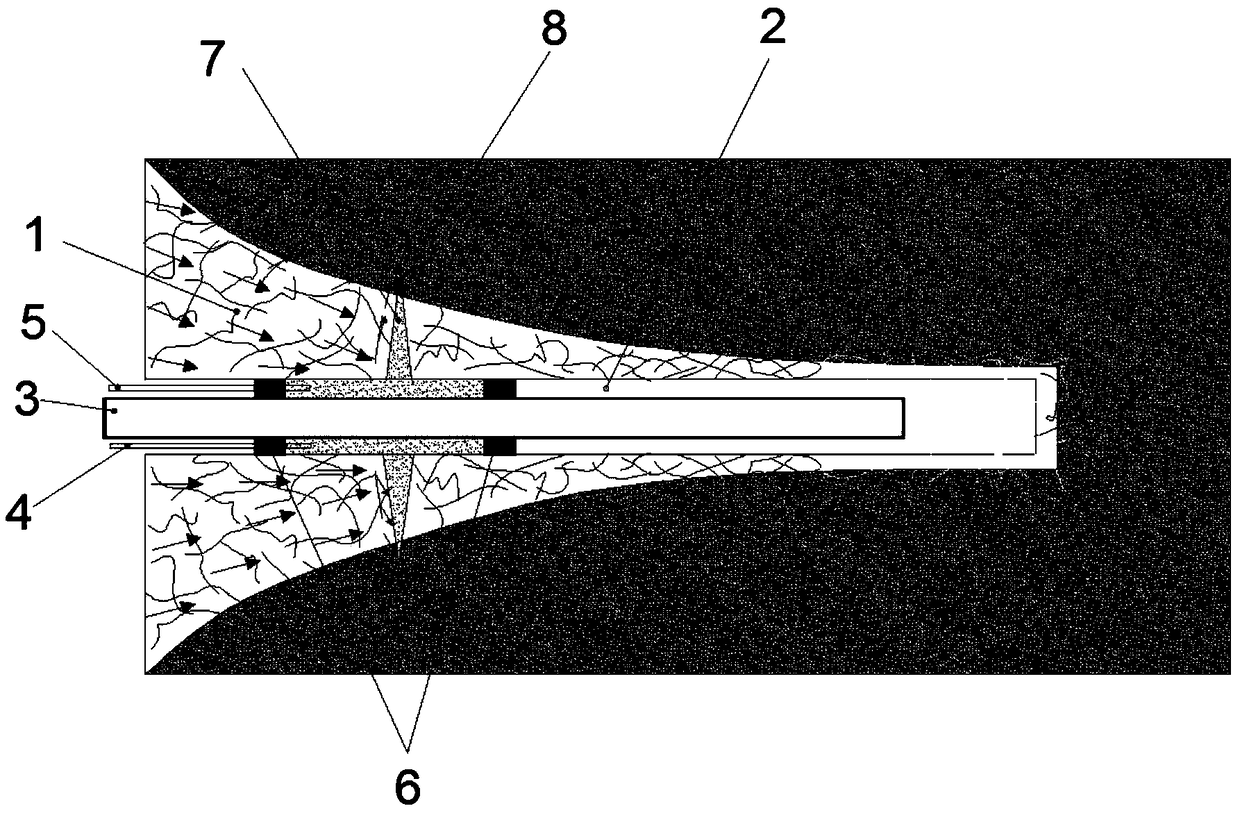

[0017] A kind of grooving-backfilling method of embodiment 1 builds the gas drainage drilling sealing method of anti-seepage barrier, concrete steps are as follows (coal quality is harder):

[0018] (a) First drill the borehole 2 for gas drainage to the designed final hole position;

[0019] (b) Replace the hydraulic slit drill bit, and perform hydraulic grooving at a depth of 6m from the orifice, and flush out the coal body in the strong air leakage area 1 of the coal body caused by roadway stress around the drill hole 2, forming a wedge-shaped disc Space 8, the disc radius is 0.5m;

[0020] (c) Send the installed gas drainage pipe 3 with two plugging capsules into the borehole 2, the distance between the two plugging capsules is 5m, and make the wedge-shaped circle cut out in step (b) The disc space 8 is between two sealed capsules;

[0021] (d) The sealing grouting pipe 4 is connected to the grouting pump, and the expansion cement slurry is injected between the sealing ca...

Embodiment 2

[0025] A kind of hydraulic cutting groove of embodiment 2 builds the gas drainage drilling hole sealing method of anti-seepage barrier, concrete steps are as follows (coal quality is softer):

[0026] (a) First drill the borehole 2 for gas drainage to the designed final hole position;

[0027] (b) Replace the hydraulic slit drill bit, and perform hydraulic grooving at a depth of 8m from the orifice, and flush out the coal body in the strong air leakage area 1 of the coal body caused by roadway stress around the drill hole 2, forming a wedge-shaped disc Space 8, disk radius 0.9m;

[0028] (c) Send the installed gas drainage pipe 3 with two plugging capsules into the borehole 2, the distance between the two plugging capsules is 6m, and make the wedge-shaped circle cut out in step (b) The disc space 8 is between two sealed capsules;

[0029] (d) The plugging grouting pipe 4 is connected to the grouting pump, and the polyurethane grout is injected between the plugging capsule 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com