Riboflavin-containing solid preparation and preparation method thereof

A technology of solid preparations and riboflavin, which is applied in the direction of medical preparations containing active ingredients, organic chemical methods, and pharmaceutical formulas, can solve the problems of increased difficulty in sewage treatment, increased sewage treatment volume, and many operating steps, and achieves an improvement The effect of product value, reduction of treatment difficulty and sewage volume, and high extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

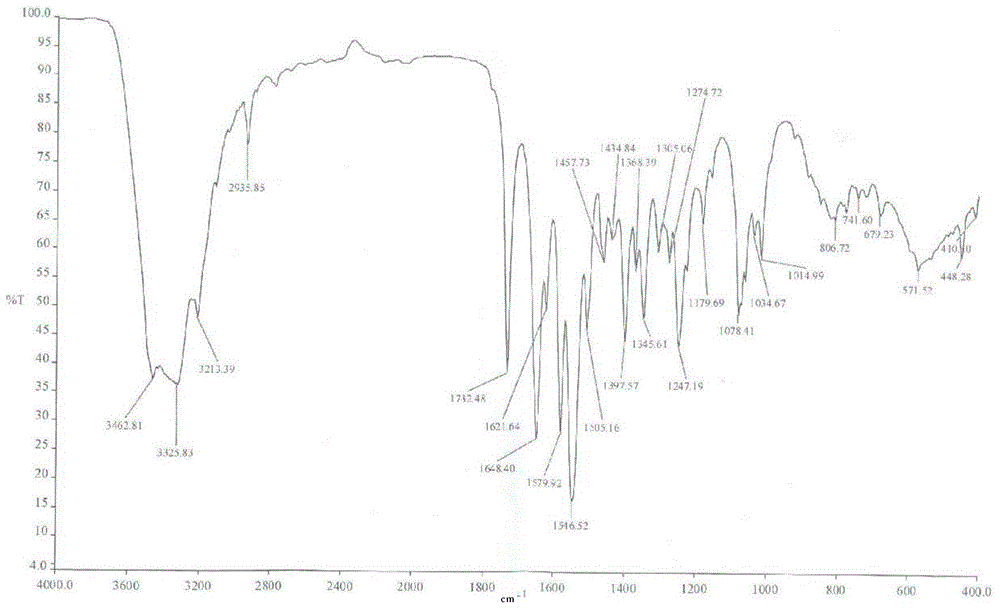

Image

Examples

Embodiment 1

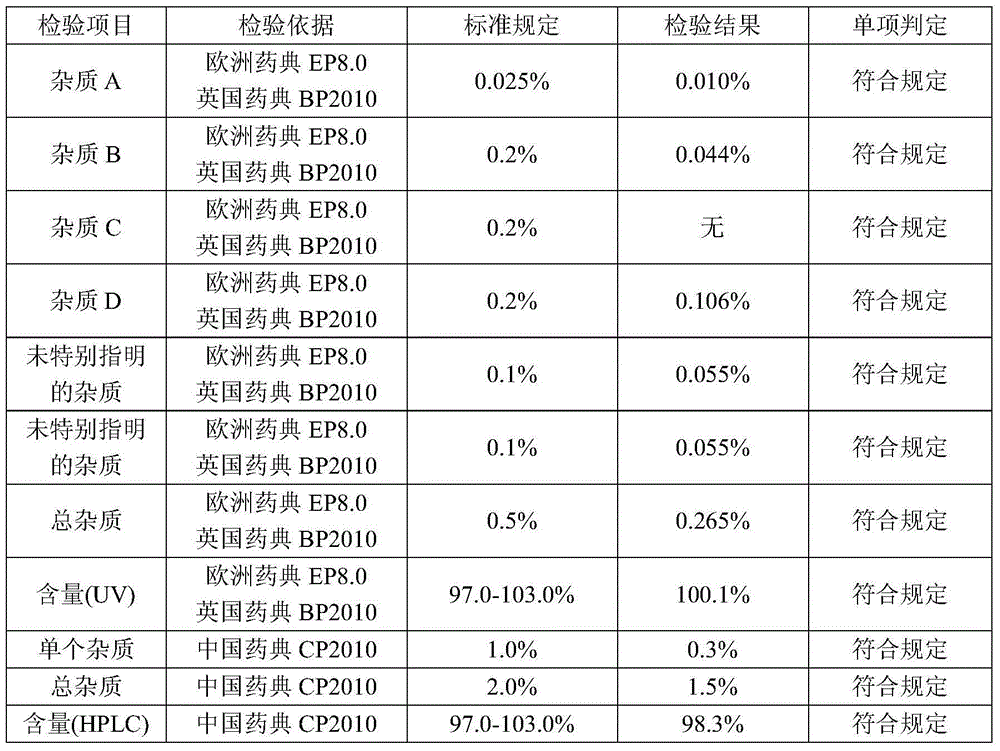

[0036] Embodiment 1: the preparation of riboflavin crystal of the present invention

[0037] (1), preparation method

[0038] The 3000L riboflavin fermented liquid is subjected to a centrifugation solid-liquid separation, and the centrifugal RCF (relative centrifugal force) of the centrifuge is about 3000xg to obtain a concentrated 30-40L riboflavin heavy phase. Use a screw pump to pump this riboflavin heavy phase into a plate and frame filter for filtration, and wash the riboflavin filter cake with 2000L deionized water to obtain 100kg of wet riboflavin crude product with 65.5% moisture content and 77% riboflavin purity . Add 120L of 36% hydrochloric acid solution in a 3t reaction tank, and add 100kg of wet riboflavin crude product to the hydrochloric acid solution and heat it to 70°C. After the riboflavin is completely dissolved, take a sample solution from the reaction tank to confirm the riboflavin To dissolve the riboflavin, add 5kg of activated carbon to the solution a...

Embodiment 2

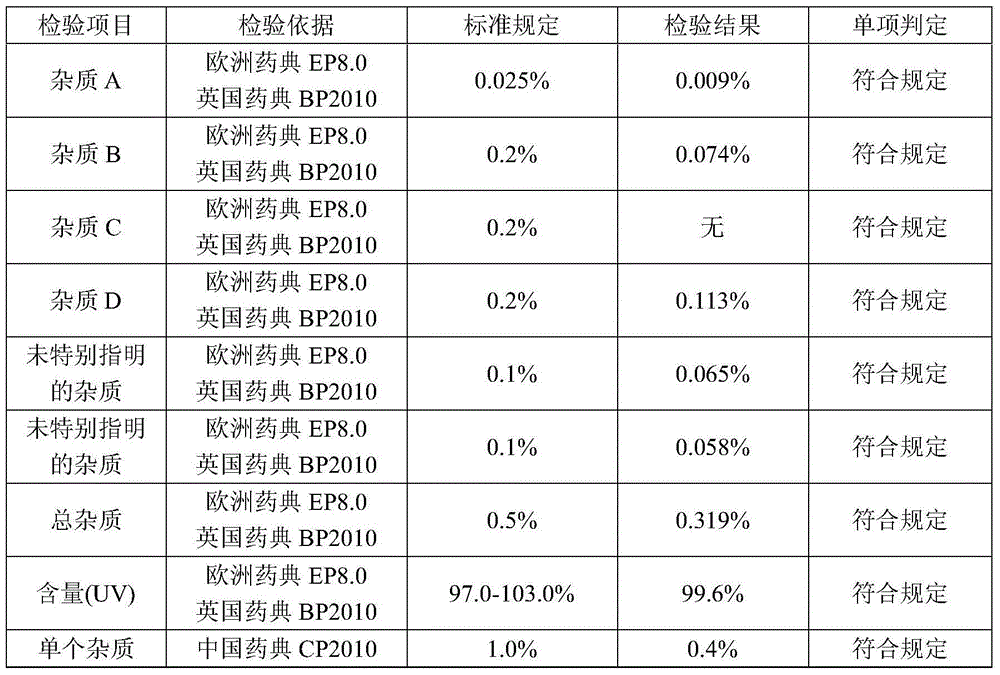

[0044] Embodiment 2: the preparation of riboflavin crystal of the present invention

[0045] (1), preparation method

[0046] 5000L riboflavin fermented liquid is subjected to a centrifuge solid-liquid separation, and the centrifugal RCF (relative centrifugal force) of the centrifuge is about 3200xg to obtain concentrated 50-60L riboflavin heavy phase. Use a screw pump to pump this riboflavin heavy phase into a plate and frame filter for filtration, and wash the riboflavin filter cake with about 2000L of deionized water to obtain about 150kg of wet riboflavin with a moisture content of 63.9% and a purity of 79% riboflavin Vegetarian crude products. Add about 180L of 35.0% hydrochloric acid into the 3t reaction tank, and add 150kg of wet riboflavin crude product to the hydrochloric acid solution and heat it to 65°C. After the riboflavin is completely dissolved, take a sample solution from the reaction tank to confirm the riboflavin To dissolve the riboflavin, add 10kg of acti...

Embodiment 3

[0053] Embodiment 3: the capsule containing riboflavin of the present invention

[0054] Bulk drug: 48% by weight of riboflavin obtained in Example 1, 44.5% by weight of microcrystalline cellulose, 1.5% by weight of croscarmellose sodium, 2.0% by weight of 40% ethanol aqueous solution, 1.0% by weight of micropowder silica gel and argentine Spartame 3.0%.

[0055] Preparation method: pass microcrystalline cellulose, croscarmellose sodium and aspartame through an 80-mesh sieve, add riboflavin and mix evenly, add 40% ethanol aqueous solution to the evenly mixed powder, knead the soft material, Pass through a 20-mesh sieve to granulate, dry, pass through a 40-mesh sieve for granulation, add micropowder silica gel and fill it into capsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com