Patents

Literature

107results about How to "Accurate feeding amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

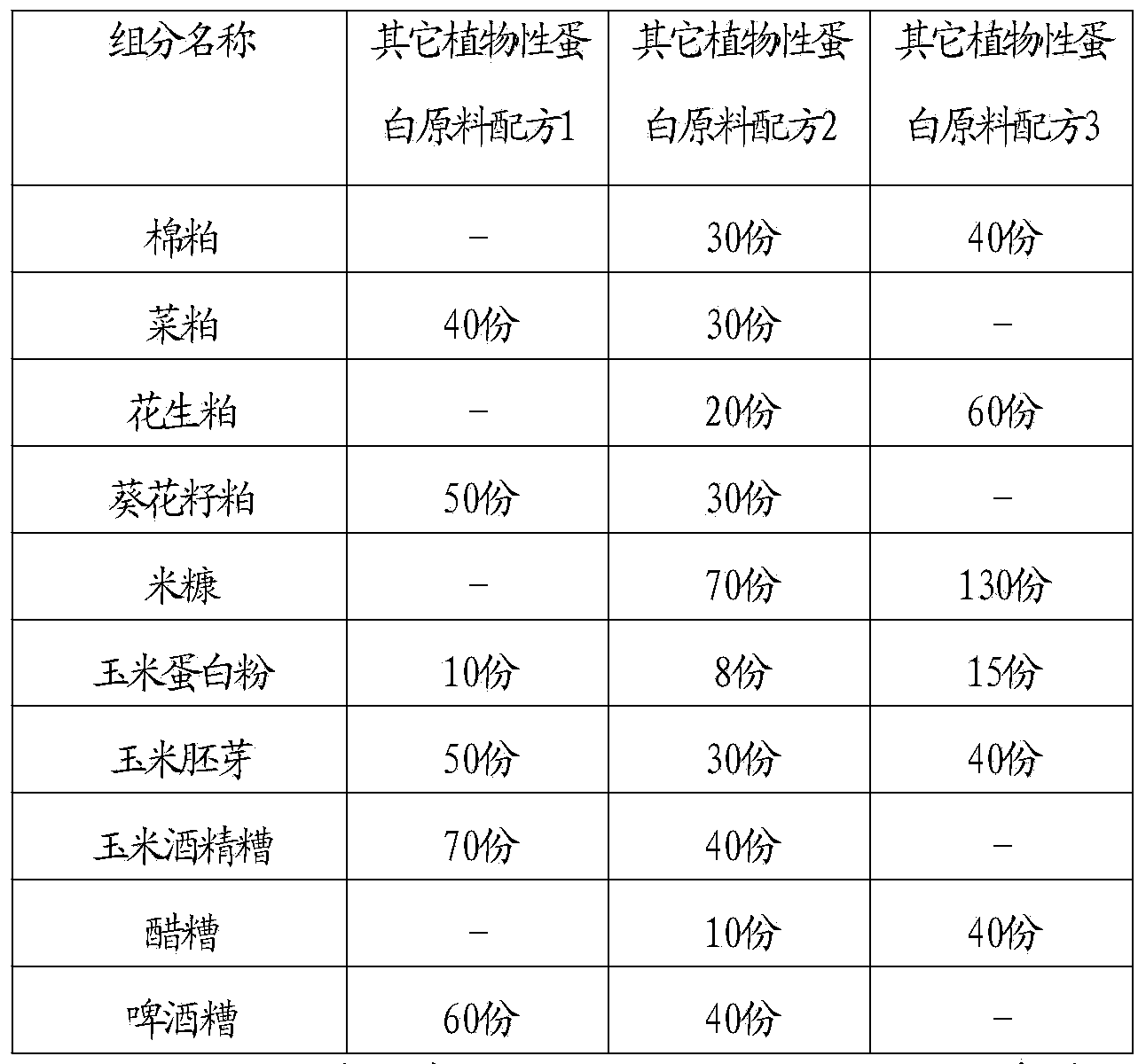

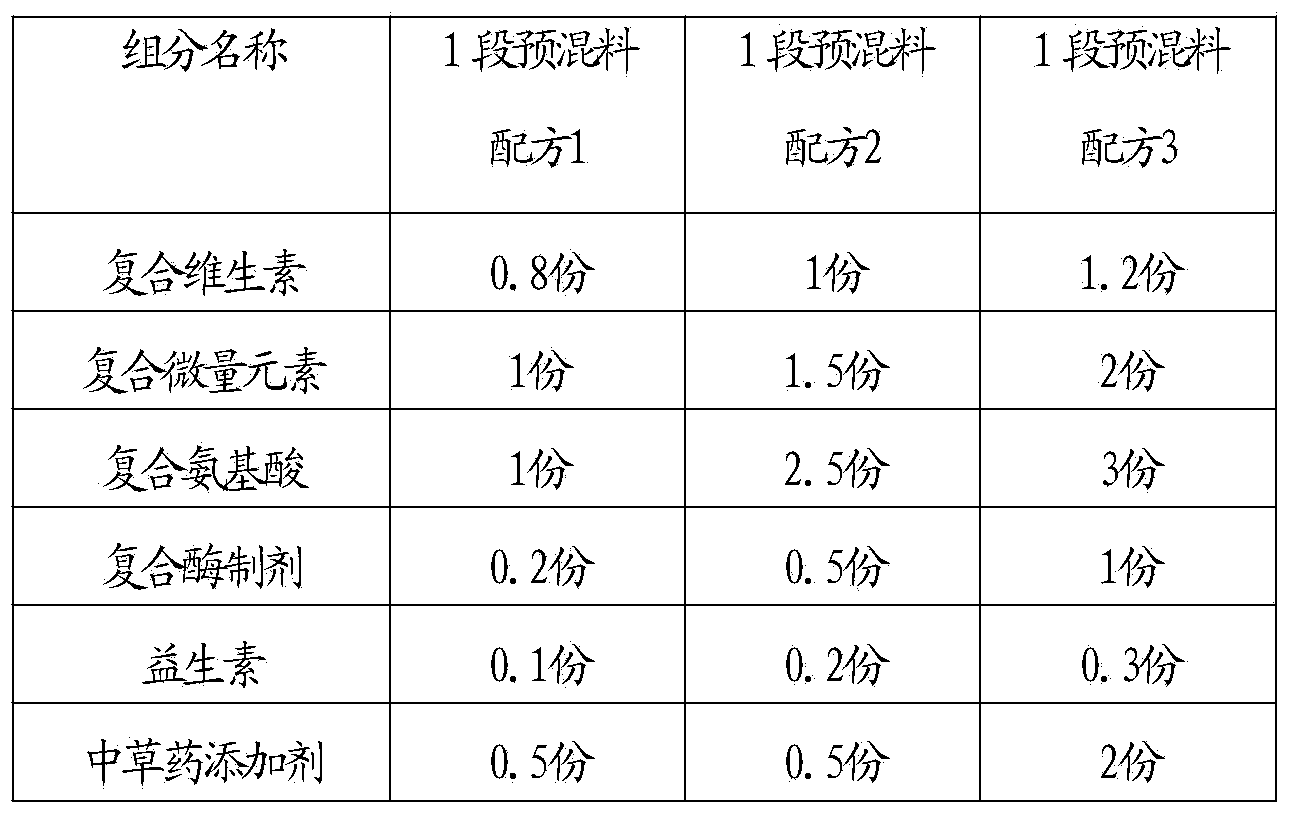

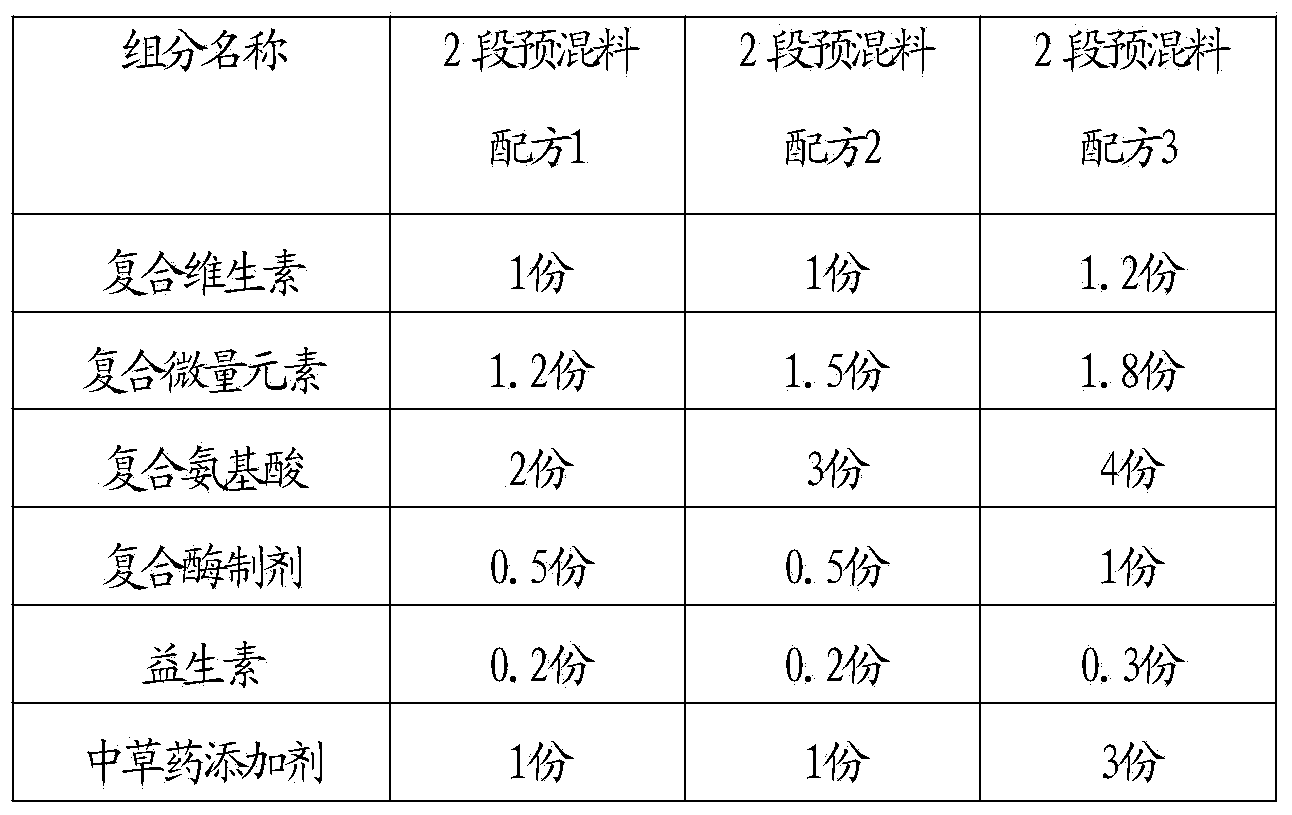

Feeds for laying hens in egg producing periods and using method of feeds

ActiveCN104256189AGuaranteed effective nutritionAccurate feeding amountFood processingAnimal feeding stuffAnimal scienceWhole egg

The invention discloses feeds for laying hens in egg producing periods, and belongs to the technical field of feeds and cultivation. According to the feeds for the laying hens in the egg producing period, corresponding scientific and reasonable nutrients are fed according to physical characteristics of the laying hens in different egg producing periods, and accurate feeding dosage is ensured, so that the requirements of the laying hens in different egg producing stages on accurate nutrition are met, the number of the laying hens rapidly peaks, and high peak duration, high egg quality, high immunity of the laying hens and great spent chicken weight are ensured; meanwhile, with the adoption of staging, the shortcoming that only one kind of feeds is used for the laying hens in the whole egg producing period at present is overcome, and the cultivation efficiency of the laying hens and the egg producing quality are effectively improved.

Owner:四川圣迪乐村生态食品股份有限公司

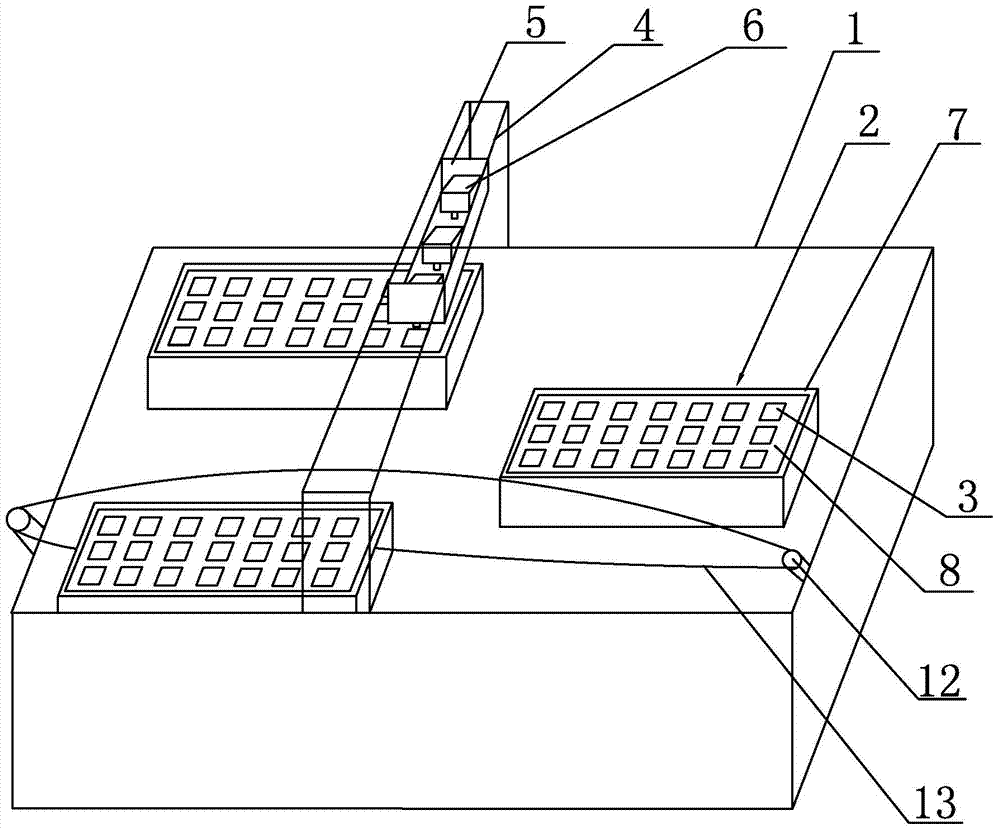

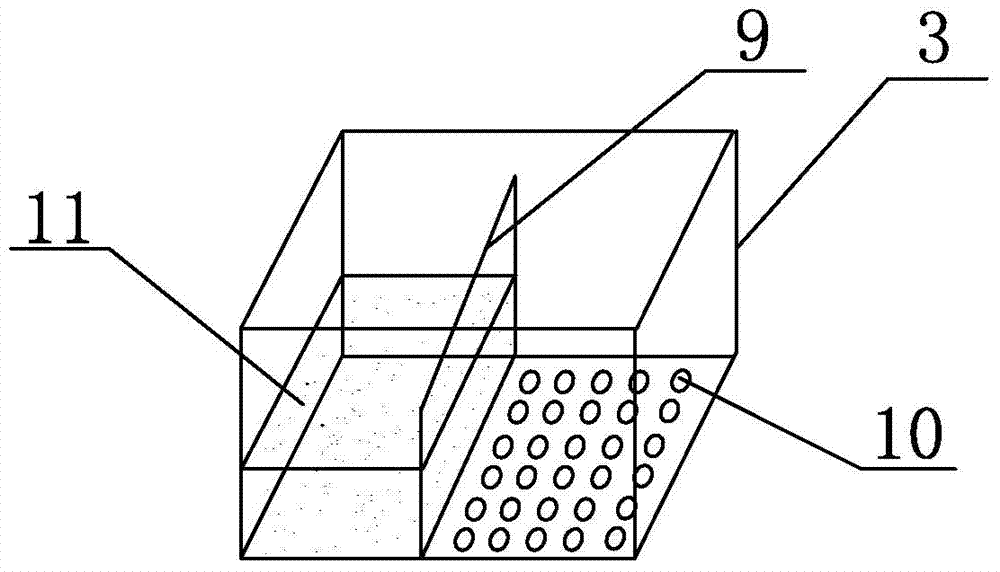

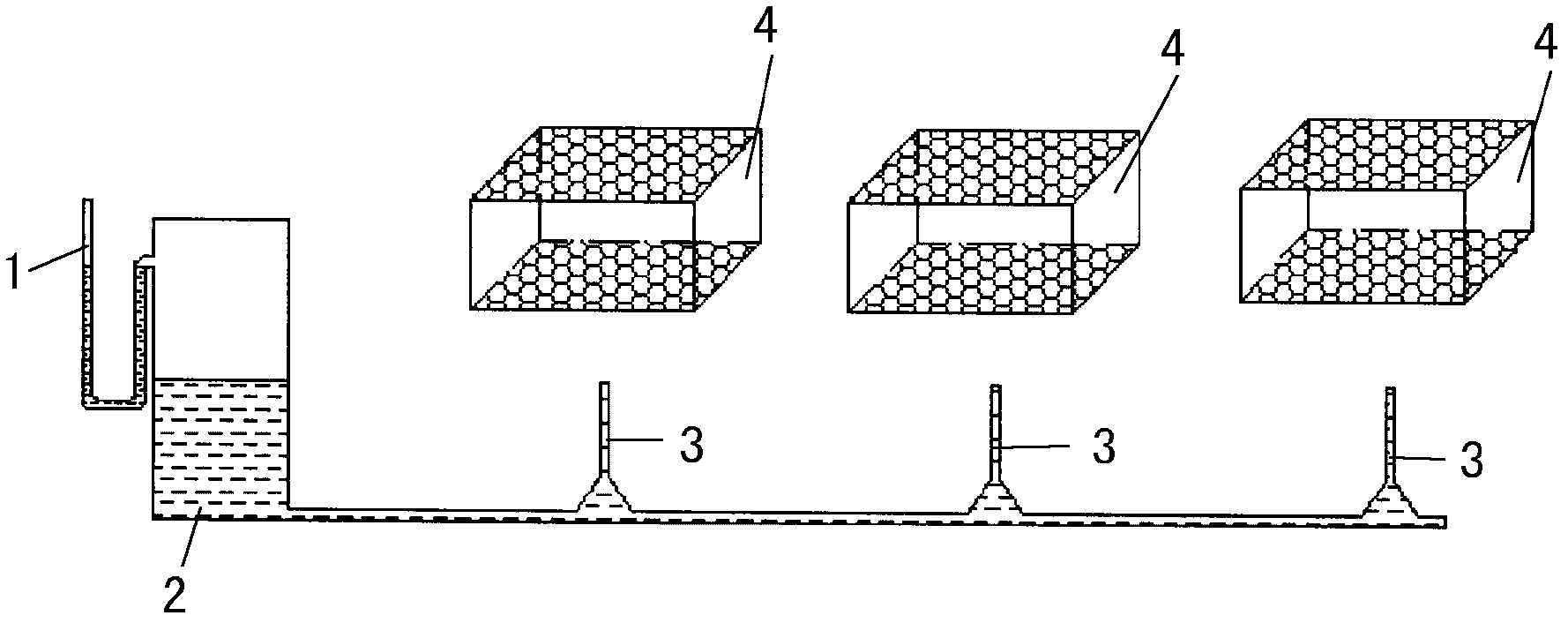

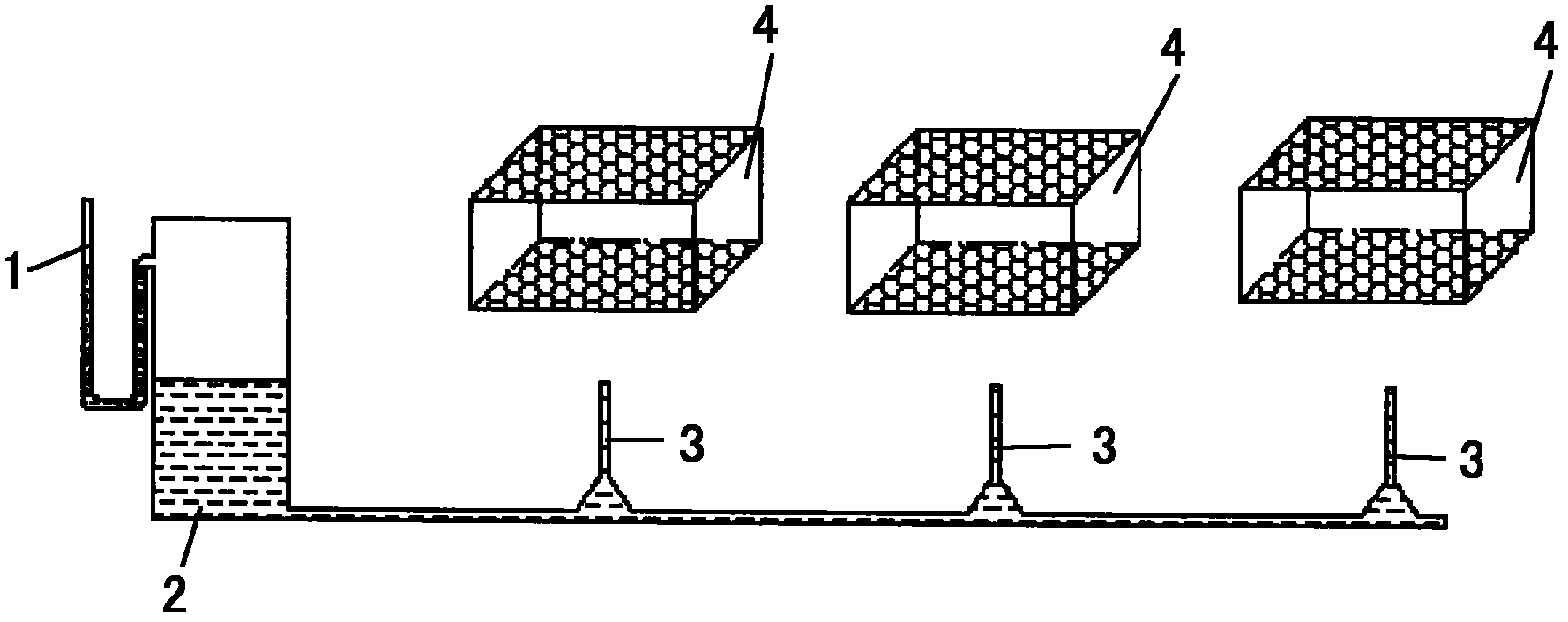

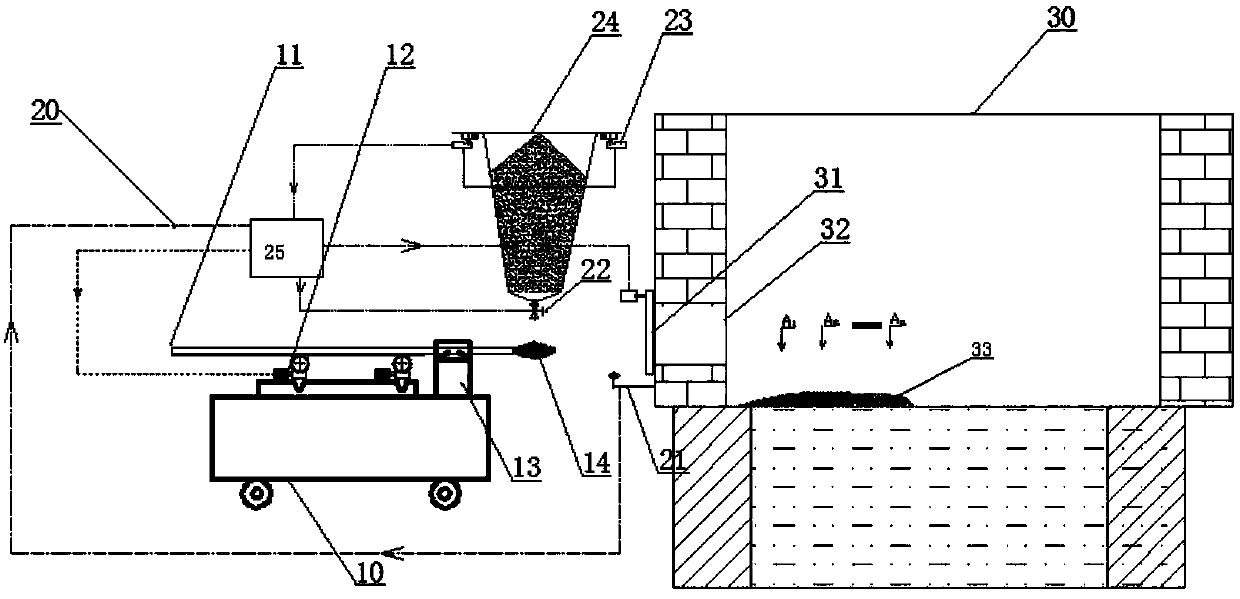

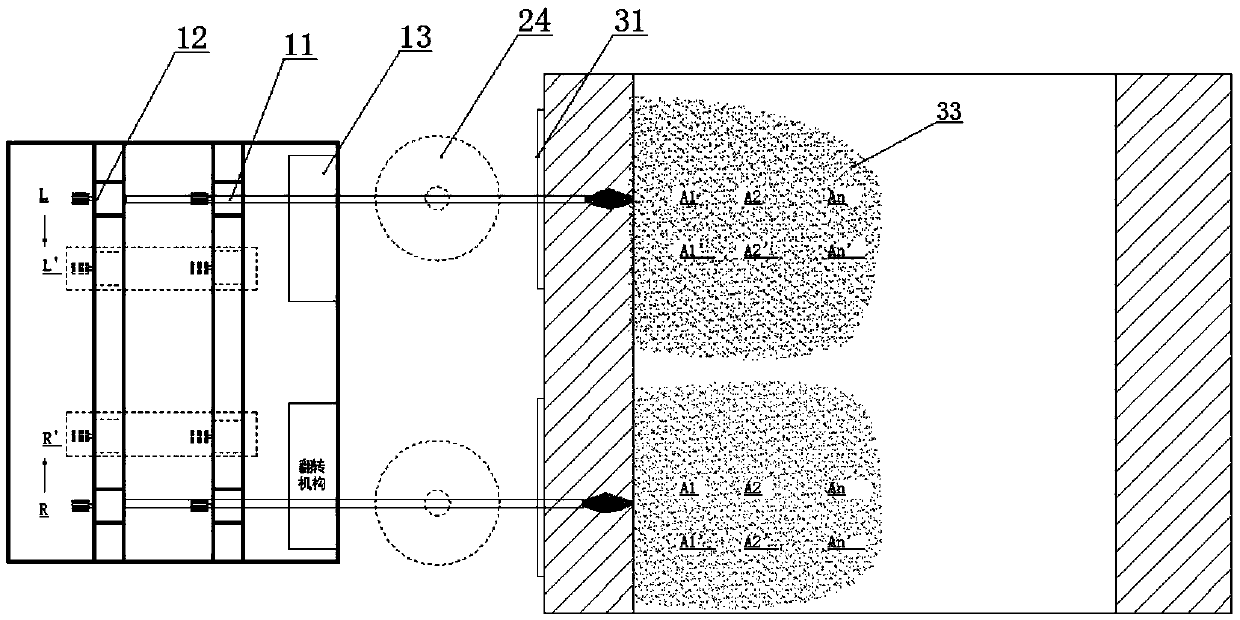

Fodder feeding system for culturing aquatic organisms in baskets on water surface

The invention discloses a fodder feeding system for culturing aquatic organisms in baskets on a water surface. The fodder feeding system comprises a rectangular aquaculture pond, and is characterized in that a plurality of rectangular aquaculture unit blocks capable of floating in water are arranged in the aquaculture pond, a plurality of aquaculture baskets are longitudinally and transversely uniformly arranged in each aquaculture unit block, overhead rails which are higher than the water surface are arranged in the middle of the aquaculture pond along the width direction of the aquaculture pond, a rectangular support capable of moving along the overhead rails back and forth is arranged on the overhead rails, a plurality of feeding machines are arranged in the rectangular support, the quantity of the feeding machines is identical to the quantity of rows of the aquaculture baskets in each aquaculture unit block, and shifting mechanisms for shifting the integral aquaculture unit blocks along the length direction of the aquaculture pond back and forth are arranged on two sides of the aquaculture pond, and can drag the aquaculture unit blocks to be slowly shifted while the feeding machines feed fodder into the aquaculture baskets column by column. The fodder feeding system has the advantage that the fodder feeding system is suitable for accurately, quickly, efficiently and conveniently feeding the fodder into the aquaculture baskets on the large-area water surface.

Owner:NINGBO UNIV

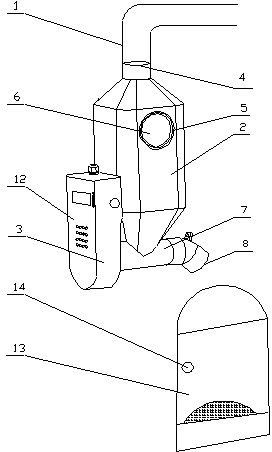

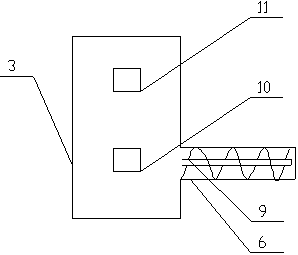

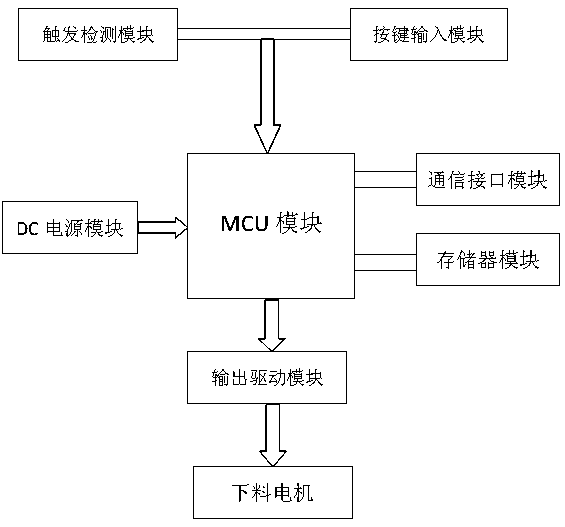

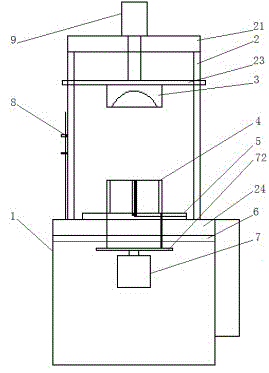

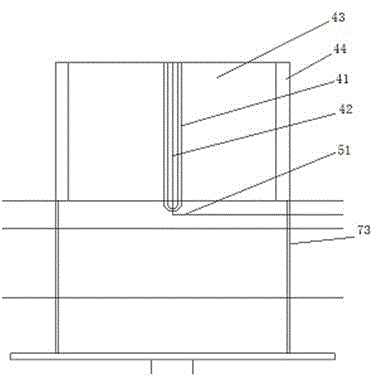

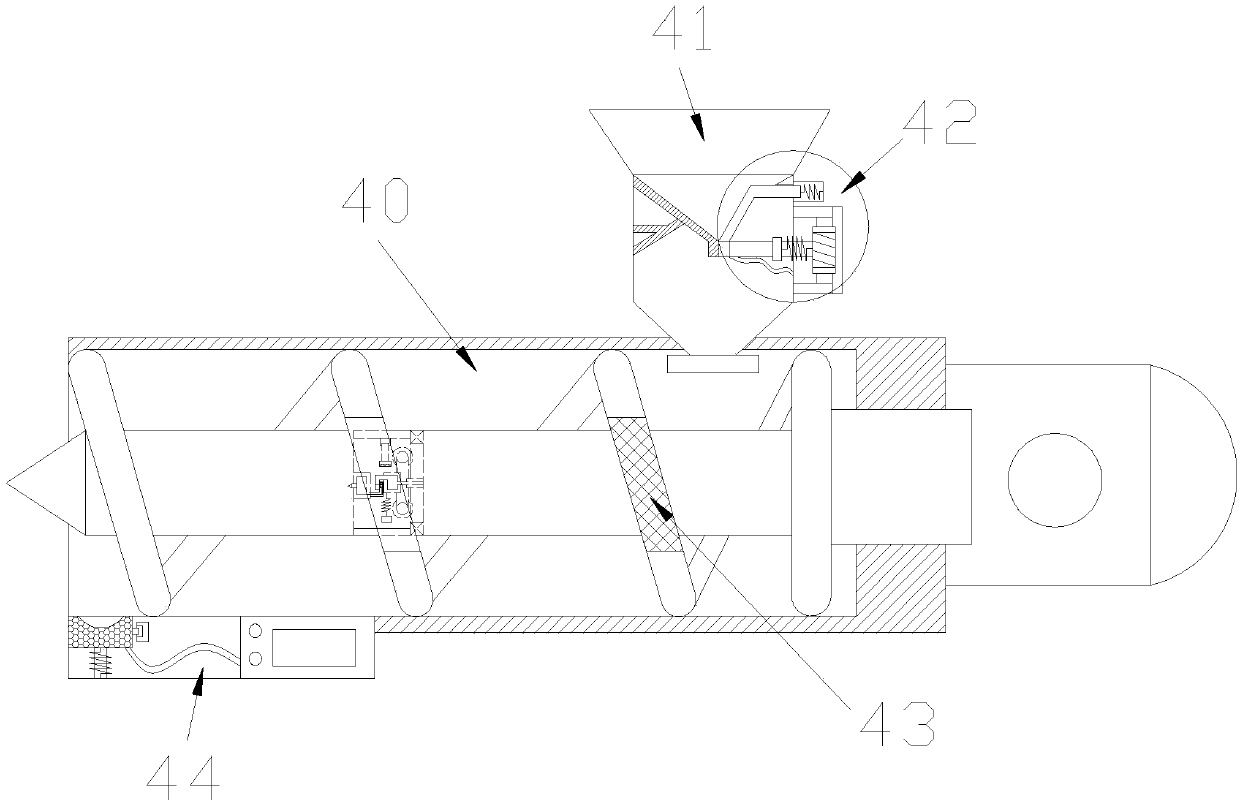

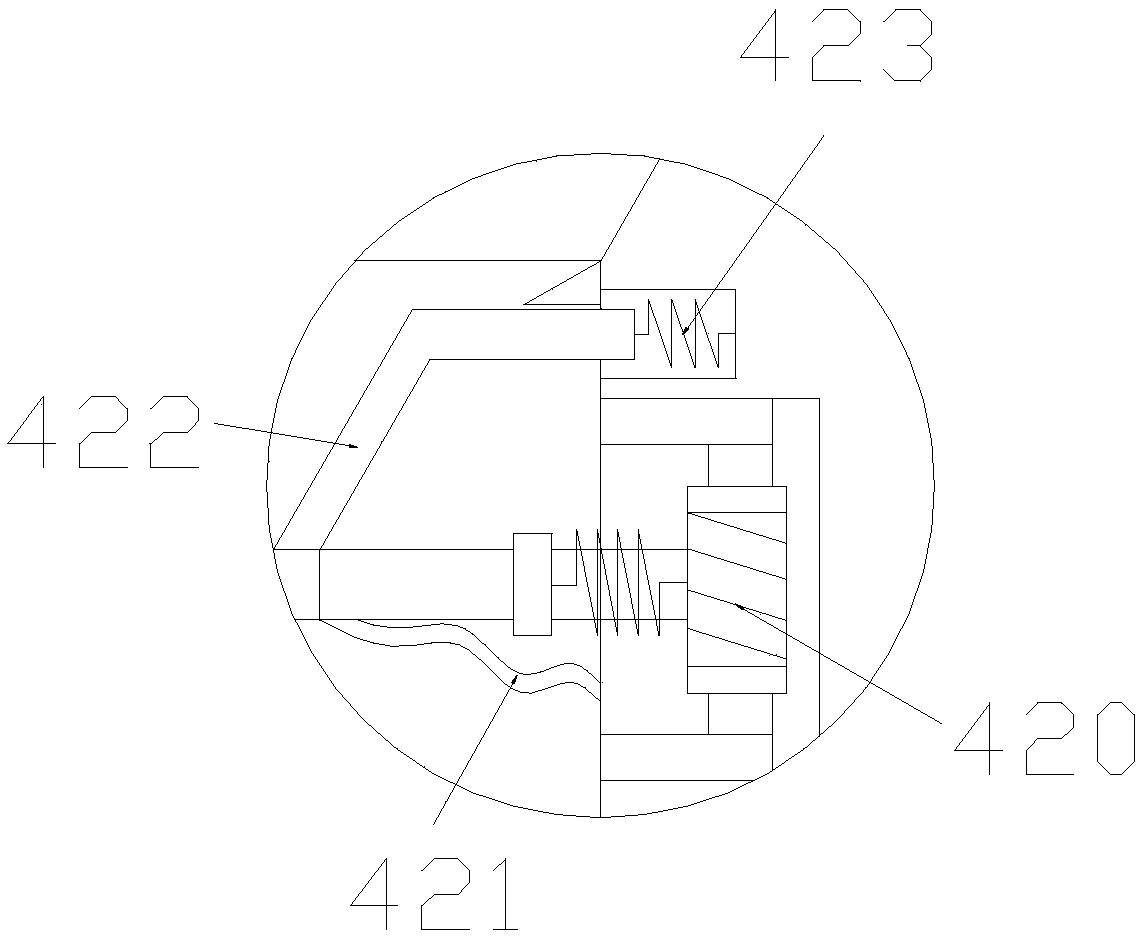

Intelligent sow feeding system and controlling method

ActiveCN103947571AAccurate feeding amountReasonable weight controlAnimal feeding devicesEar tagElectric machinery

The invention discloses an intelligent sow feeding system and a controlling method. The system comprises a controller, a feeding pipe, a storehouse connected with the controller, a discharging unit and a touching sensor, wherein the storehouse is connected with the feeding pipe; the controller comprises a mainboard controlling module, a controlling panel and a blanking motor; the mainboard controlling module is connected with the touching sensor, the controlling panel and the blanking motor respectively; input signals are received by the touching sensor and transmitted to the mainboard controlling module to control the blanking of the blanking motor; the system reduces the opportunities of people contacting with fodder, so that germ infection is further reduced. The invention further discloses the controlling method of the system. According to the invention, the mainboard controlling module judges whether key values exist, so that feeding mode can be selected and feeding parameters are set; the remaining capacity of auto-updated sow feeding in one day is read by the controller from the mainboard controlling module, and the mainboard controlling module starts or closes a triggering switch according to the triggering signals of the counters of the touching sensor and the mainboard controlling module, so that feeding restriction is realized, and the use of electronic ear tags is avoided.

Owner:广东广兴牧业机械设备有限公司

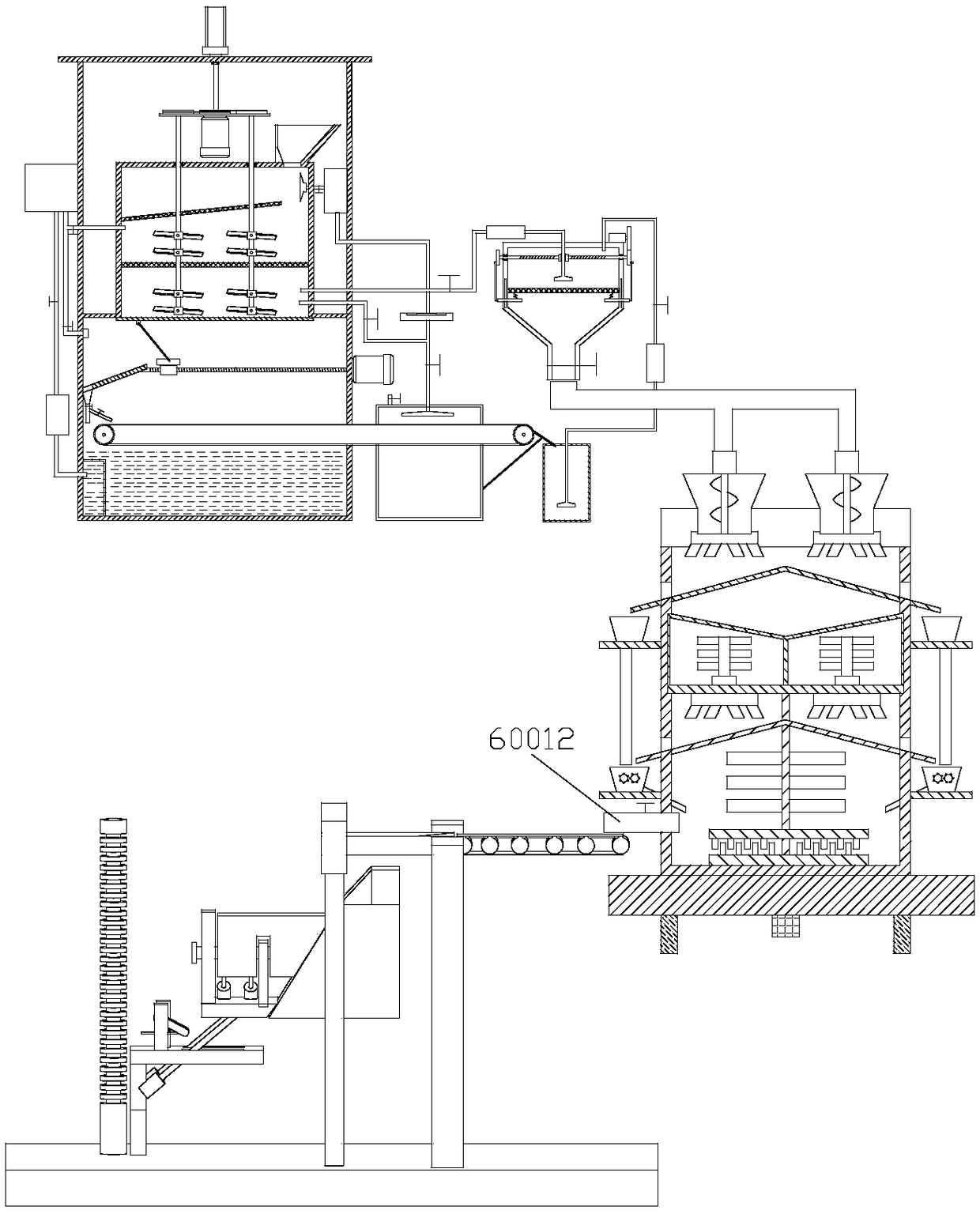

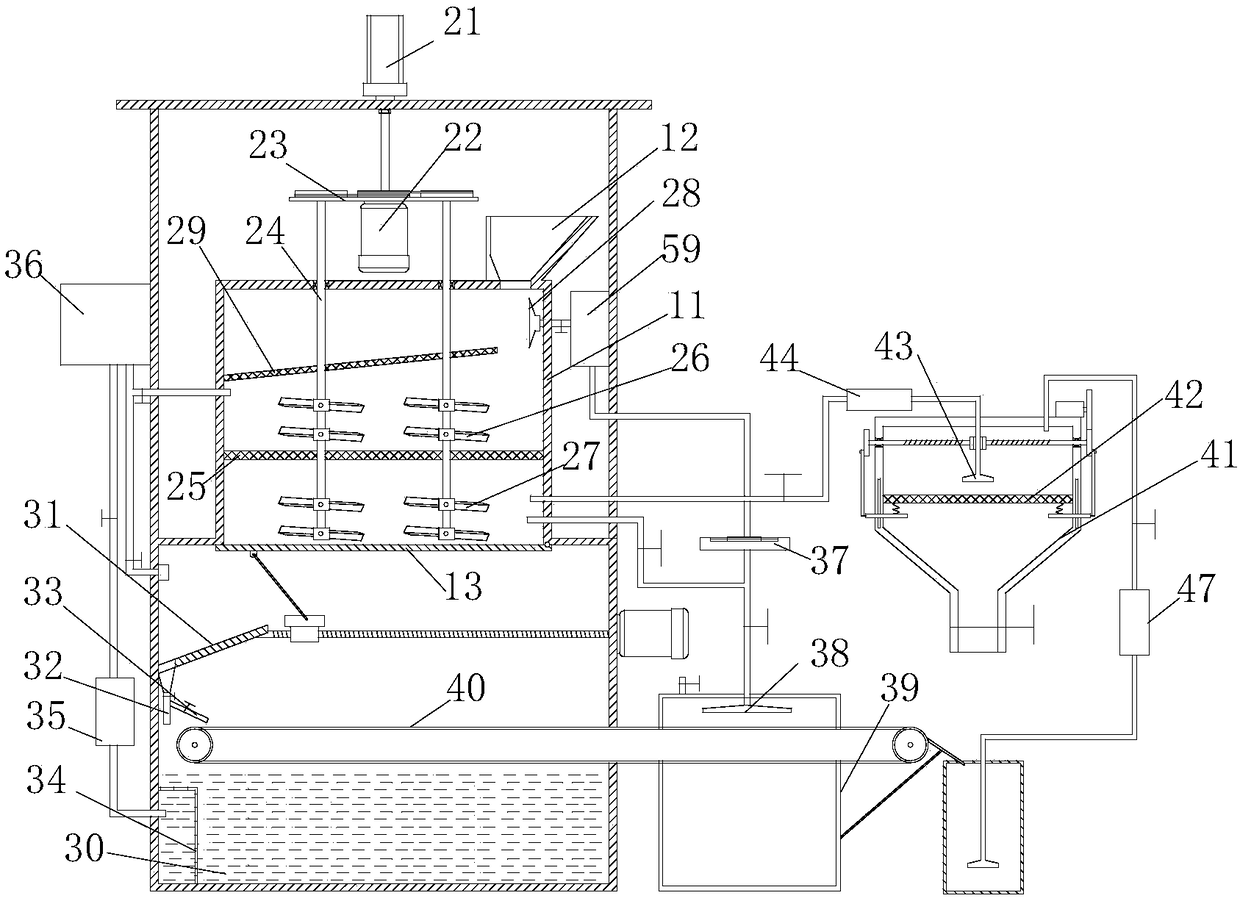

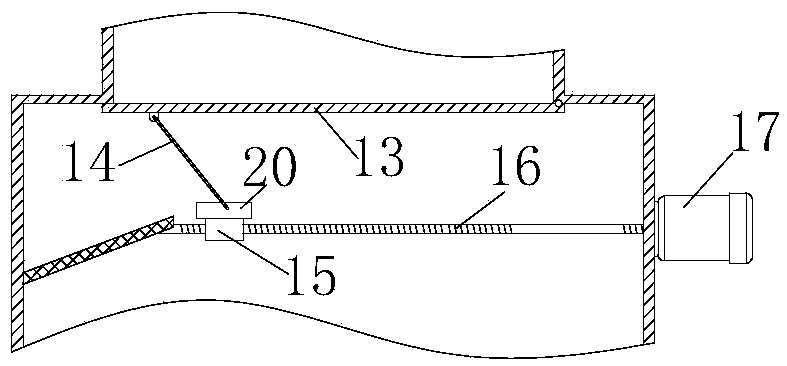

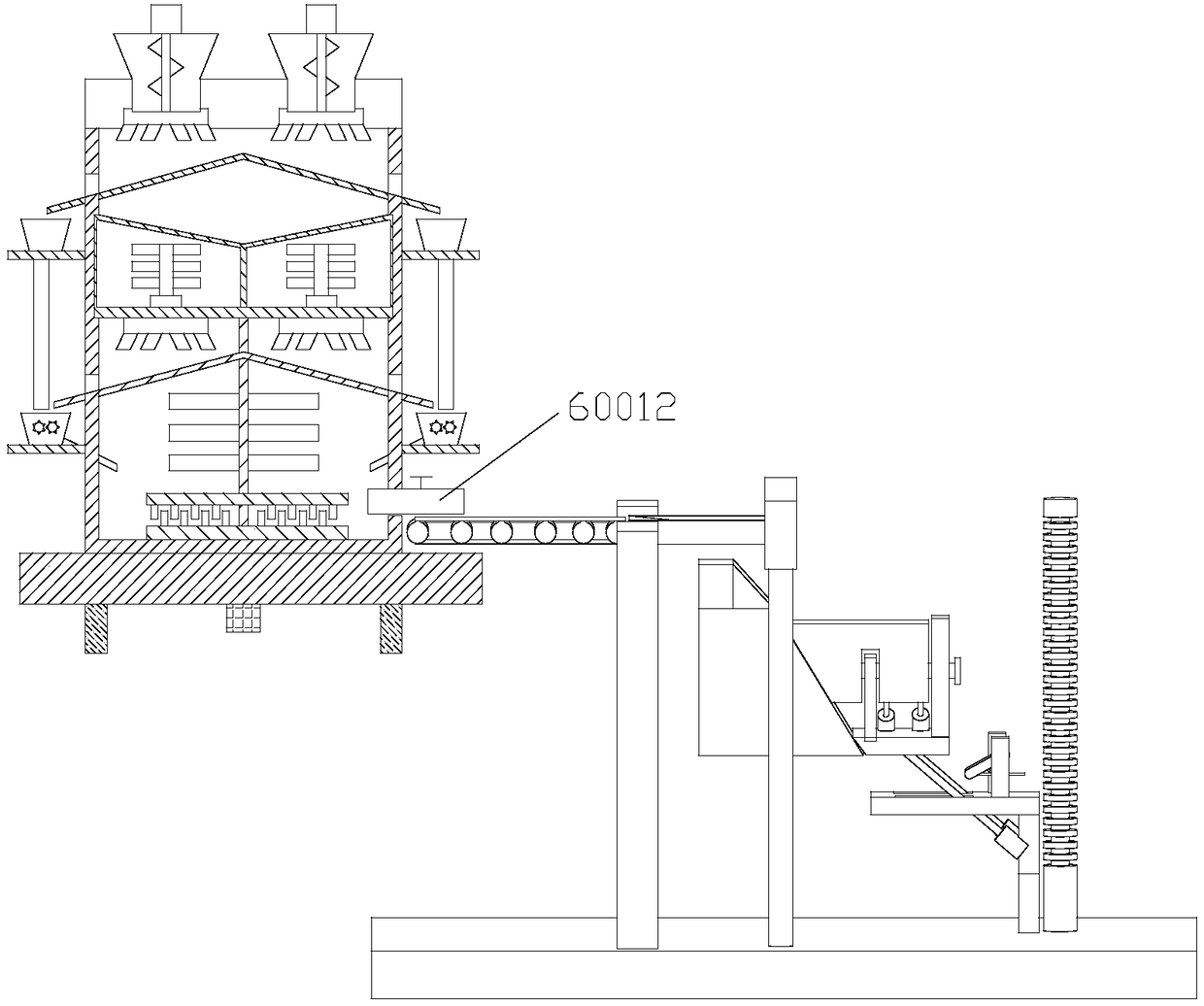

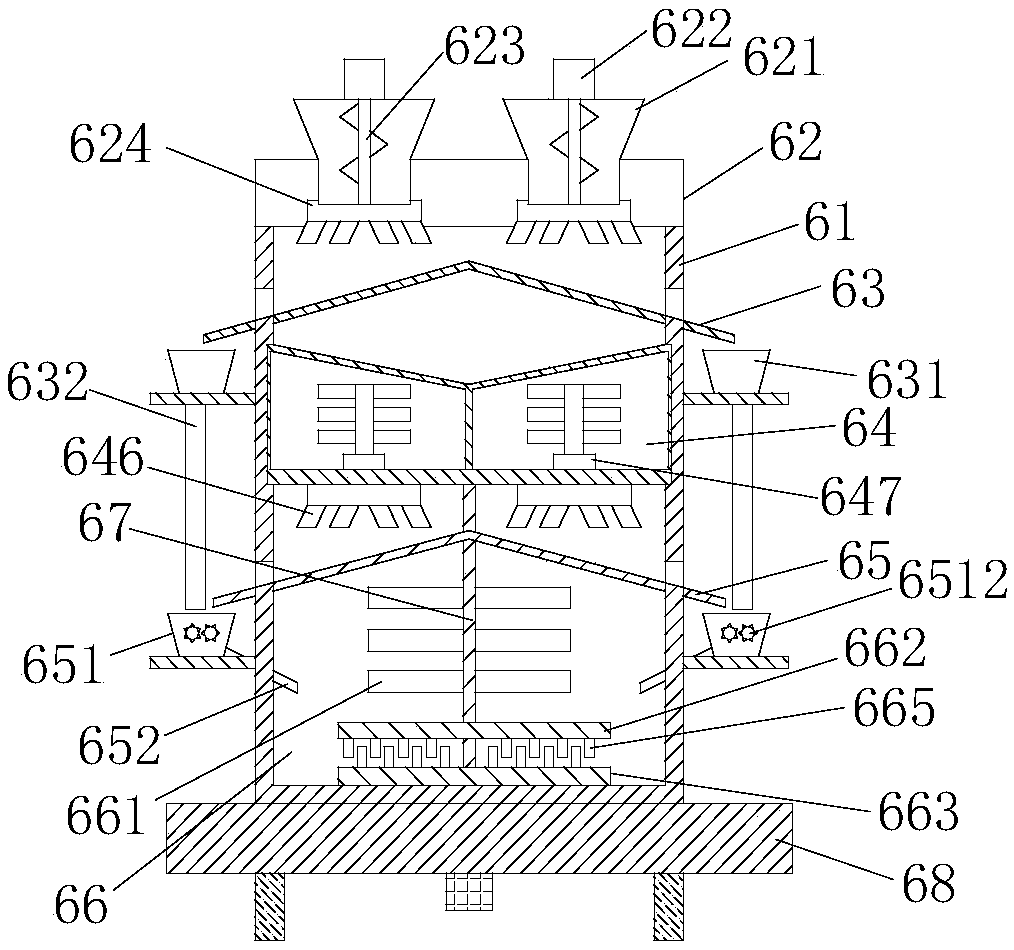

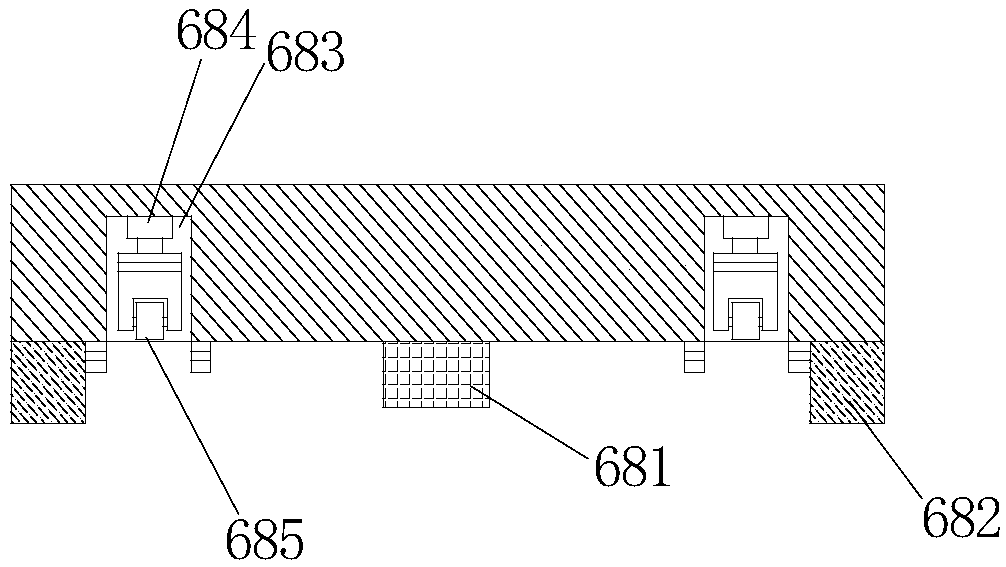

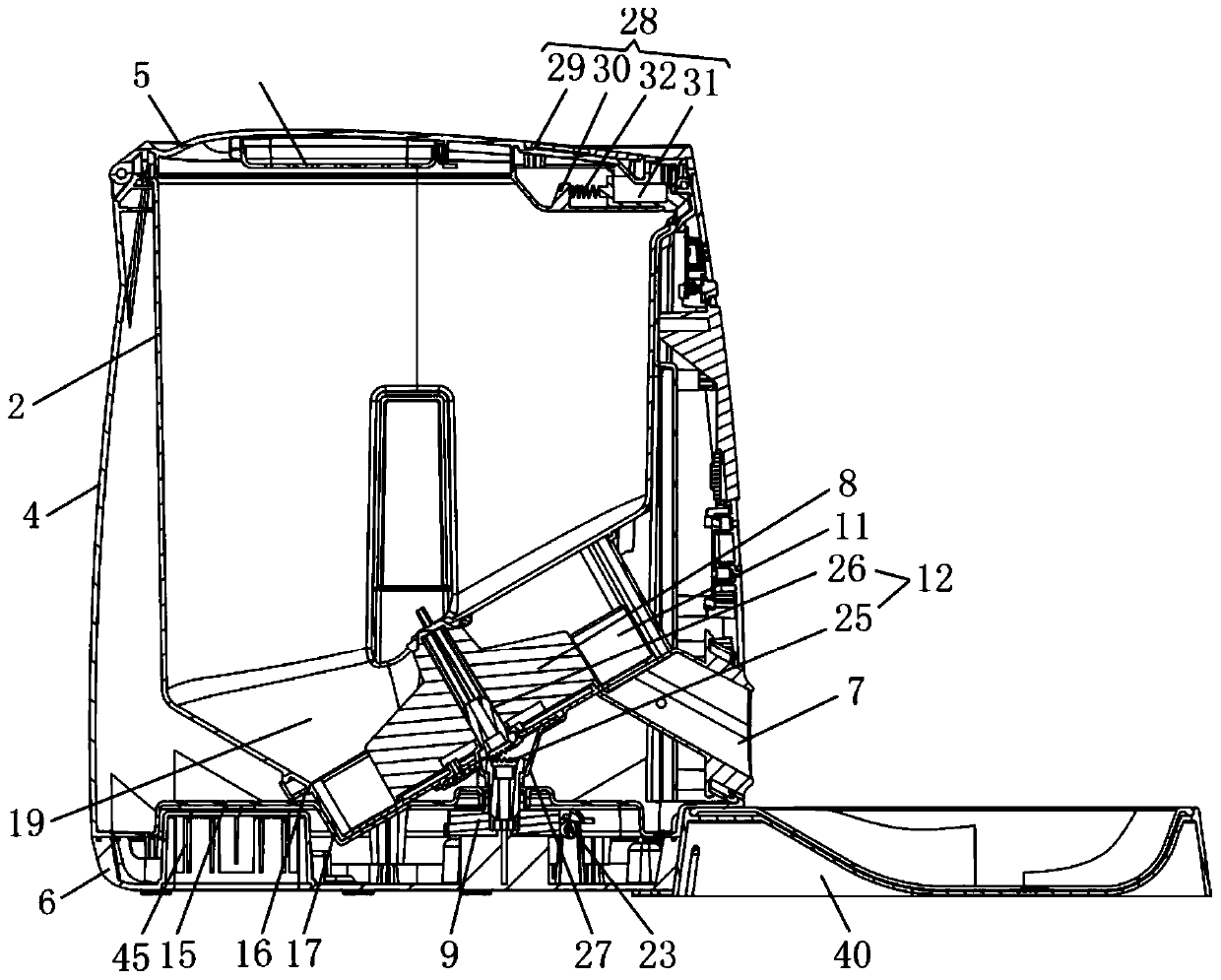

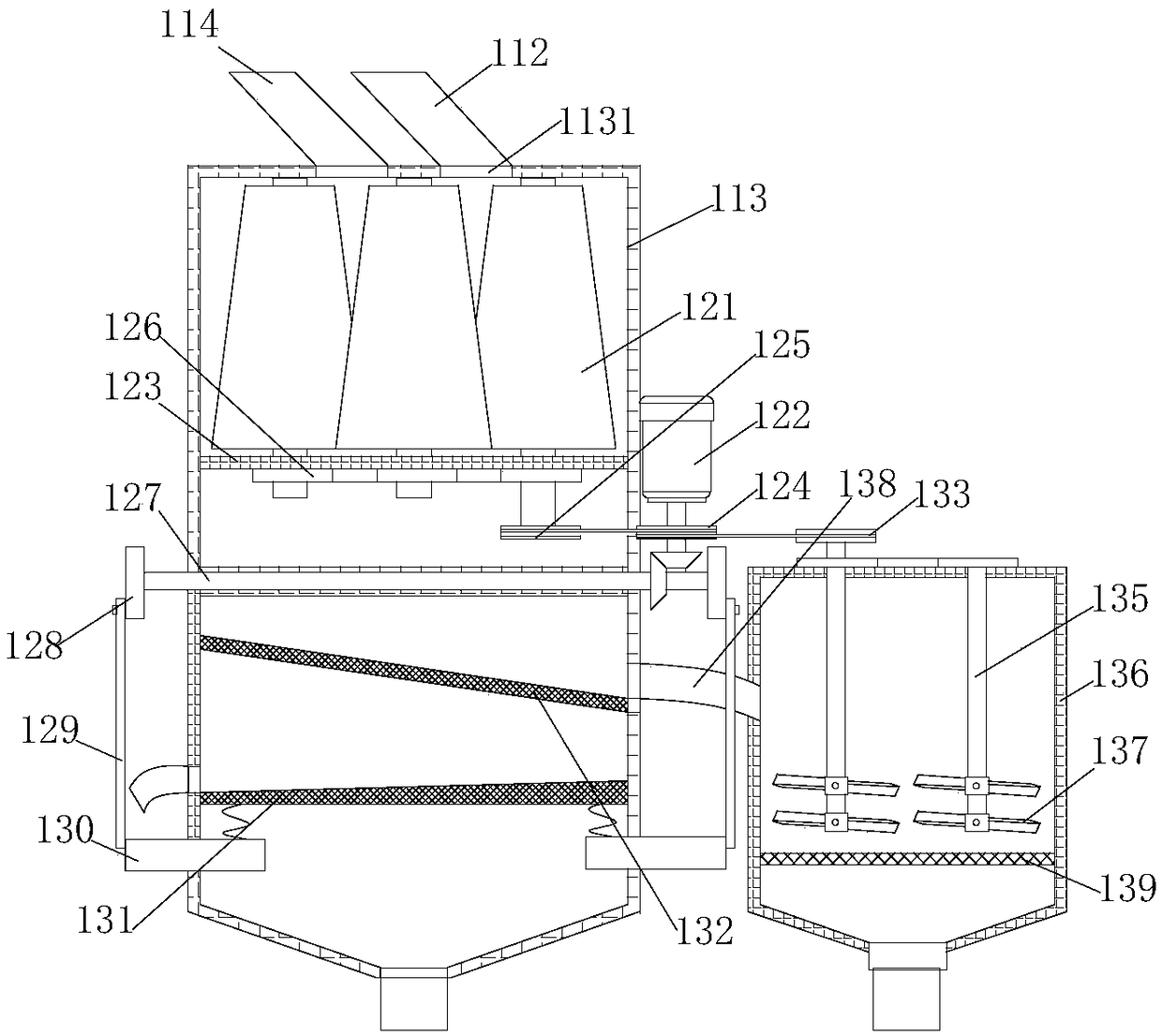

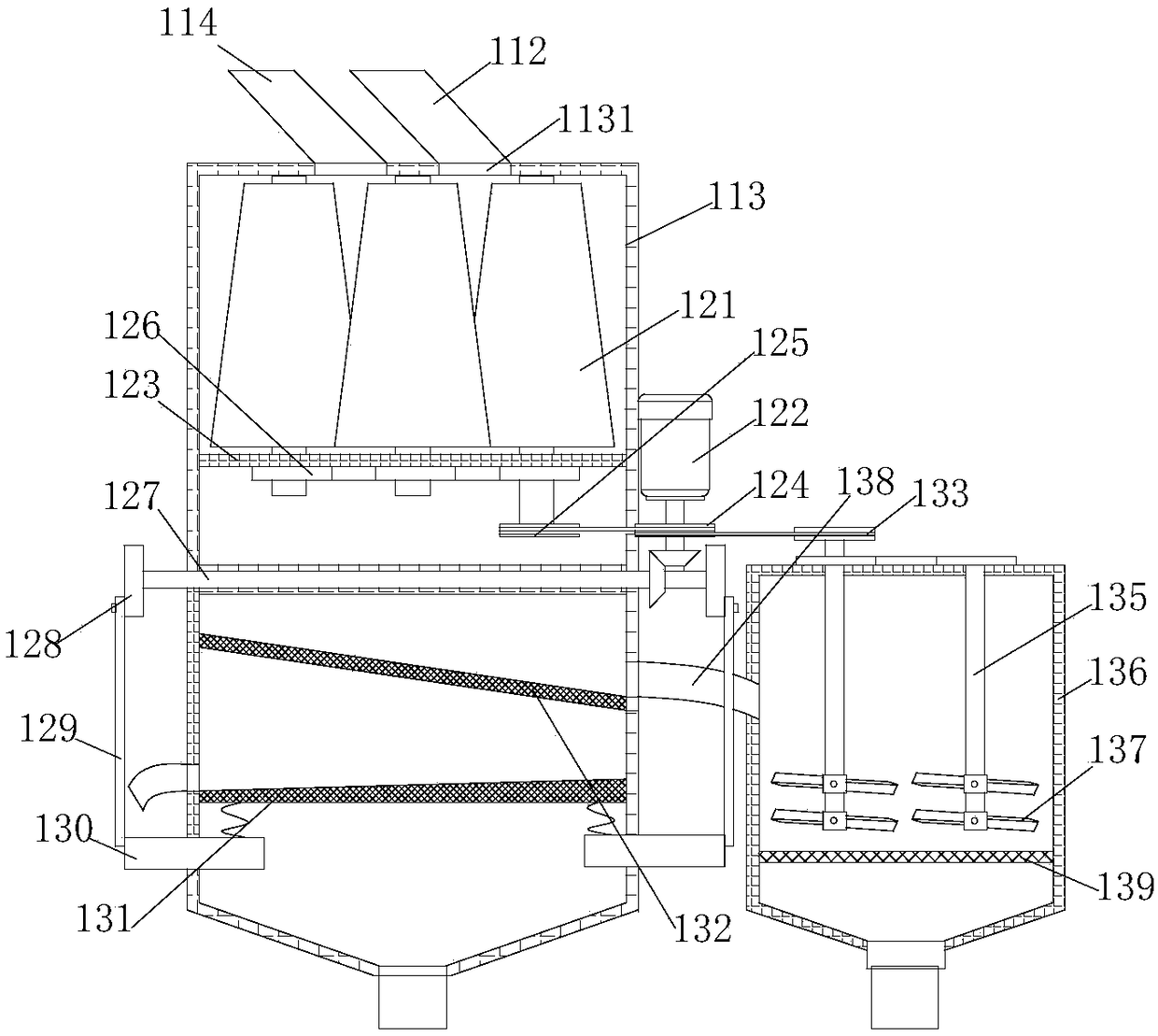

Corn flour production and processing mechanism based on multidirectional feeding

ActiveCN108654757AGuaranteed crushing efficiencyEnsure crushing efficiencySievingConveyorsCorn flourEngineering

The invention discloses a corn flour production and processing mechanism based on multidirectional feeding. The corn flour production and processing mechanism comprises a corn grain crushing device, apowder mixing device and a powder transfer device according to the technological process from front to back. The corn grain crushing device comprises a crushing unit, a drying unit and a material return device according to the technological process in sequence. The powder mixing device comprises a material mixing tank and a material mixing upper cover covering the material mixing tank, and a cavity of the material mixing tank is internally provided with a first material mixing and screening plate, a first mixing chamber, a second material mixing and screening plate and a crushing / mixing integrated chamber from top to bottom in sequence. The powder transfer device comprises a transfer conveyor belt, a turnover discharging device, a transfer baffle, a conveyer bucket, a transfer elastic device and a transfer lifting base station from front to back in sequence. The corn flour production and processing mechanism has the advantages of quality guarantee of produced corn flour, good mixing effect of corn flour and flour, high continuity of operation, precise single feeding quantity and high working efficiency, and is not liable to caking or blockage.

Owner:安徽双全面粉有限公司

Solid state powder guide mechanism based on multi-mixing chamber

InactiveCN108554300AAvoid cloggingWell mixedGas current separationTransportation and packagingEngineeringMixing effect

The invention discloses a solid state powder guide mechanism based on a multi-mixing chamber. The solid state powder guide mechanism sequentially comprises a powder mixing device and a powder transferdevice according to a process flow from the front to rear, wherein the powder mixing device comprises a mixing tank and a mixing upper cover covering the mixing tank, wherein a first mixing and screening plate, a first mixing chamber, a second mixing and screening plate and a grinding / mixing integrated chamber are sequentially formed in a cavity of the mixing tank from top to bottom; the powder transfer device sequentially comprises a transfer conveyor belt, a turning type unloading device, a transfer baffle, a conveyer bucket, an elastic transfer device and a transfer lifting base from the front to rear; the solid state powder guide mechanism further comprises a transfer guide table. The solid state powder guide mechanism disclosed by the invention has the advantages of being excellent in mixing effect, difficult to agglomerate and block, high in operating continuity, accurate in single feed capacity and high in working efficiency.

Owner:芜湖拓云农业技术有限公司

Paint preparation technology

ActiveCN103540198AReasonable standardImprove standardsUnspecified rubber coatingsPolystyreneWaste rubber

The invention discloses a paint preparation technology, which is characterized by comprising the technological steps of: (1) raw material selection, wherein by weight percent, polystyrene foam, phenolic foamed plastics, waste rubber and nitrocellulose account for 65%, industrial alcohol, coal tar, acetone and water solvent account for 15%, pigment and filler account for 15%, and a wet dispersing agent, a defoaming agent, a delustering agent and a plasticizer account for 5%; (2) fusion refining; (3) primary fining; (4) dispersing; (5) blending and color modulation; (6) filtering; (7) packaging. The technology disclosed by the invention is reasonable and compact, technological process is reduced greatly, paint source is wide, the technology belongs to waste reuse, and production cost is reduced; meanwhile, according to the raw material ratio, the technology is convenient for preparing various functional paints and can meet the requirement of production technology of the paints, dosage and ratio are accurate, deviation is small, product quality is guaranteed, and yield of enterprises is improved effectively.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

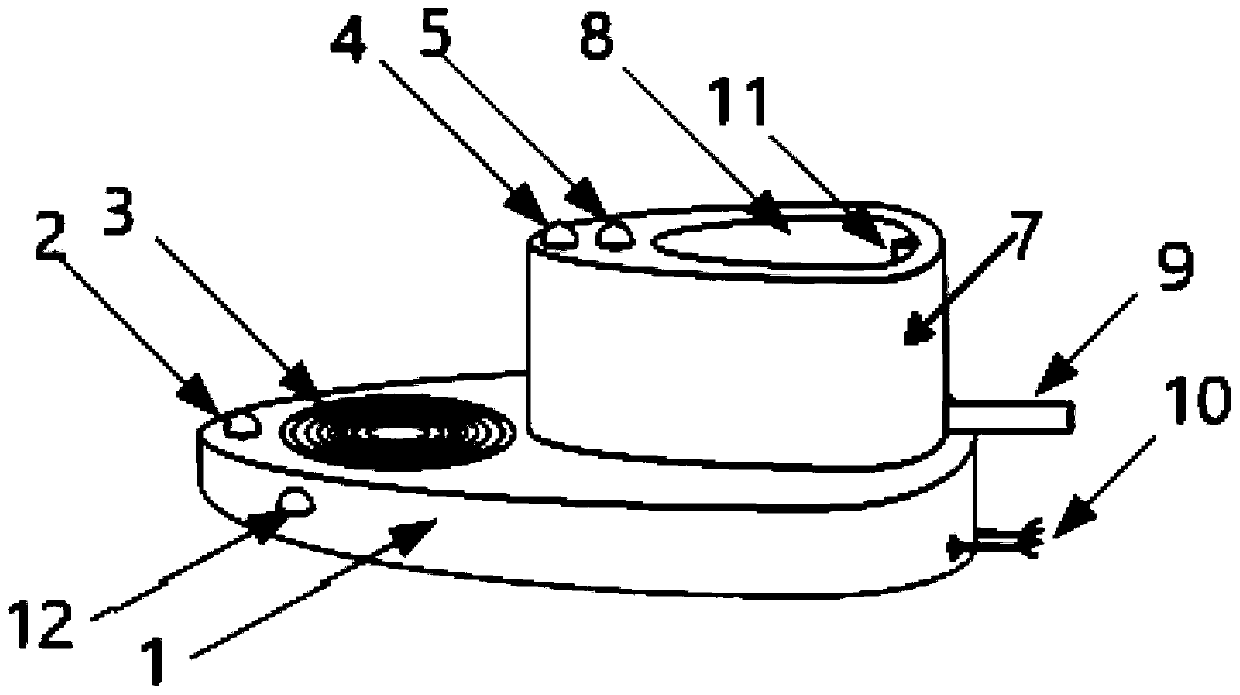

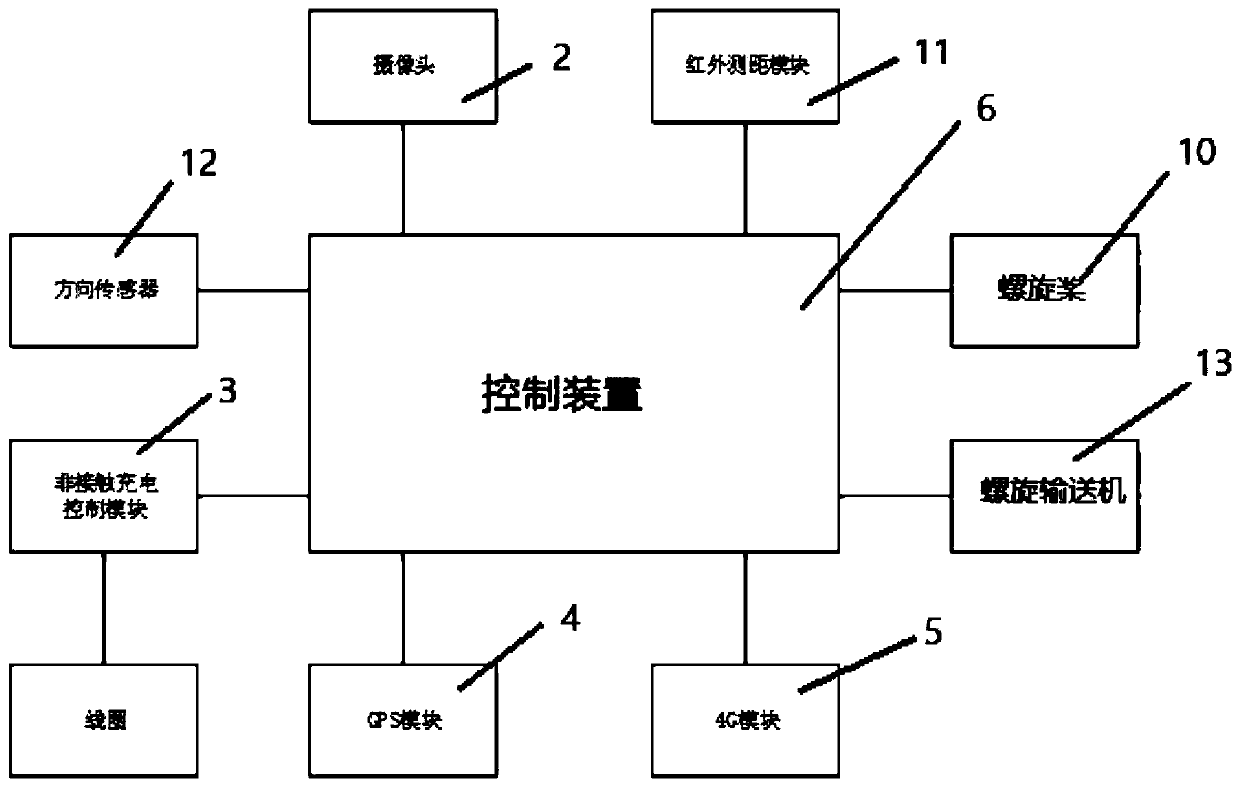

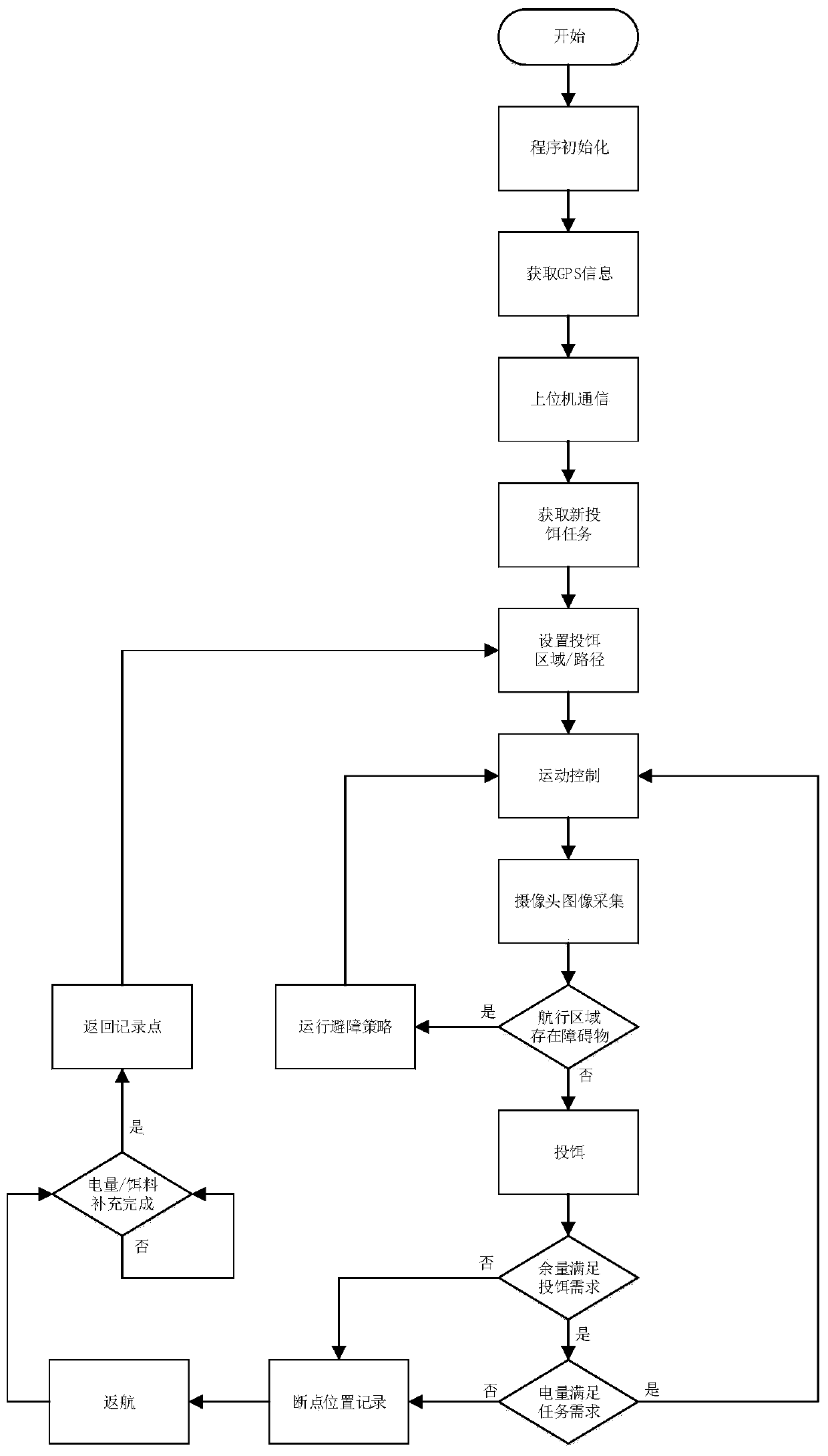

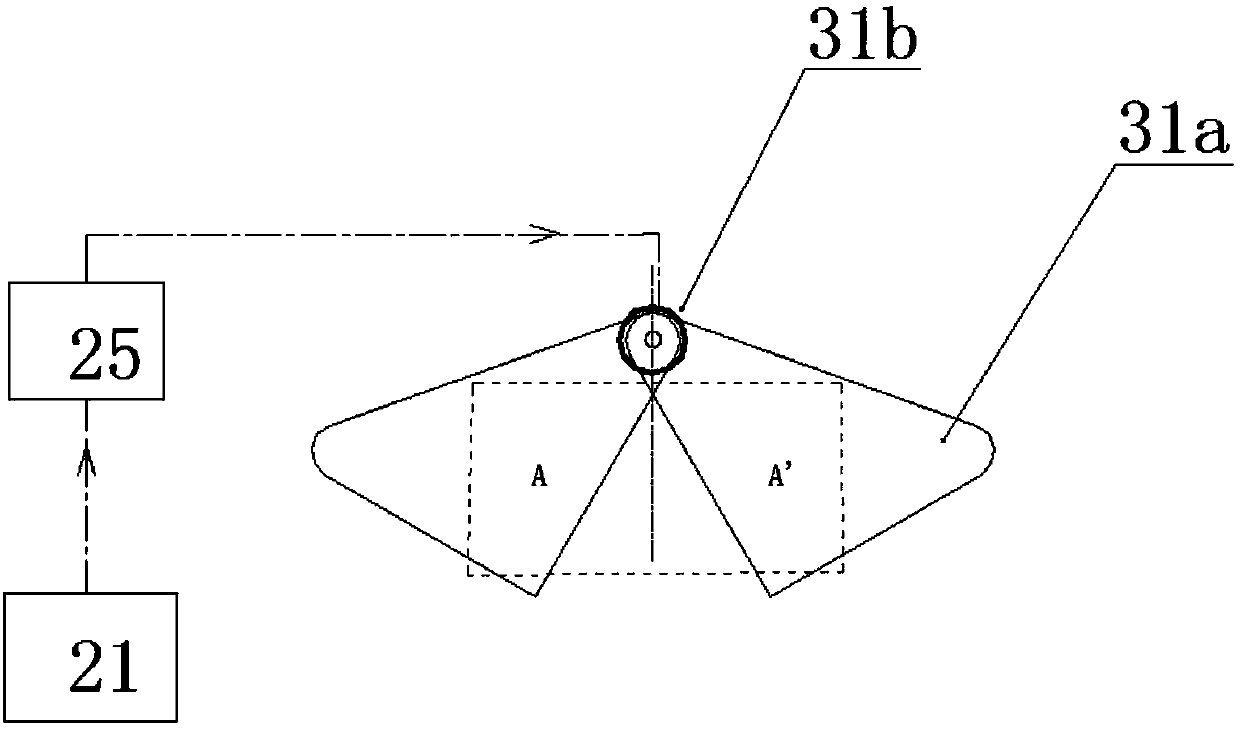

Unmanned bait feeding ship and control method thereof

ActiveCN109874722AAvoid the risk of electric shockEasy to recordCharging stationsWaterborne vesselsComputer moduleFishery

The invention discloses an unmanned bait feeding ship and a control method thereof. The unmanned bait feeding ship is characterized by comprising a bait feeding ship body, and the bait feeding ship body is provided with a storage bin for storing bait, a bait feeding mechanism for feeding the bait in the storage bin into water, a non-contact charging module, a propeller, a camera for collecting animage, a GPS module for precisely positioning the bait feeding ship body, a 4G module for receiving and transmitting a signal to the outside and a control device which is in signal connection with thenon-contact charging module, the propeller, the camera, the GPS module and the 4G module; the storage bin is located on the rear portion of the bait feeding ship body, and the storage bin is providedwith a bait inlet for the bait to enter and a feeding port for the bait to be discharged out of the storage bin; the bait feeding mechanism is a spiral conveyor arranged in the feeding port. By applying the unmanned bait feeding ship, the bait is remotely and precisely fed, and consumption of the labor resources is reduced.

Owner:SHANGHAI OCEAN UNIV +1

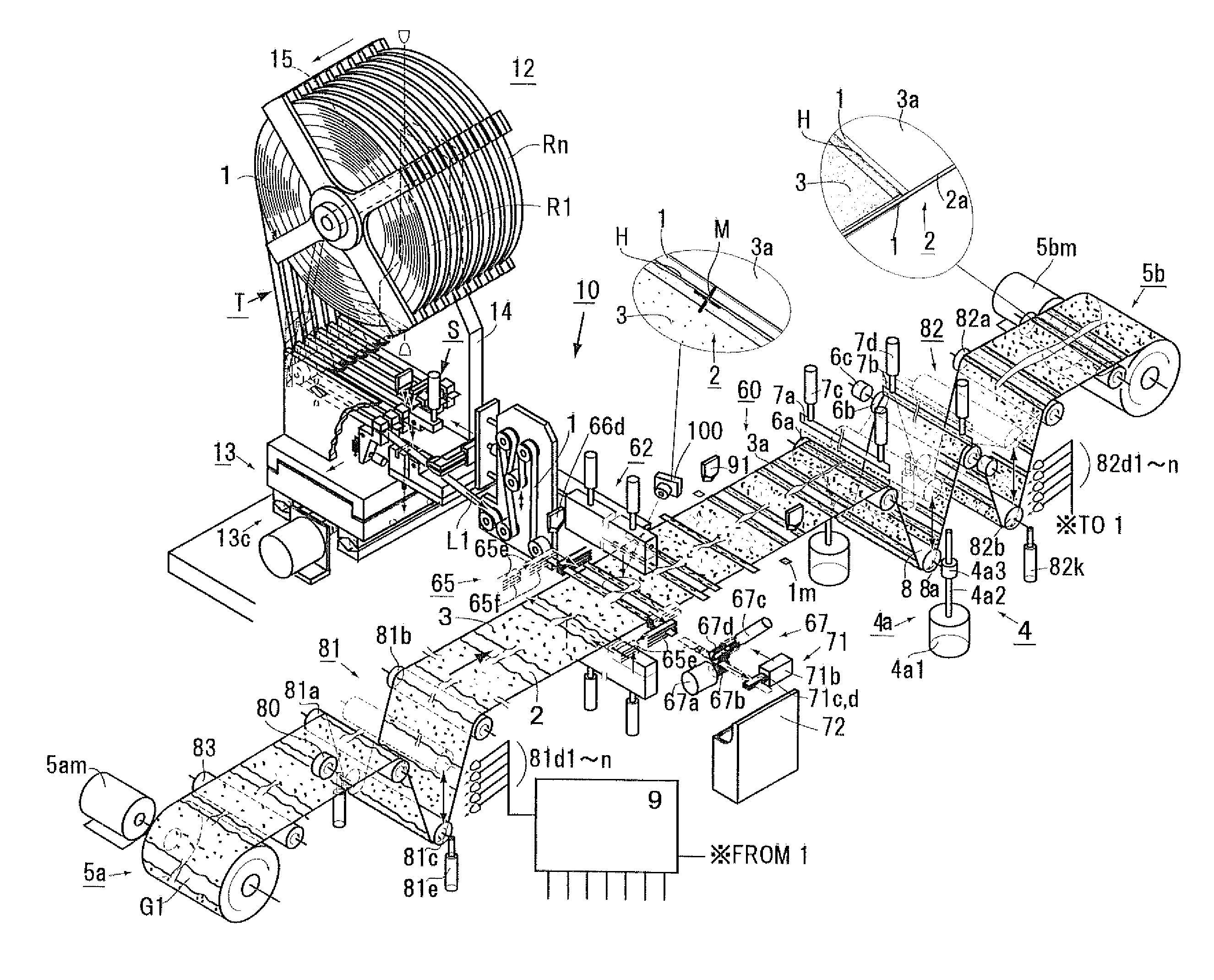

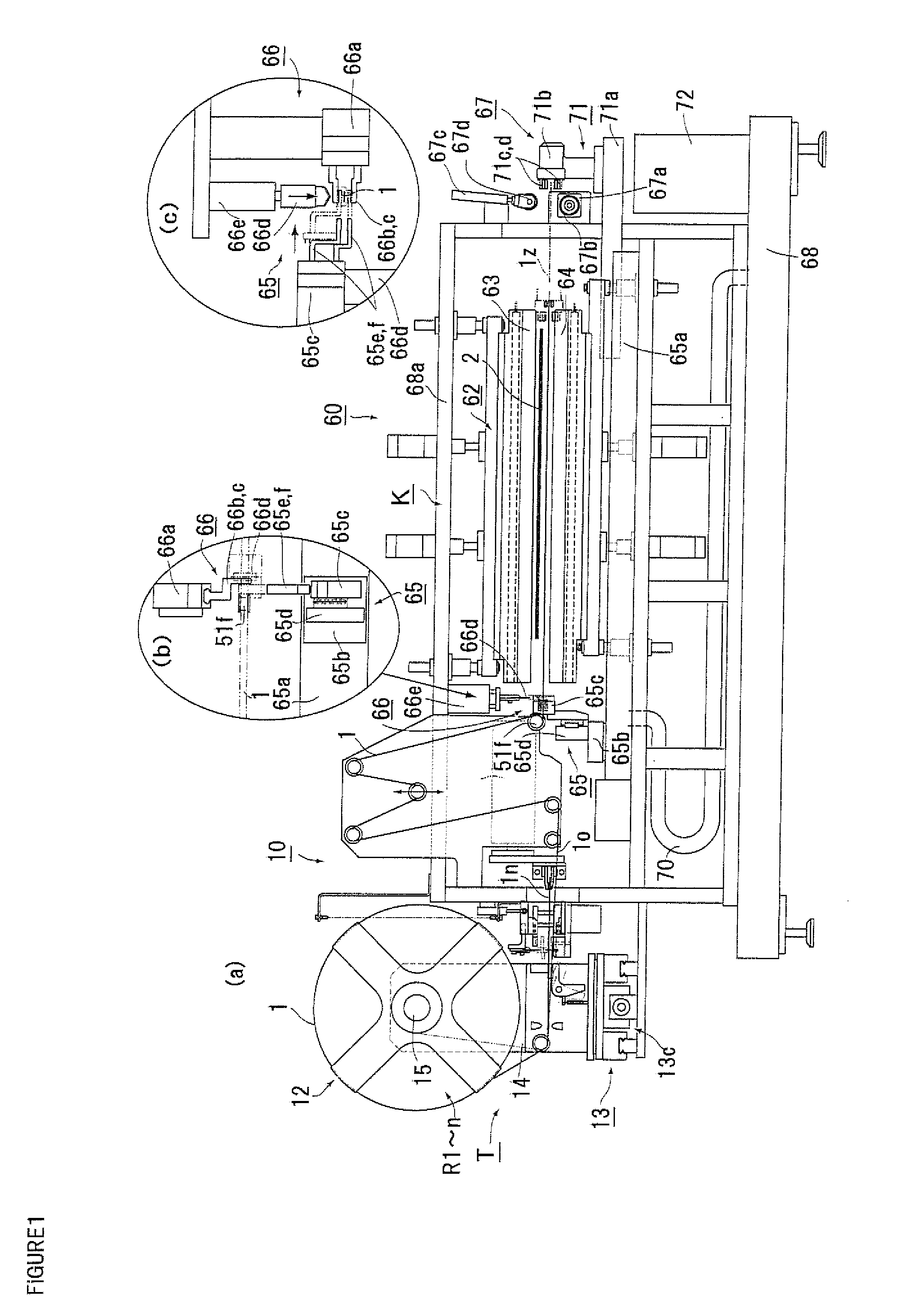

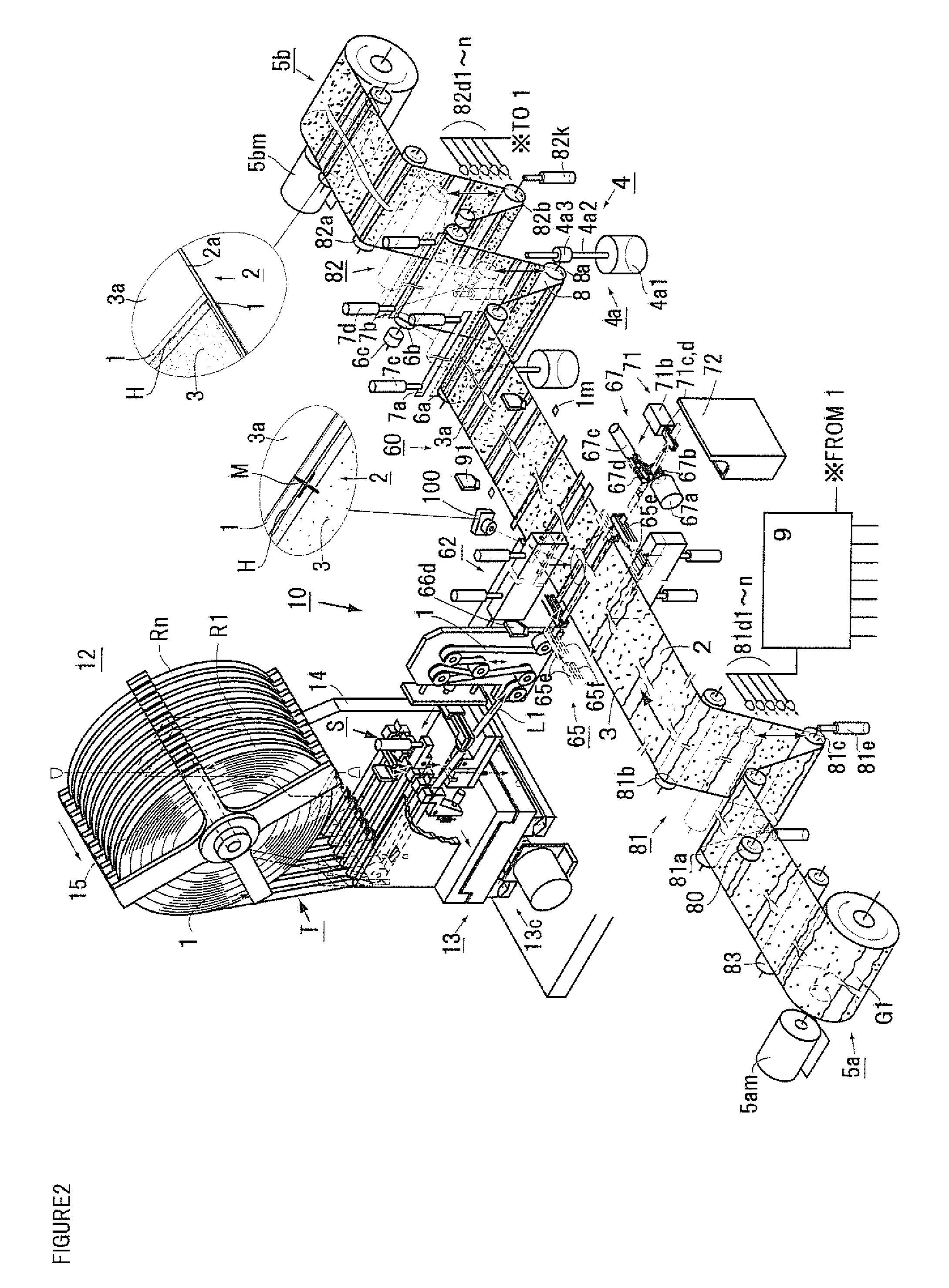

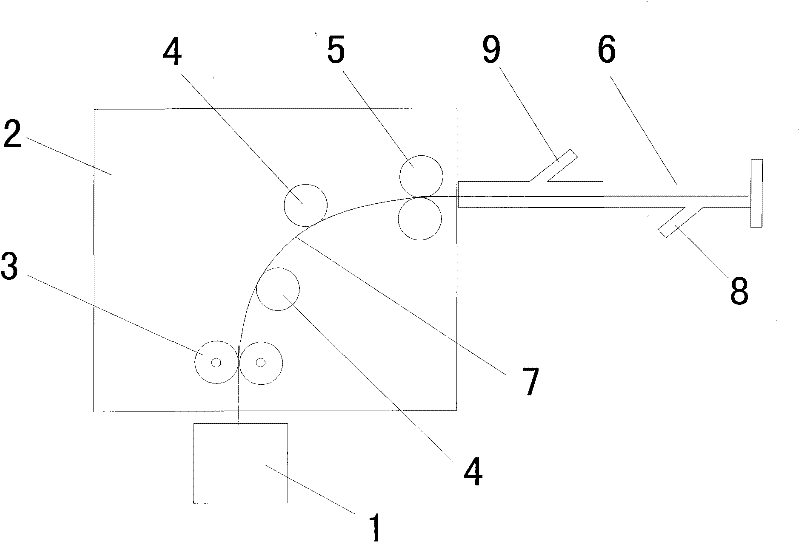

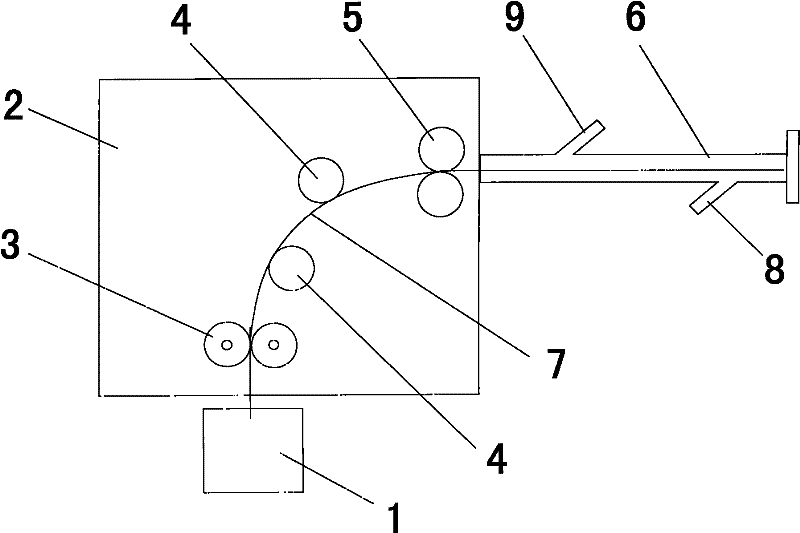

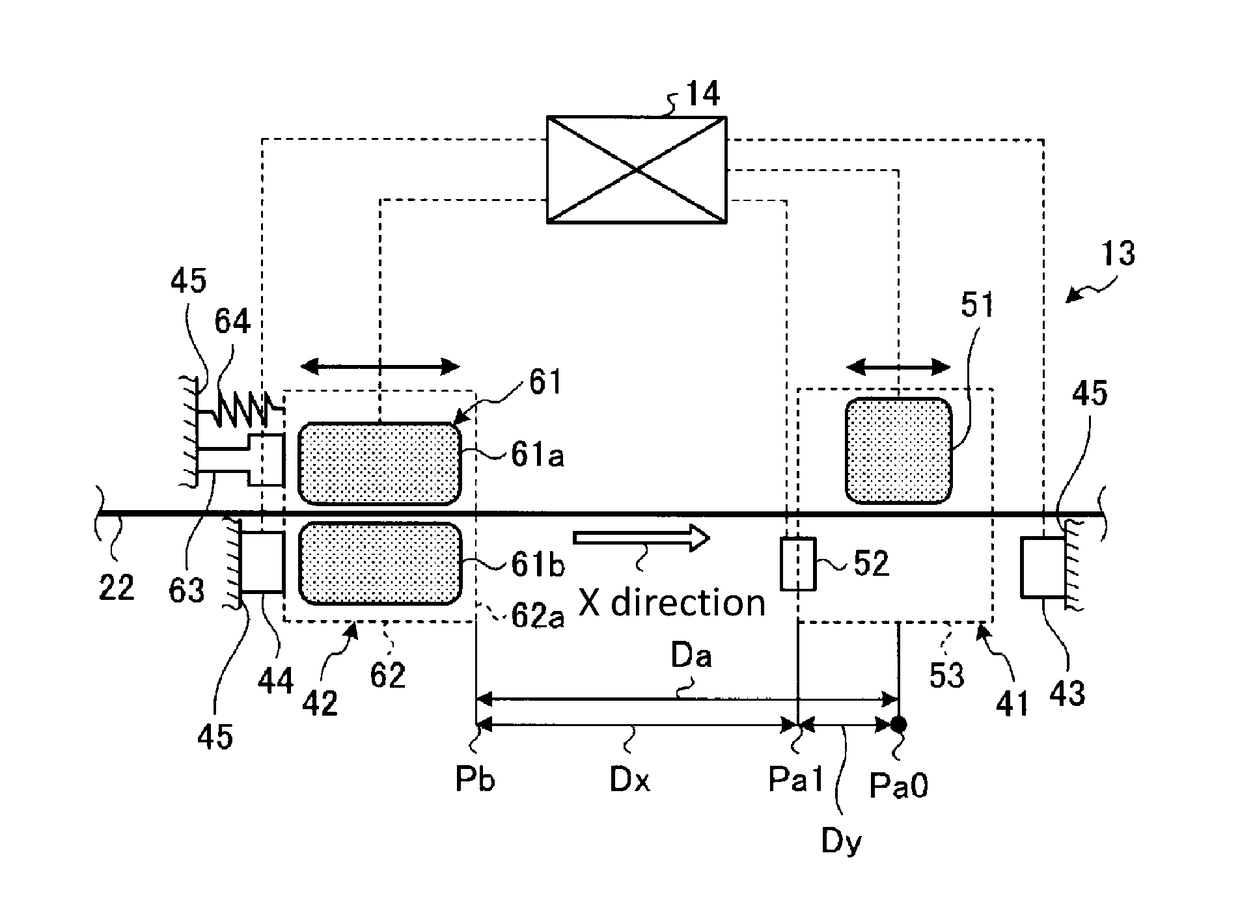

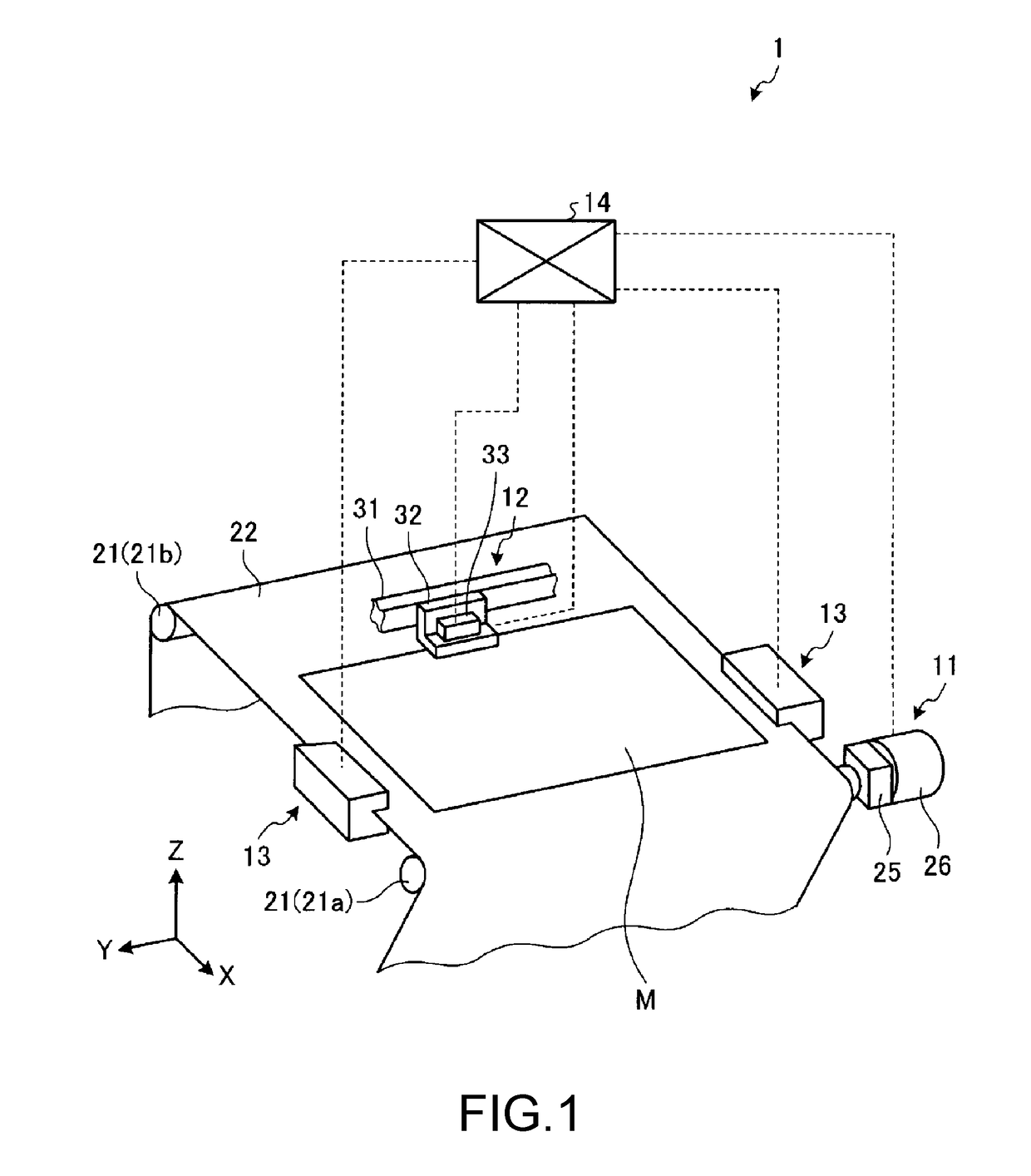

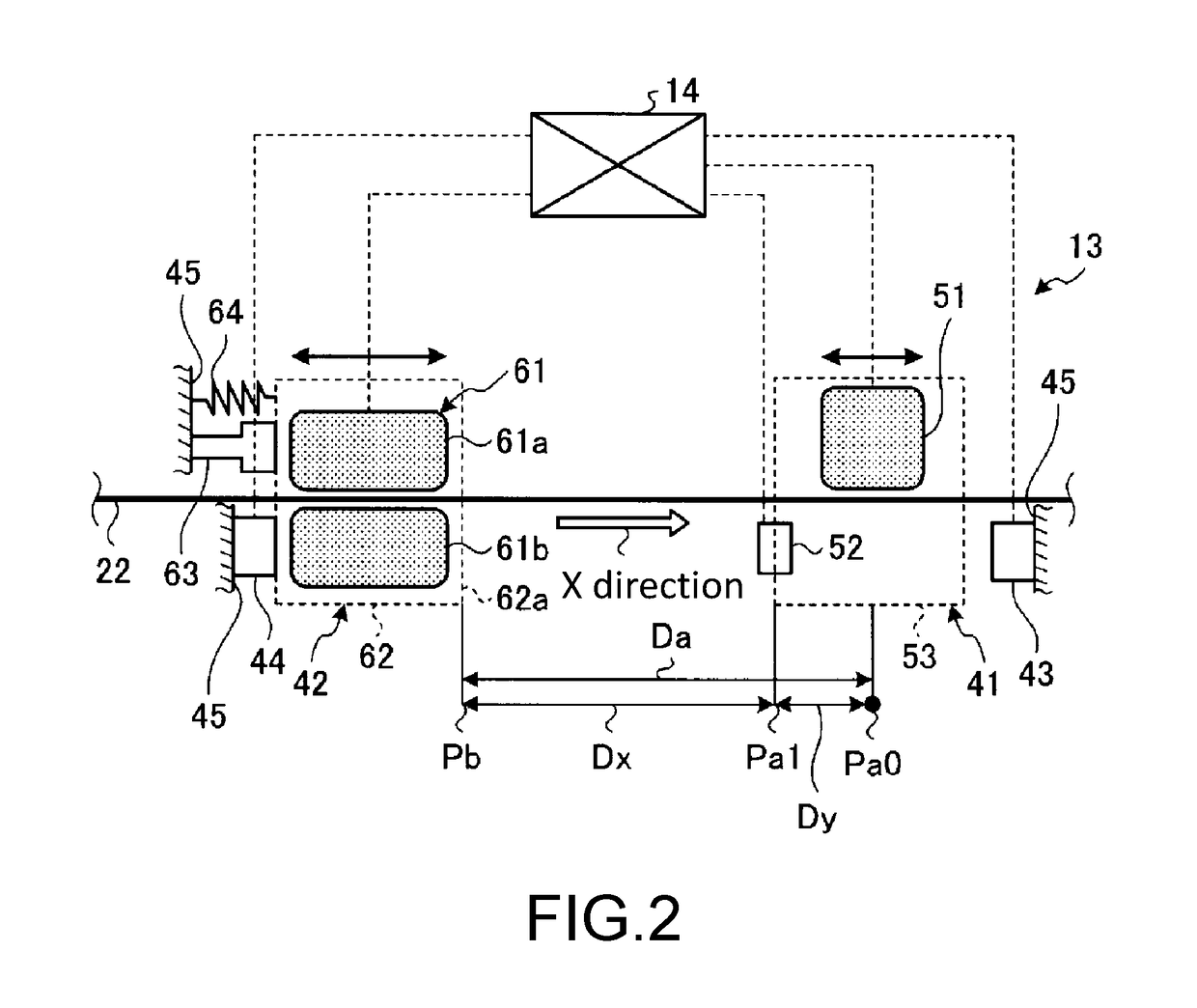

Original fabric pitch feed mechanism of original fabric manufacturing device for electrochemical element

ActiveUS20120222819A1Prevent reversalIncrease speedFinal product manufactureWinding capacitor machinesProcess regionMechanical engineering

Provided is a pitch feed mechanism which is capable of performing an accurate, high-speed pitch feed of an original fabric having unevenness on a surface thereof in a sticking operation of an insulating tape. The original fabric pitch feed mechanism that is provided on a downstream side of an insulating tape sticking process region in a long original fabric, and performs the pitch feeding of the original fabric in one direction in accordance with a boundary part, the original fabric pitch feed mechanism being characterized by comprising a feed side roller, an original fabric take-up side roller, a feed side contact and separate member, a take-up side contact and separate member, and a pitch feed roller, which is disposed between the feed side roller and the original fabric take-up side roller, and pulls out, when the feed side contact and separate member is separated from the feed side roller, and the take-up side contact and separate member is in contact with the original fabric take-up side roller to fix the original fabric with the original fabric disposed therebetween, the original fabric by a predetermined size from the feed side roller side by pressing the original fabric that is extended between the feed side roller and the original fabric take-up side roller.

Owner:O M C

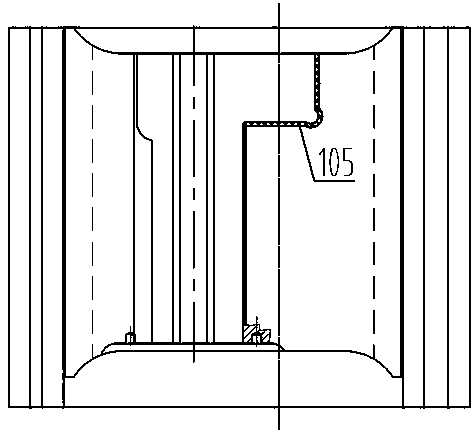

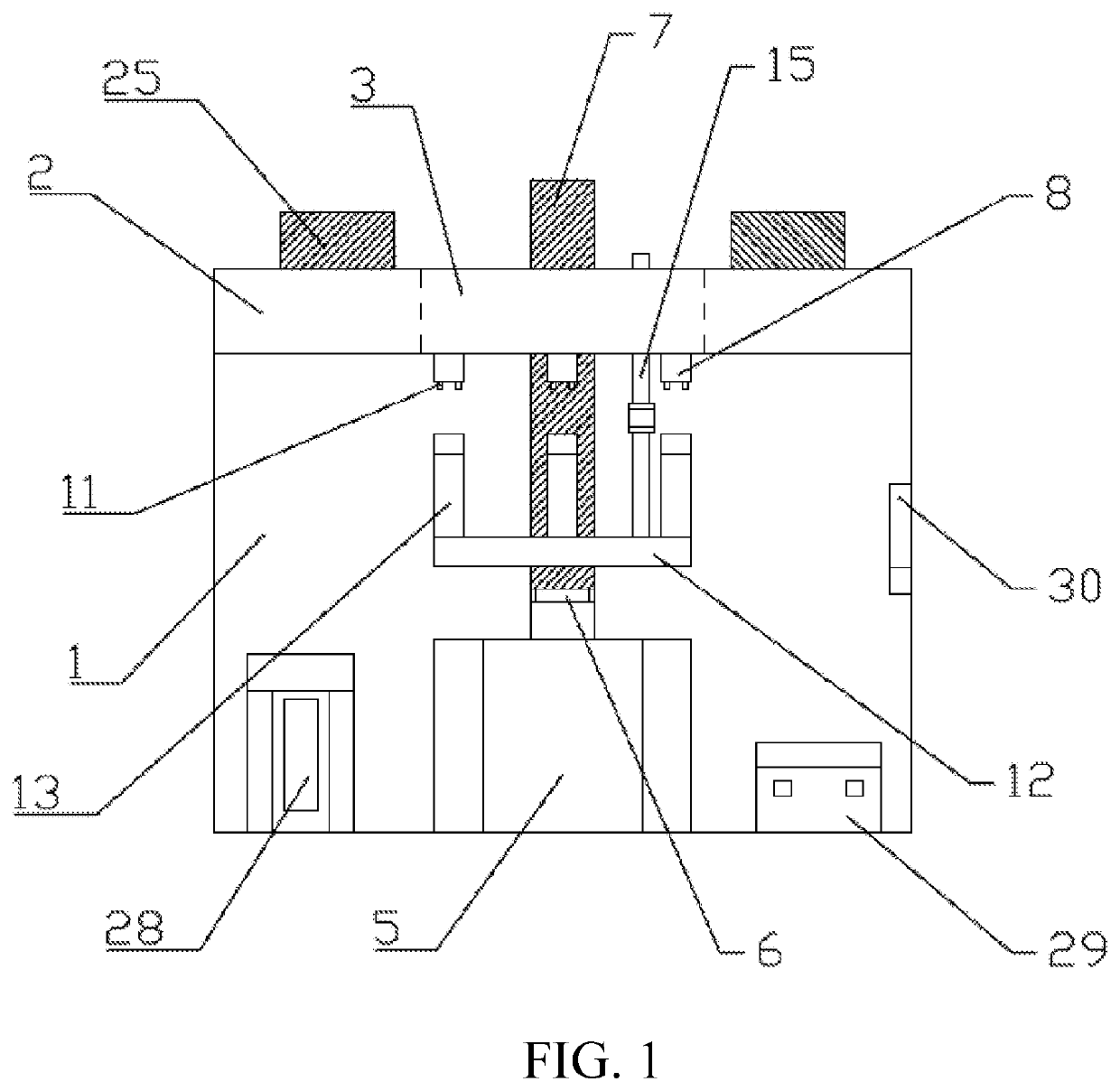

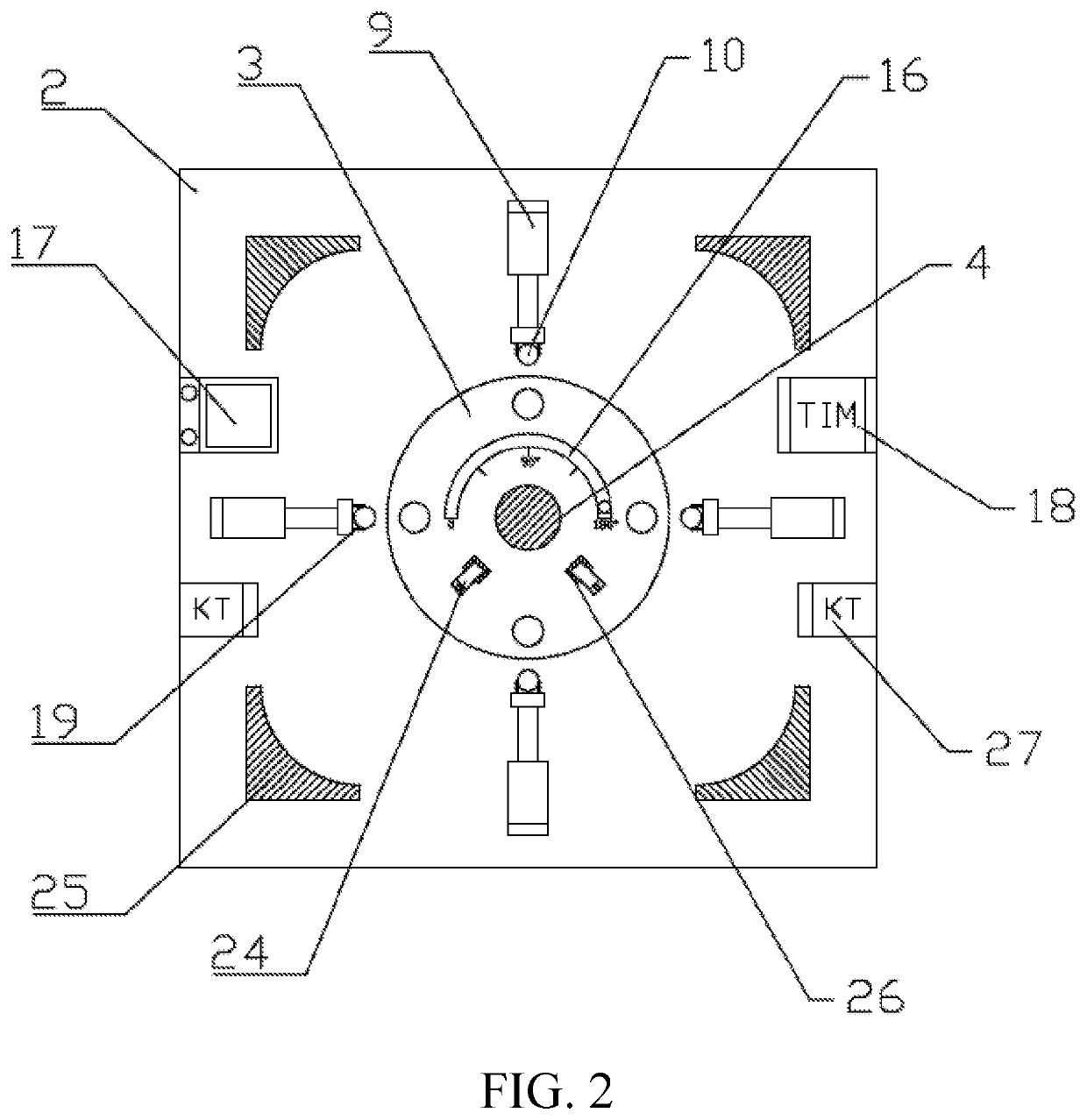

Metal vibration film forming equipment

The invention relates to metal vibration film forming equipment, which comprises a machine seat, a forming mechanism and a control mechanism, wherein the forming mechanism comprises a vibration film forming mold and a driving assembly, wherein the control mechanism comprises an upper mold cylinder pushing control circuit, a lower mold cylinder pushing control circuit and an air pressure control circuit, the upper mold cylinder pushing control circuit is used for controlling the upper mold cylinder pushing action, the lower mold cylinder pushing control circuit is used for controlling the lower mold cylinder pushing action, and the air pressure control circuit is used for controlling the air blowing of an air pressure source. The metal vibration film forming equipment is specially used for metal vibration film forming, in addition, the energy consumption is low, and the forming quality is good.

Owner:HUIZHOU JINSHAN ELECTRONICS

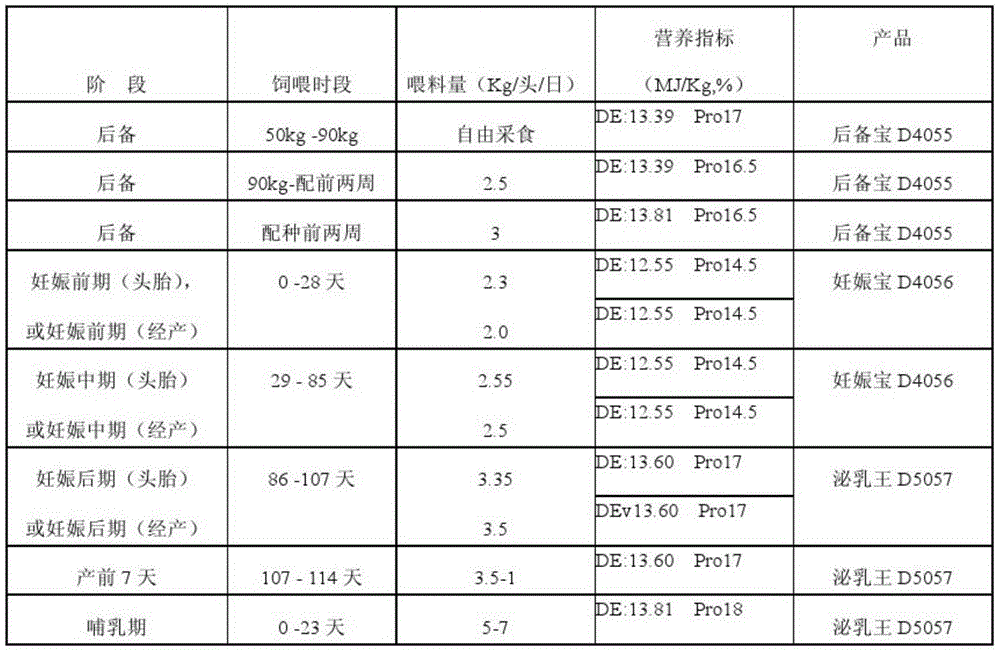

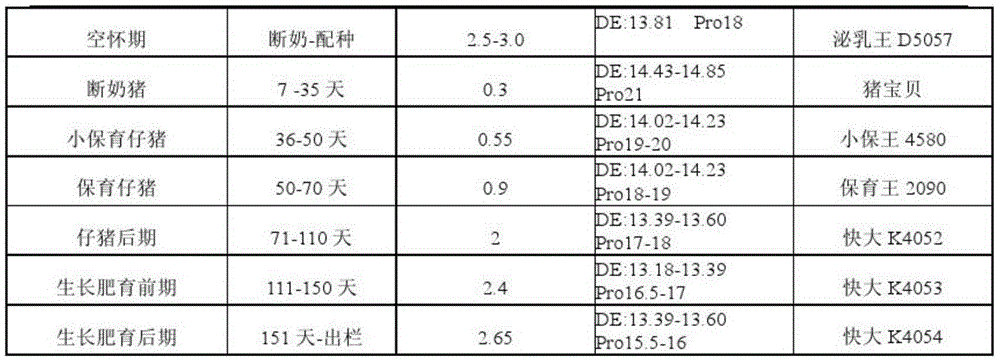

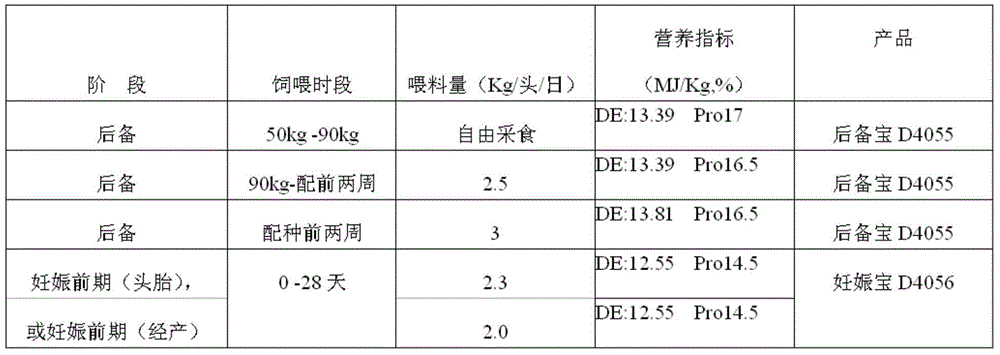

Systematic nutrition scheme for sow to increase number of market commercial pigs each year

InactiveCN104521891APromote productivityIncrease the number of commercial pigs on the market each yearAnimal feeding stuffPig farmsGut immunity

The invention relates to feed set meals for pigs in different physiological stages, and discloses a systematic nutrition scheme for sows to increase the number of market commercial pigs each year, and the benefits of pig farms are improved accordingly. The systematic nutrition scheme comprises a sow fecundity N+ series product, a piglet higher survival rate 7030 scheme, a pig growing and fattening more-profit making V+ series product and matched feeding patterns. According to the sow fecundity N+ series product, healthy reproduction of boars can be guaranteed by providing enough maintenance, growth, reproduction and immunization nutrition. According to the piglet higher survival rate 7030 scheme, the nutritional requirements of pig stocks in each production stage are met by taking a 'comprehensive nutrients + high and balance nutritional levels + high-quality nutrient sources ' scheme into account, the digestive absorption capacity and the intestinal immunity of the pig stocks are improved by guaranteeing the gastrointestinal tract health, and the self immunity of the pig stocks is reinforced by guaranteeing production nutrition and paying close attention to immune nutrition and stress nutrition. The pig growing and fattening more-profit making V+ series product is prepared according to different nutritional requirements of the pigs in different growth and development stages, and the obtained commercial pigs grow fast, low in feed ration and good in meat quality.

Owner:上海新邦生物科技有限公司

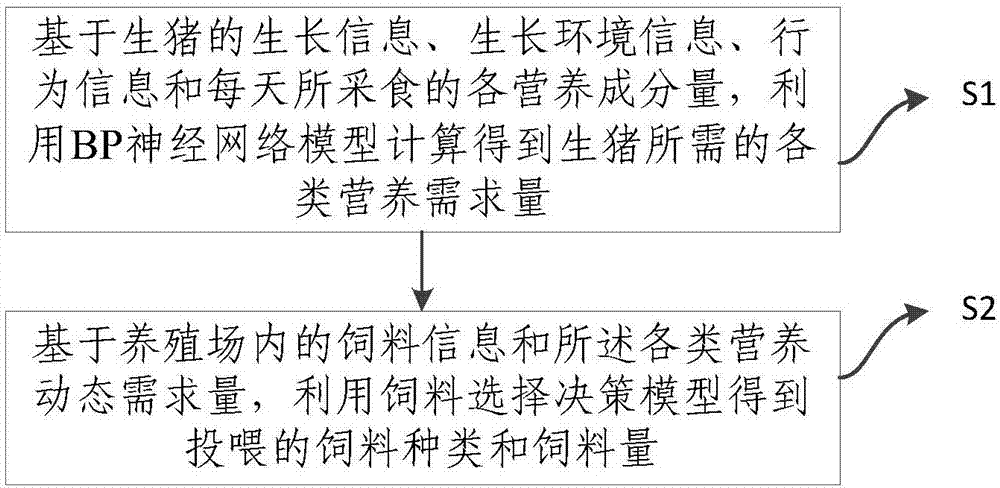

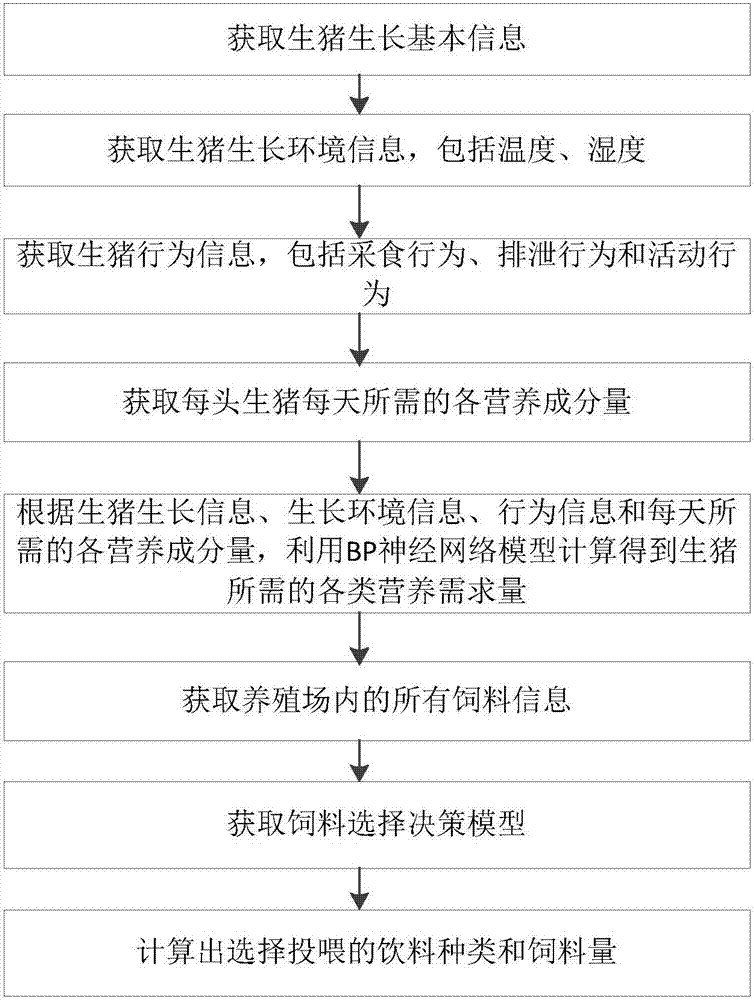

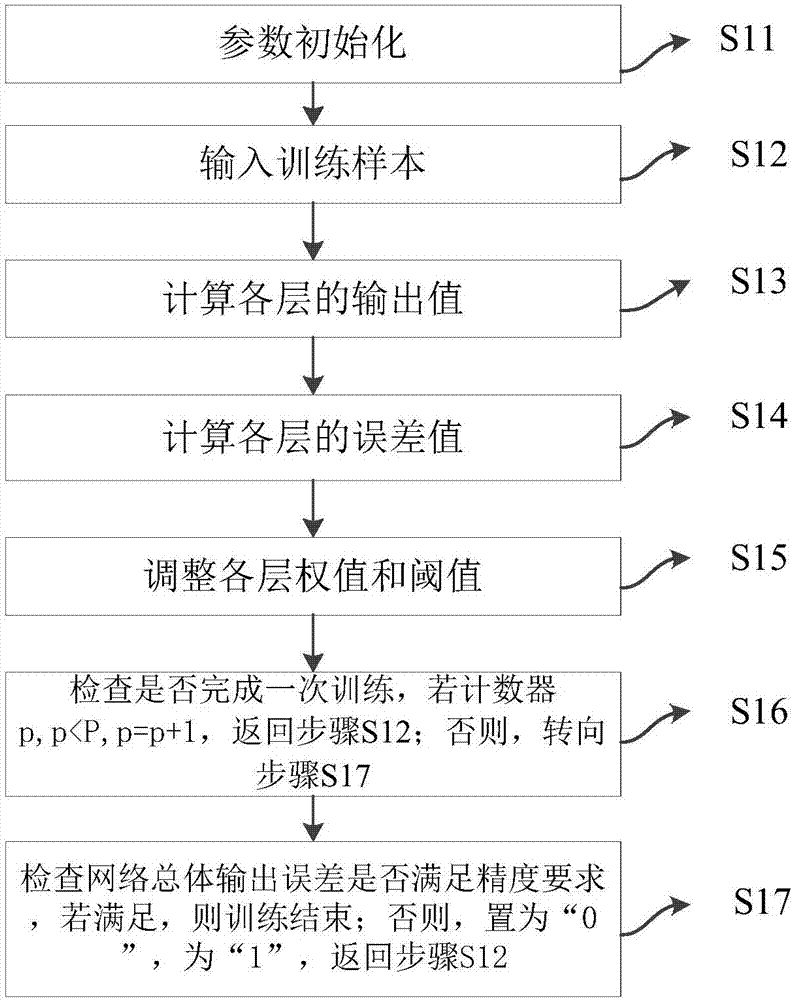

Live pig cultivation multivariable forage feeding decision-making method and system

InactiveCN106875034AImprove conversion rateReduce feeding costsForecastingNeural learning methodsNutrientNutrition

The invention provides a live pig cultivation multivariable forage feeding decision-making method and system. The feeding decision-making method includes S1 calculating the nutrition demand needed by live pigs by means of a BP nerve network model according to the growth information, the growth environment information, the behavior information, and the eating nutrient composition mount every day of the live pigs; and S2 obtaining the feeding forage kind and forage amount by means of a forage selection decision-making model according to the forage information in a culturing farm and the dynamic demand on the various nutrients. According to the live pig cultivation multivariable forage feeding decision-making method and system, the forage meeting the nutrition demand with the lowest cost can be comprehensively and dynamically selected according to the growth information, the cultivation environment information, and the behavior information of the live pigs at different growth stages, the multivariable accurate forage feeding can be realized, and on the premise of ensuring that the growth of live pigs reaches the standard, reasonable feeding is carried out, the forage utilization rate is improved, the cultivation cost is reduced, and the ecological environment pollution is reduced.

Owner:CHINA AGRI UNIV

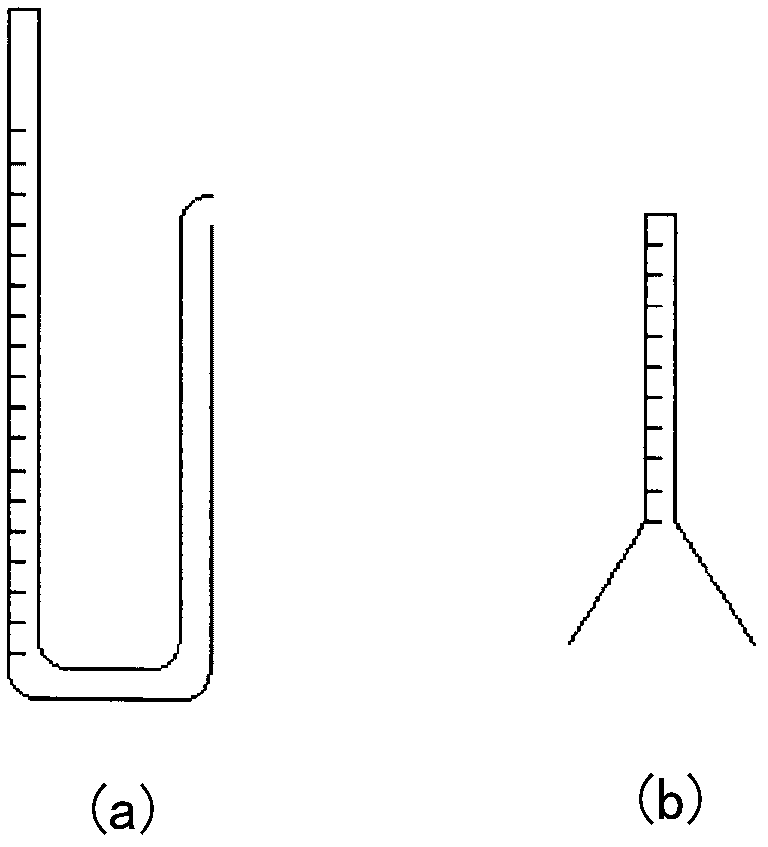

Bee toxicology experiment contamination automatic feeding device and application thereof

ActiveCN102524113ASimple structureReduced piping structureApicultureCommunicating vesselsEngineering

The invention relates to a bee toxicology experiment contamination automatic feeding device, which is mainly and structurally characterized by comprising a graduated U-shaped pipe, wherein an end opening of one side of the U-shaped pipe is connected with a sealed liquid storage device, an end opening of one side of the U-shaped pipe not connected with the liquid storage device is higher than an interface of the liquid storage device, the bottom of the liquid storage device is connected with a plurality of feeding devices through pipelines for forming a communication device, feeding openings of the feeding devices respectively and upwards penetrate into corresponding bee boxes, and the total area of the liquid level in the feeding openings is identical to the area of the liquid level of one side of the U-shaped pipe not connected with the liquid storage device. The bee toxicology experiment contamination automatic feeding device overcomes the defects of adverse factors when the traditional large-range bee automatic feeding device is used for bee toxicology experiment operation, and the pipeline structure of the bee automatic feeding device is simplified, so the bee toxicology experiment contamination automatic feeding device is more suitable for small-range bee feeding. Simultaneously, the feeding opening is upward, the communication device principle is utilized for ensuring the liquid level height, and the honey loss caused by the downward pipe opening is avoided. The consumed contaminated honey quantity can be accurately read out through scales on the U-shaped pipe.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

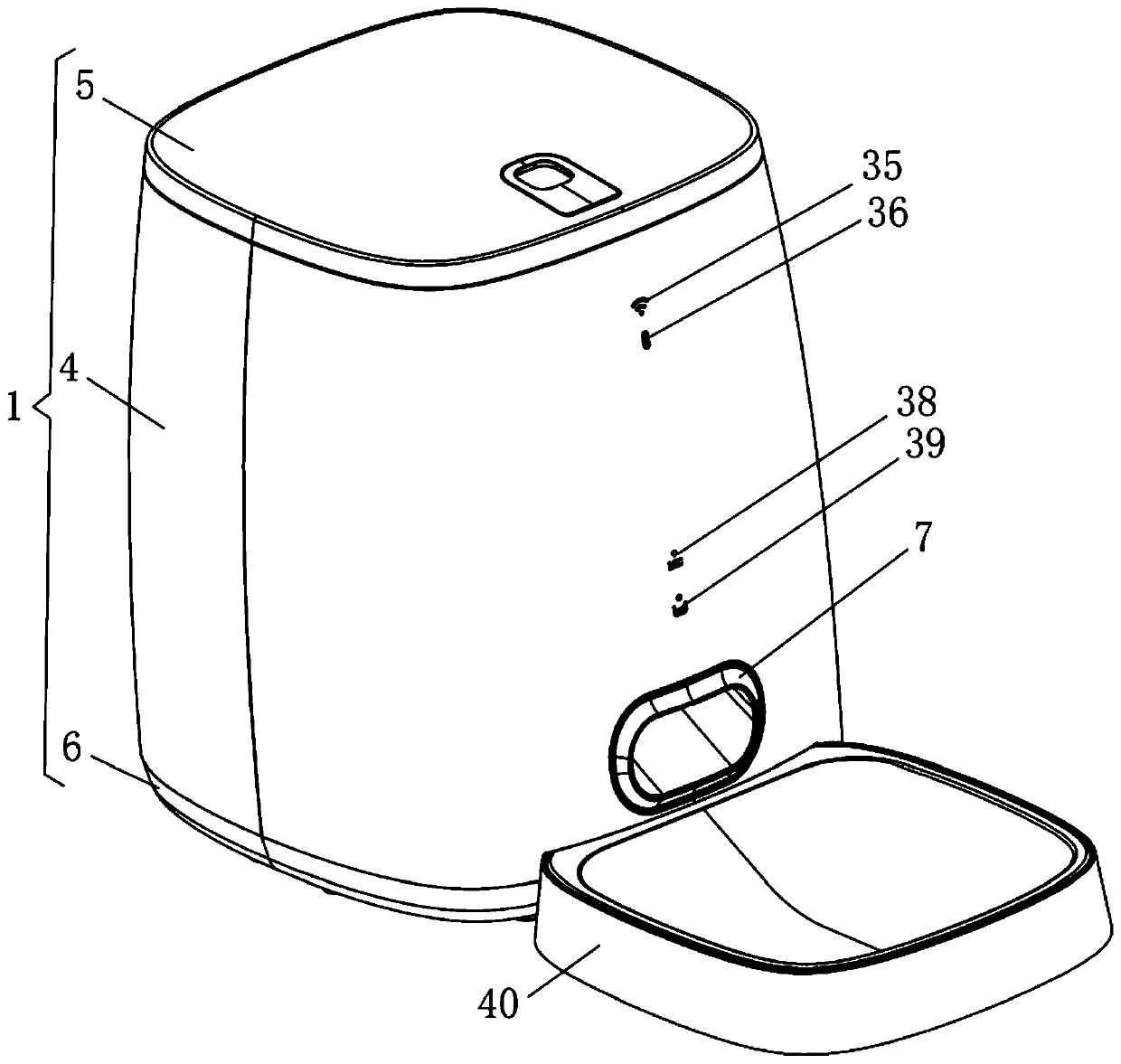

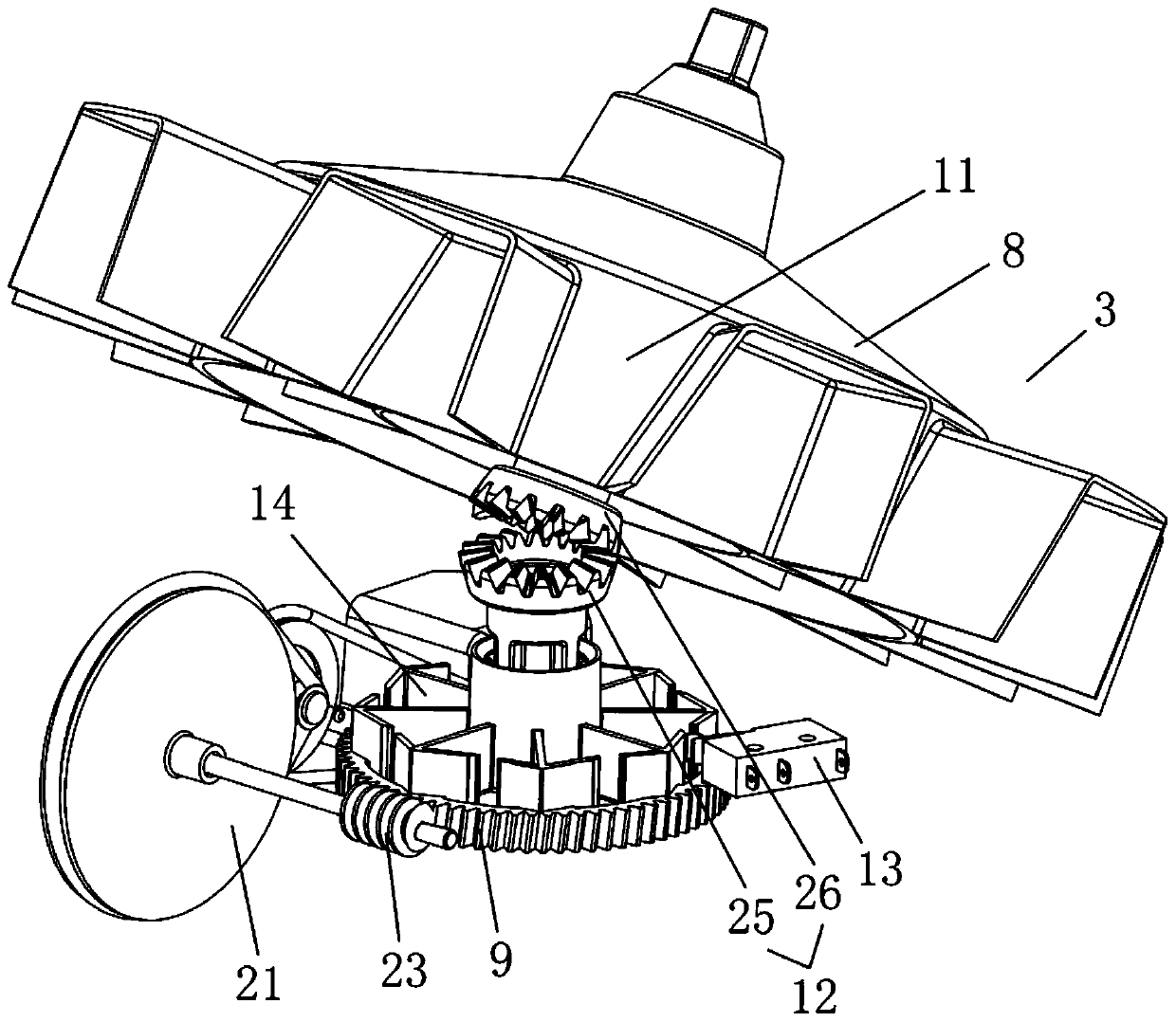

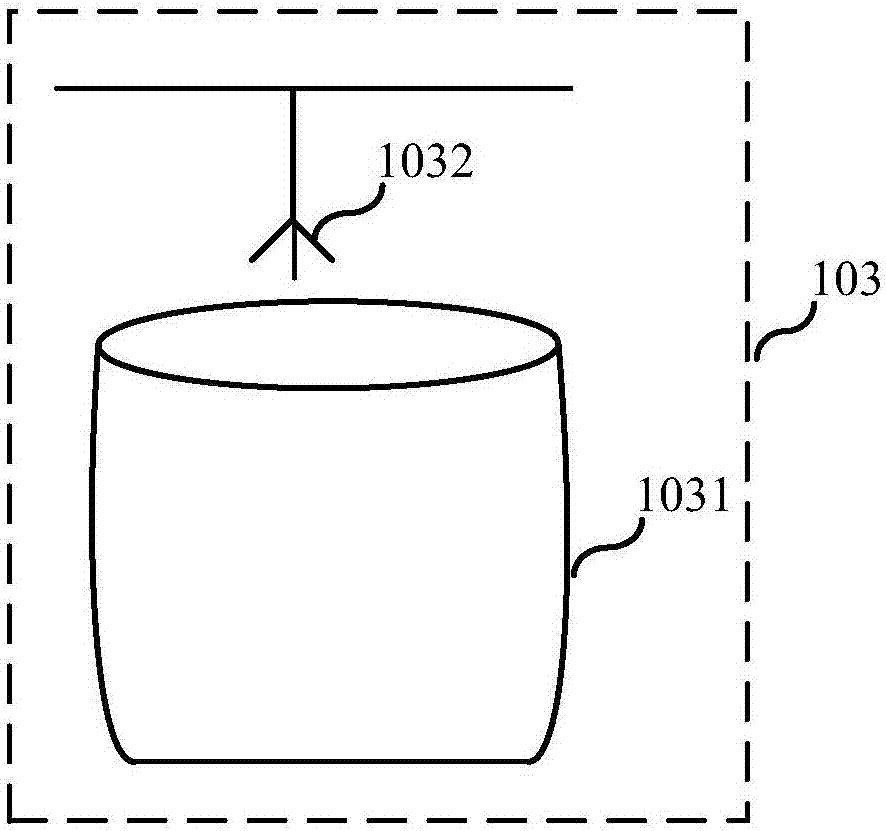

Intelligent pet feeder

InactiveCN111194700AIncrease grain loading capacityCompact internal structureAnimal feeding devicesGearingControl engineeringEngineering

The invention relates to an intelligent pet feeder. The intelligent pet feeder comprises a shell, a material bucket, and a material allocation device; the material allocation device comprises a transmission assembly, and a material allocation rotor; a baffle plate is arranged between the material bucket and the material allocation rotor; the material allocation rotor is rotatably and obliquely arranged at the bottom of the material bucket, and is provided with a plurality of storage tanks which are distributed in intervals; the transmission assembly comprises a control gear; the control gear is provided with touch bumps which are evenly distributed on the surface of the control gear, wherein the number of the touch bumps is the same with the number of the storage tanks, so that feeding control is performed on the material allocation rotor; the transmission assembly comprises dual-pulley mechanism, and a gear mechanism; and the gear mechanism and the material allocation rotor are rotatably connected to each other. The intelligent pet feeder has the following beneficial effects: speed reduction is carried out by adopting dual pulleys; a bevel gear mechanism is driven by the control gear so as to allow the material allocation rotor to deliver a food inside the material bucket to a discharge channel so as to realize feeding; the material allocation rotor adopts an oblique design, so that volume of the material bucket is increased; the baffle plate is adopted so as to achieve anti-dumping effect; and real-time control over the intelligent pet feeder can be realized by APP, so that use of the intelligent pet feeder is facilitated.

Owner:GUANGDONG LIN SHENG INTELLIGENT TECH LTD

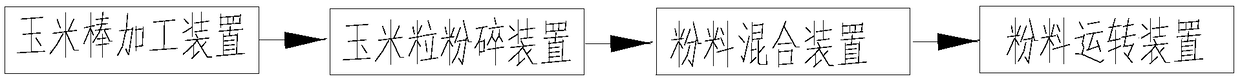

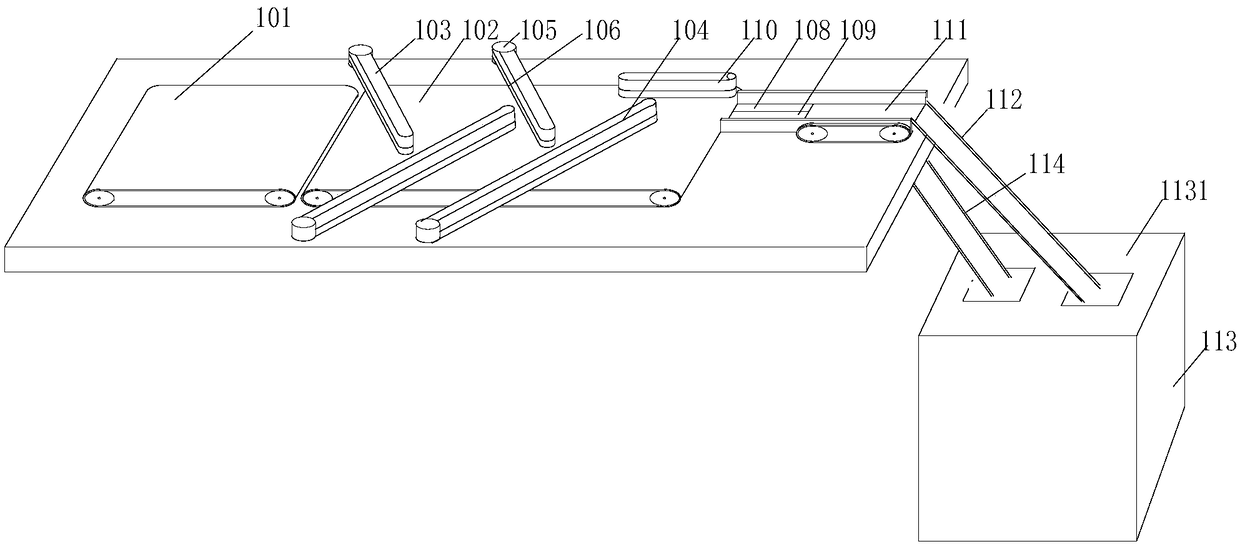

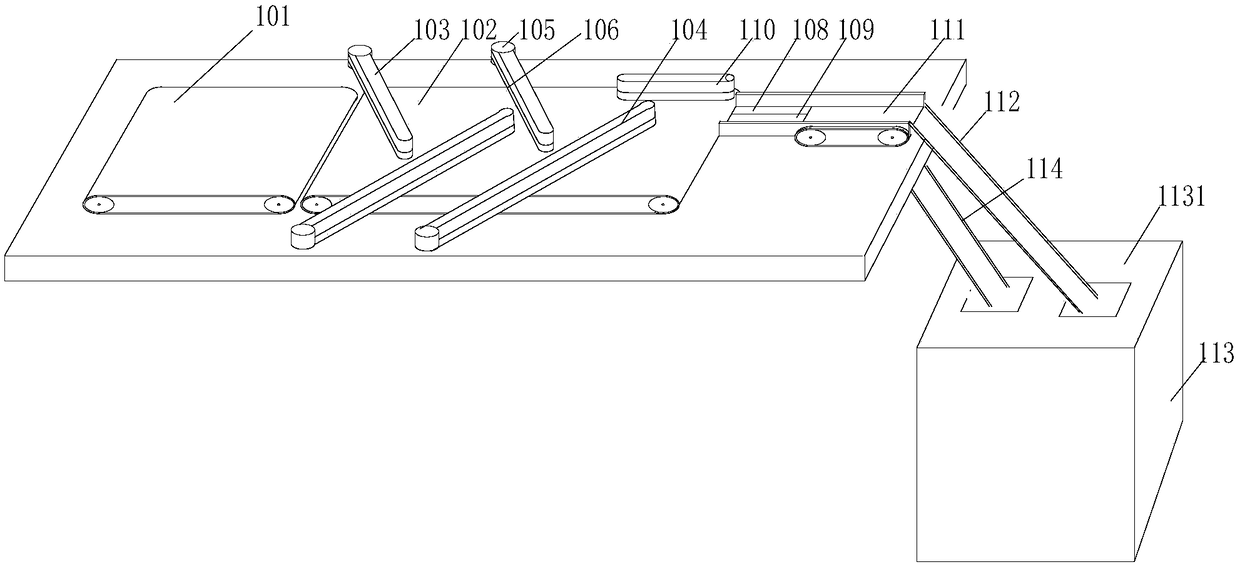

Agricultural machine for producing edible powder

InactiveCN108617277AReduced labor requirementsFree handsTransportation and packagingMixersAgricultural engineeringCorn flour

The invention discloses an agricultural machine for producing edible powder. The agricultural machine sequentially comprises a corn cob processing device, a corn grain crushing device, a powder mixingdevice and a powder operation device according to a process flow. The corn cob processing device comprises a feeding unit and a processing unit. The powder mixing device comprises a material mixing tank body and a material mixing upper cover which covers the material mixing tank body. A first material mixing and sieving plate, a first mixing chamber, a second material mixing and sieving plate, and a crushing / mixing integrated chamber are sequentially arranged in the cavity of the mixing tank body from top to bottom. The powder operation device comprises an operation conveying belt, a turnoverdischarging device, an operation baffle, a conveying hopper, an operation elastic device and an operation lifting base table. The agricultural machine provided by the invention has the advantages that the processing efficiency of corn cobs is improved, the quality of the produced corn flour is ensured, the mixing effect of the corn flour and the flour is good, the corn flour and the flour do notcake easily, blocking does not occur easily, the working continuity is strong, the feeding amount of a single time is accurate, and the working efficiency is high.

Owner:芜湖拓云农业技术有限公司

Corn flour quantitative transportation device

InactiveCN108622640AImprove processing efficiencyHigh economic added valueThreshersConveyor partsMaterial transferEngineering

The invention relates to a corn flour quantitative transportation device. The device successively comprises a corn cob processing device, a niblet crushing device, a powder material mixing device anda powder material transfer device from front to back according to a process flow, wherein the corn cob processing device comprises a feeding unit and a processing unit; the powder material transfer device comprises a transfer conveyor belt, and an overturning unloading device, a transfer baffle plate, a conveyer bucket, a transfer elastic device and a transfer lifting base station which are successively arranged from front to back. The corn flour quantitative transportation device provided by the invention has the advantages of improving the processing efficiency of corn cobs, increasing the economical additional value of the corn cobs and guaranteeing the quality of produced corn flour, and being high in working continuity, precise in single feeding amount and high in work efficiency.

Owner:芜湖拓云农业技术有限公司

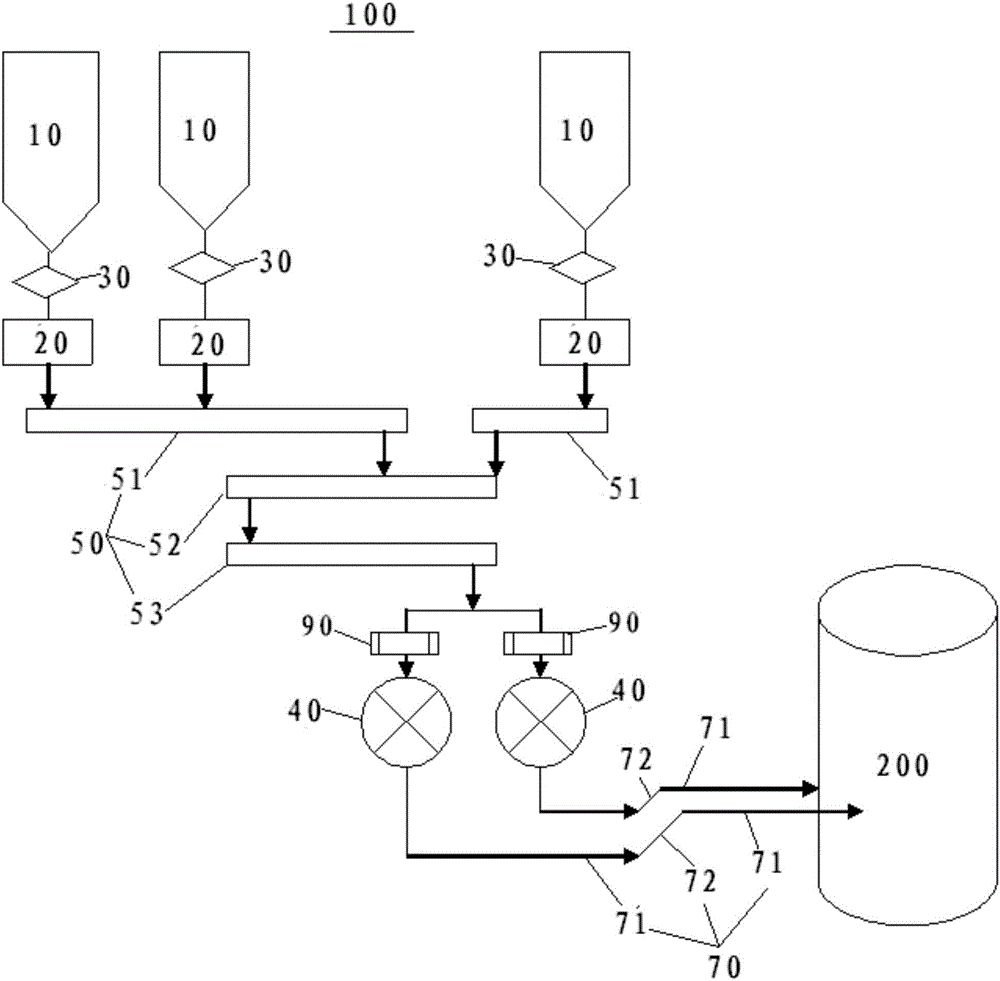

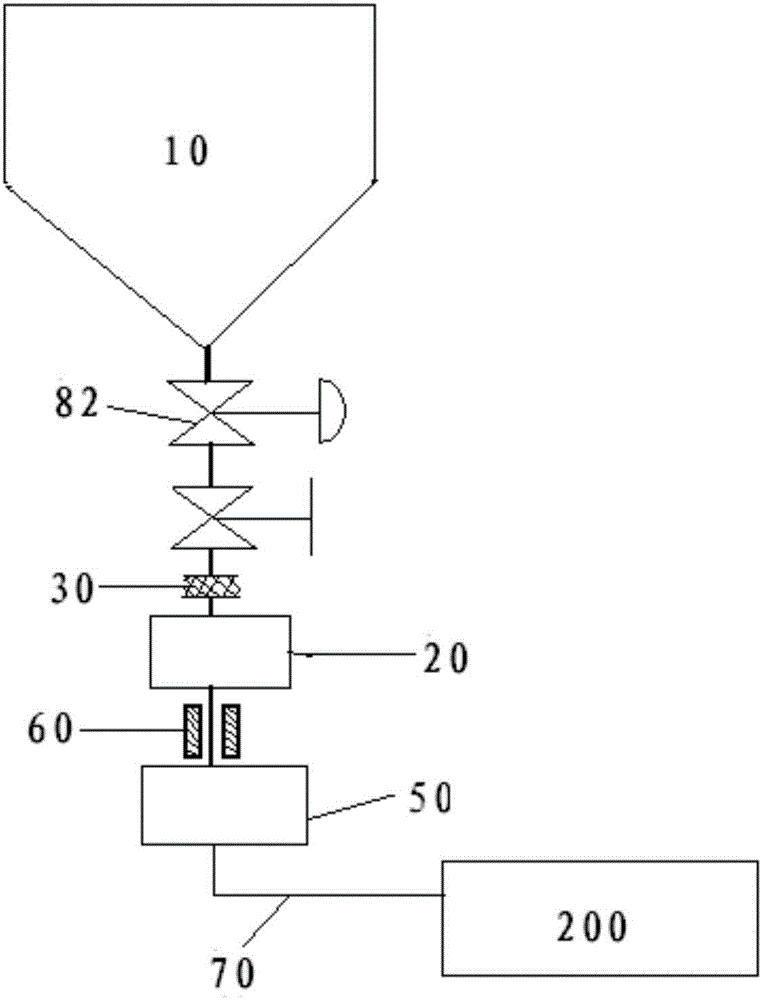

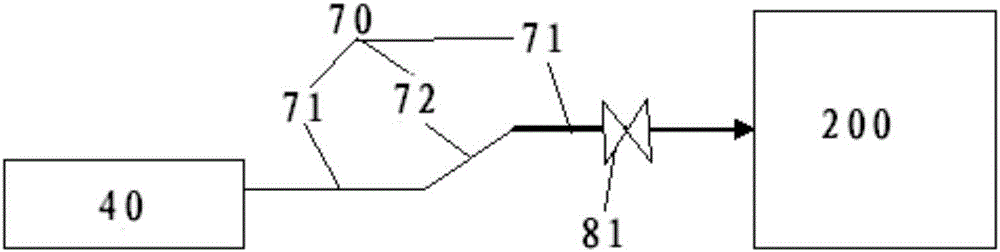

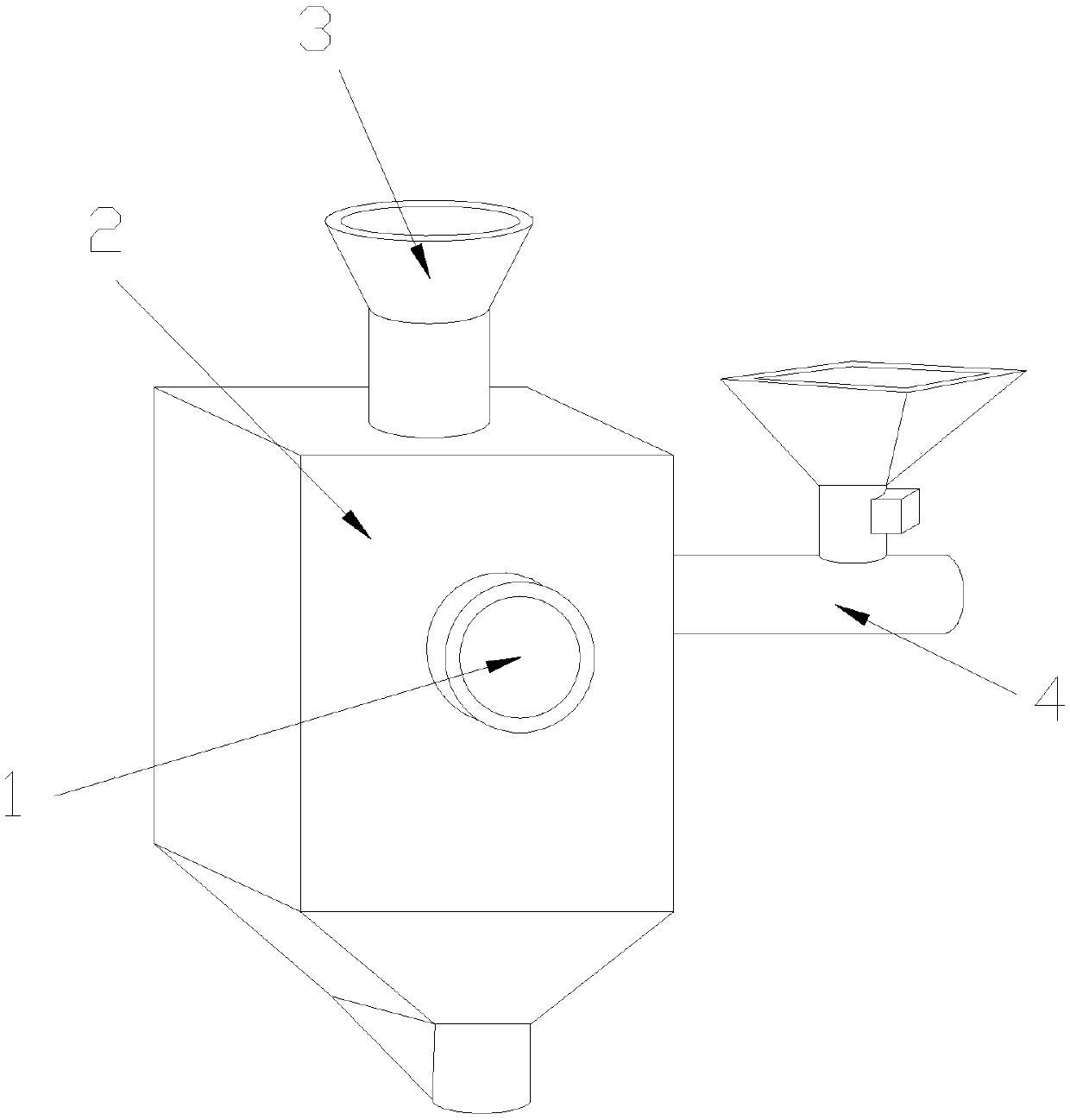

Feeding device for boiling chlorination furnace for producing titanium dioxide by chlorination

InactiveCN106082316ASmooth and continuous feedingImprove boilingTitanium tetrachlorideTitanium dioxideContinuous operationTitanium dioxide

The invention discloses a feeding device for a boiling chlorination furnace for producing titanium dioxide by chlorination. The feeding device comprises three feed bins, three weighing machines, three screens, a conveyor and a mixing spiral machine, wherein the three weighing machines are respectively and correspondingly connected with three feed bins by feeding pipelines; each screen is arranged in the corresponding feeding pipeline and is positioned between the corresponding weighing machine and the corresponding feed bin; each feeding pipeline is provided with an operation opening which is close to the corresponding screen and can be opened and closed; an outlet of the conveyor is communicated with the boiling chlorination furnace; the mixing spiral machine is arranged between the weighing machines and an inlet of the conveyor. According to the feeding device for the boiling chlorination furnace for producing the titanium dioxide by chlorination, which is disclosed by the embodiment of the invention, the feeding quantity is accurate, materials are uniform to mix, and the materials are smooth and continuous to feed, so that the stable and continuous operation of the feeding device is ensured, product quality is improved, and a boiling state of the boiling chlorination furnace is improved; meanwhile, the filtered materials are more uniformly mixed in the mixing spiral machine, so that layering of the materials entering the boiling chlorination furnace is avoided.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

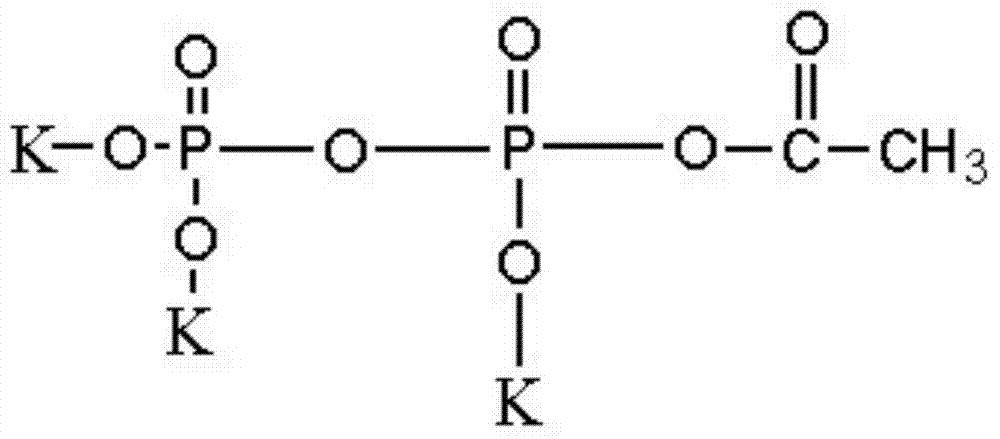

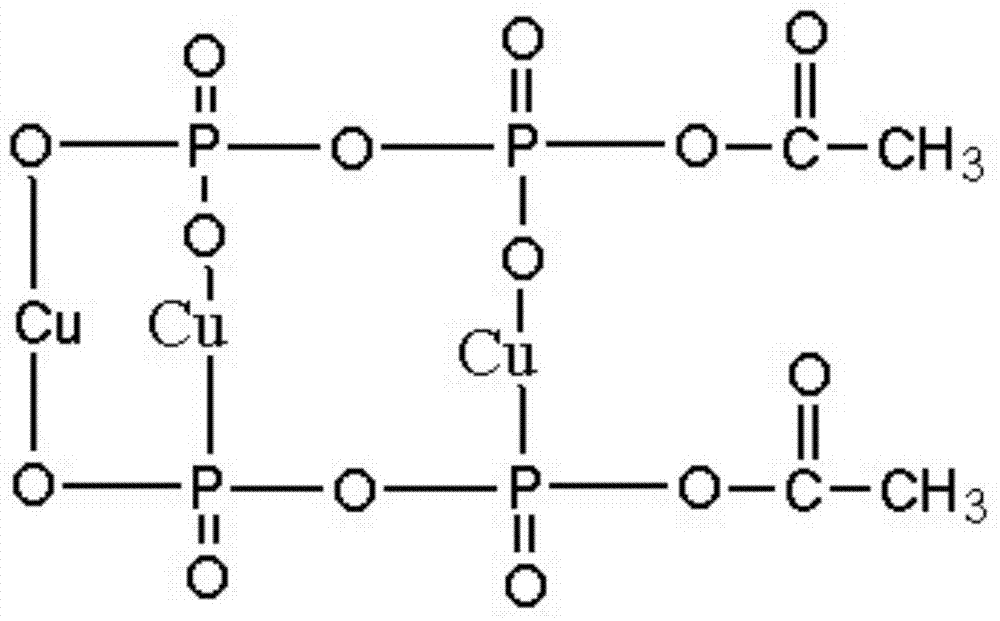

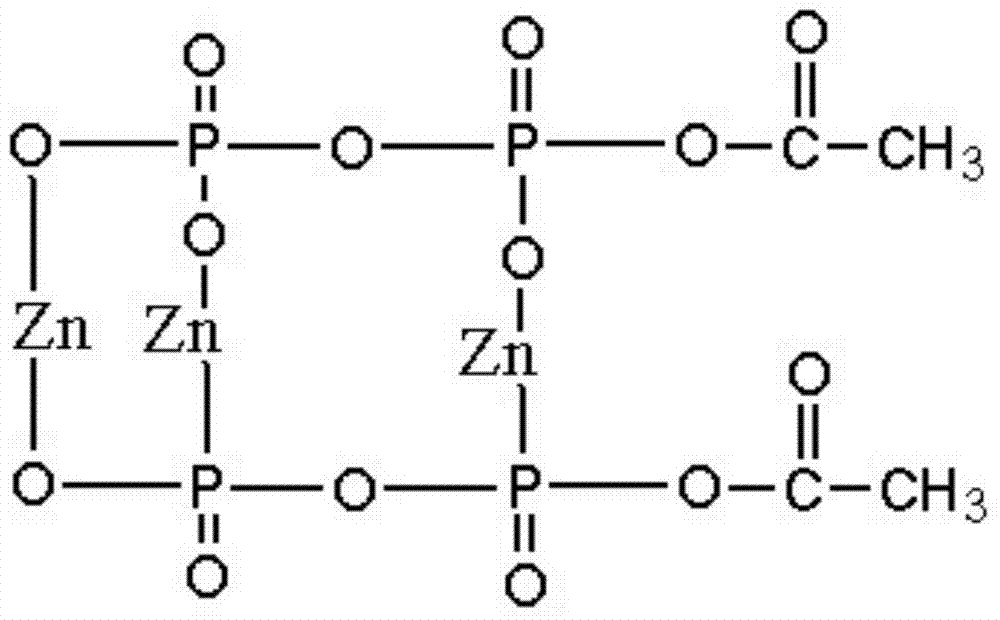

Cyanide-free copper-zinc alloy electroplating solution and preparation method thereof

The invention relates to a cyanide-free copper-zinc alloy electroplating solution and a preparation method thereof. The electroplating solution consists of the following components in percentage by weight: 1-60 percent of complexing agent, 0.3-10 percent of copper salt, 0.2-10 percent of zinc salt and the balance of water, wherein the general formula of the complexing agent is MxHyPnO(3n+1)Rz; M is any one or multiple in alkali metal ions and NH<4+>; R is acyl; the general formula of the copper salt is Cux / 2HyPnO(3n+1)Rz; the general formula of the zinc salt is Znx / 2HyPnO(3n+1)Rz; x, n and z are positive integers; y is 0 or a positive integer; x+y+z is equal to n+2. The cyanide-free copper-zinc alloy electroplating solution is prepared by mixing the complexing agent, the copper salt, the zinc salt and water, the complexing capacity of the complexing agent is high, the complexing constant of copper ions can be 10<26-27>, and the complexing agent is far superior to a conventional complexing agent in the prior art. The stability of the electroplating solution prepared from the complexing agent is greatly improved, the quality of the electroplating solution is high, when the cyanide-free electroplating solution is used for pre-plating, main salt metal ions in the electroplating solution are not subjected to a replacement reaction with a metal base material, a loose replacement layer structure is not formed, and the quality of the electroplating layer is greatly improved.

Owner:浙江洽福科技有限公司

Coating preparation process

InactiveCN104530839AReasonable standardImprove standardsUnspecified rubber coatingsPlasticizerPolystyrene

The invention discloses a coating preparation process. The coating preparation process is characterized by comprising the first step of raw material selection, wherein raw materials comprise, by weight, 55% of polystyrene foam, phenolic foam plastic, scrap rubber and nitrocellulose, 20% of industrial alcohol, coal tar, acetone and hydrosolvents, 20% of pigments and fillers and 5% of wetting dispersing agents, defoaming agents, flatting agents and plasticizer auxiliaries; the second step of fusing refining; the third step of pre-refining; the fourth step of dispersing; the fifth step of blending and color mixing; the sixth step of filtering; the seventh step of packaging. The coating preparation process is reasonable and simple, the process flow is greatly shortened, the raw materials of the coating are wide in source and are of a waste recycling type, and production cost is reduced; meanwhile, according to the raw material ratio, coating of different functions is convenient to make and meets the needs of other production processes, material capacity and the ratio are accurate, the deviation is small, product quality is guaranteed, and the enterprise yield is effectively increased.

Owner:GUANGXI UNIV

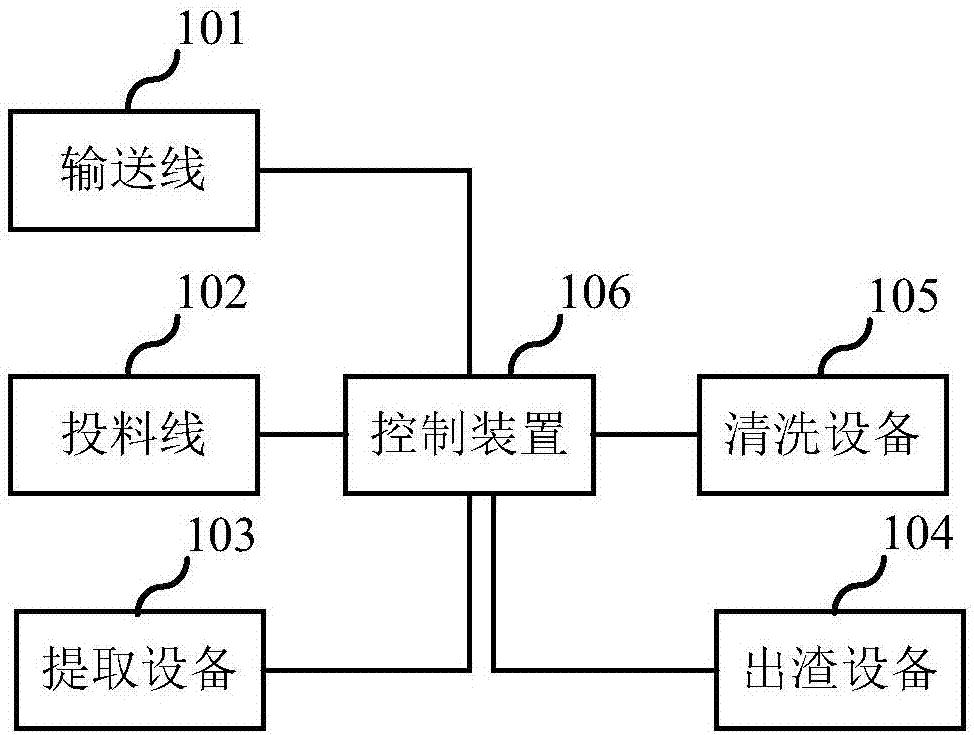

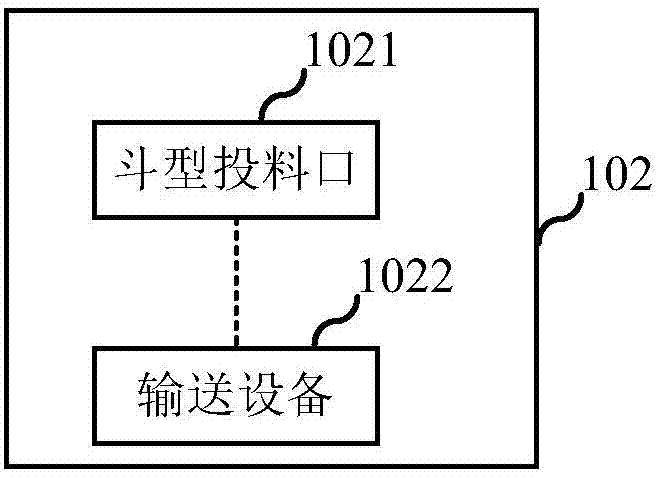

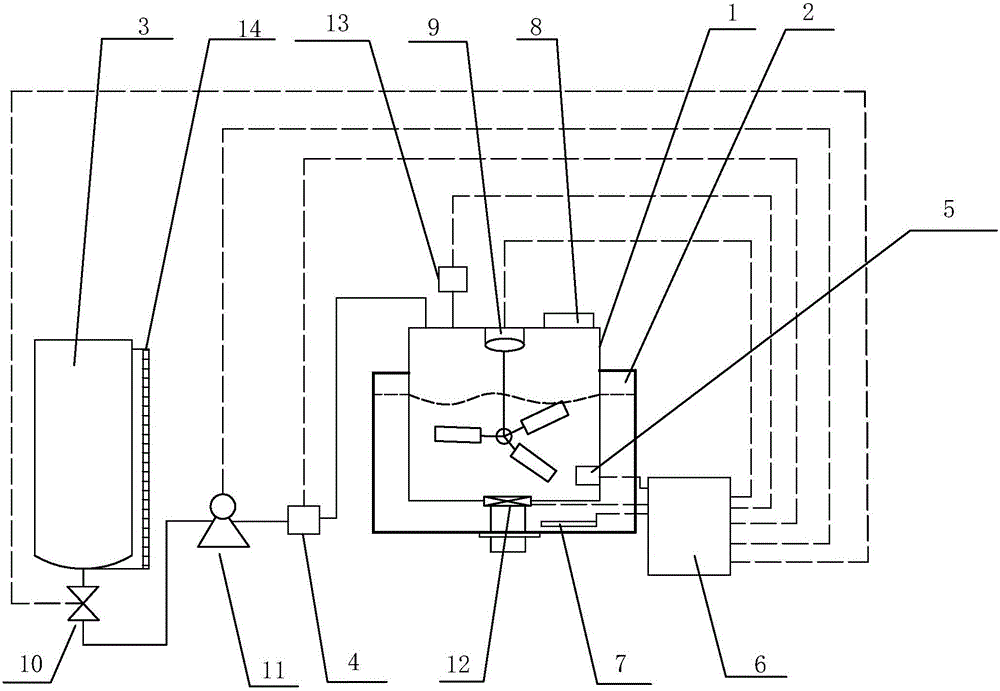

Extraction system

InactiveCN107376403AImprove extraction qualityAccurate feeding amountSolid solvent extractionEngineeringMechanical engineering

The present invention relates to the field of extraction, and discloses an extraction system, which comprises a conveying line, a feeding line, an extraction device, a residue discharging device, a washing device and a control device, wherein the control device is respectively connected to the conveying line, the feeding line, the extraction device, the residue discharging device and the washing device. The extraction system of the present invention achieves the automated extraction of the material so as to improve the material extraction efficiency and the material extraction quality, and accurately collect the production data.

Owner:SHANGHAI BANWI INFORMATION TECH

Zinc wire feeding device

The invention provides a zinc wire feeding device, which comprises a zinc wire supply mechanism, a fixing panel, a wire feeding mechanism, a zinc wire guide wheel, a zinc wire directional wheel and a zinc wire feeding sleeve. The zinc wire supply mechanism, the fixing panel and the zinc wire feeding sleeve are sequentially arranged. The wire feeding mechanism, the zinc wire guide wheel and the zinc wire directional wheel are sequentially fixed on the fixing panel. A first inert gas inlet pipe and a second inert gas inlet pipe are connected on the zinc wire feeding sleeve. By controlling rotation speed of a servo motor or an asynchronous motor, accurate feeding amount of zinc in unit time is guaranteed, and by adopting inert gases and the feeding sleeve for protection, outside air can be effectively prevented from entering a reactor of preparing polycrystalline silicon with the method of zinc reduction. The zinc wire feeding device is simple in structure, low in energy consumption, high in device stability, easy to operate and convenient to maintain.

Owner:上海太阳能工程技术研究中心有限公司

High-strength TBM center cutter box and preparation method

ActiveCN111119915AAvoid Weld CrackingAvoid large welding deformationFurnace typesTunnelsTemperingStructural engineering

The invention provides a high-strength TBM center cutter box and a preparation method. The center cutter box comprises an outer cutter box and an inner cutter box, wherein the outer cutter box is madeof a structural steel material; the inner cutter box is made of a low-carbon medium-alloy structural steel material; and the inner cutter box and the outer cutter box are combined through welding. The center cutter box provided by the invention has the beneficial effects that the inner cutter box is treated with tempering and hardening, connection is realized in a firm of welding of the inner andouter cutter boxes, the inner and outer cutter boxes are formed by a forging technology, and the inner cutter box is made of low-carbon medium-alloy structural steel, so welding stress centralization, cracking and deformation of the inner and outer cutter boxes are reduced; through surface hardening of the inner cutter box, strength and fatigue performance of bearing parts can be enhanced; and through de-stress annealing of the inner and outer cutter boxes, distribution of residual stress during forging formation and welding stress centralization points of the inner and outer cutter boxes canbe reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

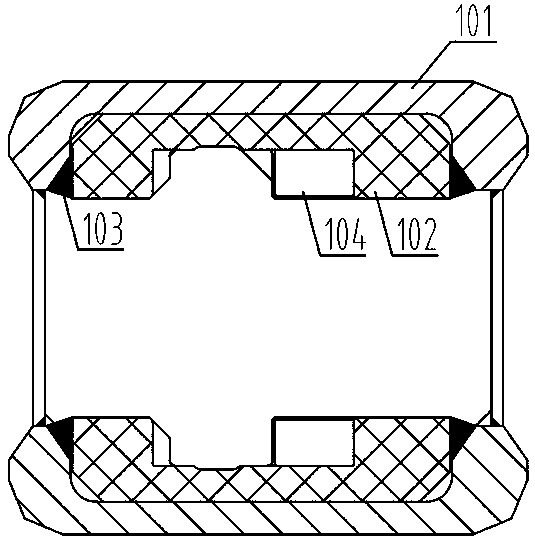

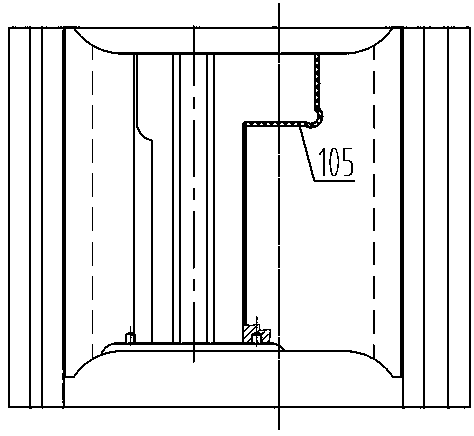

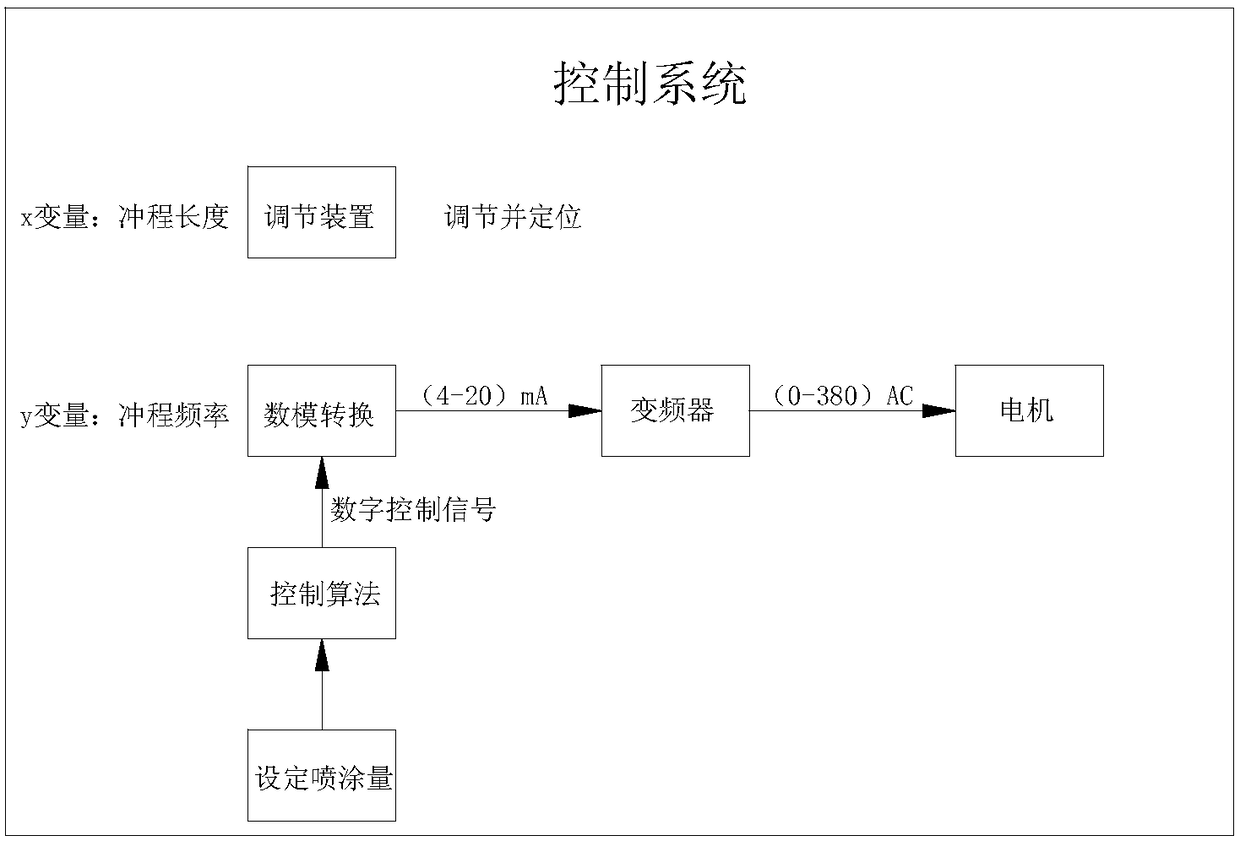

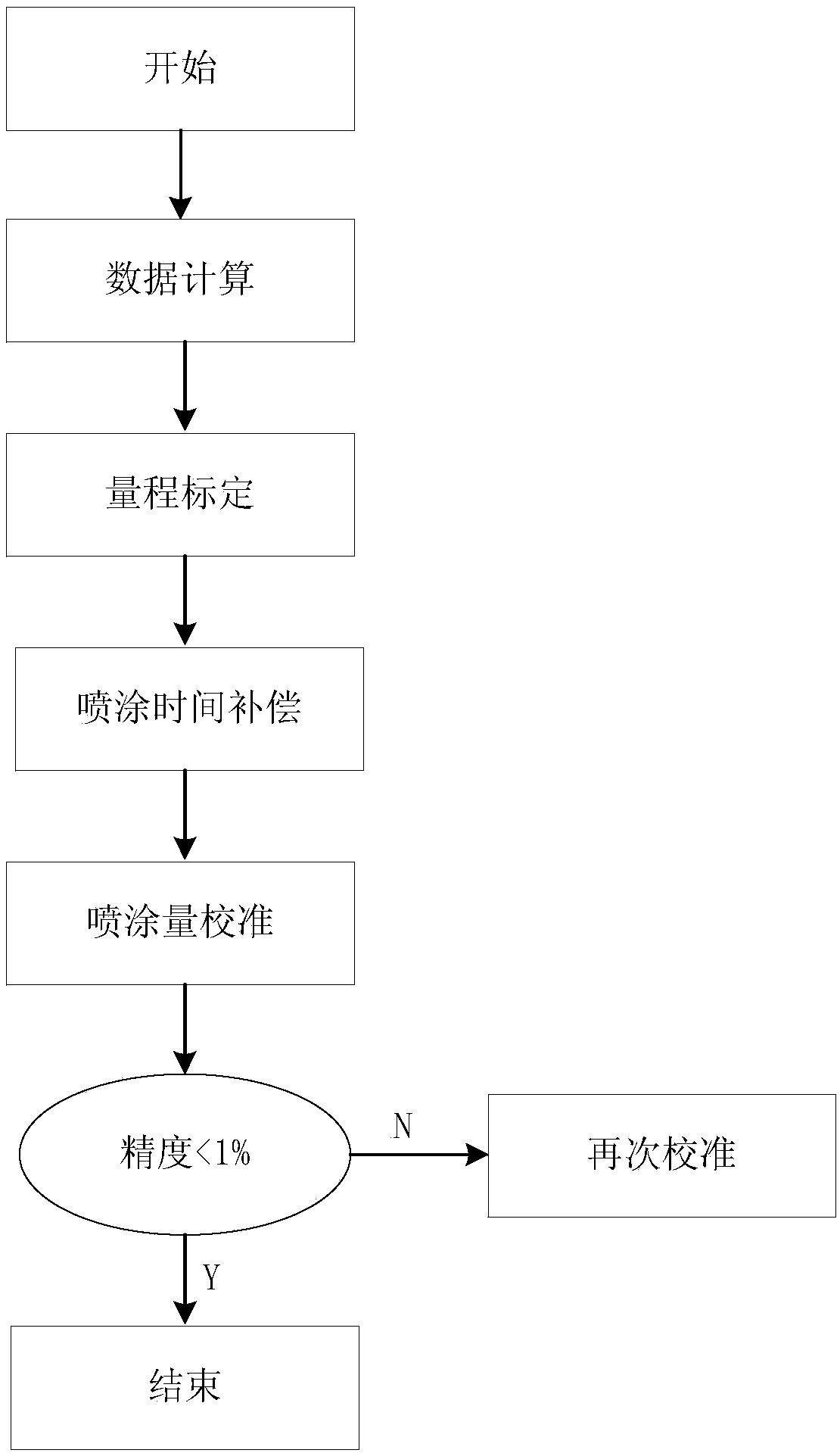

Automatic quantitative spraying control system

ActiveCN108499770AAccurate feeding amountImprove spray qualitySpraying apparatusProgramme control in sequence/logic controllersControl systemComputer module

The invention discloses an automatic quantitative spraying control system. The automatic quantitative spraying control system comprises an adjusting device used for adjusting and positioning of the spraying stroke length, and an electric control system used for controlling the spraying stroke frequency. The electric control system comprises a computer, a PLC, a digital-to-analogue conversion module, a frequency converter and an executing mechanism. The computer is used for setting the spraying amount, the PLC conducts data calculation with the stroke length and the stroke frequency as basic data, then, digital control signals are output, and after the digital-to-analogue conversion module is used for conducting digital-to-analogue conversion, the executing mechanism executes a dischargingamount automatic quantitative spraying instruction through the frequency converter. According to the automatic quantitative spraying control system, the quantitative and accurate feeding amount is automatically provided for the foam structure piece spraying process, the spraying quality and the spraying stability, accuracy and repeatability are improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Printing device

ActiveUS20180099513A1Stably carry-outSimple configurationTypewritersOther printing apparatusMechanical engineeringRecording media

Owner:MIMAKI ENG

Preparing and solidifying device for polymeric aluminum ferric sulfate

InactiveCN104961217ADehydration fastReduce air pressureIron sulfatesWater/sewage treatment by flocculation/precipitationAluminium sulfateBoiling point

The invention discloses a preparing and solidifying device for polymeric aluminum ferric sulfate. The preparing and solidifying device comprises a reaction bin, an oil bath tank, a sulfate acid storage tank, a flow detection device, a temperature detection device and a control box, and the reaction bin is used for storing high-iron bauxite. An upper cover of the reaction bin is connected with a stirring device. The temperature detection device is installed inside the reaction bin. The reaction bin is communicated with a vacuumizing device. A sulfate acid solution outlet is formed in the sulfate acid storage tank and connected into a second material inlet in the reaction bin through a first electromagnetic valve, a pressure pump and a pipeline, and the flow detection device is installed on the pipeline. Feeding operation is easy, safe and environmentally friendly, the feeding amount is accurate, air pressure inside the reaction bin is kept within a low range through continuous heating and vacuumizing, the boiling point of water is lowered through low pressure, then a lot of water in material can be evaporated at low temperature, rapid dehydration can be performed on the polymeric aluminum ferric sulfate until solidifying is achieved, and therefore transportation and storage are convenient.

Owner:开平市开物化工建材有限公司

Automobile tire discharge carrying equipment with function of instantly breaking layers by means of gravitational centrifugation

ActiveCN109569419AReduce the amount of feedAvoid enteringTransportation and packagingMixer accessoriesCentrifugationDual action

The invention discloses automobile tire discharge carrying equipment with a function of instantly breaking layers by means of gravitational centrifugation. The automobile tire discharge carrying equipment structurally comprises an observation window, a feed cushion tank, a feed funnel and a carbon black carrying device. The automobile tire discharge carrying equipment has the advantages that a control pressure plate can be assisted by a positioning telescopic rod to slide in the left-right directions under telescopic actions of an electromagnet, accordingly, the feed quantity of carbon black can be reduced, the carbon black can be prevented from being completely fed into a conveying device at one step, and increase of the conveying pressures of the conveying device can be prevented; a dustcover wraps the electromagnet, and accordingly influence on normal operation for opening and closing the electromagnet due to powdery carbon black adhered onto the electromagnet can be prevented; a movable buckle and pulleys can overcome a spring to downwardly slide close to a slide rail under the double effects of rotating centrifugal force and gravitational force when a conveying rotary rod rotates to the lower side, the movable buckle can be separated from a contact connector, a threaded lug at the leftmost end is in contact with a magnetization contact seat, accordingly, electromagnetismat the left end of the conveying rotary rod can be neutralized, the carbon black is accurate in feed quantity, errors can be reduced, the quality of tires can be improved, and the work efficiency canbe improved.

Owner:象山华民汽车配件有限公司

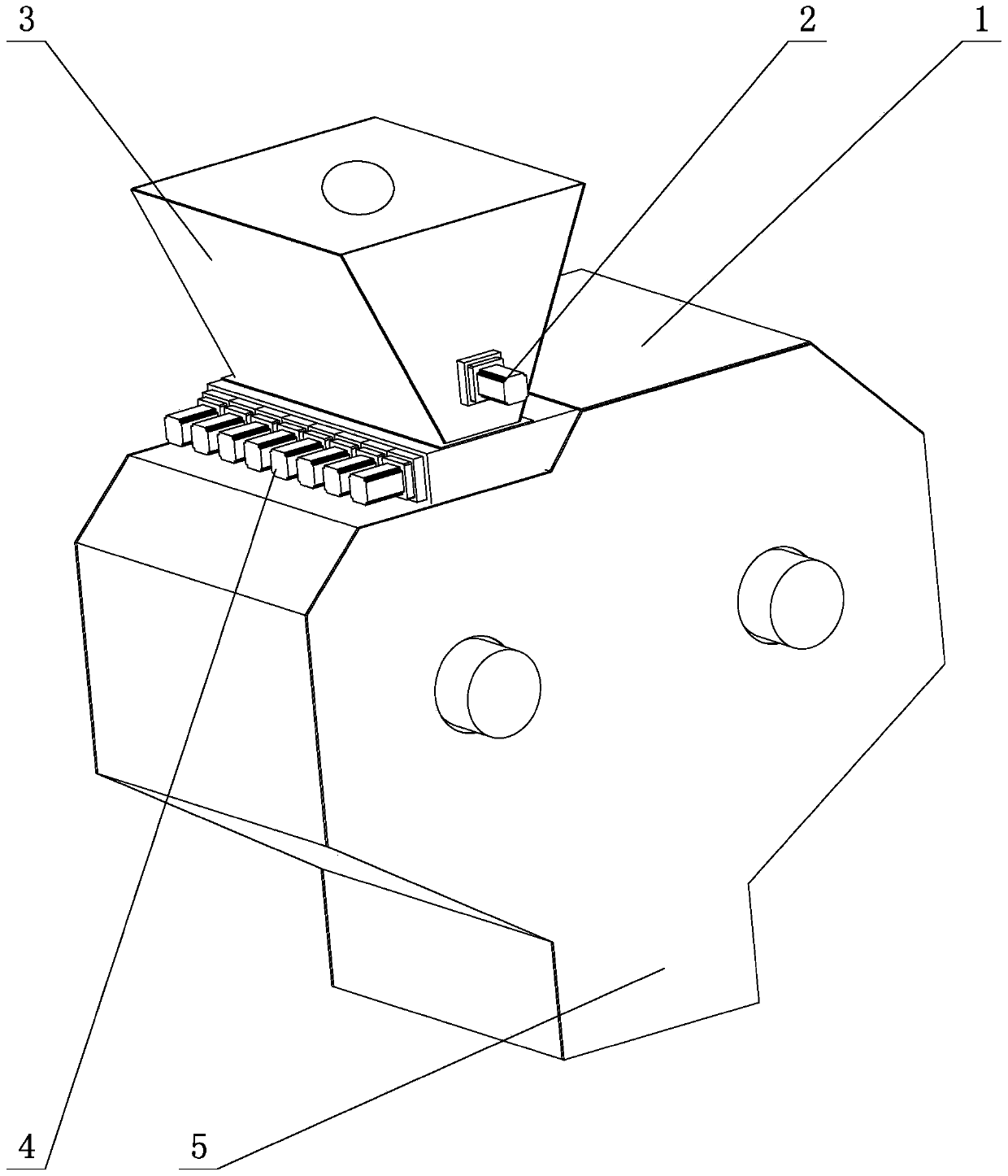

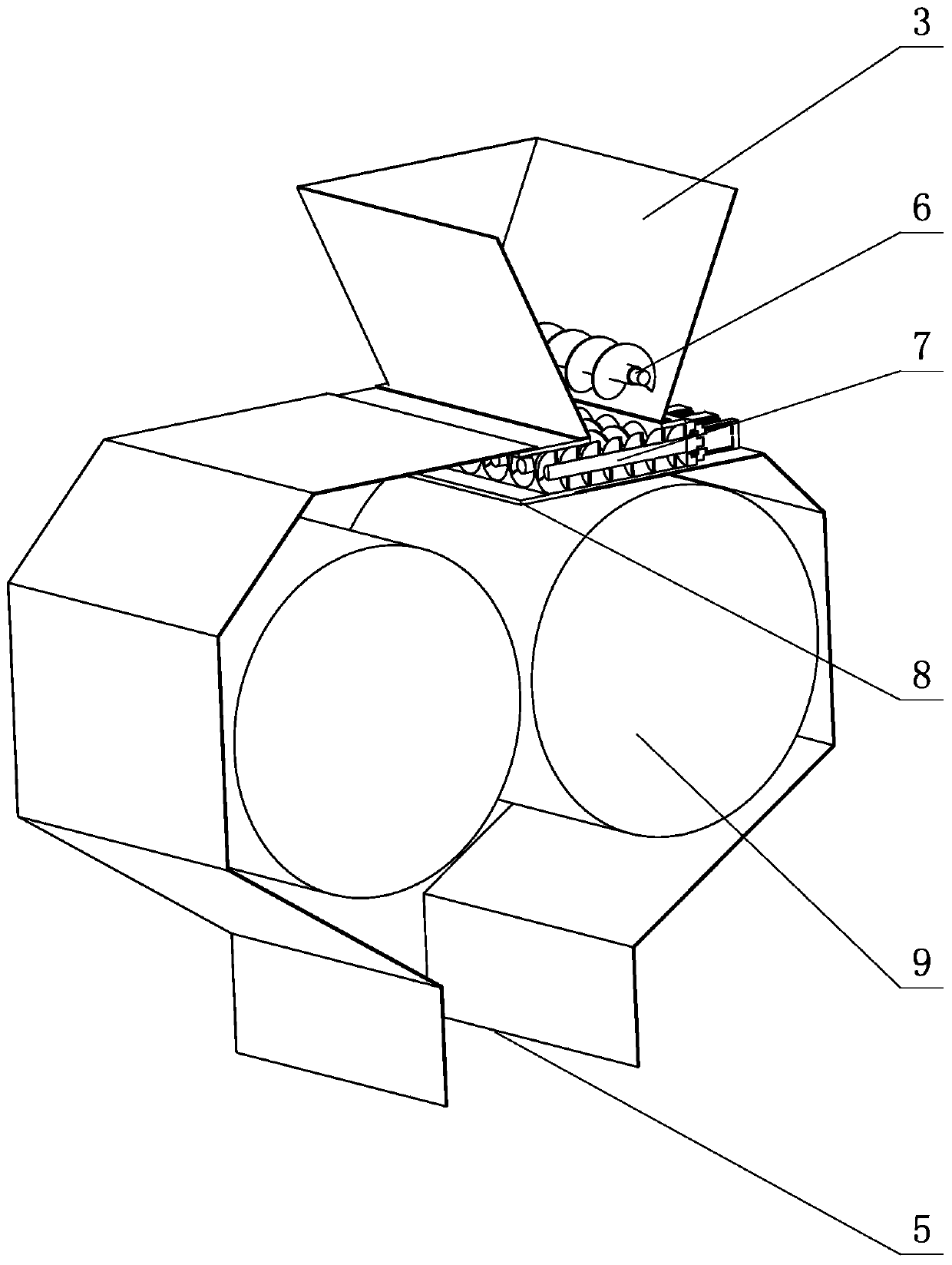

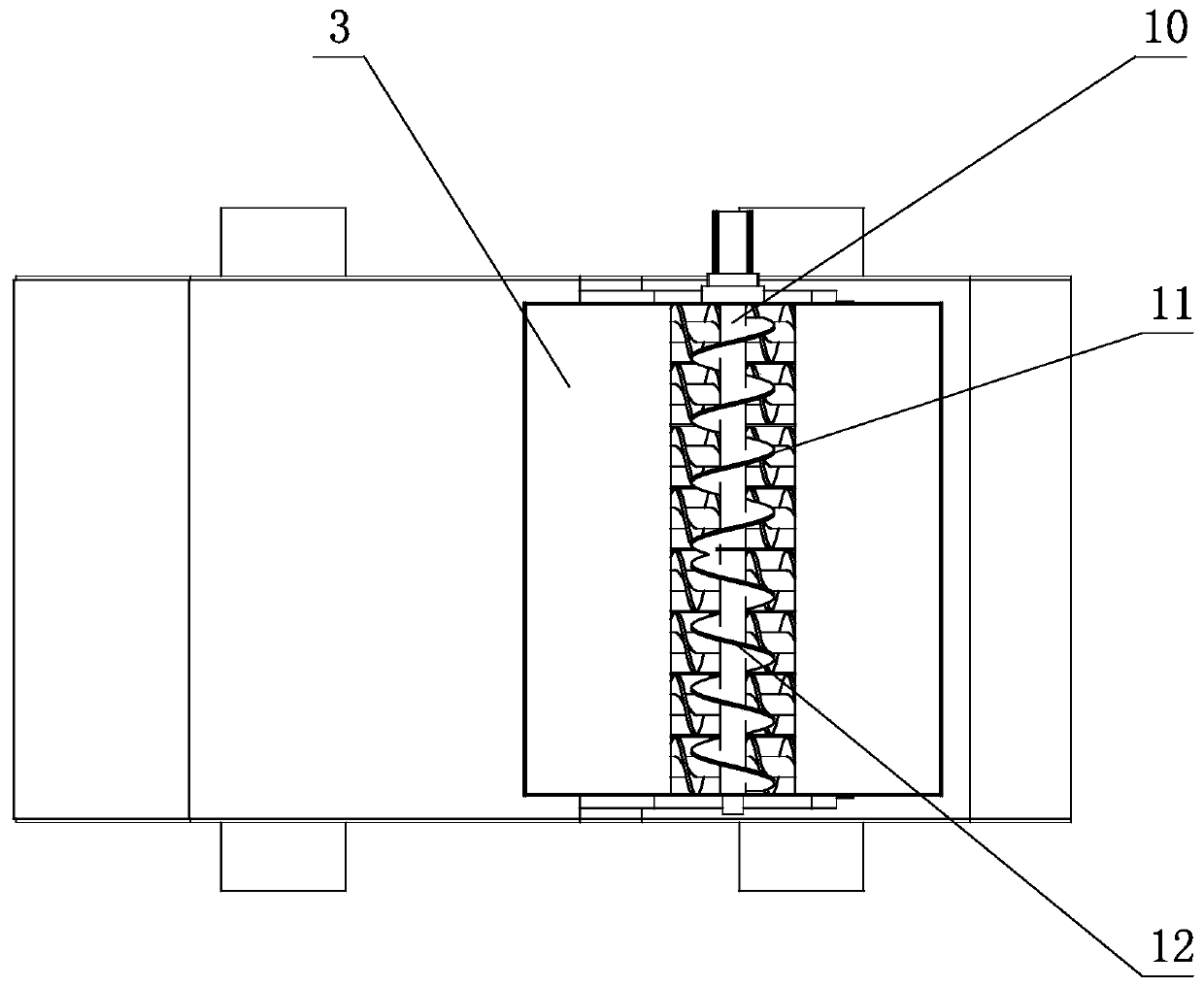

Precision feeding and dustproof distribution double-roller machine

InactiveCN110844634APrevent spillageReasonable structural designGrain treatmentsLoading/unloadingAugerElectric machinery

The invention belongs to the field of feeding double-roller crushing devices, and relates to a precision feeding and dustproof distribution double-roller machine. The machine comprises a pair of crushing rollers. The machine is characterized in that a dustproof cover is arranged at the periphery of the pair of crushing rollers; a discharge port is formed at the bottom of the dustproof cover; a hopper is mounted at the upper part of the dustproof cover, and communicates with the dustproof cover; the length direction of the hopper extends in the axial directions of the crushing rollers; the length of the hopper is matched with the lengths of the crushing rollers; a distribution auger is arranged at the lower part in the hopper; the axis of the distribution auger is parallel to the axes of the crushing rollers; the length of the distribution auger is the same as those of the crushing rollers; and a motor I is arranged at one end of the distribution auger. The machine is reasonable in structural design, and spiral sealing feeding is adopted, so that material dust is capable of being prevented from overflowing, a material is capable of being uniformly conveyed to the gap between the crushing rollers, the situations that the middle parts of the crushing rollers are seriously worn and the service life is shortened can be avoided; the crushing effect can be ensured; the crushing efficiency can also be improved; and the material can be accurately fed by adjusting the rotating speed of the distribution auger.

Owner:GONGLI MACHINE CO LTD

Automatic charging and mixing device for ointment

PendingUS20200306708A1Accurate feeding amountGuaranteed accuracyTransportation and packagingMixer accessoriesElectric machineEngineering

Owner:SHANDONG FANGMING PHARMACY GRP CO LTD

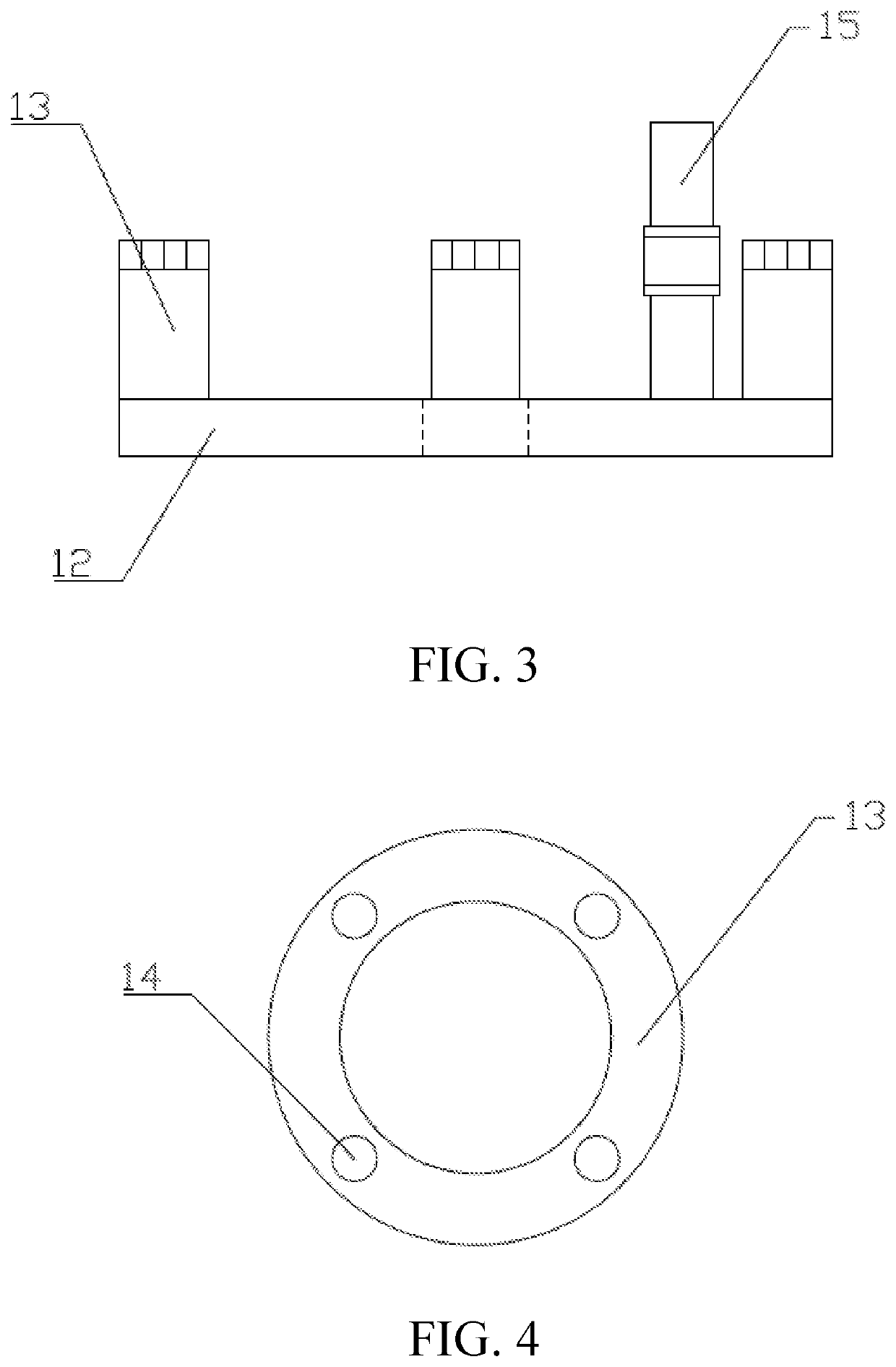

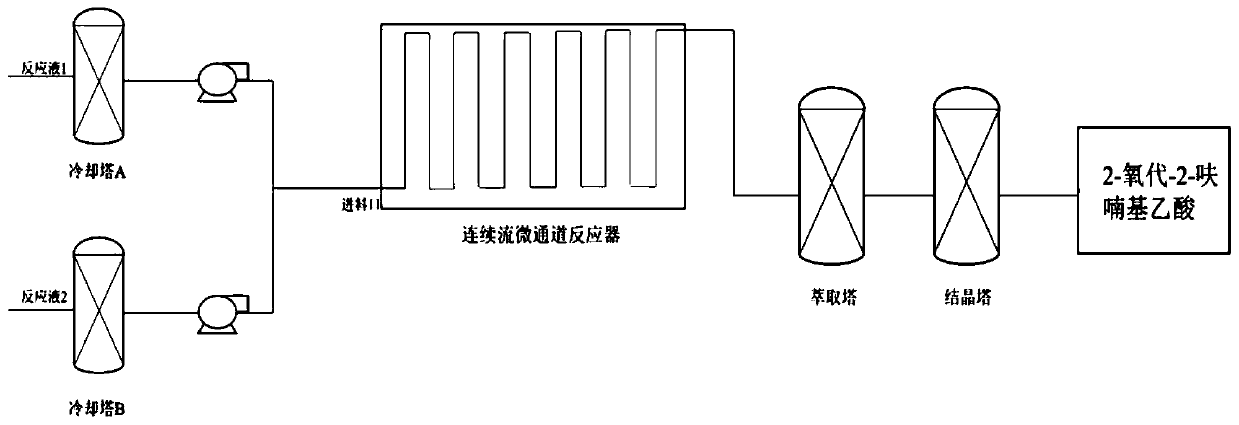

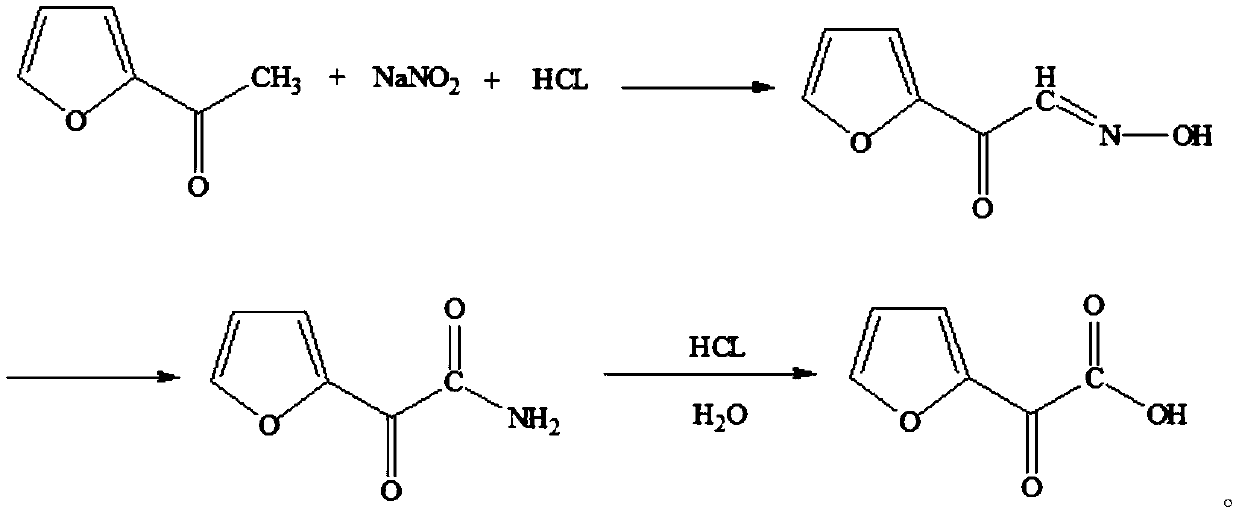

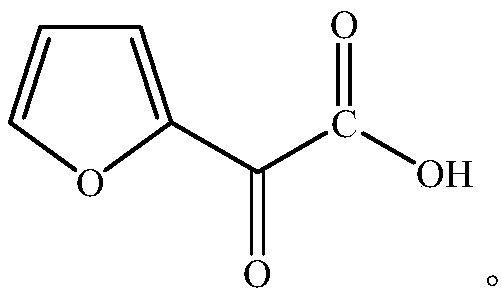

Method for preparing 2-oxo-2-furyl acetic acid by using continuous flow micro-channel reactor

ActiveCN110627754AAchieve serializationShort reaction timeOrganic chemistryChemical/physical/physico-chemical microreactorsAcetic acid2-Acetylfuran

The invention discloses a method for preparing 2-oxo-2-furyl acetic acid by using a continuous flow micro-channel reactor. The method specifically comprises the following steps: respectively pumping anitric acid solution of 2-acetylfuran treated at low temperature and a mixed solution of sodium nitrite and methylbenzenesulfonic acid into a mixed type continuous flow micro-channel reactor by usinga metering pump for reaction, and finally extracting and recrystallizing an obtained reaction solution to obtain a finished product. Compared with the prior art, the method disclosed by the inventionpossesses following advantages: operation is simple, reaction steps are few, methylbenzenesulfonic acid is used as the catalyst, the yield of the finished product is high, no three-waste pollution isgenerated, and continuous large-scale production operation can be realized.

Owner:SOUTHEAST UNIV

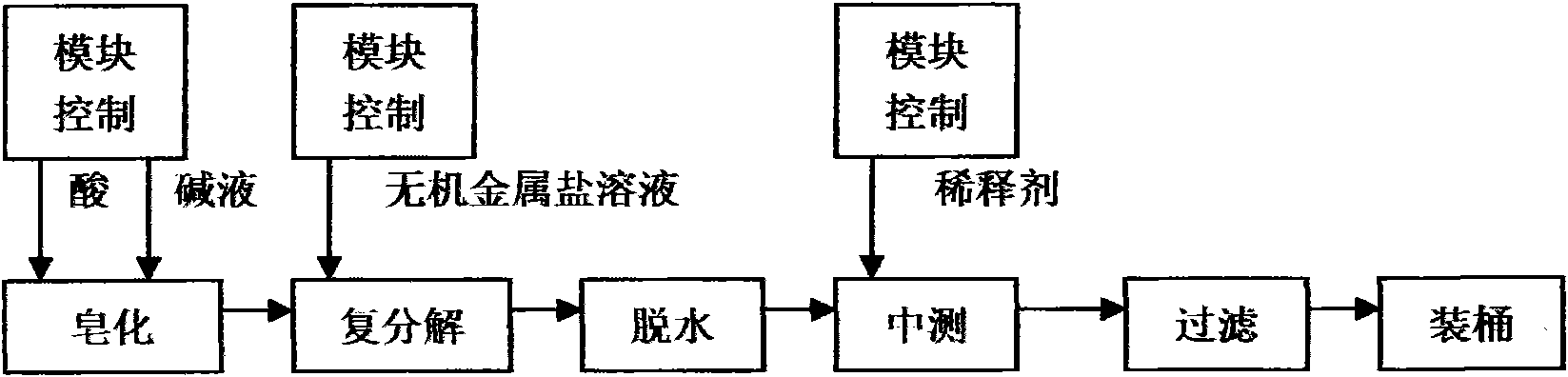

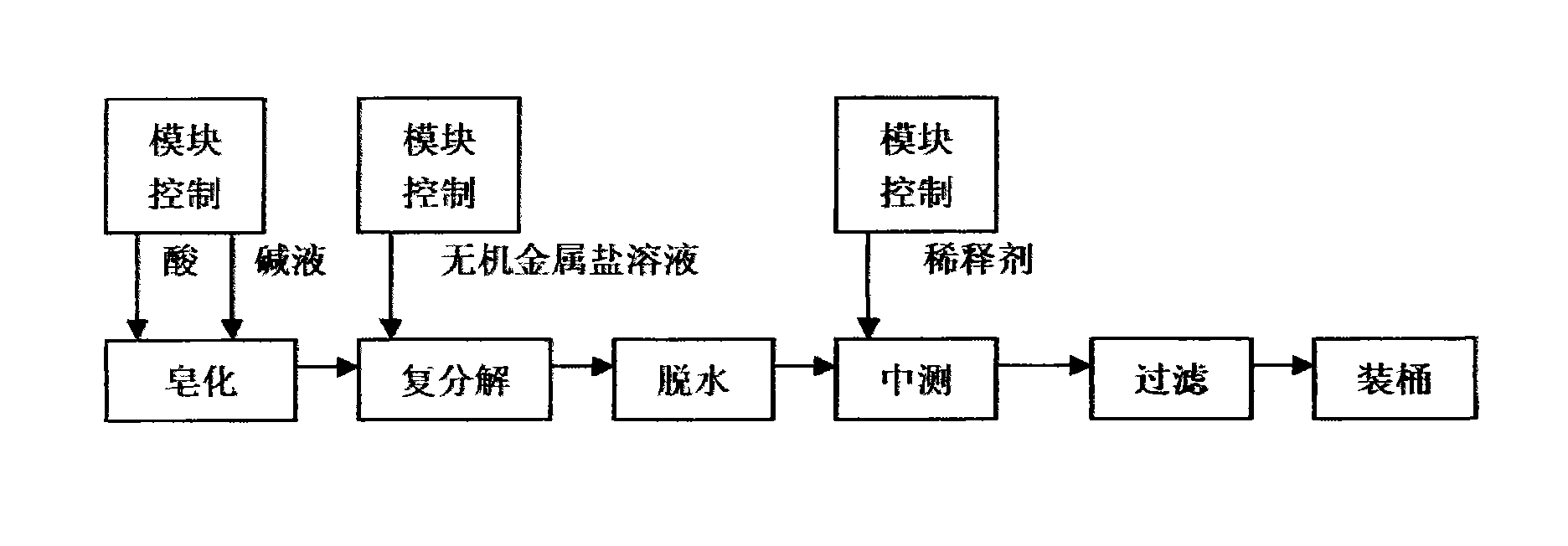

Method for producing coating drier through module control

The invention relates to a method for producing a coating drier through module control, which comprises the following steps of: (1) performing saponification reaction, namely respectively pumping isooctanoic acid or naphthenic acid serving as a raw material, alkali liquor, inorganic metal salt solution and solvent oil into respective elevated tank by using a pump, adding the isooctanoic acid or naphthenic acid serving as the raw material into a reaction kettle through a module set by a Mettler-Toledo weighing display controller, and performing saponification reaction with stirring; and (2) adding inorganic salt solution according to the set module, performing double decomposition reaction with stirring, dehydrating reaction liquid, adding No.200 solvent oil to dilute the reaction liquid, and filtering to remove solid impurities so as to obtain a coating drier product. The yield of the product produced by the method is 3 to 5 percent higher than that of the product produced by the prior art; product quality is stable, work environment is clean, and the body health of operating personnel is facilitated.

Owner:上海华谊精细化工有限公司上海长风化工厂

Glass kiln raw material feeding system and feeding method thereof

InactiveCN109928604AImprove melting efficiencyQuality improvementCharging furnaceEngineeringGlass manufacturing

The invention belongs to the field of glass manufacturing, and particularly relates to a glass kiln raw material feeding system and a feeding method thereof. The feeding system comprises a multi-station progressive shovel type feeding device, a control detecting unit and a pool furnace, wherein the multi-station progressive shovel type feeding device feeds a raw material with a set weight into theset position in the pool furnace through a feeding port under the control of the control detecting unit. According to the present invention, by using the feeding method of the feeding system, the feeding amount can be precisely controlled, and the multi-position feeding can be achieved, such that the method has advantages of uniform feeding, flat material stacking and high control precision.

Owner:IRICO DISPLAY DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com